Front shaft HONDA CR-V 1999 RD1-RD3 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 876 of 1395

Power Steering Gearbox

Removal

Note these items during removal:

. Using solvent and a brush, wash any oil and dirt off

the valve body unit its lines, and the end if the gear-

box. Blow dry with compressed air.

. Be sure to remove the steering wheel before discon-

necting the steering joint. Damage to the cable reel

can occur.

. With 4WD. tilt the engine with a jack to expand the

clearance between the transfer assembly and rear

beam when removing the steering gearbox from the

rear oeam.

Do not remove the steering gearbox by removing the

transfer assembly from the transmission.

1. Drain the power steering fluid as described on page'17-15.

Raise the vehicle, and suppon it on safety stands in

the proper locations (see section 1).

Remove the front wheels,

Remove the drive/s airbag assembly {see section 24).

Remove the steering wheel {see page 17-18).

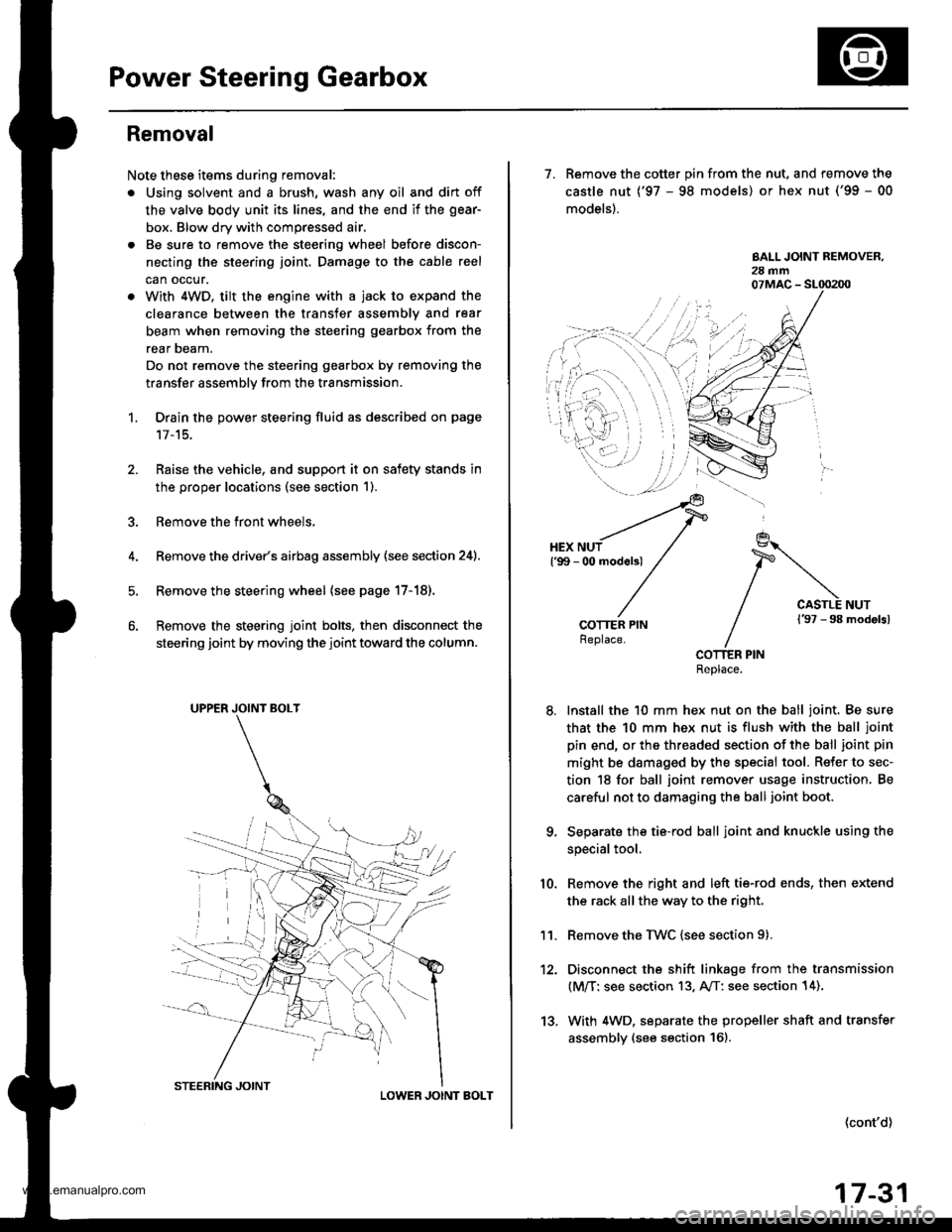

Remove the steering joint bolts, then disconnect the

steering joint by moving the joint toward the column.

UPPER JOINT BOLT

LOWER JOINT BOLT

13.

7. Remove the cotter pin from the nut, and remove the

castle nut {'97 - 98 models) or hex nut ('99 - 00

models).

COTTER PINReplace.

Install the 10 mm hex nut on the ball joint. Be sure

that the 10 mm hex nut is flush with the ball joint

pin end, or the threaded section of the ball joint pin

might be damaged by the special tool. Refer to sec-

tion 18 for ball joint remover usage instruction, Be

careful not to damaging the ball joint boot.

Separate the tie-rod ball joint and knuckle using the

special tool.

Remove the right and left tie-rod ends, then extend

the rack all the way to the right.

Remove the TWC (see section 9).

Disconnect the shift linkage from the transmission

(M/T: see section 13, A/T: see section 14).

With 4WD. separate the propeller shaft and transfer

assembly (see section 161.

10.

11.

(cont'd)

17-31

www.emanualpro.com

Page 898 of 1395

't 4.

15.

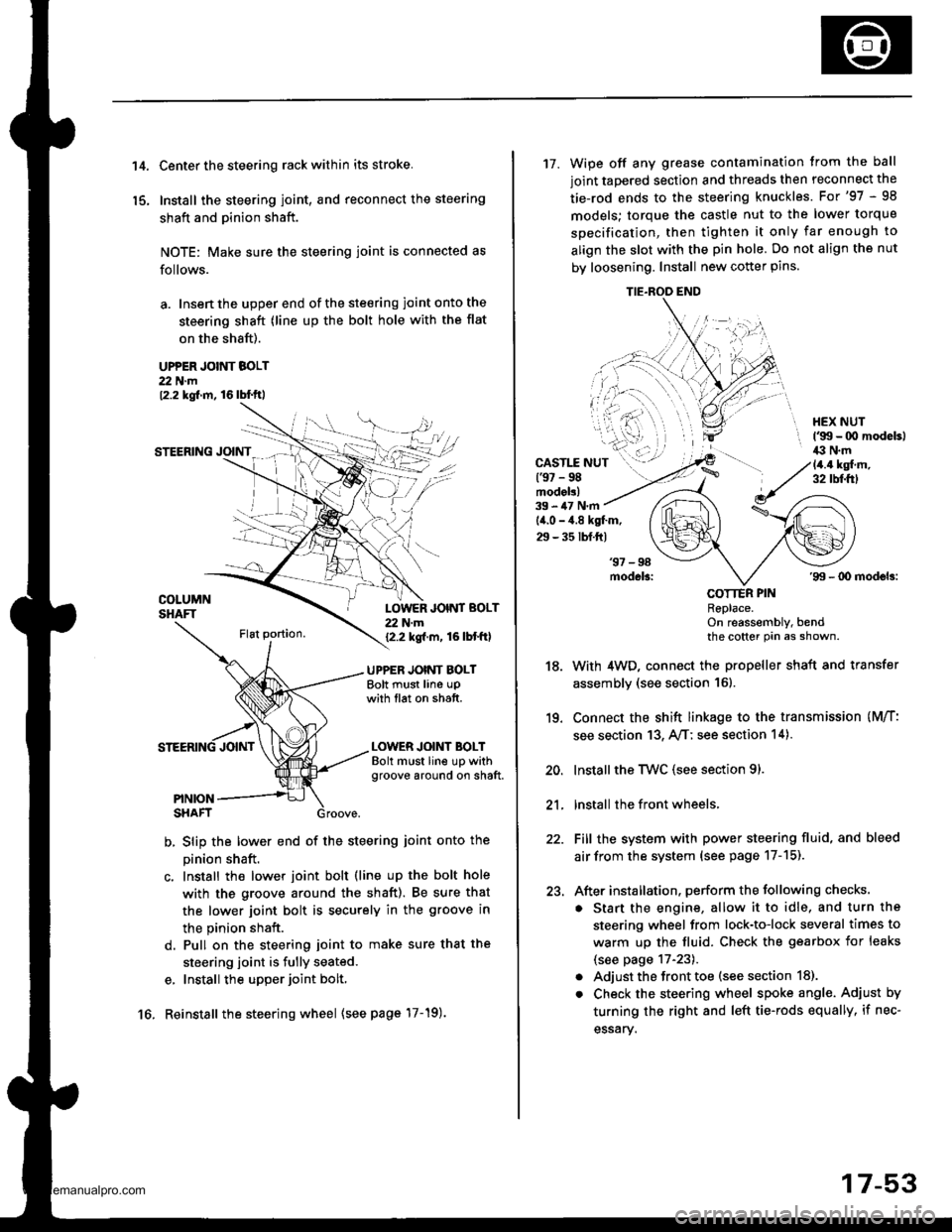

Center the steering rack within its stroke.

Install the steering joint, and reconnect the steering

shaft and pinion shaft.

NOTE: Make sure the steering joint is connected as

follows.

a. Insen the upper end of the steering joint onto the

steering shaft (line up the bolt hole with the flat

on the shaft).

UPPER JOINT BOLT22 N.m12.2 kgf.m, 16lbl.ft,

STEERING JOINT

COLUMNSHAFTLOWER JOINT BOLT22 N.m12.2 kgf.m, 16lbtftl

UPPER JOINT BOLTBolt must line upwith tlat on shatt.

LOWER JOINT BOLTBolt must line up withgroove around on shaft.

PINIONSHAFT

b, Slip the lower end of the steering ioint onto the

pinion shaft.

c. Install the lower joint bolt (line up the bolt hole

with ths groove around the shaft). Be sure that

the lower joint bolt is securely in the groove in

the pinion shaft.

d. Pull on the steering joint to make sure that the

steering joint is fully seated.

e, Install the upper joint bolt,

Reinstall the steering wheel {see page'17-19).16.

17-53

17. Wipe off any grease contamination trom the ball

joint tapered section and threads then reconnect the

tie-rod ends to the steering knuckles. For'97 - 98

models; torque the castle nut to the lower torque

specification, then tighten it only far enough to

align the slot with the pin hole. Do not align the nut

by loosening. Install new cotter pins.

CAST1T NUT(9t - 98modol!)

HEX NUTl'g!t - 00 modeb)il:l N.m14.4 ksl.m,32 tbf.f0

39 - iU N'm

lil.o - 4.8 kgl.m,

29 - 35 tbf.ftl

18.

19.

20.

21.

22.

23.

'99 - lD modeb:

COTTER PINRePlace.on reassembly, bendthe cotter Pin as shown.

With 4WD, connect the propeller shaft and transfer

assembly (see section 16).

Connect the shift linkage to the transmission (M/T:

see section 13, A,/T; see section 14).

Installthe Twc (see section 91.

lnstall the front wheels,

Fill the system with power steering fluid, and bleed

air from the system (see page 17-15).

After installation. perform the following checks.

. Start the engine, allow it to idle, and turn the

steering wheel from lock-to-lock several times to

warm up the fluid. Check the gearbox for leaks

(see page 17-23).

. Adjust the front toe (s€e section 18).

. Check the steering wheel spoke angl€. Adjust by

turning the right and left tie-rods equally, if nec-

essary.

TIE.ROO END

www.emanualpro.com

Page 910 of 1395

Front Suspension

Knuckle/Hub Replacement (cont'd)

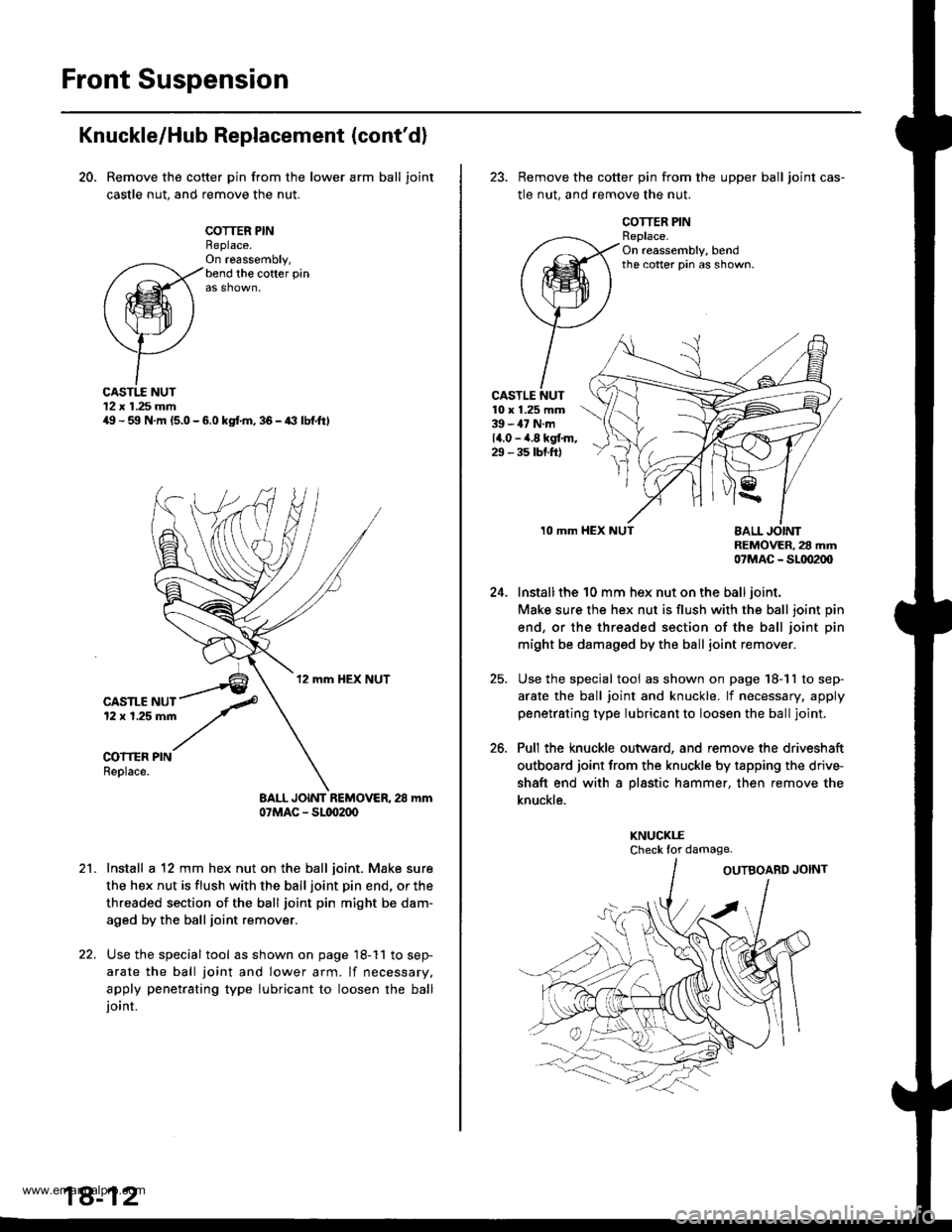

20. Remove the cotter pin from the lower arm ball joint

castle nut, and remove the nut.

COTTER PINReplace.On ra6ssembly,bend the cofter pin

CASTI.E NUT12 x 1.25 mmilg - 59 N.m (5.0 - 6.0 kgf.m, 36 - a3 lbf.ftl

CASTLE NUT12 x 1.25 mm

COITER PINReplace.

BALL JOINT REMOVER, 28 mm07MAC - Sl(xr2(x,

Install a 12 mm hex nut on the ball joint. Make sure

the hex nut is flush with the ball joint pin end, or the

threaded section of the ball joint pin might be dam-

aged by the ball joint remover.

Use the special tool as shown on page 18-11 to sep-

arate the ball joint and lower arm. lf necessary,

apply penetrating type lubricant to loosen the balljoint.

18-12

23. Remove the cotter pin from the upper ball joint cas-

tle nut, and remove the nut.

COTTER PINReplace.On reassembly, bendthe cotter pin as shown.

CASTLE NUT10 x 1.25 mm39 - 47 N.m14.0 - ,4.8 kgt m,29 - 35 tbt.ftl

24.

25.

26.

10 mmnEMOVER, 28 mm07MAC _ SLtD2(xl

Install the 10 mm hex nut on the ball joint.

Make sure the hex nut is flush with the ball joint pin

end, or the threaded section of the ball joint pin

might be damaged by the ball joint remover.

Use the special tool as shown on page 18-11 to sep-

arate the ball joint and knuckle. lf necessary, apply

penetrating type lubricant to loosen the ball joint.

Pull the knuckle outward, and remove the driveshaft

outboard joint from the knuckle by tapping the driv+

shaft end with a pl8stic hammer, then remove the

knuckle.

KNUCKI.ECheck lor damage.

www.emanualpro.com

Page 912 of 1395

Front Suspension

31.

Knuckle/Hub Replacement (cont'dl

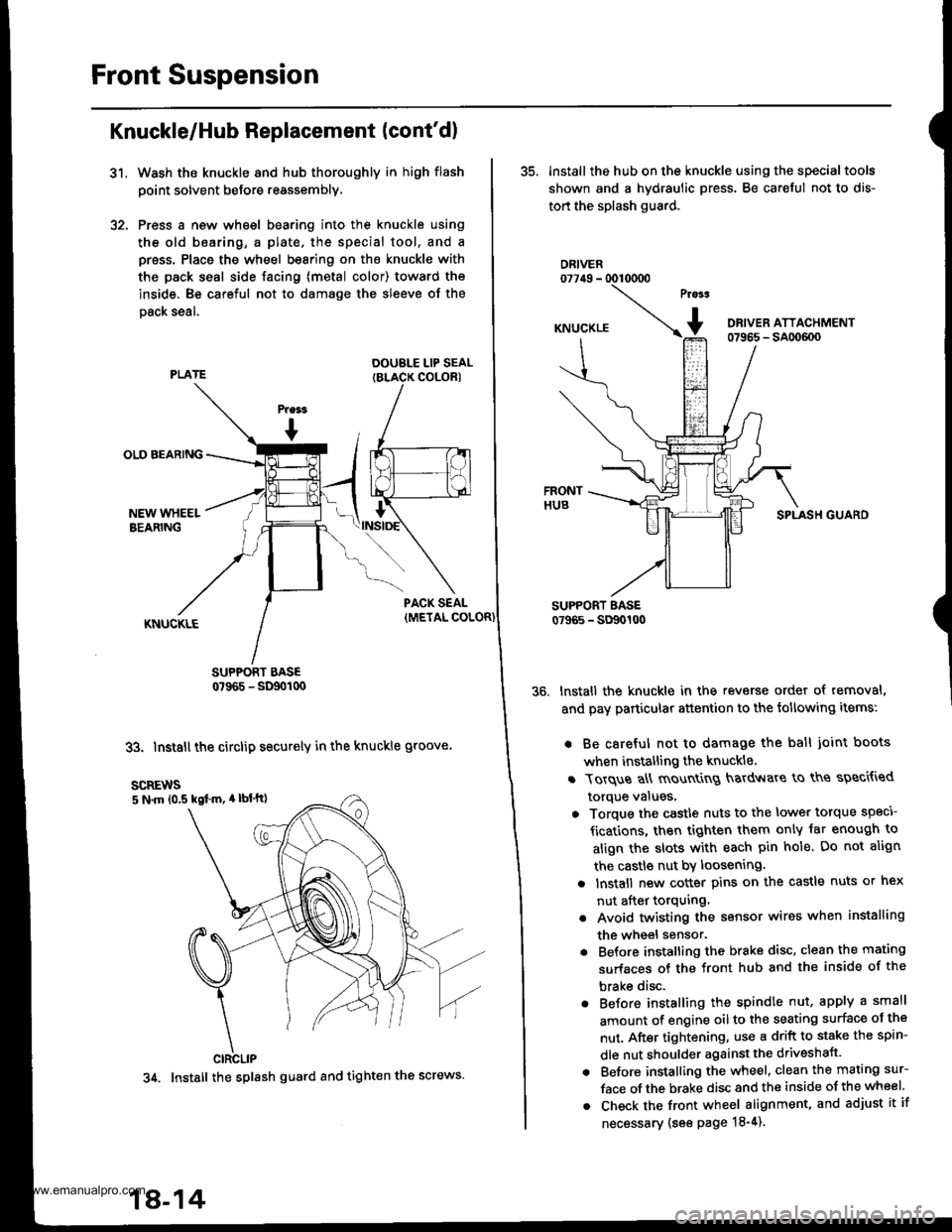

Wash the knuckle and hub thoroughly in high flash

point solvent before reassembly,

Press a new wheel bearing into the knuckle using

the old b6aring, a plate. the special tool, and a

press. Place the wheel bearing on the knuckle with

the pack seal side facing (metal color) toward the

inside. Be careful not to damage the sleeve of the

Dack seal.

DOUBLE LIP SEALIBLACK COLORI

SUPPORT BASE0?965 - SD90t00

33. Install the circlip securely in the knuckle groove.

35. lnstall the hub on the knuckle using the specialtools

shown and a hydraulic press. Be careful not to dis-

tort the splash guard.

ORIVER077irg - 0010000

SPLASH GUARO

lnstall the knuckle in the reverse order of removal,

and pay particular attention to the following items:

. Be careful not to damage the ball joint boots

when installing the knuckle.

r Torque a\ mount

g hardv{are to ths speci{ied

torque values,

o Torque the castle nuts to the lower torque speci

fications, then tighten them only iat enough to

align the slots with each pin hole. Do not align

the castle nut by loosening.

a lnstall new cotter pins on the castle nuts or hex

nut after torquing.

. Avoid twisting the sensor wires when installing

the wheel sensor.

. Before installing the brake disc, clean the mating

surfaces of the front hub and the inside of the

brake disc.

. Before installing the spindle nut, apply a small

amount of engine oil to the seating surface oJ the

nut. After tightening, use a drift to stake the spin-

dle nut shoulder against the driveshaft.

. Before installing the wheel. clean the mating sur-

face of the brake disc and the inside of the wheel.

. Check the front wheel alignment, and adjust it if

necessary {see page 18-4).

scREws5 N.m 10.5 kgl m, 4 lbl'tt)

CIRCLIP

34. Install the splash guard and tight€n the screws.

18-14

www.emanualpro.com

Page 916 of 1395

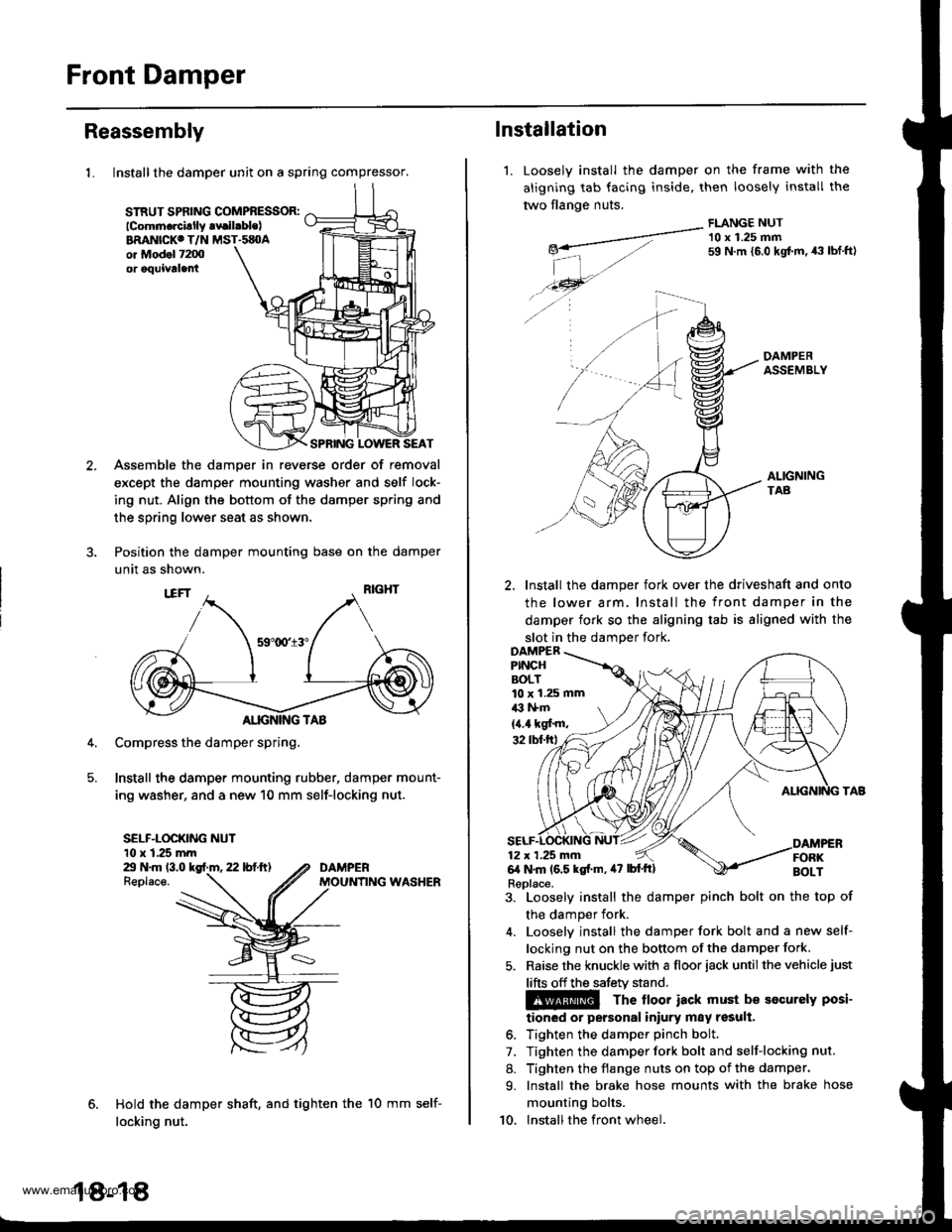

Front Damper

Reassembly

1. Install the damper unit on a spring compressor.

STRUT SPflNG COMPBESSOR:lcomm.rcillly .vrilrble)BRANICKC T/N MST.sEOAor Mod.l 7200or oquivtla

SPRING LOWER SEAT

Assemble the damper in reverse order of removal

except the damper mounting washer and self lock-

ing nut. Align the bottom of the damper spring and

the spring lower seat as shown.

Position the damper mounting base on the damper

unit as shown.

Compress the damper spring,

Install the damper mounting rubber, damper mount-

ing washer, and a new 10 mm self-locking nut.

SELF-LOCKING NUT10 x 1.25 mmZt N.m 13.0 kgf.m, 22 lbf.ft)Replace.

Hold the damper shaft, and tighten the

locking nut.

DAMPERMOUNfING WASHER

18-18

10 mm self-

1.

lnstallation

Loosely install the

aligning tab facing

two flange nuts.

damper on the frame with

inside, then loosely install

FLANGE NUT

the

tne

-__---a-"- 10 x 1.25 mmg*- 59 N.m {5.0 kgt m, 43 tbf.ftl

| -,./.46- --...

./ -4 A-

DAMPERASSEMBLY

ALIGNINGTAB

2, Install the damper fork over the driveshaft and onto

the lower arm. Install the front damper in the

damper fork so the aligning tab is aligned with the

slot in the damDer fork,

3. Loosely install the damper pinch bolt on the top of

the damper fork.

4. Looselv install the damper fork bolt and a new self-

locking nut on the bottom of the damper fork.

5. Raise the knuckle with a floor iack until the vehicle just

lifts off the safetv stand.

The lloor iack must b€ socurely posi-

tioned or personal iniury may result.

6. Tighten the damper pinch bolt.

7. Tighten the damper fork bolt and self-locking nut.

8. Tighten the flange nuts on top of the damper.

9. Install the brake hose mounts with the brake hose

mounting bolts.

10. Installthe front wheel.

10 x 1.25 mmil3 l+m

{4.4 kgf'm,

Replace.

www.emanualpro.com

Page 1206 of 1395

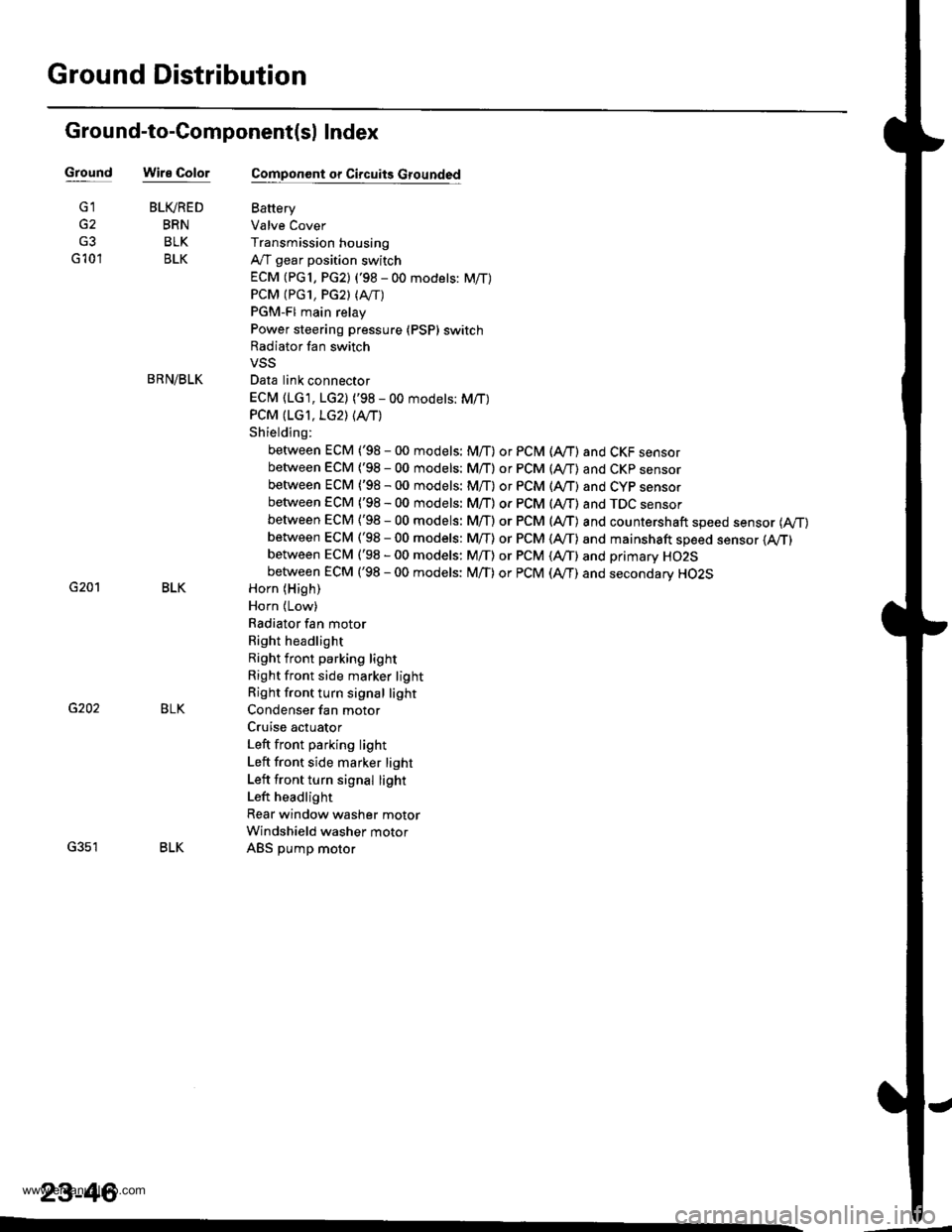

Ground Distribution

Ground-to-Component(sl Index

GroundWire Color

G2

G3

G 10'l

G201

G202

G351

BLIVRED

BRN

BLK

BLK

BRN/BLK

BLK

BLK

BLK

23-46

Component or Circuits Grounded

Battery

Valve Cover

Transmission housing

A,/T gear position switch

ECM (PG1, PG2) ('98 - 00 models: M/T)

PCM (PG1, PG2l (Avrr)

PGM-FI main relay

Power steering pressure (PSP) switch

Radiator fan switch

VSS

Data link connector

ECM (1G1, LG2) ('98 - 00 models: M/T)

PCM (LGI, LG2) (IVT)

Shielding:

between ECM ('98 - 00 models: M/T) or PCM (Ay'T) and CKF sensorbetween ECM {'98 - 00 modets: M/T} or pCM (Ay'T) and CKp sensorbetween ECM ('98 - 00 models: M/T) or PCM (rVT) and CYP sensorbetween ECM ('98 - 00 models: M/T) or PCM (Ay'T) and TDC sensorbetween ECM {'98 - 00 models: M/T) or PCM (ly'T) and countershaft speed sensor (Ay'T)

between ECM ('98 - 00 models: M/T) or PCM {A,,/T) and mainshaft sp€ed sensor {!VT)between ECM ('98 - 00 models: M/T) or PCM (A,/T) and primary HO2Sbetween ECM ('98 - 00 models: M/T) or PCM (Ay'T) and secondary HO2SHorn (High)

Horn {Low}

Radiator fan motor

Right headlight

Right front parking light

Right front side marker light

Right front turn signal light

Condenser fan motor

Cruise actuator

Left front parking light

Left front side marker light

Left front turn signal light

Left headlight

Rear window washer motor

Windshield washer motor

ABS pump motor

www.emanualpro.com

Page 1390 of 1395

)o

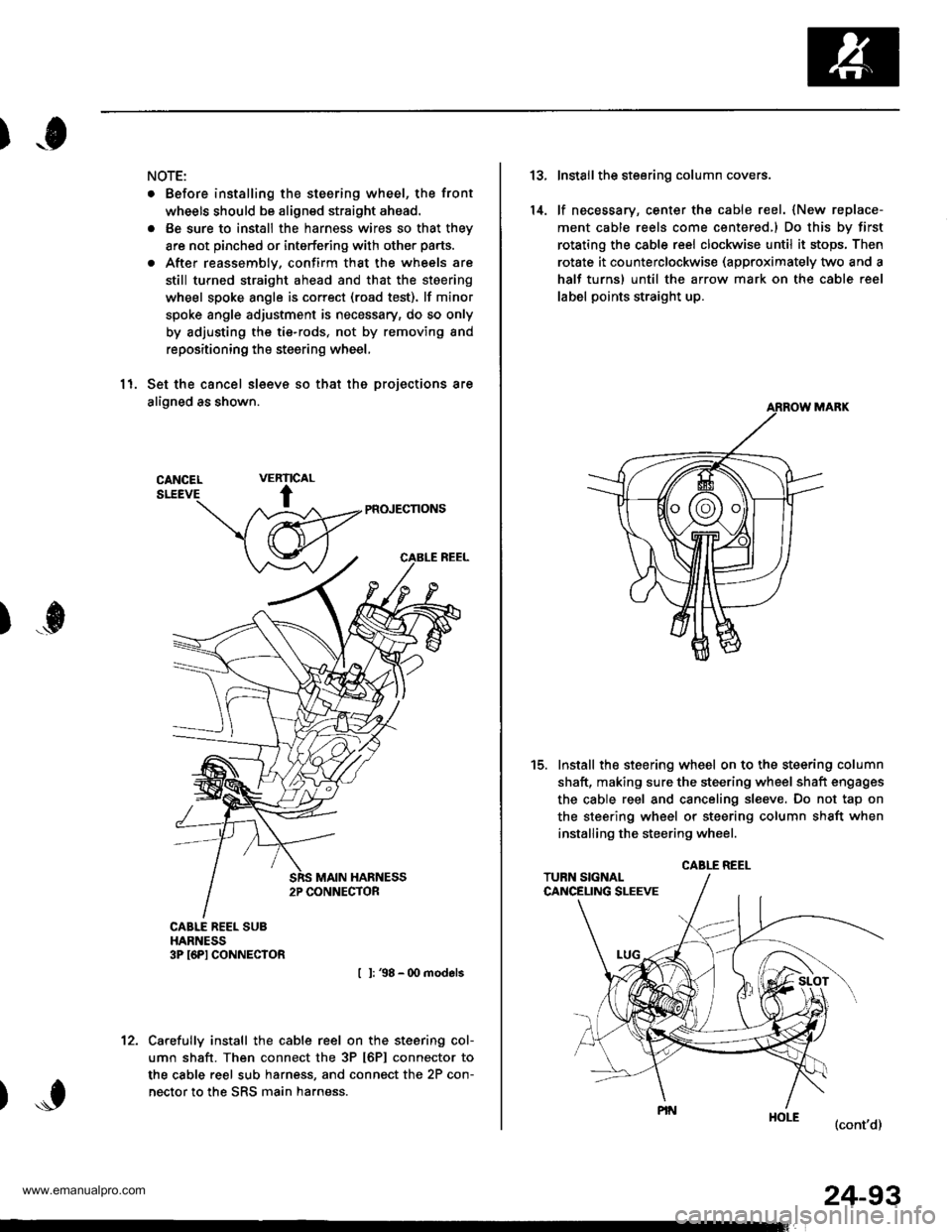

NOTE:

. Before installing the steering wheel, the front

wheels should be aligned straight ahead.

. Be sure to install the harness wires so that they

are not pinched or interfering with other parts.

. After reassemblv, confirm that the wheels are

still turned straight ahead and that the steering

wheel spoke angle is correct (road test). lf minor

spoke angle adjustment is necessary, do so only

by adjusting the tie-rods, not by removing and

repositioning the steering wheel,

11. Set the cancel sleeve so that the projections are

aligned as shown.

PR(NECNONS

I l: 38 - 00 models

Carefully install the cable reel on the steering col-

umn shaft. Then connect the 3P t6Pl connector to

the cable reel sub harness, and connect the 2P con-

nector to the SRS main harness.

RIC

t

VEAL

)...0

't2.

24-93

13.

14.

Install the steering column covers.

lf necessary, center the cable reel. {New replace-

ment cable reels come centered,l Do this by first

rotating the csble reel clockwise until it stops, Then

rotate it counterclockwise (approximately two and a

half turns) until the arrow mark on the cable reel

label points straight up.

Install the steering wheel on to the steering column

shaft, making sure the steering wheel shaft engages

the cable reel and canceling sl€eve. Do not tap on

the steering wheel or steering column shaft when

installing the steering wheel.

(cont'd)

t5.

CABLE REEL

www.emanualpro.com