Air mix HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1103 of 1395

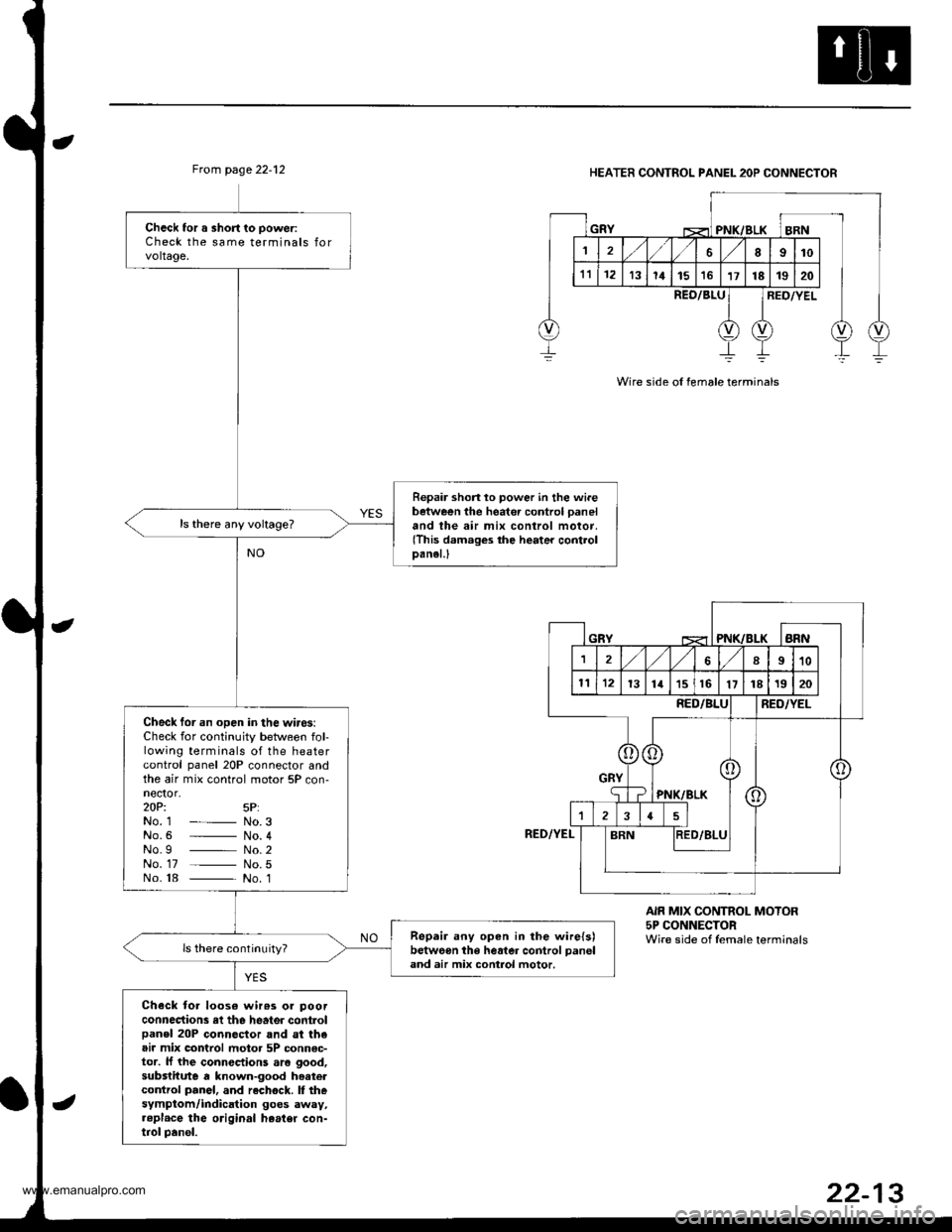

Ftom page 22.12HEATER CONTROL PANEL 2OP CONNECTOR

Wire side ol female terminals

Check tor a short to poweriCheck the same terminals forvoltage.

Repair shon lo power in the wi.ebetween the heater control paneland the air mix control motor,(This damages the heater controlDanel.l

Check tor an open in the wires:Check for continuity between fol-lowing terminals of the heatercontrol panel 20P connector andthe air mix control motor 5P con-nector,zOPi 5P:No. 1 - No.3No.6 _ No. 4No.g _ No.2No. 17 _ No.5No. 18 _ No. 1

Repair any open in the wire{s)betweon the heater control panel

and air mix control motor.

Check toa loos€ wir63 or poorconnections rl the heater controlpanel 20P connector and st theair mix control motor 5P connsc-tor. lJ the connections aro good,substitute a known-good hoatercontrol panel, and rechock. I thesymptom/indication goes away,..pl.ce the original heater con-trol panel.

REO/8LURED/YEL

RED/YEL

AIR MIX CONTROL MOTOR5P CONNECTORWire side of female terminals

www.emanualpro.com

Page 1130 of 1395

Troubleshooting

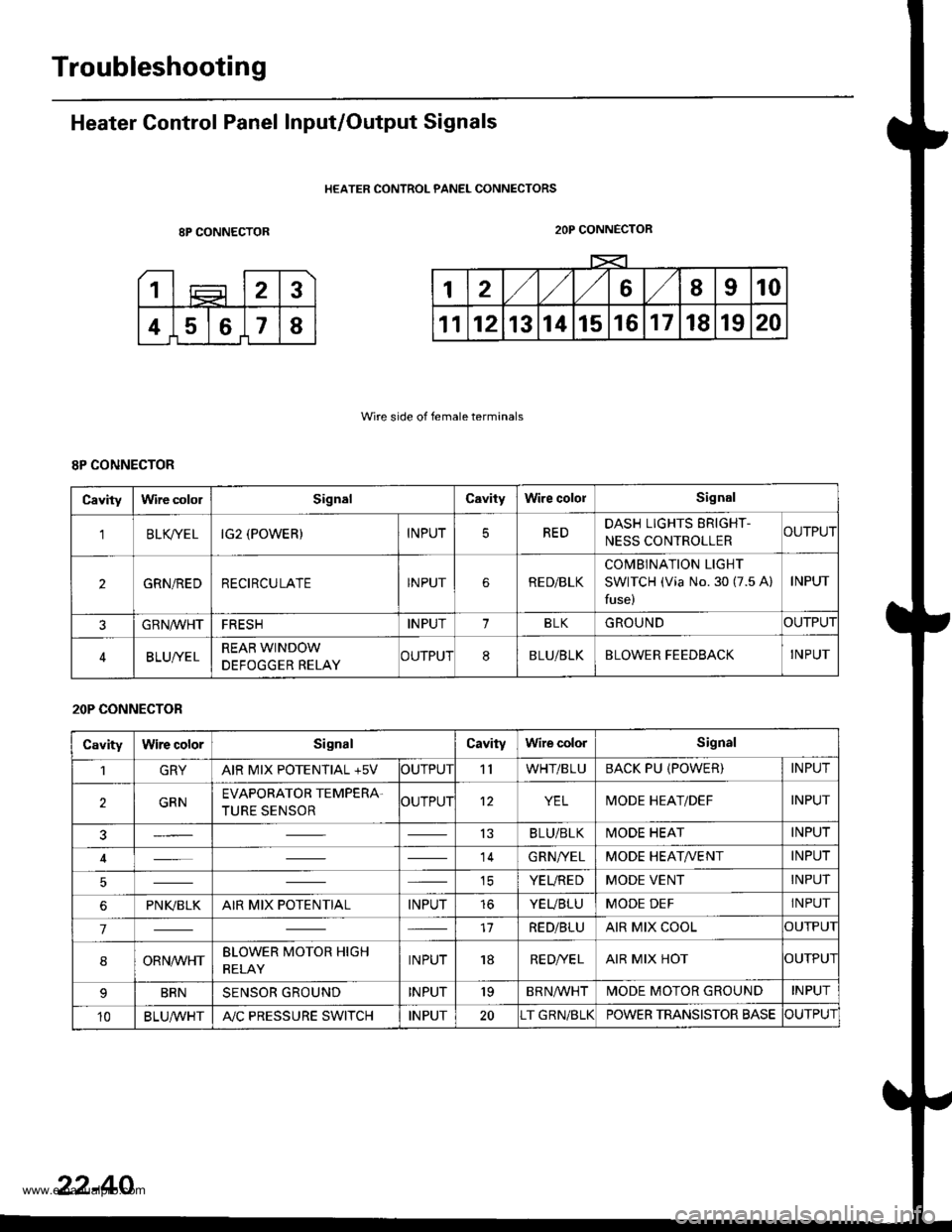

Heater Control Panel Input/Output Signals

HEATER CONTROL PANEL CONNECTORS

8P CONNECTOR

Wire side of female terminals

2OP CONNECTOR

8P CONNECTOR

Cavitylrvire cololSignalCavityWire cololSignal

'lBLK/TE LIG2 (POWER)INPUTREDDASH LIGHTS ERIGHT-

NESS CONTROLLERCUTPUT

2GRN/REDRECIRCULATEINPUTRE D/BLK

COMBINATION LIGHT

SWITCH (Via No. 30 (7.5 A)

fuse)

INPUT

GRN/VVHTFRESHINPUT1BLKGROUNDOUTPUT

BLUI/ELREAR WINDOW

DEFOGGER RELAYCUTPUT8BLU/BLKBLOWER FEEDBACKINPUT

20P CONNECTOR

CavityWire colorSignalCavityWire colorSignal

1GRYAIR MIX POTENTIAL +5VOUTPUT'llWHT/BLUBACK PU (POWER)INPUT

2GRNEVAPORATOR TEMPERA.

TURE SENSOROUTPUT12YELMODE HEAT/DEFINPUT

13BLU/BLKMODE HEATINPUT

14GRN/YELMODE HEAT/VENTINPUT

ICYEUREDMODE VENTINPUT

6PNI(BLKAIR MIX POTENTIALINPUTtoYEUBLUMODE DEFINPUT

717RED/BLUAIR MIX COOLOUTPUI

8ORNrur'HTBLOWER MOTOR HIGH

RELAYINPUT18RE D/VE LAIR MIX HOTOUTPUI

BRNSENSOR GROUNDINPUT'19BRNA/VHTIVIODE MOTOR GROUNDINPUT

10BLU,ryVHTA"/C PRESSURE SWITCHINPUT20T GRN/BLKPOWER TRANSISTOR BASECUTPUT

22-40

www.emanualpro.com

Page 1133 of 1395

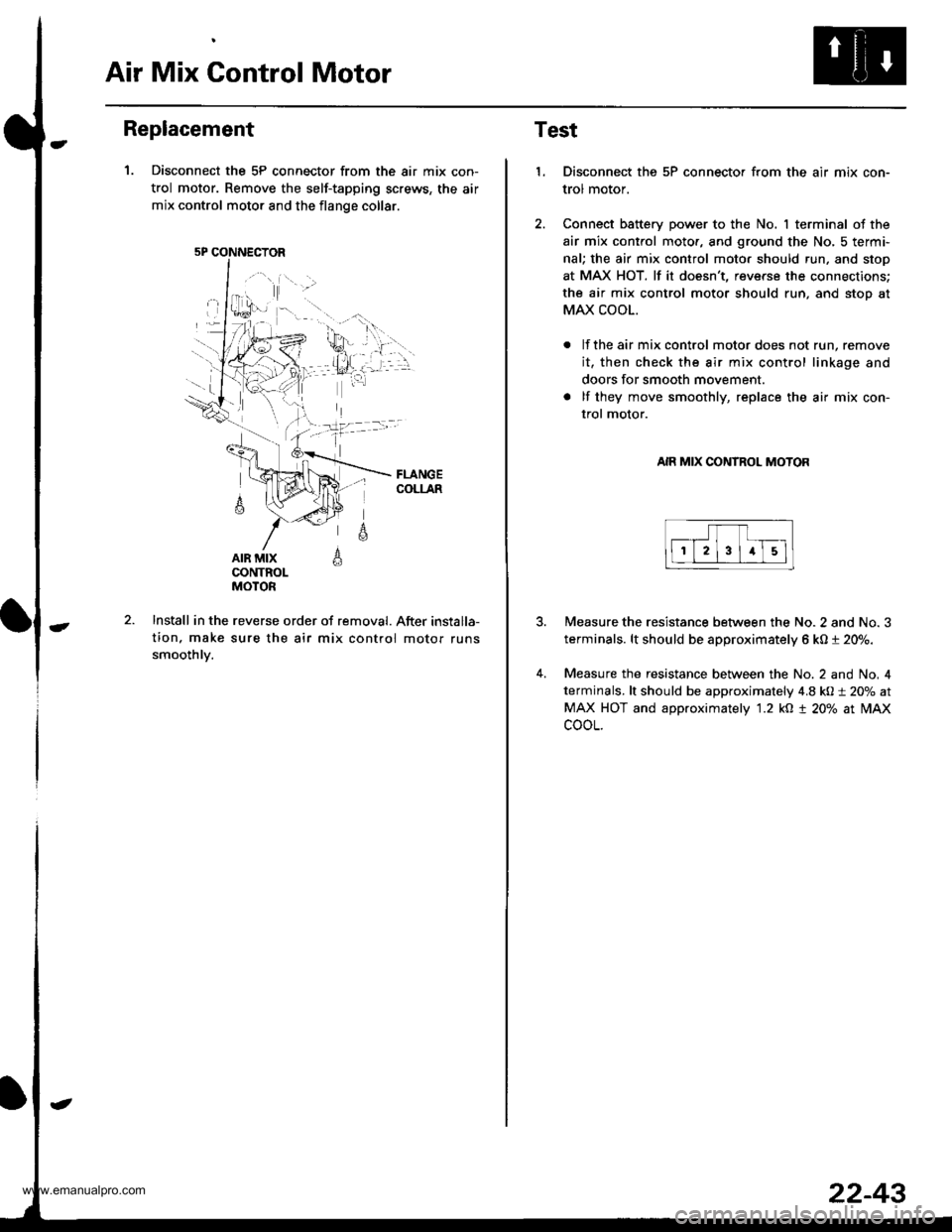

Air Mix Gontrol Motor

Replacement

1. Disconnect the 5P connector from the air mix con-

trol motor. Remove the self-tapping screws, the air

mix control motor and the flange collar.

AIR MIXCONTROLMOTOR

A

6

Install in the reverse order of removal. After installa-

tion. make sure the air mix control motor runs

smoothlv.

5P CONNECTOR

22-43

Test

1.Disconnect the 5P connector from the air mix con-

trol motor.

Connect battery power to the No. I terminal of the

air mix control moto., and ground the No, 5 termi-

nal; the air mix control moto. should run, and stop

at MAX HOT. lf it doesn't, reverse the connections;

the air mix control motor should run, and stoo at

MAX COOL.

lf the air mix control motor does not run, remove

it, then check the air mix control linkage and

doors for smooth movement.

lf they move smoothly, replace the air mix con-

trol motor.

AIR MIX CONTROL MOTOR

4.

Measure the resistance between the No. 2 and No. 3

terminals. lt should be approximately 6 kO t 20%.

Measure the resistance between the No. 2 and No, 4

terminals, lt should be approximately 4.8 kO:t 20% at

MAX HOT and approximately '1.2 kO t 20% at lilAx

cooL.

www.emanualpro.com

Page 1141 of 1395

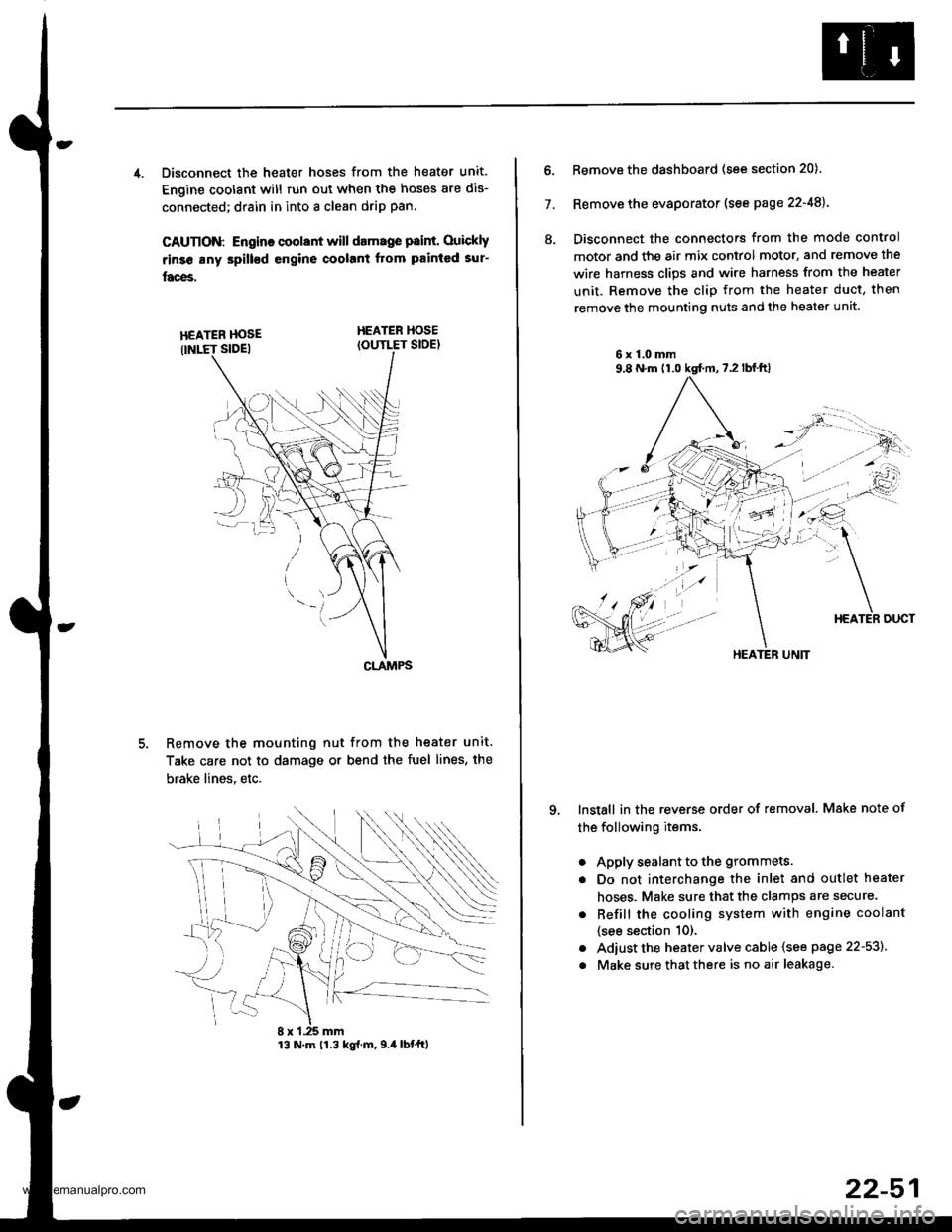

4. Disconnect the heater hoses from the heater unit.

Engine coolant will run out when the hoses are dis-

connected; drain in into a clean drip pan.

CAUTION: Engino coolant will damage p8int. Ouickly

rinse any spill€d engine coolant Itom painted sur-

faces.

HEATER HOSEIOUTLET SIDE)

Remove the mounting nut from the heater unit.

Take care not to damage or bend the fuel lines, the

brake lines. etc.

CLAMPS

13 N.m 11.3 kg{.m,9.4 lbtftl

22-51

7.

ll.

Remove the dashboard (see section 20).

Remove the evaporator (see page 22-48).

Disconnect the connectors from the mode control

motor and the air mix control motor, and remove the

wire harness clips and wire harness from the heater

unit. Remove the clip from the heater duct, then

remove the mounting nuts and the heater unit

6x1.0mm9,8 N.m (1.0 kgt m,7.2lblft)

qInstall in the reverse order of removal. Make note of

the following items.

a

a

a

a

Apply sealant to the grommets.

Do not interchange the inlet and outlet heater

hoses. Make sure that the clamps are secure.

Refill the cooling system with engine coolant

{see section 10).

Adiust the heater valve cable (see page 22-53).

Make sure that there is no air leakage.

HEATER UNIT

www.emanualpro.com

Page 1143 of 1395

Temperature Control

Adjustment

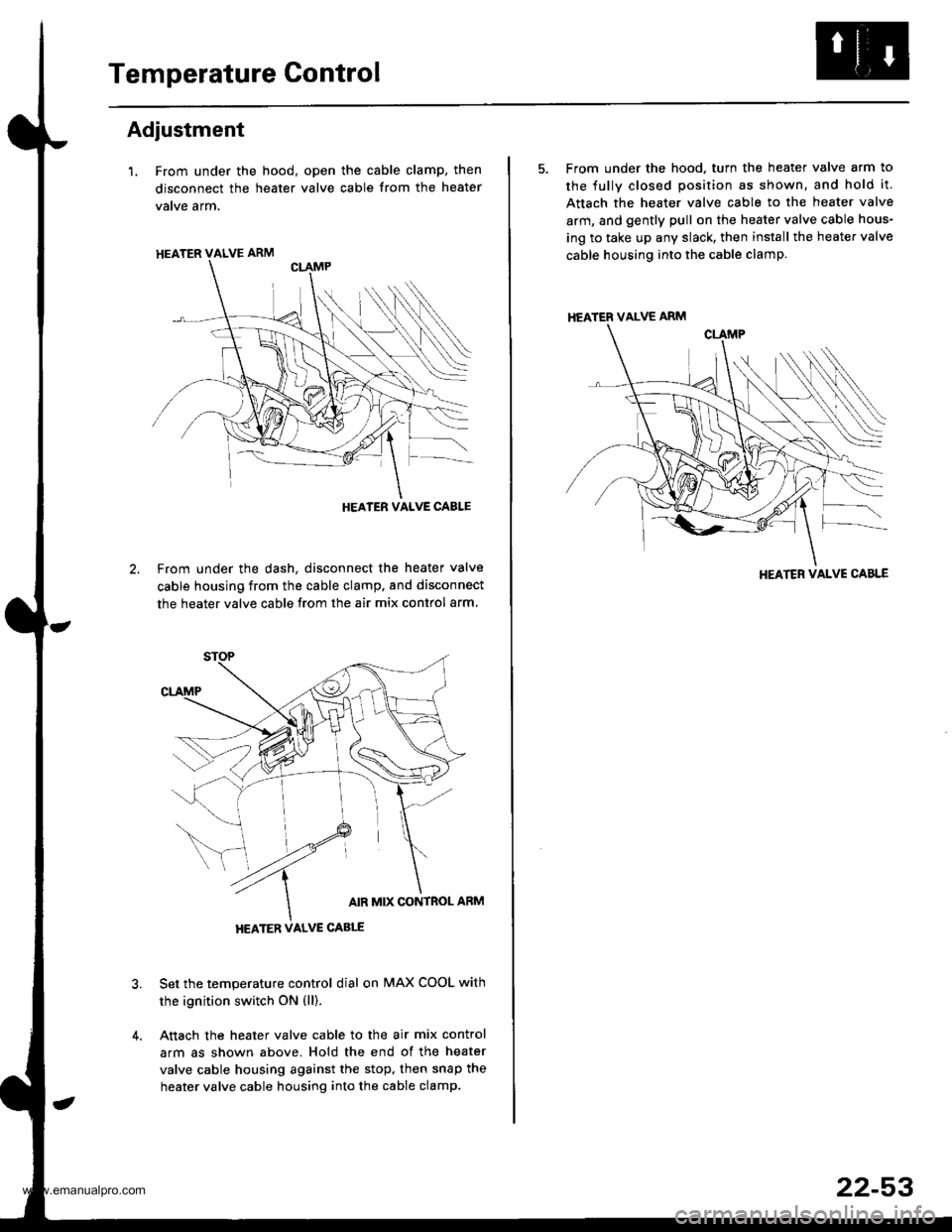

l. From under the hood, open the cable clamp, then

disconnect the heater valve cable from the heater

vatve arm.

From under the dash, disconnect the heater valve

cable housing from the cable clamp. and disconnect

the heater valve cable from the air mix contlol arm

Set the temperature control dial on MAX COOL with

the ignition switch ON (ll).

Attach the heater valve cable to the air mix control

arm as shown above. Hold the end of the heater

valve cable housing against the stop, then snap the

heater valve cable housing into the cable clamp.

HEATER VALVE ARM

HEATER VALVE CABLE

5. From under the hood. turn the heater valve arm to

the fullv closed position as shown, and hold it.

Attach the heater valve cable to the heater valve

arm, and gently pull on the heater valve cable hous-

ing to take up any slack, then install the heate. valve

cable housing into the cable clamp.

HEATER VALVE ARM

HEATER VALVE CABLE

22-53

www.emanualpro.com

Page 1144 of 1395

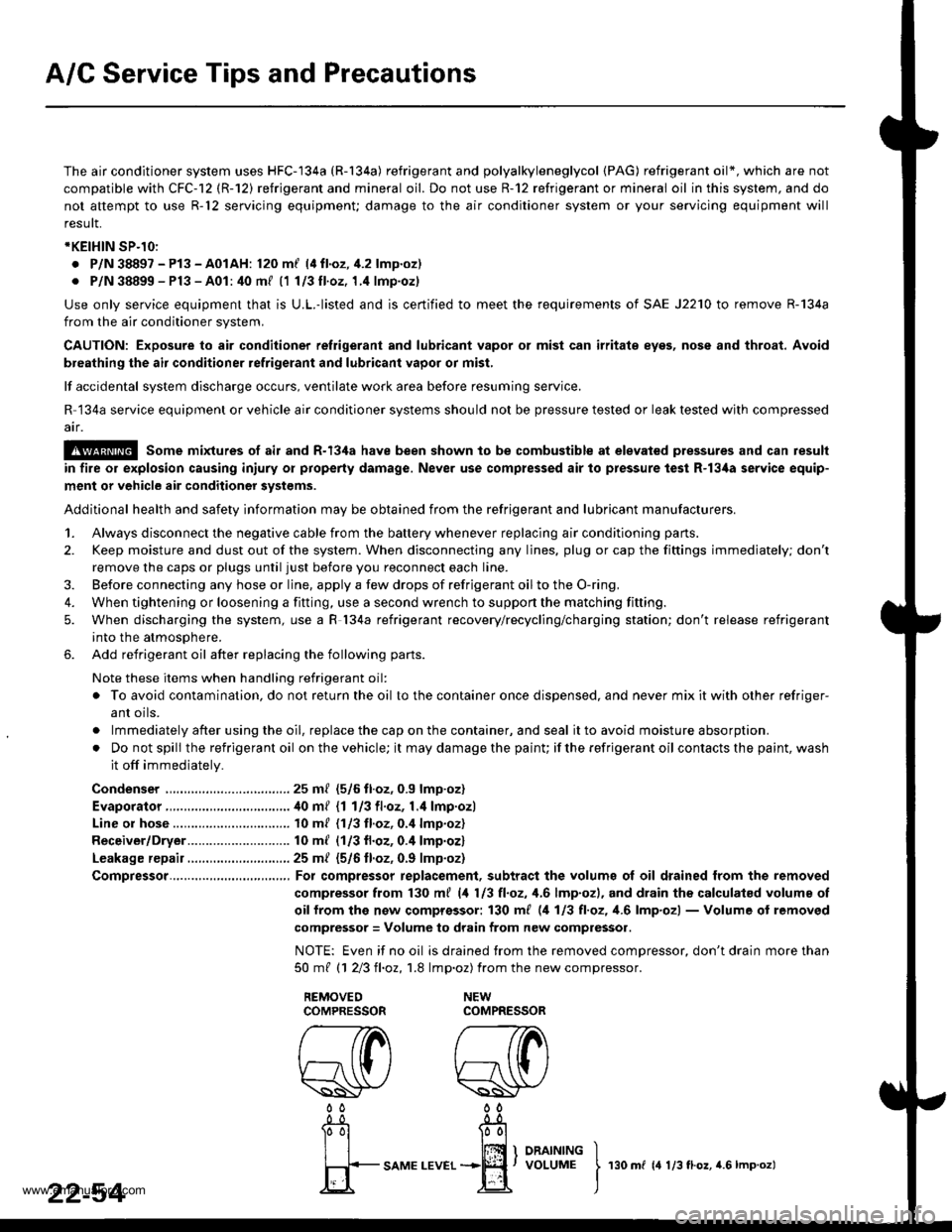

A/C Service Tips and Precautions

The air conditioner system uses HFC-'134a (R-134a) refrigerant and polyalkyleneglycol {PAG) refrigerant oil*, which are not

compatible with CFC-12 (R-12) refrigerant and mineral oil. Do not use R-12 refrigerant or mineral oil in this system, and do

not attempt to use R-12 servicing equipmenu damage to the air conditioner system or your servicing equipment will

resutr.

*KEIHIN SP-10:

. P/N 38897 - Pl3 - A01AH: 120 m{ (4 fl.oz, il.2 lmp.oz)

. P/N 38899 - Pl3 - A01: 40 mf 11113tl.oz,1.4 lmp.oz)

Use only service equipment that is U.L.-listed and is certified to meet the requirements of SAE J2210 to remove R-134a

from the air conditioner system,

CAUTION: Exposure to air conditioner refrigerant and lubricant vapor or misl can irritats eyes, nose and throat. Avoid

breathing the air conditioner refrigerant and lubricant vapor or mist,

lf accidental system discharge occurs, ventilate work area before resuming service.

R 134a service equipment or vehicle air conditioner systems should not be pressure tested or leak tested with compressed

air.

E@ Some mixtures of air and R-13,1a have been shown to be combustible at elevat€d pressures and can result

in fire or explosion causing iniury or property damage. Never use complessed air to pressure test R-l3,[a service equip-

ment or vehicle air conditioner systems.

Additional health and safety information may be obtained from the refrigerant and lubricant manufacturers.

1. Always disconnect the negative cable from the battery whenever replacing air conditioning parts.

2. Keep moisture and dust out of the system. When disconnecting any lines, plug or cap the fittings immediately; don't

remove the caps or plugs until just before you reconnect each line.

3. Before connecting any hose or line. apply a few drops of refrigerant oilto the O-ring,

4. When tightening or loosening a fitting, use a second wrench to support the matching fitting.

5. When discharging the system, use a R l34a refrigerant recovery/recycling/charging station; don't release refrigerant

into the atmosphere.

6. Add refrigerant oil after replacing the following parts.

Note these items when handling refrigerant oil:

o To avoid contamination, do not return the oil to the container once dispensed, and never mix it with other refriger-

ant oils.

. lmmediately after using the oil, replace the cap on the container, and seal it to avoid moisture absorption.

. Do not spill the refrigerant oil on the vehicle; it may damage the painu if the refrigerant oil contacts the paint, wash

it off immediately.

Condenser . 25 ml (5/6 tl.oz, 0.9 lmp.oz)

Evaporator.,................................40 m/ 11 113ll.oz,l.4 lmp.ozl

Line or hose ........... 10 ml (1/3 fl.oz, 0.4 lmp.oz)

Receiver/Dryer....... 10 ml (1/3 fl.oz, 0.4 lmp.oz)

Leakage repair............................ 25 m/ (5/6 ll.oz, 0.9 lmp.oz)

Compressor.......,..., For compressor replacement, subtract the volumg ol oil drained from the removed

compressor from 130 m{ (4 113 tl.oz, 1,6lmp.ozl, and drain the calculatsd volume of

oif from the now comprossor: 130 ml (,1 113 tl,oz, 1.6lmp'ozl - Volume of removed

compressor = Volume to drain from new compressor.

NOTE: Even if no oil is drained trom the removed compressor, don't drain more than

50mt 11 213ll,oz,1.8 lmp.oz) from the newcompressor.

22-54I

rso m r rr:0.o., r.s r-o.o.t

www.emanualpro.com

Page 1146 of 1395

A/G System Service

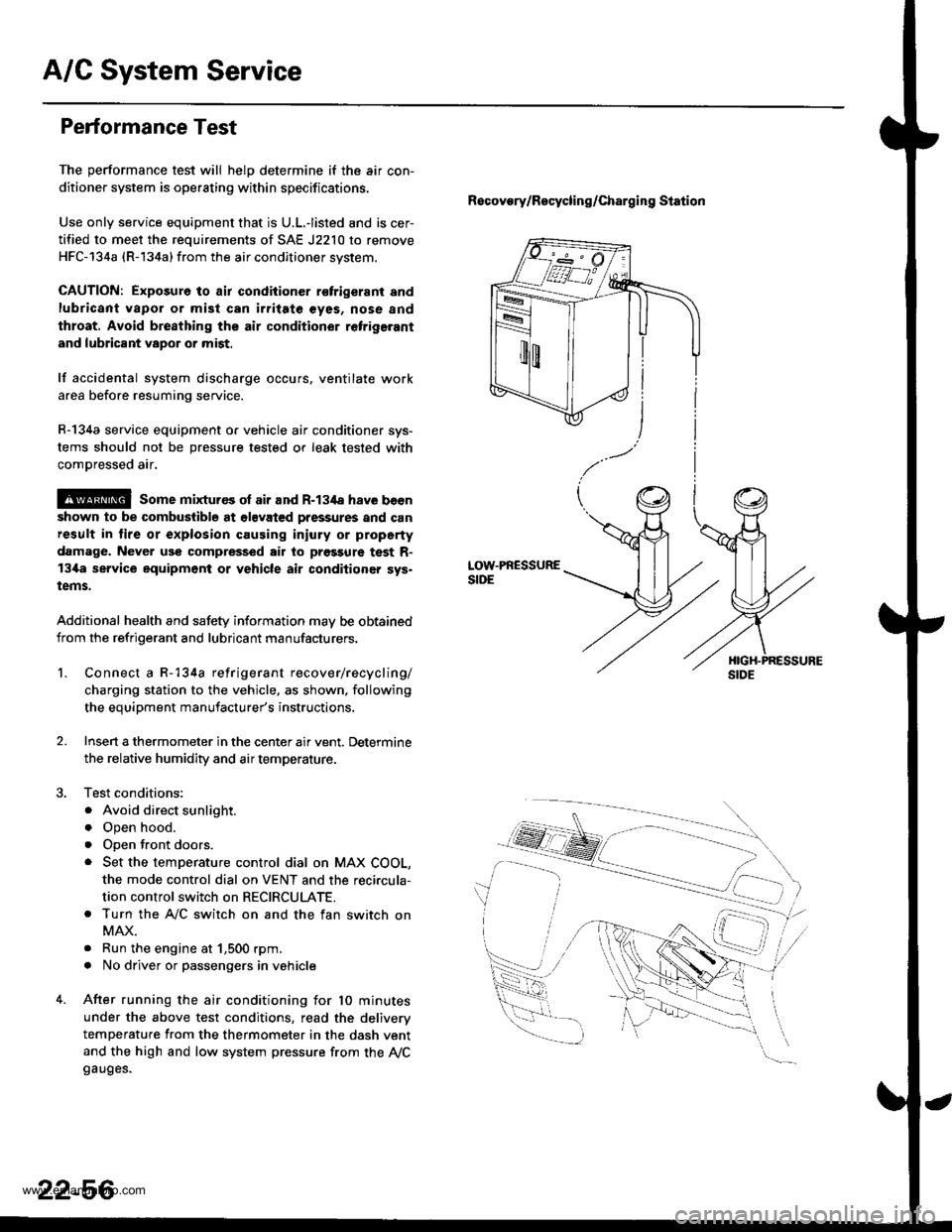

Performance Test

The performance test will helD determine if the air con-

ditioner system is operating within specifications.

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner svstem.

CAUTION: Exposure to air condiiioner r€trigerant and

lubricant vapor or mist can irritate €yes, nose and

throat. Avoid bre8thing the air conditioner retrige.ant

and lubricant vapor or mist,

lf accidental system discharge occurs. ventilate work

area before resuming service.

R-134a service equipment o. vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

comDressed air.

@ some mixtur€s ol air and R-134a have becn

shown to be combuslible at olsvated pressures and can

result in lire or explosion causing iniury or property

damage. Never use compressed air to prgssure test R-

13i[a service equipment or vehicle air conditioner sys.

tems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

Recovory/Recycling/charging station

LOW.PRESSURESIDE

1.Connect a R-134a refrigerant recover/recycling/

charging station to the vehicle, as shown. following

the equipment manufacturer's instructions,

Insen a thermometer in the center air vent. Determine

the relative humidity and air temperature.

Test conditions:

. Avoid direct sunlight.

o Open hood.

. open front doors.

. Set the temperature control dial on MAX COOL,

the mode control dial on VENT and the reci.cula-

tion control switch on RECIRCULATE.

. Turn the A,/C switch on and the fan switch on

MAX.

. Run the engine at 1,500 rpm.

. No driver or passengers in vehicle

After running the air conditioning for 10 minutes

under the above test conditions, read the deliverv

temperature from the thermometer in the dash vent

and the high and low system pressure from the Ay'Cgauges.

2.

22-56

www.emanualpro.com

Page 1149 of 1395

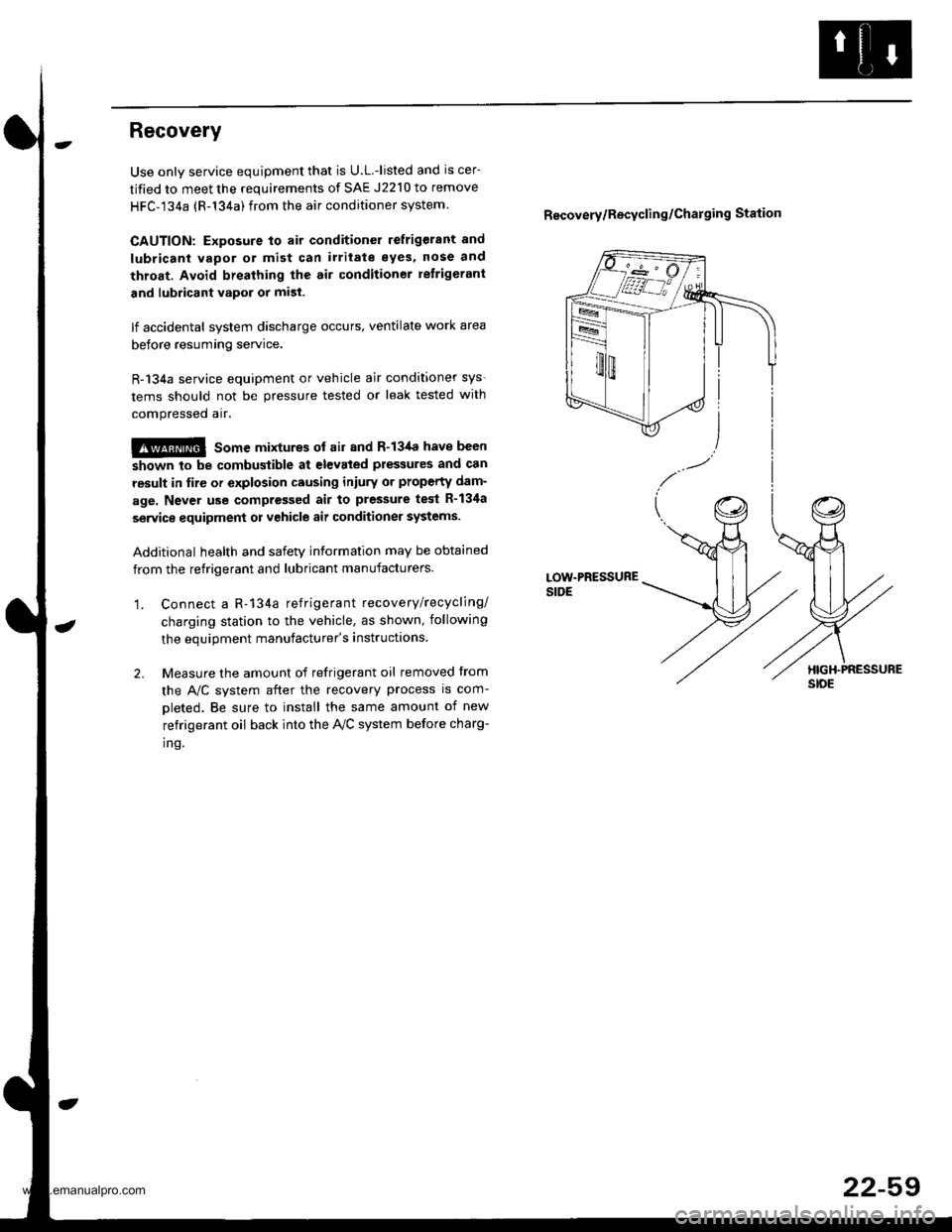

Recovery

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant and

lubricant vapor or mist can irritate eyes, nose and

throat. Avoid brqathing the air conditioner retrigerant

and lubricant vapor or mist.

lf accidental system discharge occurs, ventilate work area

before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed arr.

@@ some mixtures of air and R-134a have been

shown to be combustible at elevated plessures and can

result in fire or explosion causing iniury or property dam-

age. Never use compressed air to pressure tect R-134a

service equipment or vehicle air conditioner systems.

Additional health and safety intormation may be obtained

from the refrigerant and lubricant manufacturers.

'1. Connect a R-134a refrigerant recove rylrecycling/

charging station to the vehicle, as shown, following

the equipment manufacturer's instructions

2. Measure the amount of refrigerant oil removed trom

the A,/C system after the recovery process is com-

oleted. Be sure to install the same amount of new

refrigerant oil back into the AVC system before charg-

inq.

Recovery/Recycling/Charging Station

22-59

www.emanualpro.com

Page 1150 of 1395

A/C System Service

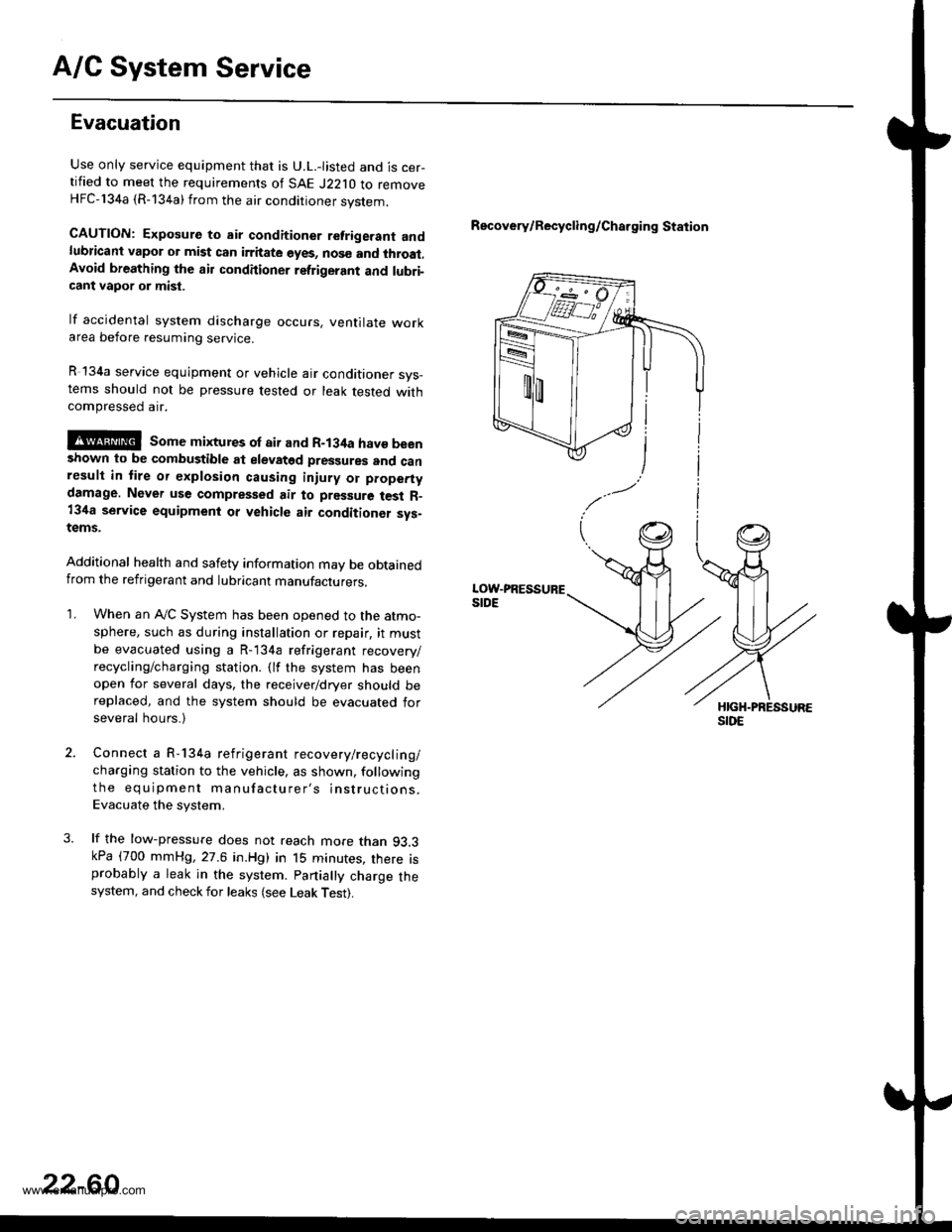

Evacuation

Use only service equipment that is U.L.-listed and is cer-tified to meet the requirements of SAE J2210 to removeHFC-134a {R-134a)from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant andlubricant vapor or mist can irrhate eyes, noso and throat.Avoid breathing the air condhioner retrigerant and lubri-cant vapor or mist.

lf accidental system discharge occu.s. ventilate workarea before resuming service.

R 134a service equipment or vehicle air conditioner sys-tems should not be pressure tested or leak tested withcompressed arr.

!@ some mixtures of air and R-134a hsvo beenshown to be combustible at elevated pressures and canresult in tire or explosion causing iniury ot property

damage. Never use compressed air to pressure test R-134a service equipment or vehicle air conditioner svs-tems.

Additional health and safety information may be obtainedfrom the refrigerant and lubricant manufacturers.

1, When an A,/C System has been opened to the atmo-

sphere, such as during installation or repair, it must

be evacuated using a R-l34a refrigerant recovery/

recycling/charging station. {lf the system has beenopen for several days, the receiver/dryer should bereplaced, and the system should be evacuated forseveral hours.)

Connect a R-134a refrigerant recovery/recyclin g/

charging station to the vehicle, as shown, following

the equipment manufacturer's instructions.

Evacuate the system,

lf the low-pressure does not reach more than 93.3kPa (700 mmHg,27.6 in.Hg) in 15 minutes, there isprobably a leak in the system. partially charge thesystem, and check for leaks (see Leak Test).

Recovery/Recycling/Charging Station

22-60

www.emanualpro.com

Page 1151 of 1395

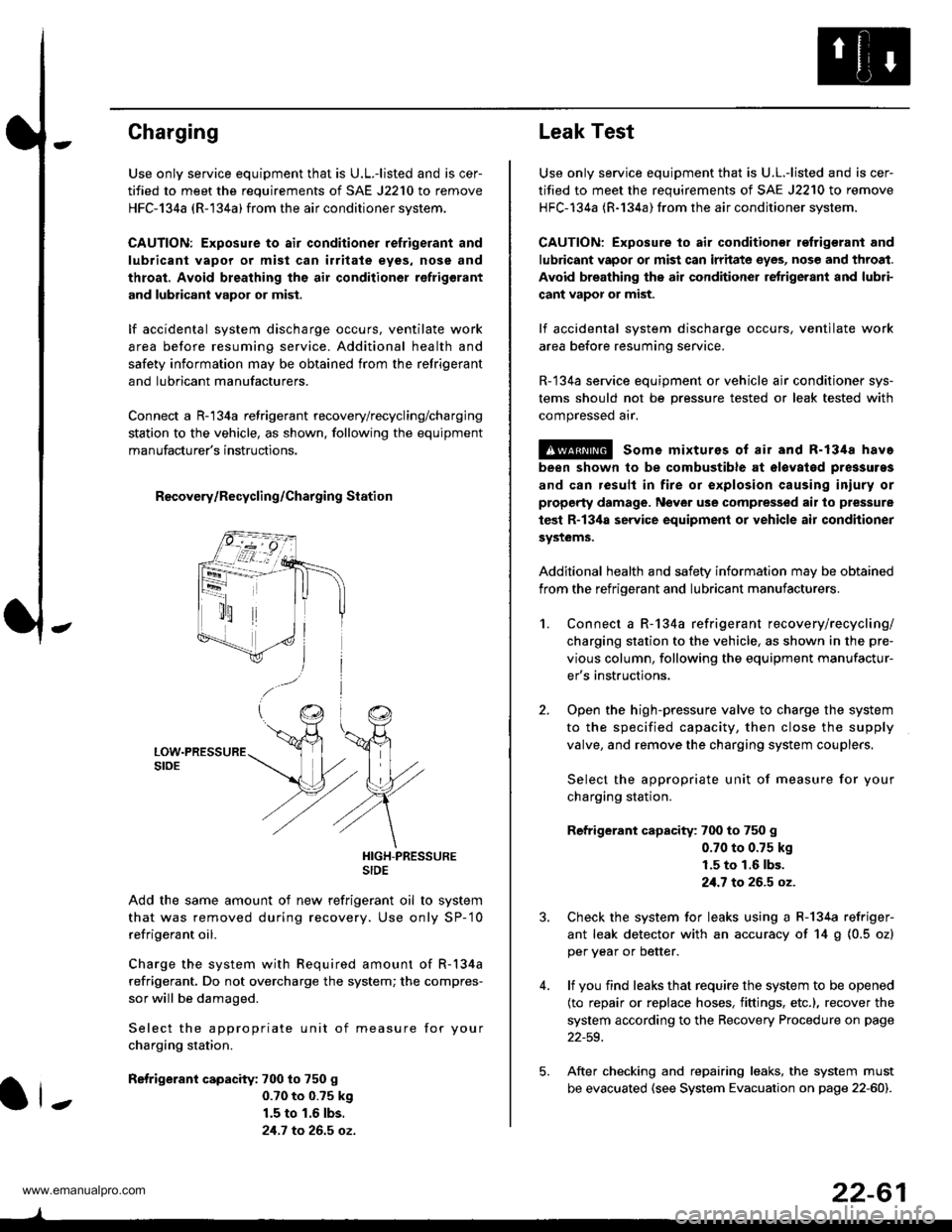

Charging

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant and

lubricant vapor or mist can irritate eyes, nose and

throat. Avoid breathing th€ air conditioner refrigerant

and lubricant vapor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming service. Additional health and

safety information may be obtained from the relrigerant

and lubricant manufacturers.

Connect a R-'134a refrigerant recovery/recycling/charging

station to the vehicle, as shown. following the equipment

manufacturer's instructions.

R€covery/Recycling/Charging Station

HIGH-PRESSURESIDE

Add the same amount of new refrigerant oil to system

that was removed during recovery. Use only SP-'10

refrigerant oil.

Charge the system with Required amount of R-134a

refrigerant. Do not overcharge the system; the compres-

sor will be damaged.

Select the appropriate unit of measure for your

charging station.

Refrigerant capacity: 700 to 750 g

0.70 to 0.?5 k9

1.5 to 1.6 lbs.

21.7 to 26.5 oz.

ll-

22-61

Leak Test

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditionor refrigerant and

lubricant vapor or mist can irritate eyes, nose and throat.

Avoid breathing the air conditioner retrigerant and lubri-

cant vapor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle ajr conditioner sys-

tems should not be pressure tested or leak tested with

compressed arr.

!@ some mixturos of air and R-1348 have

been shown to be combustible at olovatod pres3uras

and can result in fire or explosion causing iniury or

property damage. Never use comprelised air to pressure

test R-13ila service equipment or vehicle air conditioner

systems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

2.

1.Connect a R-134a refrigerant recove rylrecycling/

charging station to the vehicle, as shown in the pre-

vious column, following the equipment manufactur-

er's instructions.

Open the high-pressure valve to charge the system

to the specified capacity, then close the supply

valve, and remove the charging system couplers.

Select the appropriate unit of measure for your

charging station.

Refrigerant capacity: 700 to 750 g

0.70 to 0.75 kg

1.5 to 1.6 lbs.

21.7 to 26.5 oz.

Check the system for leaks using a R-134a refriger-

ant leak detector with an accuracy of 14 g (0.5 ozl

per year or better.

lf you find leaks that require the system to be opened

(to repair or replace hoses, fittings, etc.), recover the

system according to the Recovery Procedure on page

22-59.

After checking and repairing leaks, the system must

be evacuated (see System Evacuation on page 22-601.

5.

www.emanualpro.com