Air mix HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 194 of 1395

Radiator

Engine Coolant Refilling and Bleeding (cont'dl

Mix the recommended antifreeze with an equal

amount of water in a clean container.

NOTE:

. Always use Genuine Honda Antifreeze/Coolant.

Using a non-Honda coolant can result in corro-s\on, ca

sng t\e coo\

g sys\em \o ma\lunct\on

o. fail.

For best corrosion protection, the coolant con-

centration must be maintained year-round at50% minimum. Coolant concentrations less than

50% may not provide sufficient protection against

corrosion or freezing. Coolant concentrationsgreater than 60% will impair cooling efficiency

and are not recommended.

Do not use additional rust inhibitors or anti-rustproducts; they may not be compatible with the

coolant.

Engine Coolant Refill Capacity Iincluding 0.6 / 10.63US $, 0.53 lmp qtl for hoater and ressrvoirl:

A/T: 3.9 f {4.1 US $, 3.4 lmp qtl

M/T: 1.O t 14.2 US $, 3.5 lmp qrl

10-6

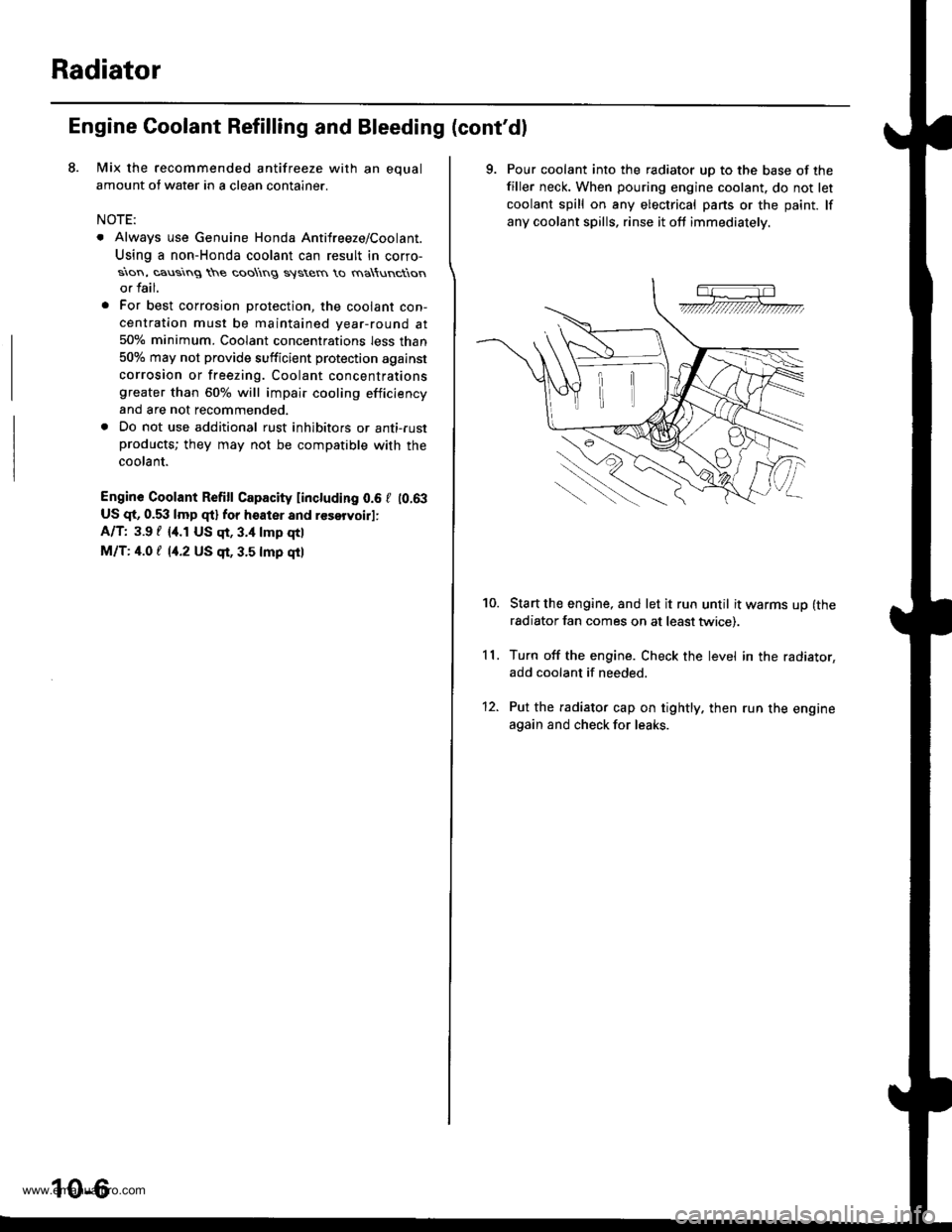

9. Pour coolant into the radiator uD to the base of the

filler neck. When pouring engine coolant. do not let

coolant spill on any electrical pans or the paint. lf

any coolant spills, rinse it oft immediately.

Start the engine, and let it run until it warms up (the

radiator fan comes on at least twice).

Turn off the engine. Check the level in the radiator,

add coolant if needed.

Put the radiator cap on tightly. then run the engine

again and check for leaks.

11.

10.

12.

www.emanualpro.com

Page 282 of 1395

PGM-FI System

System Description

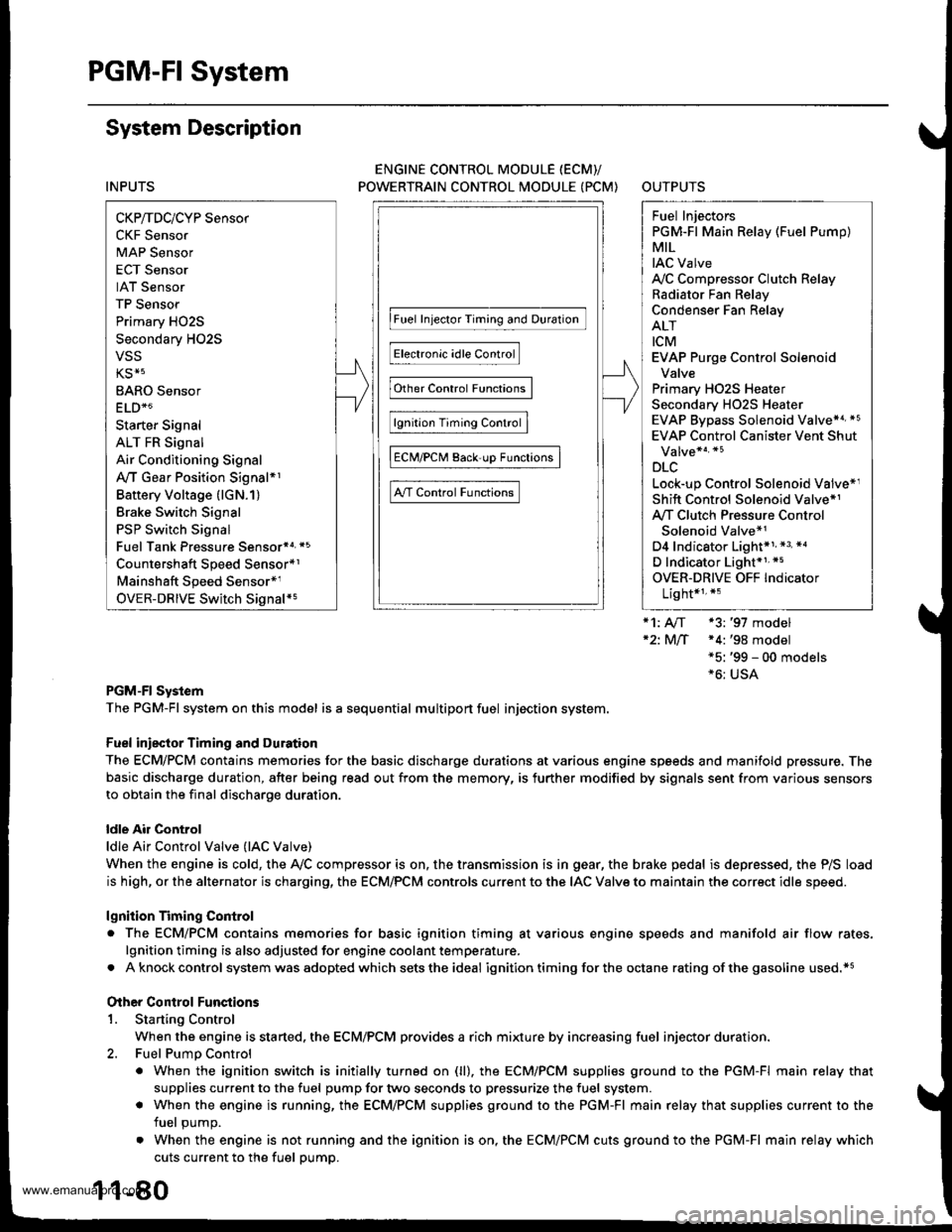

INPUTS

CKP/TDC/CYP Sensor

CKF Sensor

MAP Sensor

ECT Sensor

IAT Sensor

TP Sensor

Primary HO2S

Secondary H02S

vss

KS*5

BARO Sensor

ELD*6

Starter Signal

ALT FR Signal

Air Conditioning Signal

Ay'T Gear Position Signal*1

Baftery Voltage (lGN.1)

Brake Switch Signal

PSP Switch Signal

Fuel Tank Pressuae Sensor*4. *5

Countershaft Speed Sensor*1

Mainshaft Speed Sensor*r

OVER-DRIVE Switch Signal*s

ENGINE CONTROL MODULE (ECM)/

POWERTRAIN CONTROL MODULE (PCM) OUTPUTS

|iuel 1"j""- Th,rhg ""d Drrafr";-l

Et*-.nt"tdt"cont.orl

to,r*,c;;trffi;]

l.----.---:. .Lrgnrnon |lmrng Lonrror I

Ecir/PcM B*k',p Fr""il]

m;"t-ll-r*'io*l

Fuel Injectors

PGM-Fl Main Relay (Fuel Pump)

MIL

IAC Valve

Ay'C Compressor Clutch Relay

Radiator Fan Relay

Condenser Fan Relay

ALT

tcM

EVAP Purge Control Solenoid

Valve

Primary HO2S Heater

Secondary H02S HeaterEVAP Bypass Solenoid Valve*a *5

EVAP Control Canister Vent Shut

DLC

Lock-up Control Solenoid Valve*l

Shift Control Solenoid Valve*1

Ay'T Clutch Pressure Control

Solenoid Valve*1

D4 Indicator Light'1 *3, *a

D Indicator Light,l *5

OVER-DRIVE OFF Indicator

Lighl*t *:

*1: A/T {3:'97 model'2: M/f +4:'98 model*5: '99 - 00 models"6: USA

PGM-Fl System

The PGM-Fl system on this model is a sequential multiport fuel injection system.

Fuel iniecior Timing and Duration

The ECM/PCM contains memories for the basic discharge durations at various engine speeds and manifold pressure. The

basic discharge duration, after being read out from the memory, is further modified by signals sent from various sensors

to obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve (lAC Valve)

When the engine is cold, the Ay'C compressor is on, the transmission is in gear, the brake pedal is depressed, the P/S load

is high, or the alternator is charging, the ECM/PCM controls current to the IAC Valve to maintain the correct idle speed.

lgnition Timing Control

o The ECM/PCM contains memories for basic ionition timing at various engine speeds and manifold air flow rates.

lgnition timing is also adjusted for engine coolant temperature.

. A knock control system was adopted which sets the ideal ig nition timing for the octane rating of the gasoline used.*s

Other Control Funstions

1. Starting Control

When the engine is started. the ECM/PCM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

. When the ignition switch is initially turned on (ll). the ECMiPCM suppli€s ground to the PGM-FI main relay that

supplies current to the fuel pump for two seconds to pressurize the fuel system.

. When the engine is running, the ECM/PCM supplies ground to the PGM-FI main relay that supplies current to the

fuel oumo.

. When the engine is not running and the ignition is on, the ECM/PCM cuts ground to the PGM-FI main relay which

cuts current to the fuel pump.

1 1-80

www.emanualpro.com

Page 283 of 1395

Fuel Cut-off Control

. During deceleration with the throttle valve closed, current to the fuel injectors iscutoffto improvefuel economyat

speeds over 970 rpm ('97 - 98 models), 920 rpm ('99 - 00 modelsl.

. Fuel cut-off action also takes place when engine speed exceeds 6,500 rpm ('97 - 98 models), 6900 rpm ('99 - 00

models), regardless of the position of the throttle valve, to protect the engine from over-rewing.

With Ay'T model. the PCM cuts the fuel at engine speeds over 5,000 rpm when the vehicle is not moving.*'�

4,./C Comoressor Clutch Relav

When the ECM/PCM receives a demand for cooling from the air conditioning system, it delays the compressor from

being energized, and enriches the mixture to assure a smooth transition to the Ay'C mode.

Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is above 154"F (68'C), the ECM/PCM controls the EVAP purge control solenoid

valve which controls vacuum to the EVAP purge control canister,

Alternator Control

The system controls the voltage generated at the alternator in accordance with the electrical load and driving mode.

which reduces the engine load to improve the fuel economy.

PCM Fail-saf e/Back-up Functions

1. Fail-safe Function

When an abnormality occurs in a signal from a sensor, the ECM/PCM ignores that signal and assumes a pre-pre

grammed value for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM/PCM itself, the fuel injectors are controlled by a back-up circuit independent

of the system in order to permit minimal driving.

3. Self-diagnosis Function IMalfunction Indicator Lamp (MlL)l

When an abnormality occurs in a signal from a sensor, the ECM/PCM supplies ground for the MIL and stores the DTC

in erasable memory. When the ignition is initially turned on {ll), the ECM/PCM supplies ground for the MIL for two

seconds to check the MIL bulb condition.

4. Two Trio Detection Method

To prevent false indications, the Two Trip Detection Method is used for the HO2S*1, fuel metering-related. idle control

system, ECT sensor and EVAP control system self-diagnostic functions. When an abnormality occurs, the ECM/PCM

stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (ll) again,

the ECM/PCM informs the driver by lighting the MlL. However, to ease troubleshooting, this function is cancelled

when you jump the service check connector, The MIL will then blink immediately when an abnormality occurs.

5. Two (or Three) Driving Cycle Detection Method {'97 model)

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. lf misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles.

or TWC deterioration is detected during three consecutive driving cycles, the ECM/PCM turns the MIL on. However, to

ease troubleshooting, this function is cancelled when you jump the service check connector. The MIL will then blink

immediately when an abnormality occurs.

*1: '97 - 98 models*2: '99 - 00 models

5.

www.emanualpro.com

Page 780 of 1395

Transmission

Cooler Flushing

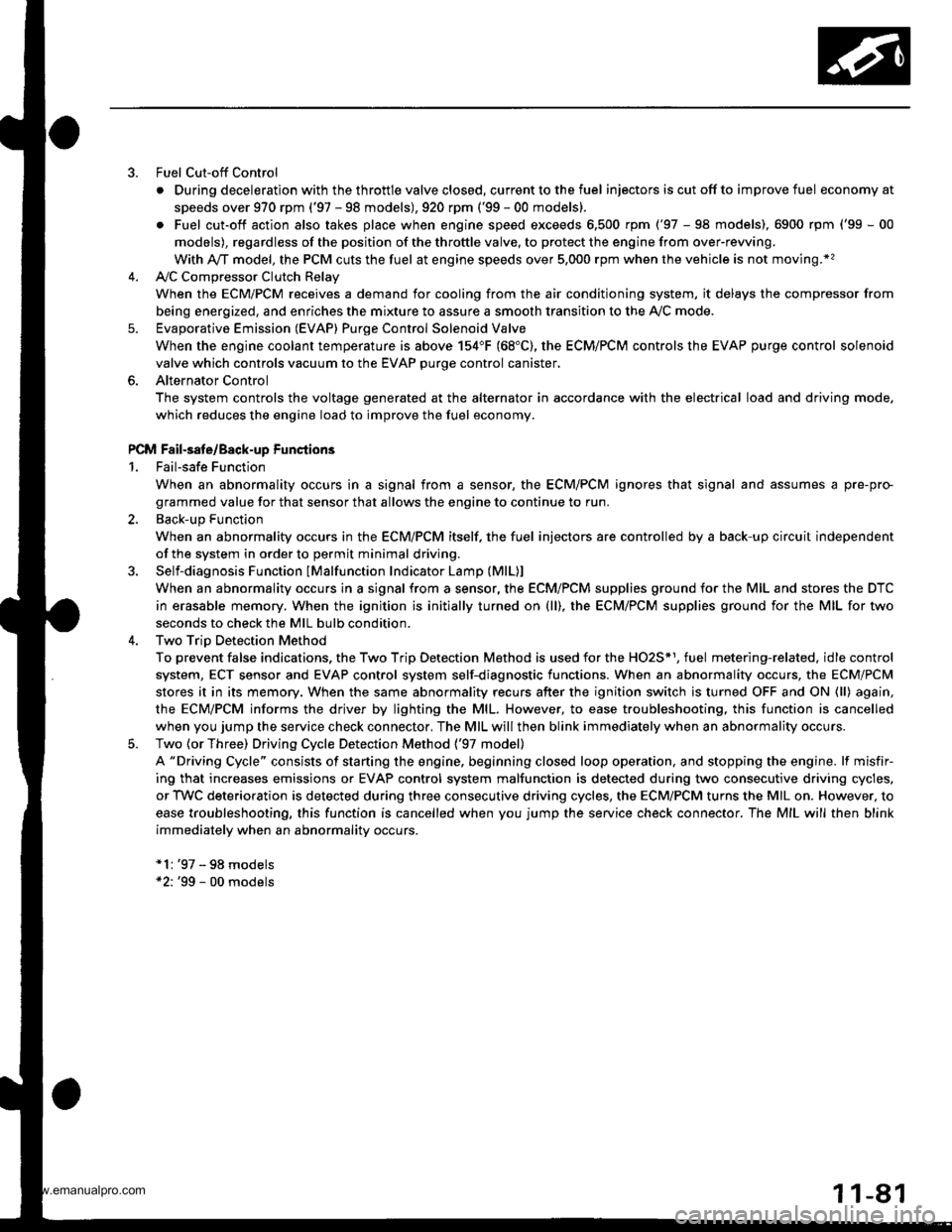

@@ To prevent in;ury to face and eyos, atwayswear safety glasses ot a face shield when using thetlansmission flusher.

This procedure should be performed before reinstallingthe transmission.

2.

LCheck equipment for wear and cracks before using.Replace any worn or cracked components.

Using the measuring cup. fill the tank with 21 ounces{approximately 213 lull) ol biodegradable flushingfluid (J35944 - 20). Do not substitute with any otherfluid. Follow the handling procedure on the fluidcontaaner.

Secure the flusher filler cap, and pressurize theflusher with compressed air to 550 - 829 kpa (5.6 _

8.45 kgf/cm,, 80 - 120psi). The air line should beequipped with a water trap to ensure a dry air sys-tem.

Hang the flusher under the vehicle.

Attach the flusher discharge hose to the return lineof the transmission cooler using a clamp.

Connect the drain hose to the inlet line on the trans-mission cooler using a clamp.

IMPORTANT:

Securely clamp the opposite end ofthe drain hose to abucket or floor drain.

DISCHARGEHOSE

tAirlp Water

TnAI{SrfiSStoN coot"€RFLUSHER{Comm.rcidly.v.il.bt.lK.r -Moor. J38,t{15.Aor aquival.nt

5.

14-264

7. With the water and air valves off, attach the water andair supplies to the flusher. (Hot water if available.)

10.

8.

1'�I.

Turn on the water valve for 1O seconds. lf waterdoes not flow through the cooler, it is completelyplugged, cannot be flushed, and must be replaced.

Depress the trigger to mix the flushing fluid into thewater flow. Use the wire clip to hold the trigger down.

While flushing with the water and flushing fluid fortwo minutes, turn the air valve on for five secondsevery 15 - 20 seconds to create a surging action.AIR PRESSURE: MAX 845 kpa (8.45 kgf/cmr, t20 psi)

Turn the water valve off. Release the trigger, thenreverse the hoses to the cooler so you can flush inthe opposite direction. Repeat steps 8 through 10.

Release the trigger, and rinse the cooler with wate.for one minute.

Turn the water valve off, and the water supply off.

Turn the air valve on for two minutes, or until nomoisture is visible leaving the drain hose. Residualmoisture in the cooler or lines can damage thetransmission.

Remove the flusher from the cooler line. Attach thedrain hose to a container.

Install the transmission, and leave the drain hoseattached to the cooler line.

12.

13.

14.

to.

www.emanualpro.com

Page 1015 of 1395

Glass

Windshield Replacement (cont'dl

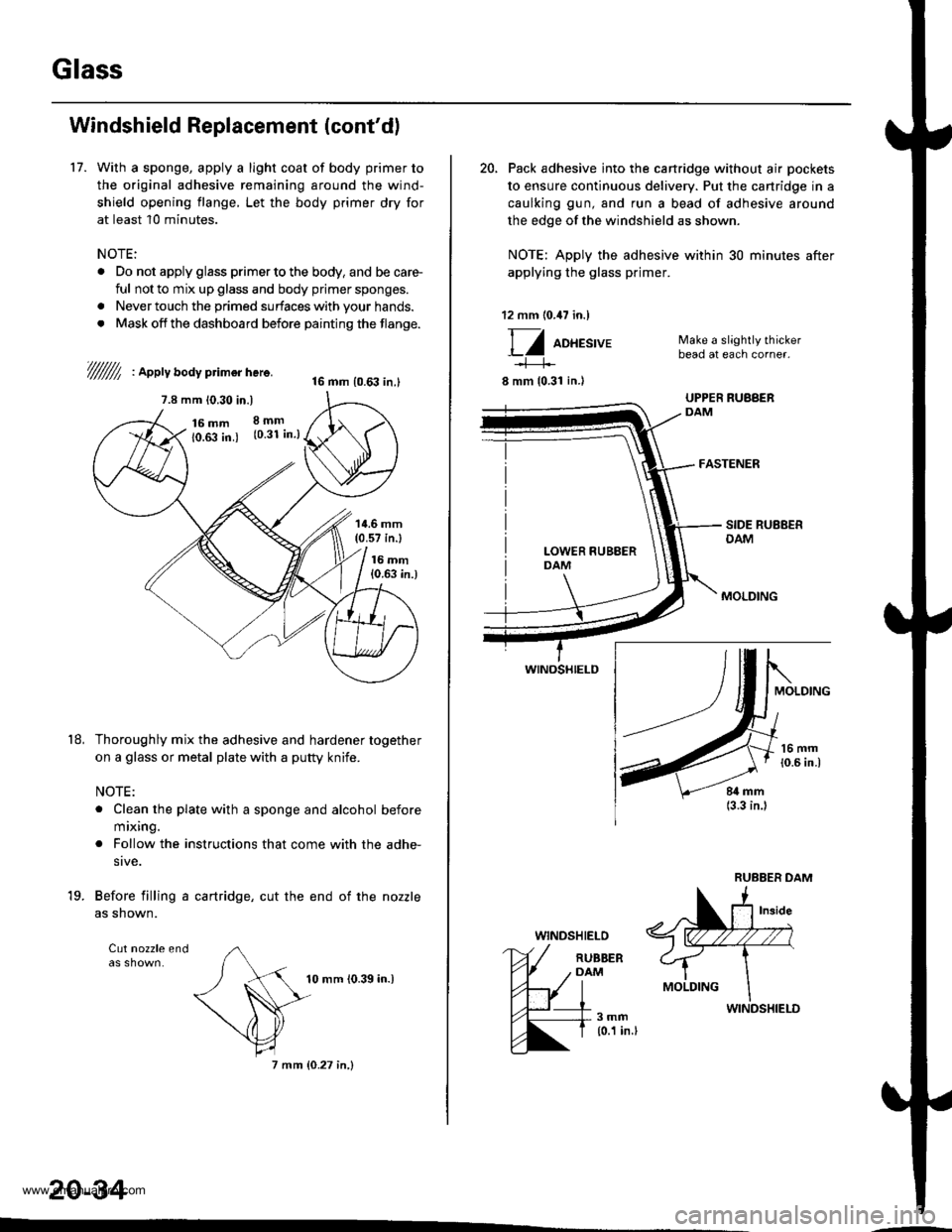

17. With a sponge, apply a light coat of body primer to

the original adhesive remaining around the wind-

shield opening flange, Let the body primer dry for

at least 10 minutes.

NOTE:

. Do not apply glass primer to the body, and be care-

ful not to mix up glass and body prjmer sponges.

. Never touch the primed surfaces with your hands.

. Mask off the dashboard before painting the flange.

///////l , apptv aoav primor here.16 mm {0.63 in.l

7.8 mm 10.30 in.)

16 mm10.fi in.)

8mm(0.31 in.)

't8,

14.6 mm(0.57 in.l

16 mm{0.63 in.)

Thoroughly mix the adhesive and hardener together

on a glass or metal plate with a putty knife.

NOTE:

. Clean the plate with a sponge and alcohol before

mixing.

. Follow the instructions that come with the adhe-

sive.

Before filling a cartridge, cut the end of the nozzle

as shown.

Cut nozzle end

'19.

10 mm {0.39 in.)

7 mm {0.27 in,}

20-34

20, Pack adhesive into the cartridge without air pockets

to ensure continuous delivery. Put the cartridge in a

caulking gun, and run a bead of adhesive around

the edge of the windshield as shown.

NOTE: Apply the adhesive within 30 minutes after

applying the glass primer.

12 mm (0.47 in.)

Ff oo*tt'u'

8 mm {0.31 in.l

WINOSHIELD

WINDSHIELO

Make a slightly thickerbead at each corner.

FASTENER

RUBBERDAM

3mm{0.1 in.l

www.emanualpro.com

Page 1096 of 1395

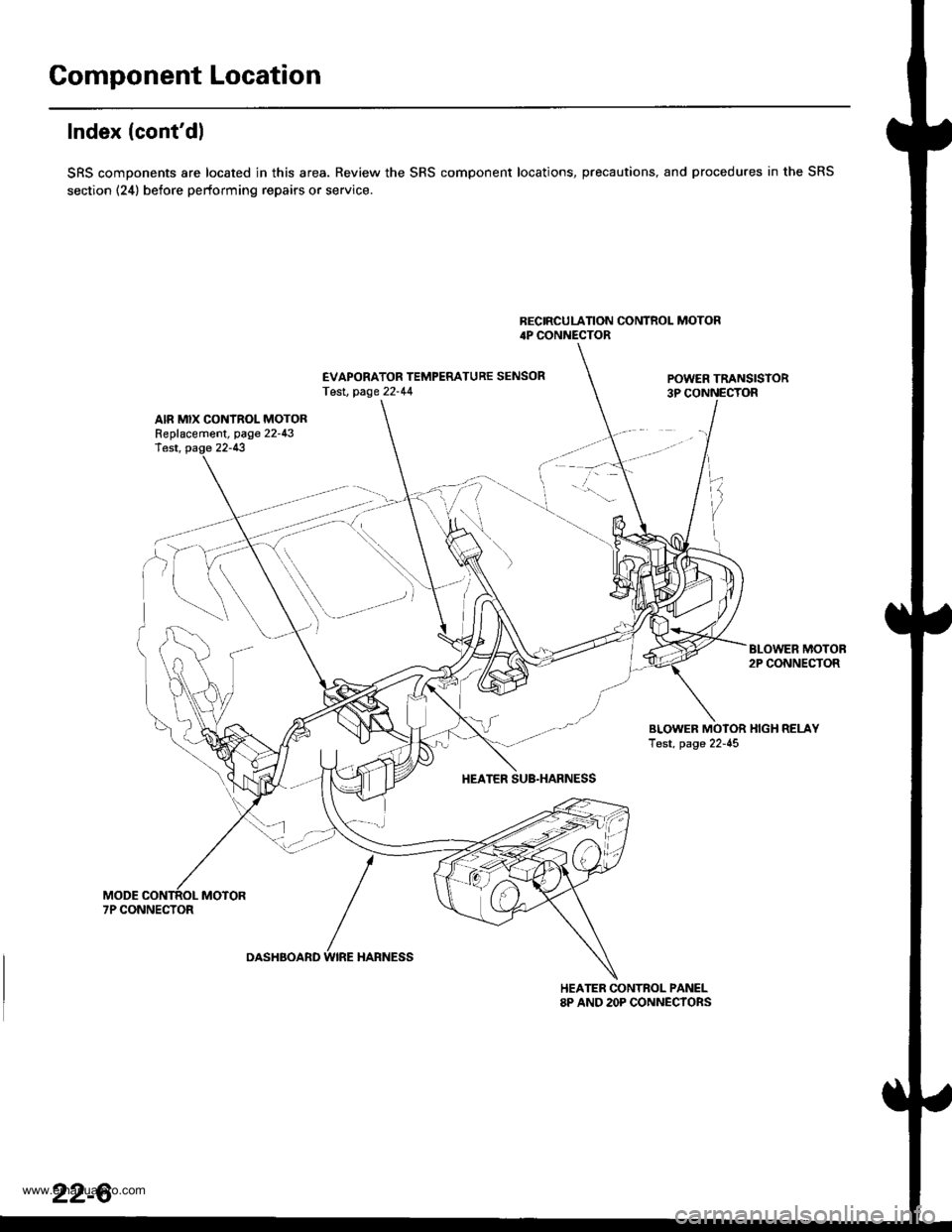

Component Location

Index (cont'dl

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

BECIRCULATION CONTROL MOTOR4P CONNECTOR

EVAPORATOR TEMPERATURE SENSORTesl, page 22-44POWER TRANSISTOR3P CONNECTOR

AIR MIX CONTROL MOTORReplacement, page 22-43lest, page 22-13

BLOWER MOTOB2P CONNECTOR

BLOWER MOTOR HIGH RELAYTest, page 22-45

HEATER SUB.HARNESS

7P CONNECTOR

DASHBOARD WIRE HARNESS

HEATER CONTROL PANEL8P AND 2OP CONNECYORS

22-6

www.emanualpro.com

Page 1097 of 1395

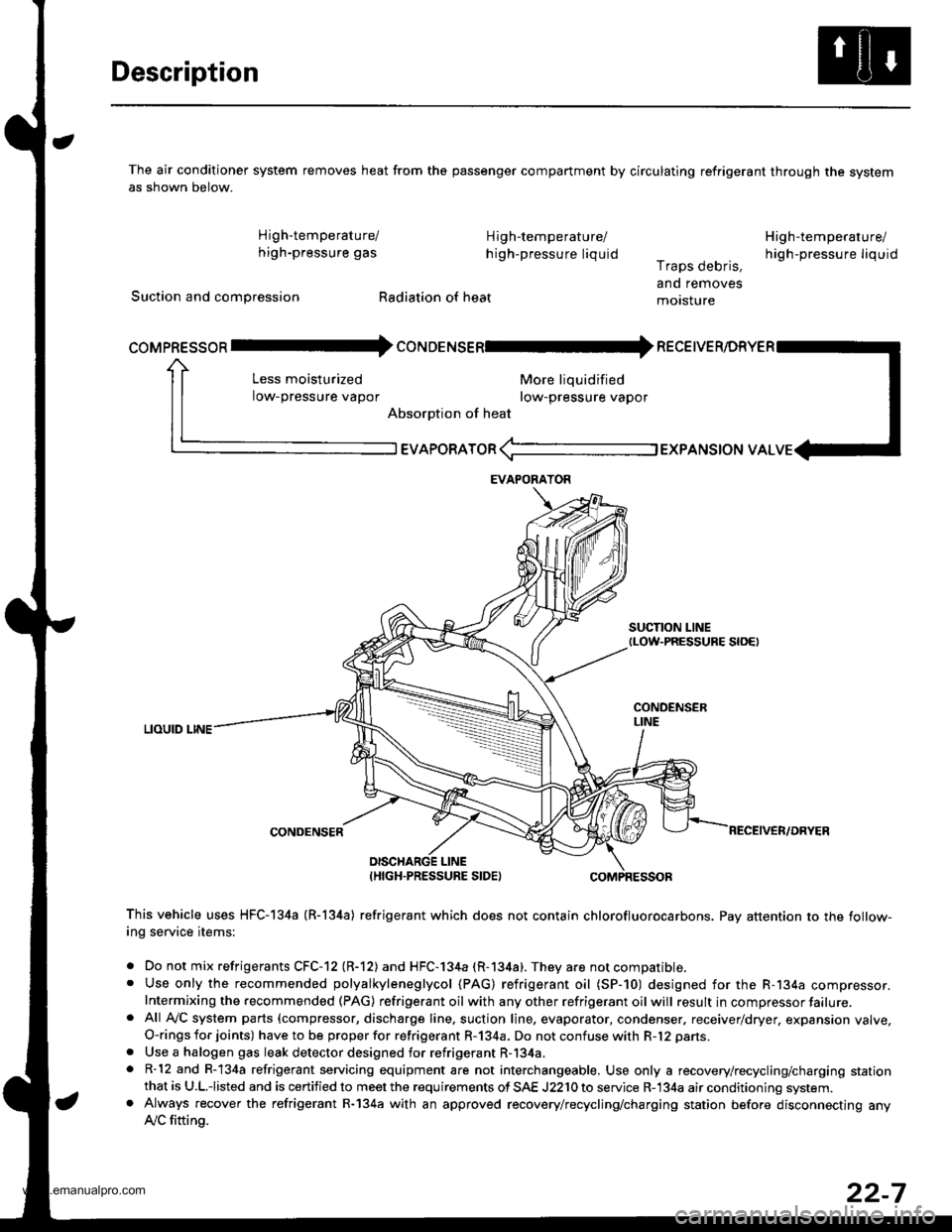

Description

The air conditioner system removes heat from the passenger compartment by circulating refrigerant through the systemas shown below.

High'temperature/ High-temperature/

high-pressure gas h igh-pressure liquid

Suction and compression Radiation of heat

High-temperature/

high-pressu re liq uidr raps oeons,

and removes

motsture

More liquidified

row-pressure vapor

EVAPoRAToR (-l EXPANSToN vAL

SUCTION LINEtLow-PRESSURE S|OEt

LIOUID LINE

CONDENSER

coMpREssoR Il- coruoerusenl* necetve

Less moisturized

low-pressure vapor

Absorption of heat

DISCHARGE LINEIHIGH.PRESSURE SIDEI

This vehicle uses HFC-I34a (R-l34a) refrigerant which does not contain chlorofluorocarbons. Pay attention to the follow-ing service items:

. Do not mix refrigerants CFC-12 (R-12) and HFC-l34a (R-134a). They are not compatible.. Use only the recommended polyalkyleneglycol (PAG) refrigerant oil (SP-10) designed for the R-134a compressor.Intermixing the recommended (PAG) refrigerant oil with any other refrigerant oil will result in compressor failure.. Afl Ay'C system parts (compressor, discharge line. suction line, evaporator, condenser. receiver/dryer, expansion valve,O-rings for joints) have to be proper for refrigerant R-134a. Do not confuse with R-12 parts.

. Use a halogen gas leak detector designed for refrigerant R-134a.. R-12 and R-134a refrigerant servicing equipment are not interchangeable. Use only a recovery/recycling/charging stationthat is U.L.iisted and is certified to meet the requirements of SAE J2210 to service R-134a air conditioning system.. Always recover the refrigerant R-134a with an approved recovery/recycling/charging station before disconnecting anylVC fitting.

EVAPORAYOR

22-7

www.emanualpro.com

Page 1099 of 1395

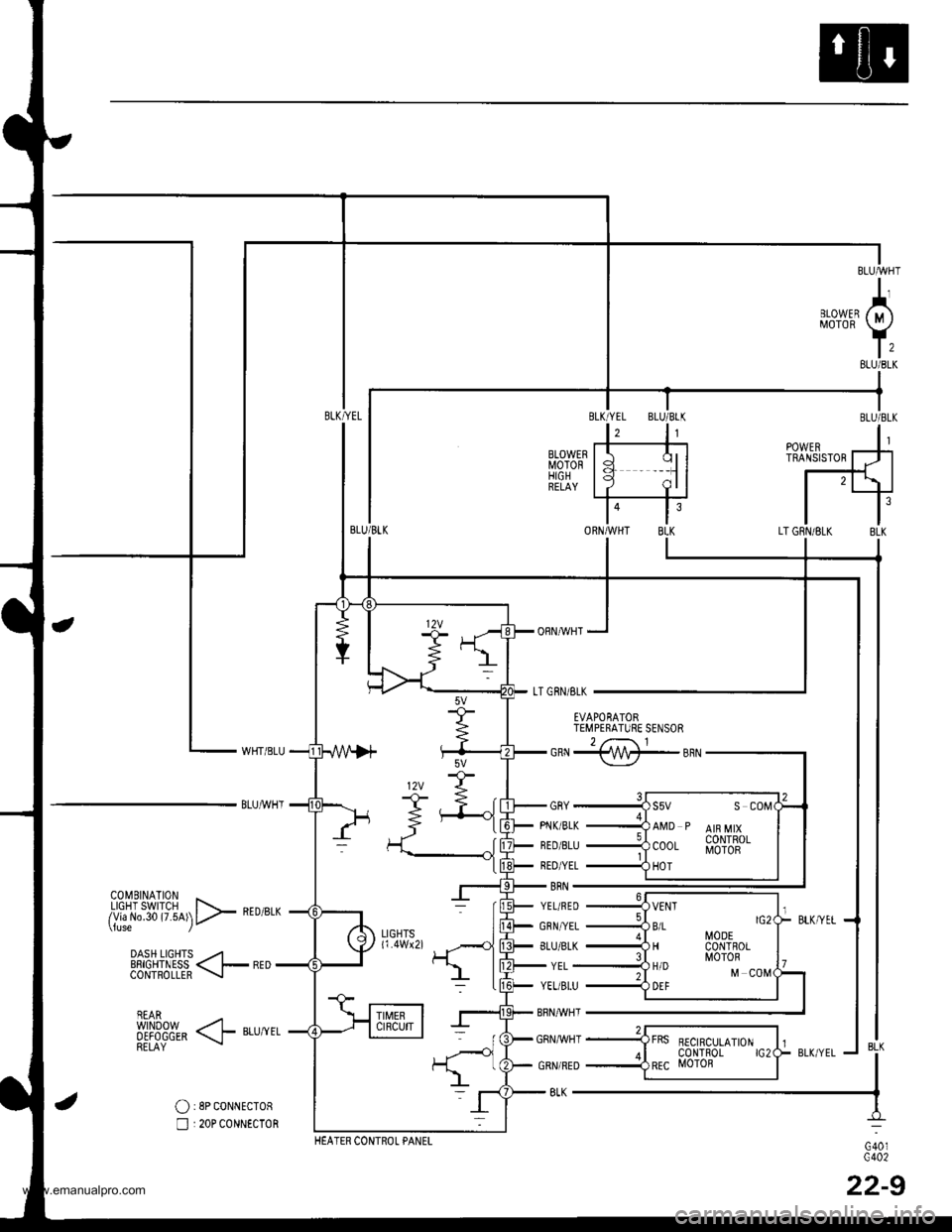

cnNj@_snN

GRY

PNK/BLK

NED/8LU

REO/YEL

YEL/BLU

8RN/WHT

GRNI/VHT

GRN/RED

POWERTRANSISTOR

c401c402

22-9

4

ORNMHT

Fg"{

EVAPONATORTEMPERATURE SENSOR

fi3'.Hfi|$l#i9D>

"'"-

DASH LTGHTS _/4EE|GHTNESS < l_ REDCONTROLLER -!

REAR

fllf$!S,* (l aLurrLRELAY

O:8P coNNEcToR

n :20P c0NN€CToR

YEL/RED

GRN/YEL

8LU/8LK

BRN

YEL

s5v s coM

AMD P AIR MIXCONTROLMOTOB

HOT

VENT

B/LI/lODEH CONT8OLl

10T0RH/D MDEF

HEATER CONTROL PANEI-

8LK

www.emanualpro.com

Page 1101 of 1395

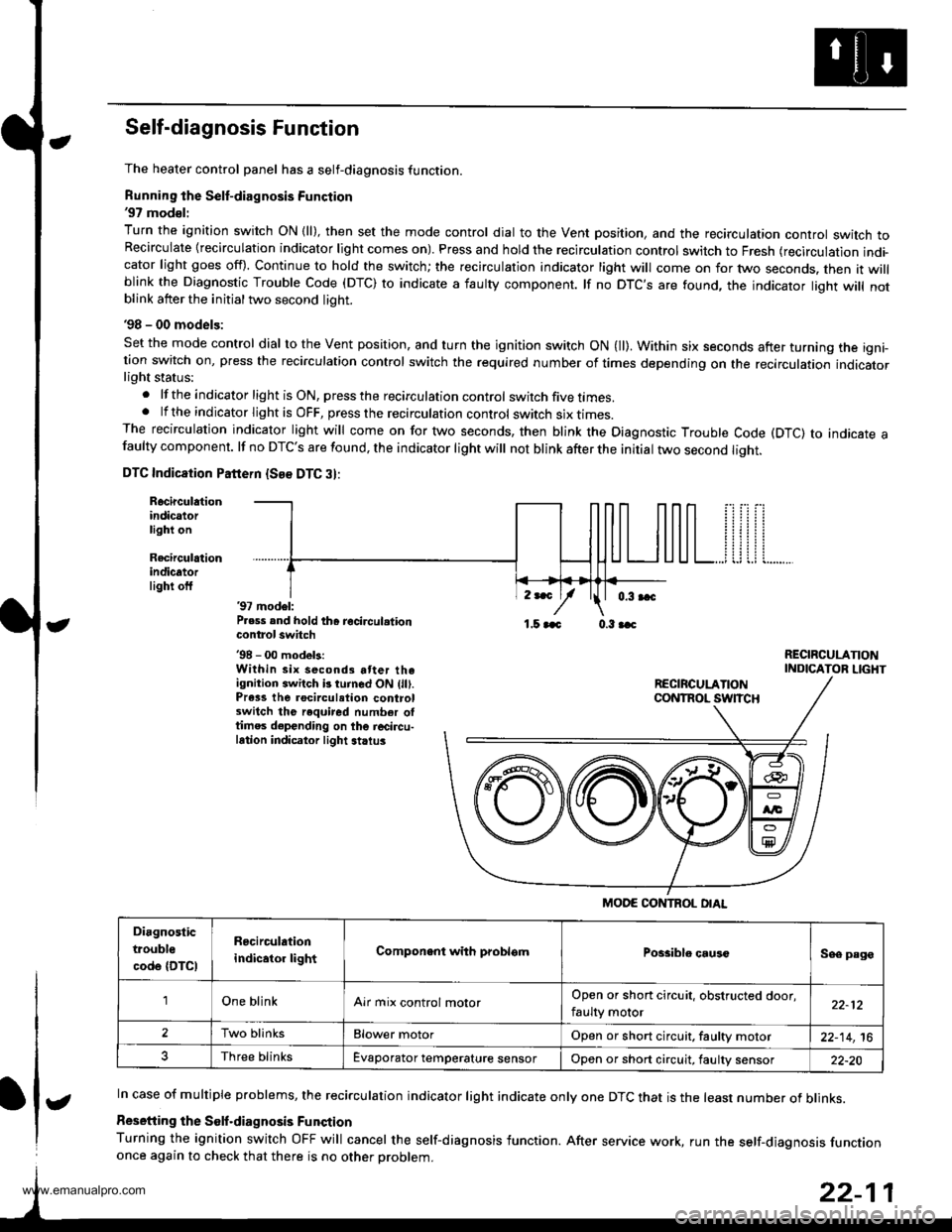

Self-diagnosis Function

The heater control panel has a self-diagnosis function.

Running the Self-diagnosis Function'97 mod€l:

Turn the ignition switch ON {ll), then set the mode control dial to the Vent position, and the recirculation controt switch toRecirculate {recirculation indicator light comes on). Press and hold the recirculation control switch to Fresh (recirculation indi-cator light goes off). Continue to hold the switch; the recirculation indicator light will come on for two seconds. then it willblink the Diagnostic Trouble Code (DTC) to indicate a iaulty component. lf no DTC'S are found, the indicator liqht will notblink atter the initial two second light.

'98 - 00 models:

Set the mode control dial to the Vent position, and turn the ignition switch ON (ll). Within six seconds after turning the igni-tion switch on, press the recirculation control switch the required number of times depending on the recirculation indicatorlight status:

.lftheindicatorlightisON,presstherecirculationcontrol switch five times..lftheindicatorlightisOFF,presstherecirculationcontrol switch six I|mes.The recirculation indicator light will come on for two seconds, then blink the Diagnostic Trouble Code (DTC) to indicate afaulty component. lf no DTC'S are found, the indicator light will not blink after the initial two second liqht.

DTC Indicaiion Pattern {See DTC 3}:

Rocirculationindicatorlight on

Recirculrtionindicatorlighi off'97 model:P.ess and hold th6 recircul.tioncontrol switch'98 - 00 modek:Within six second3 atter theignition switch b turned ON (lll.Prass the rocirculation controlswitch the required number oltimes depending on the r6circu-lation indicator light striu3

,r*

/1.5 aaa 0.3 aac

RECIRCULANONINDICATOR LIGHT

In case of multiple problems, the recirculation indicator light indicate only one DTC that is the least number of blinks.

Resetiing the Solf.diagnosis Funqtion

Turning the ignition switch OFF will cancel the self-diagnosis function. After service work, run the self-diaqnosis functiononce again to check that there is no other Droblem.

MODE CONTROL OIAL

Diagnostic

trouble

code {DTCI

R6circulation

indicator lightComponent with problsmPossiblo causcSee page

'lOne blinkAir mix control molorOpen or short circuit, obstructed door,

faulty motor22-12

2Two blinksElower motorOpen or short circuit, faultv motor22-14,16

Three blinksEvaporator temperature sensorOpon or short circuit, faulty sensor22-20

t

www.emanualpro.com

Page 1102 of 1395

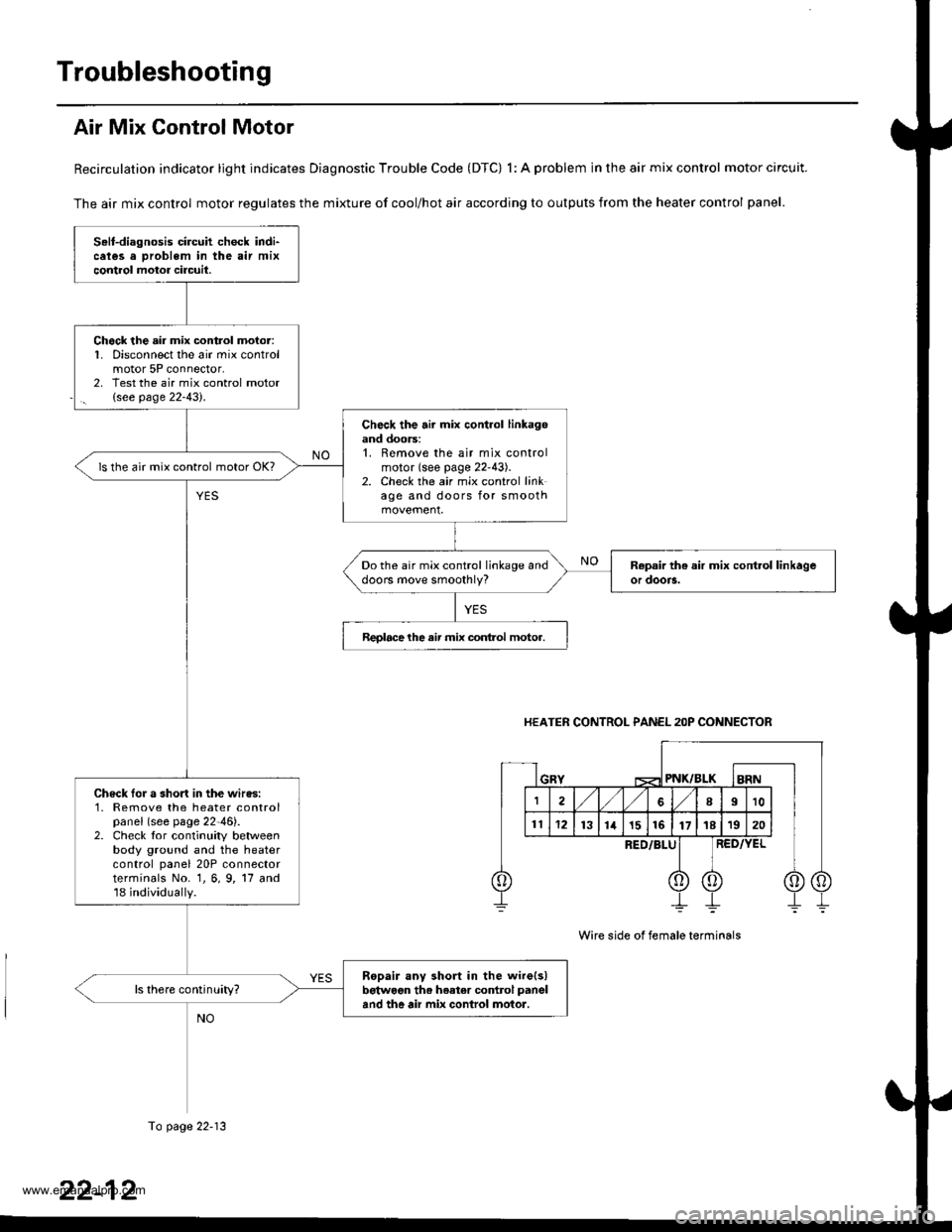

Troubleshooting

Air Mix Control Motor

Recirculation indicator light indicates Diagnostic Trouble Code (DTC) 1: A problem in the air mix control motor circuit.

The air mix control motor regulates the mixture of cool/hot air according to outputs from the heater control panel.

Selt-diagnosis circuit check indi-cates a Droblem in the air mixcontrol motor circuil.

Chock the air mix control moior:1. Disconnect the air mix controlmotor 5P connector,2, Test the air mix control motor(see page 22-43).

Check the air mix control linkagoand doors:1. Remove the air mix controlmotor (see page 22'43).2. Check the air mix control linkage and doors for smooth

ls the air mix control motor OK?

Do the air mix control linkage anddoors move smoothly?

Reolacelhe air mix conlrol motor.

Check Ior a short in the wires:1- Remove the heater controlpanel (see page 22-46).2. Check tor continuity betweenbody ground and the heatercontrol panel 20P connectorterminals No. 1, 6, 9, 17 and18 individually.

Ropair any short in the wire(s)betwoon th. heater co.rtrol panel

and the air mix conlrol motor.

HEATER CONTROL PANEL 2OP CONNECTOR

PNK/BLK

RED/BLU

Wire side of female terminals

To page 22-13

www.emanualpro.com