connector a HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1240 of 1395

Lighting SystemHeadlights

Dafime Running Lights Resistor

Test (Canada)

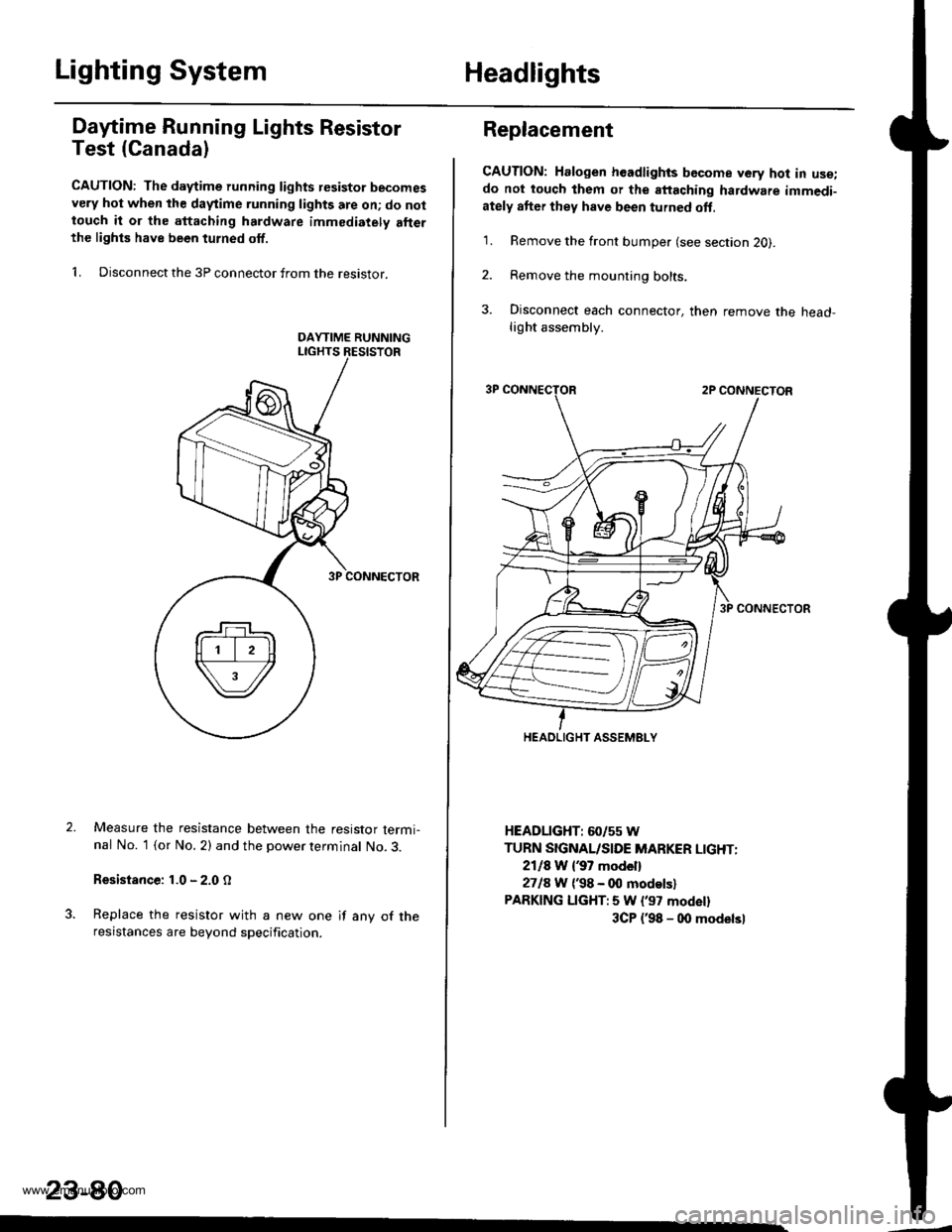

CAUTION: The d.ytime running lights resistor becomesvery hot when the daytime running lights are on; do nottouch it or the attaching hardware immediately allerthe lighls have been turned off.

1. Disconnect the 3P connector from the resistor.

Measure the resistance between the resistor termi-nal No. 1 (or No. 2) and the power terminal No. 3.

Resistance: 1.0 - 2.0 O

Replace the resistor with a new one if any of theresistances are beyond specification.

23-80

Replacement

CAUTION: Halogen headlights bGcome very hot in use;do not touch them or the attaching hardware immedi-ately after they have been turned oft.

1. Remove the front bumper (see section 2O).

2. Remove the mounting bolts.

3. Disconnect each connector, then remove the head-light assembly.

HEADLIGHT: 60/55 W

TURN SIGNAL/SIDE MARKER LIGHT:

2118 W {37 model}

2718 W ('98 - 00 modelsl

PARKING LIGHT:5 W l'97 modell

3CP {'98 - 00 modelsl

HEADLIGHT ASSEMELY

www.emanualpro.com

Page 1242 of 1395

Rear Side Marker Lights/

License Plate LightTaillights

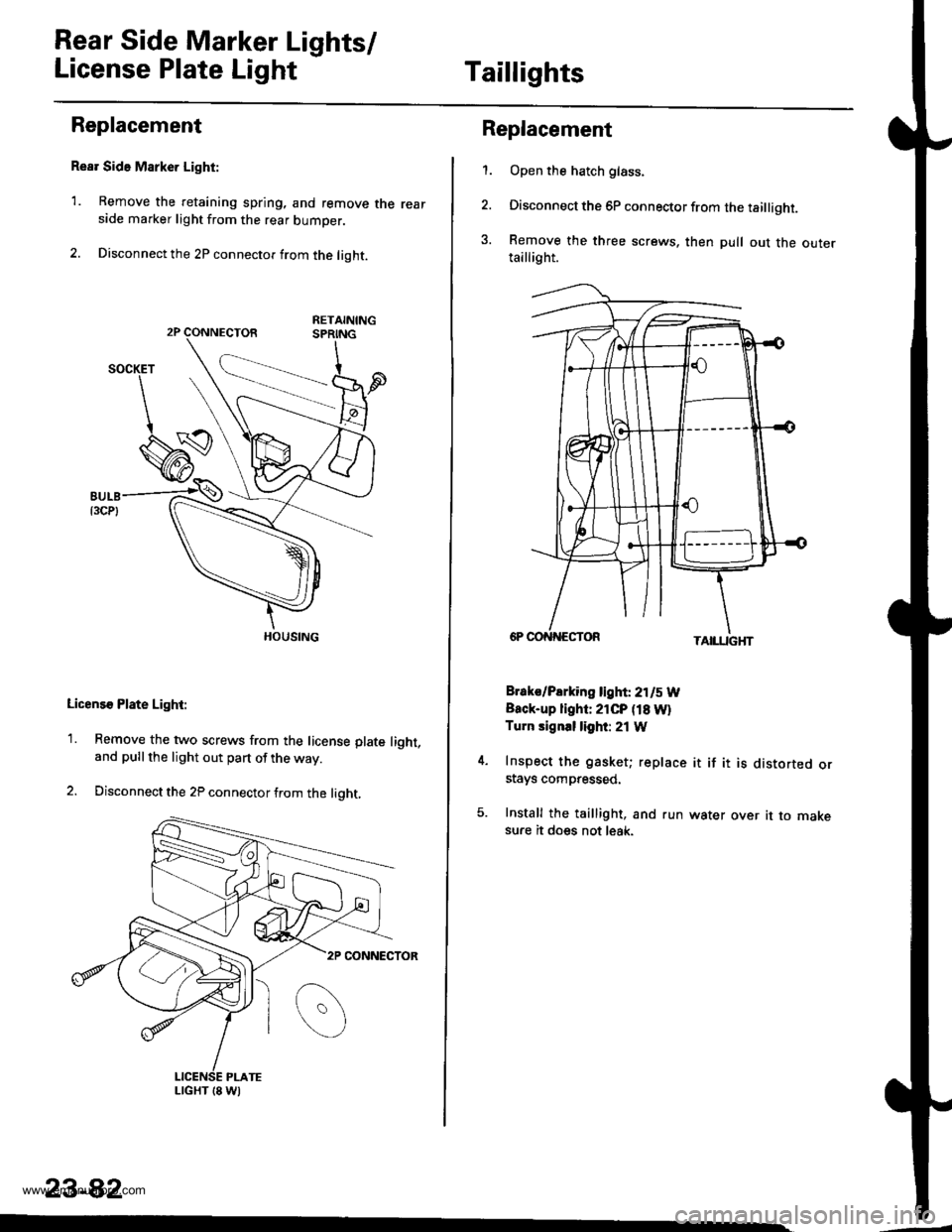

Replacement

Rear Side Marke. Light:

1. Remove the retaining spring, and remove the rearside marker light from the rear bumper.

2. Disconnect the 2P connector from the light.

RETAINING

HOUSING

Licens€ Plate Light:

1. Remove the two screws from the license plate light,and pull the light out part of the way.

2. Disconnect the 2P connector from the light,

23-A2

LIGHT (8 WI

Replacement

1. Open the hatch glass.

2. Disconnect the 6P connector from the taillight.

3. Remove the three screws, then pull out the outertaillight.

Brak€/Plrking light 2115 W

Back-up light: 21CP (18 W)

Turn signll light 21 W

Inspect the gasket; replace it if it is distorted or$ays compressed.

Install the taillight, and run water over it to makesure it does not leak.

www.emanualpro.com

Page 1244 of 1395

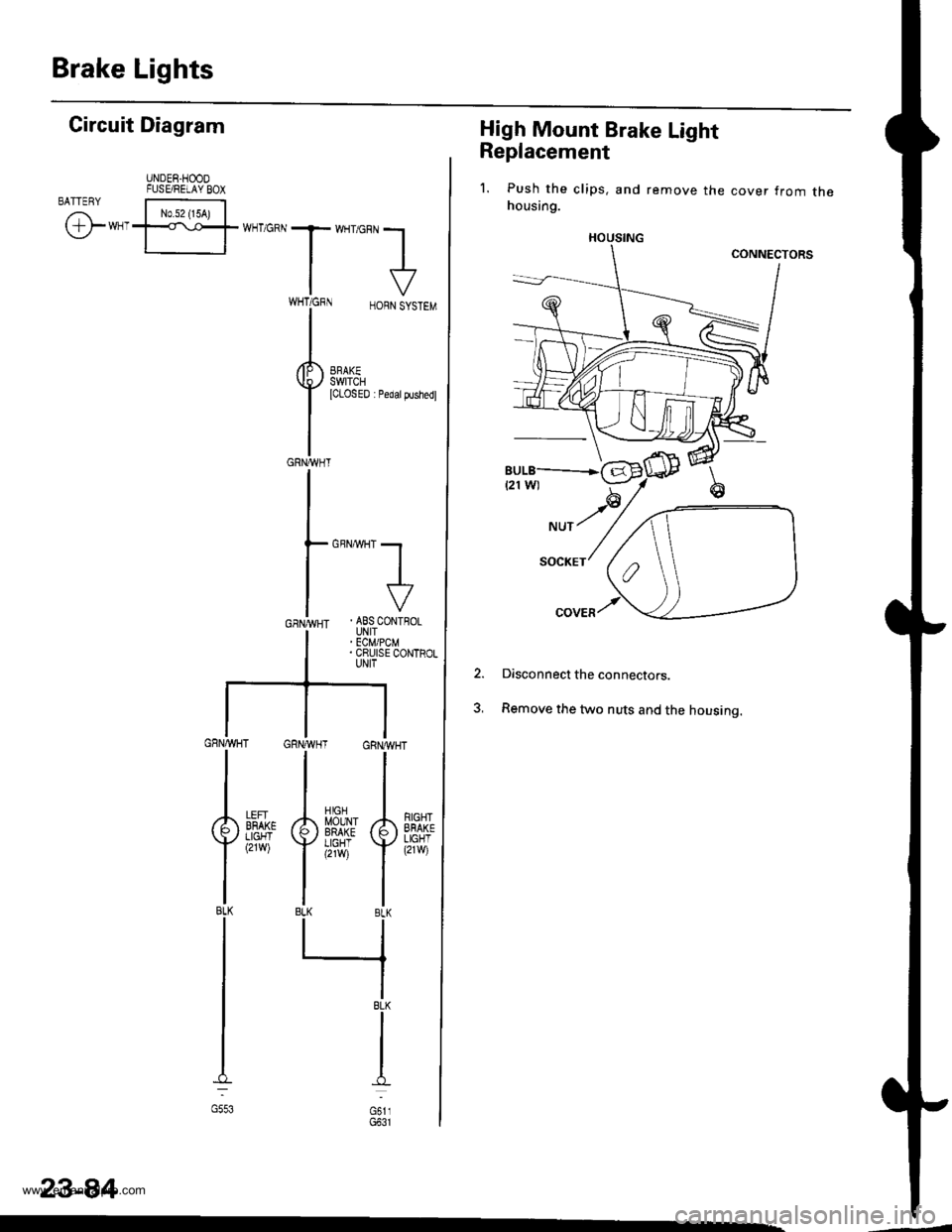

Brake Lights

High Mount Brake Light

Replacement

1. Push the clips, and remove the cover from thehousing.

Disconnect the connectors.

Remove the two nuts and the housing.

2.

HOUSING

Gircuit Diagram

UNDER.HOODFUSE/RELAY BOXBATTENY

/,i | No.s2 {15A) |

\Y*-I=f*-'o*T*'no"l

IV

T:,^-,

HORNSYSTEM

I

i.t53l| *",*"",

GRNA,VHT

GBNMHT -.1

I

I

. ABS CONTFOLUNIT' ECM/PCM. CRUISE CONTROLUNIT

GRNAVHT GRNWH

ll

tl

A[$^Jlr A

Yi,?'il Y

tlBLK BLK

llrl

IBLK

I

I

d

oi,,

RIGHTEFAKELIGHT(21w)

LEFIBFAKELIGHT(2rw)

BLK

G553

23-84

www.emanualpro.com

Page 1245 of 1395

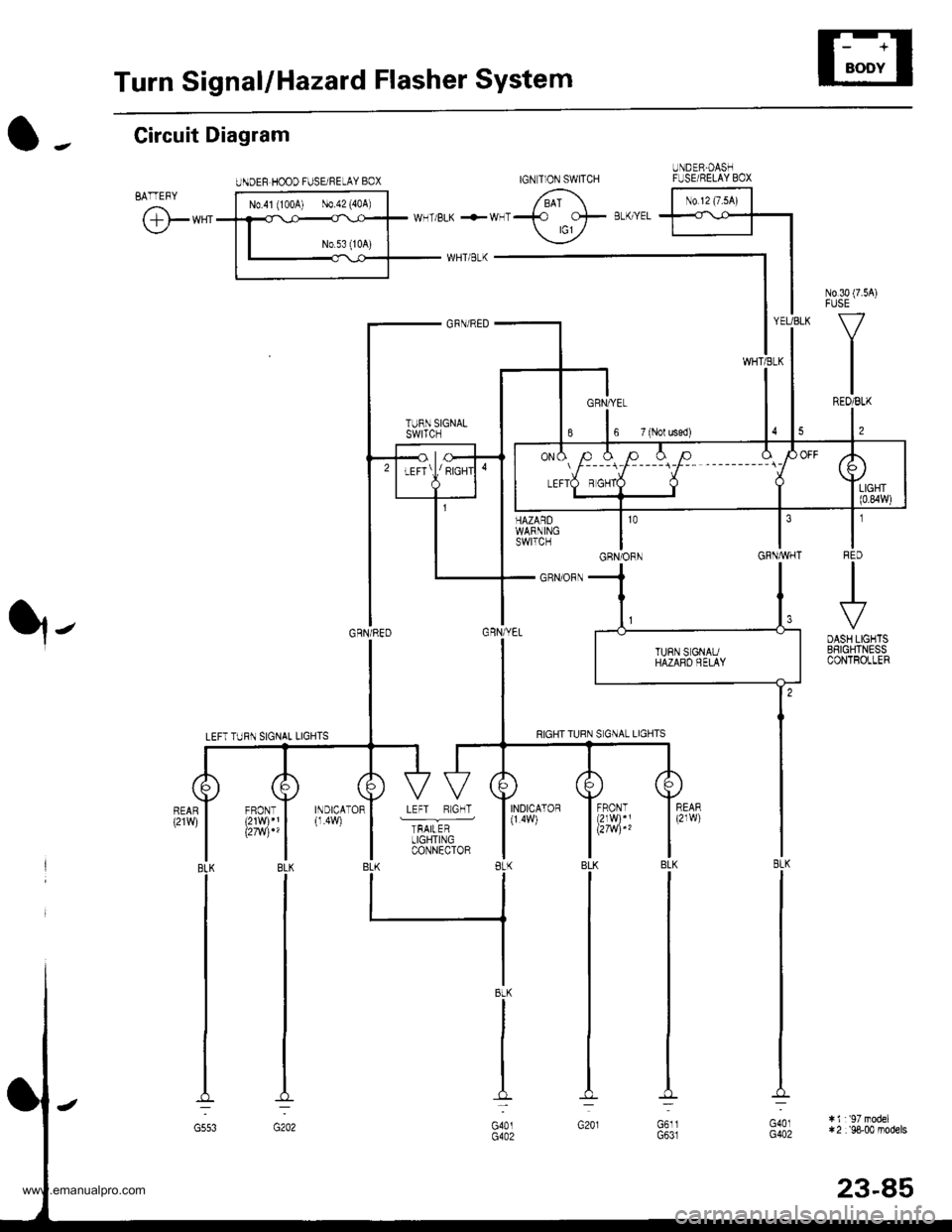

Turn SignallHazard Flasher System

UNDEF HOOD FUSE/NELAY BOX

N0.30 (7.54)FUSE

V

IREO/BLK

l,

t'IFqD

.+

DASH LIGHTSBSIGHTNESSCONTROLLER

HAZARDWARNINGswtTcH

_ GRN/ORN

YEUBLK

WHTiELK

GRNAVHT

O -. Circuit Diagram

BATTEFY

@**'

q-

103

GRN/ORN

INDICATOR

TFAILERLIGHTINGCONNECTOR

INDICATOR(1.4W)

BLK

G553

IGN T]ON SWITCHUNDER.OASHFUSE/RELAY BOX

No 12 (7.sA)

l----r-l-----i-F-- --------_ \

BtK

G401G402

:i1r'97model*2 :'98-00 models

23-85

www.emanualpro.com

Page 1247 of 1395

![HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

Turn Signal Switch Test

1.

4.

Remove the drivers dashboard lower cover and the

knee bolster (see section 20).

Remove the steering column covers {see section

17]-.

Disconnect the 4P and 7P connectors HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

Turn Signal Switch Test

1.

4.

Remove the drivers dashboard lower cover and the

knee bolster (see section 20).

Remove the steering column covers {see section

17]-.

Disconnect the 4P and 7P connectors](/img/13/5778/w960_5778-1246.png)

Turn Signal Switch Test

1.

4.

Remove the driver's dashboard lower cover and the

knee bolster (see section 20).

Remove the steering column covers {see section

17]-.

Disconnect the 4P and 7P connectors from the

switch.

Remove the screws, and slide the switch toward the

driver's door.

Check for continuity between the terminals in each

switch position according to the table.

Position

Terminal12

RIGHTo-

Neutral

LEFTo---o

q

tl-

swtTcH

Hazard Warning Switch Test

1. Remove the center panel {see section 20).

2. Remove the two screws, then remove the switch

from the center air vent.

HAZARD

Check for continuitv between the terminals in each

switch position according to the table.

Terminal

t**--\

2357810

OFF(9U(_)

ONo@oooo

lNol us€d)

23-87

www.emanualpro.com

Page 1249 of 1395

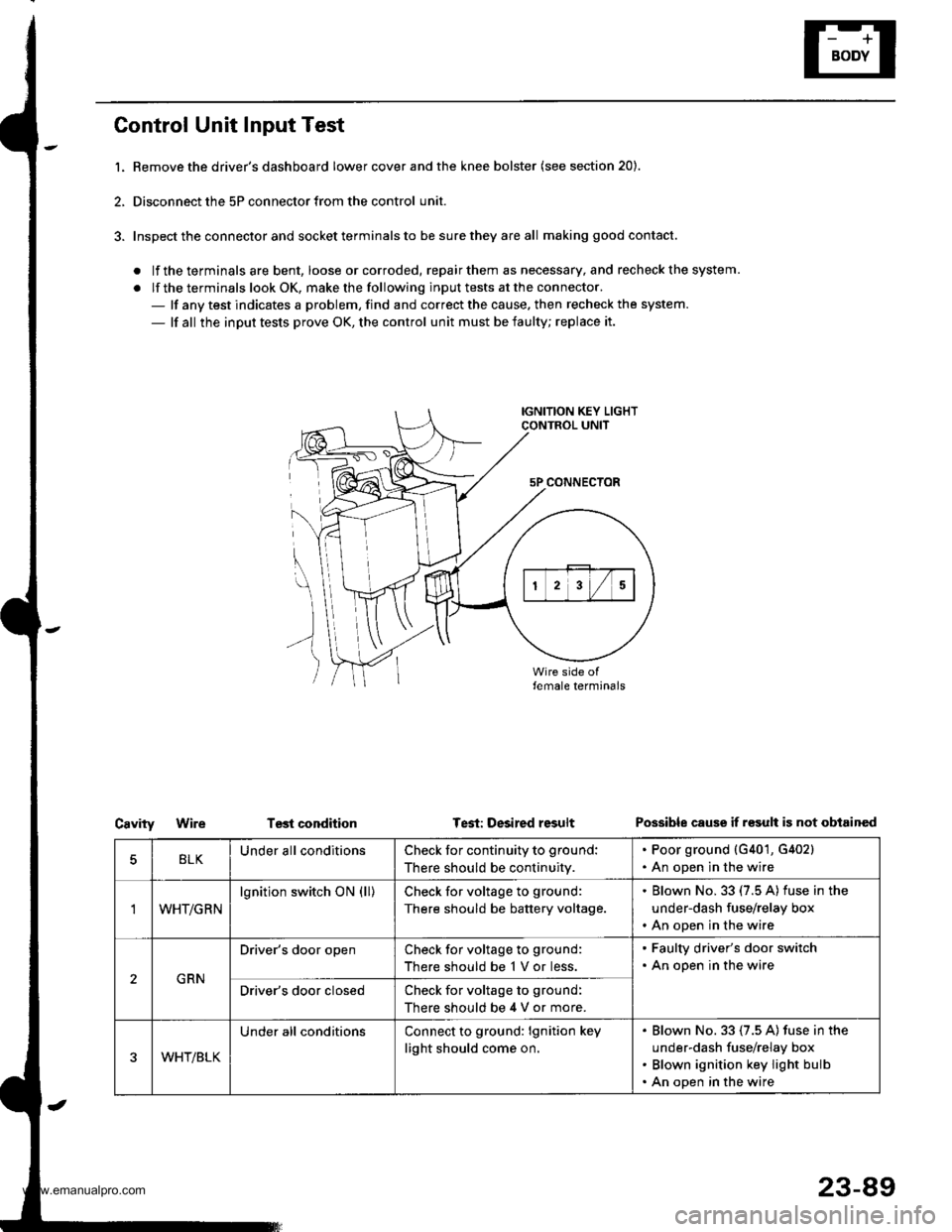

Control Unit Input Test

l. Bemove the driver's dashboard lower cover and the knee bolster (see section 20).

2, Disconnect the 5P connector from the control unit.

3. Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose orcorroded, repairthem as necessary, and recheck the system.

. lf the terminals look OK, make the following input tests at the connector.- lf any test indicates a problem, find and correct the cause. then recheck the system.

- lf all the input tests prove OK, the control unit must be faulty; replace it.

IGNITION KEY LIGHTCONTROL UNIT

5P CONNECTOR

\

))

Test conditionCavityWireTest: Desired resultPossible cause if r€sult is not obtained

BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground {G401, G402}. An open in the wire

'IWHT/GRN

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage.

. Blown No. 33 (7.5 A) fuse in the

under-dash fuse/relay box. An open in the wire

GRN

Driver's door openCheck for voltage to ground:

There should be 1 V or less.

. Faulty driver's door switch. An open in the wire

Driver's door closedCheck for voltage to ground:

There should be 4 V or more.

WHT/BLK

Under all conditionsConnect to ground: lgnition key

light should come on.

Blown No. 33 (7.5 A) fuse in the

under-dash fuse/relay box

Blown ignition key light bulb

An open in the wire

23-89

www.emanualpro.com

Page 1251 of 1395

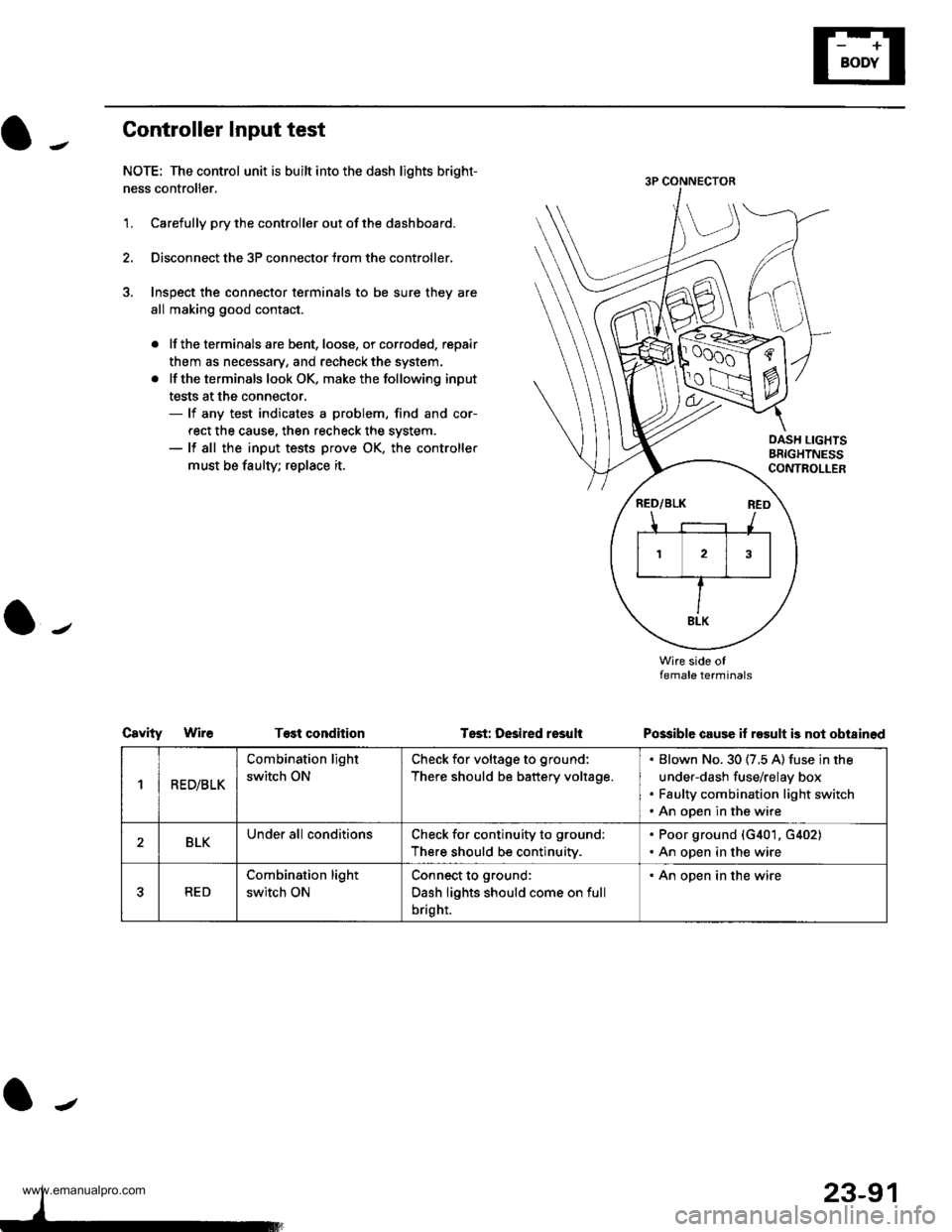

Controller Input test

NOTE: The control unit is built into the dash lights bright-

ness controller.

1.Carefully pry the controller out of the dashboard.

Disconnect the 3P connector trom the controller,

Inspect the connector terminals to be sure they are

all making good contact.

. lf the terminals are bent, loose, or corroded, repair

them as necessary, and recheck the system.

. lf the terminals look OK, make the following input

tests at the connector.- lf any test indicates a problem, find and cor-

rect the cause. then recheck the system.- lf all the input tests prove OK, the controller

must be taulty; replace it.

CsvityWireT€st condhion

Wire side oflemale terminals

Possible cause if result is not obi8inod

OASH LIGHTSBRIGHTNESSCONTROLLER

Tsst: Desired resuli

1R ED/BLK

Combination light

switch ON

Check for voltage to ground:

There should be battery voltage.

Blown No. 30 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty combination light switch

An open in the wire

2BLKUnder all conditionsCheck for continuity to ground:

There should be continuitv.

. Poor ground (G401, G402). An open in the wire

5RED

Combination light

switch ON

Connect to ground:

Dash lights should come on full

bright.

. An open in the wire

23-91

www.emanualpro.com

Page 1254 of 1395

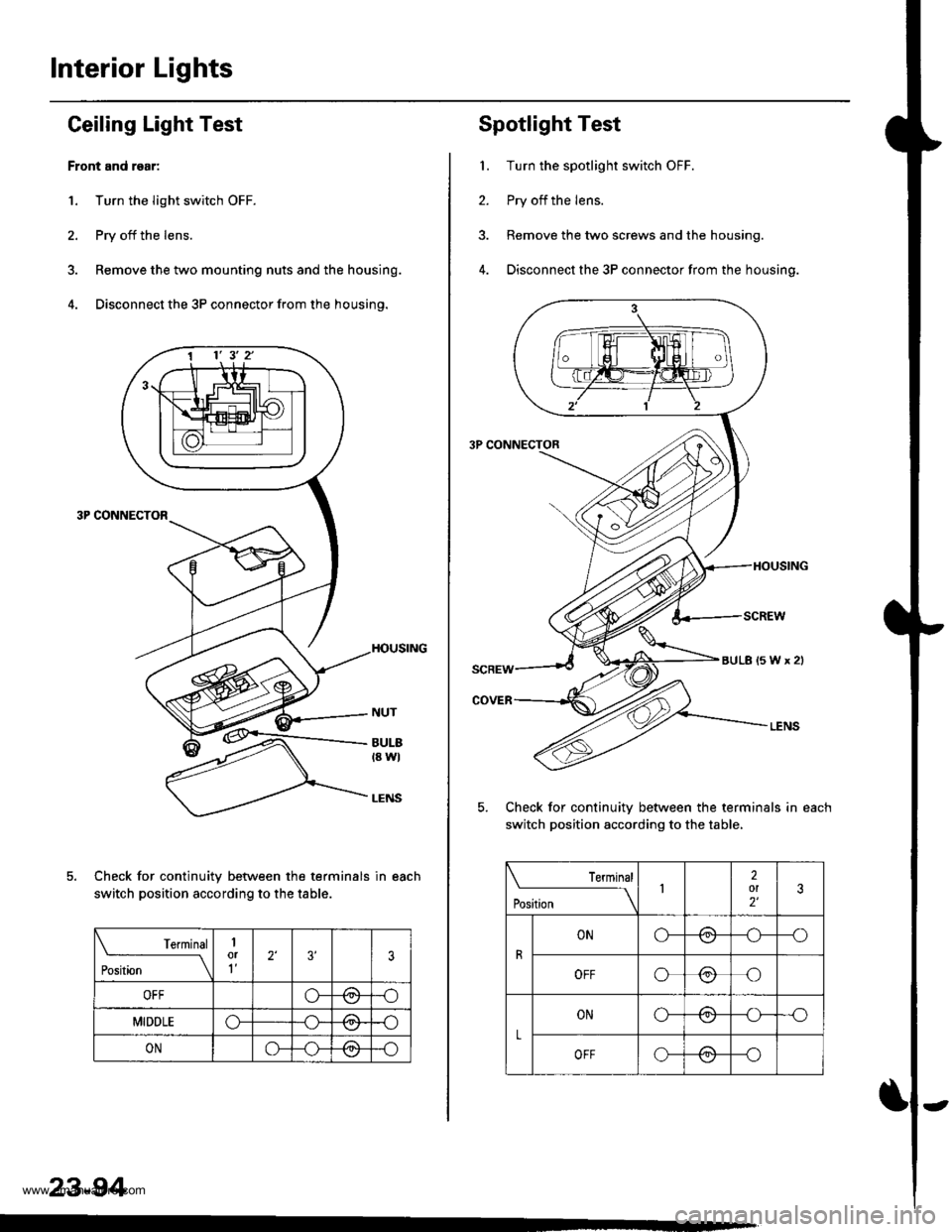

Interior Lights

Ceiling Laght Test

Front and rgar:

1. Turn the light switch OFF.

2. Pry off the lens.

3. Remove the two mounting nuts and the housing.

4. Disconnect the 3P connector from the housing.

Check for continuity between the terminals in each

switch position according to the table.

t€rmtnar

Position \

1or1'�2'3'�3

OFFo-Pd'l-o

MIDDLEo-/=\-o

ONo-/a\-o\:/

23-94

1 1' 3' 2'

Spotlight Test

1. Turn the spotlight switch OFF.

2. Pry off the lens.

3. Remove the two screws and the housing.

4. Disconnect the 3P connector from the housing.

Check for continuitv between the terminals in each

switch position according to the table,

Terminal

t"",rr" \12ol2'�3

R

ONo-/-\--o\:./

OFFo@o

L

ONo-/a--o\:./

OFFo-(9--o

aULB(5Wx2l

www.emanualpro.com

Page 1256 of 1395

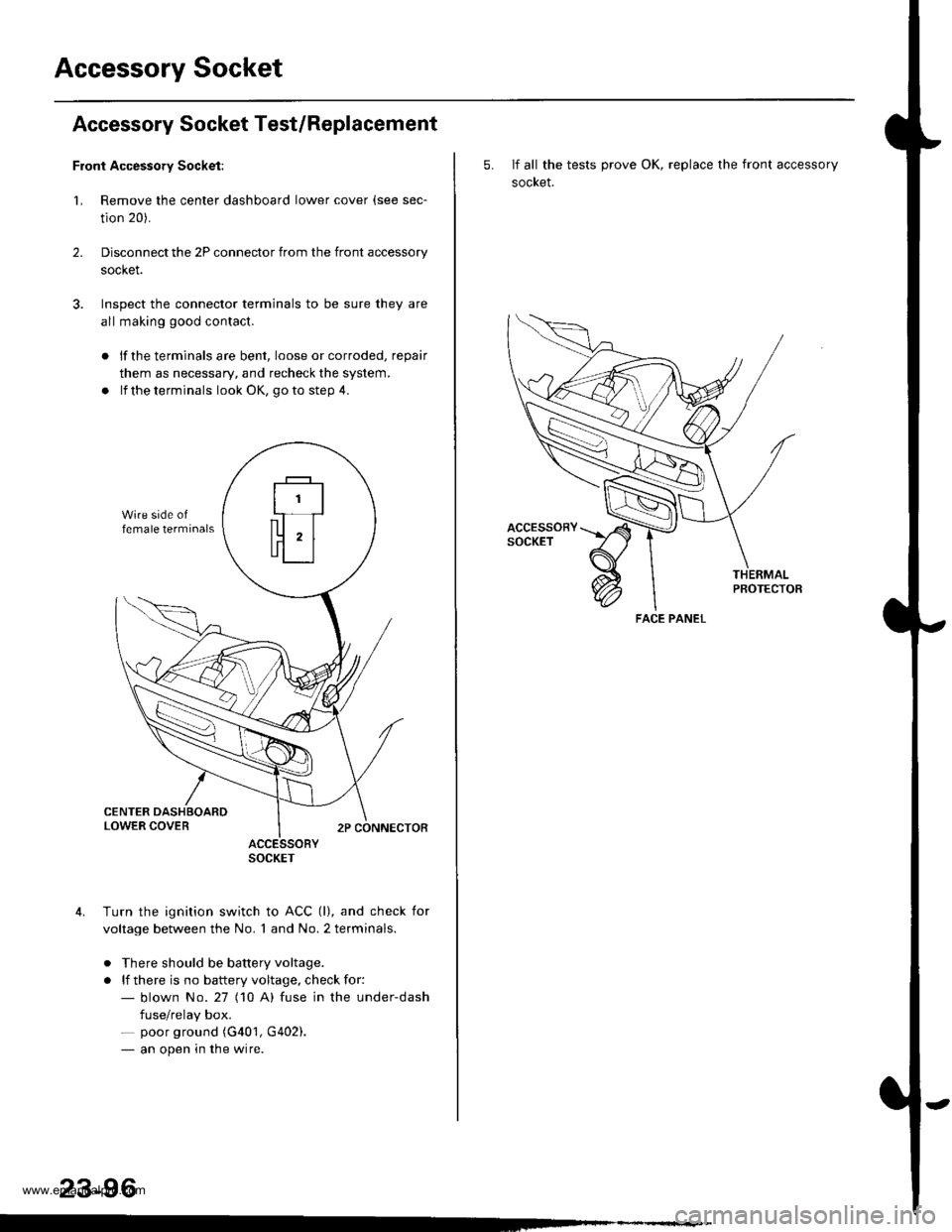

Accessory Socket

Accessory Socket Test/Replacement

Front Accessory Socket:

1. Remove the center dashboard lower cover (see sec-

tion 20).

Disconnect the 2P connector from the front accessory

socket.

Inspect the connector terminals to be sure they are

all making good contact.

2.

lf the terminals are bent, loose or corroded, repair

them as necessary, and recheck the system.

lf the terminals look OK, go to step 4.

ACCESSORYSOCKET

Turn the ignition switch to ACC (l), and check for

voltage between the No. 1 and No. 2 terminals.

. There should be battery voltage.

. lf there is no battery voltage, check for:- blown No.27 (10 A) fuse in the under-dash

fuse/relay box.- poor ground (G401, G402).- an open in the wire.

23-96

5. If all the tests prove OK, replace the front accessory

socket.

PBOTECTOB

FACE PANEL

www.emanualpro.com

Page 1257 of 1395

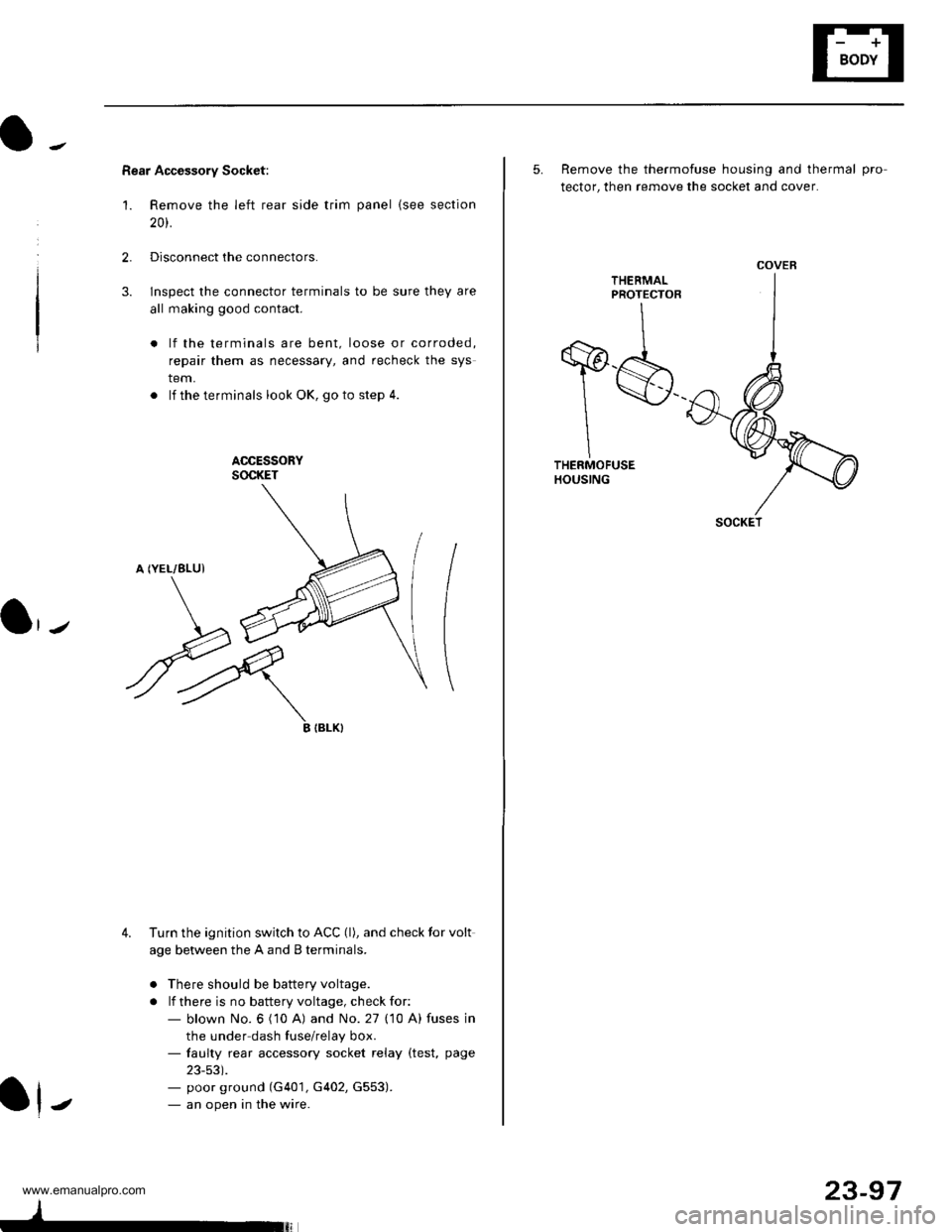

Rear Accessory Socket:

'1. Remove the left rear side trim panel {see section

20t.

2.Disconnect the connectors.

lnspect the connector terminals to be sure they are

all making good contact.

lf the terminals are bent, loose or corroded,

repair them as necessary, and recheck the sys

tem.

. lf theterminals look OK, goto step 4.

ACCESSORYSOCKET

A (YEL/8LUI

3.

\J

ryIIBLK}

4. Turn the ignition switch to ACC (l), and check tor volt

age between the A and B terminals.

o There should be battery voltage.

. lf there is no battery voltage, check for:- blown No. 6 ('10 A) and No. 27 (10 A) fuses in

the under dash fuse/relay box.- faulty rear accessory socket relay (test, page

23-53).- poor ground (G401, G402, G553).- an open in the wire.J

23-97

5. Remove the thermofuse housing and thermal pro

tector, then remove the socket and cover.

THEEMALPROTECTOR

T$THERMOFUSEHOUSING

COVER

SOCKET

www.emanualpro.com