clock HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 199 of 1395

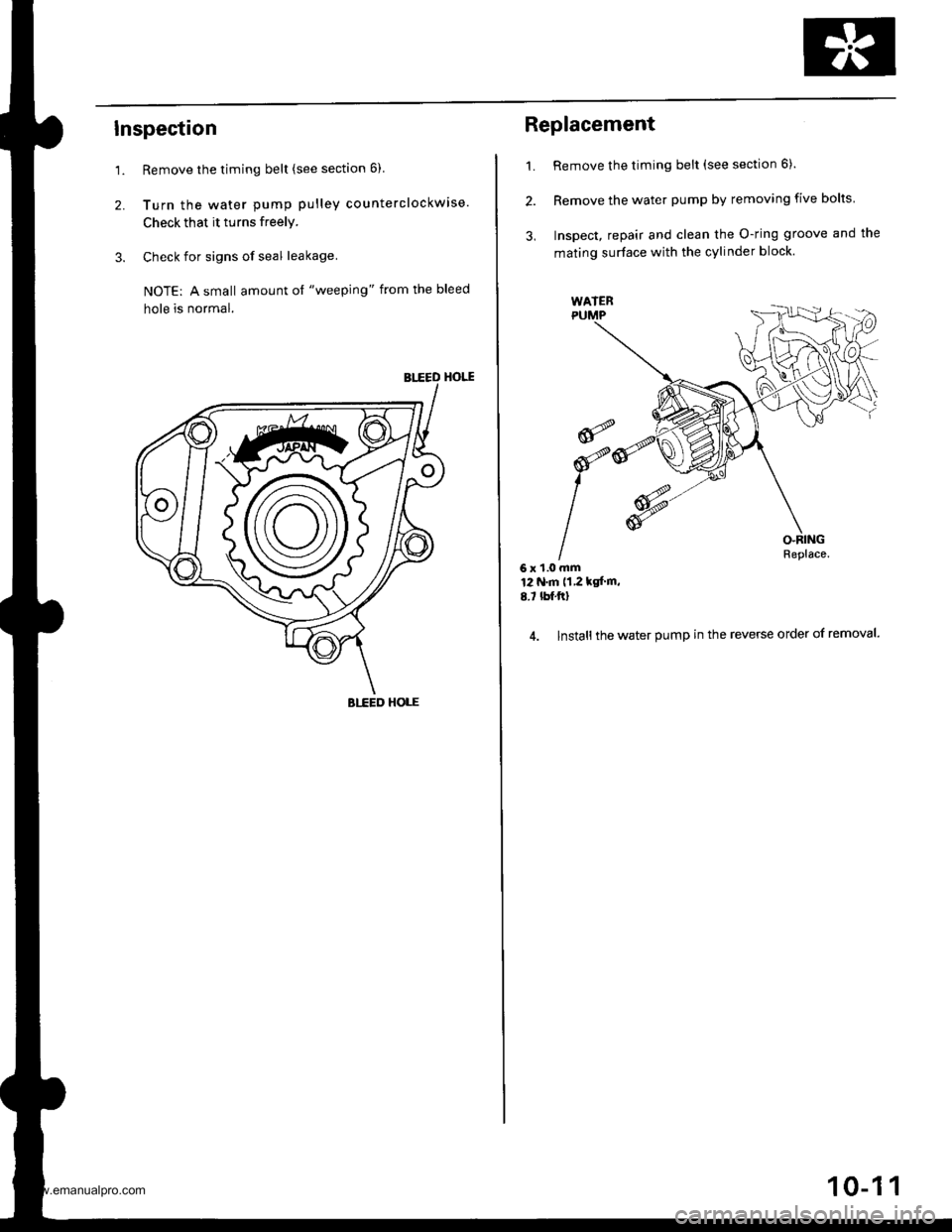

Inspection

1.

2.

Remove the timing belt (see section 6)

Turn the water pump pulley counterclockwise.

Check that it turns freely.

Check for signs of seal leakage.

NOTE: A small amount ol "weeping" from the bleed

hole is normal.

BIIED HOLE

Replacement

1. Remove the timing belt (see section 6).

2. Remove the water pump by removing five bolts

3, Inspect, repair and clean the O-ring groove and the

mating surface with the cylinder block.

Replace.6x1.0mm't2 N.m 11 2 kgf m.

8.7 tbf.ftl

4. lnstall the water pump in the reverse order of removal.

-

I

I

10-1 1

www.emanualpro.com

Page 453 of 1395

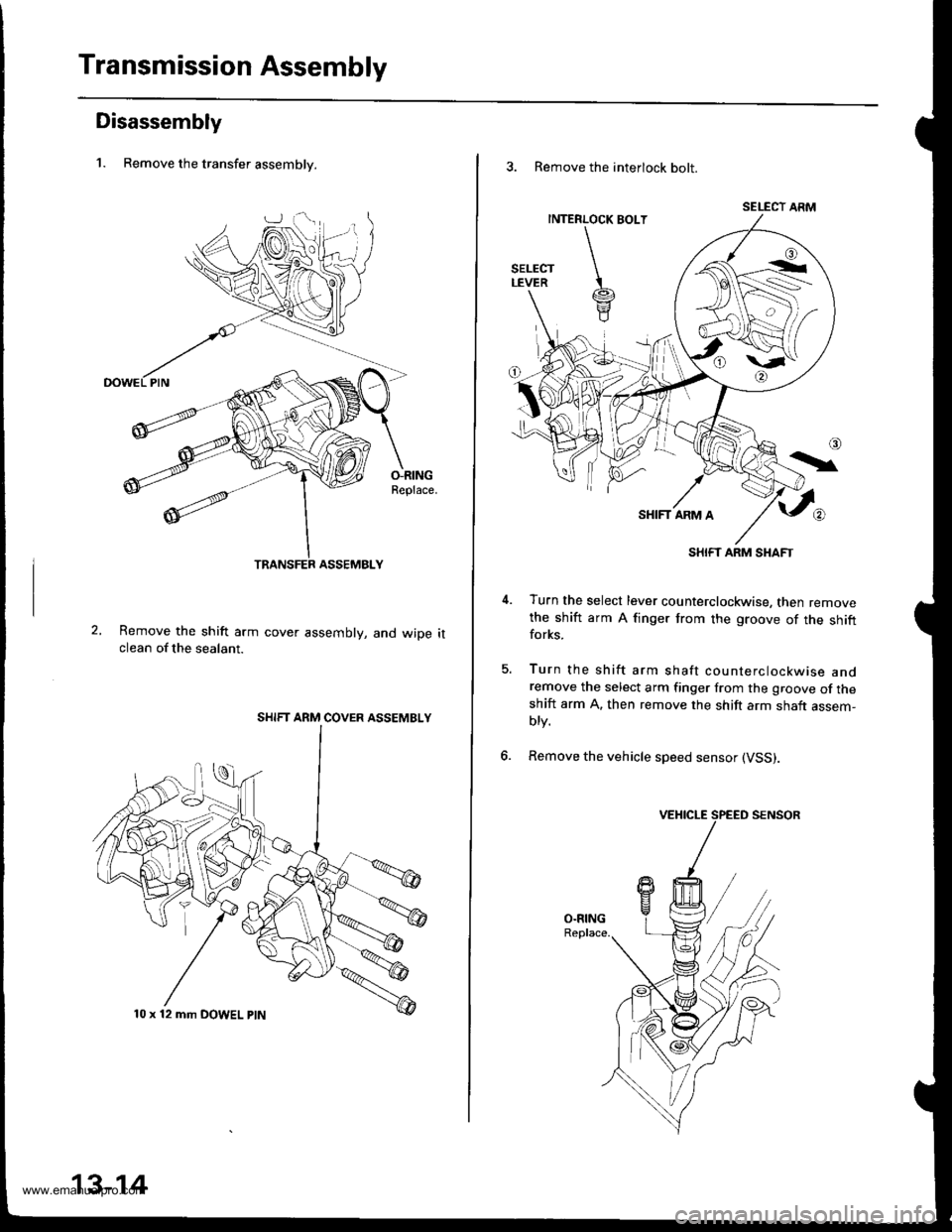

Transmission Assembly

Disassembly

1. Remove the transfer assemblv.

O-RINGReplace.

Remove the shift arm cover assembly, and wiDe itclean of the sealant.

SHIFT ARM COVER ASSEMBLY

10 x 12 mm DOWEL ptN

13-14

3. Remove the interlock bolt.

SELECT ARM

SHIFT ARM SHAFT

Turn the select lever counterclockwise, then removethe shift arm A finger from the groove of the shiftforks.

Turn the shift arm shaft counterclockwise andremove the select arm finger from the groove of theshift arm A. then remove the shift arm shaft assem-blv.

Remove the vehicle speed sensor (VSS).

5.

6.

www.emanualpro.com

Page 505 of 1395

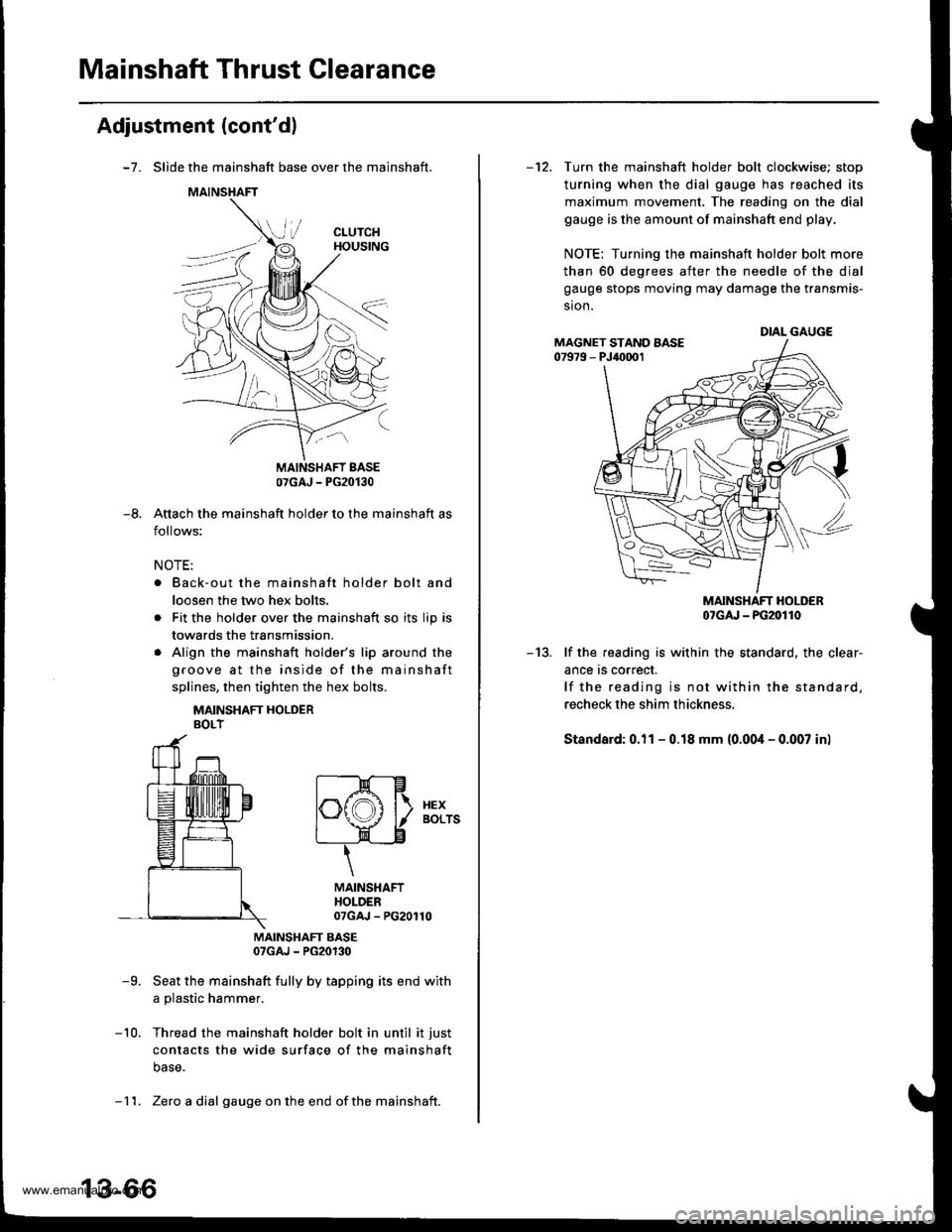

Mainshaft Thrust Clearance

Adjustment (cont'dl

-7. Slide the mainshaft base over the mainshaft.

Attach the mainshaft holder to the mainshaft as

follows:

NOTE:

. Back-out the mainshaft holder bolt and

loosen the two hex bolts.

. Fit the holder over the mainshaft so its lip is

towards the transmission.

. Align the mainshaft holder's lip around the

groove at the inside of the mainshaft

splines, then tighten the hex bolts.

MAINSHAFT HOLDERBOLT

MAINSHAFT EASE07GAJ - PG20130

-9. Seat the mainshaft fully by tapping its end with

a plastic hammer.

-10. Thread the mainshaft holder bolt in until it just

contacts the wide surface of the mainshaft

base.

07GAJ - PG20130

-8.

t--E-Hlf\f,A l\. xex

l"\y I aors

t____=__)"n-____"8

\

MAINSHAFTHOLDER07GAJ - PG20110

- 11. Zero a dial gauge onthe end ofthe mainshait.

-12. Turn the mainshaft holder bolt clockwise; stop

turning when the dial gauge has reached its

maximum movement, The reading on the dial

gauge is the amount of mainshaft end play.

NOTE: Turning the mainshaft holder bolt more

than 60 degrees after the needle of the dial

gauge stops moving may damage the transmis-

sion.

MAINSHAFT HOLDER07cru - PG20110

-13. lf the reading is within the standard, the clear-

ance rs correct.

lf the reading is not within the standard,

recheck the shim thickness.

Standard: 0.11 - 0.18 mm (0.00i1- 0.007 inl

DIAL GAUGEMAGNET STAND AASE07979 - PJ40001

www.emanualpro.com

Page 510 of 1395

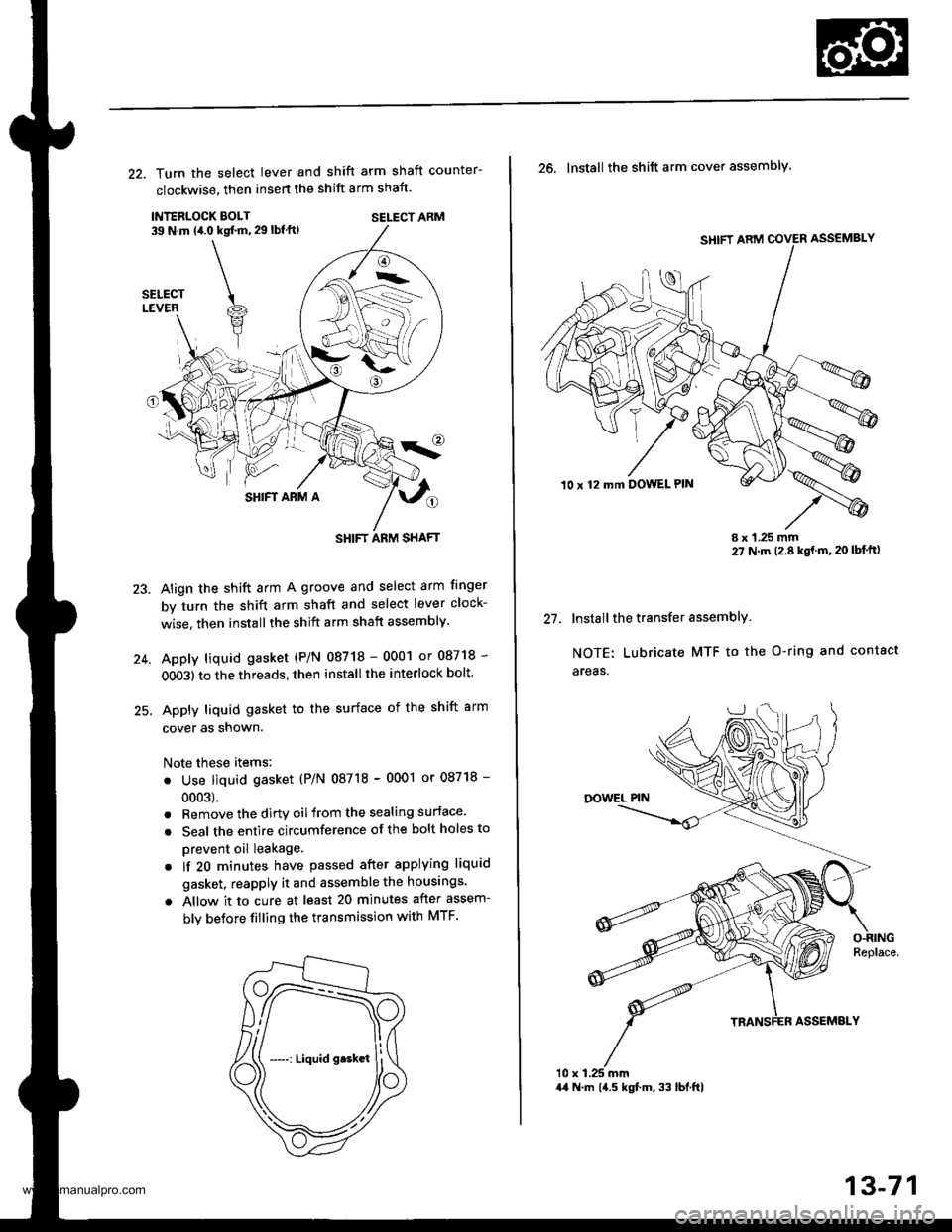

22. Turn the select lever and shift arm shaft counter-

clockwise, then insert the shift arm shaft.

INTERLOCK EOLT39 N.m (4.0 kqt ft, 29 lbf ft)SELECT ARM

SHIFT ARM A

Align the shift arm A groove and select arm finger

by turn the shift arm shaft and select lever clock-

wise. then installthe shift arm shaft assembly.

Apply liquid gasket (P/N 08718 - 0001 or 08718 -

OO03) to the threads, then install the interlock bolt'

Apply liquid gasket to the surface of the shift arm

cover as snown.

Note these items:

. Use liquid gasket (P/N 08718 - 0001 or 08718 -

0003).

. Remove the dirtv oilfrom the sealing surface.

. Seal the entire circumference of the bolt holes to

prevent oil leakage.

. lf 20 minutes have passed after applying liquid

gasket. reapply it and assemble the housings.

a Allow it to cure at least 20 minutes after assem-

bly betore filling the transmission with MTF.

23.

-->.-

(

SHIFT ARM SHAFT

SHIFT ARM COVER ASSEMBLY

10 x 12 mft DOWEL PIN

t1

26. Install the shift arm cover assembly.

I x 1.25 mm27 N m 12.8 kgt m,20 lbf'ft)

Install the transfer assemblY.

NOTE: Lubricate MTF to the O-ring and contact

areas.

10 x 1.25 mm44 N.m 14.5 kgf.m, 33 lbl.ftl

13-71

www.emanualpro.com

Page 572 of 1395

Troubleshooting Procedures

Checking ths Diagnostic Trouble Code (DTC)

with an O8D ll Scan tool or Honda PGM Tsster

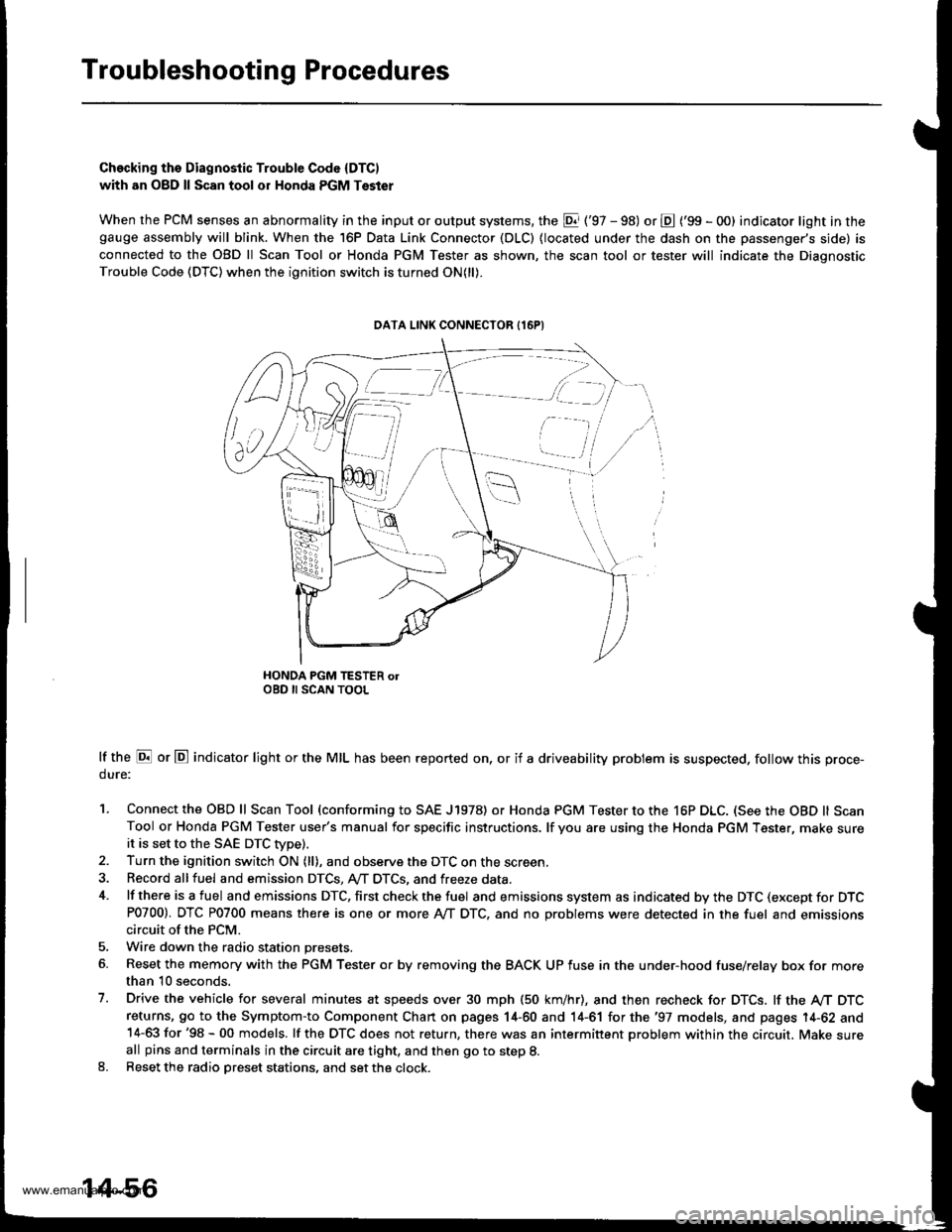

When the PCM senses an abnormality in the input or output systems, the El ('97 - 98) or E ('99 - O0) indicator light in thegauge ass€mbly will blink. When the 16P Data Link Connector (DLC) {located under the dash on the passenger's side) is

connected to the OBD ll Scan Tool or Honda PGM Tester as shown, the scan tool or tester will indicate the Diagnostic

Trouble Code (DTC) when the ignition switch is turned ON(ll).

HONDA PGM TESTER olOBD II SCAN TOOL

lf the E or E indicator light or the MIL has been reported on, or if a driveability problem is suspected, follow this proce-

dure:

1. Connect the OBD ll Scan Tool (conforming to SAE J1978) or Honda PGM Tester to the 16P DLC. (See the OBD ll ScanTool or Honda PGM Tester user's manual for specific instructions. lf you are using the Honda PGM Tester, make sureit is set to the SAE DTC Wpe).2. Turn the ignition switch ON (ll), and observe the DTC on the screen

3. Record allfuel and emission DTCS, A,,/T DTCS, and freeze data.

4. lf there is a fuel and emissions DTC, first check the fuel and emissions system as indicated by the DTC (except for DTCP0700). DTC P0700 means there is one or more Ay'T DTC, and no Droblems were detected in the fuel and emissionscircuit of the PCM.

5. Wire down the radio station presets.

6. Reset the memory with the PGM Tester o. by removing the BACK UP fuse in the under-hood fuse/relay box for morethan 10 seconds.

7. Drive the vehicle for several minutes at speeds over 30 mph (50 km/hr), and then recheck for DTCS. lf the A/T DTCreturns, 9o to the Symptom-to Component Chart on pages 14-60 and 14-61 for the '97 models, and pages 14-62 and14-63 for '98 - 00 models. lf the OTC does not return, there was an intermittent problem within the circuit. Make sureall pins and terminals in the circuit are tight, and then go to step 8.8. Reset the radio Dreset stations, and set the clock.

DATA LINK CONNECTOR {16PI

[ -=.r,

ili,i /i,

v,., i

14-56

www.emanualpro.com

Page 575 of 1395

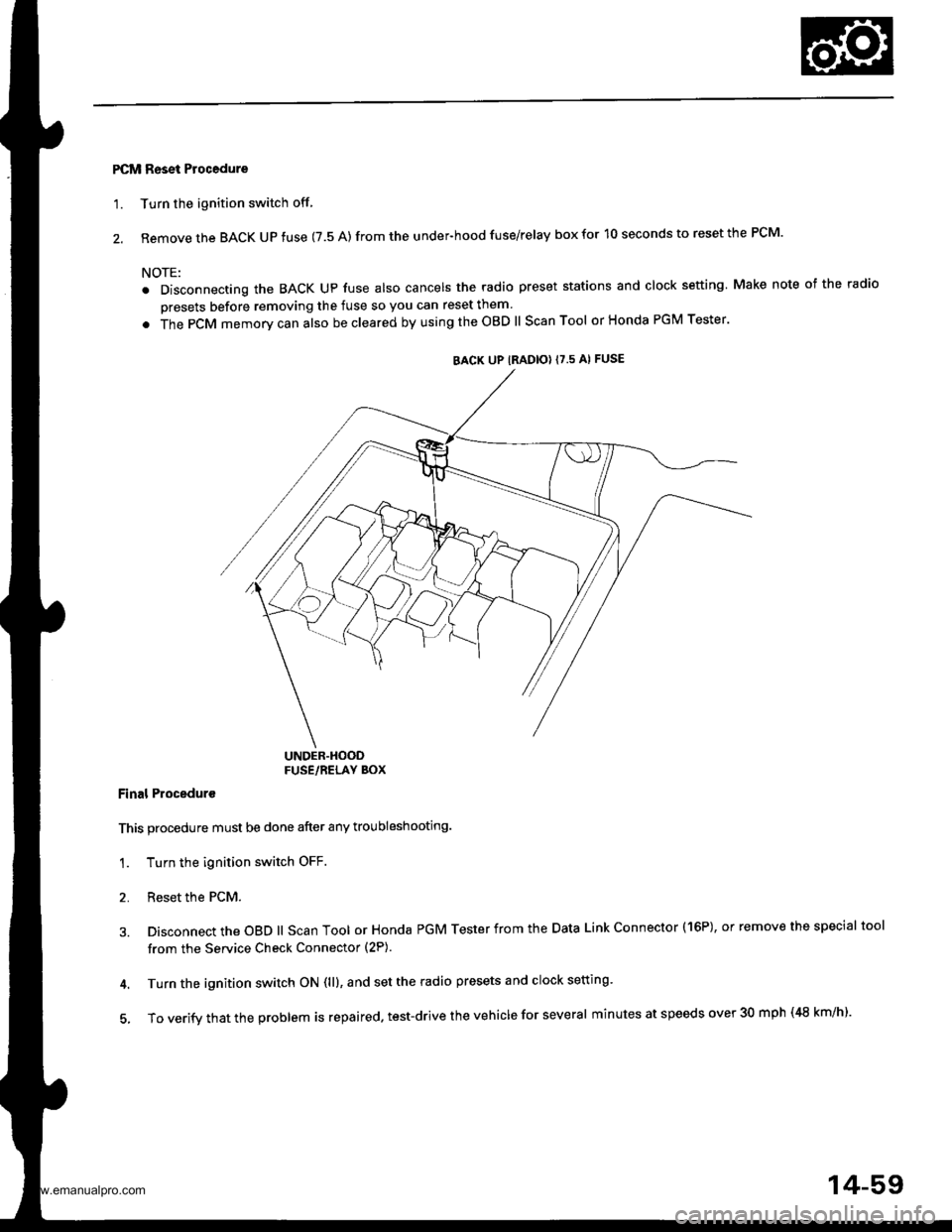

PCM Reset Procedure

'1. Turn the ignition switch off

2. Remove the BACK UP fuse (7.5 A) from the under-hood fuse/relay box for 10 seconds to reset the PCM.

NOTE:

. Disconnecting the BACK Up fuse also cancels the radio preset stations and clock setting Make note of the radio

presets before removing the fuse so you can reset them

. The PCM memorv can also be cleared by using the OBD ll Scan Tool or Honda PGM Tester'

UNDER.HOODFUSE/RELAY BOX

Final Proceduro

This procedure must be done after any troubleshooting.

1. Turn the ignition switch OFF.

2. Reset the PCM.

3. Disconnect the OBD ll Scan Tool or Honda PGM Tester from the Data Link Connector (16P), or remove the special tool

from the Service Check Connector (2P).

4. Turn the ignition switch ON (ll), and set the radio presets and clock setting'

5, To verify that the problem is repaired. test-drive the vehicle for several minutes at speeds over 30 mph (48 km/h).

BACK UP IRADIO} {7.5 AI FUSE

14-59

www.emanualpro.com

Page 802 of 1395

Real-time 4WD-Dual Pump System

Troubleshooting (Automatic Transmission/Manual Transmission)

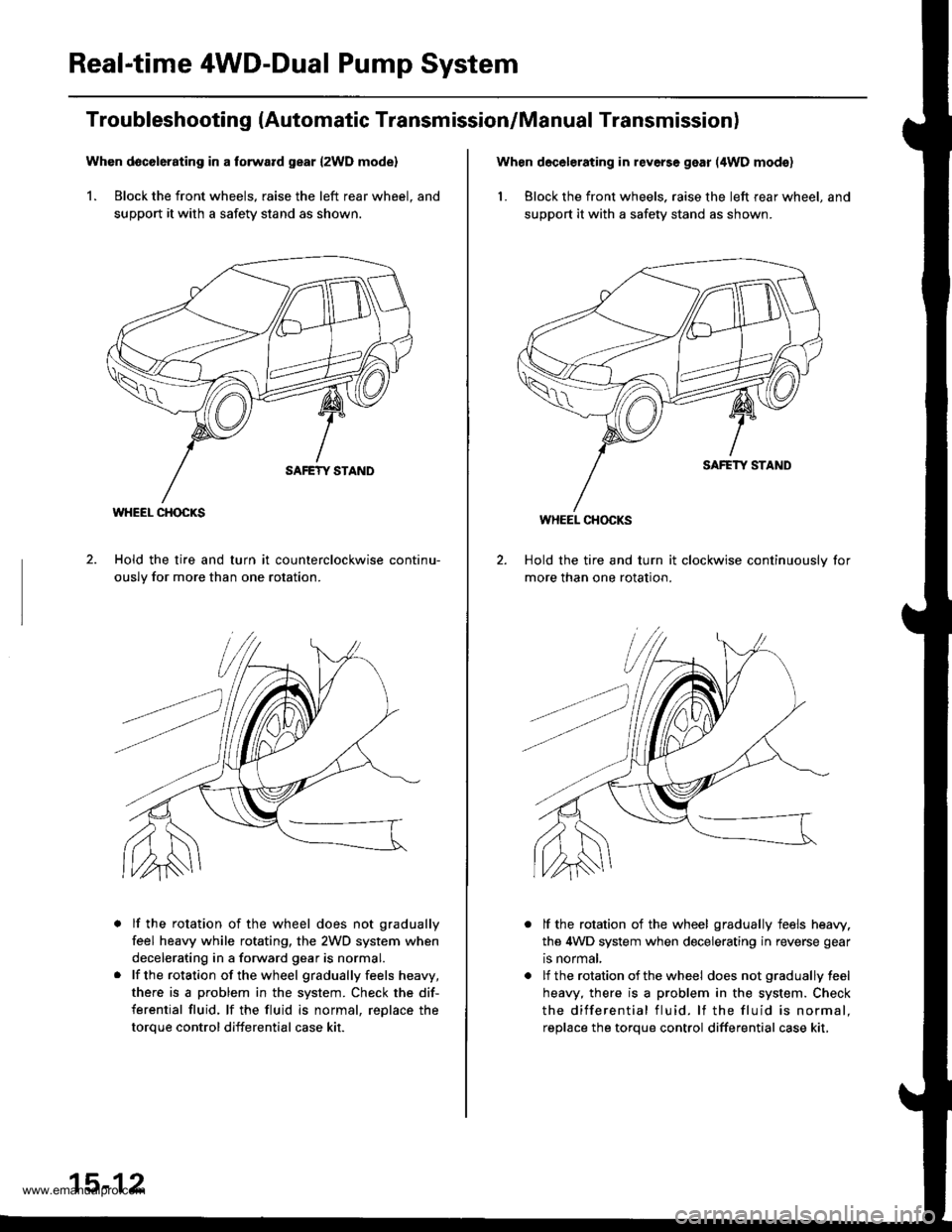

Whon d6c6l6rating in a torward gear {2WD mode}

1. Block the front wheels, raise the left rear wheel. and

support it with a safety stand as shown.

Hold the tire and turn it counterclockwise continu-

ouslv for more than one rotation.

lf the rotation of the wheel does not gradually

feel heavy while rotating, the 2WD system when

decelerating in a forward gear is normal.

lf the rotation of the wheel gradually feels heavy,

there is a problem in the system. Check the dif-

ferential fluid, lf the fluid is normal, reDlace the

toroue control differential case kit.

WHEEL CHOCKS

15-12

When decelerating in reverse gear (4WD mod€)

1. Block the front wheels. raise the left rear wheel, and

suppo( it with a safety stand as shown.

Hold the tire and turn it clockwise continuouslv for

more than one rotation.

lf the rotation of the wheel gradually feels heaw.

the 4WD system when decelerating in reverse gear

is normal,

lf the rotation of the wheel does not gradually feel

heavy, there is a problem in the system. Check

the differential fluid. lf the fluid is normal.

reolace the torque control differential case kit,

WHEEL CHOCKS

www.emanualpro.com

Page 811 of 1395

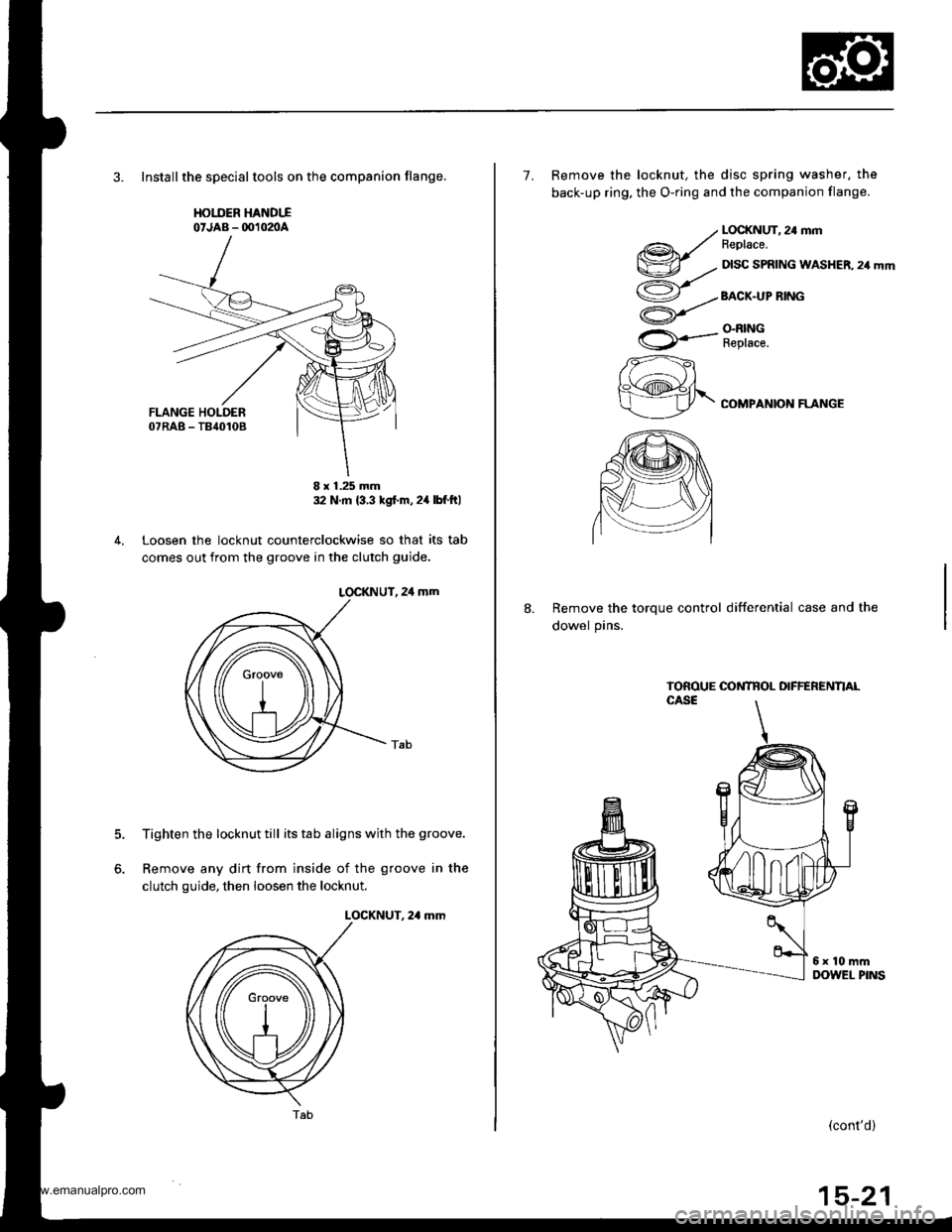

3. Installthe speclaltools on the companion flange,

HOIIIER HANDTIo'JAB - OO102nA

32 N m {3 3 tgt m,24lbf ftl

Loosen the locknut counterclockwise so that its tab

comes out from the groove in the clutch guide.

LOCKNUT, 24 mm

Tighten the locknut till its tab aligns with the groove.

Remove any dirt from inside of the groove in the

clutch guide, then loosen the locknut.

LOCKNUT. 2,1 mm

5.

6.

8 x 1.25 mm

Tab(cont'd)

7. Remove the locknut, the disc spring washer, the

back-up ring, the O-ring and the companion flange.

@r/v-.,.

ao/

U

rA*..-

zzft

h\@fr\

LOCKNUT, 24 mmFeplace.

DISC SPRING WASHER, 24 mm

BACX.UP RING

O.N|NGReplace.

COMPANION FLANGE

8.Remove the torque control differential case and the

dowel pins.

www.emanualpro.com

Page 864 of 1395

lnstallation

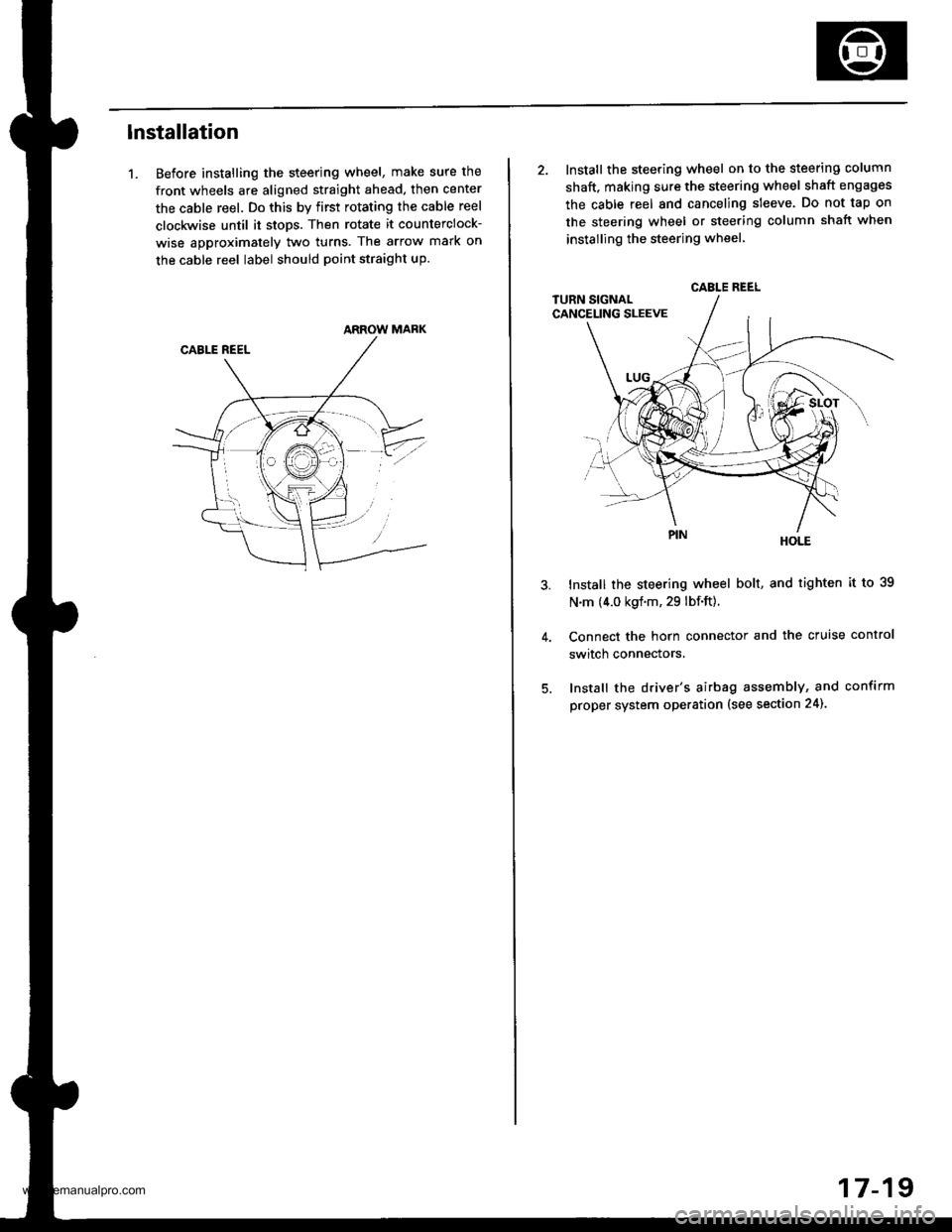

1. Before installing the steering wheel, make sure the

front wheels are aligned straight ahead, then center

the cable reel. Do this by first rotating the cable reel

clockwise until it stops. Then rotate it counterclock-

wise approximately two turns. The arrow mark on

the cable reel label should point straight up.

ARROW MARK

2. Install the steering wheel on to the steering column

shaft, making sure the steering wheel shaft engages

the cable reel and canceling sleeve. Do not tap on

the steering wheel or steering column shatt when

instailing the steering wheel

HOLE

Install the steering wheel bolt, and tighten it to 39

N.m (4.0 kgf.m, 29 lbf.ft).

Connect the horn connector and the cruise control

switch connectors,

Install the driver's airbag assembly, and confirm

proper system operation (see section 24).

CABLE REEL

17-19

www.emanualpro.com

Page 1161 of 1395

Body Electrical

Speciaf Toofs ,...,..,.............-.23-2

Troubleshooting

Tips and Precautions ......,.,..........,.................. 23-3

Five-step Troubleshooting ........,.,.,...,,.,......... 23-5

Wire Color Codes ...,....,.. 23-5

Relay and Control Unit Locations

Engine Compartment ..,.,......,......................... 23-6

Dashboard ,.,.,..............-.- 23-7

Door ....................... .........23-10

Index to Cilcuits and Sysiems

Accessory Socket .. ,....,.,..,.,. 23-95*Airbags ................ .,....,. Sestion 24

Air Conditioning ,.,.,.... Section 22

Alternator ................... Section 4

Anti-lock Brake System {ABSI ................... Section 19'A/T Gear Position Indicator ....................... Section 1,1

Automatic Transmission System ...........,.. Section 14

Battery ................... ..............23-50

Blower Controls .,...,.,, Section 22

Charging System ....... Seqtion il

Clock -'98 Model ................ 23-98

Connector ldentification and Wire HarnessRouting .................. ......... 23.11

Cruise Control ............ Ssction 4

Dash Lights Brightness Contlo||er ..................... 23-90

Fan Conlrols ...,......,.... Section 10

Fuel Pump ,..,.,...,....,.... Section 11

Fuses...................... .,,.,.,.,.,,.,23-40*Gauges

Circuit Diagram ......-....-..23-58

Fuel Gauge .....,.,..... Section 11

Speedometer ..,..........,... 23-56

Ground Distribution ,....,.,...23-46

Hatch Glsss ODenor .........................,.,.,.,.,..,.,.,.,,. 23-121

Heater Controls .-........ Soction 21*Horns.,...,..,.,.,....... ................23"104*fgnition Switch ,,.,.,..,.,.,,.,.,.,23-51

lgnition Key Light System -'97 Mod6l .............. 23.88

-+

BODY

www.emanualpro.com