Harness HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 248 of 1395

![HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

System Description

System Connectors lEngine Gompartment] -98 Model

MAIN WIREHARNESS

UNDER.HOODFUSE/RELAYBOX

ENGINEw|REHARNESS

*2: USA

11-46

www.emanualpro.com HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

System Description

System Connectors lEngine Gompartment] -98 Model

MAIN WIREHARNESS

UNDER.HOODFUSE/RELAYBOX

ENGINEw|REHARNESS

*2: USA

11-46

www.emanualpro.com](/img/13/5778/w960_5778-247.png)

System Description

System Connectors lEngine Gompartment] -'98 Model

MAIN WIREHARNESS

UNDER.HOODFUSE/RELAYBOX

ENGINEw|REHARNESS

*2: USA

11-46

www.emanualpro.com

Page 250 of 1395

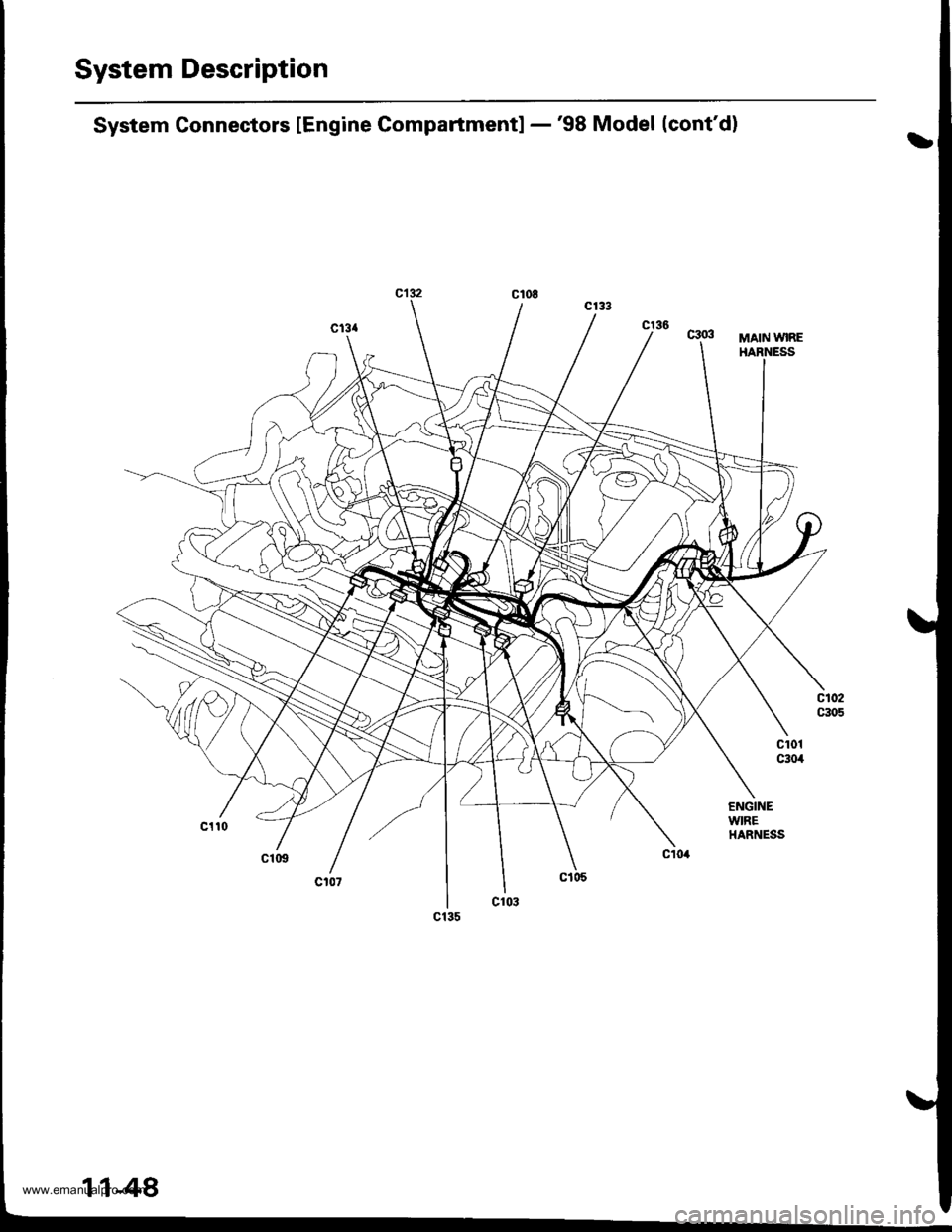

System Description

System Connectors lEngine Compartmentl -'98 Model (cont'd)

MAIN WIRE

ENGINEWIREHARNESS

www.emanualpro.com

Page 252 of 1395

![HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

System Description

System Gonnectors lEngine Compartment] -99 - 00 Models

MAIN WIREHAENESS

UNDER.HOOOFUSE/RELAYBOX

ENGINEWIREHARNESS

www.emanualpro.com HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

System Description

System Gonnectors lEngine Compartment] -99 - 00 Models

MAIN WIREHAENESS

UNDER.HOOOFUSE/RELAYBOX

ENGINEWIREHARNESS

www.emanualpro.com](/img/13/5778/w960_5778-251.png)

System Description

System Gonnectors lEngine Compartment] -'99 - 00 Models

MAIN WIREHAENESS

UNDER.HOOOFUSE/RELAYBOX

ENGINEWIREHARNESS

www.emanualpro.com

Page 254 of 1395

![HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

System Description

System Gonnectors [Engine Compartment] -99 - 00 Models {contdl

MAIN WIREHARNESS

11-52

www.emanualpro.com HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

System Description

System Gonnectors [Engine Compartment] -99 - 00 Models {contdl

MAIN WIREHARNESS

11-52

www.emanualpro.com](/img/13/5778/w960_5778-253.png)

System Description

System Gonnectors [Engine Compartment] -'99 - 00 Models {cont'dl

MAIN WIREHARNESS

11-52

www.emanualpro.com

Page 258 of 1395

![HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

System Description

System Connectors lDash and Floorl -98 - 00 Models (contd]

c510DASHBOARD WIREHARNESS

MAIN WIEEHARNESS

4: 99 - 00 models

1 1-56

www.emanualpro.com HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

System Description

System Connectors lDash and Floorl -98 - 00 Models (contd]

c510DASHBOARD WIREHARNESS

MAIN WIEEHARNESS

4: 99 - 00 models

1 1-56

www.emanualpro.com](/img/13/5778/w960_5778-257.png)

System Description

System Connectors lDash and Floorl -'98 - 00 Models (cont'd]

c510DASHBOARD WIREHARNESS

MAIN WIEEHARNESS

'4: '99 - 00 models

1 1-56

www.emanualpro.com

Page 260 of 1395

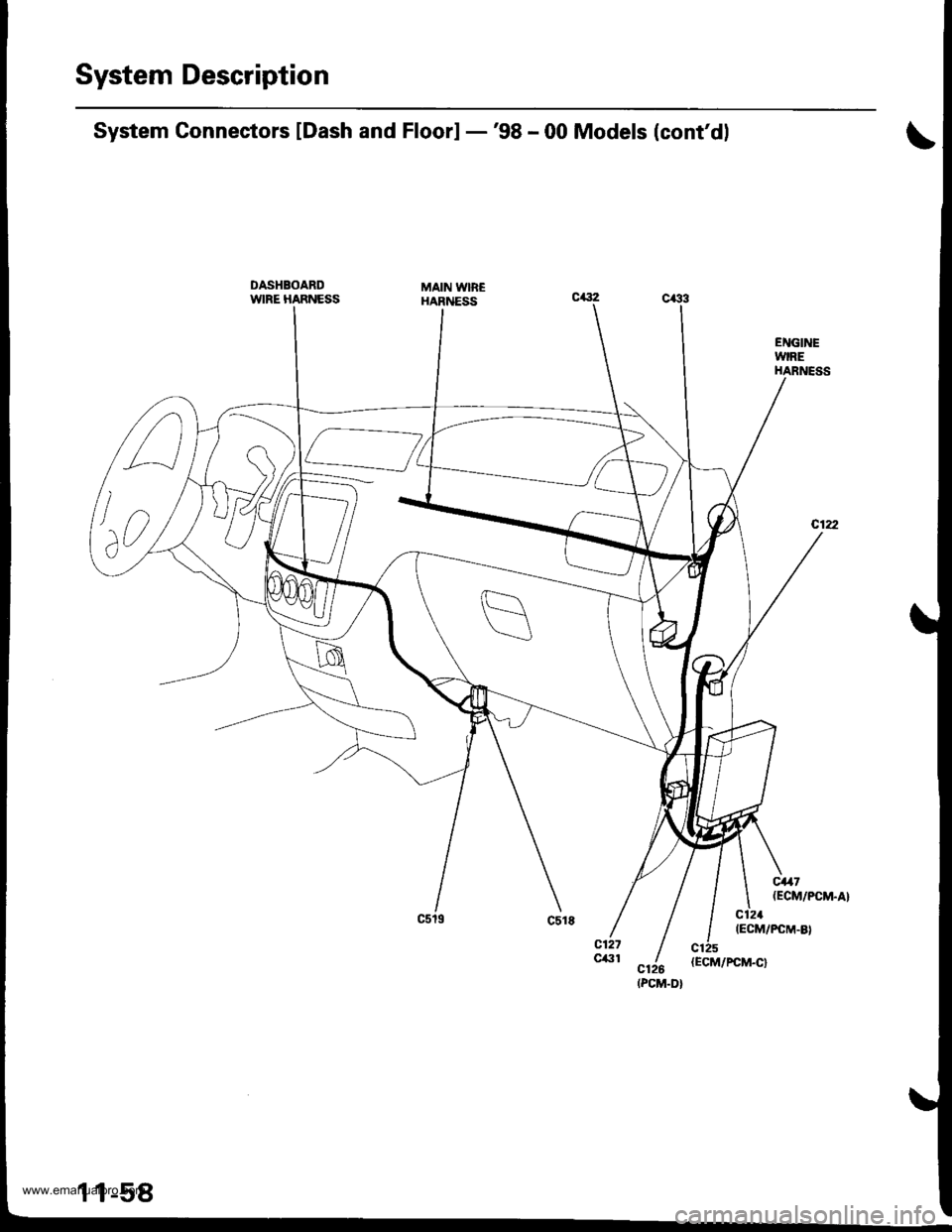

System Description

ENGINEWIREHARNESS

System Conneetors lDash and Floorl -'98 - 00 Models (cont'dl

DASHBOARDWIRE HARNESSMAIN WIB€HARNESS

c,47(ECM/PCM.A}

c121(ECM/PCM-8)

n

lno,

(PCM.D}

www.emanualpro.com

Page 330 of 1395

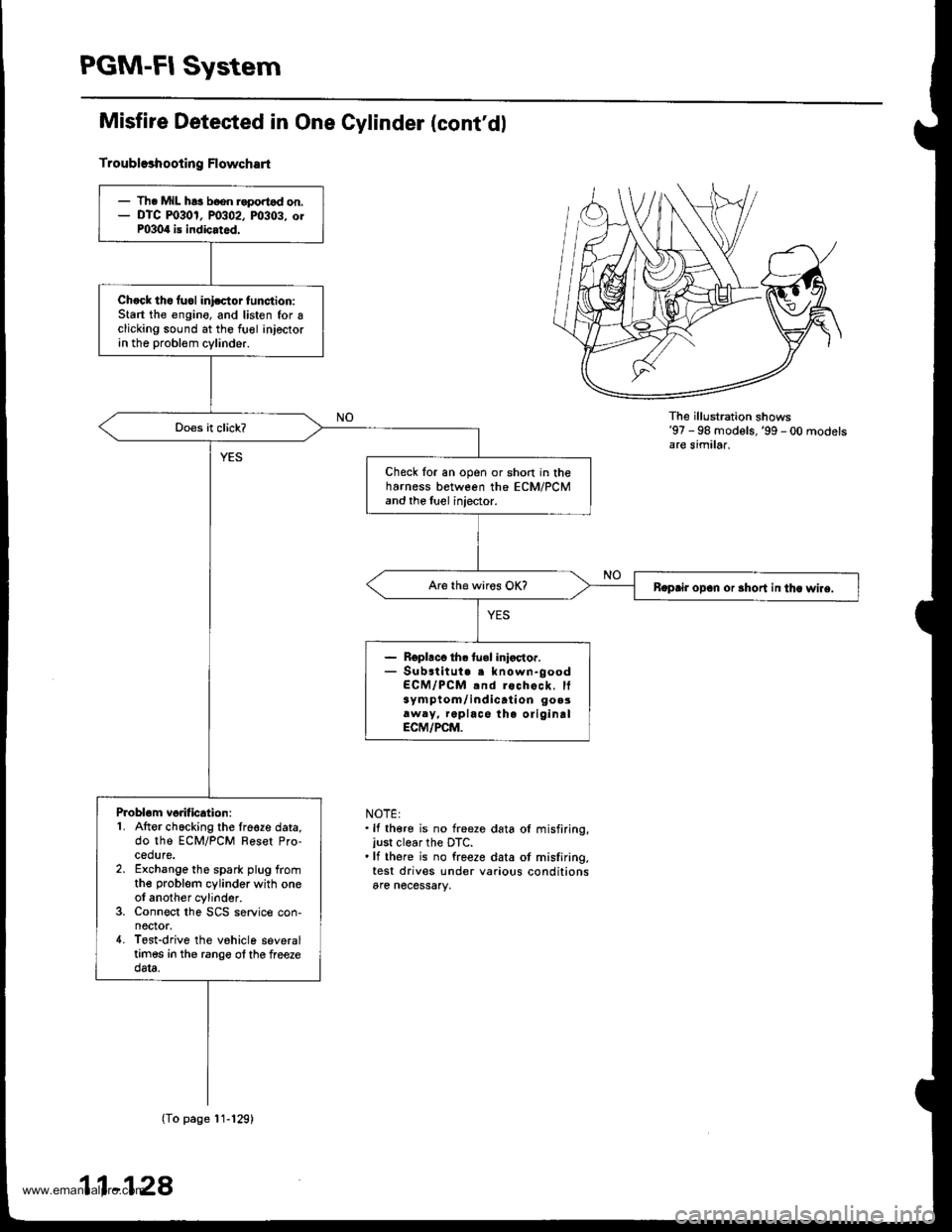

PGM-FI System

Misfire Detested in One Cylinder (cont'dl

Troubl93hooting Flowchart

The illu stration shows'97 - 98 models,'99 - 00 modelsare similar.

NOTE:.lf there is no freeze data ol misfiring,just clear the DTC..lf there is no freeze data ot misfiring,test drives under various conditionsare necessary,

- Th. MIL h!3 b6on r.portod on.- DTC m30r, P0302, m303. orP0304 is indicated.

Ch.ck tho fuol inicctor tunction:Start the engino, and listen for Iclicking sound at the fuol injectorin the probl€m cylinder.

Check for an open or short in theharness between the ECM/PCMand the luel injector.

Boprir opan or 3hort in tha wlre.

- Roplaco th. tuel inioctor.- Substitut. . known-goodECM/PCM .nd rochock. It3ym ptom/ indicati on go.3aw.y, replace the oliginalECM/PCM.

Problom vorification:1. Atter chacking the lre€ze data,do the ECM/PCM Reset Pro-cedure.2. Exchange the spark plug fromthe problem cylinder with oneol another cylinder.3. Connect the SCS service con-nector.4. Tost-drive the vohicle severaltimes in the rango ol the freezedata.

(To page'11-129)

11-128

www.emanualpro.com

Page 364 of 1395

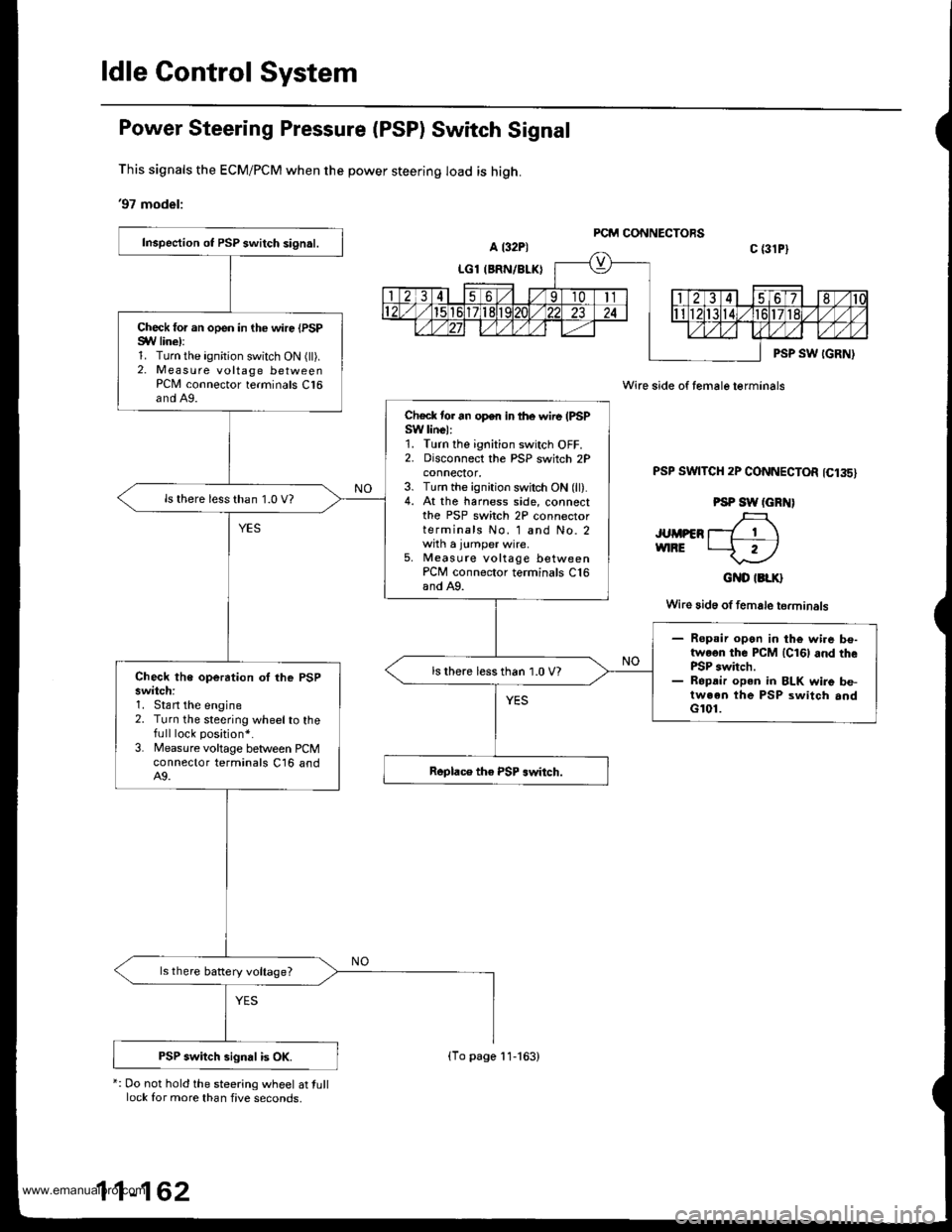

ldle Gontrol System

Power Steering Pressure (PSP) Switch Signal

This signals the ECM/PCM when the power steering load is high.

'97 model:

*: Do not hold the steering wheel at tulllock for more than five seconds,

Wire side of female terminals

PSP SWTTCH 2P CONNECTOR 1C135)

PSP SW (GRN)

JUMPER T_7 1 \vnRE t--f r)

GND IBLK}

Wire 3id6 of female terminals

Inspection ot PSP switch signal.

Check for an open in the wire {PSPSYV line):1. Turn the ignition switch ON (ll).2. Measure voltage betweenPCN4 connector terminals C16and A9.

Check tor an open in lhe wire (PSPSW linel:1. Turn the ignition switch OFF.2. Disconnect the PSP switch 2Pconnecror,3. Turn the ignition switch ON (ll).4. At the harness side, connectthe PSP switch 2P connectorterminals No. 1 and No. 2with a jumper wire.5, Measute voltage betweenPCM connector terminals C16and A9.

ls there less than 1.0 V?

- Ropsir open in the wi.e be-twoon the PCM lcl6l and thePSP switch.- Ropdir open in BLK wire be-tween the PSP switch andG101.

ls there less than 1.0 V?Check the operation oI lhe PSPswitch:1. Stan the engine2. Turn the steering wheelto thefull lock position*.

3. Measure voltage between PCMconnector terminals C16 andA9.

ls there battery voltage?

PSP switch signal is OK.(To page 11-163)

www.emanualpro.com

Page 384 of 1395

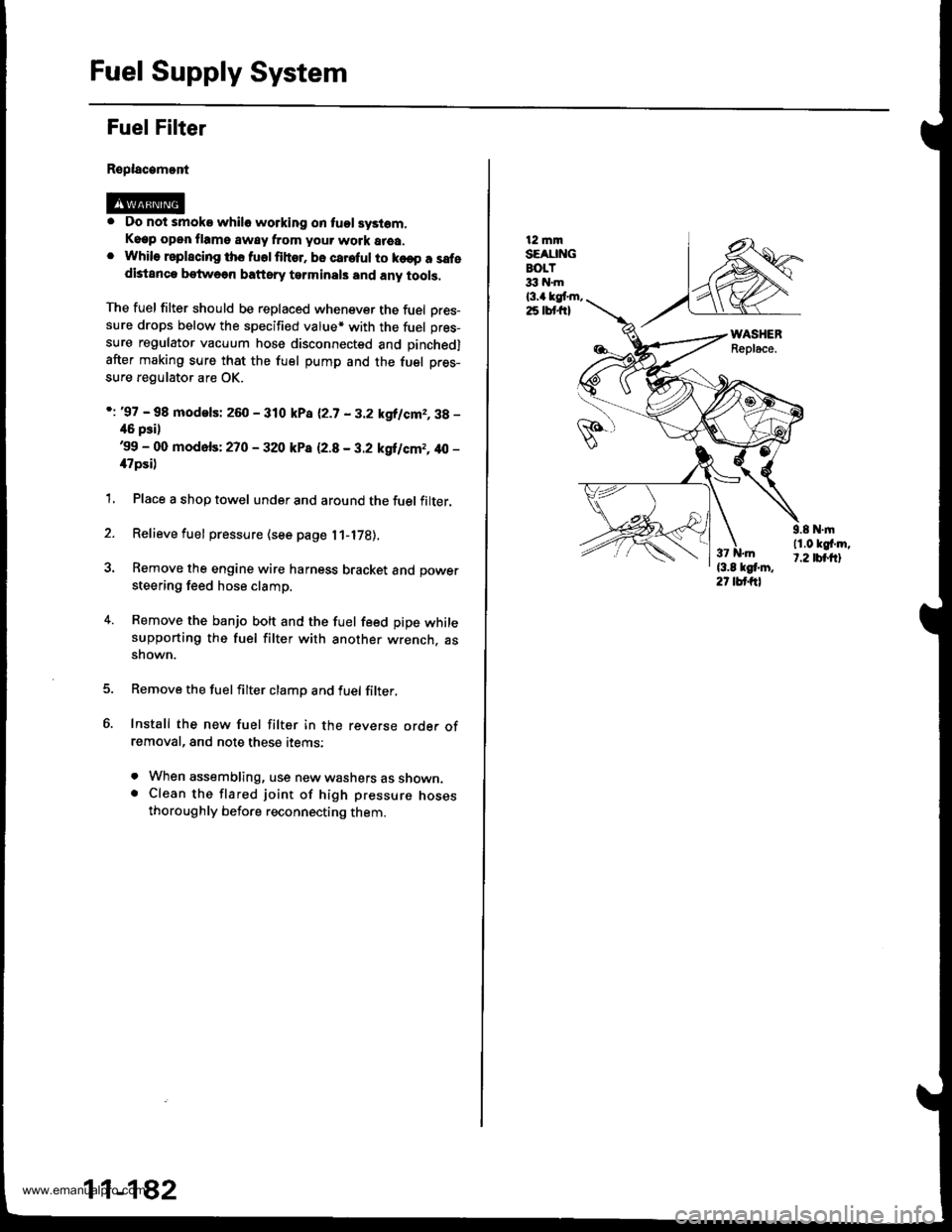

Fuel Supply System

Fuel Filter

Replacamont

. Do not smoke whilo working on tuol syslom,Keep open flame away from your work area.. While rsplscing ths fuolfihor. bo careful to ko€p a safedistanca betweon baftsry tarminals and any tools,

The fuel filter should be replaced whenever the fuel Dres-sure drops below the specified value* with the fuel pres-

sure regulator vacuum hose disconnected and pinchedl

after making sure that the fuel pump and the fuel pres-

sure regulator are OK.

i: '97 - 98 modelsi 260 - 310 kPa 12.7 - 3.2 kgllcm2,3g -

46 psil'99 - 00 mod6fs: 270 - 320 kP8 12.8 - 3.2 kgilcm2, 40 -

il7psi)

1, Place a shop towel under and around the fuel filter.

2. Relieve fuel pressure (see page l1-l7B).

3. Remove the engine wire harness bracket and power

steering feed hose clamp.

4. Remove the banjo bolt and the fuel feed pipe whilesupporting the fuel filter with another wrench. assnown.

Remove the fuelfilter clamp and fuel filter,

Install the new fuel filter in the reverse orde. ofremoval, and note these items:

. When assembling, use new washers as shown.. Clean the flared joint of high pressure nosesthoroughly before reconnecting them.

11-182

12 mmSEAUNGBOLT33 hl.m

l3.a kgt m,25 lbt frl

9.8 N.|n11.0 kgf'm,t.2 tbt.ftl

www.emanualpro.com

Page 385 of 1395

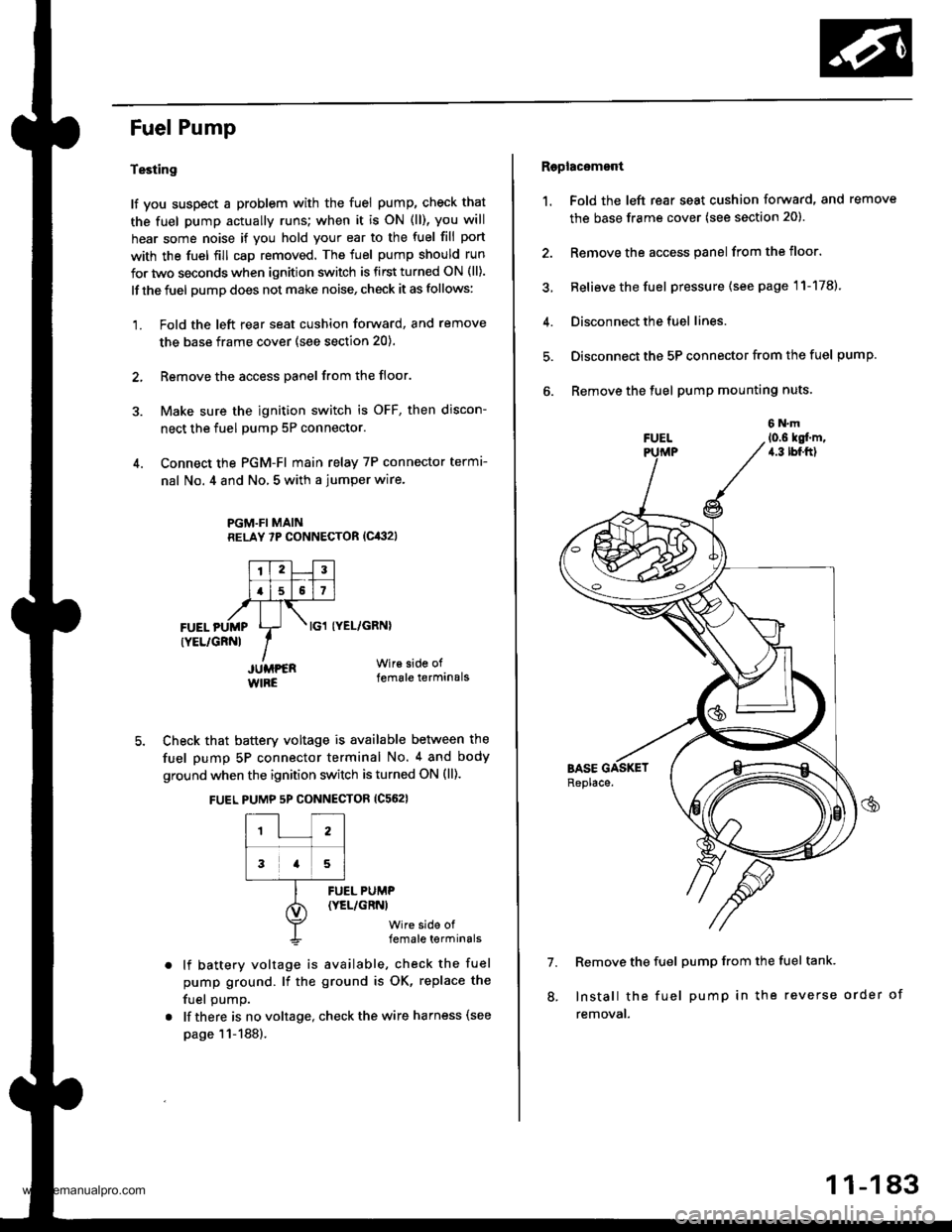

Fuel Pump

Testing

lf you suspect a problem with the fuel pump, check that

the fuel pump actually runs; when it is oN (ll), you will

hear some noise if you hold your ear to the fuel fill port

with the fuel fill cap removed. The fuel pump should run

for two seconds when ignition switch is first turned ON (ll).

lf the fuel pump does not make noise, check it as follows:

1. Fold the left rear seat cushion forward, and remove

the base frame cover (see section 20).

2, Remove the access panel from the floor.

3. Make sure the ignition switch is OFF, then discon-

nect the fuel pumP 5P connector.

4. Connect the PGM-FI main relay 7P connector termr-

nal No. 4 and No, 5 with a jumper wire.

PGM.FI MAINRELAY 7P CONNECTOR (Cit:}2l

I'TtlJilt f -r'-r ll.l5l517l,frTt-,at\FUEL pUMp Lr- . tcl tyEL/cRNl

rYEL/cRNl IIJUMPER Wir€ side of

WIRE female terminals

5. Check that battery voltage is available between the

fuel pump 5P connector terminal No. 4 and body

ground when the ignition switch is turned ON (ll).

FUEL PUMP 5P CONNECTOR {C562}

12

3a5

lf battery voltage is available, check the fuel

pump ground. lf the ground is OK, replace the

fuel oumo.

lf there is no voltage, check the wire harness (see

page 11-188).

FUEL PUMP(YEL/GRNI

wire side offemale terminals

Raplac6mont

1. Fold the left rear seat cushion forward, and remove

the base frame cover (see section 20).

2. Remove the access panel from the floor.

3, Relieve the fuel pressure (see page 11-178).

4. Disconnect the fuel lines.

5. Disconnect the 5P connector from the fuel pump.

6. Remove the fuel pump mounting nuts.

7. Remove the fuel pump from the fuel tank.

Install the fuel pump in the reverse order of

removal.

8.

11-183

www.emanualpro.com