connector a HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 784 of 1395

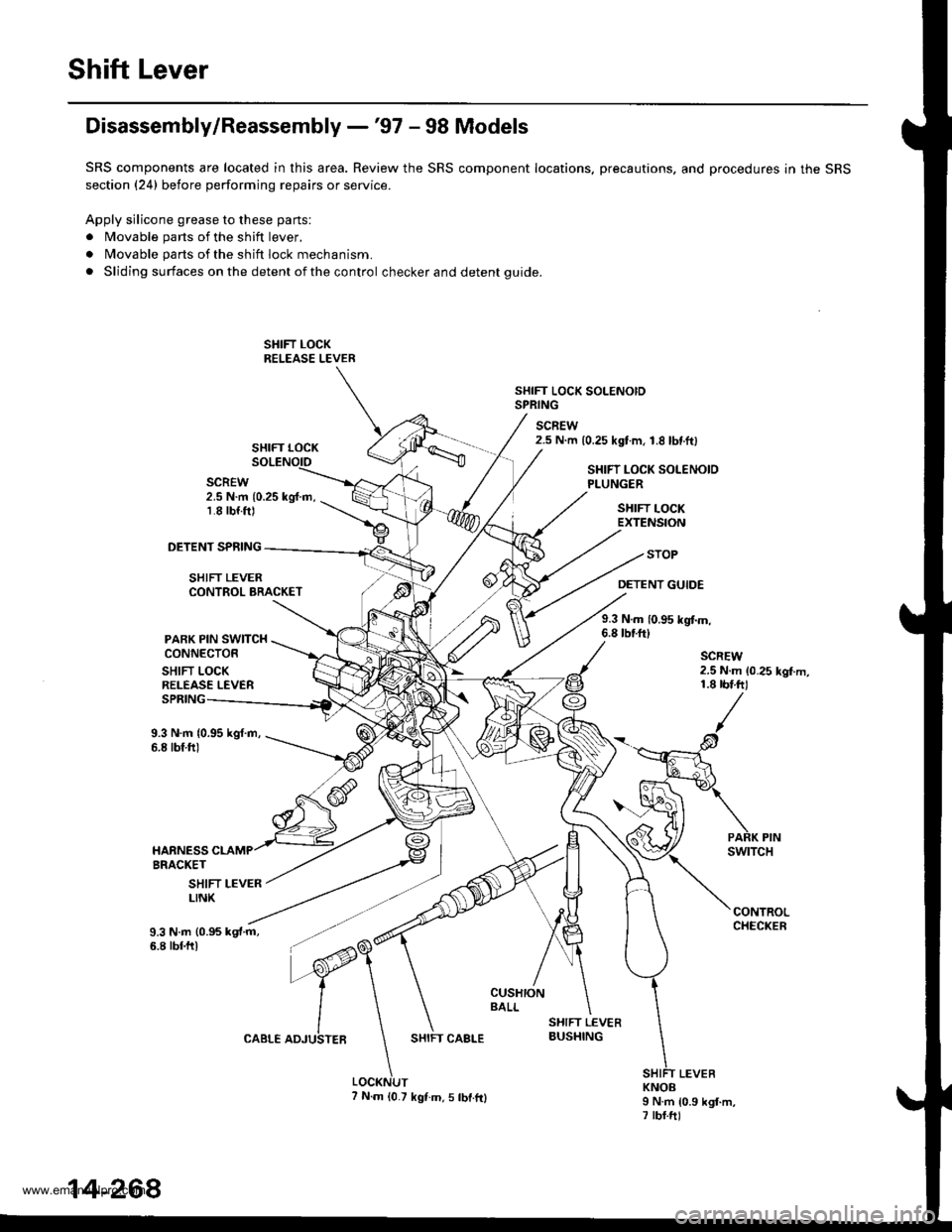

Shift Lever

Disassembly/Reassembly -'97 - 98 Models

SRS components are located in this area. Review the SRS component locations. precautions. and procedures in the SRS

section (24) before performing repairs or service.

Apply silicone grease to these parts'

. Movable parts of the shift lever,

. Movable parts of the shift lock mechanism.

. Sliding surfaces on the detent of the control checker and detent guide.

SHIFT LOCK SOLENOIDSPRING

SCREW

SHIFT LOCK2.5 N.m {0.25 kgtm, 1.8 lbtftl

SCREW2.5 N.m {0.25 kg{.m,1.8 rbf.ft)

SHIFT LOCK SOLENOIDPLUNGER

SHIFT LOCKEXTENSION

DETENT SPFING

SHIFT LEVER

PARK PIN SWITCHCONNECTOR

SHIFT LOCKRELEASE LEVER

CONTROL BRACKET

STOP

DETENT GUIDE

9.3 N.m 10.95 kgtm,6.8 tbrft)

SPRING

9.3 N.m {0.95 kgf.m,6.8 tbf.ftl

SHIFT LEVERLINK

9.3 N.m (0.95 kgt.m,6.8 tbf.ftl

SHIFT CAALE

KNOBI N.m 10.9 kgt.m,7 rbf.ftl

14-268

7 N.m {0.7 kgf.m.5 tbt.fr}

www.emanualpro.com

Page 853 of 1395

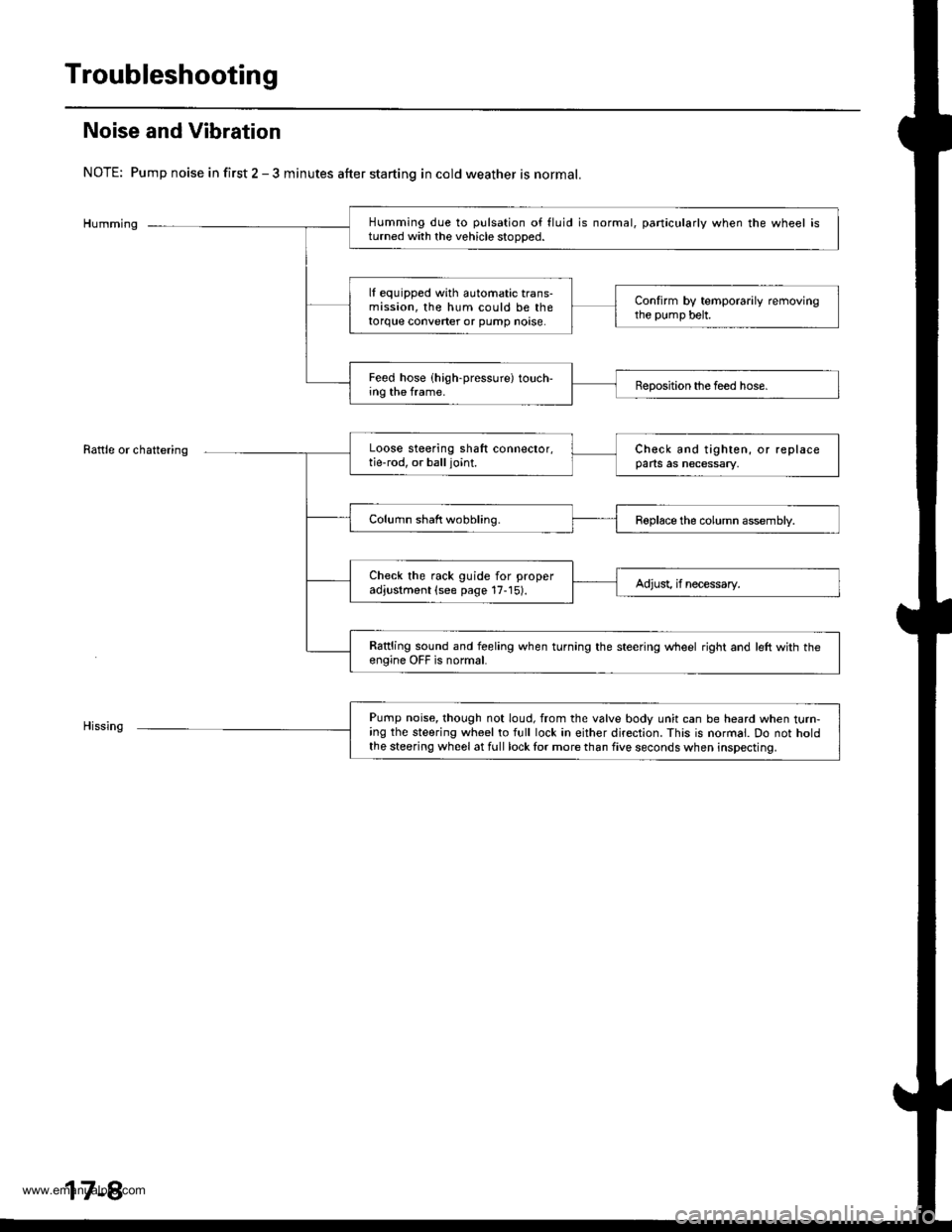

Troubleshooting

Noise and Vibration

NOTE: Pump noise in first 2 - 3 minutes after starting in cold weather is normal.

Humming

Rattle or chattering

Humming due to pulsation of fluid is normal, particularly when the wheel isturned with the vehicle stooDed.

lf equipped with automatic trans-mission, the hum could be thetorque converter or pump noase.

Confirm by temporarily removingthe pump belt.

Feed hose (high-pressure) touch-ing the frame.Beposition the feed hose.

Loose steering shaft connector,tie-rod, or balljoint.Check and tighten, or replaceparts as necessary,

Column shaft wobbling.Roplace the column assembly.

Check the rack guide for properadjustment (see page 17-15).Adjust, if necessary.

Rattling sound and feeling when turning the steering wheel right and left with th€engine OFF is normal.

Pump noise, though not loud, from the valve body unit can be heard when turn-ing the steering wheel to full lock in either direction. This is normal. Do not holdthe steering wheel at full lock lor more than five seconds when inspecting.

17-8

www.emanualpro.com

Page 855 of 1395

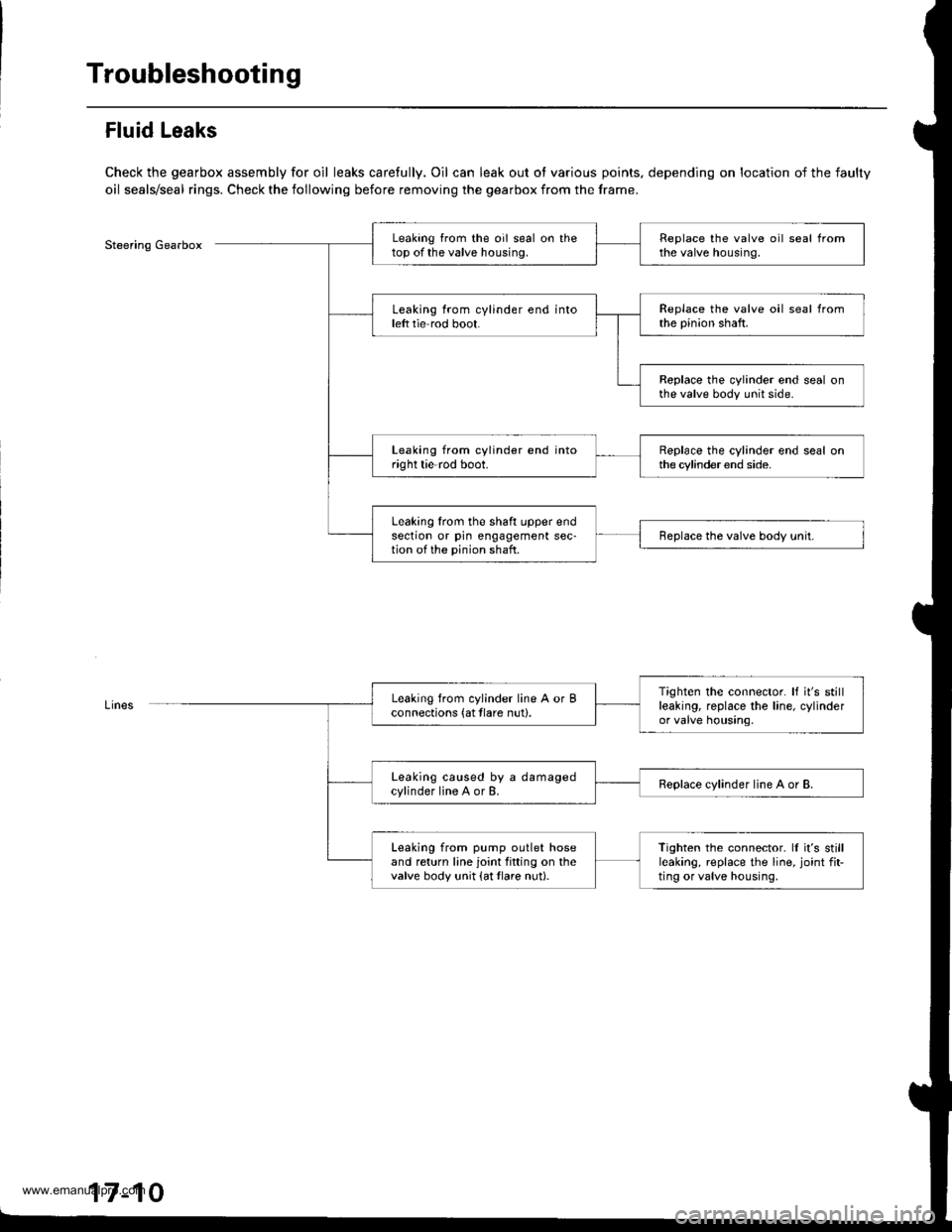

Troubleshooting

Fluid Leaks

Check the gearbox assembly for oil leaks carefully. Oil can leak out ot various points, depending on location of the faulty

oil seals/seal rings. Check the following before removing the gearbox from the frame.

Steering GearboxLeaking from the oil seal on thetop of the valve housing.Replace the valve oil seal fromthe valve housing.

Leaking from cylinder end intoleft tie rod boot.Replace the valve oil seal fromthe pinion shaft.

Replace the cylinder end seal onthe valve body unit side.

Leaking from cylinder end intoright tie-rod boot.Replace the cylinder end seal onthe cylinder end side.

Leaking lrom the shaft upper endsection or pin engagement sec-tion of the pinion shaft.Replace the valve body unit.

Tighten the connector. It it's stillleaking, replace the line, cylinderor valve housing.

Leaking from cylinder line A or Bconnections (at tlare nut).

Leaking caused by a damagedcylinder line A or B.Replace cylinder line A or B.

Leaking from pump outlet hoseand return line joint fitting on thevalve body unit {at tlare nut}.

Tighten the connector. ll it's stillleaking, replace the line, joint fit-ting or valve housing,

17-10

www.emanualpro.com

Page 863 of 1395

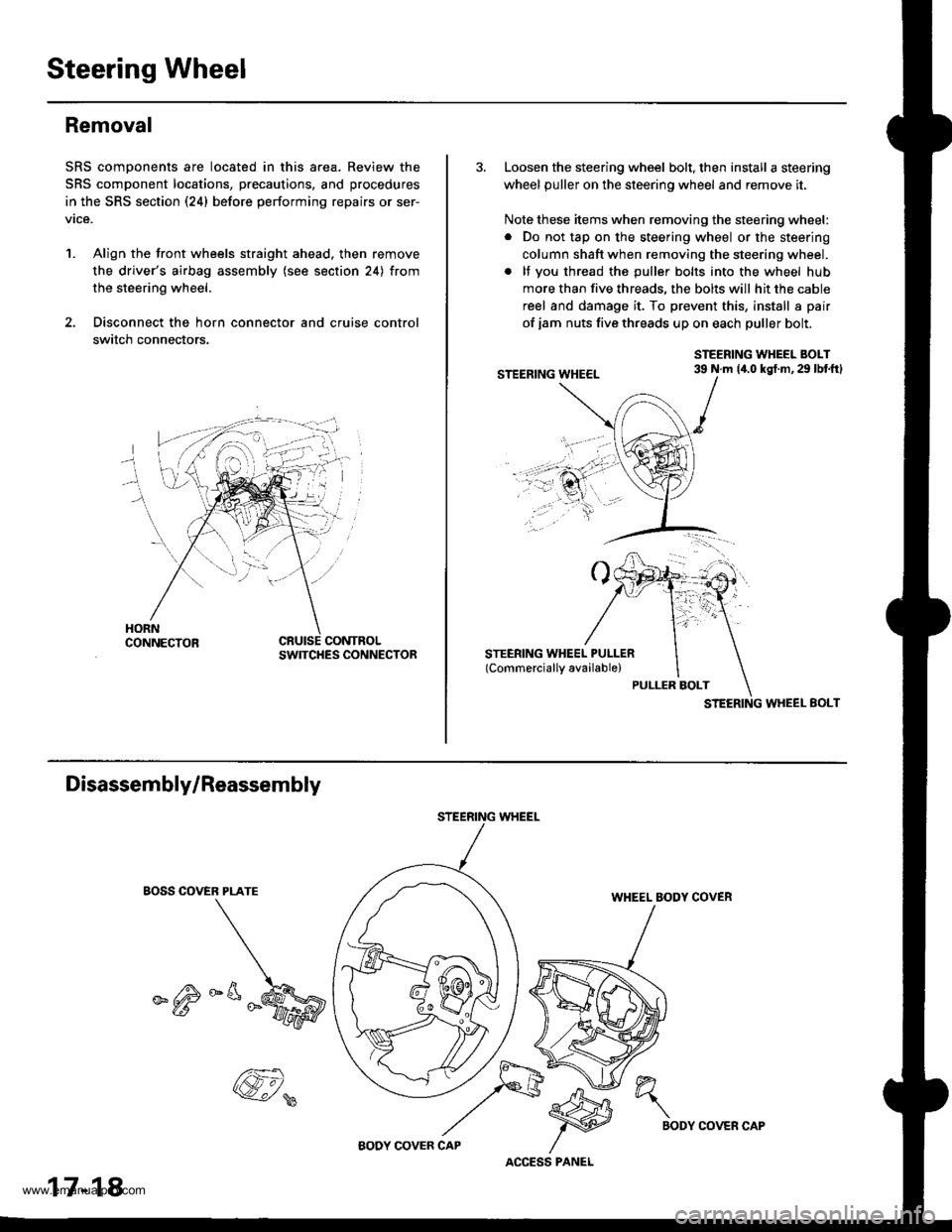

Steering Wheel

Removal

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (24) before performing repairs or ser-

vice.

1. Align the front wheels straight ahead. then remove

the driver's airbag assembly (see section 24) from

the steering wheel.

2. Disconnect the horn connector and cruise control

switch connectors.

CONTROLSWITCHES CONNECTOR

3. Loosen the steering wheel bolt, then install a steering

wheel puller on the steering wheel and remove it.

Note these items when removing the steering wheel:

. Do not tap on the steering wheel or the steering

column shaft when removing the steering wheel.

. lf you thread the puller bolts into the wheel hub

more than five threads, the bolts will hit the cable

reel and damage it. To prevent this, install a pair

of jam nuts five threads up on each puller bolt.

STEERING WHEEL BOLT39 N.m 14.0 kgt.m,29 lbtftl

STEERING WHEEL EOLT

Disassembly/Reassembly

EOSS COVER PLATE

_^M

STEERING WHEEL

WHEEL BODY COVER

17-18

@,

ACCESS PANEL

h"\

BODYCOVER CAP

www.emanualpro.com

Page 864 of 1395

lnstallation

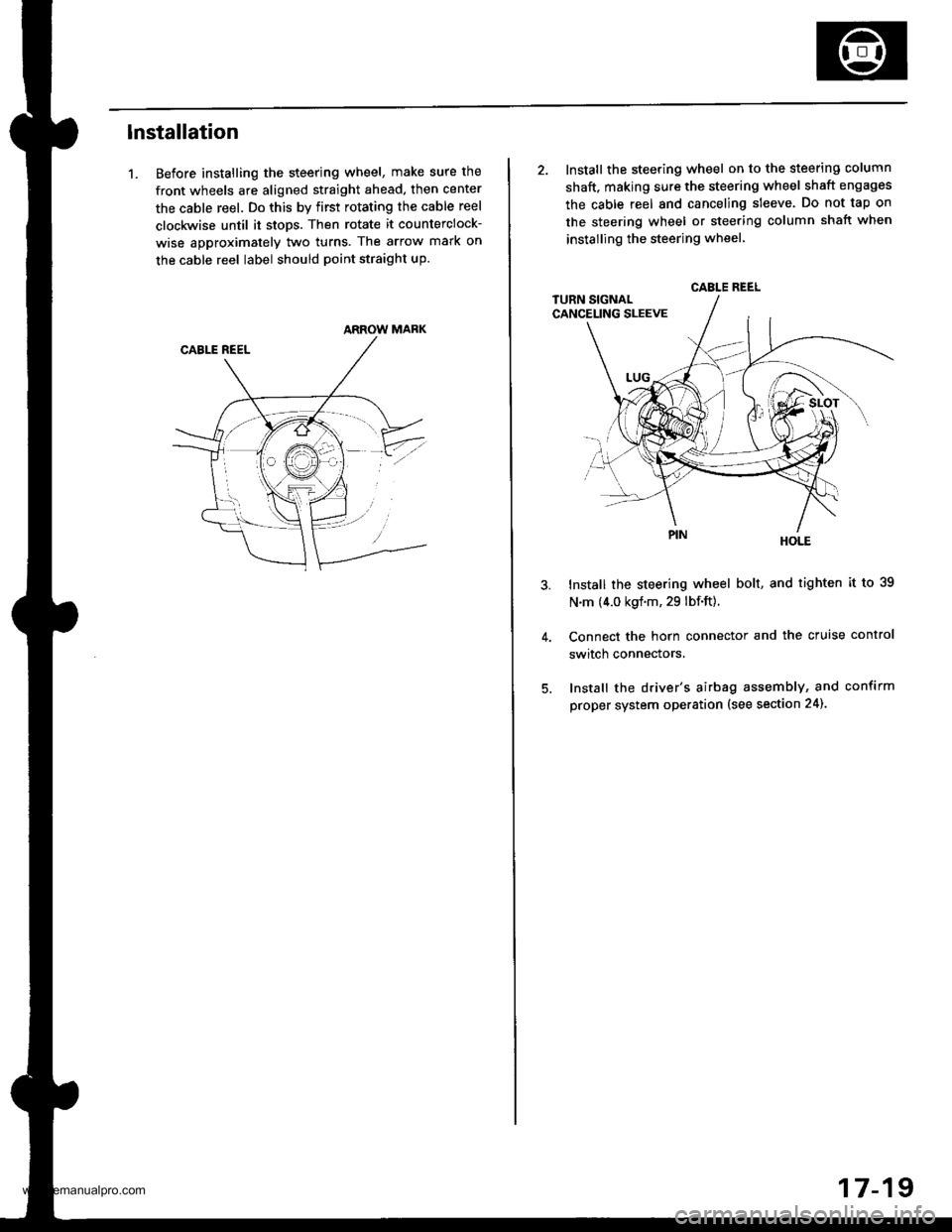

1. Before installing the steering wheel, make sure the

front wheels are aligned straight ahead, then center

the cable reel. Do this by first rotating the cable reel

clockwise until it stops. Then rotate it counterclock-

wise approximately two turns. The arrow mark on

the cable reel label should point straight up.

ARROW MARK

2. Install the steering wheel on to the steering column

shaft, making sure the steering wheel shaft engages

the cable reel and canceling sleeve. Do not tap on

the steering wheel or steering column shatt when

instailing the steering wheel

HOLE

Install the steering wheel bolt, and tighten it to 39

N.m (4.0 kgf.m, 29 lbf.ft).

Connect the horn connector and the cruise control

switch connectors,

Install the driver's airbag assembly, and confirm

proper system operation (see section 24).

CABLE REEL

17-19

www.emanualpro.com

Page 866 of 1395

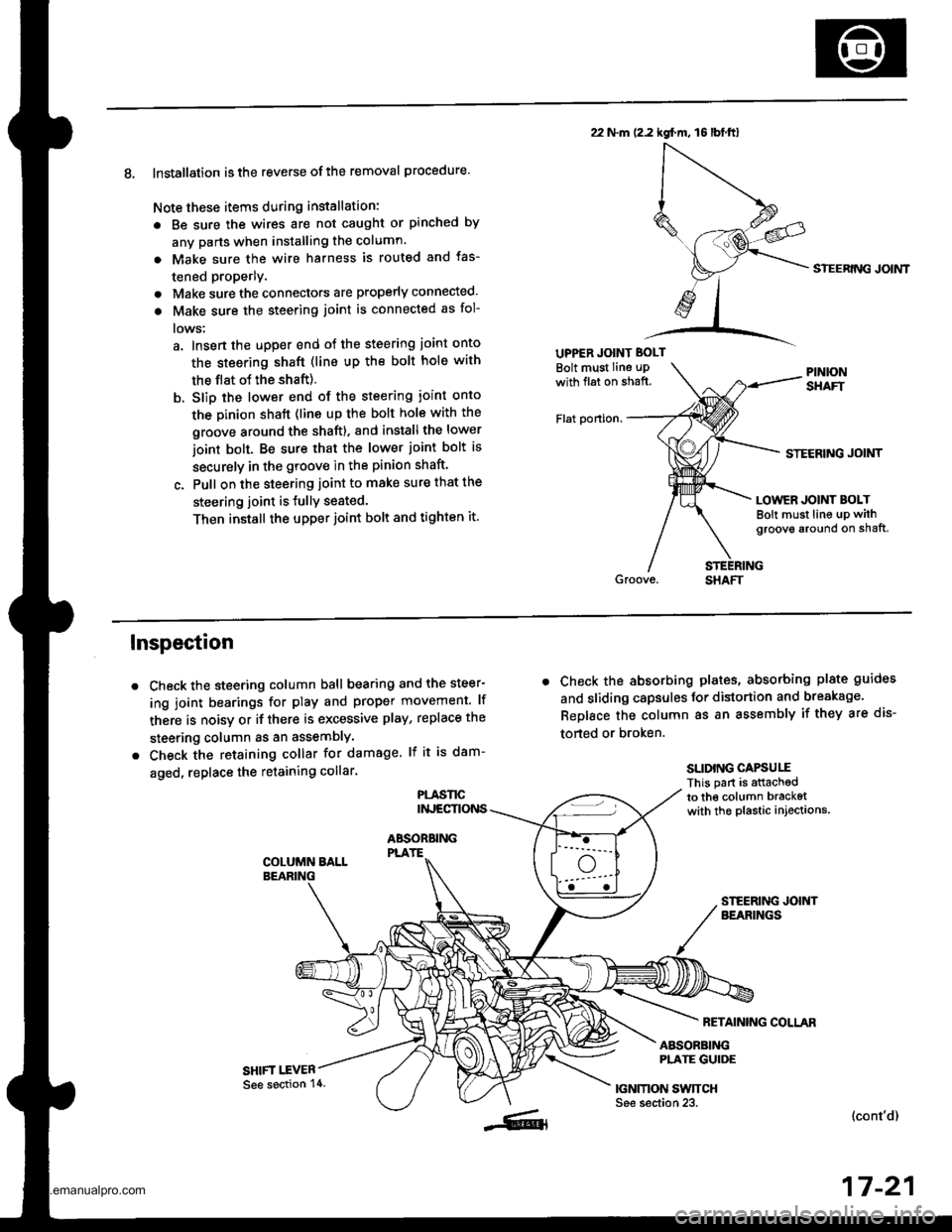

8. Installation is the reverse ofthe removal procedure.

Note these items during installation:

. Be sure the wires are not caught or pinched by

any parts when installing the column.

a Make sure the wire harness is routed and fas-

tened properly.

. Make sure the connectors are properly connected.

. Make sure the steering joint is connected as fol-

lows:

a. lnsert the uDper end of the steering joint onto

the steering shaft (line up the bolt hole with

the flat ot the shaft).

b. Slip the lower end of the steering ioint onto

the Dinion shaft (lins up the bolt hole with the

groove around the shaft). and installthe lower

ioint bolt. Be sure that the lower joint bolt is

securely in the groove in the pinion shaft'

c. Pull on the steering joint to make sure that the

steering joint is JullY seated.

Then install the upper joint bolt and tighten it.

22 N.m (2.2 kgf.m, 16lbt.ftl

UPPER JOINT BOLT

Bolt must Iine uPwith fl6t on shaft.

Flat ponion.

SIEERING JOIMT

STECRING JOINT

LOWER JOINT BOLTBolt must line up withgroove around on shaft,

Inspection

Check the steering column ball bearing and the steer-

ing joint bearings for play and proper movement. lf

there is noisy or if there is excessive play, replace the

steering column as an assemblY

Check the retaining collar for damage. lf it is dam-

aged, replace the retaining collar.

PLASl'tCINJECTIONS

ABSOBBINGPLATE

SHIFT I.EVER

. Check the absorbing plates, absorbing plate guides

and sliding capsules Jor distortion and breakage.

ReDlace the column as an assembly if they are dis-

torted or broken.

SLIDING CAPSUIIThis part is attachedto the column bracketwith the plastic injections.

FETAINING COLLAR

ABSORBINGPLATE GUIDE

|GNMON SWTTCHSee section 23.(cont'd)

17-21

See section 14.

www.emanualpro.com

Page 908 of 1395

Front Suspension

Knuckle/Hub Replacement (cont'dl

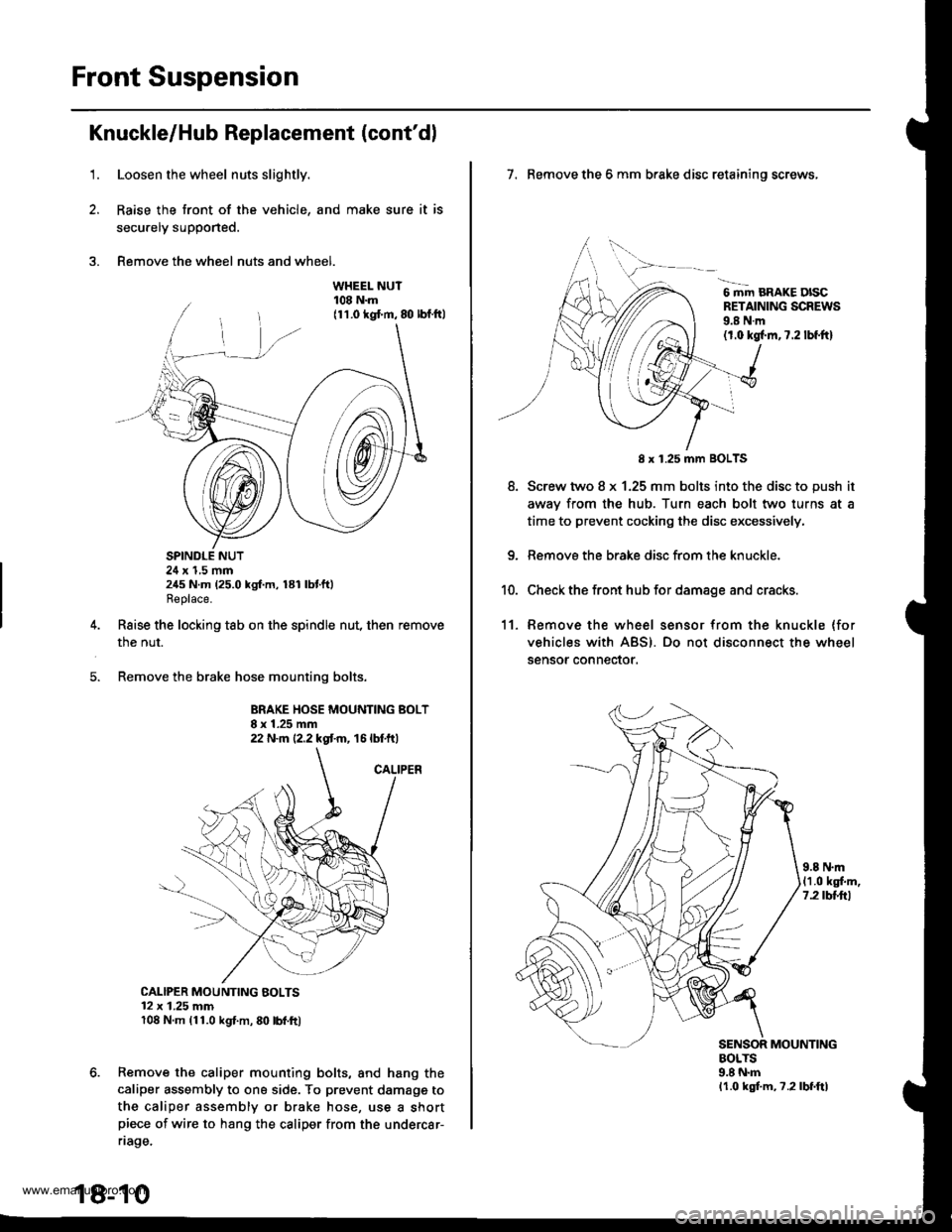

1.Loosen the wheel nuts slightly.

Raise the front of the vehicle, and make sure it is

secu.ely supported.

Remove the wheel nuts and wheel.

SPINDLE NUT24 x 1,5 mm245 N.m (25.0 kgf.m, 181 lbtft)Replace.

Raise the locking tab on the spindle nut, then remove

the nut.

Remove the brake hose mounting bolts.

BRAKE HOSE MOUNTING BOLT8 x 1.25 mm22 N.m {2.2 kgt m, 16 lbtft)

CALIPER MOUNTING BOLTS12 x 1.25 mm108 N.m (11.0 kgl.m, 80 lbl.ft)

Remove the caliper mounting bolts, and hang the

caliper assembly to ona side. To prevent damagg to

the caliper assembly or brake hose, use a shortpiece of wire to hang the caliper from the undercar-

riage.

18-10

7. Remove the 6 mm brake disc retaining screws,

6 mm BRAKE DISCRETAINING SCREWS9.8 N.m(1.0 kgl.m,7.2 lbf.ftl

8.

8 x 1.25 mm BOLTS

Screw two 8 x 1.25 mm bolts into the disc to push it

awav from the hub. Turn each bolt two turns at a

time to prevent cocking the disc excessively,

Remove the brake disc from the knuckle.

Check the front hub for damage and cracks.

11. Remove the wheel sensor from the knuckle (for

vehicles with ABS). Do not disconnect the wheel

sensor connector.

9.8 N.m(1.0 kgf.m,7.2 tbttrl

MOUNTINGBOLTS9.8 N.mlr.0 kgf.m, ?.2lbf.ftl

www.emanualpro.com

Page 919 of 1395

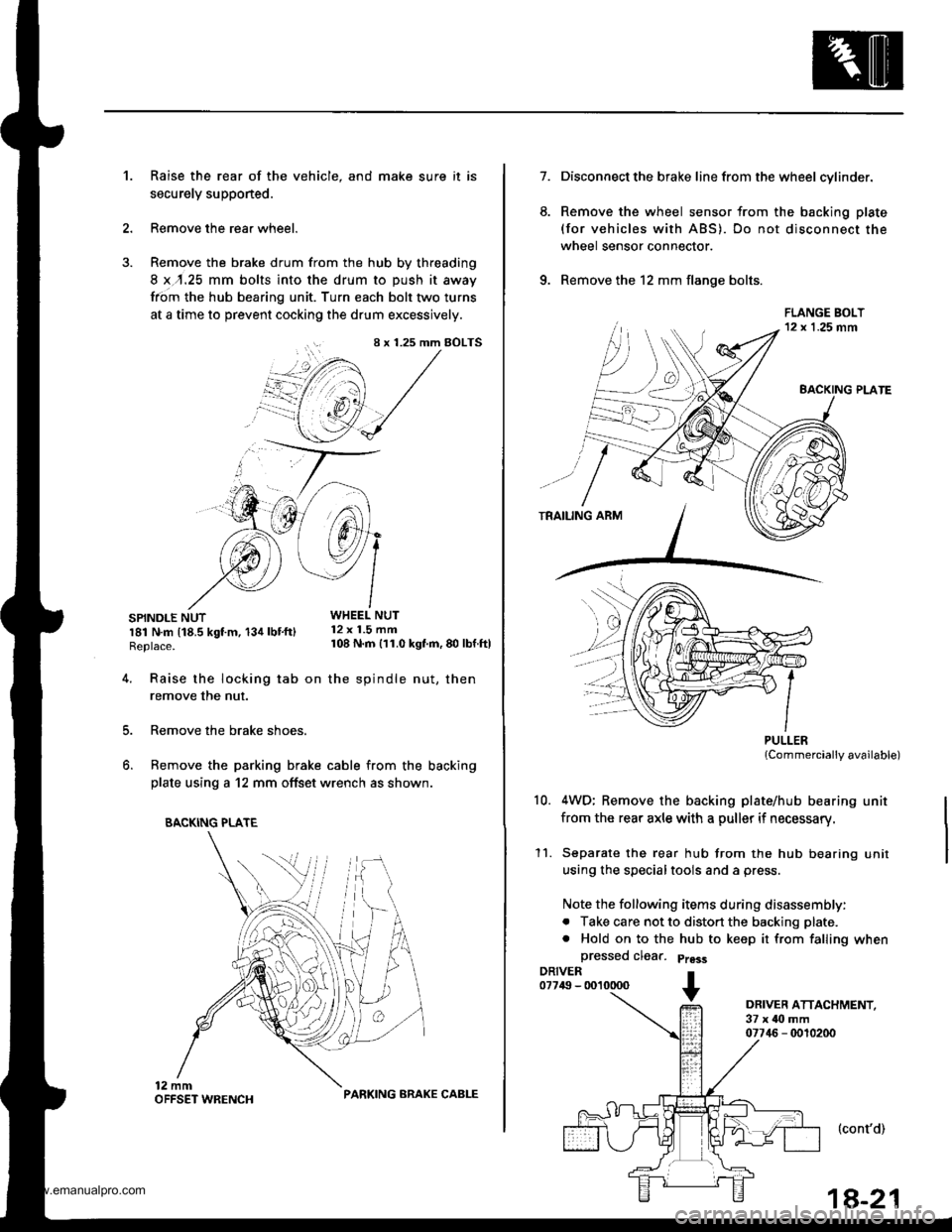

Raise the rear of the vehicle, and make sure it is

securely supponed.

Remove the rear wheel.

Remove the brake drum from the hub by threading

8 x,r.25 mm bolts into the drum to push it away

from the hub bearing unit. Turn each bolt two turns

at a time to prevent cocking the drum excessively.

SPINDLE NUTWHEEL NUT

r81 N.m t18.5 kgt m, 134 lbt'ftl 12 x 1.5 mm

Replace. 108 N m 111.0 kgf'm, 80 lbf ftl

't.

4.

8 x 1.25 mm BOLTS

i+/3 /',1

"@,1 /

.'--7 J-->-

5.

6.

Raise the locking tab on the spindle nut, then

remove the nut.

Remove the brake shoes.

Remove the parking brake cable from the backing

plate using a 12 mm offset wrench as shown.

BACKING PLATE

PARKING ARAKE CABLE

1a-21

7.

6.

Disconnect the brake line from the wheel cylinder.

Remove the wheel sensor from the backing plate

(for vehicles with ABS). Do not disconnect the

wheel sensor connector.

Remove the 12 mm flange bolts.

PULLERlCommercially available)

4WD; Remove the backing plate/hub bearing unit

from the rear axle with a puller if necessary.

Separate the rear hub from the hub bearing unit

using the specialtools and a press.

Note the following items during disassembly:

. Take care not to distort the backing plate.

. Hold on to the hub to keep it from falling when

a

10.

11.

DRIVER ATTACHMENT,37 x ilo mm07746 - 0010200

(cont'd)

www.emanualpro.com

Page 929 of 1395

Brake Pedal

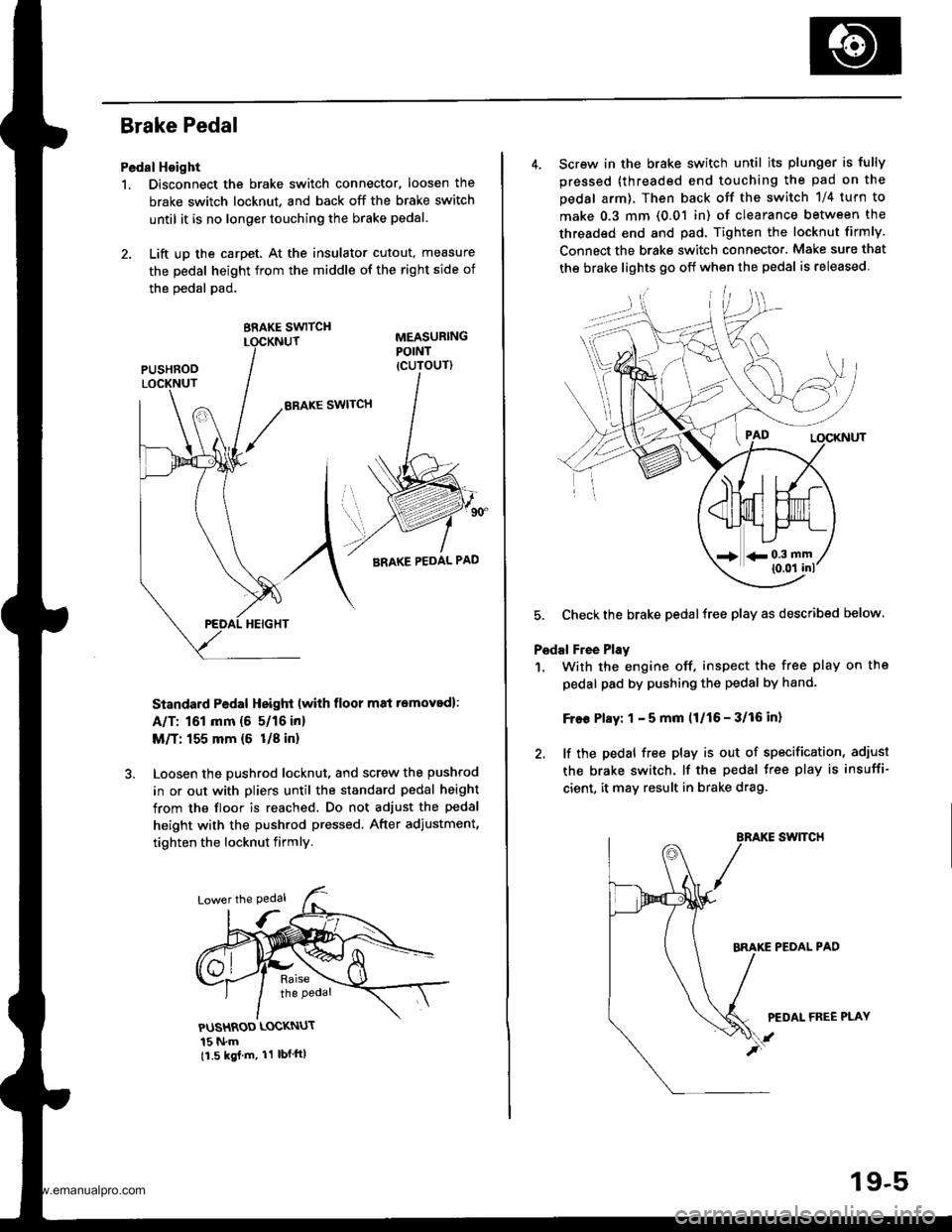

Pedal Hoight

1. Disconnect the brake switch connector, loosen the

brake switch locknut, and back off the brake switch

until it is no longer touching the brake pedal.

2. Lift up the carpet, At the insulator cutout, measure

the pedal height from the middle of the right side of

the oedal pad.

BRAKE SWITCH

ERAKE SWITCH

Standard Pedal Height (with floor m8i removed):

A/T: 161 mm (5 5/16 in)

M/T: 155 mm {6 U8 in}

Loosen the pushrod locknut, and screw the pushrod

in or out with pliers until the standard pedal height

from the floor is reached. Do not adjust the pedal

height with the pushrod pressed. After adiustment,

tighten the locknut firmly.

PUSHROD LOCKNUT

15 N.m11.5 kgj m, 11 lbf ftl

4. Screw in the brake switch until its plunger is fully

pressed (threaded end touching the pad on the

pedal arm), Then back otf the switch 1/4 turn to

make 0.3 mm (0.01 in) of clearance between the

threaded end and pad. Tighten the locknut firmly.

Connect the brake switch connecto.. Make sure that

the brake lights 90 off when the pedal is released

5. Checkthe brake pedalfree play as described below

Pedal Free Play

1. With the engine off. inspect the free play on the

pedal pad by pushing the pedal by hand-

Free Play: 1 - 5 mm (1/16 - 3/16 in)

2. lf the pedal free play is out of specification, adiust

the brake switch. lf the pedal free play is insuffi-

cient, it may result in brake drag.

swtTcH

PEOAL PAD

PEDAL FREE PLAY

19-5

www.emanualpro.com

Page 932 of 1395

![HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

Inspection and Adjustment

Brake System Indicator

Circuit Diagram lNuLR.HorJDGNrT 0llSt!ITCHUNDEB.DASHFUSE]NEtAY BOIrllA Nl] 42 4!A

PAF�K NC BRA(E S\IICH

GBNiBEO

Io\lt j I ERAKE tuU 0 rEVEr 9!1 I(N

| HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

Inspection and Adjustment

Brake System Indicator

Circuit Diagram lNuLR.HorJDGNrT 0llSt!ITCHUNDEB.DASHFUSE]NEtAY BOIrllA Nl] 42 4!A

PAF�K NC BRA(E S\IICH

GBNiBEO

Io\lt j I ERAKE tuU 0 rEVEr 9!1 I(N

|](/img/13/5778/w960_5778-931.png)

Inspection and Adjustment

Brake System Indicator

Circuit Diagram lNuLR.HorJDGNrT 0llSt!ITCHUNDEB.DASHFUSE]NEtAY BOIrllA Nl] 42 4!A

PAF�K NC BRA(E S\I'ICH

GBNiBEO

Io\lt j I ERAKE tuU 0 rEVEr 9!1 I(N

| oPt^r'f,'1 .r

BIKI-o-:G401

Parking Brake Switch Test

1. Remove the parking brake cover,

2. Disconnect the connector from the parking brakeswitch.

3. Check for continuity between the terminal and bodyground in each position according to the table.

Terminal

Lever Position \

Positive

TerminalBody Ground

Lever Up--o

Lever Down

NOTE (Canada): lf the parking brake switch is OK, butthe brake system indicator does not function, perform

the input test for the daytime running lights control unit(see section 23).

Brake Fluid Level Switch Test

1. Remove the reservoir cap. Check that the float

moves up and down freely; if it doesn't, replace the

reservoir cap assembly.

2. Check for continuity between the terminals in each

switch position according to the table.

- r9''r

Position12

FLOAT UP

FLOAT DOWNo

RESERVOIR CAP

GROUND

Switch contacts open atproper fluid level.

19-8

www.emanualpro.com