Drive HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 852 of 1395

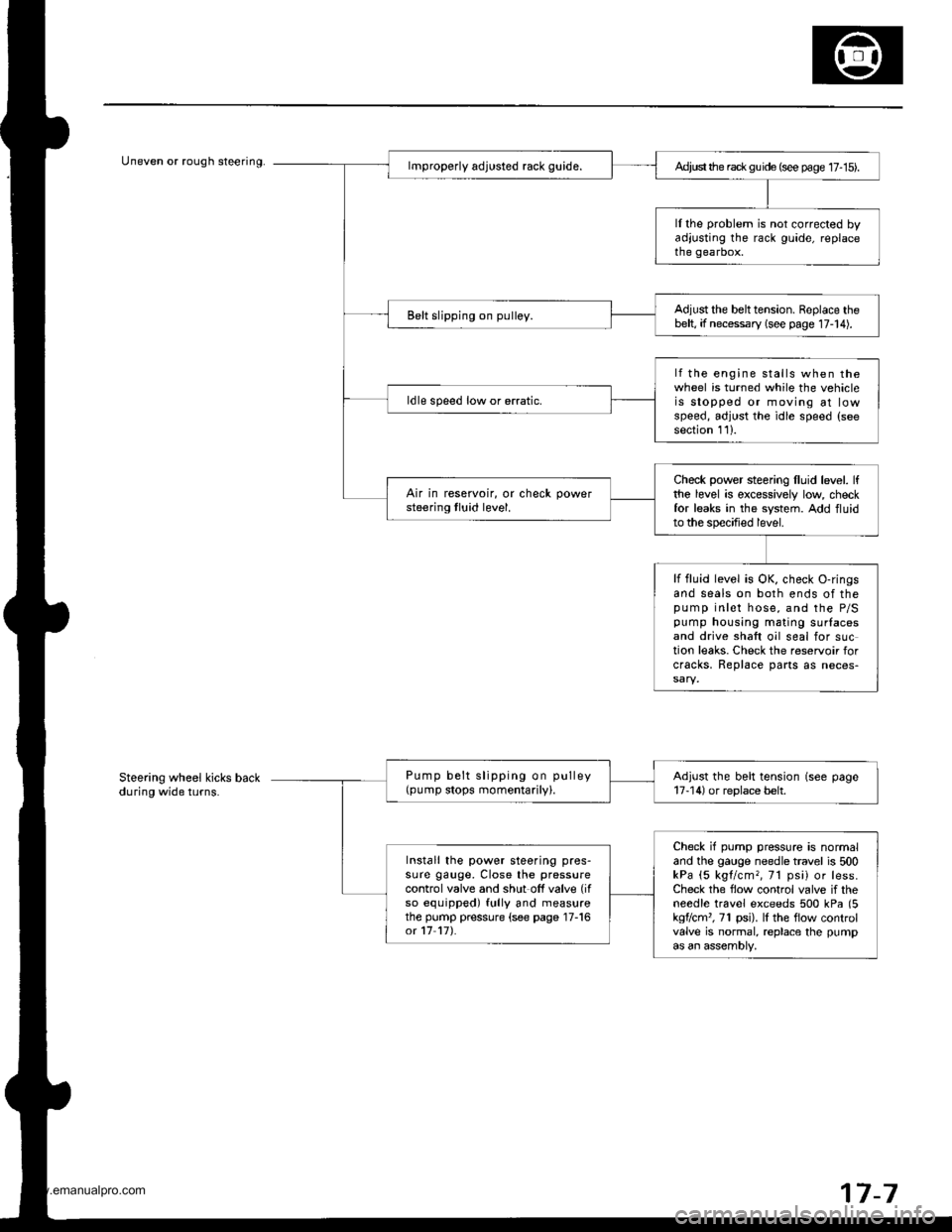

Uneven or rough steering.Ad,ust the rack gu ide (see page 17- 15).

ll the problem is not corrected byadjusting the rack guide, replacethe gearbox.

Adjust the belttension. Replace thebelt, if necessary (see page 17-14).Belt slipping on pulley.

lf the engine stalls when thewheel is turned while the vehicleis stopped or moving at lowspeed, adjust the idle speed (seesection 111.

ldle speed low or erratic.

Check power steering lluid level. lfthe level is excessively low checkfor leaks in the system. Add fluidto the specified level.

Air in reservoir, or check powersteering tluid level.

lf fluid level is OK, check O-ringsand seals on both ends of thepump inlet hose, and the P/Spump housing mating surlacesand drive shaft oil seal for suction leaks. Check the reservoir forcracks, Replace parts as neces-

Pump belt slipping on pulley(pump stops momentarily).Adjust the belt tension (see page17-14) or replace belt.

Check if pump pressure is normaland the gauge needle travel is 500kPa (5 kgl/cm,, 71 psi) or less.Check the flow control valve if theneedle travel exceeds 500 kPa (5kgflcm'�, 71 psi). lI the flow controlvalve is normal, replace the pumpas an assembly,

Install the power steering pres-sure gauge, Close the pressurecontrol valve and shut off valve (if

so equipped) fully and measurethe pump pressure (see page 17-16ot 17 17).

Steering wheel kicks backduring wide turns.

7-7

www.emanualpro.com

Page 854 of 1395

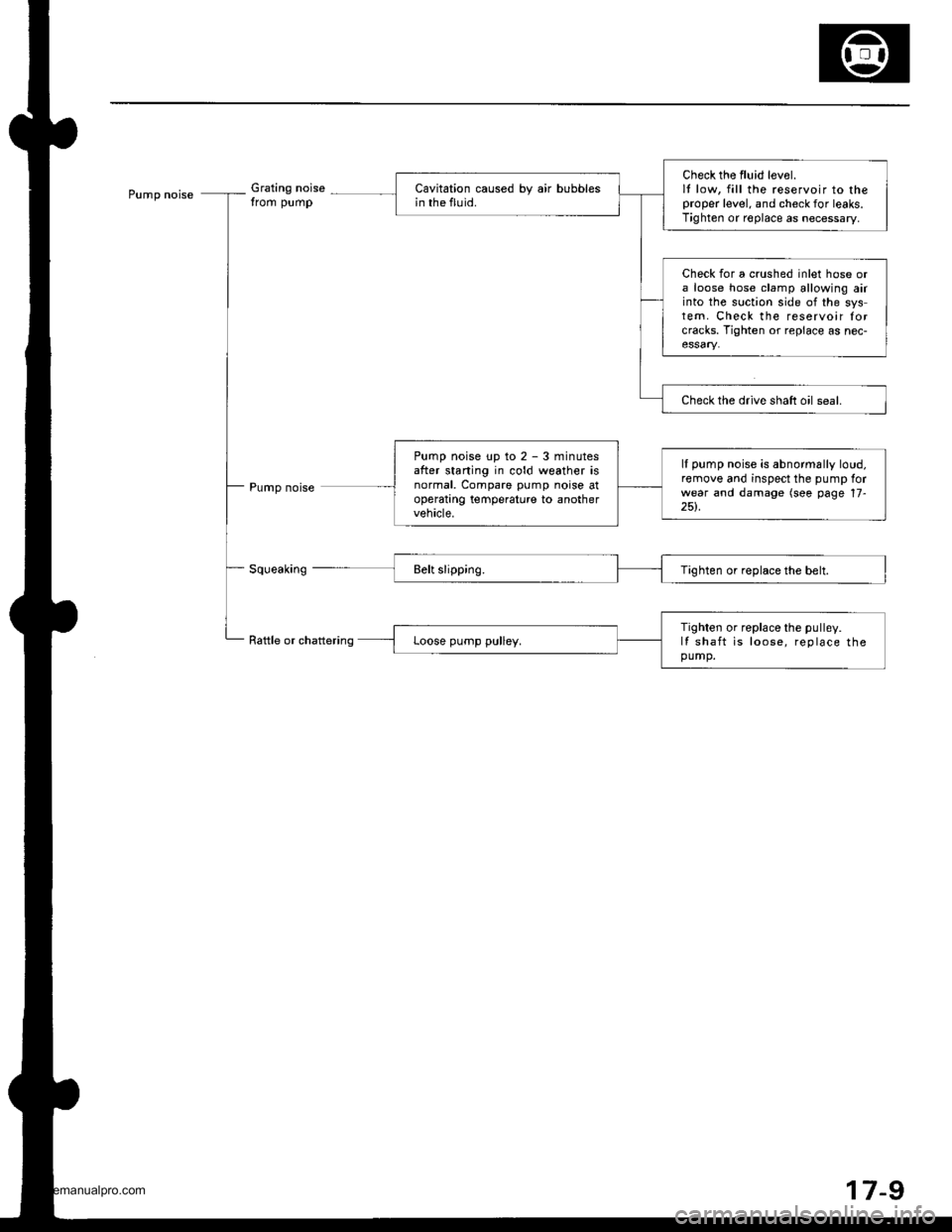

Pump noiseGrating nois€trom pump

Pump noise

Raftle or chattering

Check the fluid lev€1.lt low, fill the reservoir to theproper level. and check for leaks.Tighten or roplace as necessary,

Cavitation caused by air bubblesin the fluid.

Check for a crushed inlet hose ora loose hose clamp allowing airinto the suction side of the system. Check the reservoir forcracks. Tighten or replace as nec-

Check the drive shaft oil seal.

Pump noise up to 2 - 3 minutesafter starting in cold weather isnormal, Compare pump noise atoperatrng temperature to anothervehicle.

ll pump noise is abnormally loud,remove and inspect the pump forwear and damage (see page 17-251.

Tighten or replace the pulley.lI shaft is loose, replace thepump.

17-9

www.emanualpro.com

Page 859 of 1395

Inspection and Adjustment

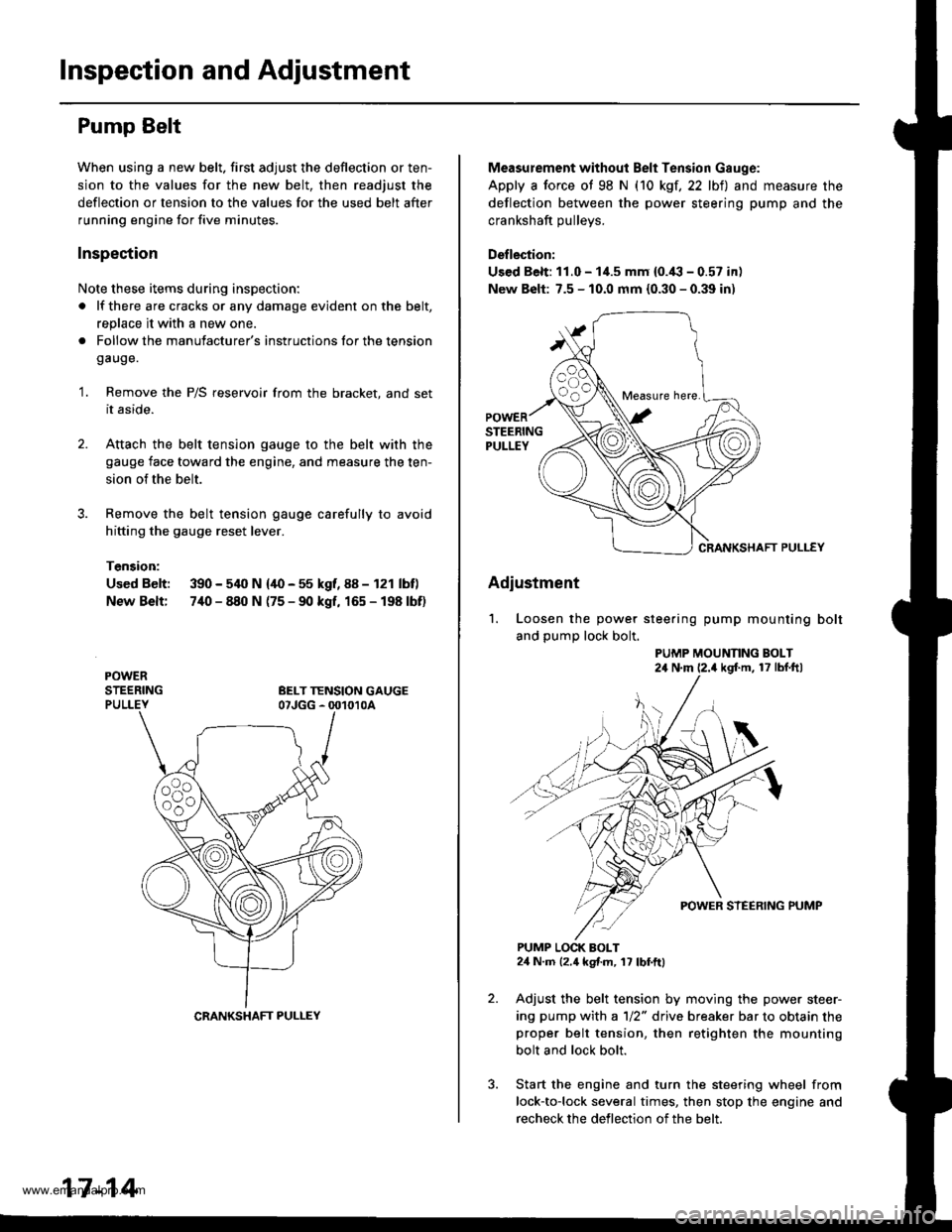

Pump Belt

When using a new belt. first adjust the deflection or ten-

sion to the values for the new belt, then readjust the

deflection or tension to the values for the used belt after

running engine for five minutes.

Inspection

Note these items during inspection:

a lf there are cracks or any damage evident on the belt,

replace it with a new one.

. Follow the manufacturer's instructions lor the tension

gauge.

'1. Remove the P/S reservoir from the bracket, and set

it aside.

2. Attach the belt tension gauge to the belt with the

gauge face toward the engine, and measure the ten-

sion of the belt.

Remove the belt tension gauge carefully to avoid

hitting the gauge reset lever.

Tension:

Used Belt: 390 - 540 N {40 - 55 kgf, 88 - 121 lbf)

New Belt: 7,[0 - 840 N (75 - 90 kgf, 165 - 198 lbf)

CRANKSHAFT PULLEY

17-14

Measurement without Belt Tension Gauge:

Apply a force ot 98 N (10 kgf,22 lbt) and measure the

deflection between the power steering pump and the

crankshaft oullevs.

Deflection:

Used Belt: 11.0 - 1i1.5 mm {0.'(l - 0.57 in)

New Belt: 7.5 - 10.0 mm {0.30 - 0.39 in)

CRANKSHAFT PULLEY

Adiustment

'1. Loosen the power steering pump mounting bolt

and pump lock bolt.

PUMP MOUNNNG BOLT24 N'm (2.4 kgf'm, 17 lbf ftl

PUMP LOCK BOLT24 N.m 12.4 kgf.m, 17 lbf.ftl

Adjust the belt tension by moving the power steer-

ing pump with a 1/2" drive breaker bar to obtain theproper belt tension, then retighten the mounting

bolt and lock bolt.

Start the engine and turn the steering wheel from

lock-to-lock several times, then stop the engine and

recheck the deflection of the belt.

Measure here.

www.emanualpro.com

Page 863 of 1395

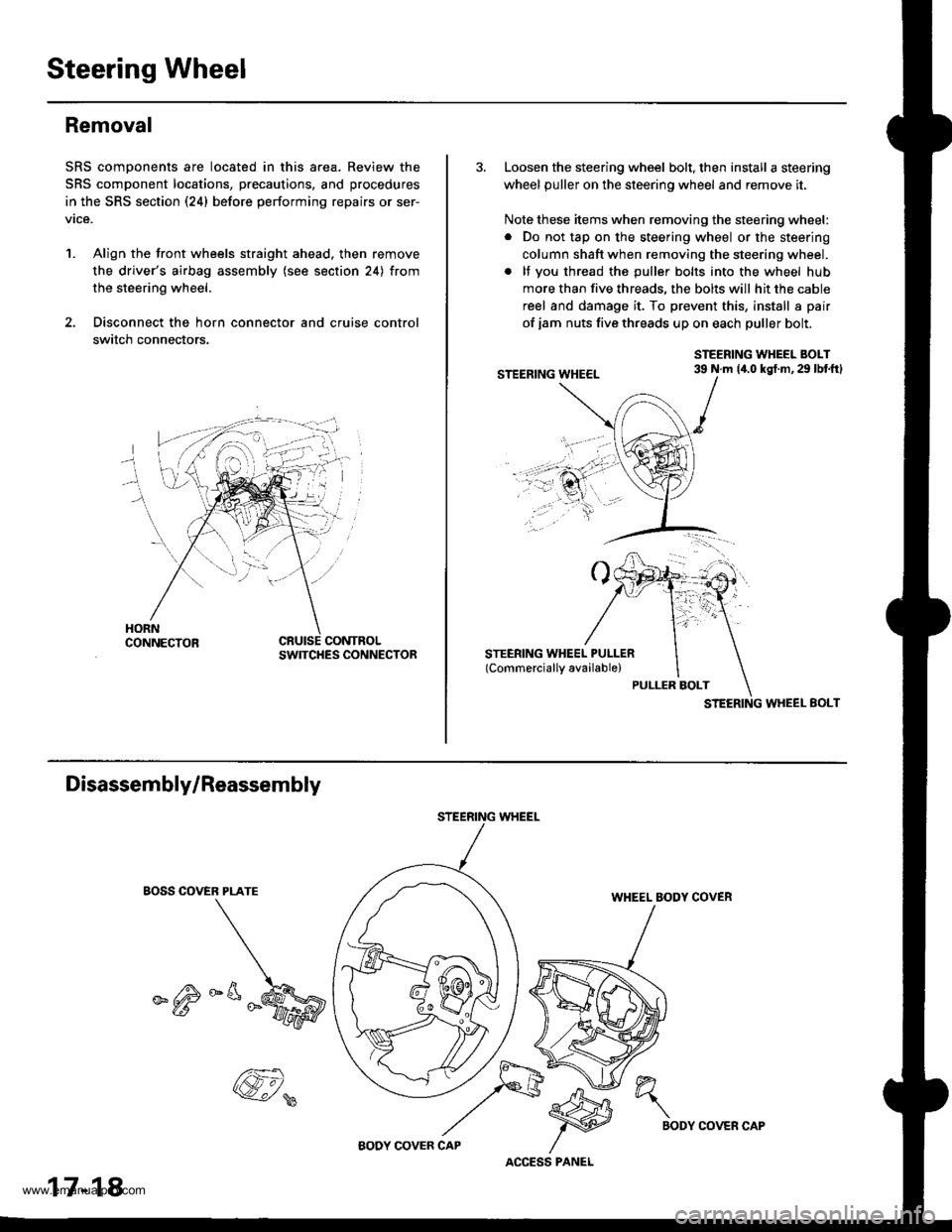

Steering Wheel

Removal

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (24) before performing repairs or ser-

vice.

1. Align the front wheels straight ahead. then remove

the driver's airbag assembly (see section 24) from

the steering wheel.

2. Disconnect the horn connector and cruise control

switch connectors.

CONTROLSWITCHES CONNECTOR

3. Loosen the steering wheel bolt, then install a steering

wheel puller on the steering wheel and remove it.

Note these items when removing the steering wheel:

. Do not tap on the steering wheel or the steering

column shaft when removing the steering wheel.

. lf you thread the puller bolts into the wheel hub

more than five threads, the bolts will hit the cable

reel and damage it. To prevent this, install a pair

of jam nuts five threads up on each puller bolt.

STEERING WHEEL BOLT39 N.m 14.0 kgt.m,29 lbtftl

STEERING WHEEL EOLT

Disassembly/Reassembly

EOSS COVER PLATE

_^M

STEERING WHEEL

WHEEL BODY COVER

17-18

@,

ACCESS PANEL

h"\

BODYCOVER CAP

www.emanualpro.com

Page 864 of 1395

lnstallation

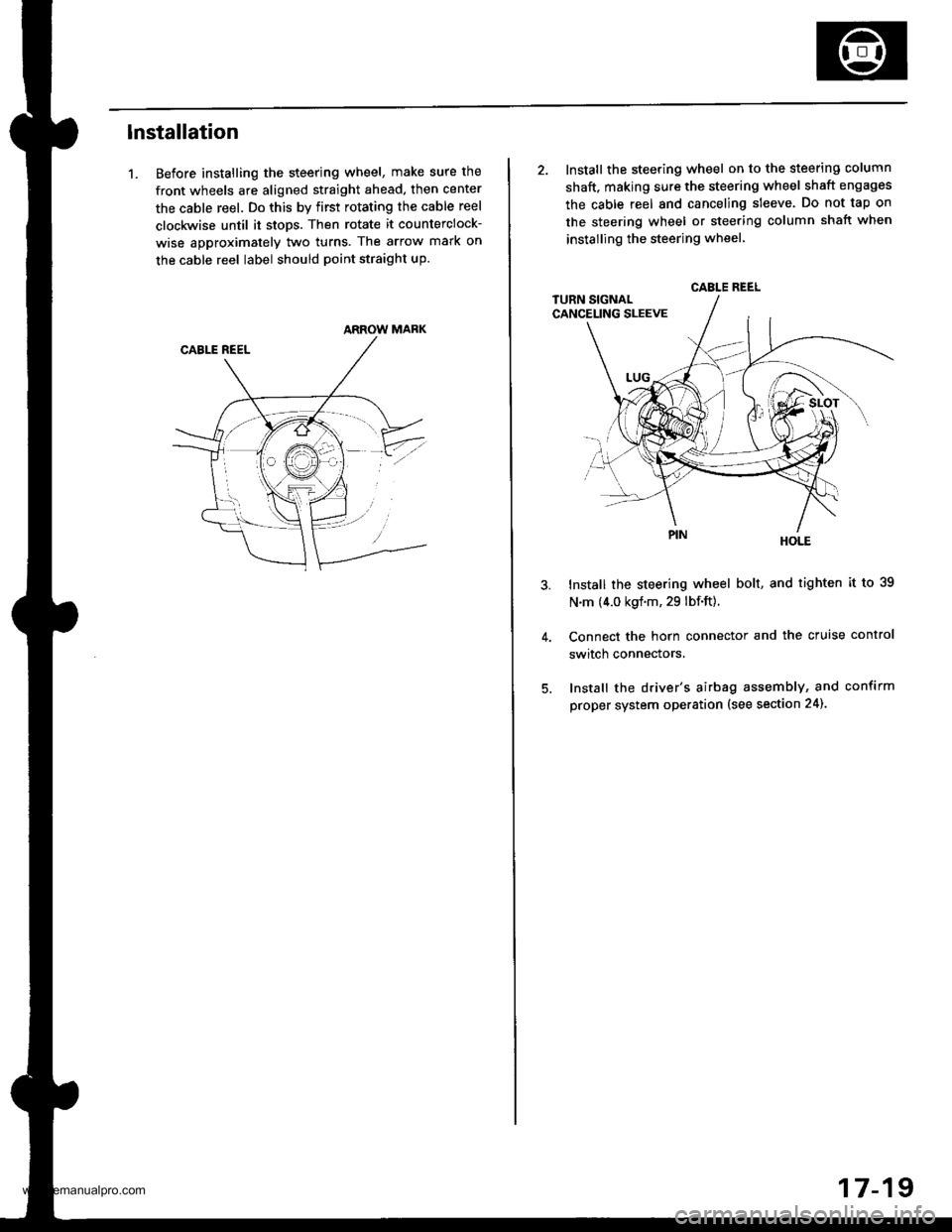

1. Before installing the steering wheel, make sure the

front wheels are aligned straight ahead, then center

the cable reel. Do this by first rotating the cable reel

clockwise until it stops. Then rotate it counterclock-

wise approximately two turns. The arrow mark on

the cable reel label should point straight up.

ARROW MARK

2. Install the steering wheel on to the steering column

shaft, making sure the steering wheel shaft engages

the cable reel and canceling sleeve. Do not tap on

the steering wheel or steering column shatt when

instailing the steering wheel

HOLE

Install the steering wheel bolt, and tighten it to 39

N.m (4.0 kgf.m, 29 lbf.ft).

Connect the horn connector and the cruise control

switch connectors,

Install the driver's airbag assembly, and confirm

proper system operation (see section 24).

CABLE REEL

17-19

www.emanualpro.com

Page 865 of 1395

Steering Column

Removal/lnstallation

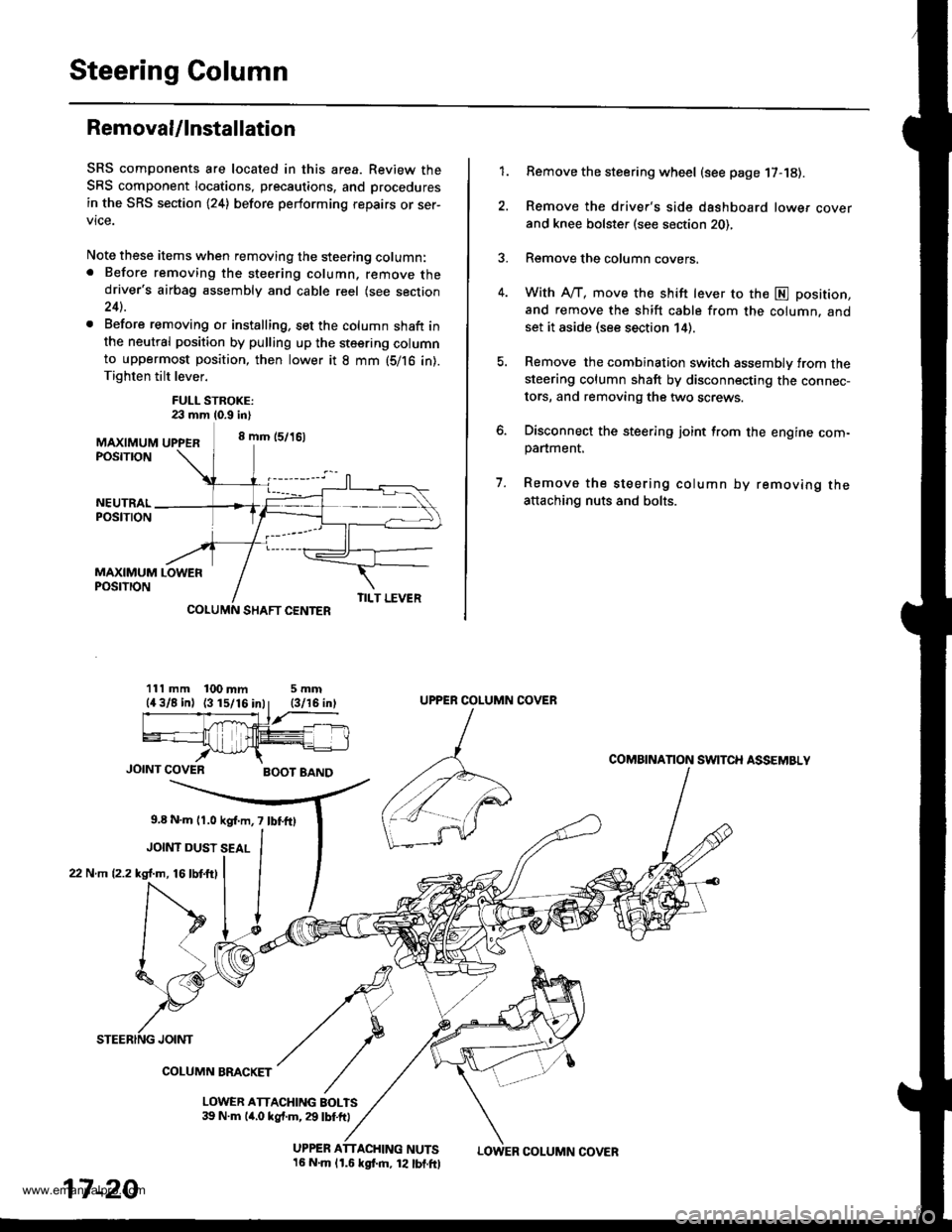

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (24) before performing repairs or ser-

vice.

Note these items when removing the steering column:. Before removing the steering column, remove thedriver's airbag assembly and cable reel (see section24).

. Before removing or installing, set the column shaft inthe neutral position by pulling up the steering columnto uppermost position, then lower it 8 mm (5/16 in).Tighten tilt lever.

FULL STROKE:23 mm 10.9 in)

MAXIMUM UPPER8 mm (5/16)

POSTTTON

Remove the steering wheel (see page 17-18).

Remove the driver's side dashboard lower cover

and knee bolster (see section 20),

Remove the column covers.

With A"/T, move the shift lever to the E position,

and remove the shift cable from the column. andset it aside (see section 14).

Remove the combination switch assembly from thesteering column shaft by disconnecting the connec-

tors, and removing the two screws.

Disconnect the steering joint from the engine com-panment.

Remove the steering column by removing theattaching nuts and bolts.

7.

1.

MAXIMUM LOWERPOSTTTON

SHAFT CENTER

111 mm 100 mm5mm

JOINT COVERBOOT BAND

9,8 N.m l r .0 kgf.m, 7 lbf.fO

JOINT DUST SEAL

22 N.m (2.2 kgl.m, 16lbtftl

TILT LEVER

UPPER ATTACHING NUTS16 N.m lr.6 kgf.m, 12 lbf.ftl

UPPER COLUMN COVER

COMAINANON SWITCH ASSEMBLY

JOINT

COLUMN BMCKET

LOWER ATTACHING BOLTS39 N.m lir,o kgf.m, 29 lbf.ft)

17-20

LOWER COLUMN COVER

www.emanualpro.com

Page 870 of 1395

Disassembly

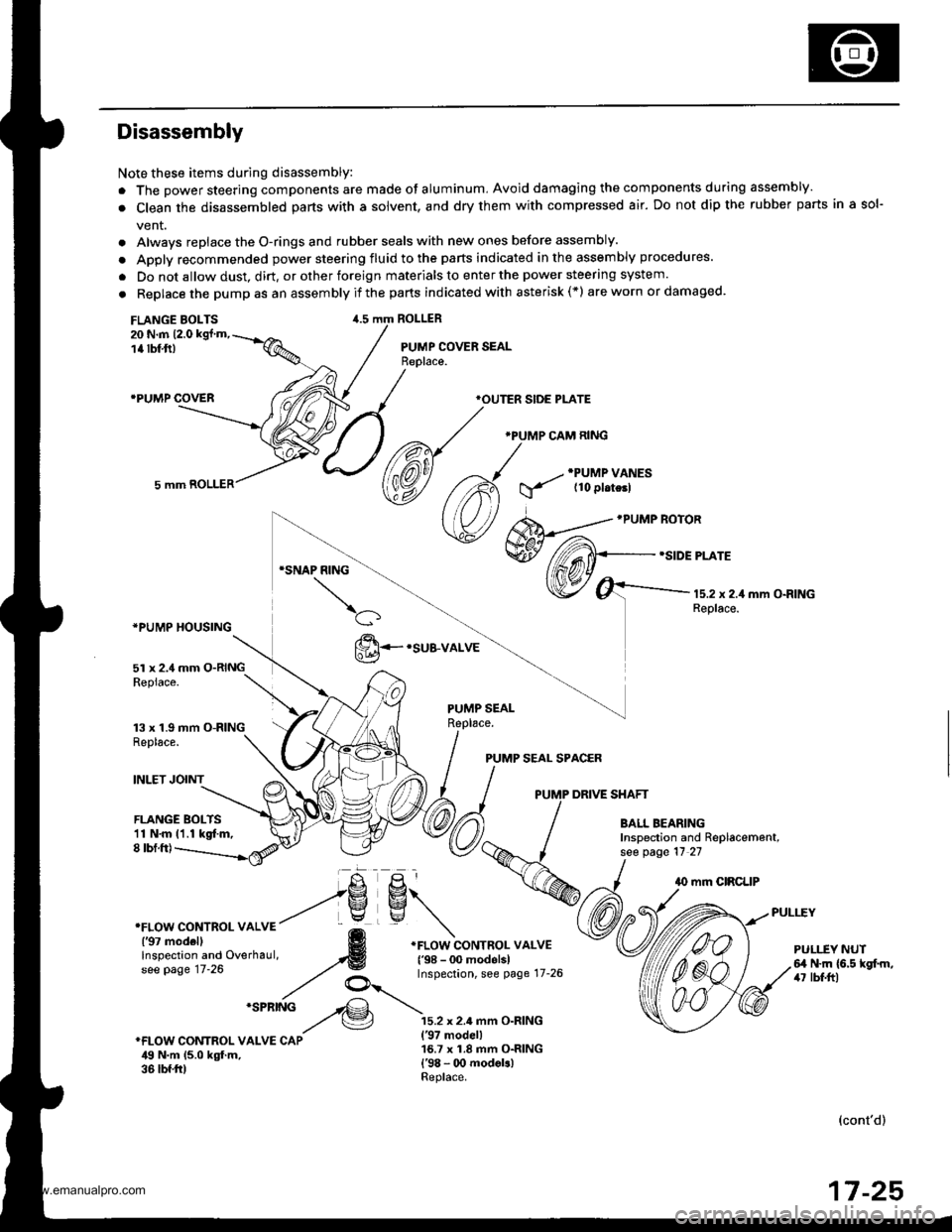

Note these items during disassembly:

. The power steering components are made of aluminum, Avoid damaging the components during assembly.

. Clean the disassembled parts with a solvent, and dry them with compressed air. Do not dip the rubber parts in a sol-

vent.

. Always replace the O-rings and rubber seals with new ones before assembly.

. Apply recommended power steering fluid to the parts indicated in the assembly procedures.

. Do not allow dust, dirt, or other foreign materials to enter the power steering system.

. Replace the pump as an assemblyif the parts indicated with asterisk(*) areworn ordamaged.

FLANGE BOLTS20 N.m 12.0 kgt'm,

1a tbf,ft)

.PUMP COVER

ROLLER

PUMP COVER SEAL

*PUMP HOUSING

5l x 2.4 mm O-RINGRepiace.

13 x 1.9 mm O-RINGReplace.

INLET JOINT

*OUTER SIDE PLATE

.PUMP CAM RING

PUMP SEAL SPACER

PUMP DRIVE SHAFT

FLANGE BOLTS11 N.m 11.1 kgt m,8 tbf.ft)

PULI.-EY NUTfl N.m (6.5 kgf.m,/r7 lbf.ftl

(cont'd)

17 -25

www.emanualpro.com

Page 871 of 1395

Power Steering Pump

Disassembly (cont'dl

1.

7.

9.

10.

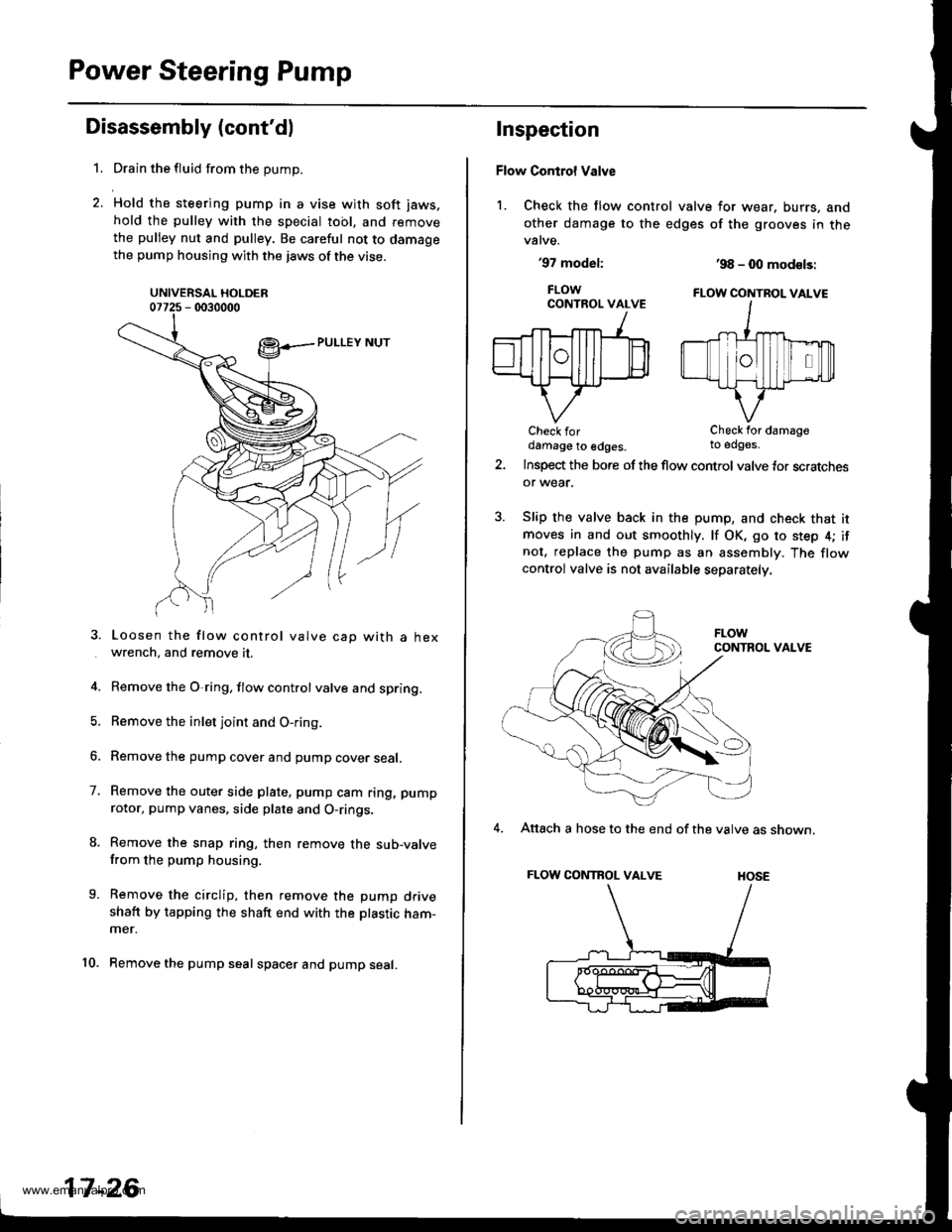

Drain the fluid from the pump.

Hold the steering pump in a vise with soft jaws.

hold the pulley with the special tool, and remove

the pulley nut and pulley. Be careful not to damagethe pump housing with the jaws of the vise.

UNIVERSAL HOLDER07725 - 0030000

Loosen the flow control valve cap with a hexwrench, and remove it.

Remove the O,ring, flow control valve and spring.

Remove the inlet joint and O-ring.

Remove the pump cover and pump cover seal.

Remove the outer side plate, pump cam ring, pump

rotor, pump vanes, side plate and O-rings.

Remove the snap ring, then remove the sub-valvefrom the pump housing.

Remove the circlip, then remove the pump driveshaft by tapping the shaft end with the ptastic ham-mer.

Remove the pump seal spacer and pump seal.

17-26

Inspection

Flow Control Valve

1. Check the flow control valve for wear, burrs, and

other damage to the edges of the grooves in thevalve.

'97 model:

FLOWCONTROL VALVE

Check fordamage to edges.

'98 - 0O mod€ls:

FLOW CONTBOL VALVE

Check for damageto edges.

Insp€d the bore of the flow control valve tor scratchesor wear.

Slip the valve back in the pump, and check that itmoves in and out smoothly. lf OK, go to step 4; ifnot, replace the pump as an assembly. The flowcontrolvalve is not available separately.

CONTROL VALVE

4. Attach a hose to the end of the valve as shown.

FLOW CONTROL VALVE HOSE

www.emanualpro.com

Page 873 of 1395

Power Steering Pump

Reassembly

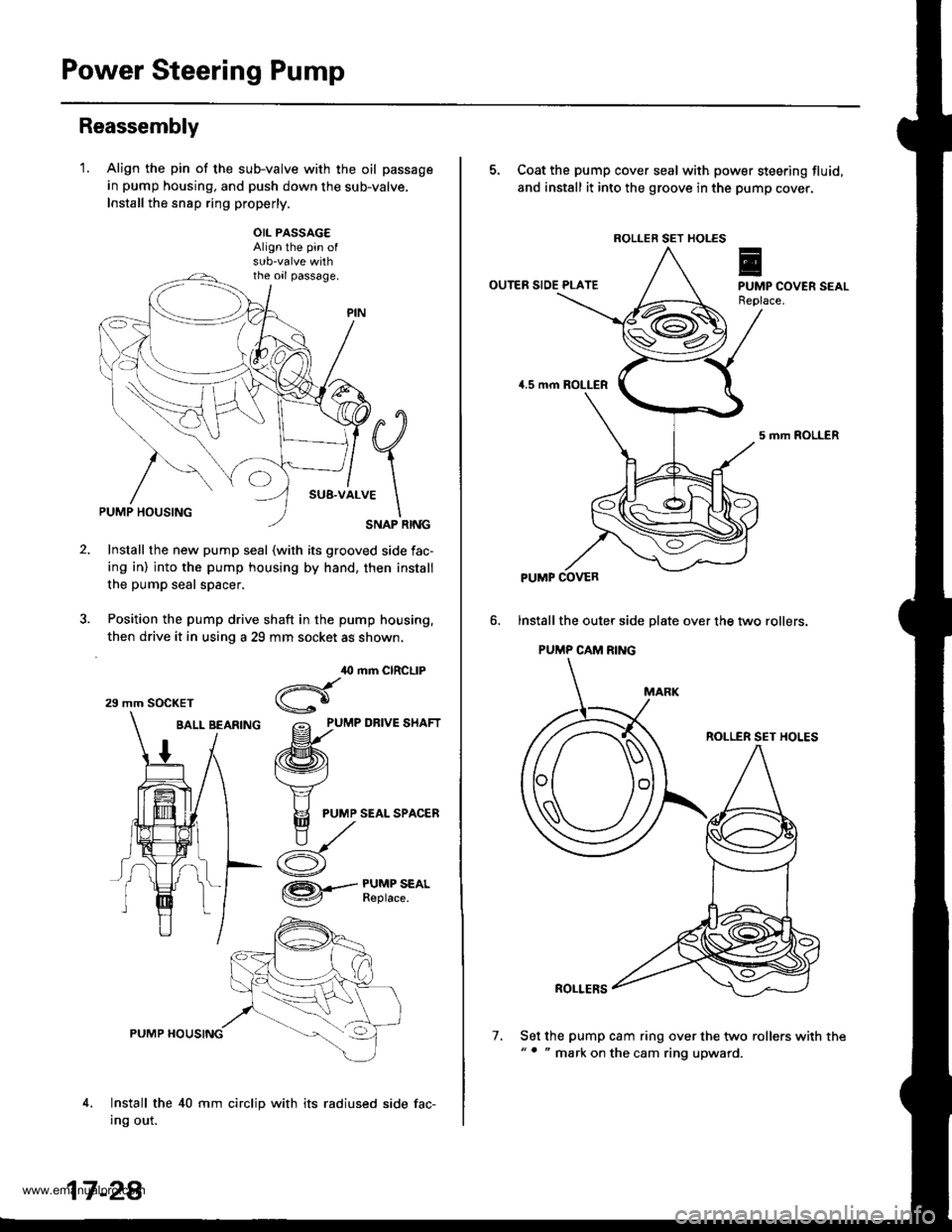

'1.Align the pin of the sub-valve with the oil passage

in pump housing, and push down the sub-valve.

Install the snsp ring properly.

OIL PASSAG€Align the pin of

the oil passage.

#q

;1..*

\SNAP RINGPUMP HOUSING

Install the new pump seal (with its grooved side fac-

ing in) into the pump housing by hand, then install

the pump seal spacer.

Position the pump drive shaft in the pump housing,

then drive it in using a 29 mm socket as shown,

BALL BEARfNG grlu,e un.t

/ /ffi\

1 / t\v4

t/ Y

# I F

PUMP SEALSPAC,ER

ry^

i- d

,O mm CIRCLIP

Hgo

/= PUMP DRIVE SHAFT

@.--#$i":*'

4,

PUMP HOUSING

Install the 40 mm circlip with its radiused side fac-

Ing out.

29 mm SOCKET

17 -2A

7.

5. Coat the pump cover seal with power steering fluid,

and install it into the groove in the pump cover.

OUTER SIDE PLATE

5 mrh ROLLER

lnstall the oute. side plate over the two rollers.

PUMP CAM RING

ROLLER SET HOLES

ROLLERS

Set the pump cam ring over the two rollers with the"' " mark on the cam ring upward.

ROLLER SET HOLES

PUMP COVER

www.emanualpro.com

Page 876 of 1395

Power Steering Gearbox

Removal

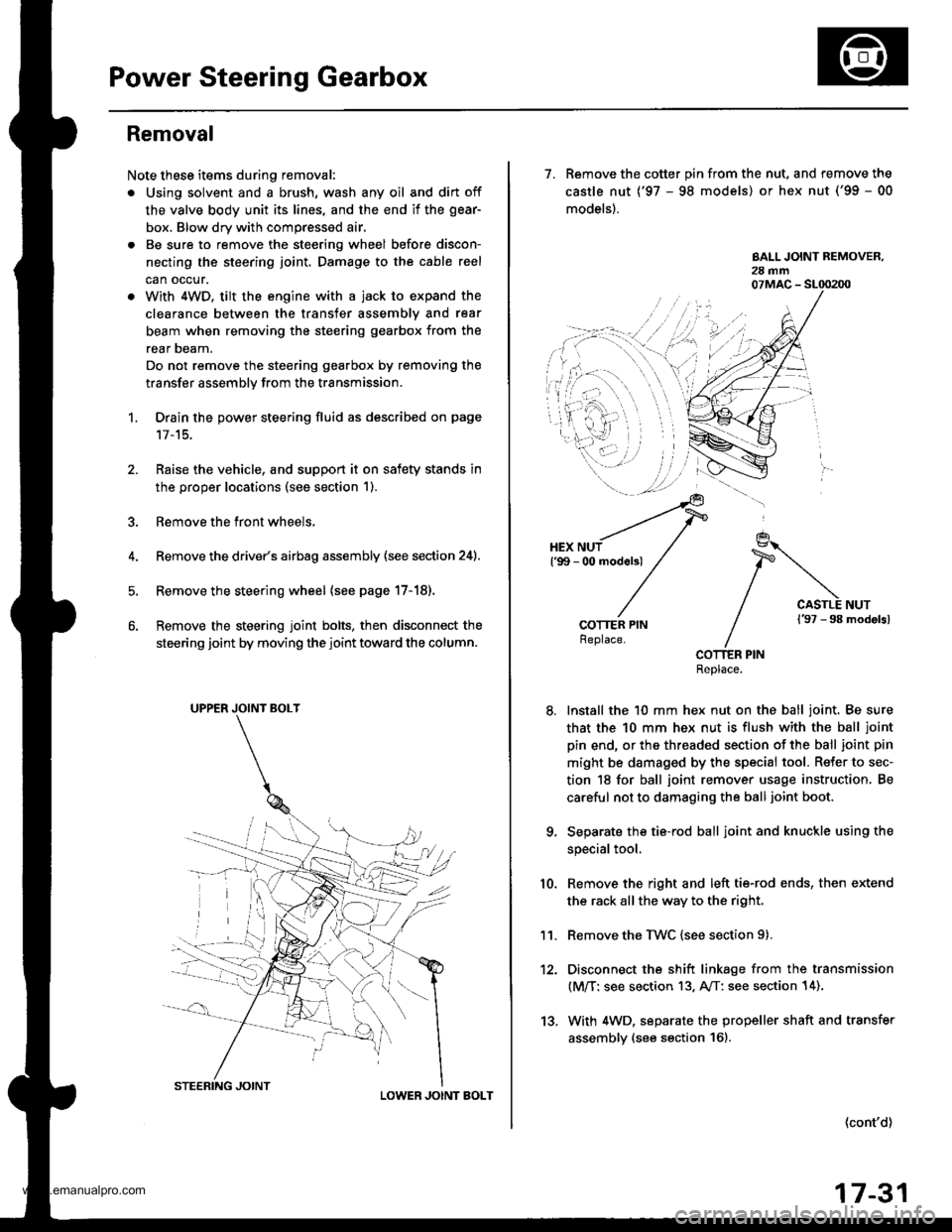

Note these items during removal:

. Using solvent and a brush, wash any oil and dirt off

the valve body unit its lines, and the end if the gear-

box. Blow dry with compressed air.

. Be sure to remove the steering wheel before discon-

necting the steering joint. Damage to the cable reel

can occur.

. With 4WD. tilt the engine with a jack to expand the

clearance between the transfer assembly and rear

beam when removing the steering gearbox from the

rear oeam.

Do not remove the steering gearbox by removing the

transfer assembly from the transmission.

1. Drain the power steering fluid as described on page'17-15.

Raise the vehicle, and suppon it on safety stands in

the proper locations (see section 1).

Remove the front wheels,

Remove the drive/s airbag assembly {see section 24).

Remove the steering wheel {see page 17-18).

Remove the steering joint bolts, then disconnect the

steering joint by moving the joint toward the column.

UPPER JOINT BOLT

LOWER JOINT BOLT

13.

7. Remove the cotter pin from the nut, and remove the

castle nut {'97 - 98 models) or hex nut ('99 - 00

models).

COTTER PINReplace.

Install the 10 mm hex nut on the ball joint. Be sure

that the 10 mm hex nut is flush with the ball joint

pin end, or the threaded section of the ball joint pin

might be damaged by the special tool. Refer to sec-

tion 18 for ball joint remover usage instruction, Be

careful not to damaging the ball joint boot.

Separate the tie-rod ball joint and knuckle using the

special tool.

Remove the right and left tie-rod ends, then extend

the rack all the way to the right.

Remove the TWC (see section 9).

Disconnect the shift linkage from the transmission

(M/T: see section 13, A/T: see section 14).

With 4WD. separate the propeller shaft and transfer

assembly (see section 161.

10.

11.

(cont'd)

17-31

www.emanualpro.com