Front shaft HONDA CR-V 1999 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 823 of 1395

![HONDA CR-V 1999 RD1-RD3 / 1.G Owners Manual

Front Driveshafts

parts with solvent.

o *4@] :Thoroughly pack the inboard and outboard joints and both joint boots with the joint grease included in the

new driveshaft set.. The98 Canada model andal HONDA CR-V 1999 RD1-RD3 / 1.G Owners Manual

Front Driveshafts

parts with solvent.

o *4@] :Thoroughly pack the inboard and outboard joints and both joint boots with the joint grease included in the

new driveshaft set.. The98 Canada model andal](/img/13/5778/w960_5778-822.png)

Front Driveshafts

parts with solvent.

o *4@] :Thoroughly pack the inboard and outboard joints and both joint boots with the joint grease included in the

new driveshaft set.. The'98 Canada model andall '99 - 00 models use a TPE (Thermoplastic Polyester E lastomer) outboard joint boot.

Use the ear clamp type boot band in the outboard boot set.

Grease quantity:

Inboard Joint: All models 120 - 130 g (i1.2 - 4.6 oz)

Left inboard joint splines (Al: 0.5 - 1.0 g (0.018 - 0.035 oz)

Outboard Joint: '97 model and'98 USA model 130 - 140 g (4.6 -,1.9 oz)'98 Canada model and all '99 - 0O models 140 - 150 g 14.9 - 5.3 oz)

Reassembly

Note these items during reassembly

. Clean the disassembled parts with solvent, anddry them thoroughly with compressed air. Do not wash the rubber

INBOARO JOINT

SPIOERINBOARD BOOT

SET RINGReplace.

LEFT INBOAROJOINT

SPLINES: (Al-6rPack cavity with grease.

wtn grease.

BANDS

DYNAMIC DAMPER

STOP RINGReplace.

OUTBOARD BOOT

EAR CLAMPReplace.

ITPE)*I

-611

-/ Pack cavity with grease.

DOUELEReplace.BAND+'BAND*1

__G1Pack cavitywrtn grease.

OUTBOARD BOOT*'(RUBBERI

-GrjPack cavity*l: '98 Canada models, all '99-00models

*2: '97 - 98 models (except'98 Canada model)

16-8

wtrn grease.

www.emanualpro.com

Page 825 of 1395

Front Driveshafts

Reassembly {cont'd)

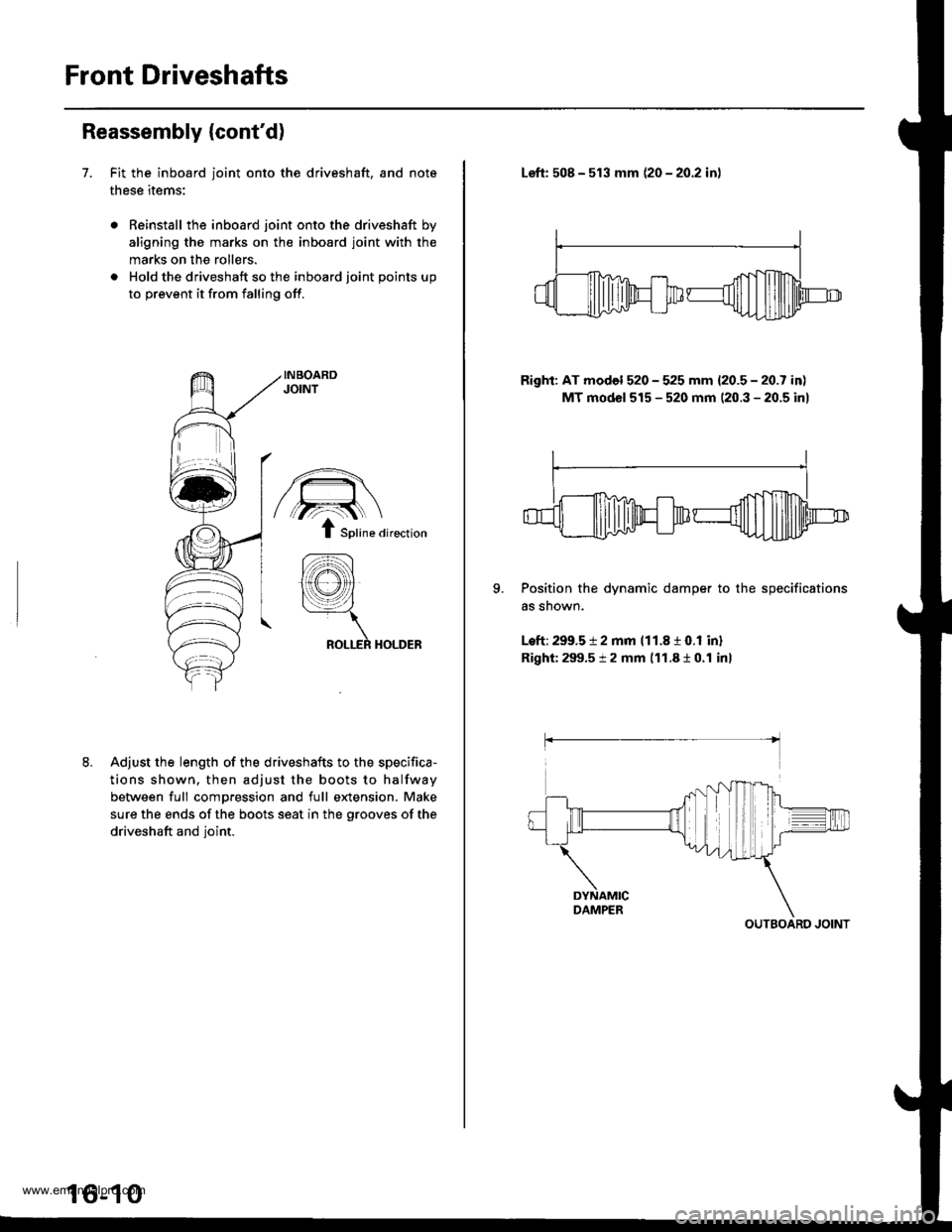

7. Fit the inboard joint onto the driveshaft, and note

these items:

Reinstall the inboard joint onto the driveshaft by

aligning ths marks on the inboard joint with the

marks on the rollers.

Hold the driveshaft so the inboard joint points up

to prevent it from falling off.

Adjust the length of the driveshafts to the specifica-

tions shown. then adjust the boots to halfway

between full compression and full e)dension. Make

sure the ends of the boots seat in the grooves of the

driveshaft and Ioint.

/€\

/,?:..�{ \

t Sptine airection

lffi

tYl:\

ROLLER HOLDER

16-10

Left: 508 - 513 mm 120 - 2O.2 inl

Right: AT model 520 - 525 mm {20.5 - 20.7 in)

MT mod6l 515 - 520 mm (20.3 - 20.5 inl

II

-flm+dm@

9. Position the dynamic damper to the specifications

as snown.

Left: 299.5 t 2 mm 111.8 r O.l inl

Right: 299.5 t 2 mm 111.810.1 inl

OUTBOARO JOINT

www.emanualpro.com

Page 827 of 1395

Front Driveshafts

Reassembly (cont'd)

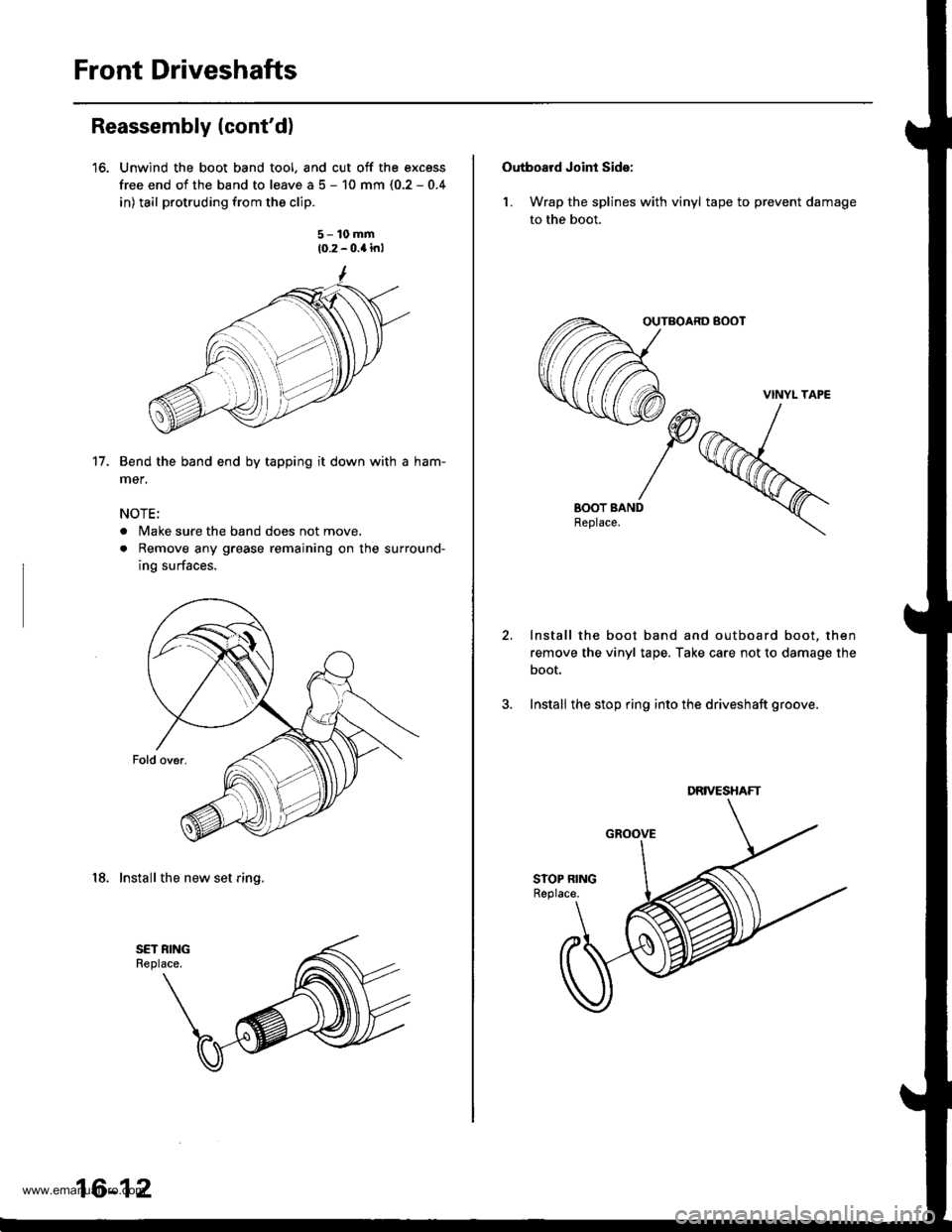

16. Unwind the boot band tool. and cut off the excess

free end of the band to leave a 5 - 10 mm (0.2 - 0.4

in) tail protruding from the clip.

5- 10 mm

10.2 - 0.4 in,

Bend the band end by tapping it down with a ham-

mer,

NOTE;

. Make sure the band does not move,

. Remove any grease remaining on the surround-

ing surfaces.

18, Install the new set ring.

17.

16-12

Outbosrd Joint Sids:

1. Wrap the splines with vinyl tape to prevent damage

to the boot.

OUTBOARD BOOT

2, Install the boot band and outboard boot, then

remove the vinyl tape. Take care not to damage the

boot.

3. Install the stop ring into the driveshaft groove.

VINYL TAPE

DRIVESHAFT

www.emanualpro.com

Page 829 of 1395

Front Driveshafts

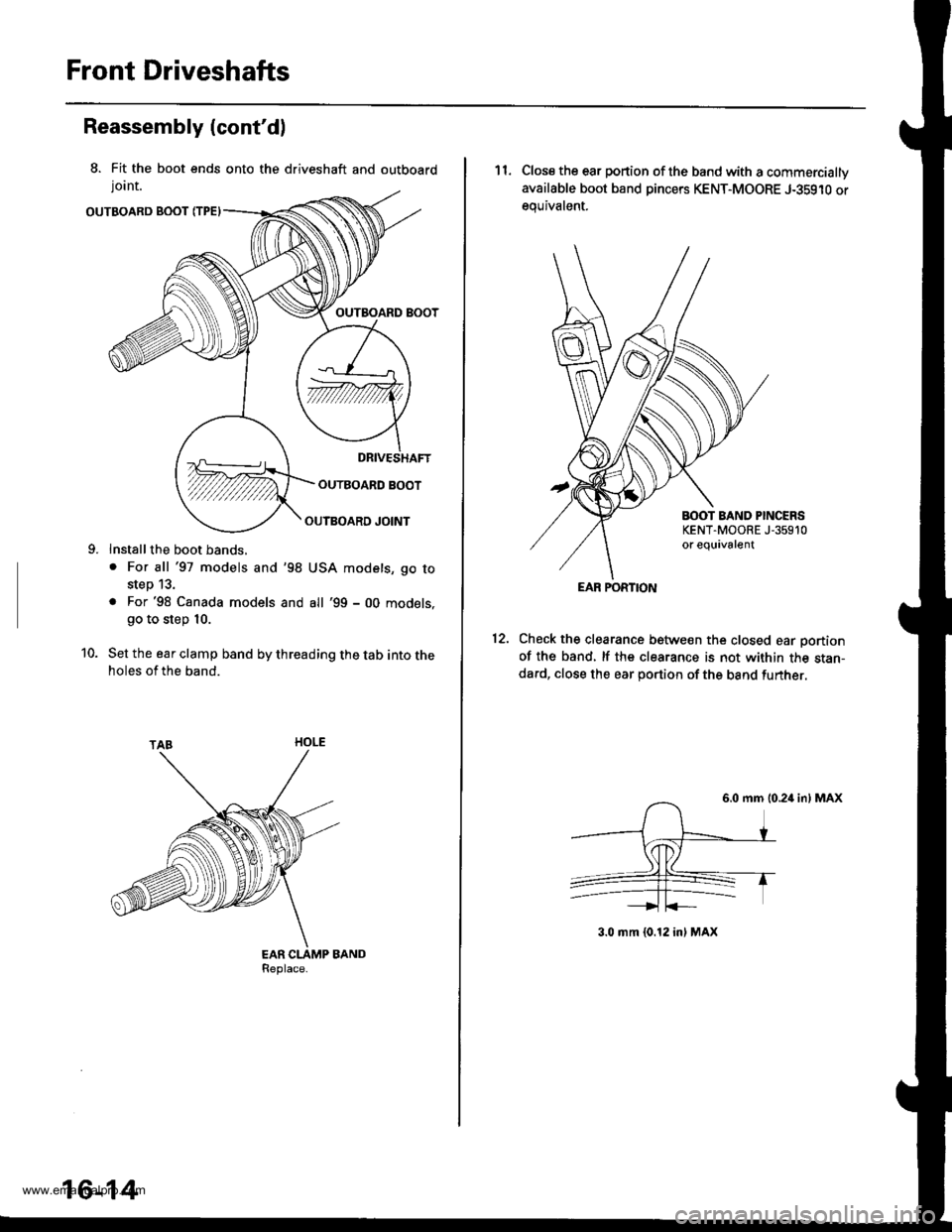

8. Fit the boot ends onto the driveshaft and outboard

lornt.

OUTBOARD BOOT fiPE)

OUTBOARD BOOT

OUTBOARD BOOT

Reassembly (cont'd)

Install the boot bands,

. For all '97 models and'98

step 13.

. For'98 Canada models andgo to step 10.

OUTBOARD JOINT

USA models, go to

all '99 - 00 models,

10. Set the ear clamp band by threading the tab into theholes of the band.

16-14

11. Close the ear portion of the band with a commercially

available boot band pincers KENT-MOORE J-35910 or

equivalent.

BOOT BAND PINCERSKENT.MOORE J-35910or equivalent

12.Check the clearance between the closed ear Dortionof the band, lf the clearance is not within the stan-dard, close the ear portion of the band further.

6.0 mm 10.24 in) MAX

3.0 mm {0.12 in} MAX

EAR PORTION

www.emanualpro.com

Page 831 of 1395

Front Driveshafts

Reassembly (cont'dl

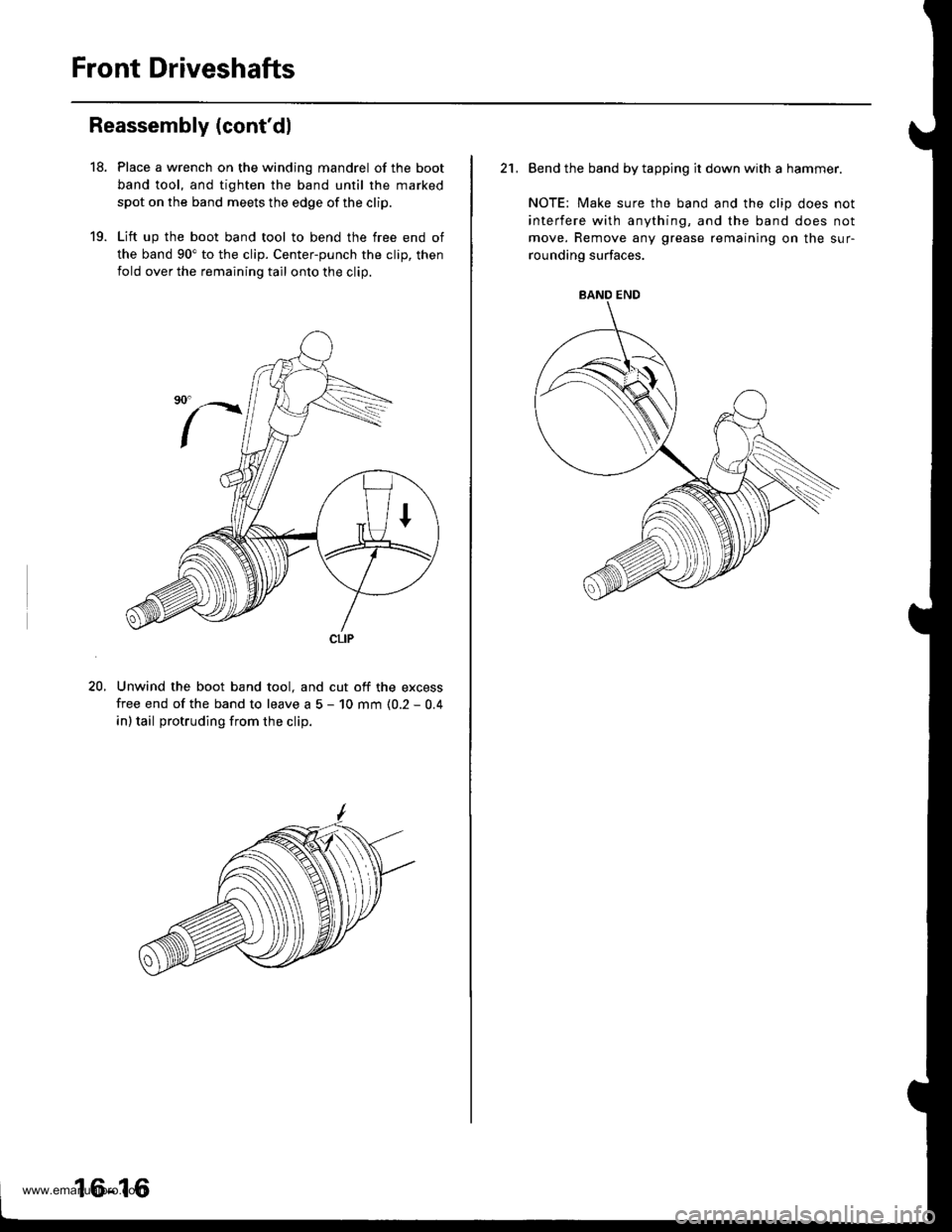

18.

19.

Place a wrench on the winding mandrel of the boot

band tool, and tighten the band until the marked

spot on the band meets the edge of the clip.

Lift up the boot band tool to bend the free end of

the band 90" to the clip. Center-punch the clip, then

fold over the remaining tail onto the clip.

Unwind the boot band tool. and cut off the excess

free end of the band to leave a 5 - 10 mm (0.2 - 0.4

in) tail protruding from the clip.

20.

CLIP

16-16

21, Bend the band by tapping it down with a hammer.

NOTE: Make sure the band and the clip does not

interfere with anything, and the band does not

move, Remove any grease remaining on the sur-

rounding surfaces.

BAND END

www.emanualpro.com

Page 832 of 1395

Front Driveshafts

lnstallation

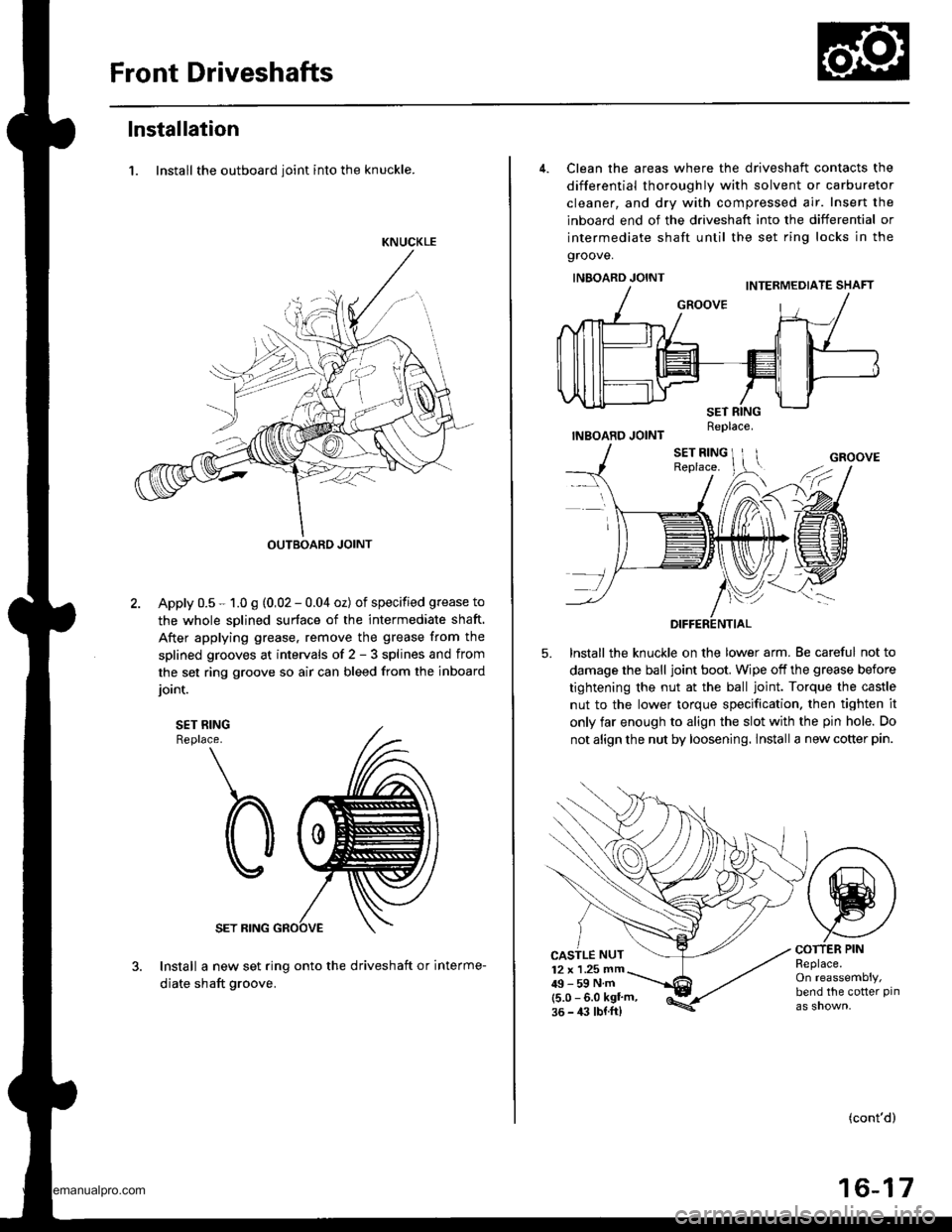

1. Install the outboard ioint into the knuckle.

KNUCKLE

OUTBOARD JOINT

Apply 0.5 - 1.0 g (0,02 - 0.04 oz) of specified grease to

the whole sDlined surface of the intermediate shaft.

After applying grease. remove the grease from the

splined grooves at intervals of 2 - 3 splines and from

the set ring groove so air can bleed from the inboard

ioint.

SET RINGReplace.

SET RING

Install a new set ring onto the driveshaft or interme-

diate shaft groove.

4. Clean the areas where the driveshaft contacts the

differential thoroughly with solvent or carburetor

cleaner, and dry with compressed air. Insert the

inboard end of the driveshaft into the differential or

intermediate shaft until the set ring locks in the

groove.

INBOARD JOINT

INBOARD JOINT

lnstall the knuckle on the lower arm. Be careful not to

damage the ball joint boot. Wipe off the grease before

tightening the nut at the ball joint. Torque the castle

nut to the lower torque specification. then tighten it

only far enough to align the slot with the pin hole. Do

not align the nut by loosening. lnstall a new cotter pin.

5.

CASTLE NUT12 x 1 .25 mm49-59Nm(5.0 - 6.0 kgl'm,36 - 4:l lbl.ft)

COTTER PINReplace.On reassembly,bend the cotter pin

(cont'd)

16-17

Replace.

www.emanualpro.com

Page 833 of 1395

Front DriveshaftsIntermediate Shaft

Installation {cont'd}

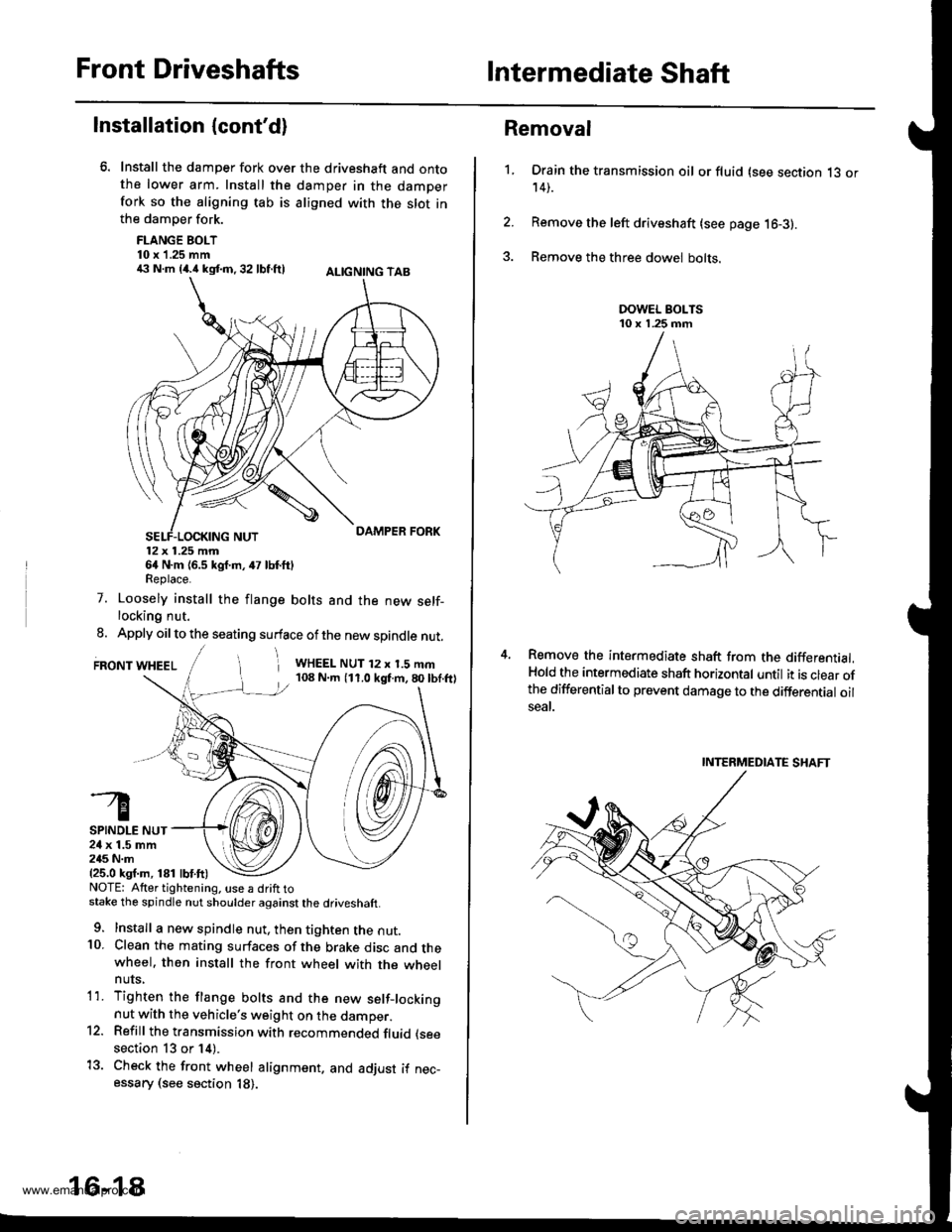

Install the damper fork over the driveshaft and ontothe lower arm. Install the damper in the damperfork so the aligning tab is aligned with the slot inthe damper fork.

FLANGE BOLT10 x 1.25 mm€ N.m {4.i1kst.n,32 lbf.ftl ALtcNtNG TAB

12x 1.25 mm64 N.m {6.5 kgf.m, 47 lbf.ftlReplace.

7. Loosely install the flange bolts and the new self-locking nut.

8. Apply oil to the seating surface of the new spindle nut.

FRONT WHEELi WHEEL NUT 12 x 1.5 mm108 N.m (11.0 kgf.m,80lbf.ftl

SPINDLE NUT24 x 1.5 mm245 N.m{25.0 ksf.m, 181 lbf.ft)NOTE: Atter tightening. use a drift tostake the spindle nut shoulder against the driveshaft.

9. Install a new spindle nut, then tighten the nut.10. Clean the mating surfaces of the brake disc and thewheel. then install the front wheel with the wheelnuts,

1'1. Tighten the flange bolts and the new setf-lockingnut with the vehicle's weight on the damper.12. Refill the transmission with recommended fluid (see

section 13 or 14).

13. Check the front wheel alignment. and adjust if nec-essary (see section 18).

16-18

1.

Removal

Drain the transmission oil or fluid (see section 13 or14).

Remove the left driveshaft (see page 16-3).

Remove the three dowel bolts.

Remove the intermediate shaft from the differential.Hold the intermediate shaft horizontal until it is clear ofthe differentialto prevent damage to the differential oilseal.

INTERMEDIATE SHAFT

www.emanualpro.com

Page 841 of 1395

Rear Driveshafts

Reassembly (cont'd)

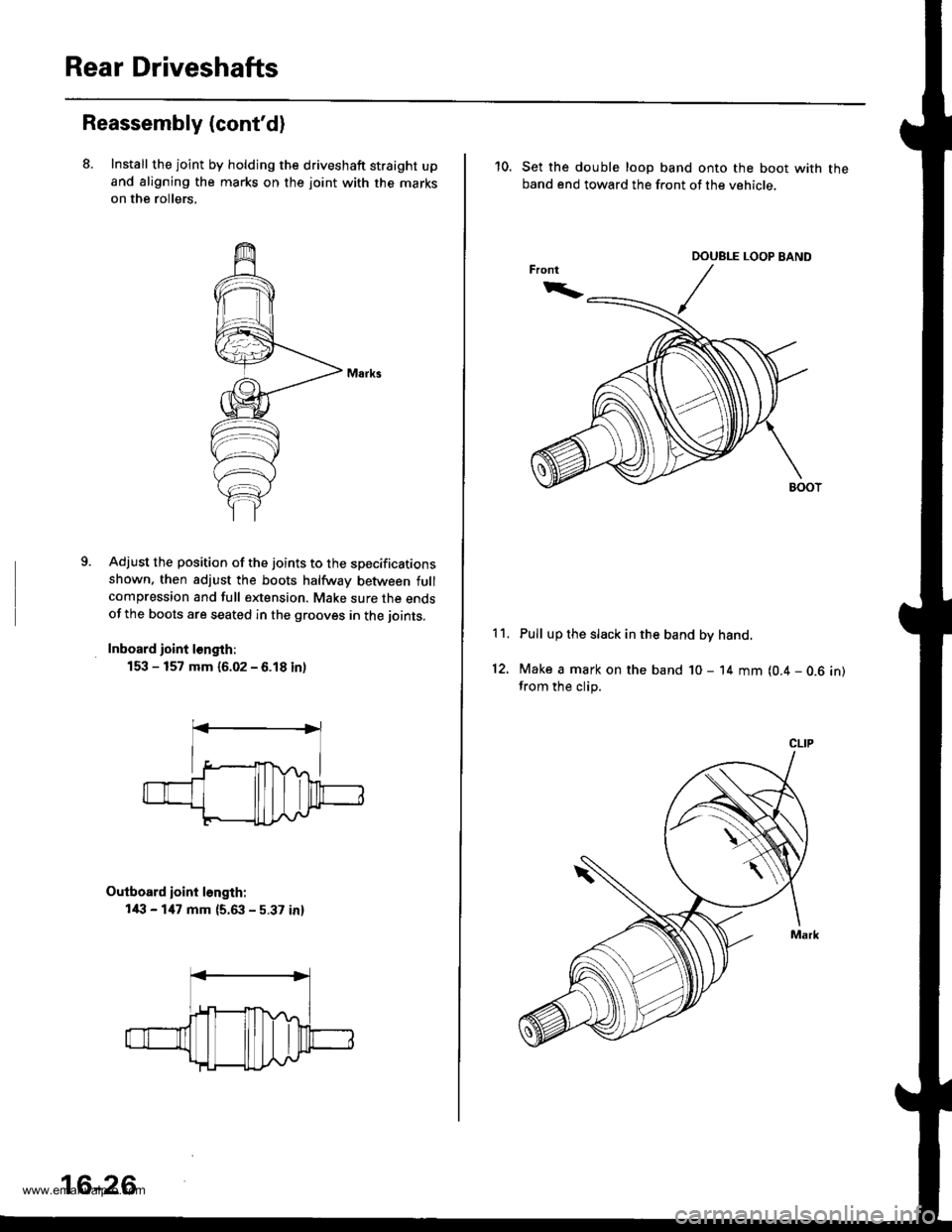

8. Install the joint by holdjng the driveshaft straight upand aligning the marks on the joint with the marks

on the rollers,

9.Adjust the position of the joints to the specificationsshown. then adjust the boots halfway between fullcompression and full extension. Make sure the endsof the boots are seated in the grooves in the joints.

Inboard ioint l€ngth:

153 - 157 mm {6.02 - 6.18 inl

Outboard ioint l6ngth:

l/l:' - 147 mm {5.63 - 5.37 in}

16-26

10. Set the double loop band onto the boot with theband end toward the front of the vehicle,

Pull up the slack in the band by hand.

Make a mark on the band 10 - 14 mm (0.4 - 0.6 in)from the clip.

11.

12.

CLIP

www.emanualpro.com

Page 863 of 1395

Steering Wheel

Removal

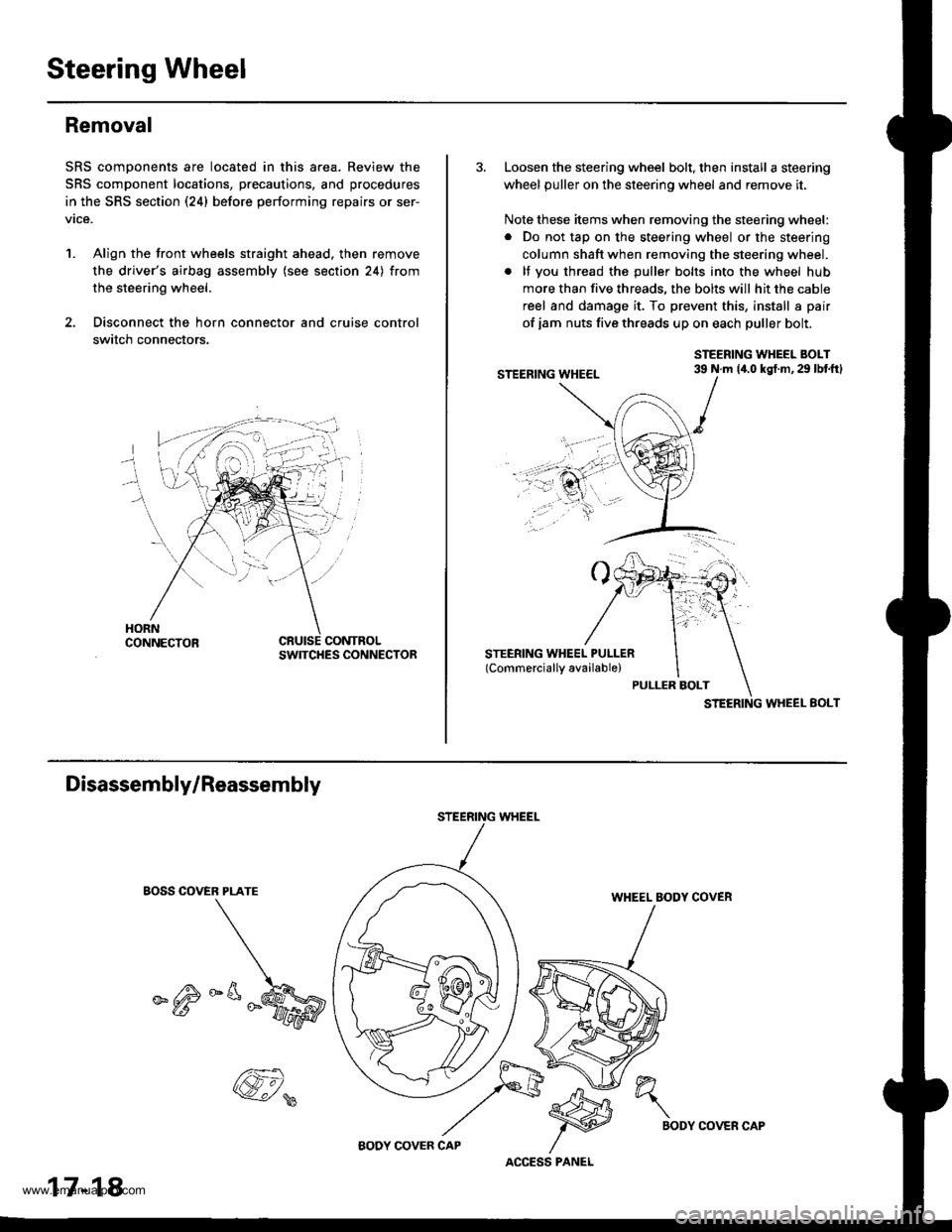

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (24) before performing repairs or ser-

vice.

1. Align the front wheels straight ahead. then remove

the driver's airbag assembly (see section 24) from

the steering wheel.

2. Disconnect the horn connector and cruise control

switch connectors.

CONTROLSWITCHES CONNECTOR

3. Loosen the steering wheel bolt, then install a steering

wheel puller on the steering wheel and remove it.

Note these items when removing the steering wheel:

. Do not tap on the steering wheel or the steering

column shaft when removing the steering wheel.

. lf you thread the puller bolts into the wheel hub

more than five threads, the bolts will hit the cable

reel and damage it. To prevent this, install a pair

of jam nuts five threads up on each puller bolt.

STEERING WHEEL BOLT39 N.m 14.0 kgt.m,29 lbtftl

STEERING WHEEL EOLT

Disassembly/Reassembly

EOSS COVER PLATE

_^M

STEERING WHEEL

WHEEL BODY COVER

17-18

@,

ACCESS PANEL

h"\

BODYCOVER CAP

www.emanualpro.com

Page 864 of 1395

lnstallation

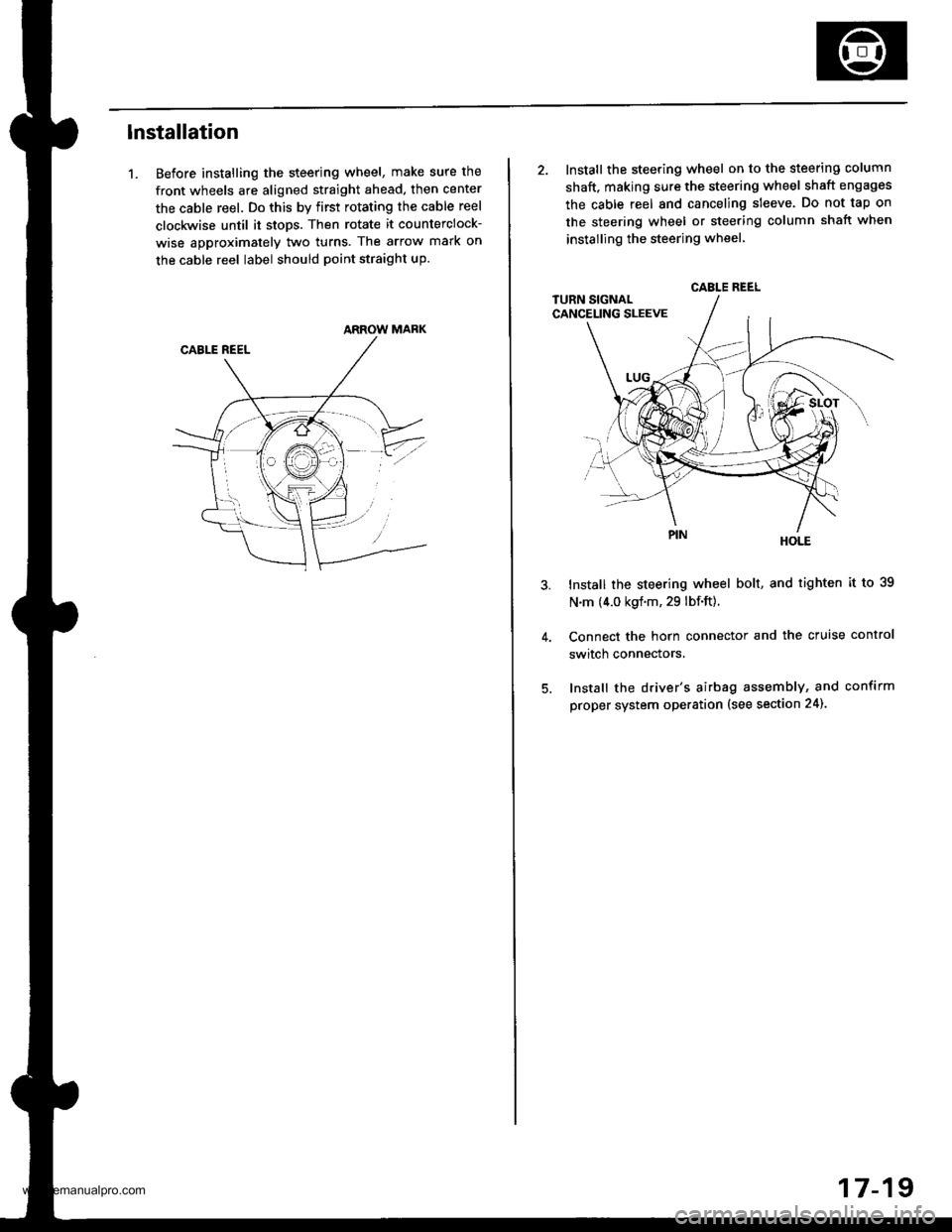

1. Before installing the steering wheel, make sure the

front wheels are aligned straight ahead, then center

the cable reel. Do this by first rotating the cable reel

clockwise until it stops. Then rotate it counterclock-

wise approximately two turns. The arrow mark on

the cable reel label should point straight up.

ARROW MARK

2. Install the steering wheel on to the steering column

shaft, making sure the steering wheel shaft engages

the cable reel and canceling sleeve. Do not tap on

the steering wheel or steering column shatt when

instailing the steering wheel

HOLE

Install the steering wheel bolt, and tighten it to 39

N.m (4.0 kgf.m, 29 lbf.ft).

Connect the horn connector and the cruise control

switch connectors,

Install the driver's airbag assembly, and confirm

proper system operation (see section 24).

CABLE REEL

17-19

www.emanualpro.com