connector a HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1141 of 1395

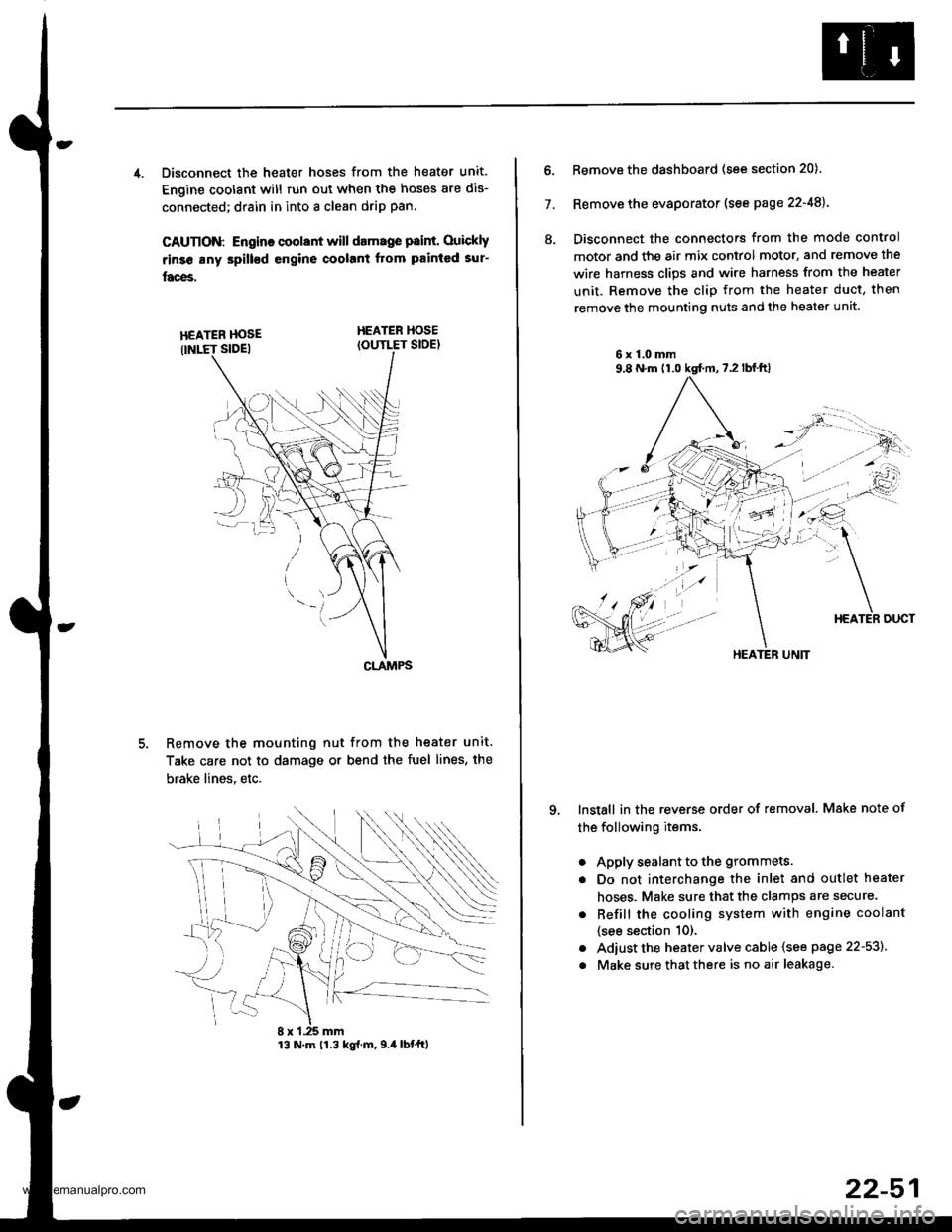

4. Disconnect the heater hoses from the heater unit.

Engine coolant will run out when the hoses are dis-

connected; drain in into a clean drip pan.

CAUTION: Engino coolant will damage p8int. Ouickly

rinse any spill€d engine coolant Itom painted sur-

faces.

HEATER HOSEIOUTLET SIDE)

Remove the mounting nut from the heater unit.

Take care not to damage or bend the fuel lines, the

brake lines. etc.

CLAMPS

13 N.m 11.3 kg{.m,9.4 lbtftl

22-51

7.

ll.

Remove the dashboard (see section 20).

Remove the evaporator (see page 22-48).

Disconnect the connectors from the mode control

motor and the air mix control motor, and remove the

wire harness clips and wire harness from the heater

unit. Remove the clip from the heater duct, then

remove the mounting nuts and the heater unit

6x1.0mm9,8 N.m (1.0 kgt m,7.2lblft)

qInstall in the reverse order of removal. Make note of

the following items.

a

a

a

a

Apply sealant to the grommets.

Do not interchange the inlet and outlet heater

hoses. Make sure that the clamps are secure.

Refill the cooling system with engine coolant

{see section 10).

Adiust the heater valve cable (see page 22-53).

Make sure that there is no air leakage.

HEATER UNIT

www.emanualpro.com

Page 1152 of 1395

Compressor

Replacement

lf the compressor is marginally operable. run the

engine at idie speed, and let the air conditioner

work for a few minutes. then shut the engine off.

Disconnect the negative cable from the battery.

Recover the refrigerant with a recovery/recycling/

charging station (see page 22-59).

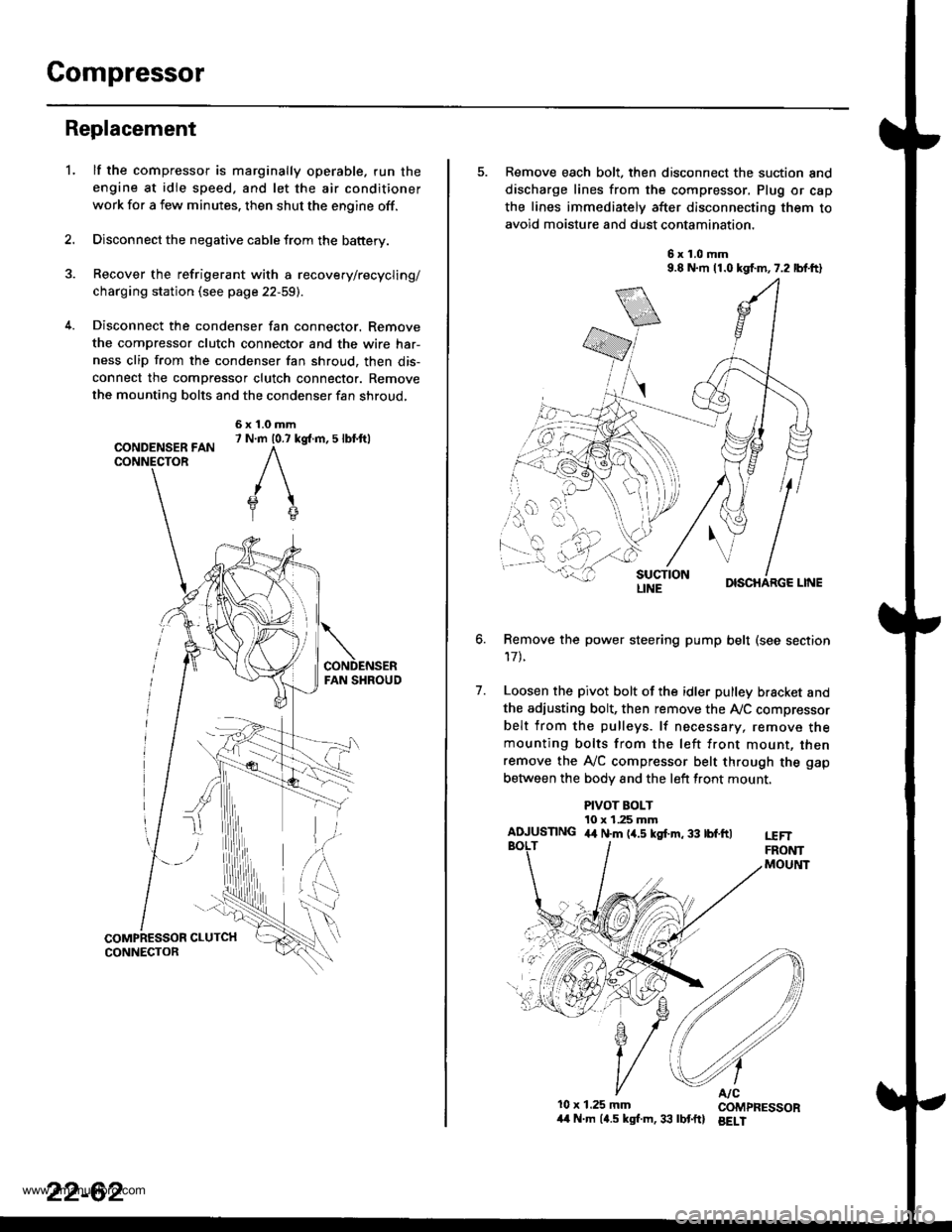

Disconnect the condenser fan connector. Remove

the compressor clutch connector and the wire har-

ness clip from the condenser fan shroud, then dis-

connect the compressor clutch connector. Remove

the mounting bolts and the condenser fan shroud,

CONDENSER FANCONNECTOR

6x1.0mm7 N.m 10.7 kg{.m, 5 lbl.ftl

'L

2.

5. Remove each bolt, then disconnect the suction and

discharge lines from the compressor. Plug or cap

the lines immediately after disconnecting them to

avoid moisture and dust contamination,

6x1.0mm9.8 N.m 11.0 kgf.m,7.2 lbf.ft)

DISCHARGE LINE

Remove the power steering pump belt (see section

17t.

Loosen the pivot bolt of the idler pulley bracket and

the adiusting bolt, then remove the Ay'C compressor

belt from the pulleys. lf necessary, remove themounting bolts from the left front mount, thenremove the A,/C compressor belt through the gap

between the bodv and the left front mount.

6.

7.

PIVOT BOLT10 x 1.25 mmAIUUSTING 4,t N.m (4.5 kgf.m, 33 tbf.ftlt€FTFRONTMOUltlT

10x 1.25 mm COMPRESSOR/t4 N.m (4.5 kgl.m,33 lbtftl BELI

LINE

www.emanualpro.com

Page 1155 of 1395

Clutch Inspection

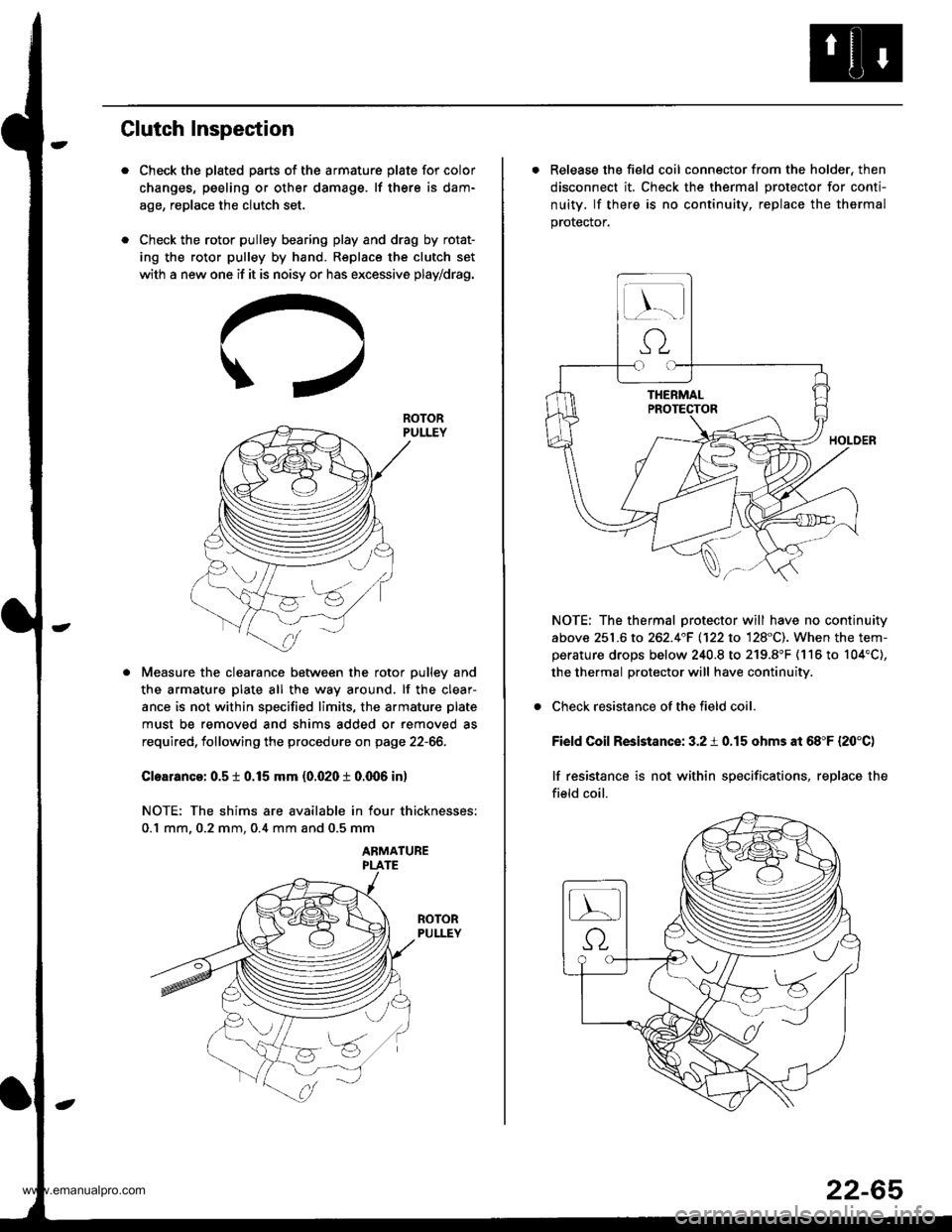

Check the plated parts of the armature plate for color

changes, peeling or other damage. lf there is dam-

age, replace the clutch set.

Check the rotor pulley bearing play and drag by rotat-

ing the rotor pulley by hand. Replace the clutch set

with a new one if it is noisy or has excessive play/drag.

Measure the clearance between the rotor pulley and

the armature plate all the way around. lf the clear-

ance is not within specified limits, the armature plate

must be removed and shims added or removed as

required, following the procedure on page 22-66.

Cloarance: 0.5 t 0.15 mm {0.020 t 0.q)6 in)

NOTE: The shims are available in four thicknesses:

0.1 mm. 0.2 mm. 0.4 mm and 0.5 mm

ABMATUBE

ROTOR

. Release the field coil connector from the holder, then

disconnect it. Check the thermal protector for conti-

nuity, lf there is no continuity, replace the thermal

prorecror.

NOTE: The thermal protector will have no continuity

above 251.6 to 262.4"F 1122 to 128"C). When the tem-perature drops below 240.8 to 219.8"F (116 to 104'C),

the thermal protector will have continuity.

Check resistance of the field coil.

Field Coil Resistance: 3.2 i 0.15 ohms at 68"F {20'C)

lf resistance is not within specifications, replace the

field coil.

22-65

www.emanualpro.com

Page 1157 of 1395

l-

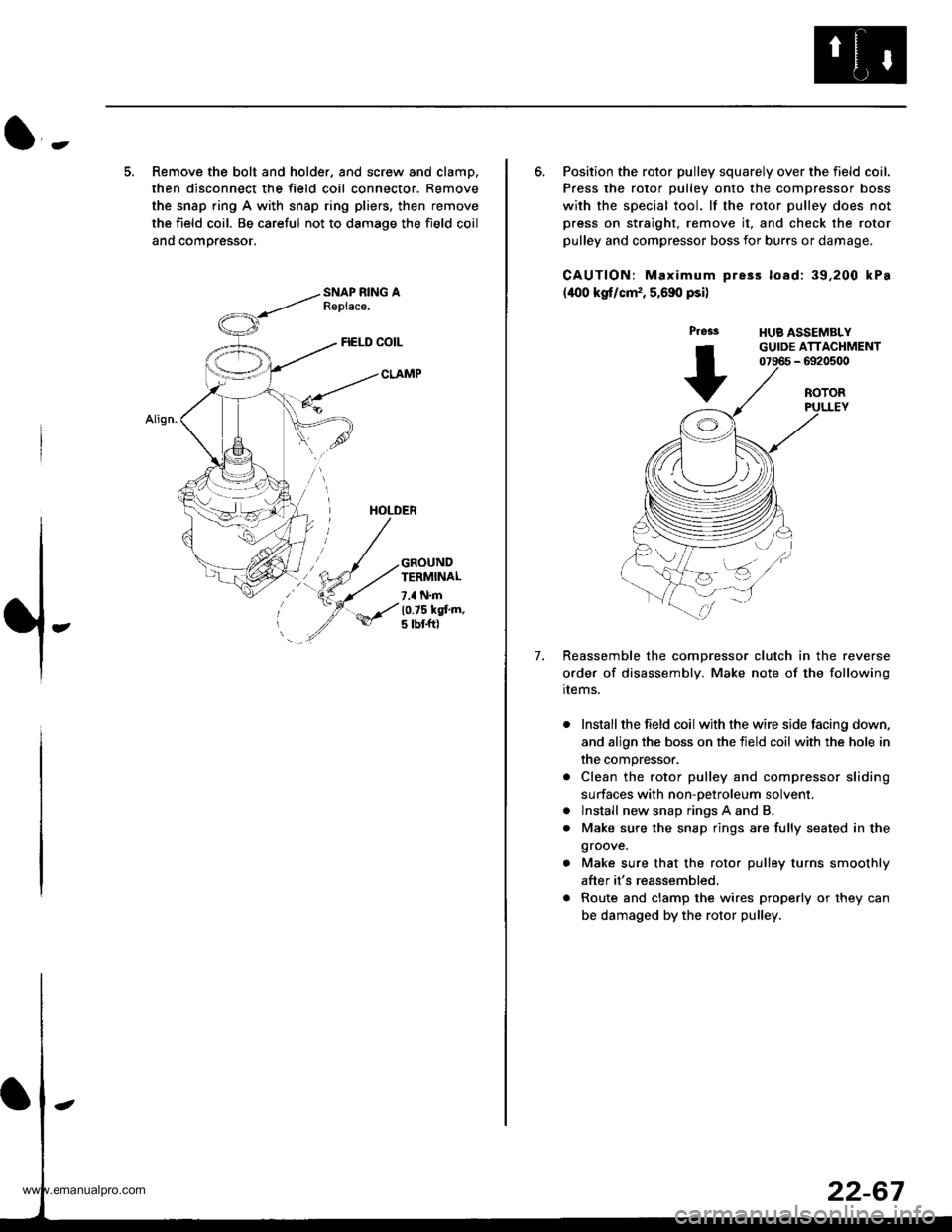

5. Remove the bolt and holder, and screw and clamp.

then disconnect the field coil connector. Remove

the snap ring A with snap ring pliers, then remove

the field coil. Be careful not to damage the field coil

and comoressor.

FIELD COIL

CLAMP

HOLDER

GROUNDTERMINAL

7,a N.m

10.75 kgt'm,5 tbt ftl

6. Position the rotor pulley squarely over the field coil.

Press the rotor pulley onto the compressor boss

with the special tool. lf the rotor pulley does not

press on straight, remove it, and check the rotor

pulley and compressor boss for burrs or damage.

CAUTION: Maximum pre3s load: 39,200 kPa

(400 kgf/cm,, 5,690 psi)

Press

+

HUB ASSEMBLYGUIDE ATTACHMENT07966 - 6920500

7.

ROTORPULLEY

Reassemble the comDressor clutch in the reverse

order of disassembly. Make note of the following

rrems.

Install the field coil with the wire side facing down,

and align the boss on the tield coil with the hole in

the compressor.

Clean the rotor pulley and compressor sliding

surfaces with non-oetroleum solvent.

lnstall new snap rings A and B.

Make sure the snap rings are fully seated in the

groove.

Make sure that the rotor pulley turns smoothly

after it's reassembled.

Route and clamp the wires properly or they can

be damaged by the rotor pulley.

a

a

www.emanualpro.com

Page 1158 of 1395

Compressor

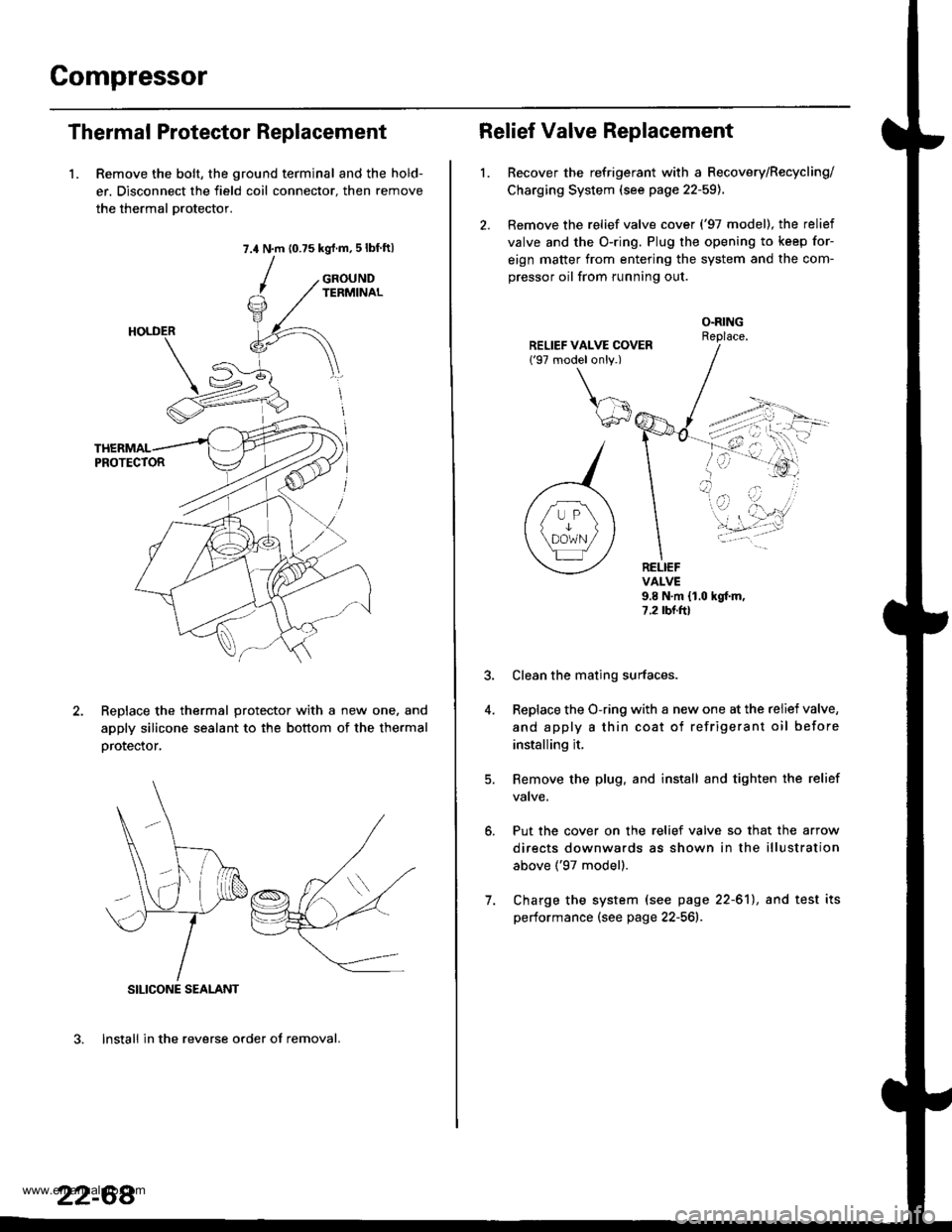

Thermal Protector Replacement

1. Remove the bolt, the ground terminal and the hold-

er. Disconnect the field coil connector. then remove

the thermal Drotector.

7.4 N.m (0.75 kgrf.m,5lbf ftl

GROUNDTERMINAL

ReDlace the thermal protector with a new one, and

apply silicone sealant to the bottom of the thermal

orotector,

3. lnstall in the reverse order of removal.

SILICONE SEALANT

22-68

Relief Valve Replacement

l.Recover the refrigerant with a Recovery/Recycling/

Charging System (see page 22-59).

Remove the relief valve cover ('97 model), the relief

valve and the O-ring. Plug the opening to keep for-

eign matter from entering the system and the com-

pressor oil from running out.

O.RINGReplace.

RELIEFVALVE9.8 N.m {1.0 hgf.m,7.2 rbr.ftl

Put the cover on the relief valve so that the arrow

directs downwards as shown in the illustration

above ('97 model).

Clean the mating surfaces.

Replace the O-ring with a new one at the relief valve,

and apply a thin coat of refrigerant oil before

installing it.

Remove the plug. and install and tighten the relief

valve.

7. Charge the system (see page 22-61), and test its

performance (see page 22-561r.

www.emanualpro.com

Page 1161 of 1395

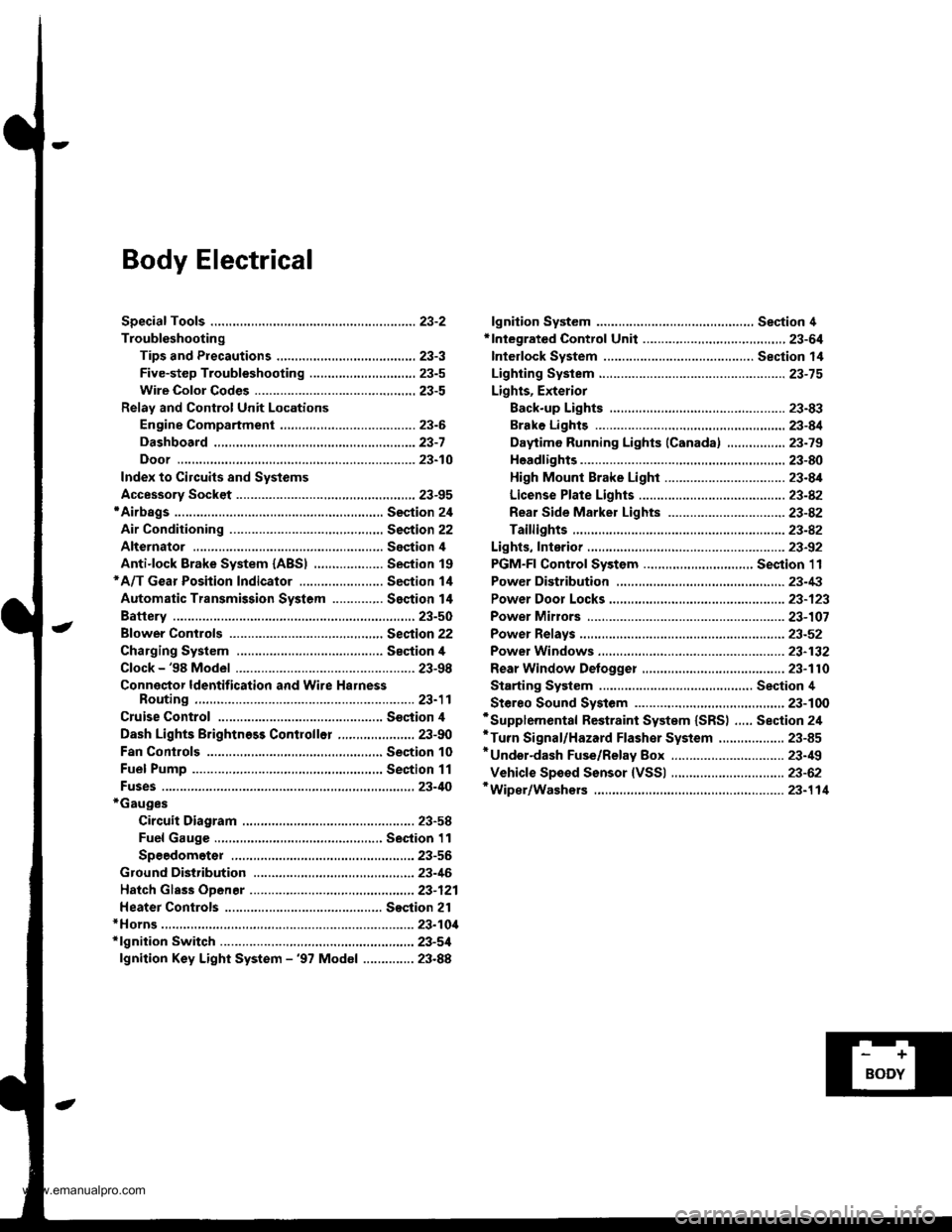

Body Electrical

Speciaf Toofs ,...,..,.............-.23-2

Troubleshooting

Tips and Precautions ......,.,..........,.................. 23-3

Five-step Troubleshooting ........,.,.,...,,.,......... 23-5

Wire Color Codes ...,....,.. 23-5

Relay and Control Unit Locations

Engine Compartment ..,.,......,......................... 23-6

Dashboard ,.,.,..............-.- 23-7

Door ....................... .........23-10

Index to Cilcuits and Sysiems

Accessory Socket .. ,....,.,..,.,. 23-95*Airbags ................ .,....,. Sestion 24

Air Conditioning ,.,.,.... Section 22

Alternator ................... Section 4

Anti-lock Brake System {ABSI ................... Section 19'A/T Gear Position Indicator ....................... Section 1,1

Automatic Transmission System ...........,.. Section 14

Battery ................... ..............23-50

Blower Controls .,...,.,, Section 22

Charging System ....... Seqtion il

Clock -'98 Model ................ 23-98

Connector ldentification and Wire HarnessRouting .................. ......... 23.11

Cruise Control ............ Ssction 4

Dash Lights Brightness Contlo||er ..................... 23-90

Fan Conlrols ...,......,.... Section 10

Fuel Pump ,..,.,...,....,.... Section 11

Fuses...................... .,,.,.,.,.,,.,23-40*Gauges

Circuit Diagram ......-....-..23-58

Fuel Gauge .....,.,..... Section 11

Speedometer ..,..........,... 23-56

Ground Distribution ,....,.,...23-46

Hatch Glsss ODenor .........................,.,.,.,.,..,.,.,.,,. 23-121

Heater Controls .-........ Soction 21*Horns.,...,..,.,.,....... ................23"104*fgnition Switch ,,.,.,..,.,.,,.,.,.,23-51

lgnition Key Light System -'97 Mod6l .............. 23.88

-+

BODY

www.emanualpro.com

Page 1163 of 1395

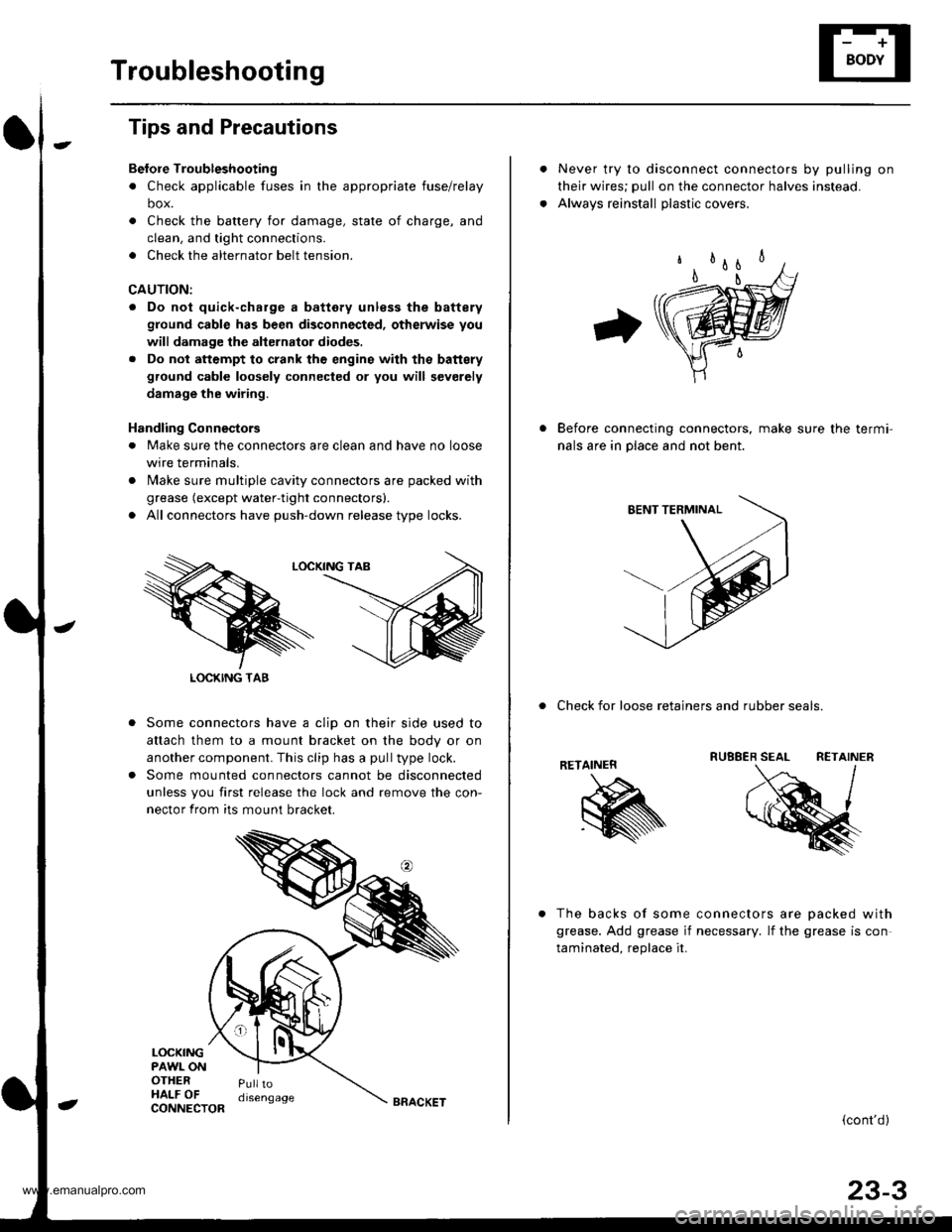

Troubleshooting

Tips and Precautions

Bef ore Troubleshootin g

. Check applicable fuses in the appropriate fuse/relay

box.

. Check the battery for damage, state of charge, and

clean. and tight connections.

. Check the alternator belt tension.

CAUTION:

. Do not quick-charge a battery unless the battery

ground cable has been disconnected, otherwise you

will damage the alternator diodes.

. Do not attempt to crank thc engins wilh the battery

ground cable loosely connected or you will severely

damage the wiring.

Handling Connestors

. Make sure the connectors are clean and have no loose

wire terminals,

. N4ake sure multiple cavity connectors are packed with

grease (except water-tight connectors).

. All connectors have push-down release type locks.

Some connectors have a clip on their side used to

attach them to a mount bracket on the body or on

another component. This clip has a pull type lock.

Some mounted connectors cannot be disconnected

unless you first release the lock and remove the con-

nector from its mount bracket.

LOCKINGPAWL ONOTHERHALF OFPulltodisengage

LOCKING TAB

CONNECTORBRACKET

Never try to disconnect connectors by pulling on

their wires; pull on the connector halves instead.

Alwavs reinstall olastic covers.

Before connecting connectors, make sure the termi-

nals are in place and not bent.

. Check for loose retainers and rubber seals.

RETAINER

The backs of some connectors are oacked with

grease. Add grease if necessary. lf the grease is con

taminated. reolace it.

{cont'd}

23-3

www.emanualpro.com

Page 1164 of 1395

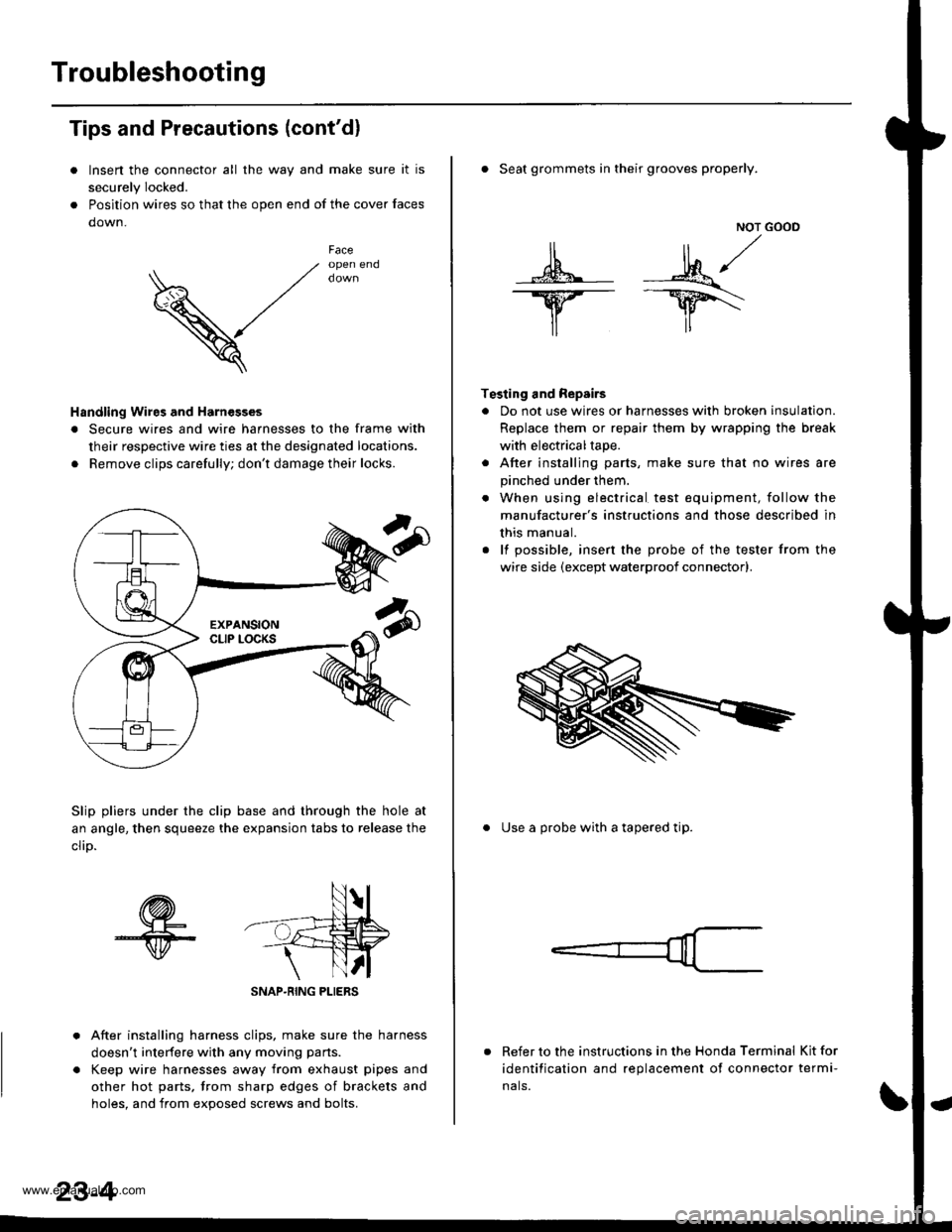

Troubleshooting

Tips and Precautions (cont'dl

Insen the connector all the way and make sure it is

securely Iocked.

Position wires so that the open end of the cover faces

down.

V

Faceopen end

Handling Wires and Harnesges

. Secure wires and wire harnesses to the frame with

their respective wire ties at the designated locations.

. Remove clips carefully; don't damage their locks.

Slip pliers under the clip base and through the hole at

an angle, then squeeze the expansion tabs to release the

clrD.

After installing harness clips, make sure the harness

doesn't interfere with any moving pans.

Keep wire harnesses away from exhaust pipes and

other hot parts, trom sharp edges of brackets and

holes. and from exoos€d screws and bolts.

NOT GOOD

A -M/

lr lr*

T€sting and Repairs

. Do not use wires or harnesses with broken insulation.

Replace them or repair them by wrapping the break

with electricaltape.

. After installing parts, make sure that no wires are

pinched under them.

. When using electrical test equipment, follow the

manufacturer's instructions and those described in

this manual.

. lf possible, insert the probe of the tester from the

wire side (except waterproof connector).

. Seat grommets in their grooves properly.

. Use a probe with a tapered tip.

Refer to the instructions in the Honda Terminal Kit for

identification and replacement of connector termi-

nals.

www.emanualpro.com

Page 1171 of 1395

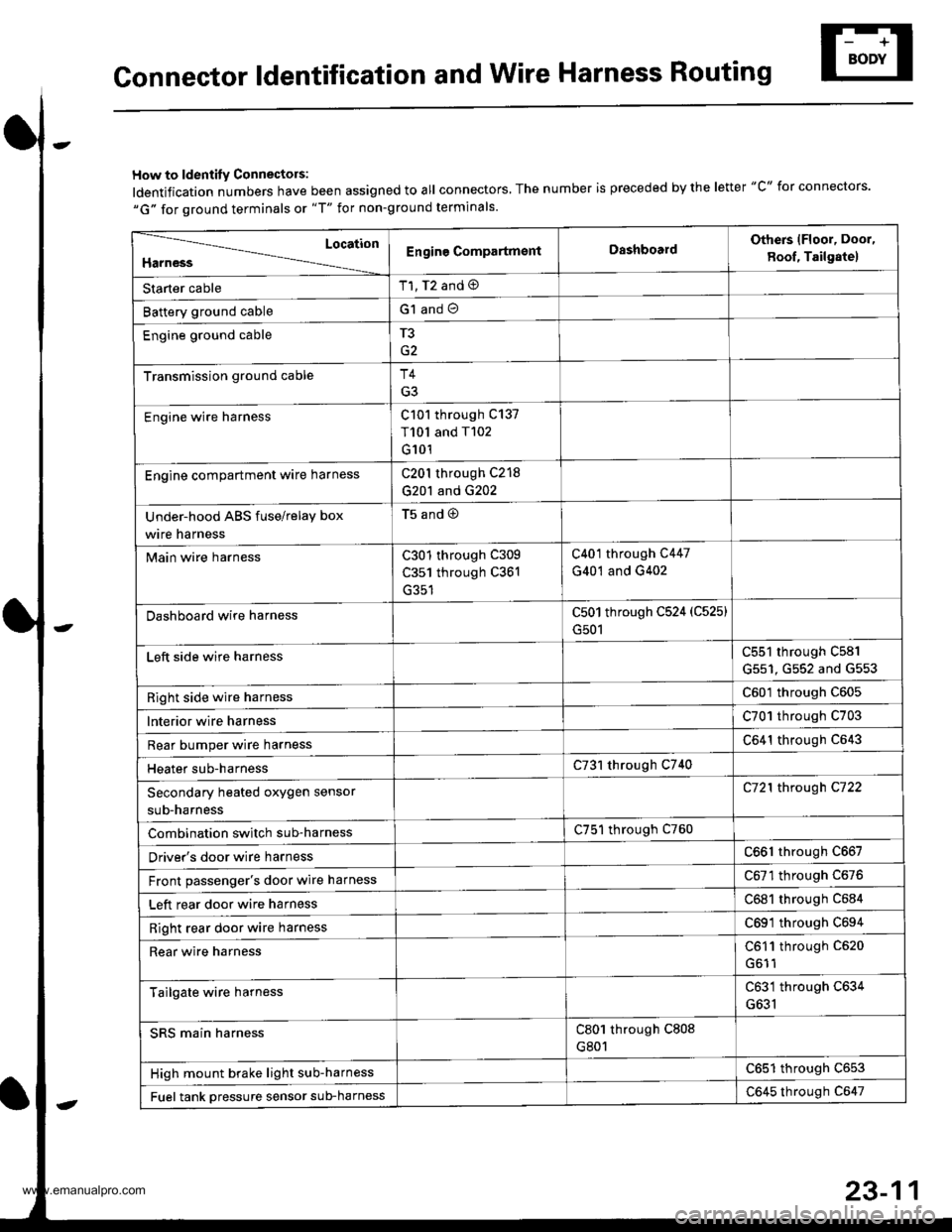

Gonnector ldentification and Wire Harness Routing

How to ldentity Connectors:

ldentification numbers have been assigned to all connectors, The number is preceded by the letter "C" for connectors.

"G" for ground terminals or "T" for non-ground terminals.

Location

HarnessEngine CompartmsntDashboardOthers lFloor, Door,

8oof, Tailgate)

Starter cableT1, T2 and @

Battery ground cableG1 and O

Engine ground cableT3

Transmission ground cableT4

G3

Engine wire harnessC101 through C137

T101 and T102

G101

Engine compartment ware harnessC201 through C218

G201 and G202

Under-hood ABS fuse/relay box

wire harness

t5ano9

Main wire harnessC301 through C309

C351 through C361

C401 through C447

G401 and G402

Dashboard wire harnessC501 through C524 (C525)

G501

Left side wire harnessC551 through C581

G551, G552 and G553

Right side wire harnessC601 through C605

lnterior wire harnessC701 through C703

Rear bumper wire harnessC641 through C643

Heater sub-harnessC731 through C740

Secondary heated oxygen sensor

sub-harness

C721 through C722

Combination switch sub-harnessC751 through C760

Driver's door wire harnessC661 through C667

Front passenger's door wire harnessC6Tl through C676

Left rear door wire harnessC681 through C684

Right rear door wire harnessC69'l through C694

Rear wire harnessC611 through C520

Tailgate wire harnessC631 through C634

G631

SRS main harnessC801 through C808

G801

High mount brake light sub-harnessC651 through C653

Fuel tank oressure sensor sub-harnessC645 through C647

www.emanualpro.com

Page 1172 of 1395

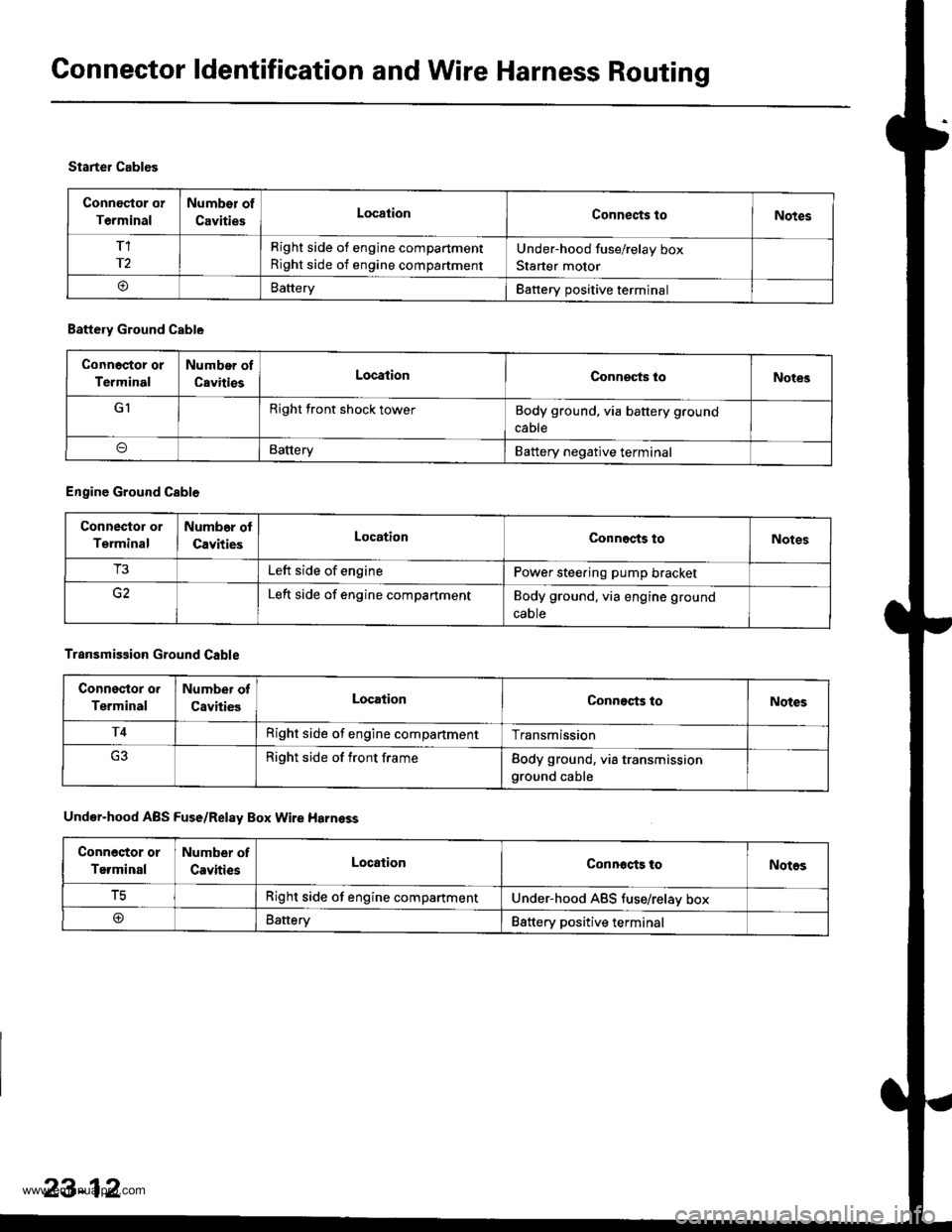

Connector ldentification and Wire Harness Routing

Connoctor or

Terminal

Number of

CavitiesLocationConnects toNotes

T1

r2

Right side of engine compartment

Right side of engine compartment

Under-hood fuse/relay box

Starter motor

oBatteryBattery positive terminal

Starter Cables

Battery Ground Cable

Connoctor or

Terminal

Number of

CavitiesLocationConneqts loNotes

GIRight front shock towerBody ground, via battery ground

cable

BatteryBattery negative terminal

Engine Ground Cable

Connector or

Terminal

Numb6r ol

CavitiesLocationConnects toNotes

T3Left side of enginePower steering pump bracket

Left side of engine compartmentBody ground. via engine ground

caote

Transmission Ground Cable

Connsstor o.

Terminal

Number of

CavitiesLocationConnects toNotes

T4Right side of engine compartmentTransmission

Right side of front frameBody ground, via transmissionground cable

Under-hood ABS Fuse/Relay Box Wire Harnsss

Conn6stor or

Terminal

Number of

CavitiesLocationConnocts toNotos

tcRight side of engine compartmentUnder-hood ABS tuse/relav box

@Battery88ttery positive terminal

23-12

www.emanualpro.com