Ckp HONDA CR-V 1999 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1126 of 1395

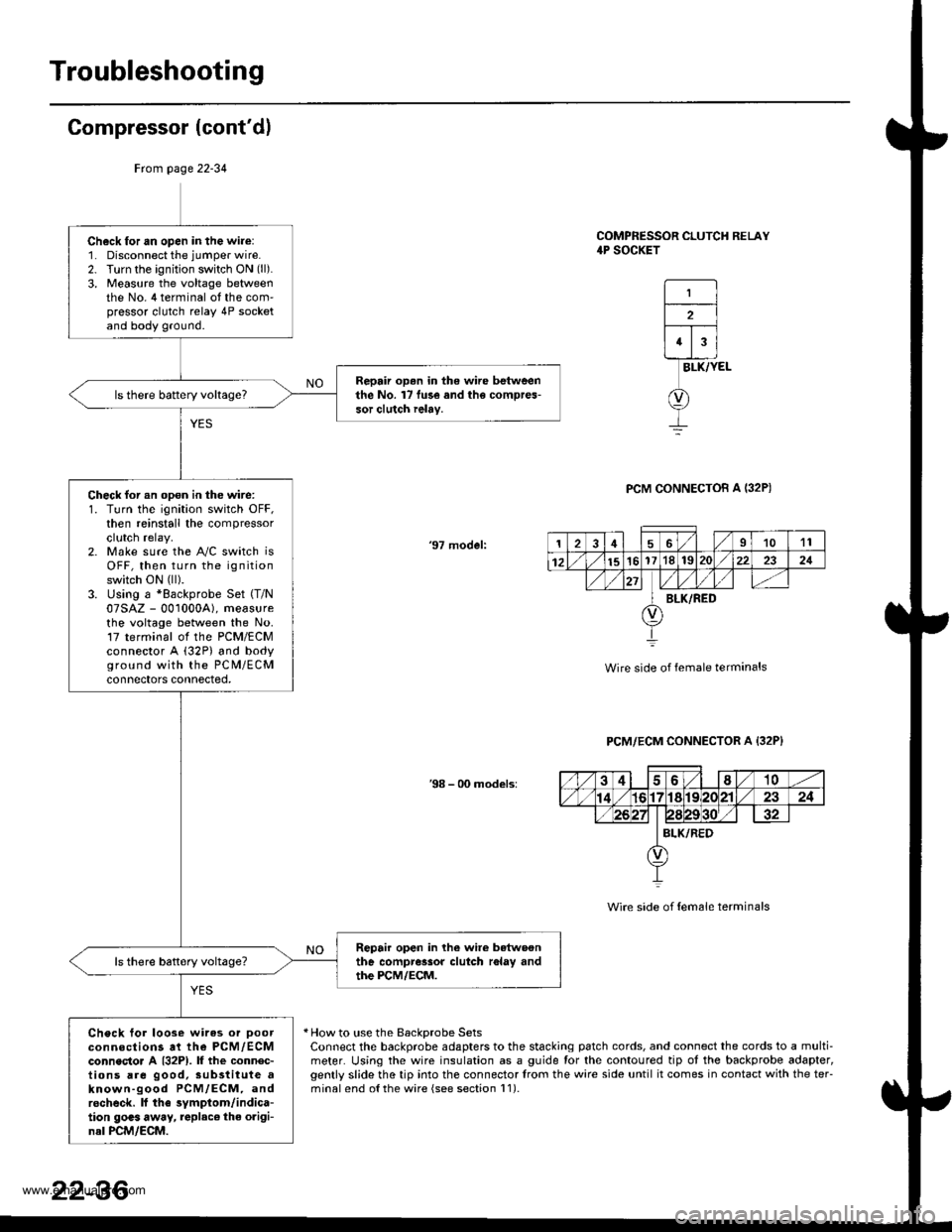

Troubleshooting

Compressor (cont'dl

COMPRESSOR CLUTCH RELAY4P SOCKET

1

2

43

BLK/YEL

PCM CONNECTOB A I32P)

'97 model:

Wire side of female terminals

PCM/ECM CONNECTOR A {32P}

38 - 00 models:

Wire side of {em6le terminals

* How to use the BackDrobe SetsConnect the backprobe adapters to the stacking patch cords, and connect the cords to a multi-meter. Using the wire insulation as a guide for the contoured tip ot the backprobe adapter,gently slide the tip into the connector trom the wire side until it comes in contact with the teFminalend o{the wire {see section l1).

Frcm page 22-34

Ch6ck for an open in the wire:1. Disconnect the jumper wire.2. Turn the ignition switch ON (ll).

3, Measure the voltage betweenthe No. 4 terminal ot the com'pressor clutch relay 4P socketand body ground.

Repair op.n in the wire betweenthe No. l7 fu3e and the compres-sor clutch ielay.

Check for an opon in the wire:1. Turn the ignition switch OFF,then reinstall the compressorclutch relay.2. Make sure the A"/C switch isOFF, then turn the ignitionswitch ON (ll).

3. Using a *Backprobe Set (T/N

07SAZ - 001000A), measurethe voltage between the No.17 terminal ol the PCM/ECMconnector A (32P) and bodyground with the PC M/ECMconnectors connected,

Repair open in lhe wire betwoonthe compressor clutch r6lay andthe PCM/ECM.

Check tor loose wires or Doorconnections at the PCM,/ECMconnecto. A {32P1. lf the connec-tions are good, sub3titute aknown-good PCM/ECM, androcheck. lf the symptom/indica-tion goas away, replac€ the origi-nal PCM/ECM.

126I1011

12151617'181S222321

BLK/RED

22-36

www.emanualpro.com

Page 1127 of 1395

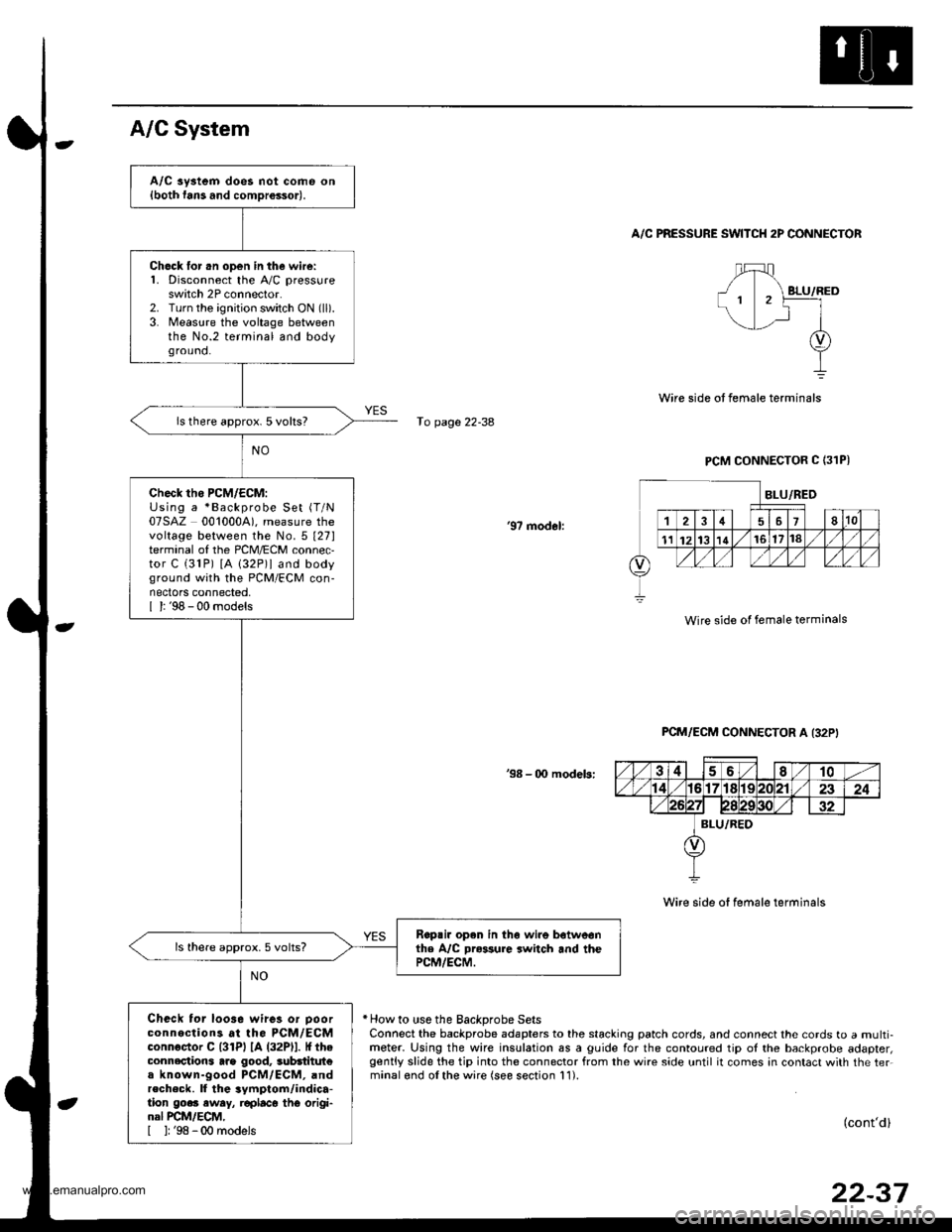

A/C aystem does not come on{both fans and comDrossor).

Ch6ck lor .n open in the wire:1. Disconnect the A,/C pressureswitch 2P connector.2. Turn the ignition switch ON (ll).

3. Measure the voltage betweenthe No.2 terminal and bodyground.

ls there approx. 5 volts?

check tho PcM/EcM:Using a *Backprobe Set (T/N

07SAZ 0010004). measure thevoltage between the No.5 t27lterminal of the PCM/ECM connec,tor C (31P) [A 132P)l and bodyground with the PCM/ECM con-nectors connected,I l: '98 - 00 models

Rop.ir open in th6 wire botweonthe A/C Dr*sure switch and thePCM/ECM.

ls there approx.5 volts?

Check tor loo3e wires or Doorconnections at the PCM/ECMconnoctor C l3lPl lA (32Pll. It theconnections arg good, 3ubdtitut€a known-good PCM/ECM, andrecheck. ll the 3ymptom/indica-tion go.. eway, r€placo thG origi-nal PCM/ECM,[ ]: '98 -00 models

A/C System

A/C PRESSURE SWITCH 2P CONNECTOR

fo page 22-38

PCM CONNECTOR C (31PI

'97 modol:

Wire side of female terminals

PCM/ECM CONNECTOR A I32P'

38 - 00 modeb:

Wire side of female terminals

* How to use the Backprobe SetsConnect the backprobe adapters to the stacking patch cords, and connect the cords to a multi-meter. Using the wire insulation as a guide for the contoured tip ol the backprobe adapter,gently slide the tip into the connector from the wire side until it comes in contact with the ter.minalond olthe wire (see section 11).

(cont'd)

22-37

www.emanualpro.com

Page 1206 of 1395

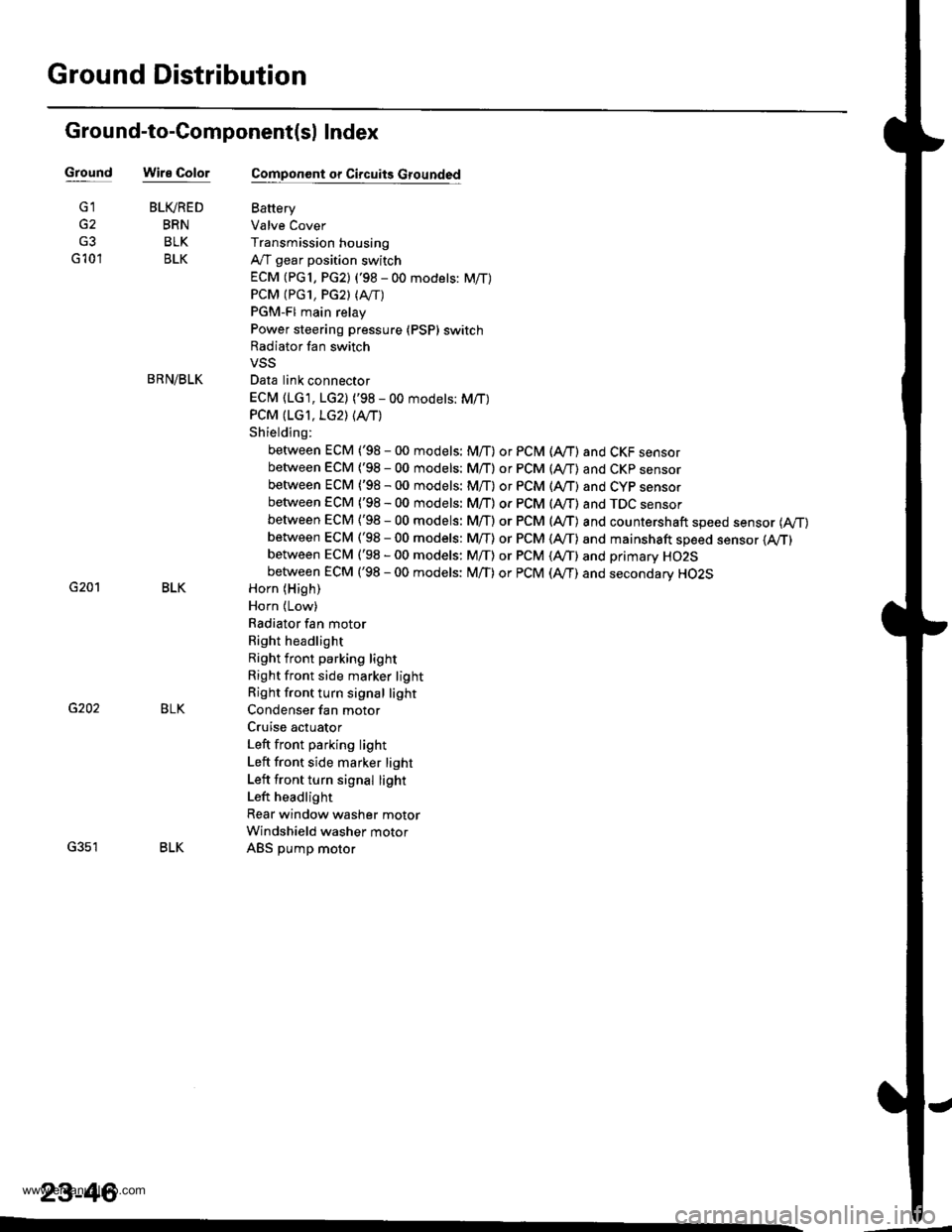

Ground Distribution

Ground-to-Component(sl Index

GroundWire Color

G2

G3

G 10'l

G201

G202

G351

BLIVRED

BRN

BLK

BLK

BRN/BLK

BLK

BLK

BLK

23-46

Component or Circuits Grounded

Battery

Valve Cover

Transmission housing

A,/T gear position switch

ECM (PG1, PG2) ('98 - 00 models: M/T)

PCM (PG1, PG2l (Avrr)

PGM-FI main relay

Power steering pressure (PSP) switch

Radiator fan switch

VSS

Data link connector

ECM (1G1, LG2) ('98 - 00 models: M/T)

PCM (LGI, LG2) (IVT)

Shielding:

between ECM ('98 - 00 models: M/T) or PCM (Ay'T) and CKF sensorbetween ECM {'98 - 00 modets: M/T} or pCM (Ay'T) and CKp sensorbetween ECM ('98 - 00 models: M/T) or PCM (rVT) and CYP sensorbetween ECM ('98 - 00 models: M/T) or PCM (Ay'T) and TDC sensorbetween ECM {'98 - 00 models: M/T) or PCM (ly'T) and countershaft speed sensor (Ay'T)

between ECM ('98 - 00 models: M/T) or PCM {A,,/T) and mainshaft sp€ed sensor {!VT)between ECM ('98 - 00 models: M/T) or PCM (A,/T) and primary HO2Sbetween ECM ('98 - 00 models: M/T) or PCM (Ay'T) and secondary HO2SHorn (High)

Horn {Low}

Radiator fan motor

Right headlight

Right front parking light

Right front side marker light

Right front turn signal light

Condenser fan motor

Cruise actuator

Left front parking light

Left front side marker light

Left front turn signal light

Left headlight

Rear window washer motor

Windshield washer motor

ABS pump motor

www.emanualpro.com

Page 1310 of 1395

)

Supplemental Restraint System (SRS)

Special Tools .."....."" 24-14

Component/Wring Location

lndex - '97 model ..........'.." '.....""" 24-15

Component/Wiring Location

lndex - '98 - 00 models ..............." 24-16

Description .'.........."'.24'17

Circuit Diagram .........24'14

Precautions/Procedures

General Precautions ......".."'........... 24-19

Airbag/Seat Belt Tensioner

Handling and Stolage ....''........... 24-19

SRS Unit Precautions ...............'...... 24-20

lnspeciion After Deployment .......'.24'20

)

with Built-in Short Contact '...'....24-21

Spring-loaded Lock Connectors .."' 24-22

BackProbing SPring-loaded Lock

Conneetors ,.......24-22

Disconnecting the Airbag Connectors and

the Seat Beh Tensioner

Connectors ....'....24-23

Steering-lelated Precautions .......... 24-25

Troubleshooting

Self -diagnostic Procedures ............. 24-26

Reading the DTC .................. .....".."' 24'26

Erasing the DTC Memory ................24-28

Troubleshooting lntermittent

Faifures "'...........24'24

Diagnostic Trouble Gode {DTC}

Chart -'97 model ....""....... "......24-29

Diagnostic Trouble Gode (DTCI

Chart -'98 - 00 models ............. 24-31

SRS Indicator Light Wire

Connections ','," 24'33

Ff owcharts ....-........24'34

Driver's Airbag

Repf acement ..'......21'87

Front Passenger's Airbag

Repfacement .....'.',24'AS

Gable Reel

Replacement .......'.24-91

SRS Unit

Replacement .........24-95

Airbag/Seat Belt Tensioner

Disposaf .................24'97

)-e

www.emanualpro.com

Page 1311 of 1395

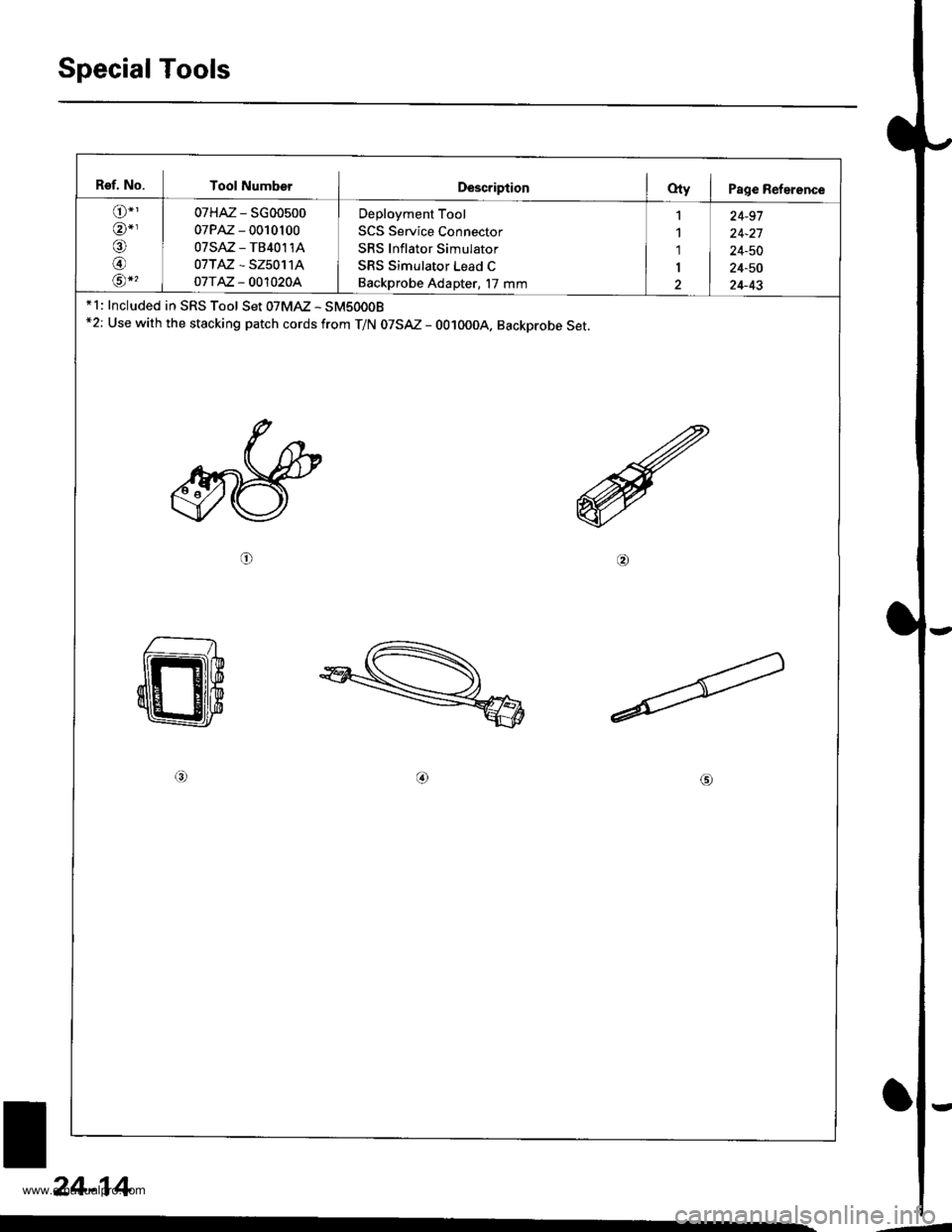

Special Tools

Ref. No. Tool NumberDescriptionOty I Page Reference

o"'

@-,/a\

@rA*,

07HAz - SG00500

07PM - 0010100

07sAz - TB40114

07TAZ - SZ50114

o7T AZ - OO1O20A

Deployment Tool

SCS Service Connector

SRS Inflator Simulator

SRS Simulator Lead C

Backprobe Adapter, l7 mm

1

1'1

I

2

24-91

24-21

24-50

24-50

24-43* 1: Included in SRS Tool Set 07MAZ - SM5000B*2: Use with the stacking patch cords from T/N 07SAZ - 0010004, Backprobe Set.

o@

/no

24-14

.-

www.emanualpro.com

Page 1319 of 1395

Precautions/Procedures

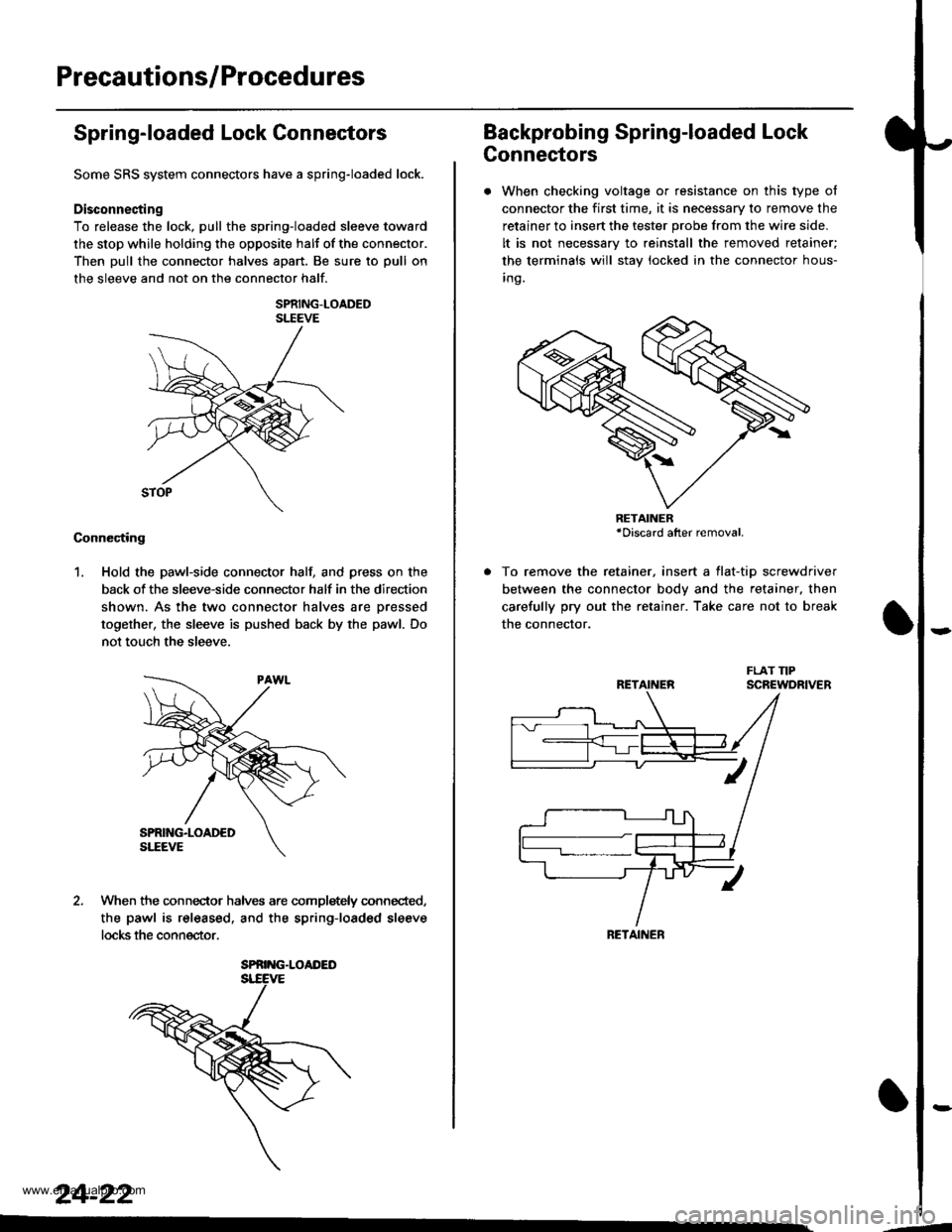

Spring-loaded Lock Connectors

Some SRS system connectors have a spring-loaded lock.

Disconnecting

To release the lock, pull the spring-loaded sleeve toward

the stop while holding the opposite halt of the connector.

Then pull the connector halves apart. Be sure to pull on

the sleeve and not on the connector half.

SPRING-LOADEDSLEEVE

Connecting

1. Hold the pawl-side connector hall and press on the

back of the sleeve-side connector half in the direction

shown. As the two connector halves are Dressed

together, the sleeve is pushed back by the pawl. Do

not touch the sleeve.

When the connec-tor halves are completely connected,

the pawl is released. and the spring-loaded sleeve

locks the connector.

SPRING.LOAI'ED

24-22

Backprobing Spring-loaded Lock

Connectors

. When checking voltage or resistance on this type of

connector the first time, it is necessary to remove the

retainer to insert the tester probe from the wire side.

It is not necessary to reinstall the removed retainer;

the terminals will stay locked in the connector hous-

inq.

To remove the retainer, insert a tlat-tip screwdriver

between the connector body and the retainer. then

carefully pry out the retainer. Take care not to break

the connector.

RETAINER*Discard after removal.

RETAINEN

RETAINER

---

www.emanualpro.com

Page 1323 of 1395

Troubleshooting

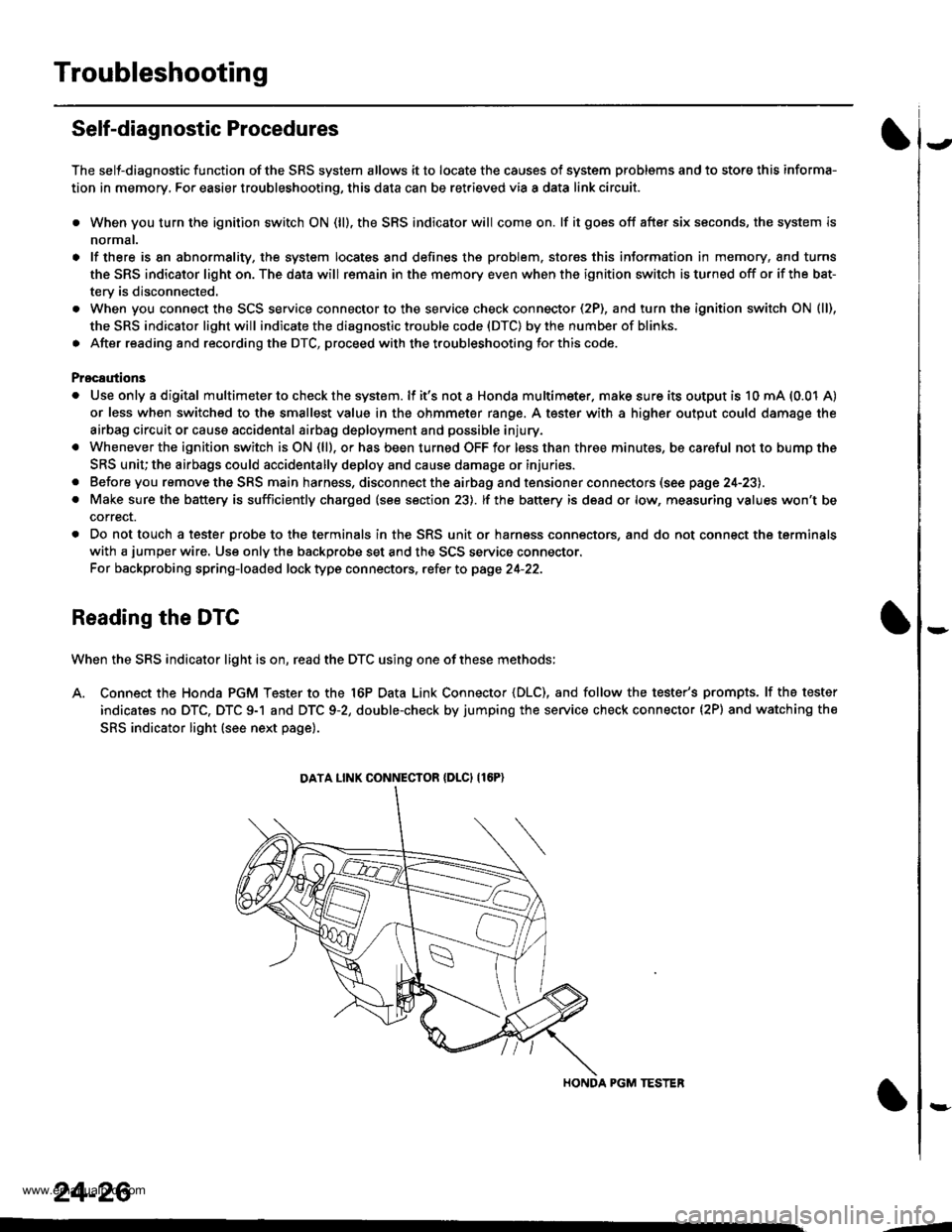

Self-diagnostic Procedures

The self-diagnostic function of the SRS system allows it to locate the causes of system problems and to store this informa-

tion in memory, For easier troubleshooting, this data can be retrieved via a data link circuit.

. When you turn the ignition switch ON (ll). the SRS indicator will come on. lf it goes off after six seconds, the system is

normal.

. lf there is 8n abnormality, the system locates and defines the problem. stores this information in memory, and turns

the SRS indicator light on. The data will remain in the memory even when the ignition switch is turned off or if the bat-

terv is disconnected.

. When you connect the SCS service connector to the service check connector (2P), and turn the ignition switch ON (ll),

the SRS indicator light will indicate the diagnostic trouble code (DTC) by the number of blinks.

. After reading and recording the DTC, proceed with the troubleshooting forthis code.

Precsutions

. Use only a digital multimeter to check the system. lf it's not a Honda multimeter. make sure its output is 10 mA (0.01 A)

or less when switched to the smallest value in the ohmmeter range. A tester with a higher output could damage the

airbag circuit or cause accidental airbag deployment and possible injury.

. Whenever the ignition switch isON (ll). or has been turned OFF for less than three minutes, be careful nottobumpthe

SRS unit; the airbags could accidentally deploy and cause damage or injuries.

. Before you remove the SRS main harness, disconnect the airbag and tensioner connectors (see page 24-23).

. Make sure the battery is sufficiently charged (see section 23). lf the battery is dead or low, measuring values won't be

correct.

. Do not touch a tester probe to the terminals in the SRS unit or harness connectors, and do not connect the terminals

with a jumper wire. Use only the backprobe set and the SCS service connector.

For backprobing spring-loaded lock type con nectors, .efet to page 24-22.

Reading the DTC

When the SRS indicator light is on, read the DTC using one of these methods;

A. Connect the Honda PGM Tester to the 16P Data Link Connector {DLC), and follow the tester's prompts. lf the tester

indicates no DTC, DTC 9-1 and DTC 9-2, double-check by jumping the service check connector (2P) and watching the

SRS indicator light (see next page).

HONDA PGM TESTER

DATA LINK CONNECIOR {DLCI {16P)

24-26

,1

www.emanualpro.com

Page 1335 of 1395

Troubleshooting

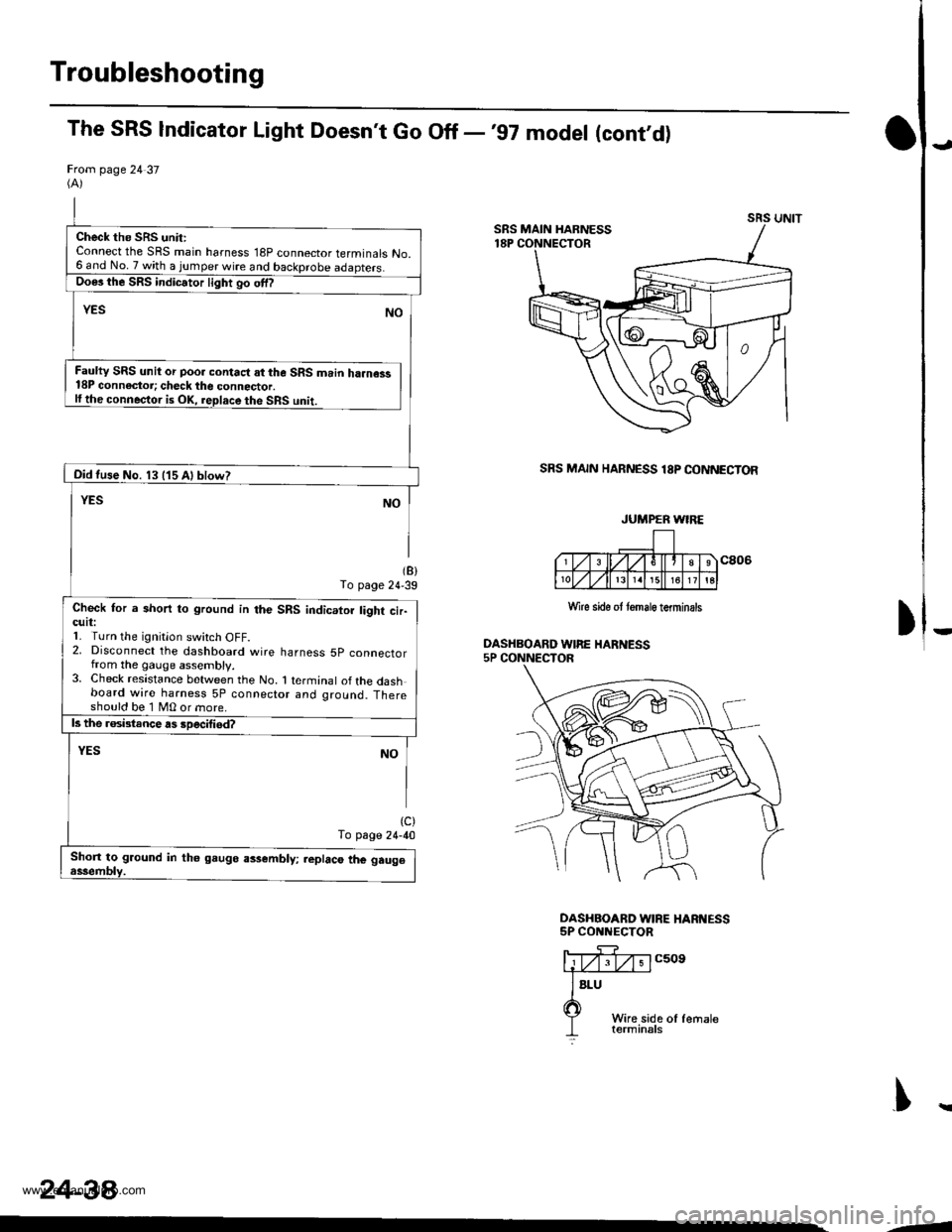

The SRS Indicator Light Doesn't Go Off - '97 model (cont,d)

From page 24 37(A)

SRS MAIN HARNESS 18P CONNECTOR

(B)To page 24'39

DASHBOARD WIRE HARNESS5P CONNECTOR

(c)To page 24-40

DASHBOAND WIRE HARI{ESS5P CONNECTOR

)

J

c509

Wire side ol femaleterminals

T

Check the SRS unit:Connect the SRS main harness 18P connector terminals No.6 and No.7 with a jumper wire and backprobe

Faulty SRS unit or poo. contact at the SRS main ha.ness18P connectoi; check the connector.lfthe conneqtor is OK, replace the SRS unit.

Oid tuse No. 13 (15 Al blow?

Check for a short to ground in the SRS indicator tight cir-cutl:1. Turn the ignitlon switch oFF.2, Disconnect the dashboard wire harness 5p connectorfrom the gauge assembly.3. Check resistance between the No. 1 terminal ofthe dashboard wire harness 5P connector and ground. Thereshould be 1 MO or more.

Shon to ground in th6 gaugo assembly; replaco the gau96

JUMPER WIRE

Wlre sido ot tomale terminsls

243a

--

www.emanualpro.com

Page 1340 of 1395

)

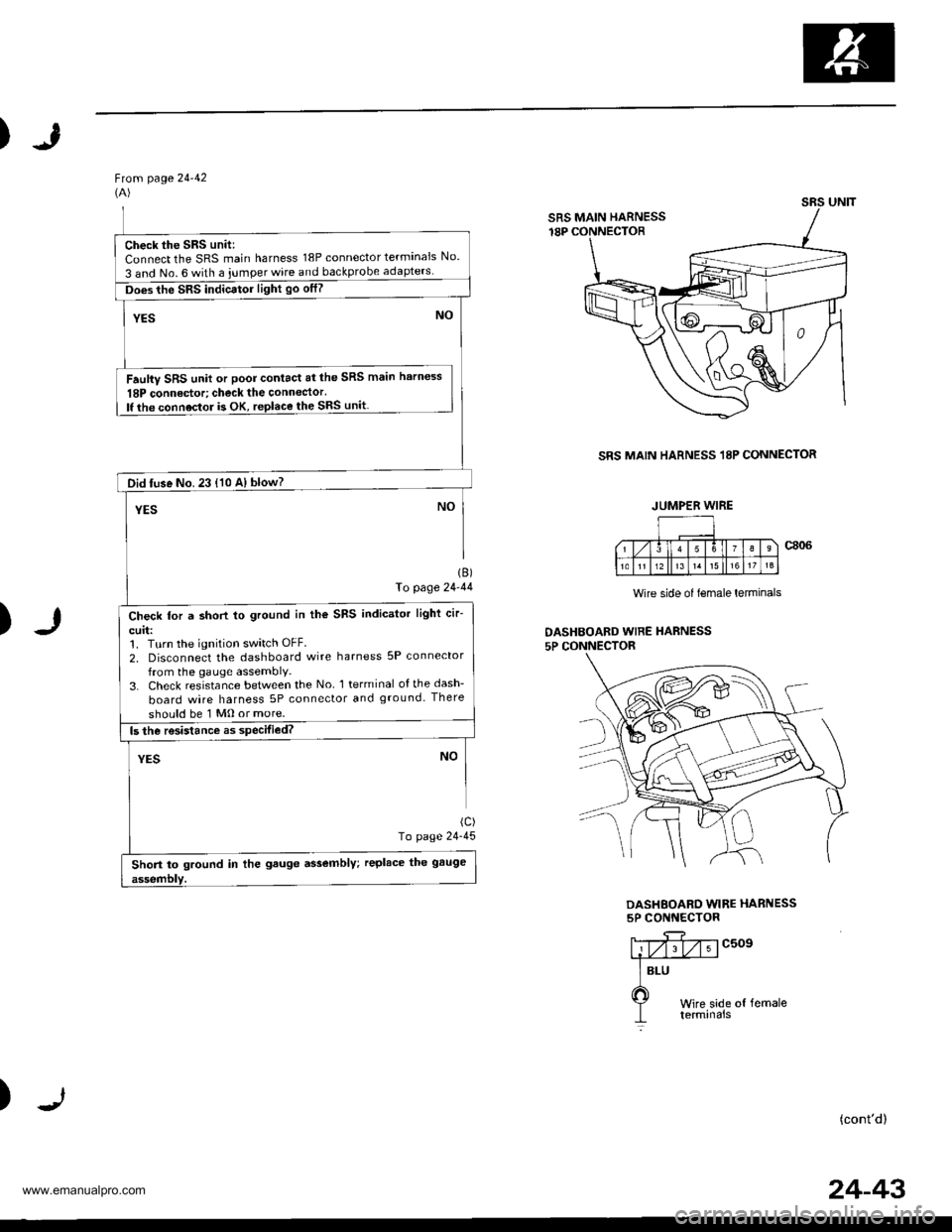

Ftom page 24-42(A)

SRS MAIN HARNESS 18P CONNECTOR

)

1B)fo page 24-44

(c)

To page 24-45

Wire side of lemale lerminals

DASHBOAED WIRE HARNESS5P CONNECTOR

DASHEOARD WIRE HARNESS5P CONNECTOR

c509

)(cont'd)

SRS UNIT

SRS MAIN HARNESS

Check the SRS unit:Connect the SRS main harness 18P connector terminals No.

3 and No. 6 with a iumper wire and backprobe

Does the SRS indicator light go otf?

Faulty SRS unit or poor contact at the SRS main harness

18P connedor; check the connector.lf the connoctor is OK, replace the SRS unit

Did tuse No. 23 {10 A} blow?

Check for a short to ground in the SRS indicator light cir-

curl:1. Turn the ignition switch OFF.

2, Disconnect the dashboard wire harness 5P connector

from the gauge assembly,3. Check resistance between the No l terminal ofthedash-

board wire harness 5P connector and ground. There

should be 1 Mo or more.

Short to ground in the gauge assembly; replace the gauge

JUMPER WIRE

24-43

www.emanualpro.com