Throttle position sensor HONDA CR-V 1999 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 315 of 1395

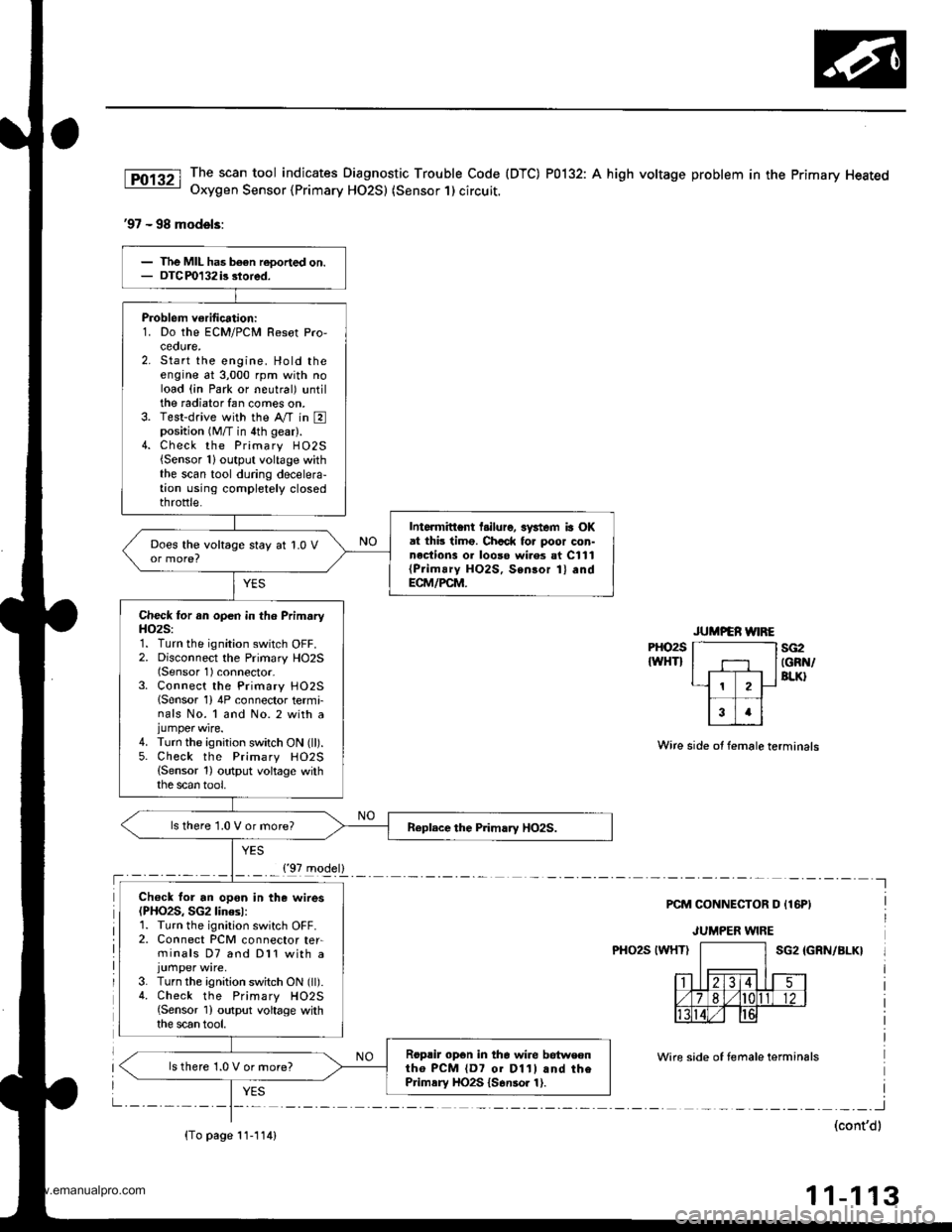

The scan tool indicates Diagnostic Trouble Code (DTC) P0132: A high voltage problem in the Primary HeatedOxygen Sensor {Primary HO2S) (Sensor 1) circuit.

'97 - 98 models:

PHO2S

IWHTIsG2IGRN/BLK}

Wire side ot female terminals

PCM CONNECTOR D {16PI

JUMPER WIRE

PHO2S IWHTISG2 IGRN/BLK}

Wire side of temale terminals

I

(cont'dl

11-113

Problem verification:1. Do the ECM/PCM Resot Pro,ceoute,2. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on.3. Test-drive with the Ay'T in Eposition (M/T in 4th gear).4. Check the Primary H02S{Sensor 1}output voltage withthe scan tool during decelera-tion using completely closedthrottle.

Intormittent l.ilure, 3ystem ia OKat thb timo. Chcck fo. poor con-nections 01 looso wi.es at C111{Prim!ry HO2S, Sensor 1} andECM/PCM.

Does the voltage stay at 1.0 V

Check for an open in th6 PrimaryH()2S:1. Turn the ignition switch OFF.2. Disconnect the Primary HO2S(Sensor 1) connector-3. Connect the Primary HO25lSensor 1) 4P connector termi-nals No. 1 and No. 2 with ajumper wire.4. Turn the ignition switch ON (ll).5. Check the Primary HO2S(Sensor 1) output voltage withthe scan tool,

ls there 1.0 V or more?

Ch€ck for an opon in the wires(PHO2S, SG2linesl:1. Turn the ignition switch OFF.2. Connect PCM connector ter-minals D7 and Dl1 with a

3. Turn the ignition switch ON (ll).4. Check the Primary HO2S{Sensor 1) output voltage withthe scan tool.

Roprir opon in the wire betweontho PCM {D7 01 D11l and thePrimsry HO2S {S6nsor 1).

ls there 1.0 V or more?

{'97 model}

{To page 11-114)

www.emanualpro.com

Page 339 of 1395

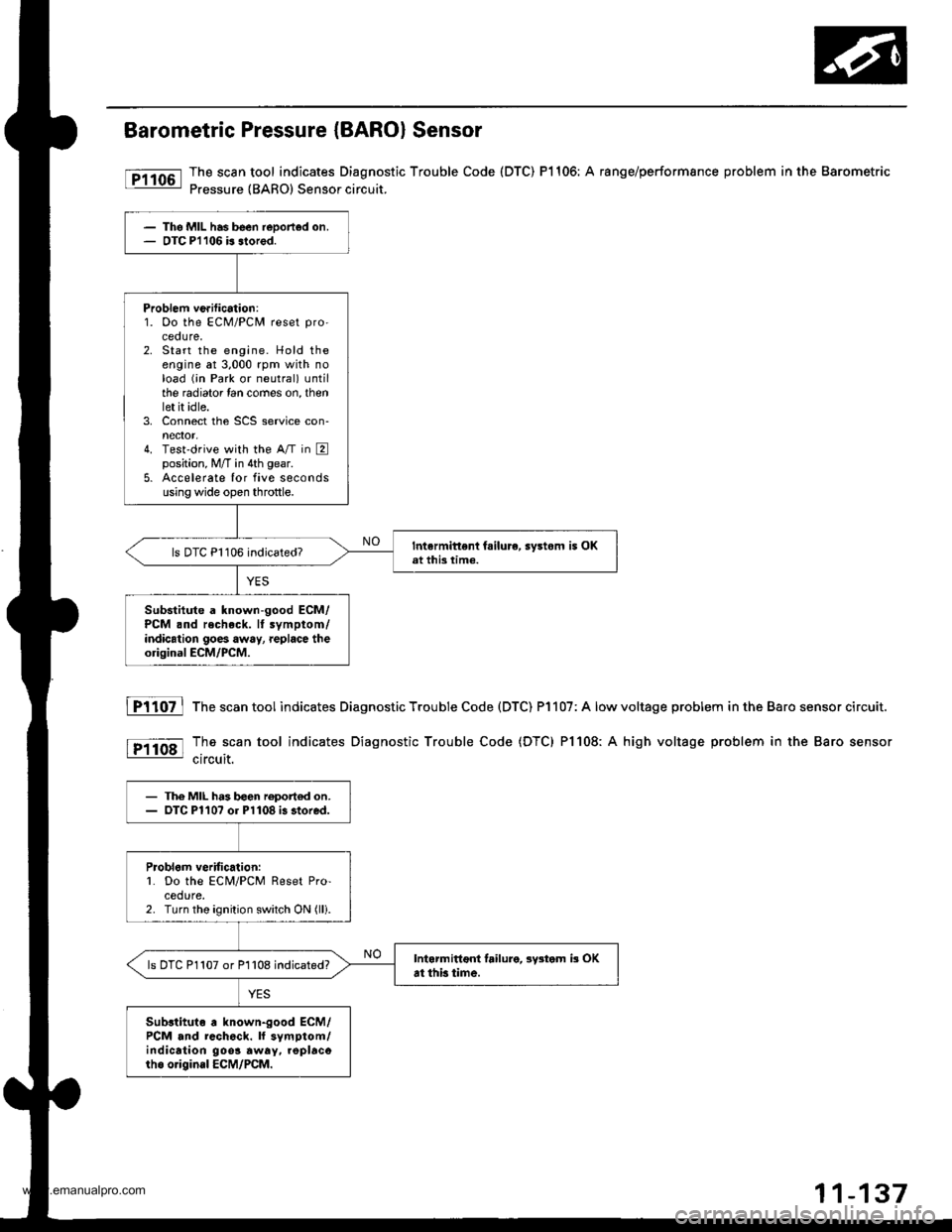

Barometric Pressure (BARO) Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) P1106: A range/performsnce problem in the Barometric

Pressure {BARO) Sensor circuit.

The MIL has been reDorted on.OTC Pl106 b slored.

Problem ve.ification:1. Oo the ECM/PCM reset pro'

ceoure.2. Start the engine. Hold theengine at 3,000 rpm with noload (;n Park or neutral) untilthe radiator lan comes on, thenlet it idle.3. Connect the SCS service con-nector,4. Test'drive with the A/T in Eposition, M/T in 4th gear.

5. Accelerate Ior five secondsusing wide open throttle.

Intermittent fsilure, sy3tom i5 OKat this time.ls DTC P1106 indicated?

Substitute a known-good ECM/PCM .nd recheck. It symptom/indication goes away, replace theorigioal ECM/PCM.

fTiloz l

tP11o8l

The scan tool indicates Diagnostic Trouble Code (DTC) P1107: A low

The scan tool indicates Diagnostic Trouble Code (DTC) Pl108: A

circuit.

voltage problem in the Baro sensor circuit.

high voltage problem in the Baro sensor

- The MIL h.3 b€en roport€d on.- OTC Pl10? or Pl108 i3 stored.

Problom veritic.lion:L Do the ECM/PCM Reset Pro-cedure.2. Turn the ignition switch ON (lli.

Intarmittoni failure, lystom b OKat thb time.ls DTC P1107 or P1108 indicated?

Sub3tituto a known-good ECM/PCM and rcch6ck. ll symptom/indication 9oo3 away. .oplacorho o.igin.l ECM/PCM.

www.emanualpro.com

Page 352 of 1395

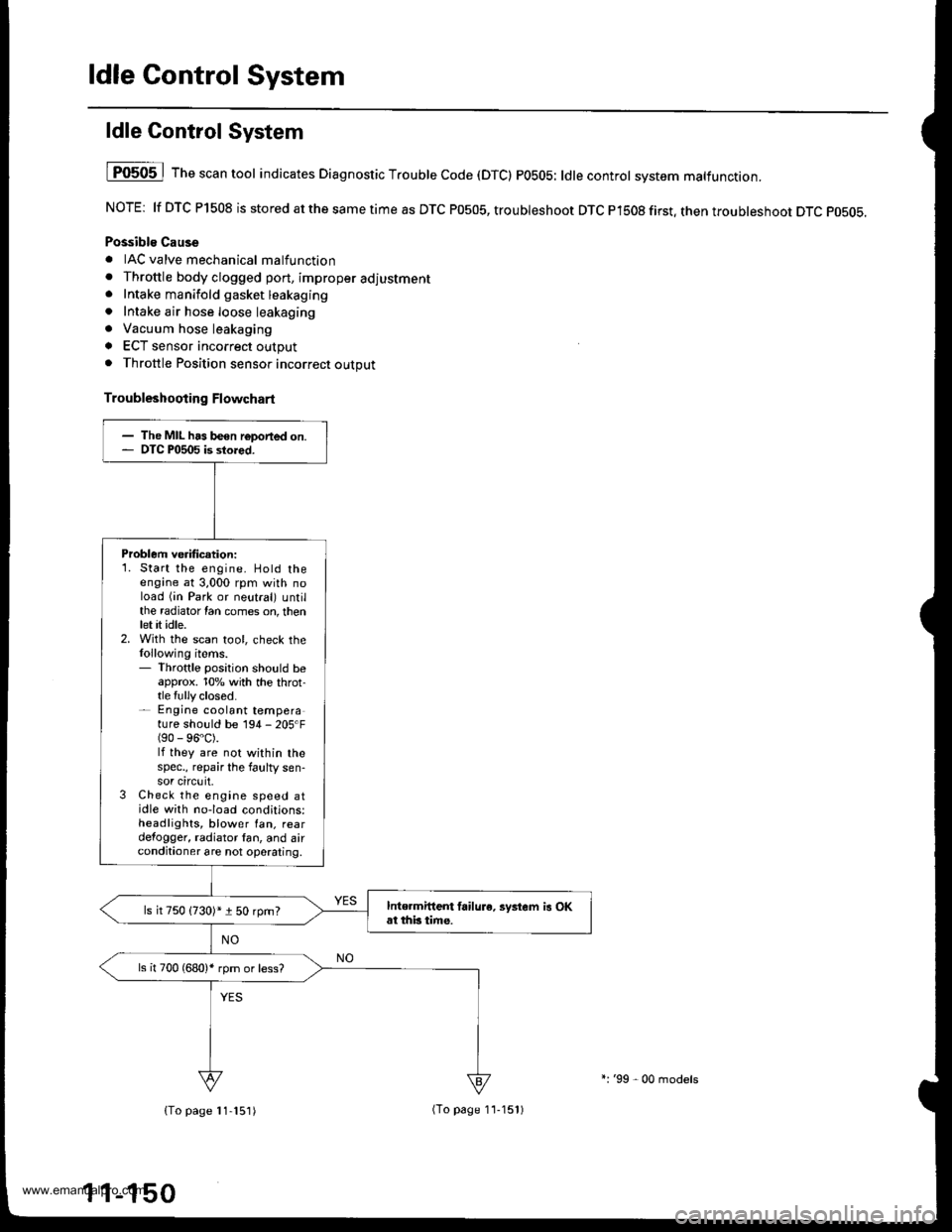

ldle Control System

ldle Control System

I P0505 | The scan tool indicates Diagnostic T.ouble Code (DTCI PO5O5: ldlecontrol svstem mattunction.

NOTE: lf DTC P1508 is stored at the same time as DTC P0505, troubleshoot DTC P1508 first. then troubleshoot DTC p0505.

Possibls Cause

. IAC valve mechanical malfunction. Throttle body clogged port, improper adlustment. Intake manifold gasket leakaging. Intake air hose loose leakaging. Vacuum hose leakaging

a ECT sensor incorrect output. Throttle Position sensor incorrect output

Troubleshooting Flowchart

The MIL has been reDorted on.DTC P0505 is sto.ed.

Problem verificationi1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator Ian comes on, thenlet it idle.2. With the scan tool, check thelollowing items.- Throttle position should beapprox. 10% with the throt-tle {ully closed.- Engine coolant temperature shorJld be 194 - 205'F(90 - 96"C).lf they are not within thespec., repair the faulty sen-sor circuit.3 Check the engine speed atidle with no-load conditions:headlights, blower fan. reardefogger, radiator lan, and airconditioner are not operaling,

Inte.mittent failure. syltem is OKat this time.ls it 750 {730)* i 50 rpm?

ls il 700 (680)' rpm or less?

{To page 11-151)(To page 1'l-151)

l:'99 - 00 models

www.emanualpro.com

Page 532 of 1395

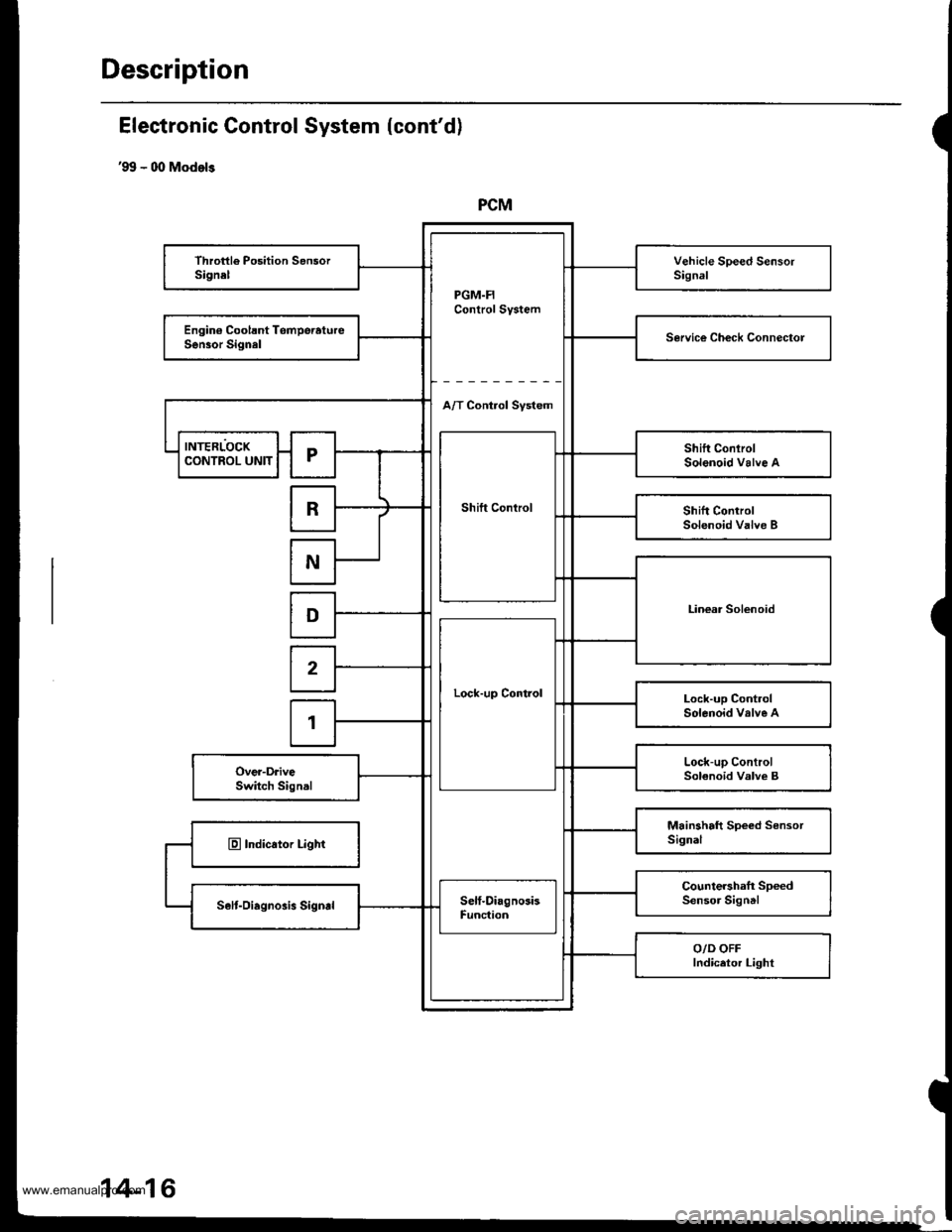

Description

PCM

PGM.FIControl System

Throttle Position SensorSignelVehicle Speed SensorSignal

Engin€ Coolsnt TomperatureSen30r SignalService Ch€ck Connectol

A/T Control Svstem

INTERLOCK

Shift Control

Shift ConlrolSolenoid Valve ACONTROL UNITr

RShift ControlSolenoid Valve B

N

Linear SolenoidD

Lock-up Control

2

Lock-up ControlSolenoid valve A1

Lock-up ControlSolenoid Valve BOver-DriveSwitch Signal

Mainshaft Speed SensorSignalE Indicator Light

Countershaft SpeedSensor SigntlSelt-Oiagnosis SigndSelf-DiagnosisFunc{ion

O/D OFFIndicetor Light

Electronic Gontrol System (cont'd)

'99 - 00 Models

14-16

www.emanualpro.com

Page 534 of 1395

Description

Electronic Control System (cont'dl

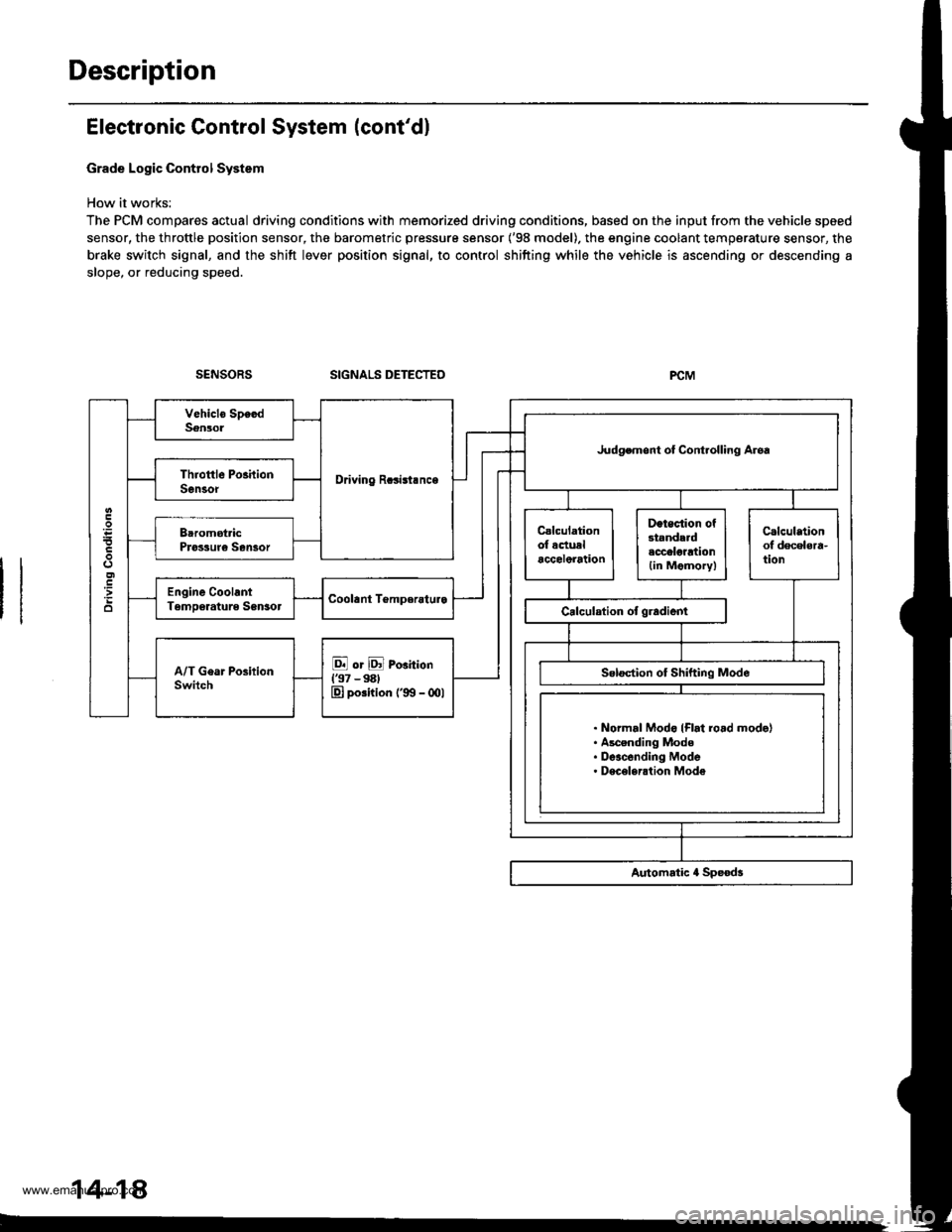

Grade Logic Control System

How it works:

The PCM compares actual driving conditions with memorized driving conditions, based on the input from the vehicle speed

sensor, the throttle position sensor, the barometric pressure sensor ('98 model). the engine coolant temperature sensor, the

brake switch signal, and the shift lever position signal, to control shifting while the vehicle is ascending or descending a

slope, or reducing speed.

SIGNALS DETECTED

Driving Rcsisl.nce

Judgemont ot Controlling Aroa

. Normal Modo {Flrt ro.d mode}. Ascending Mode. Deacending Mode. Deceleration Mode

14-14

www.emanualpro.com

Page 643 of 1395

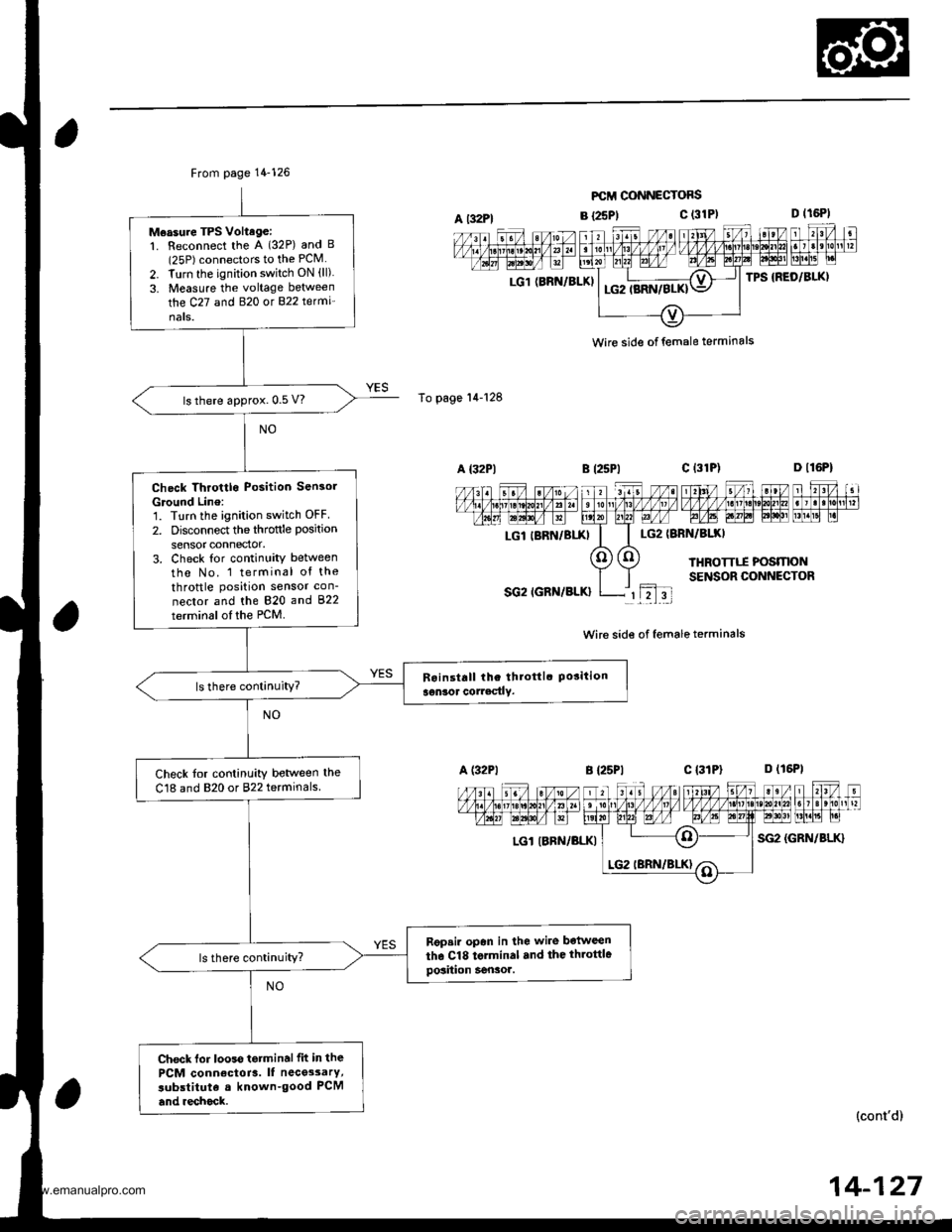

From page 14-126

Measure TPS Voltage:1. Reconnect the A (32P) and B(25P) connectors to the PCM

2. Turn the ignition switch ON (ll)

3. Measure the voltage between

the C27 and B�20 ot 822 te(mi'

nats.

ls there approx. 0.5 V?

Check Throttlo Position Sensol

Ground Line:'1. Turn the ignition switch OFF

2. Disconnect the throftle position

sensor connector.3. Check tor continuity between

tho No. 1 terminal of the

throttle position sensor con-

nector and the 820 and 822

terminsl of the PCM.

ls there continuity?

Check tor continuity betlveen the

C18 and 820 or 822 terminals

Rgpsir opan in lhe wire botween

the Cl8 torminal .nd the throttlegosiiion Sensor.ls there continuity?

Check lor looss tetminalfit in the

PCM conn€ctoia. It nece3sarY,

subslituta a known-good PCM

and .echock.

A t32Pl

To page'14-128

LG1 (BRN/BLKI

FCII CONNECTOFS

B {25P1c (31P)

LG2IBRN/BIXI

THROTTTI POSMONSENSOR CONNECTOR

SG2 IGRN/BLK}rL2l3t

Wire side of female terminals

B {25P1c l3lPl D (16P1

LGl IBRN/BLKISG2 {GRN/BLK}

n l,I-il nFFFTI,T';T;IEFML"| -

(cont'd)

wire side of female terminals

LGl IBRN/BIXI

14-127

www.emanualpro.com

Page 661 of 1395

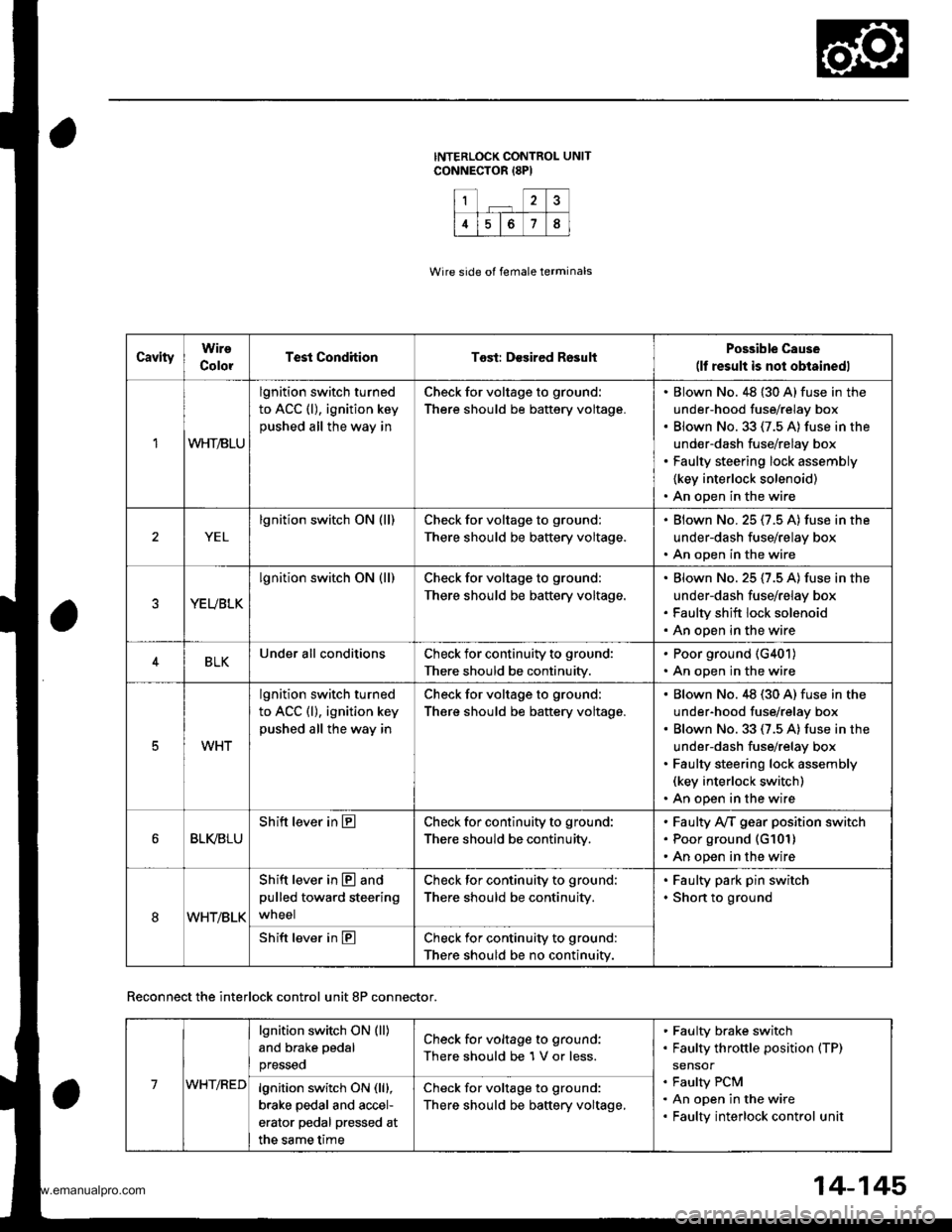

1?

4678

CavityWire

ColorTest CondhionTost: Desired RosultPossible Cause(lf result is not obtainedl

1WHT/BLU

lgnition switch turned

to ACC (l), ignition key

pushed all the way in

Check for voltage to ground:

There should be battery voltage.

Blown No. 48 {30 A} fuse in the

under-hood fuse/relay box

Blown No.33 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty steering lock assembly

{key interlock solenoid)

An open in the wire

YEL

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage.

Blown No.25 (7.5 A) fuse in the

under-dash fuse/relay box

An open in the wire

YEUBLK

lgnition switch ON (ll)Check for voltage to ground:

There should be baftery voltage.

Blown No. 25 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty shift lock solenoid

An open in the wire

4BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G401)

. An open in the wire

5WHT

lgnition switch turned

to ACC (l), ignition key

pushed all the way in

Check for voltage to ground:

There should be battery voltage.

Blown No.48 (30 A) fuse in the

under-hood fuse/relay box

Blown No. 33 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty steering lock assembly(key interlock switch)

An open in the wire

BLI(BLU

Shift lever in ECheck for continuity to ground:

There should be continuity,

Faulty Ay'T gear position switch

Poor ground (G101)

An open in the wire

8WHT/BLK

Shift lever in @ and

pulled toward steering

wneel

Check for continuity to ground:

There should be continuity.

Faulty park pin switch

Shon to ground

Shift lever in ECheck for continuity to ground:

There should be no continuity.

Wire side of female terminals

Reconnect the interlock control unit 8P connector.

14-145

7WHT/RED

lgnition switch ON (ll)

and brake pedal

presseo

Check for voltage to ground:

There should be 1 V or less.

Faulty brake switch

Faulty throttle position (TP)

sensor

Faulty PCM

An open in the wire

Faulty interlock control unit

lgnition switch ON (lll,

brake pedal and accel-

erator pedal pressed at

the same time

Check for voltage to ground:

There should be baftery voltage,

www.emanualpro.com

Page 673 of 1395

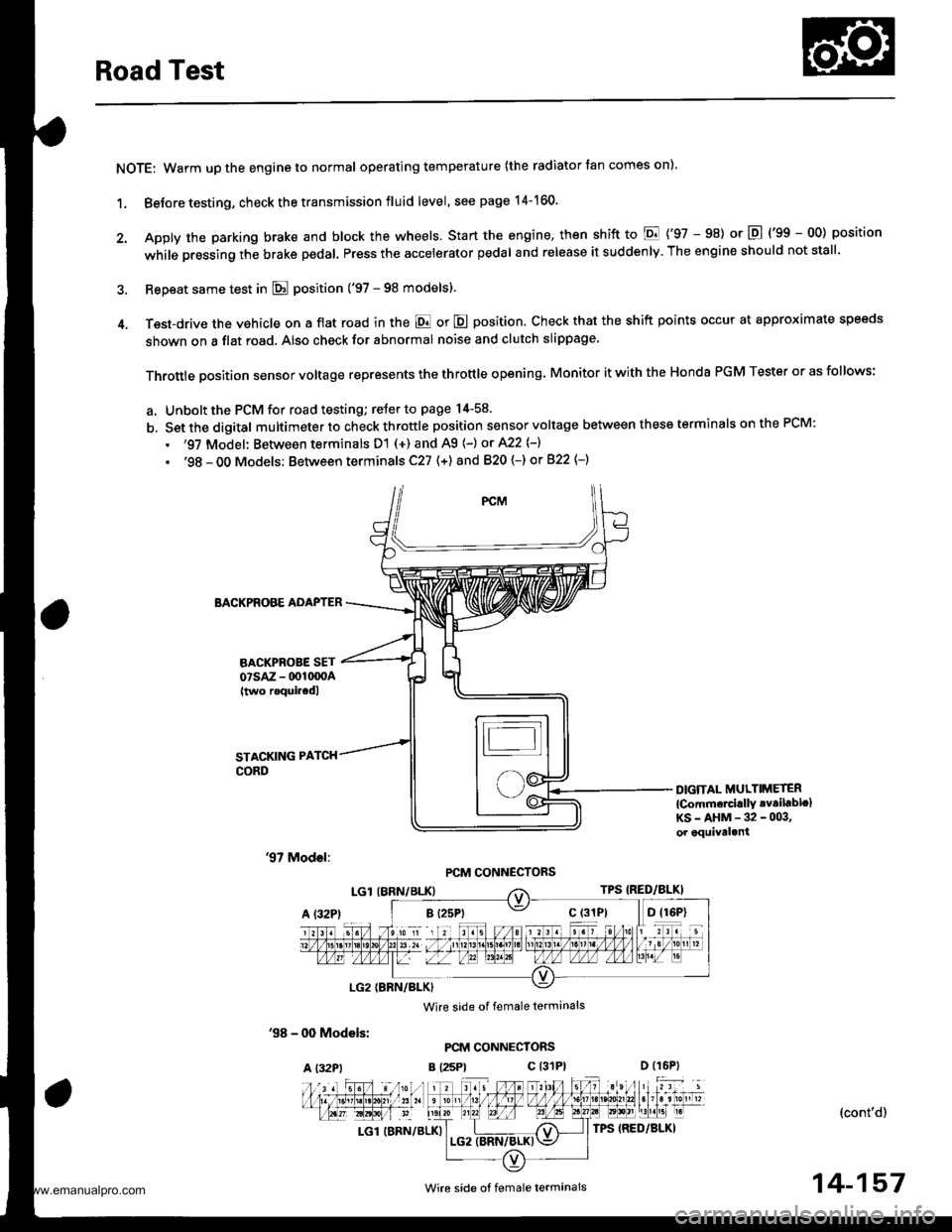

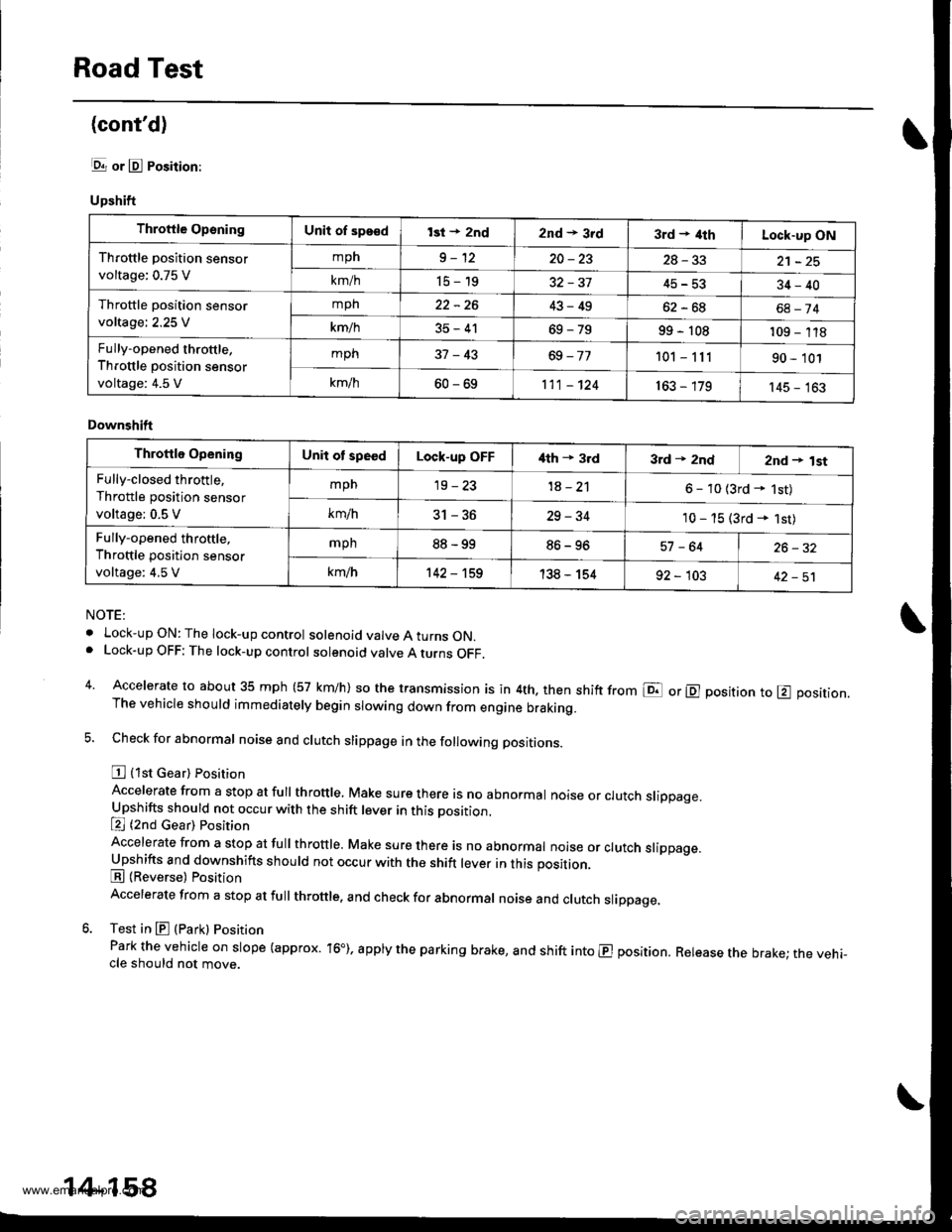

Road Test

NOTE: Warm up the engine to normal operating temperature (the radiator tan comes on).

1. Before testing, check the transmission fluid level, see page 14-160.

2. Apply the parking brake and block the wheels. start the engine, then shift to E {'97 - 98) or E {'gg - 00) position

while pressing the brake pedal. Press the accelerator pedal and release it suddenly. The engine should not stall.

3. Repeat same test in E position ('97 - 98 models).

4. Test-drive the vehicle on a flat road in the E or E position. Check that the shift points occur at approximate speeds

shown on a flat road. Also check for abnormal noise and clutch slippage.

Throttle position sensor voltage represents the throttle opening. Monitor it with the Honda PGM Tester or as follows:

a. Unbolt the PCM for road testing; reJer to page 14-58.

b. Set the digital multimeter to check throttle position sensor voltage between these terminals on the PCM:

. '97 Model: Between terminals D'! (+) and A9 (-) or A22 {-}

. '98 - OO Models; Between terminals C27 (+) and 820 (-) or 822 {-)

BACKPROBE ADAPTER

BACKPROBE SETorsAz - 001moA(two roquircdl

STACKING PATCH

CORD

DIGiTAL MULTIMETER

{Comm€rcirllY .vailablc}KS-AHM-32-003,or equival.nt

'97 Model:PCM CONNECTORS

'98 - 0O Models:

A l32Pt

Wire side of female terminals

PCM CONNECTORS

B {25Pt c l31P}

(cont'd)

LGl (BRN/BLK)

'. //B 1 l'o ti , jl. to a 2r / / 11111t1.t nait la t1 t213tr / t6t, tl / / / / 1 3 / 10n v

t-'a:IM-&E -Llfiffi-fl)\"".'E

Wire side ot female termanals14-157

www.emanualpro.com

Page 674 of 1395

Road Test

(cont'd)

lgrr or E Position:

Upshift

NOTE:

. Lock-upON:The lock-up control solenoid valve A turns ON.. Lock-up OFF: The lock-up control solenoid valve A turns OFF.

4. Accelerate to about 35 mph (57 km/h) so the transmission is in 4th. then shift from E or E position to E position.The vehicle should immediately begin slowing down from engine braking.

5. Check for abnormal noise and clutch slippage in the following positions.

E {1st Gear) Position

Accelerate from a stop at full throttle, Make sure there is no abnormal noise or clutch slippage.Upshifts should not occur with the shift lever in this position.

E (2nd cear) Position

Accelerate from a stop at fuI throttre. Make sure there is no abnormar noise or crutch srippage.Upshifts and downshifts should not occur with the shift lever in this position.

E (Reverse) Position

Accelerate from a stop at full throttle. and check for abnormal noise and clutch slippage.

6. Test in E (Park) Position

Park the vehicle on slope (approx. 16"), apply the parking brake, and shift into E position. Release the brake; the vehi-cle should not move.

Throftle OpsningUnit of sps€dlsi + 2nd2nd * 3rd3rd + ilthLock-up ON

Throttle position sensor

voltage: 0.75 V

mph9-1220-2328-33

km/h15-1945-5334-40

Throttle position sensor

voltage; 2.25 V

mph22-2643-49oz - ott68-74

km/h35-4169-7999 - 108109 - 118

Fully-opened throttle,

Throttle position sensor

voltage: 4.5 V

mph37-43101 - 11190 - 101

k-/h60-69111 - 124163 - 179145 - 163

Downshift

Throttle OpeningUnit ot speedLock-up OFFi{th + 3rd3rd * 2ndznd + lst

Fully-closed throttle,

Throttle position sensor

voltage; 0.5 V

mpn19-231A - 2'l6 - 10 {3rd - 1st)

km/h5t-5D29-3410 - 15 (3rd * 1st)

Fully-opened throttle,

Throttle position sensor

voltage: 4,5 V

mph88-9986-9657 -6426-32

km/h142 - 't59138 - 15492 - 10342-51

14-158

www.emanualpro.com

Page 1174 of 1395

![HONDA CR-V 1999 RD1-RD3 / 1.G Owners Manual

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1ll HONDA CR-V 1999 RD1-RD3 / 1.G Owners Manual

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1ll](/img/13/5778/w960_5778-1173.png)

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1l'l

c112

c113

c't 14

cl16

cl16

c117

c118

c119

c120

c121

c't22

c't23

c't25

cl26

cl27

cr 28

cl29

c130

c131

c132

c 133

c134

c134

c135

c 136

10

6

1

2

1

2

1

10

20

31

16

22

l0

l0'14

14

1

Left side of engine compartment

Left side of engine compartment

Middle of engine

Middle of engine

Left side of engine compartment

Left side of engine compartment

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Right side of engine

Middle of engine

Behind right kick panel

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Right side of engine

Right side of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Left side of engine compartment

Middle of engine

Middle of engine

Main wire harness (C304)

Main wire harness (C305):'97 - 98 models

No. 1 fuel injector

Crankshaft speed fluctuation (CKF) sensor

Alternator

Alternator

Engine oil pressure switch

No.2 fuel injector

Evaporative emission (EVAP) purge

control solenoid valve

No. 3 fuel injector

No. 4 fuel injector

Primary heated oxygen sensor(Primary HO2S) (sensor 1)

Radiator fan switch

Coolant temperature sending unit

Engine coolant temperature (ECT) sensor

Mainshaft speed sensor

Lock-up control solenoid valve

Back-up light switch

Shift control solenoid valve

Linear solenoid valve

Countershaft speed sesnsor

Starter solenoid

Distributor

Junction connector

PCM

ECIWPCM

ECM/PCM

ECM/PCM

Main wire harness (C,|:}1)

IVT gear position switch

Vehicle speed sensor (VSS)

Throttle position (TP) sensor

MAP sensor

ldle air control (lAC)valve

lntake air temperature (lAT) sensor

Junction connector

Junction connector

Power steering pressure (PSP) switch

Junction connector

Knock sensor (KS)

A/r

USA

Canada

Alr

AlT

M/'r

Afi

'97mooel

'97 model'98 - 00

mooets

'99 - 00

models

T101

r102

Left side of en0ine companment

Right side of engine compartment

Alternator

Under-hood fuse/relay box

G101Middle of engineEngine ground, via engine wire harness

23-14

www.emanualpro.com