transmission fluid HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 30 of 1395

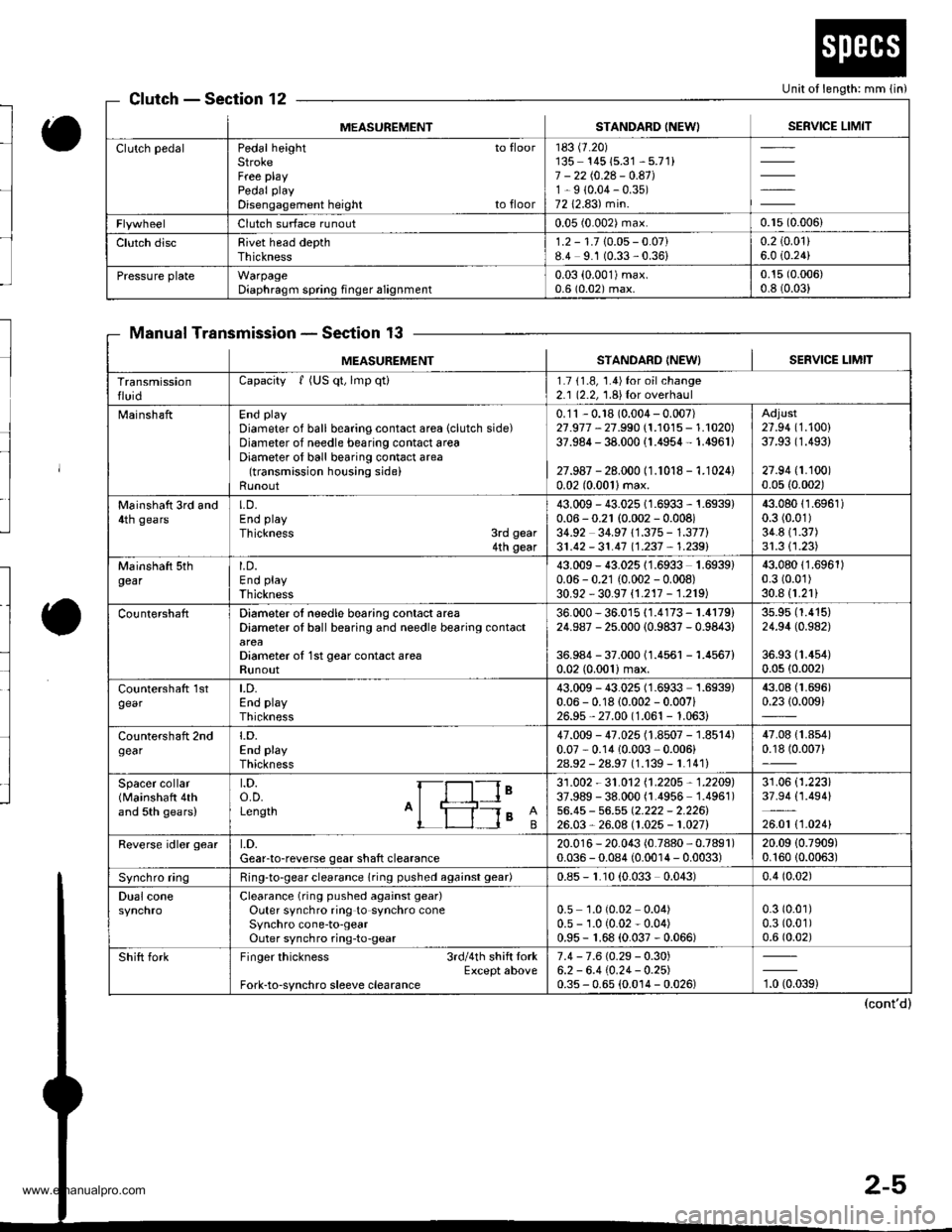

Unit of length: mm lin)ClutchSection 12

Manual TransmissionSection 13

MEASUREMENTSTANDARD INEWISERVICE LIMIT

Clutch pedalPedal height to floorStrokeFree playPedal play

Disengagement height to floor

183 (7.20)

135- 14515.31 - 5.71)7 - 2210.24 - 0.41J1-9 (0.04-0.35)

7212.83) min.

Clutch surface runout0.05 (0.002) max.0.r5 (0.006)

Clutch discRivet head depthThickness1.2 - 1.710.05- 0.07)8.4 9.1 (0.33,0.36)0.2 (0.01)

6.0 i0.24)

Pressure plateWarpageDiaphragm spring finger alignment0.03 (0.001)max.

0.6 (0.02) max.0.15 (0.006)

0.8 (0.03)

MEASUREM€NTSTANDARD INEW} I SERVICE I-IMIT

TransmissionfluidCapacity f (US qt, lmp qti1.7 11.8, 1.4)for oilchange2.1 (2.2, 1.8){or overhaul

MainshaftEnd play

Diameter of ball bearing contact area (clutch side)Diameter of needle bearing contact areaDiameter of ball bearing contact area(transmission housing side)Runout

0.'11 - 0.18 (0.004 - 0.007)27.977 - 27.990 (1.1015 - 1.1020)37.984 - 38.000 (1.4954- 1.4961)

27.987 - 28.000 (1.1018 - 1.1024)0.02 (0.0011max.

Adjust27.94 (1.100)

37.93 (1.493)

27.94 (1.100)

0.05 {0.002)

Mainshatt 3rd and4th gearsLD.End play

Thickness 3rd gear4th gear

43.009 - 43.025 1 1.6933 - 1.6939)0.06 - 0.21 (0.002 - 0.008)34.92 34.97 11.375 - 1.377)31.42 - 31.4'7 11.237 , 1.2391

43.08011.6961)0.3 (0.01)

34.811.37)31.311.23)

Mainshaft sthgearLD.End play

Thickness

43.009 - 43.02511.6933 1.6939)0.06 - 0.21 (0.002 - 0.008)30.92 - 30.97 {1.217 - 1.219)

43.08011.6961)0.3 (0.01)

30.8 (1.21)

CountershaftDiameter ol needle bearing contact areaDiameter oI ball bearing and needle bearing contact

Diameter o{ 1st gear contact areaRunout

36.000 - 36.015 {1.4173 - 1.4179)24.987 - 25.000 (0.9837 - 0.9843)

36.984 - 37.00011.4561 -1.4567)

0.02 (0.001)max.

3s.95 (1.415)

24.94 (0.982)

36.93 (1.4s4)

0.0s (0.002)

countershatt 1stgearLD.End playThickness

43.009 - 43.025 (1.6933 1.6939)0.06 - 0.18 (0.002 - 0.007i26.9s,27.00 (1.061 - 1.063)

43.08 (1.696)

0.2310.009)

Countershaft 2ndgeart.D.End playThickness

47.009 - 47.025 (1.8507 - 1.8514)0.07 - 0.14 10.003 ,0.006)

2As2 - 2a.97 l�1.139-1.1411

47.08 {1.854)0.18 (0.007)

Spacer collar(Mainshaft 4thand 5th gears)

t.D.o.D.Length A'ls I

le31 .002 - 31 .O12 11 .2205 , 1 .2205)37.989 - 38.000 (1.4956 1.4961)56.45 - 56.55 Q.222 - 2.226126.03,26.08 (1.025 - 1.027)

31.06 (1.223)

37.94 (1.494)

26.01 t1 .0241

Reverse idler geart.D.Gear-to-reverse gear shaft clearance20.01 6 - 20.043 (0.7880, 0.7891)0.036 - 0.084 (0.0014 - 0.0033)20.09 (0.7909)

0.16010.0063)

Synchro ringRing-to-gear clearance (ring pushed againsl gear)0.85 - r.10 (0.033 0.043)0.4 (0.02)

Dual coneClearance (ring pushed against gear)

Outer synchro ring to synchro coneSynchro cone-to-gearOuter synchro ring-to-gear

0.5 1.0 (0.02 0.04)0.5 - 1.0 (0.02 - 0.04)0.95 - 1.68 (0.037 - 0.066)

0.3 (0.01)

0.3 (0.01)

0.6 (0.02)

Shift forkFinger thickness 3rdl4th shift lorkExcept aboveFork-to-synchro sleeve clearance

7.4 - 7.6 (0.29 - 0.30)6.2 - 6.4 (0.24- 0.2s)0.35 - 0.65 (0.0't4 - 0.026)'t, torag)

www.emanualpro.com

Page 32 of 1395

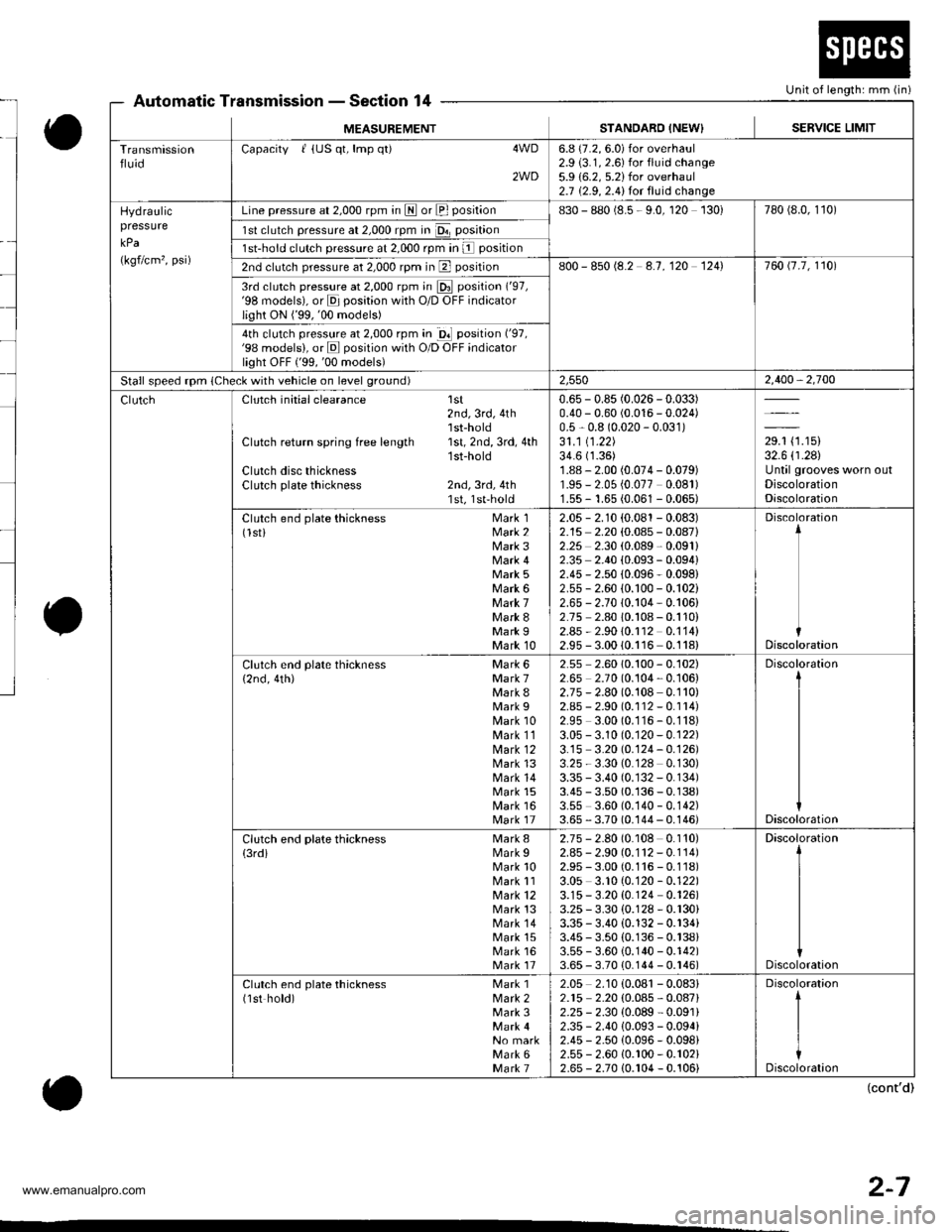

Unit of length: mm (in)Automatic TransmissionSection 14

MEASUREMENTSTANDARO INEW}SERVICE LIMIT

TransmissionfluidCapacity I {US qt, lmp q0 4WD

2WD

6.8 (7.2, 6.0) for overhaul2.9 (3.1, 2.6) for fluid change5.9 {6.2, 5.2)for overhaul2.7 {2.9, 2.4}for fluid change

Hydraulicpressure

kPa

(kgflcm'�, psi)

Line pressure at 2,000 rpm in LII or El position830 - 880 (8.5 - 9.0, 120 130)780 (8.0, 1'�t0)

1sl clutch pressure at 2,000 rpm in Da position

1st-hold clutch pressure at 2,000 rpm In l position

2nd clutch pressure at 2,000 rpm in El position800 - 850 (8.2 4.7,120 1241760 t7.7, 1101

3rd clutch pressure at 2,000 rpm in E position ('97,'98 models), or E position with O/D OFF indicatorlight ON ('99,'00 models)

4th clutch pressure at 2,000 rpm in gl position ('97,'98 models), or E position with O/D OFF indicatorlight oFF ('99,'00 models)

Stall speed rpm (Check with vehicle on level ground)2,5502,400,2,700

Clutch initial clearance 1st2nd,3rd,4th'lst-hold

Clutch return spring free length 1st, 2nd, 3rd, 4th'1st-hold

Clutch disc thicknessClutch plate thickness 2nd, 3rd, 4th1st, 1st-hold

0.65 - 0.85 (0.026 -0.033)

0.40 - 0.60 (0.016 - 0.024)0.5 - 0.8 (0.020 - 0.031)31 .1 11 .22)34.6 (1.36)

1.88 - 2.00 (0.074 - 0.079)'r.95 - 2.05 {0.077 0.081)'1.55- 1.65 (0.061 - 0.065)

29.1 (1.15)

32.6 (r.28)

Until grooves worn outDiscolorationDiscoloration

Clutch end plate thickness Mark 1(lsti Mark 2Mark 3Mark 4Mark 5Mark 6Mark 7Mark 8Mark IMark 10

2.05 - 2.r0 (0.081 - 0.083)2.15 2.20 (0.085 - 0.08712.25 2.30 (0.089,0.091)

2.35 2.40 {0.093 - 0.094}2.45 - 2.50 {0.096- 0.098}2.55 - 2.60 (0.100 - 0.102)2.65 - 2.70 (0.104 - 0.106)2.75 2.80 i0.108 - 0.110)2.85 - 2.9010.r 12 0.114)2.95 - 3.0010.116 0.118)

Discoloration

Discoloration

Clutch end plate thickness Mark 6{2nd, 4th) Mark 7Mark 8Mark 9Mark 10Mark 11lvlark 12Mark 13Mark 14Mark 15Mark 16Mark 17

2.55 2.60 10.100 - 0.102)2.65 2.70(0.104,0.106)2.75 - 2.80 (0.108 0.110)2.85 - 2.90 (0.112 -0.rr4)

2.95 3.00 (0.116-0.118)

3.05 - 3.10 (0.120 - 0.122)3.15 3.20 (0.124-0.126)

3.25 - 3.30 (0.128 0.130)3.35 - 3.40 (0. r32 - 0.134)3.45 - 3.50 (0.136 - 0.138)3.55 3.60 (0.140 - 0.142)3.65 - 3.70 (0.144 - 0.146)

Discoloration

Discoloration

Clutch end plate thickness Mark 8

{3rdi Mark IMark 10Mark 11Mark 12Mark 13Mark 14Mark 15Mark 16Mark 17

2.75 - 2.80 (0.108 0.110)2.85- 2.90 (0.112 - 0.114)2.95 - 3.00 (0.116 - 0.1'�j8)3.05 3.10 (0.120 - 0.122)3.15-3.20 {0.124 0.126)3.25 - 3.30 (0.128 - 0.r30)3.35 - 3.40 (0.132 - 0.r34i3.45 - 3.50 (0.136 - 0.138)3.55 - 3.60 {0.140 - 0.142)3.65 - 3.70 {0.144 - 0.r46)

Discoloration

Discoloration

Clutch end plate thickness Mark 1(1st hold) Mark 2Mark 3

No markMark 6Mark 7

2.05 2.10 (0.081 - 0.08312.r5 2.20 (0.085 - 0.087)2.25 - 2.30 {0.089 - 0.091}2.35 - 2.40 10.093 - 0.094i2.45 - 2.50 (0.096- 0.098i2.55 - 2.60 (0.r00 - 0.102)2.65 - 2.70 (0.r04 - 0.106)

(cont'd)

2-7

www.emanualpro.com

Page 35 of 1395

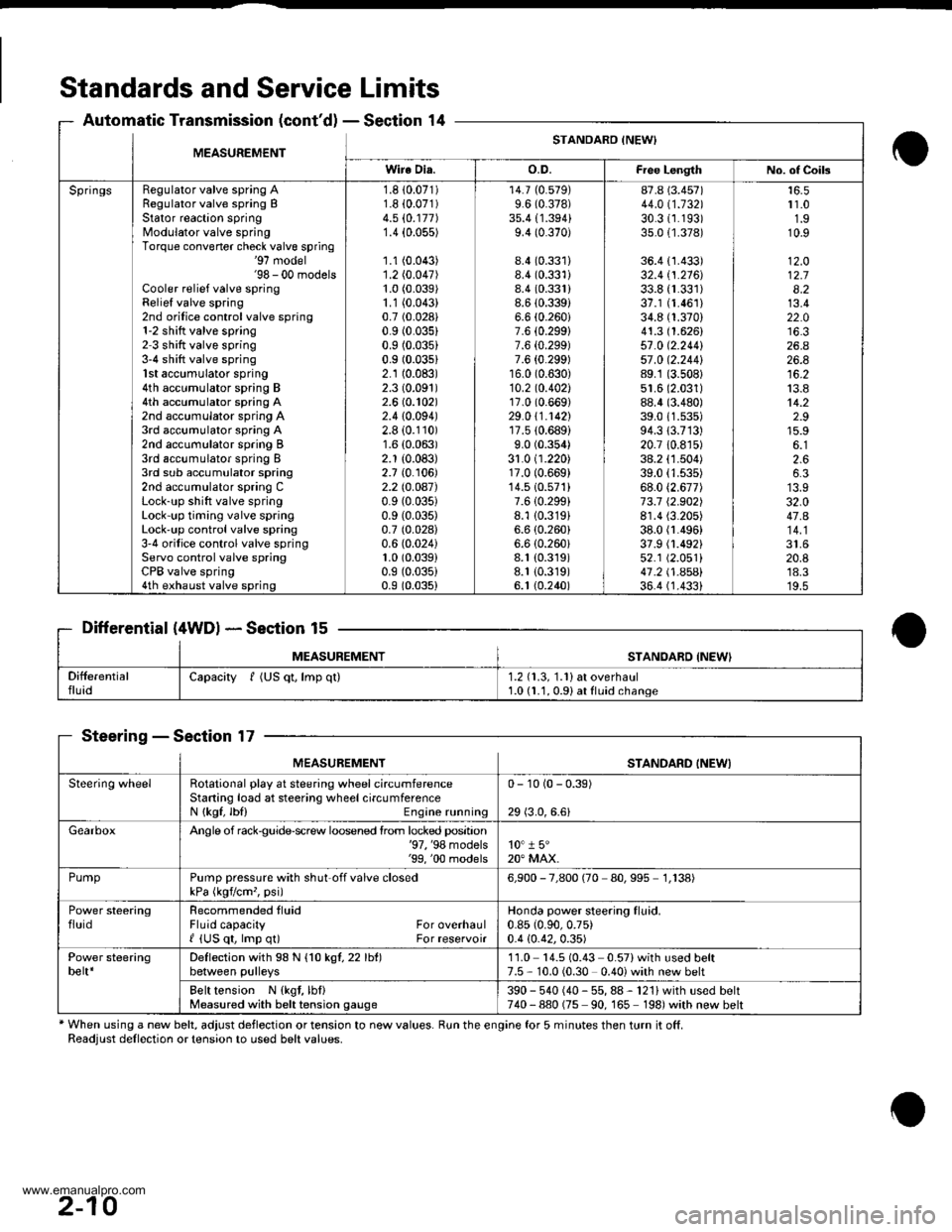

Standards and Service Limits

Automatic Transmission (cont'dl - Section 14

Differential (4WDl * Section 15

MEASUREMENTSTANOABD {NEW'

SteeringSection 17

* When using a new belt, adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off.Readjust dellection or tension to used belt values.

MEASUREMENTSTANDARO INEWI

Wire Dia.o.D.Fiee LengthNo. of Coils

SpringsRegulator valve spring ARegulator valve spring BStator reaction springModulator valve springTorque convener check valve spring'97 model'98 - 00 modelsCooler relief valve springRelief valve spring2nd orilice control valve spring1-2 shitt valve spring2 3 shift valve spring3-4 shift valve spring1st accumulator spring4th accumulator spring B4th accumulator spring A2nd accumulator spring A3rd accumulator spring A2nd accumulator spring B3rd accumulator spring I3rd sub accumulator spring2nd accumulator spring CLock-up shift valve springLock-up timing valve springLock'up control valve spring3'4 orifice control valve springServo control valve springCPB valve spring4th exhaust valve spring

1.8 10.071)1.8 i0.071)4.5 (0.177)

1.4 {0.055)

1.1 (0.043)

1.2 (0.047)

1.0 (0.039)

1.1 (0.043)

0.7 (0.028)

0.9 (0.035)

0.9 (0.035)

0.9 (0.03s1

2.1 (0.083)

2.3 (0.091)

2.6 (0.102)

2.410.094)2.8 (0.110)

1.6 (0.063)

2.1 (0.083)

2.7 {0. r06)2.2lO.OA7)0.9 (0.035)

0.9 (0.035)

0.7 (0.028)

0.6 (0.024)

1.0 (0.039)

0.9 (0.035)

0.9 (0.035)

14.7 (0.579)

9.6 (0.378)

35.4 {1.394}9.4 (0.370)

8.4 (0.331)

8.4 (0.331)

8.4 (0.331)

8.6 (0.3391

6.6 (0.260i

7.6 {0.299}7.6 {0.299)7.6 {0.299)16.0 (0.630)

10.2 to.402l17.0 (0.669)

29.0 \1.1421'r7.510.689)

9.0 (0.354)

31.0 (1.220)17.0 (0.669)

14.510.571)7.610.299i8.1 {0.319}6.6 (0.260)

6.6 (0.260i

8.1 (0.319)

8.1 {0.319)6. t (0.240)

87.8 (3.457)

44.011.132130.31r.193)35.0 {1.378)

36.4 {1.433)32.4 tl.216J33.8 {r.331)37.1 (1.461)

34.8 (1.370)

41.3 (1.626)

57 .0 (2.2441

57 .0 12.244189.1 (3.508)

51.6 (2.031)

88.4 (3.480)

39.011.s35)94.313.713)20.7 10.8r5)38.2 (1.504)

39.0 (1.535)

68.0 (2.677)

73.7 12.902)8r.4 (3.205)

38.0 fl.496)37.9 (1.492)

52.1 (2.051)

41 .2 t .A5Al36.4 (1.4331

r 1.01.910.9

12.O12.78.213.422.0

26.426.8

13.814.22.915.9

2.66.3

32.047.A

20.8'18.3'19.5

Capacity f (US qt, lmp ql)1.2 (1.3, 1.1) at overhaul1.0 (1.1, 0.91 at fluid change

MEASUREMENTSTANDARD INEWI

Steering wheelRotational play at steering wheel circumferenceStaning load at steering wheelcircumferenceN {kgf, lbl) Engine running

0- 10 (0 - 0.39)

29 (3.0,6.6)

GearboxAngle of rack$uide-screw loosened lrom locked position'97, '98 models'99, '00 models10" 1 5"20" MAX.

PumpPump pressure with shut off valve closedkPa (kgvcm,, psi)6,900 - 7,800 (70 80,995 1,138)

Power steeringfluidRecommended tluidFluid capacity For overhaulI {US qt, lmp q0 For reservoir

Honda power steering fluid.0.85 (0.90,0.75)

0.4 {0.42,0.35)

Power steeringbelt*Deflection with 98 N {1O kgl,22lht)between pulleys11.0 14.5 (0.43 0.57)with used belt7.5 - 10.0 (0.30 0.40) with new belt

Belt tension N {kgt, lbf}Measured with belt tension gauge390 - 540 (40 - 55, 88 - 121) with used belt740-880 (75 90, 165 198)with new belt

2-10

www.emanualpro.com

Page 41 of 1395

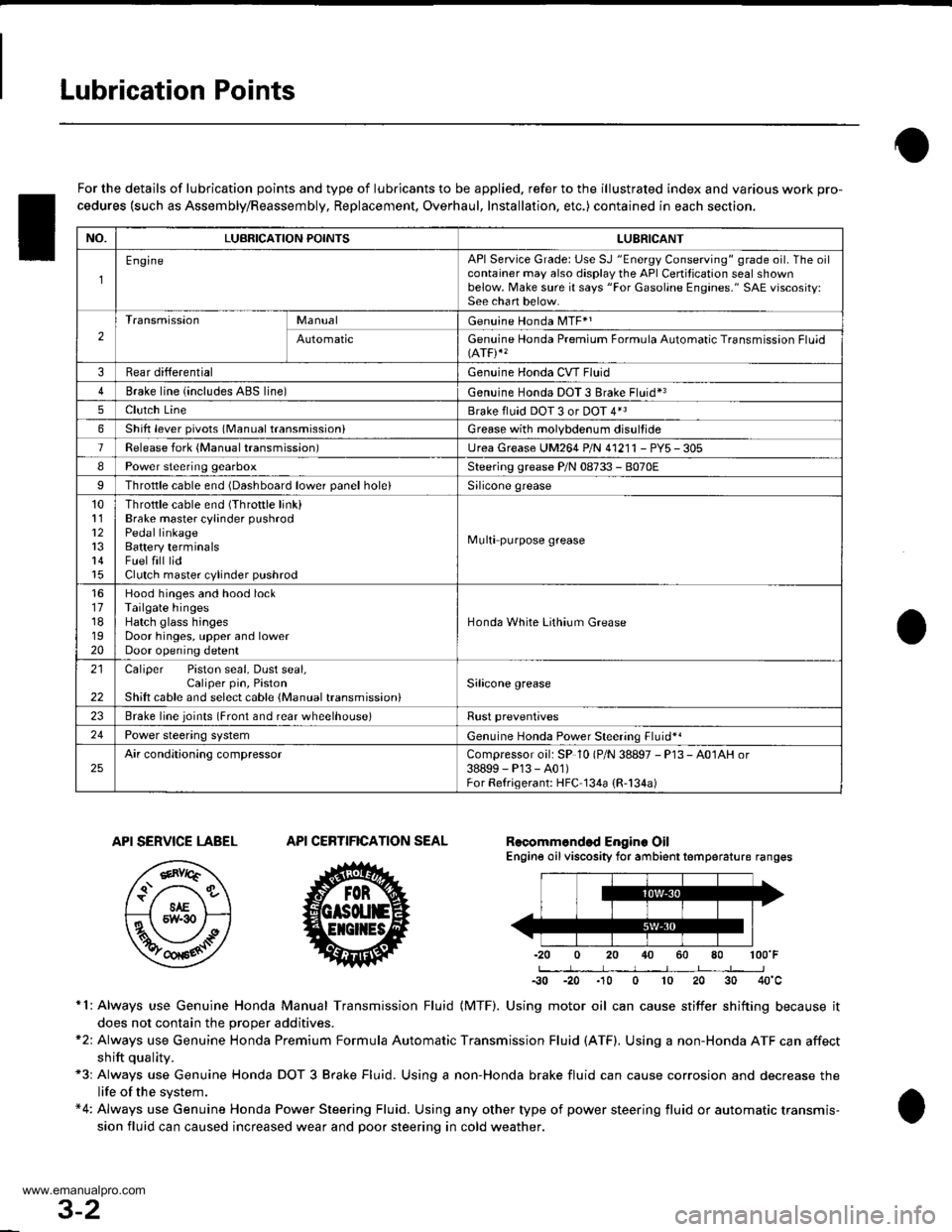

Lubrication Points

For the details of lubrication points and type of lubricants to be applied. refer to the illustrated index and various work pro-

cedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

Recomm6nded Engine OilEngine oil viscosity for ambient temperature ranges

100'F

-30 -20 .10 0 10 20 30 40'c

r1: Always use Genuine Honda Manual Transmission Fluid {MTF). Using motor oil can cause stiffer shifting because it

does not contain the orooer additives.*2: Always use Genuine Honda Premium Formula Automatic Transmission Fluid (ATF). Using a non-Honda ATF can affect

shift qualitv.+3r Always use Genuine Honda DOT 3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.*4: Always use Genuine Honda Power Steering Fluid. Using any other type of power steering fluid or automatic transmis-

sion fluid can caused increased wear and poor steering in cold weather.

API SERVICE LABEL

/,.*-G\

/.'z-\e\t/6AE\ll-;-1 5w-30 /---l

w

API CERTIFICATION SEAL

ffi-20 0 20

NO.LUBRICATION POINTSLUBRICANT

EngineAPI Service Grade: Use SJ "Energy Conserving" grade oil. The oilcontainer may also display the API Certitication seal shownbelow. Make sure it says "For Gasoline Engines." SAE vjscosity:See chart below.

2

TransmissionManualGenuine Honda MTF*1

AutomaticGenuine Honda Premium Formula Automatic Transmission Fluid(ATF)*'

3Rear differentialGenuine Honda CVT Fluid

4Brake line (includes ABS line)Genuine Honda DOT 3 Brake Fluid*3

5Clutch LineBrake fluid DOT 3 or DOT 4*3

6Shift lever pivots (Manual transmission)Grease with molybdenum disultide

1Release fork (Manual transmission)LJrea Grease UM264 P/N 4'1211 - PYs - 305

IPower steering gearboxSteering grease P/N 08733 - B070E

Throttle cable end {Dashboard lower panel holelSilicone grease

10l112

14

Throttle cable end (Throttle link)Brake master cylinder pushrodPedal linkageBattery terminalsFuelfill lidClutch master cylinder pushrod

Multi purpose grease

1617181920

Hood hinges and hood lockTailgate hingesHatch glass hingesDoor hinges, upper and lowerDoor opening detent

Honda White Lithium Grease

21

22

Caliper Piston seal, Dust seal,Caliper pin, PistonShilt cable and select cable {Manual transmission)Silicone grease

23Brake line ioints (Front and rear wheelhouse)Rust preventives

24Power steering systemGenuine Honda Power Steering Fluid-.

25Air conditioning compressorCompressor oil: SP 10 lP/N 38897 - P13 - A0lAH or38899-P13-A01)For Refrigerant: HFC 134a (R,134a)

3-2

www.emanualpro.com

Page 103 of 1395

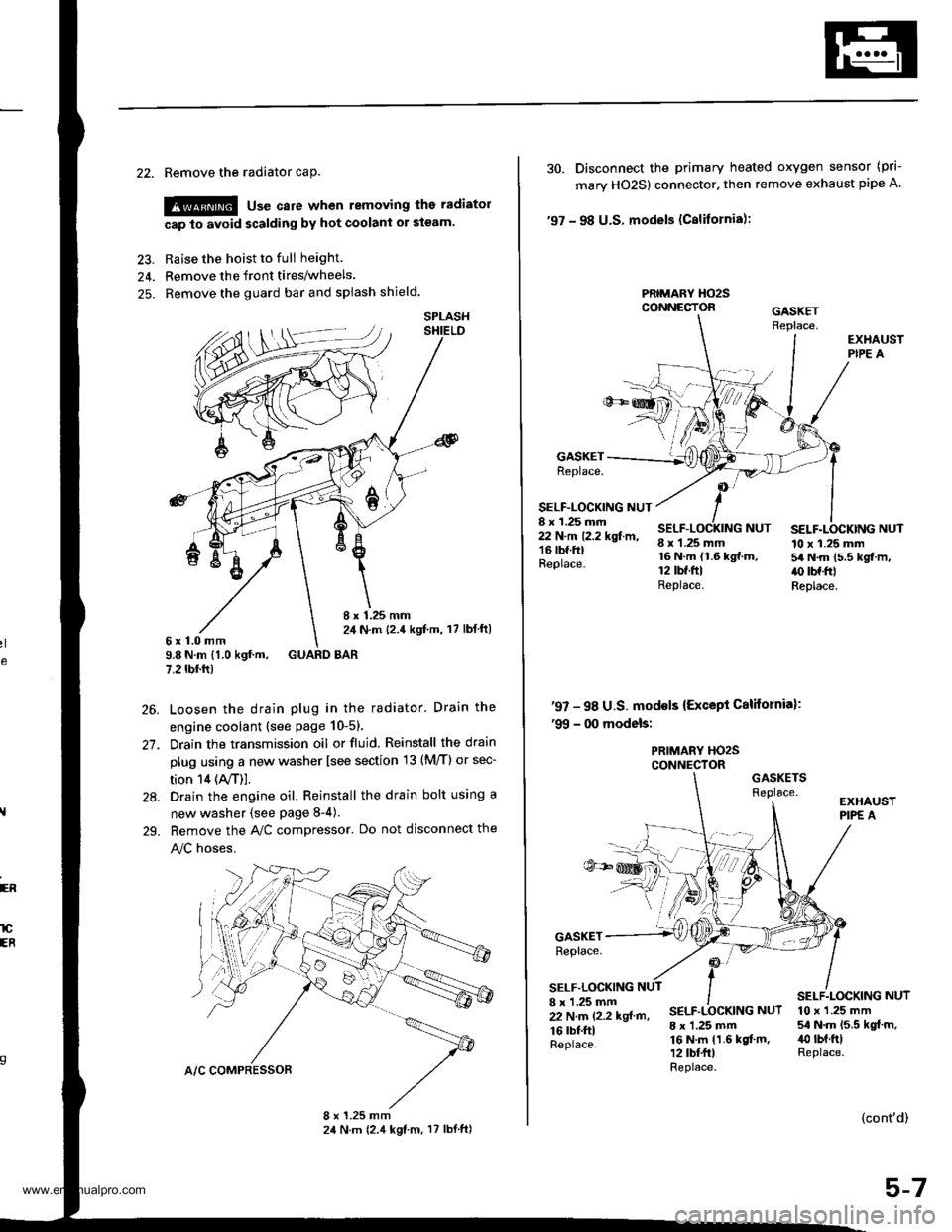

22. Remove the radiator caP.

!@ use care when removing the radiatol

cap to avoid scalding by hot coolani or steam.

23. Raise the hoist to full height

24. Remove the front tires/wheels.

25. Remove the guard bar and splash shield.

8 x 1.25 mm2,1 N.m {2.4 kgf,m, 17 lbl ft)6x1.0mm9.8 N.m {1.0 kgf.m, GUARD BAR7.2 tbf.rr)

Loosen the drain plug in the radiator. Drain the

engine coolant (see page 10-51.

Drain the transmission oil or fluid. Reinstall the drain

plug using a new washer lsee section 13 (M/T) or sec-

tion 14 (ly'T)].

Drain the engine oil. Reinstall the drain bolt using a

new washer {see page 8-4).

Bemove the A,/C compressor. Do not disconnect the

!y'C hoses.

SPLASH

26.

27.

28.

29.

ER

lCEB

30. Disconnect the primary heated oxygen sensor (prl-

mary HO2S) connector. then remove exhaust pipe A

'97 - 98 U.S. models (Cslifornia):

PRIMARY HO2SCONNECTOR

GASKETReplace.

SELF-LOCKING NUT8 x 1.25 mm22 N.m 12.2 kgf.m,16 lbf.ftlReplace.

8 x 1.25 mm16 N.m {1.6 kgf.m.12 tbt.ftlReplace.

SELF.LOCKING NUT10 x 1.25 mm54 N.m 15.5 kgf.m,.() tbf.frlReplace.

NUT

'97 - 98 U.S. mod€ls {Except California):'99 - 00 models:

PRIMARY HO2SCONNECTORGASKETSReplace.

GASKETReplace.

SELF.LOCKING8 x 'l.25 mm22 N.m (2.2 kgf m,

16 rbf.ftlReplace.

SELF.LOCKING NUT

8 x 1.25 mm16 N.m 11.6 kgf.m,12 tbt fr)Replace.

10 x 1.25 mm54 N.m 15.5 kgt.m,40 rbt.ftlReplace.

{cont'd)

5-7

www.emanualpro.com

Page 112 of 1395

Engine Removal/lnstallo cton

Installation (cont'd)

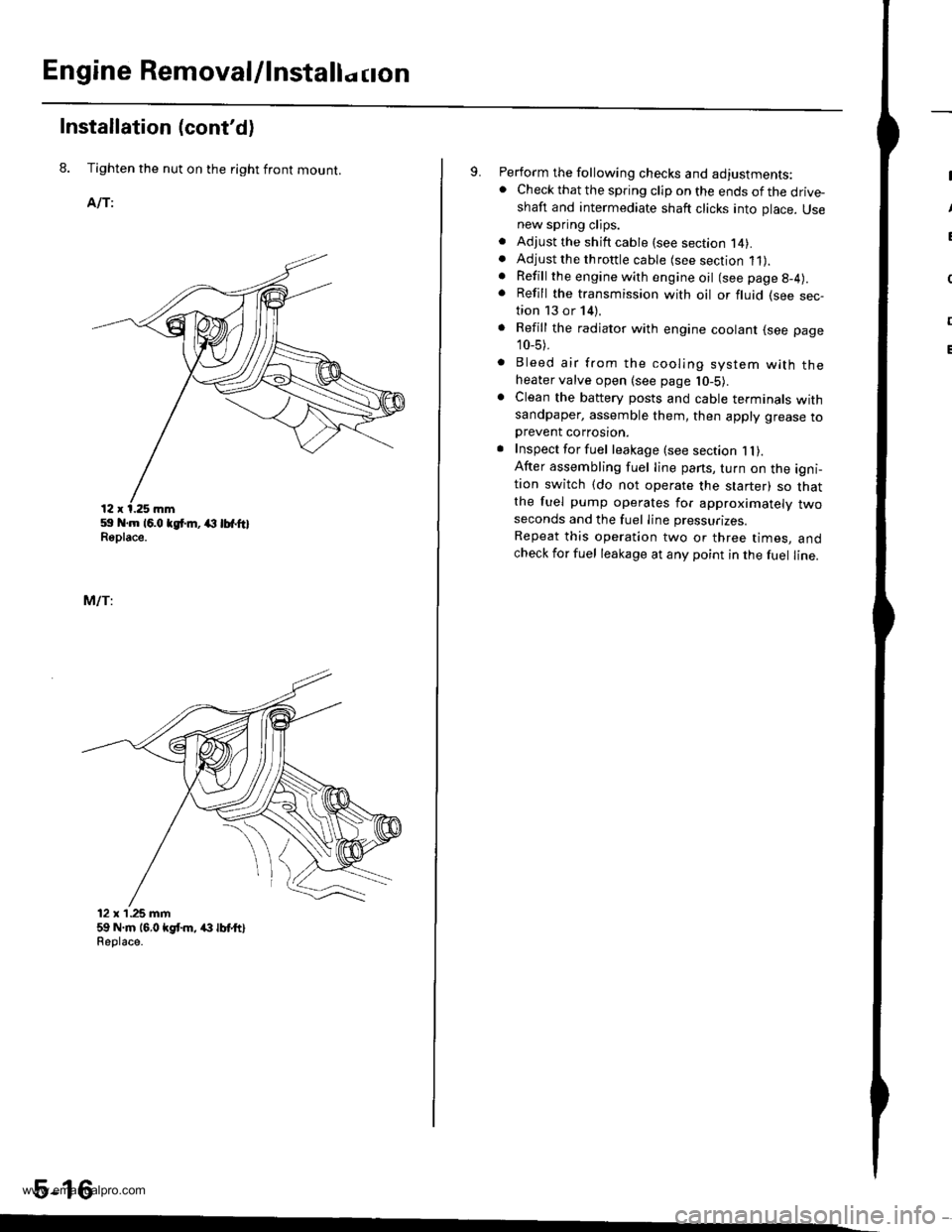

8. Tighten the nut on the right front mount.

AlTi

59 .m 16.0 tgt m, (l lbfftlReplace.

MlTi

12 x'1.25 mm59 N.m 16,0 kgt m, /(} lbt ttlReolace.

5-16

9. Perform the following checks and adjustments:. Check that the spring clip on the ends of the drive-shaft and intermediate shaft clicks into place. Usenew spring clips.. Adjust the shift cable (see section l4).. Adjust the throttle cable (see section 11).. Refill the engine with engine oil (see page g-4).

. Refill the transmission with oil or fluid (see sec-tion 13 or 14).

. Refill the radiator with engine coolant (see page

10_5).

. Bleed air from the cooling system with theheater valve open (see page l0-5).. Clean the battery posts and cable terminals withsandpaper, assemble them, then apply grease toDrevent corrosron.. Inspect for fuel leakage (see section 1l).After assembling fuel line pans, turn on the igni-tion switch (do not operate the starter) so thatthe fuel pump operates for approximately twoseconds and the fuel Iine pressurizes.

Repeat this operation two or three times, andcheck for fuel leakage at any point in the fuel line.

www.emanualpro.com

Page 442 of 1395

MaintenanceBack-up Light Switch

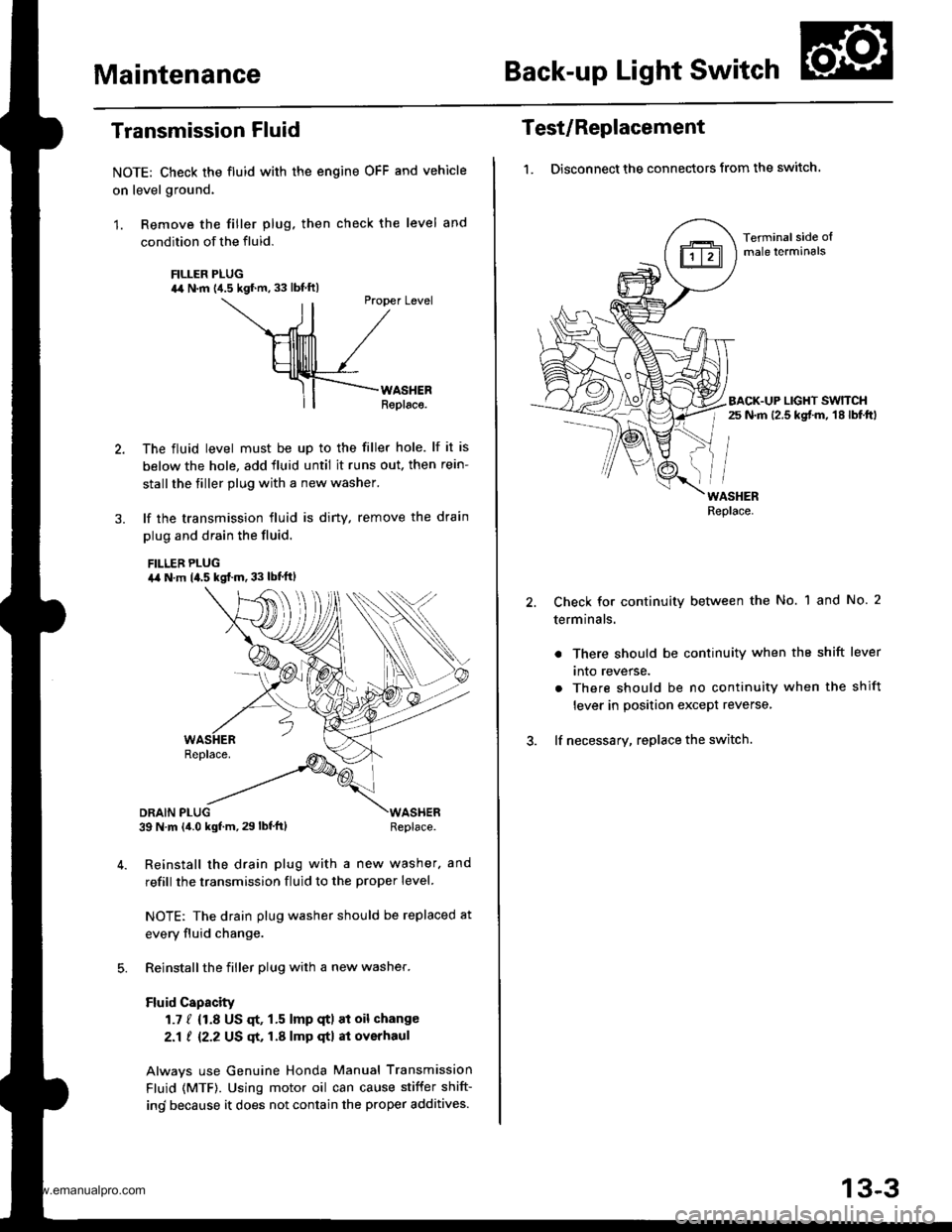

Transmission Fluid

NOTE: Check the fluid with the engine OFF and vehicle

on level ground.

1. Remove the filler plug. then check the level and

condition of the fluid.

FILLER PLUG44 N.m {4.5 kgf.m. 33 lbf ftl

ll

Ptopet Level

\--ril /

HllllllTl /

Hllllrlll /_rf-F{--rno."."

ll| | Replaco.

The fluid level must be up to the filler hole. lf it is

below the hole, add fluid until it runs out. then rein-

stall the tiller plug with a new washer.

lf the transmission fluid is diny, remove the drain

plug and drain the fluid.

FILLEB PLUGa,a N.m 14.5 kgf..n. 33 lbt'ftl

DRAIN PLUG39 N m (4.0 kgf.m, 29 lbf'ft)WASHERReplace.

Reinstall the drain plug with a new washer. and

refill the transmission fluid to the proper level.

NOTE: The drain plug washer should be replaced at

every fluid change.

Reinstall the filler plug with a new washer.

Fluid Capacity

1.7 / {1.8 US qt, 1.5 lmp qtl at oil change

2.1 ! 12.2 US qt, 1.A lmp qtl at overhaul

Alwavs use Genuine Honda Manual Transmission

Fluid (MTF). Using motor oil can cause stiffer shift-

ind because it does not contain the proper additives.

Test/Replacement

1. Disconnect the connectors from the switch.

Terminal side oImale lerminals

BACK.UP LIGHT SWTTCHr 25 N.m 12.5 kgt m, 18 lbf.ftl

WASHERReplace.

Check for continuity between the No. 1 and No. 2

terminals.

. There should be continuity when the shift lever

tnto reverse.

. There should be no continuity when the shift

lever in position except reverse,

lf necessary, replace the switch.

13-3

www.emanualpro.com

Page 443 of 1395

Transfer Assembly

lnspection

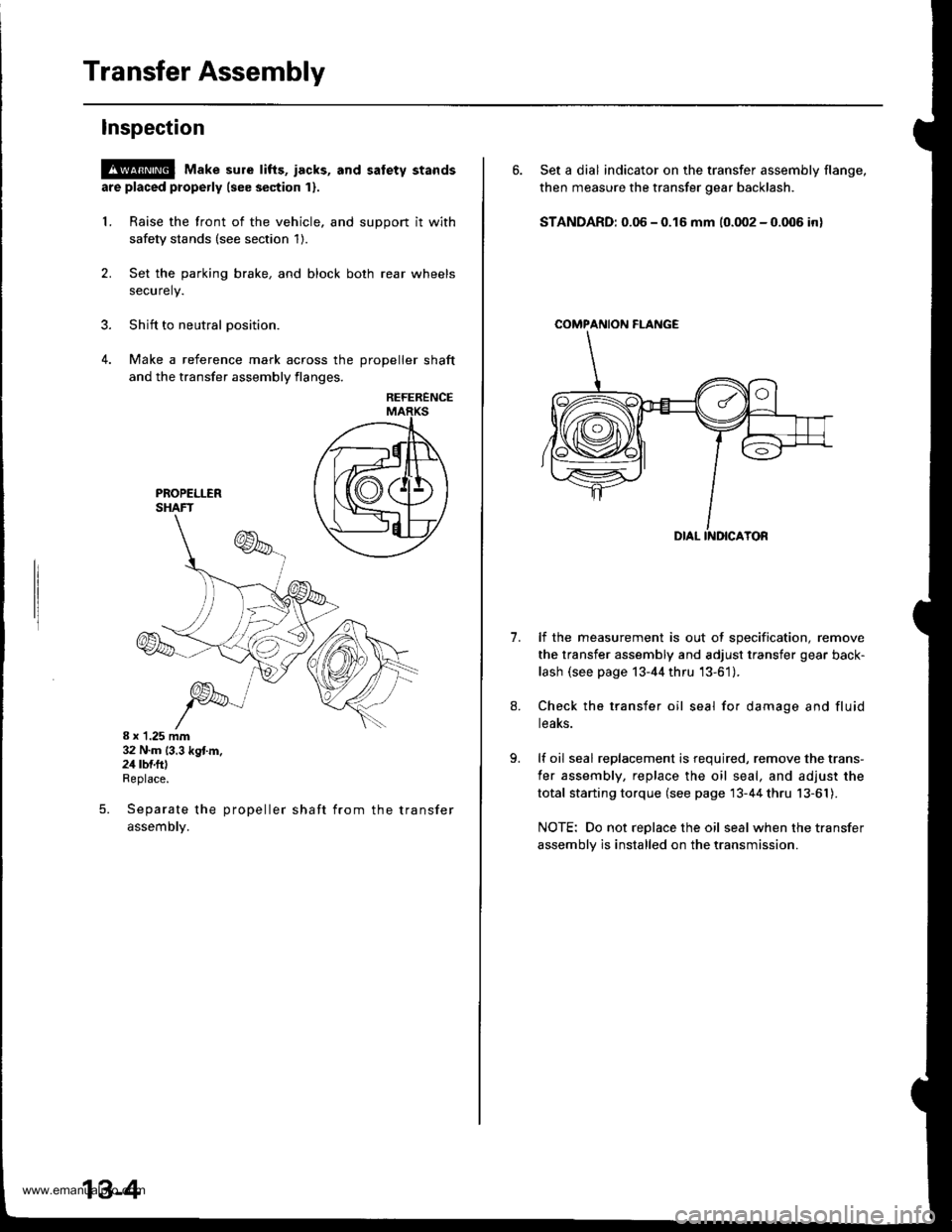

@ Make sure tifts, iacks, and satety stands

are placed properly (see section 1).

L Raise the front of the vehicle, and support it with

safety stands (see section 1).

2. Set the parking brake, and block both rear wheels

securely.

3. Shift to neutral oosition.

4. Make a reference mark across the DroDeller shaft

and the transfer assembly flanges,

REFERENCE

8 x 1.25 mm32 N.m (3.3 kg{.m.24 rbf.ftlReplace.

Separate the propeller shaft from the transfer

assemDty.

5.

13-4

6. Set a dial indicator on the transfer assembly flange,

then measure the transfer gear backlash.

STANDARD: 0.06 - 0.16 mm (0.002 - 0.006 in)

COMPAf{ION FI-ANGE

1.lf the measurement is out of specification, remove

the transfer assembly and adjust transfer gear back-

lash (see page 13-44 thru '13-61).

Check the transfer oil seal for damage and fluid

teaKs.

lf oil seal replacement is required, remove the trans-

fer assembly, replace the oil seal, and adjust the

total starting torque (see page 13-44 thru 13-61).

NOTE: Do not replace the oil seal when the transfer

assembly is installed on the transmission.

www.emanualpro.com

Page 444 of 1395

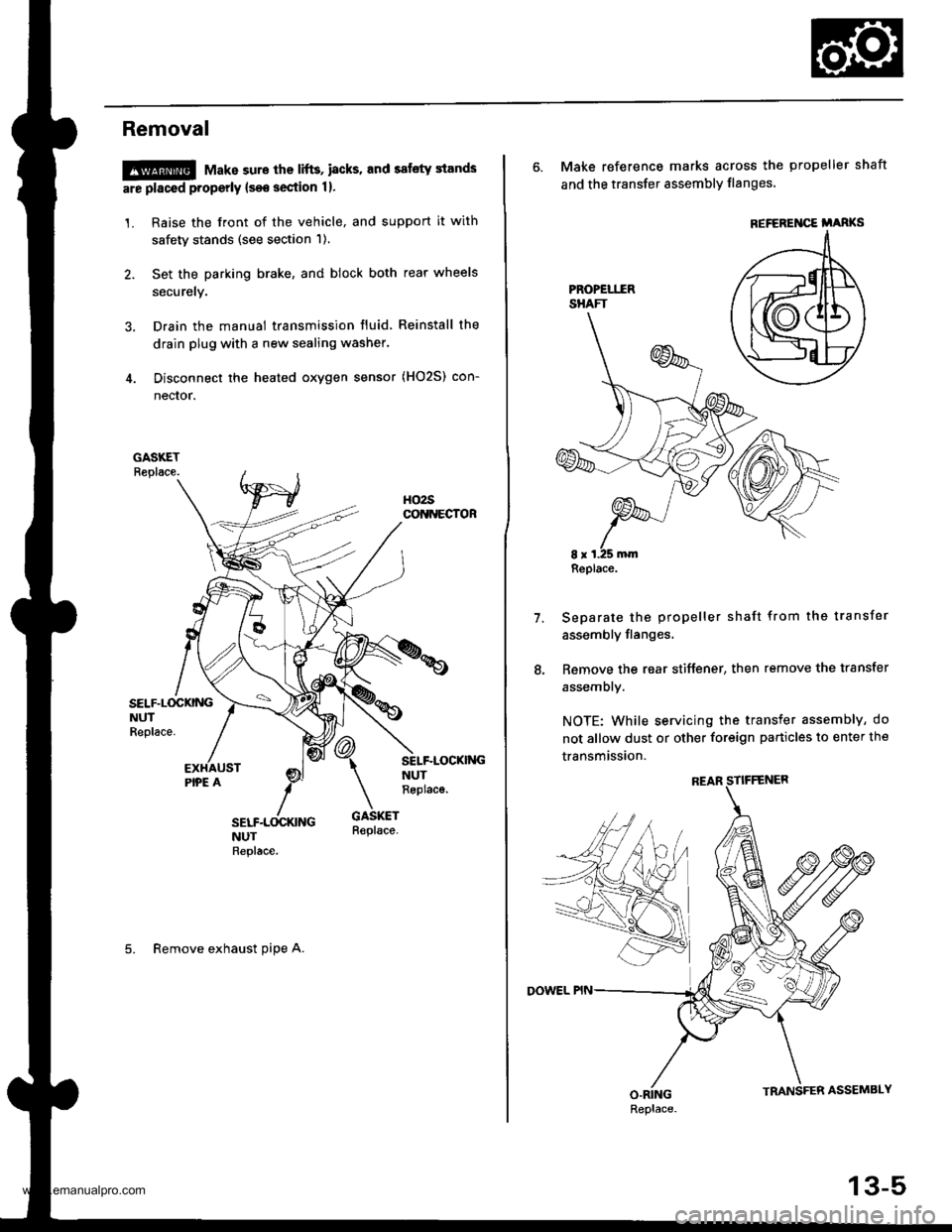

Removal

!@@ Make sure the lifts, i8cks. and safety stands

are placed properly {see section 1}.

1. Raise the front of the vehicle, and support it with

safety stands (see section 1).

2. Set the parking brake, and block both rear wheels

securely.

3. Drain the manual transmission fluid Reinstall the

drain plug with a new sealing washer.

4. Disconnect the heated oxygen sensor (HO2S) con-

nector.

SELF.L(rcKNGNUTReplace.

SELF-LOCKI'{GNUTReplac€.

5. Remove exhaust oipe A.

6. Make reference marks across the propeller shaft

and the transfer assembly flanges'

Separate the propeller shaft from the transfer

assembly flanges,

Remove the rear stiffener, then remove the transfer

assembly.

NOTE: While servicing the transfer assembly, do

not allow dust or other foreign particles to enter the

transmission.

7.

REFEREI{CE i'ARKS

Replace.

Replace.

13-5

www.emanualpro.com

Page 445 of 1395

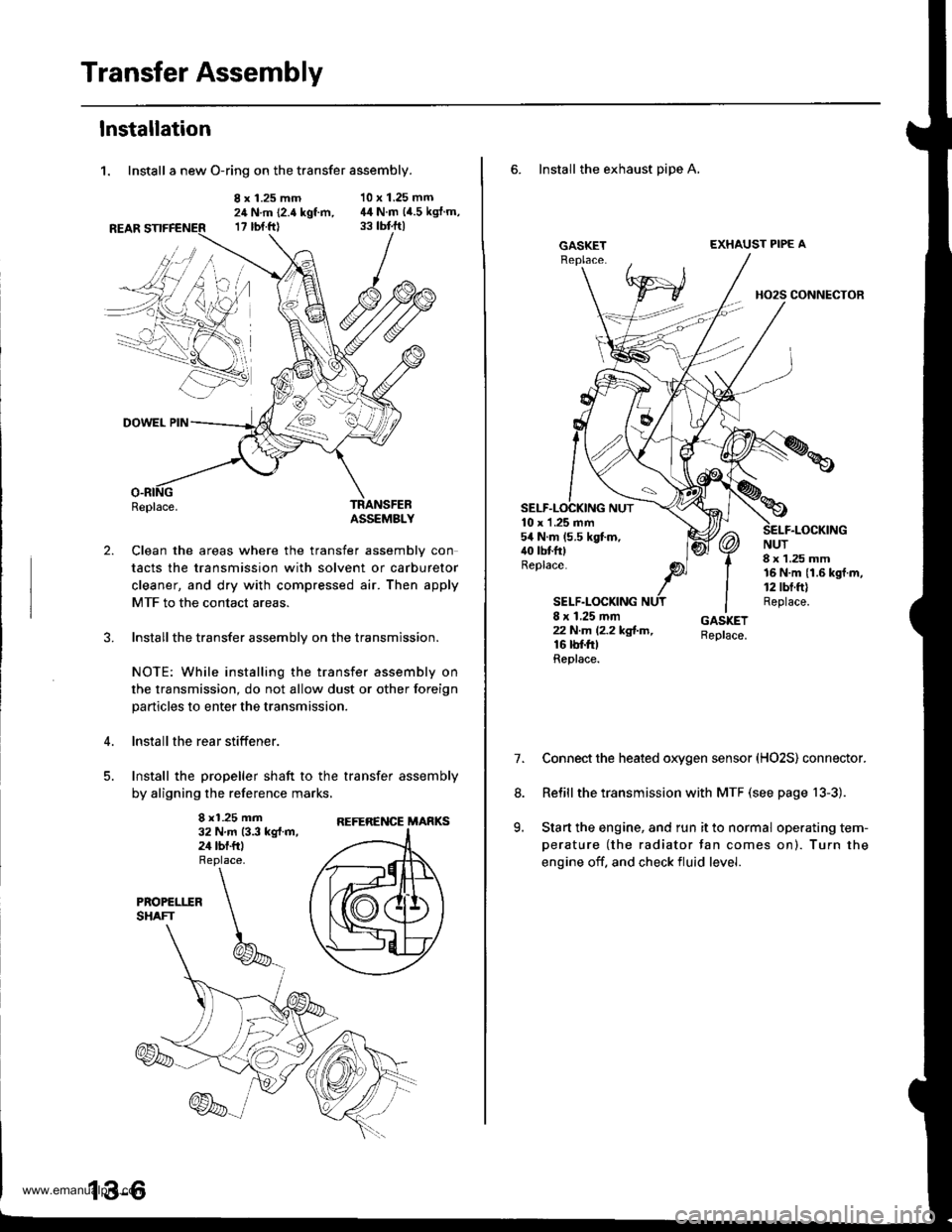

Transfer Assembly

lnstallation

1. Install a new O-ring on the transfer assembly.

8 x 1.25 mm24 N.m (2.4 kgt m,17 rbt.ftl

10 x 1.25 mm44 N.m (4.5 kgJ.m,

2.

DOWEL PIN

Replace.TRANSFEBASSEMBLY

Clean the areas where the transfer assembly con

tacts the transmission with solvent or carburetor

cleaner, and dry with compressed air. Then apply

MTF to the contact areas.

Installthe transfer assembly on the transmission.

NOTE: While installing the transfer assembly on

the transmission, do not allow dust or other foreign

particles to enter the transmission.

lnstall the rear stiffener.

Install the propeller shaft to the transfer assembly

by aligning the reference marks,

8 x1.25 mm32 N.m 13.3 kg{.m,24 tbf.ftl

REFERENCE MARKS

6. Install the exhaust pipe A,

GASKETEXHAUST PIPE A

HO2S CONNECTOR

10 x 1 .25 mm54 N.m (5.5 kgt m,40 tbtfttReplace.

SELF.LOCKING

NUT8 x 1.25 mm16 N.m {1.6 kgf.m,12 tbt.ft)Replace.8 x 1.25 mmzzN.m l2.2kg!-m,16 rbf.trtReplace.

7.Connect the heated oxygen sensor (HO2S) connector.

Relill the transmission with MTF (see page 13-3).

Start the engine, and run it to normal operating tem-

perature (the radiator tan comes on). Turn the

engine off. and check fluid level.

8.

9.

www.emanualpro.com