Adjust Ac HONDA CR-V 1999 RD1-RD3 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 125 of 1395

Timing Belt

Installation (cont'd)

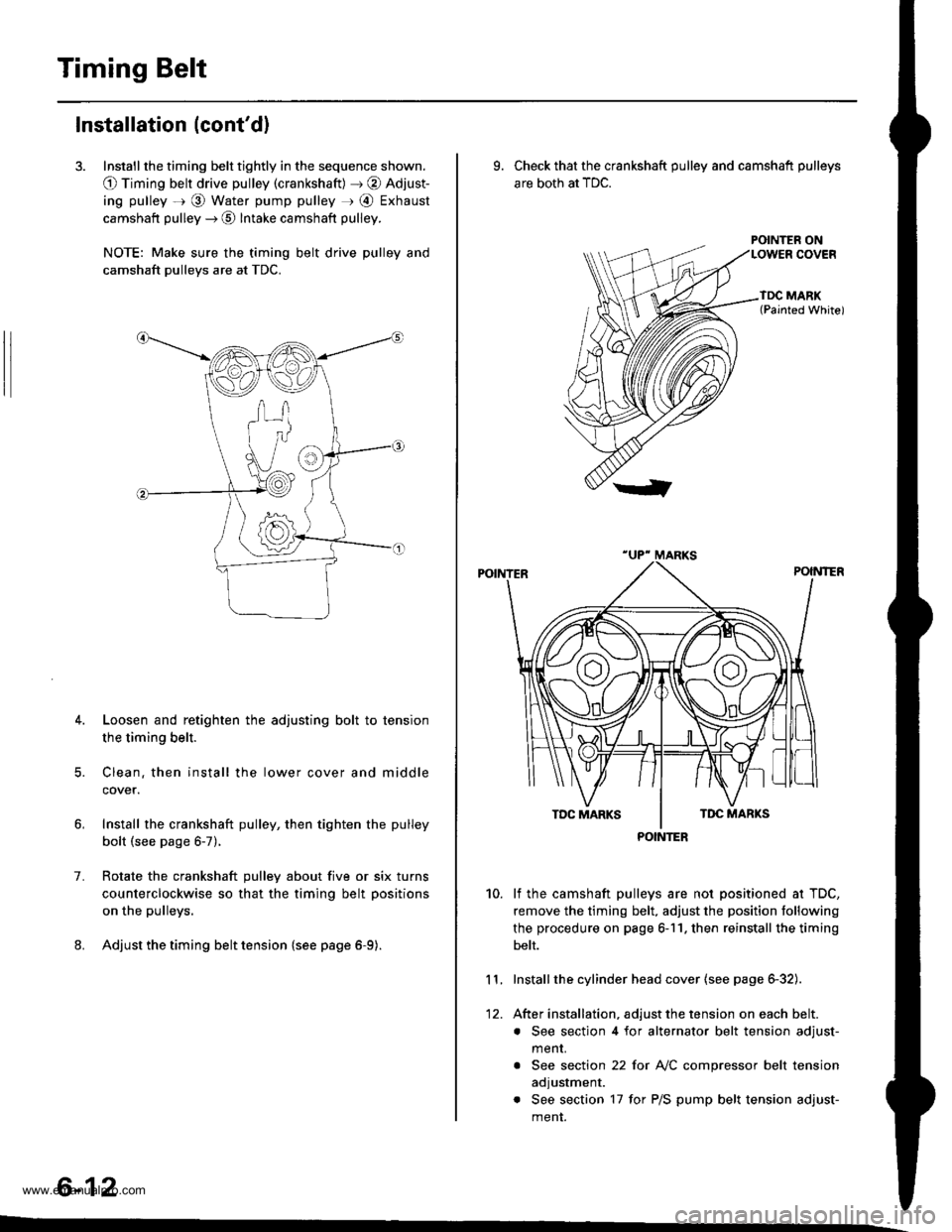

3. Install the timing belt tightly in the sequence shown.

O Timing belt drive pulley (crankshaft) J @ Adjust-

ing pulley =r @ Water pump pulley r @ Exhaust

camshaft pulley --) @ Intake camshaft pulley.

NOTE: Make sure the timing belt drive pulley and

camshaft pulleys are at TDC.

4. Loosen and retighten the adjusting bolt to tension

the timing belt.

5. Clean. then install the lower cover and middle

cover.

Install the crankshaft pulley, then tighten the pulley

bolt (see page 6-7).

Rotate the crankshaft pulley about five or six turns

counterclockwise so that the timing belt positions

on the pulleys.

Adjust the timing belt tension {see page 6-9).

1.

6-12

9. Check that the crankshaft pulley and camshaft pulleys

are both at TDC.

POINTER ON

lf the camshaft pulleys are not positioned at TDC,

remove the timing belt. adjust the position following

the procedure on page 6-11. then reinstall the timing

belt.

Installthe cylinder head cover (see page 6-32).

After installation, adjust the tension on each belt.

. See section 4 for alternator belt tension adjust-

menr.

. See section 22 for NC compressor belt tension

adjustment.

. See section 17 for P/S pump belt tension adjust-

ment.

10.

11.

12.

POINTER

www.emanualpro.com

Page 126 of 1395

CKF Sensor

Replacement

1.

|o|'ln PUUCY BMCKET SOLIl0 r 1.25 mm14 .m 14.5 kgl.m,3:' lbtftl

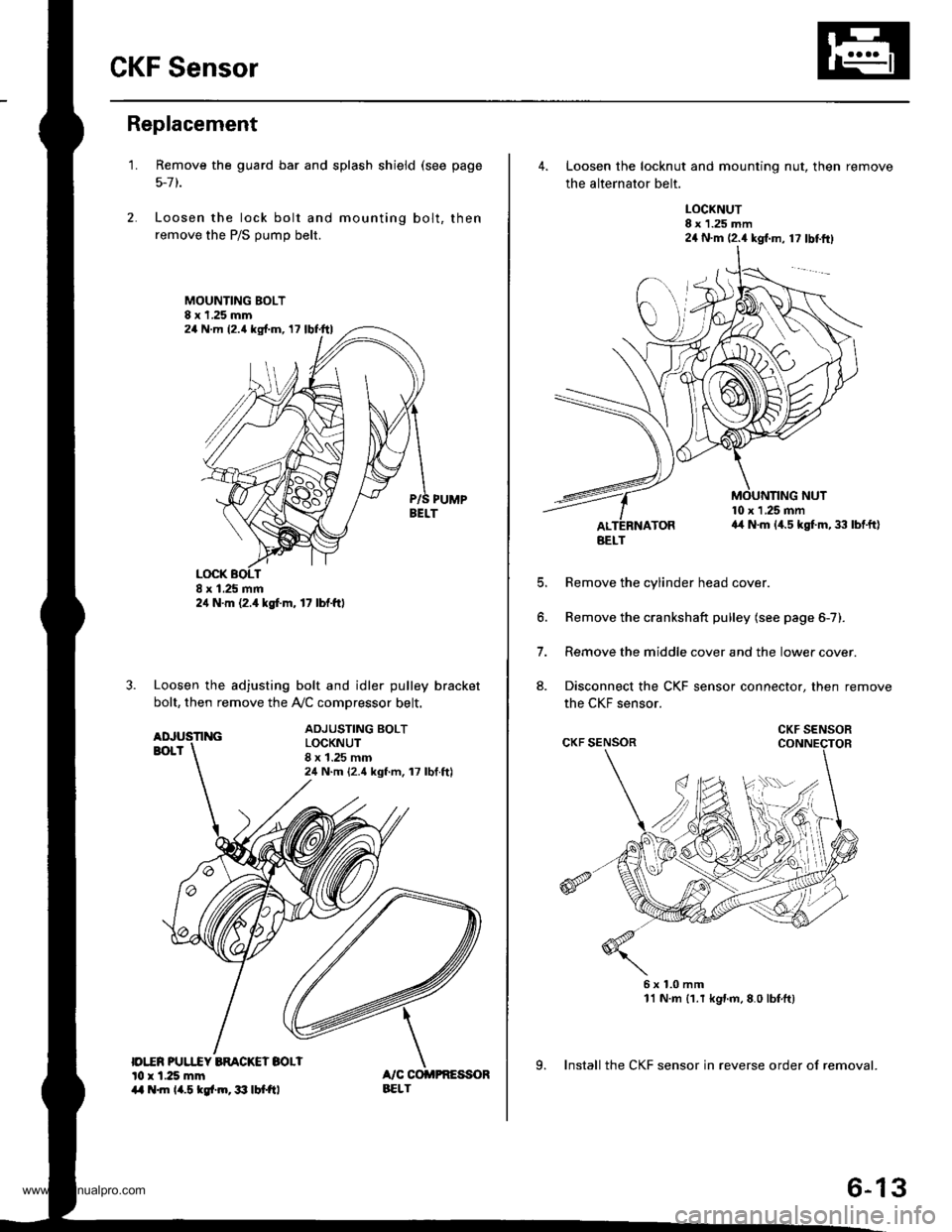

Remove the guard bar and splash shield (see page

5-7 t.

Loosen the lock bolt and mounting bolt, then

remove the P/S pump belt.

MOUNTING BOLT8 x 1.25 mm

PUMPBELT

Loosen the adjusting bolt and idler pulley bracket

bolt, then remove the Ay'C comDressor belt.

ADJUSTING BOLTLOCKNUT8 x 1.25 mm24 N.m {2.4 kgf.m, 17 lbf.ft)

24 N.m (2.{ kgf.m, 17 lbf.ttl

24 N.m 12.4 lgf.m, 17 lbl.ftl

4. Loosen the locknut and mounting nut, then remove

the alternator belt.

LOCKNUT8 x 1.25 mm24 N.m (2.4 kgl.m, 17 lbtftl

10 x 1 .25 mma4 N.m (4.5 kgt m, 33 lbtft)

E

6.

7.

aJ.

Remove the cylinder head cover.

Remove the crankshaft pulley (see page 6-7).

Remove the middle cover and the lower cover.

Disconnect the CKF sensor connector, then remove

the CKF sensor.

6x1.0mm11 N.m {1.r kgnm,8.0 lbfft)

9. Install the CKF sensor in reverse order of removal.

BELT

CKF SENSOR

6-13

www.emanualpro.com

Page 129 of 1395

Gylinder Head

Removal

Engine removal is not required for this procedure.

l!@ Make sure iacks and safety stands are

placed properly, and hoist blackels ale attachgd to the

correct position on the engine.

NOTE:

o Use fender covers to avoid damaging painted sur-

faces.

o To avoid damage, unplug the wiring connectors care-

fully while holding the connector portion.

. To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100"F (38'C)

before loosening the retaining bolts.

. Mark all wiring and hoses to avoid misconnection.

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

2.

4.

5.

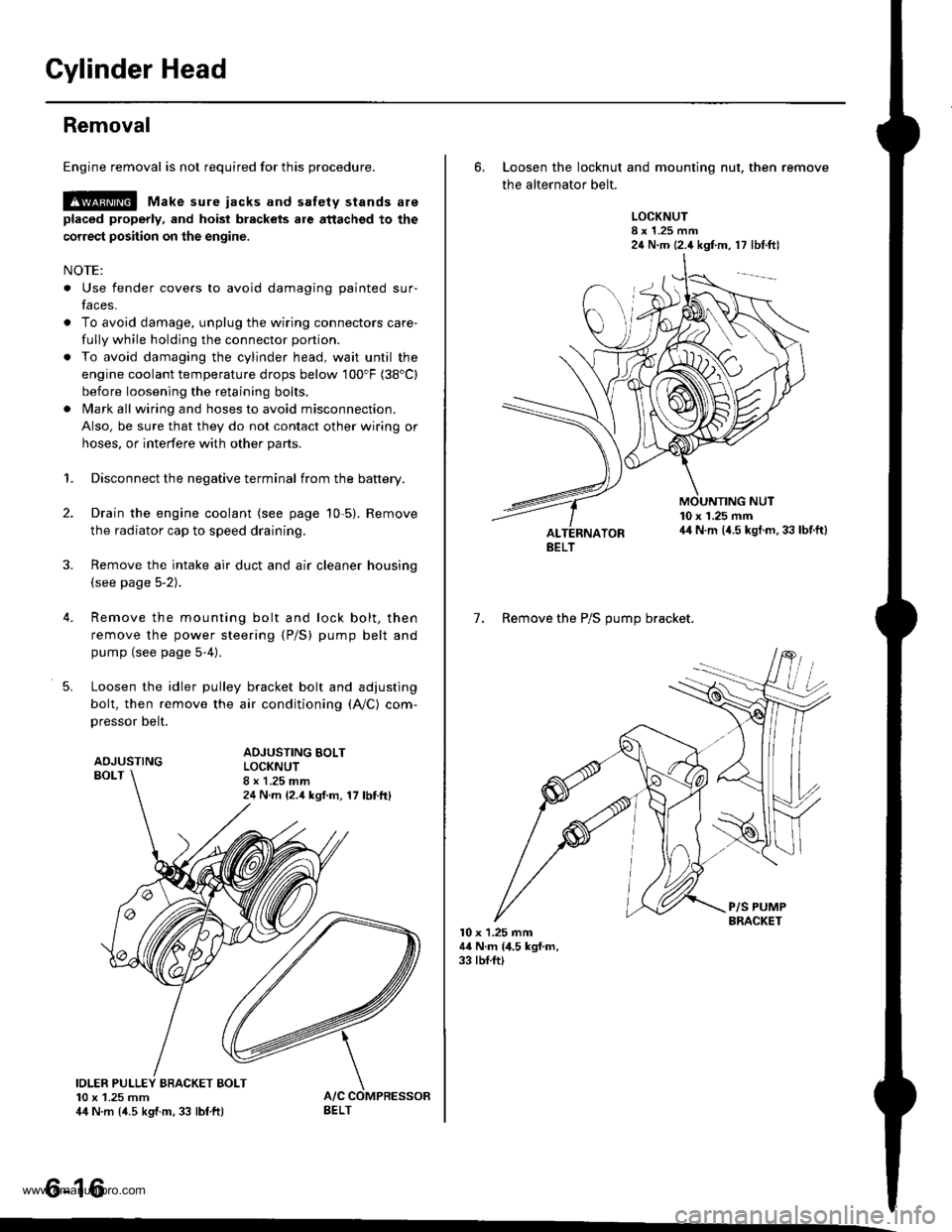

1.Disconnect the negative terminal from the battery.

Drain the engine coolant (see page 10-5). Remove

the radiator cap to speed draining.

Remove the intake air duct and air cleaner housing(see page 5-2).

Remove the mounting bolt and lock bolt, then

remove the power steering (P/S) pump belt and

pump (see page 5-4).

Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (A,/C) com,

pressor belt.

ADJUSTINGBOLT

ADJUSTING BOLTLOCKNUT8 x 1.25 mm24 N m {2.4 ksf.m, 17 lbttt}

IOLER PULLEY BBACKET BOLT10 x 1.25 mm44 N.m {4.5 kgtm, 33 lbf ft)

tt aAo-Io

6. Loosen the locknut and mounting nut, then remove

the alternator belt.

LOCKNUT8 x 1.25 mm24 N.m (2.4 kgf.m, 17 lbt.ftl

10 x 1.25 mm44 N.m (4.5 kgt.m. 33 lbf.ft)

7. Remove the P/S OUmo bracket.

l0 x 1.25 mm44 N.m (4.5 kgf.m,33 rbf.ft)

BELT

www.emanualpro.com

Page 134 of 1395

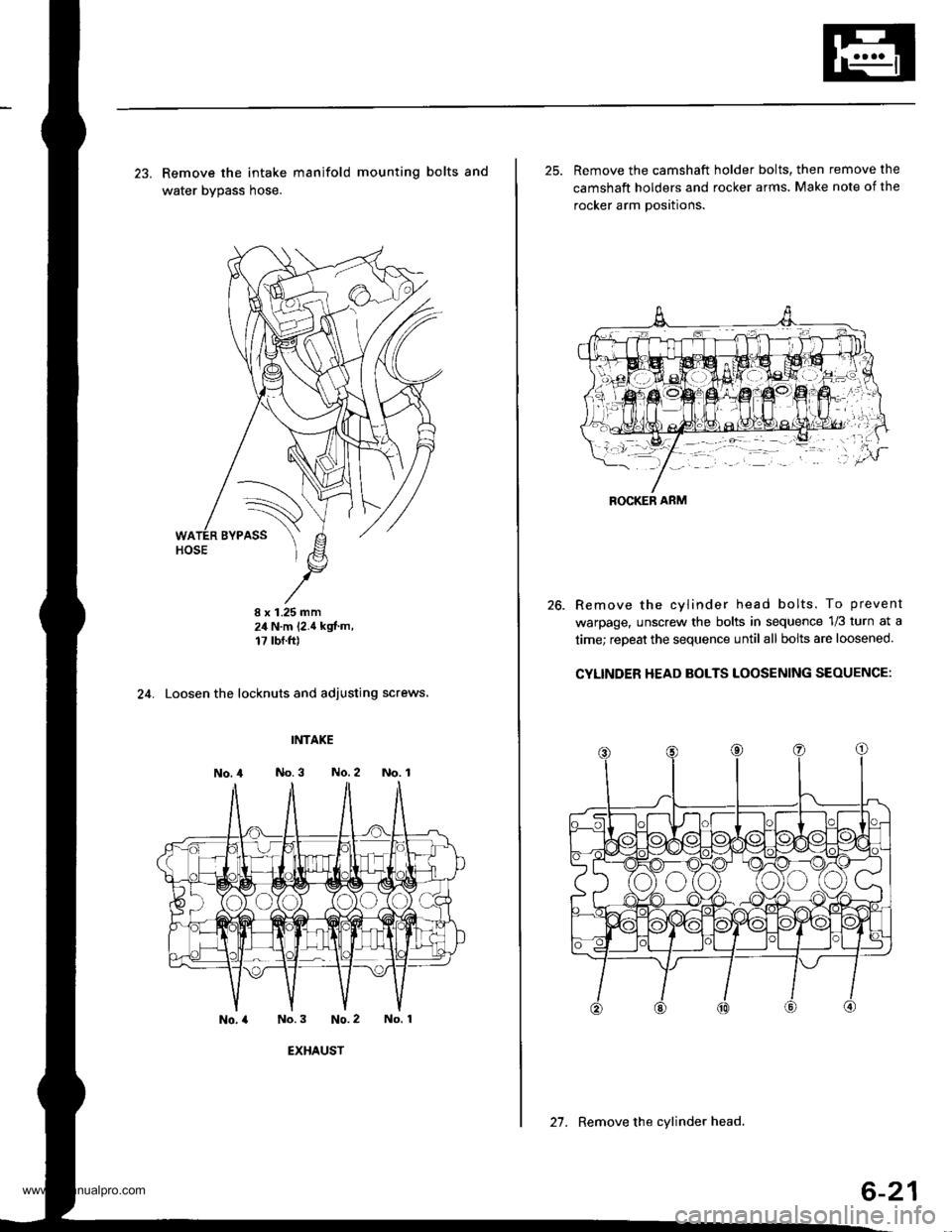

23. Remove the intake manifold mounting bolts and

water bvDass hose.

8 x 1.25 mm2,1 N.m 12.4 kgt.m,17 tbf.ft)

24. Loosen the locknuts and adjusting screws,

INTAKE

No.3 No.2 No. 1

No.3 No.2 No. 1

EXHAUST

No. 4

27. Remove the cylinder head.

6-21

25. Remove the camshaft holder bolts, then remove the

camshaft holders and rocker arms. Make note of the

rocker arm Dositions.

26. Remove the cylinder head bolts. To prevent

warpage, unscrew the bolts in sequence 1/3 turn at a

time; repeat the sequence until all bolts are loosened.

CYLINDER HEAD BOLTS LOOSENING SEOUENCE:

ROCKER ARM

www.emanualpro.com

Page 135 of 1395

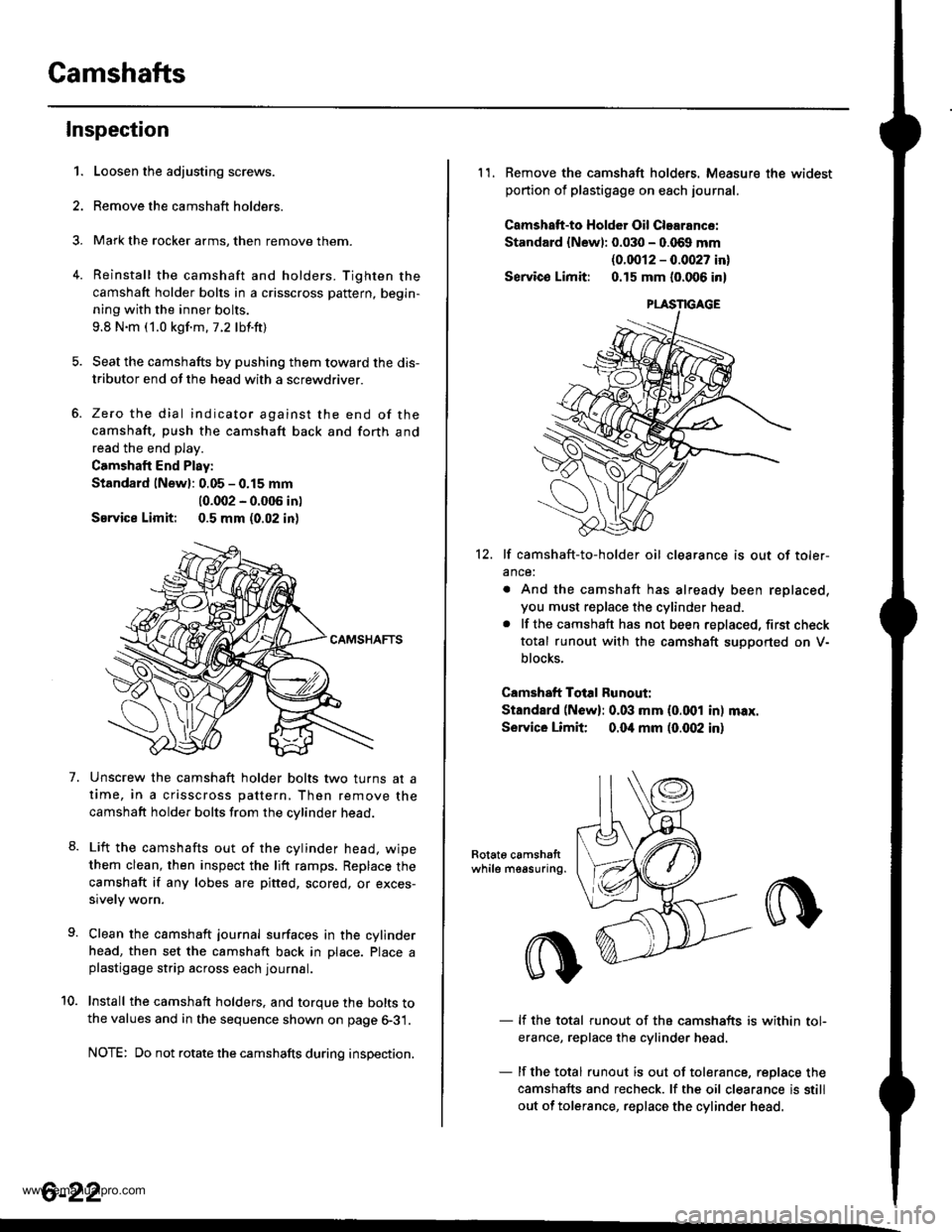

Camshafts

4.

Inspection

1.

7.

Loosen the adjusting screws.

Remove the camshaft holders.

Mark the rocker arms, then remove them.

Reinstall the camshaft and holders. Tighten the

camshaft holder bolts in a crisscross pattern, begin-

ning with the inner bolts.

9.8 N.m (1.0 kgf.m.7.2 lbf.ft)

Seat the camshafts by pushing them toward the dis-

tributor end of the head with a screwdriver.

Zero the dial indicator against the end of the

camshaft, push the camshaft back and forth and

read the end play.

Camshaft End Play:

Standard lNewl: 0.05 - 0.15 mm

10.002 - 0.005 in)

Service Limit: 0.5 mm (0.02 in)

Unscrew the camshaft holder bolts two turns at a

time, in a crisscross pattern, Then remove the

camshaft holder bolts from the cvlinder head.

Lift the camshafts out of the cylinder head. wipe

them clean, then inspect the lift ramps, Replace the

camshaft if any lobes are pitted, scored, or exces-

sively worn.

Clean the camshaft journal surfaces in the cylinder

head, then set the camshaft back in Dlace. Place aplastigage strip across each journal.

Install the camshaft holders. and torque the bolts tothe values and in the sequence shown on page 6-31.

NOTE: Do not rotate the camshafts during inspection.

8.

10.

6-22

11. Remove the camshaft holders. Measure the widest

portion of plastigage on each journal.

Camshatt-to HoldGr Oil Clearance:

Standard {Newl: 0.030 - 0.069 mm

{0.0012 - 0.0027 in}

Servico Limit: 0.15 mm (0.006 in)

12. lf camshaft-to-holder oil clearance is out of toler-

ance:

. And the camshaft has already been replaced,

you must replace the cylinder head.. lf the camshaft has not been replaced, first check

total runout with the camshaft suoDorted on V-

blocks.

Camshaft Total Runout:

Standard (N6w): 0.03 mm (0.001 in) max.

Service Limit 0.04 mm (0.(X)2 in)

Rotat6 camshattwhile measuring.

- lf the total runout of the camshafts is within tol-

erance, replace the cylinder head

- lf the total runout is out of tolerance, replace the

camshafts and recheck. lf the oil clearance is still

out of tolerance, replace the cylinder head.

www.emanualpro.com

Page 141 of 1395

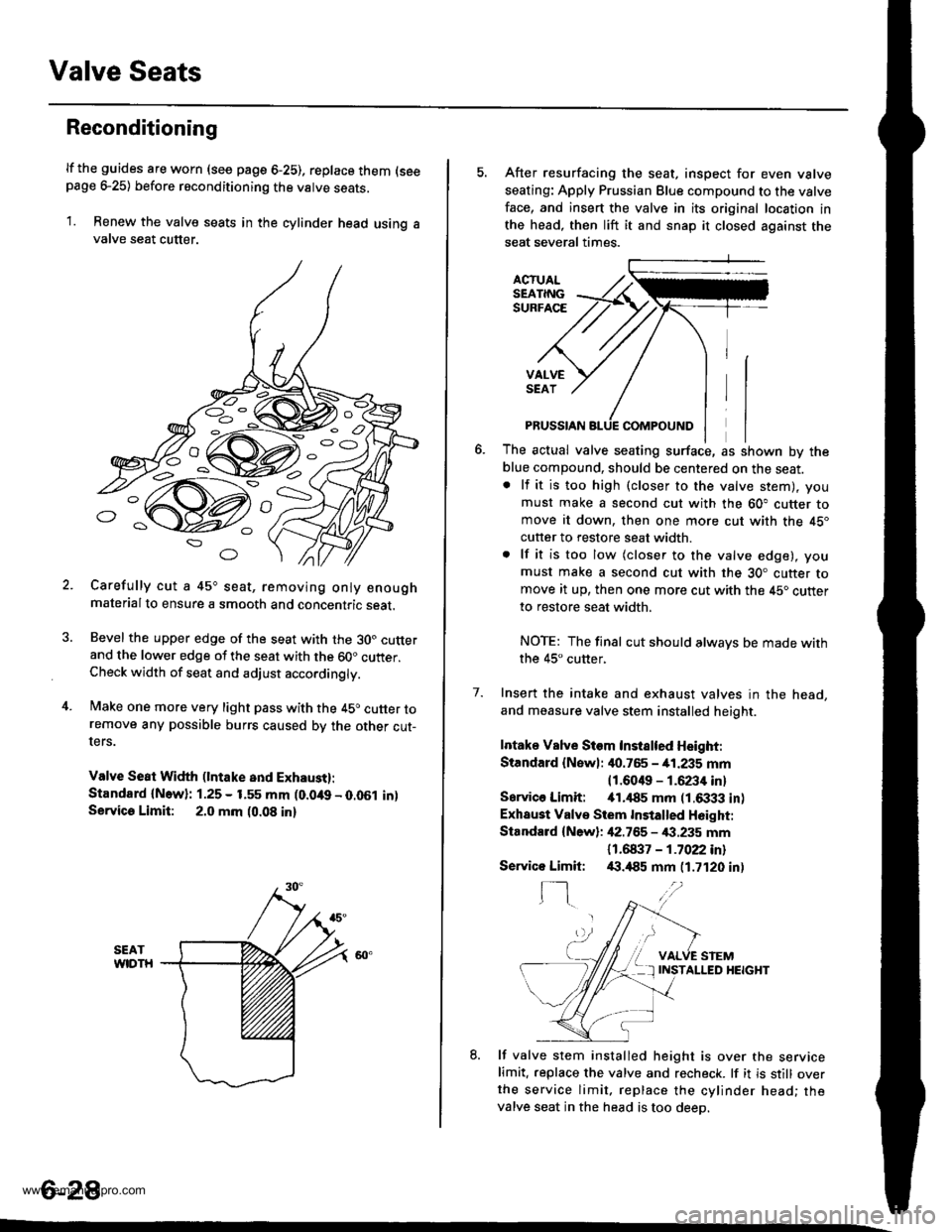

Valve Seats

Reconditioning

lf the guides are worn (see page 6-25), replace them (seepage e25) before reconditioning the valve seats.

1. Renew the valve seats in the cylinder head using avalve seat cutter.

Carefully cut a 45o seat, removing only enoughmaterialto ensure a smooth and concentric seat.

Bevel the upper edge of the seat with the 30. cutterand the lower edge of the seat with the 60" cutter.Check width of seat and adjust acco.dingly.

Make one more very light pass with the 45o cutter toremove any possible burrs caused bv the other cut-ters.

Valve Seat Width (lntake and Exhaust):

Standard {N.w}: 1.25 - 1.55 mm (0.049 - 0.051 in)Servica Limit: 2.0 mm (0.08 in)

o

o

5. After resurfacing the seat, inspect for even valve

seating: Apply Prussian Blue compound to the valve

face, and insert the valve in its original location in

the head, then lift it and snap it closed against the

seat several times.

ACTUALSEATINGSURFACE

VALVESEAT

7.

PRUSSIAN

The actual valve seating surface, as shown by the

blue compound, should be centered on the seat.. lf it is too high (closer to the valve stem), you

must make a second cut with the 60" cutter tomove it down, then one more cut with the 45"

cutter to restore seat width.

. lf it is too low (closer to the valve edge), you

must make a second cut with the 30. cutter tomove it up, then one more cut with the 45. cutter

to restore seat width.

NOTE: The final cut should alwavs be made withthe 45" cutter,

Insert the intake and exhaust valves in the head,

and measure valve stem installed heioht.

Intake Vslve Siem Instslted Height:

Standard {Newl: it0.765 - 41.235 mm

11.6049 - 1.6234 inl

Sarvico Limit: itl.il85 mm (1.6333 in)

Exhaust Valve Stem Installed H6ight:

Standard {New}: 42.755 - €.235 mm

11 .61137 - 1 .7022 inl/(|.,185 mm (1.7120 in)

VALVE STEMINSTALLED HEIGHT

8. lf valve stem installed height is over the servicelimit. replace the valve and recheck. lf it is still overthe service limit. replace the cylinder head; thevalve seat in the head is too deeo.

Servico Limit:

f-]

6-28

www.emanualpro.com

Page 145 of 1395

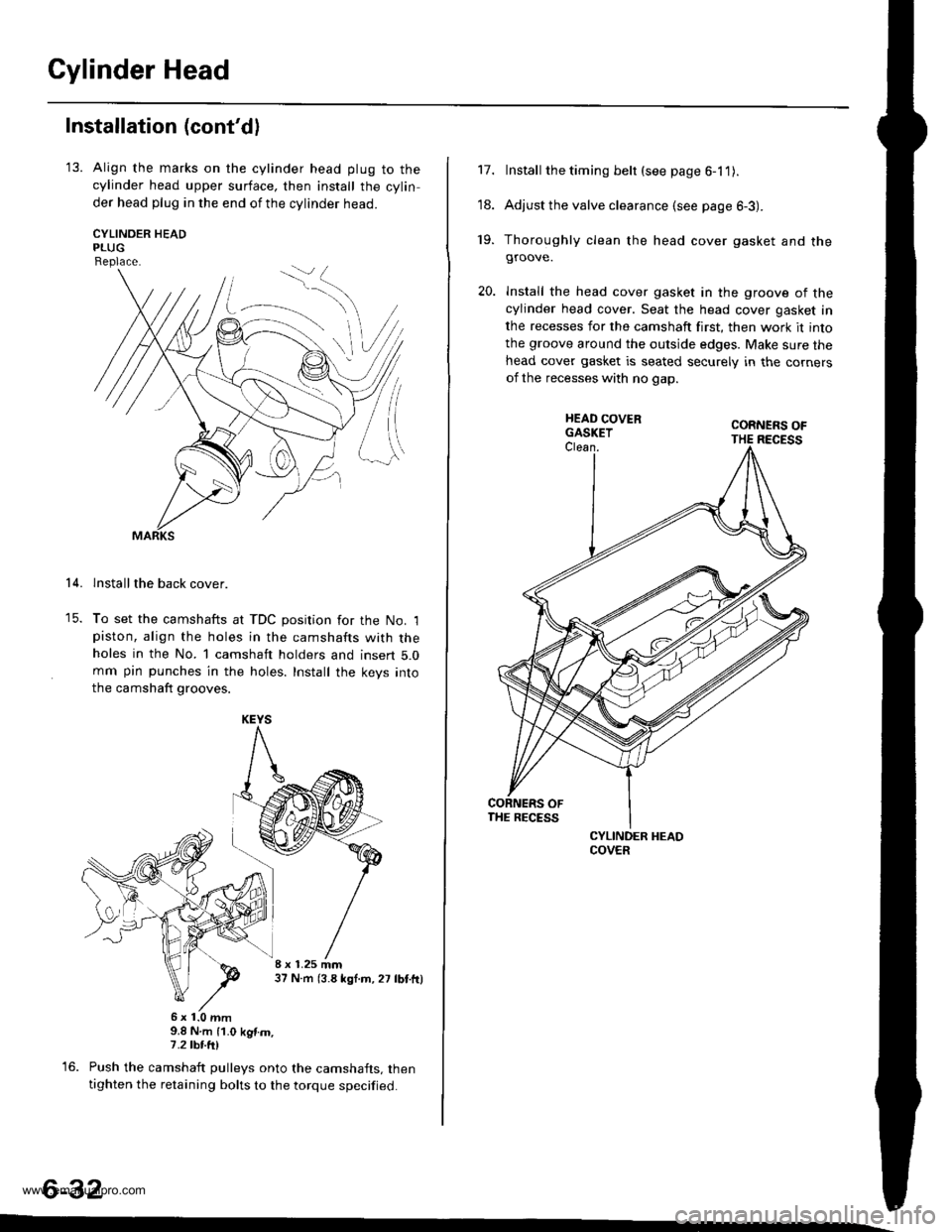

Cylinder Head

Installation (cont'dl

'13. Align the marks on the cylinder head plug to thecylinder head upper surface, then install the cylin

der head plug in the end of the cylinder head.

CYLINOER HEADPLUGReplace.

lnstallthe back cover.

To set the camshafts at TDC position for the No. lpiston, align the holes in the camshafts with theholes in the No. l camshaft holders and insert 5.0mm pin punches in the holes. Install the keys into

the camshaft grooves.

37 N m (3.8 *gl.m, 27 lbt.tr)

9.8 N.m (1.0 kgtm,7.2|hrftl

Push the camshaft pulleys onto the camshafts. thentighten the retaining bolts to the torque specified.

6-32

14.

KEYS

I x 1.25 mm

6x1.0mm

Install the timing belt (see page 6-1 1).

Adjust the valve clearance (see page 6-3).

Thoroughly clean the head cover gasket and thegroove.

lnstall the head cover gasket in the groove of thecylinder head cover. Seat the head cover gasket in

the recesses for the camshaft first, then work it into

the groove around the outside edges. Make sure thehead cover gasket is seated securely in the corners

of the recesses with no gap.

17.

'18.

19.

www.emanualpro.com

Page 153 of 1395

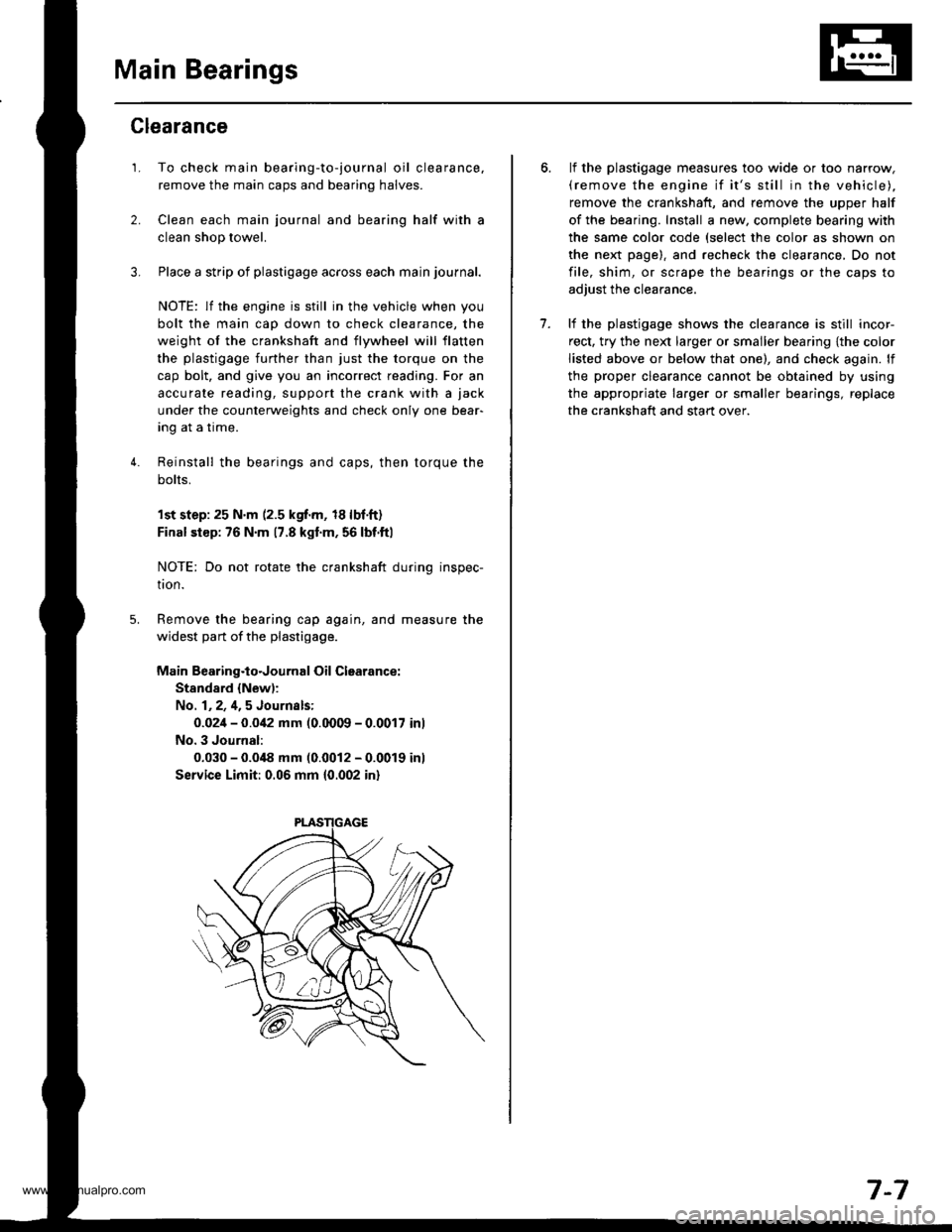

Main Bearings

2.

3.

1.

4.

Clearance

To check main bearing-to-journal oil clearance,

remove the main caps and bearing halves.

Clean each main journal and bearing half with a

clean shop towel.

Place a strip of plastigage across each main journal.

NOTE: lf the engine is still in the vehicle when you

bolt the main cap down to check clearance, the

weight of the crankshaft and flywheel will flatten

the plastigage further than just the torque on the

cap bolt, and give you an incorrect reading. For an

accurale reading, support the crank with a jack

under the counterweights and check only one bear-

Ing aI a Irme.

Reinstall the bearings and caps, then torque the

bolts,

1st step:25 N'm (2.5 kgf.m, 18lbf.ft)

Final siep: 76 N'm 17.8 kgl.m, 56 lbf.ftl

NOTE: Do not rotate the crankshaft during inspec-

tron.

Remove the bearing cap again, and measure the

widest part of the plastigage.

Main Bearing.to.Journal Oil Clearance:

Stand8.d {New):

No. 1,2,4,5 Journsls:

0.02i1- 0.0i12 mm (0.0009 - 0.0017 inl

No. 3 Journal:

0.030 - 0.0i18 mm (0.0012 - 0.0019 inl

Service Limit: 0.06 mm 10.002 in)

lf the plastigage measures too wide or too narrow,(remove the engine if it's still in the vehicle),

remove the crankshaft, and remove the upper half

of the bearing. Install a new, complete bearing with

the same color code (select the color as shown on

the next page). and recheck the clearance, Do not

file, shim, or scrape the bearings or the caps to

adjust the clearance.

lf the plastjgage shows the clearance is still incor-

rect, try the ne)d larger or smaller bearing {the color

listed above or below that one), and check again. lf

the proper clearance cannot be obtained by using

the appropriate larger or smaller bearings, replace

the crankshaft and start over.

7.

7-7

www.emanualpro.com

Page 154 of 1395

Main BearingsConnecting Rod Bearings

Selection

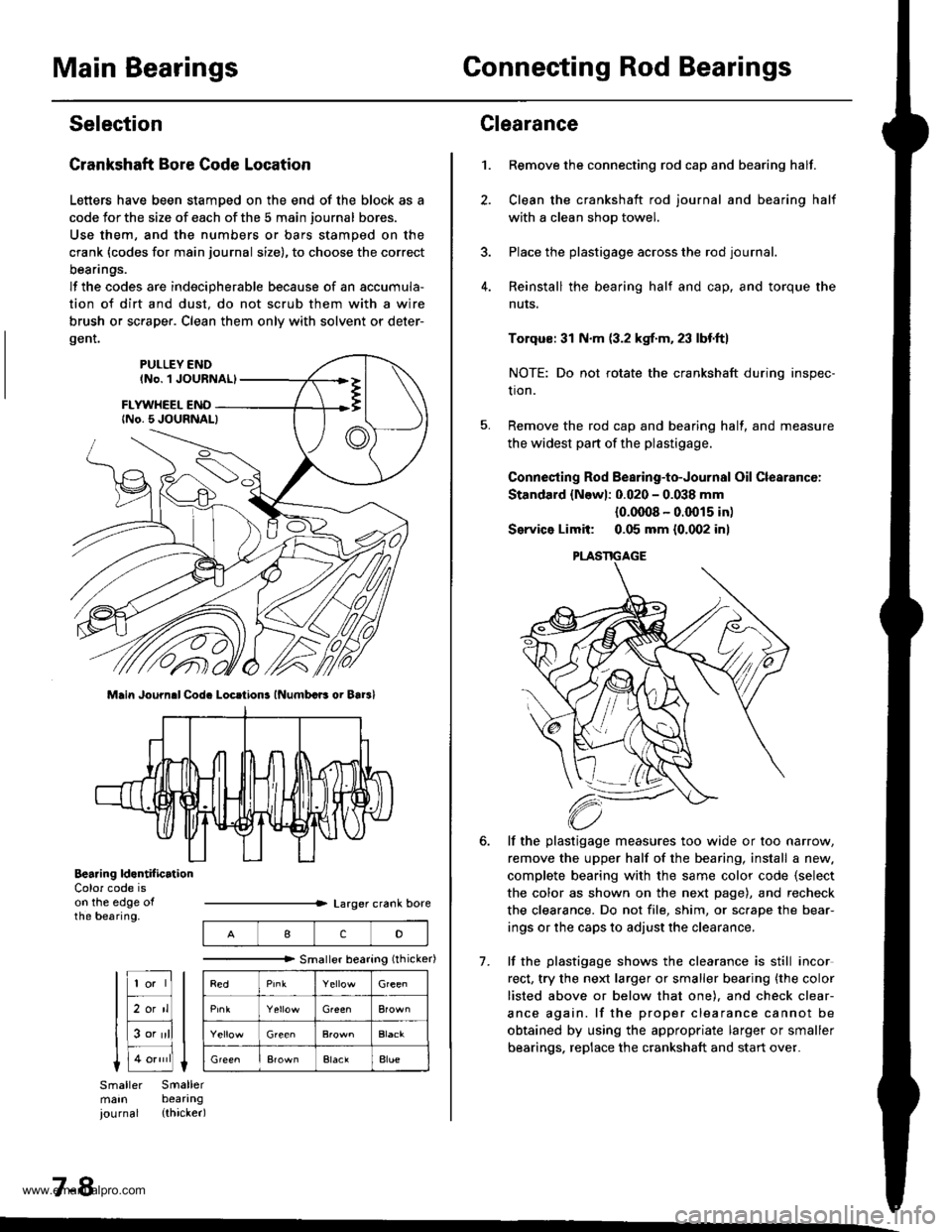

Crankshaft Bore Code Location

Letters have been stamDed on the end of the block as a

code Jor the size of each of the 5 main journal bores.

Use them, and the numbers or bars stamped on the

crank (codes for main journal size), to choose the correct

beanngs.

lf the codes are indecipherable because of an accumula-

tion of dirt and dust. do not scrub them with a wire

brush or sc.aper. Clean them only with solvent or deter-

gent.

Main Journ.l Cod. Locrtions lNumbcB oi Bar3l

Bearing ld.ntif icrtionColor code ison the edge ofthe bearing.

7-8

IcD

"""""""" Smallerbearing(rhicker)

Green

Green

ElaclAlue

Clearance

Remove the connecting rod cap and bearing half.

Clean the crankshaft rod journal and bearing half

with a clean shop towel.

Place the plastigage across the rod journal.

Reinstall the bearing half and cap, and torque the

nuts.

1.

7.

Torqus: 31 N.m (3.2 kgf.m. 23 lbf.ft)

NOTE: Do not rotate the crankshaft during inspec-

tion.

Remove the rod cap and bearing half, and measure

the widest part of the plastigage.

Connesting Rod Bearing-to-Journal Oil Clearancc:

Standard {Newl: 0.020 - 0.038 mm

{0.0008 - 0.0015 in)

Service Limit: 0.05 mm {0.002 inl

lf the plastigage measures too wide or too narrow,

remove the upper half of the bearing, install a new.

complete bearing with the same color code {select

the color as shown on the next page), and recheck

the clearance. Do not file, shim, or sc.ape the bear-

ings or the caps to adjust the clearance.

lf the plastigage shows the clearance is still incor

rect, try the next larger or smaller bearing {the color

listed above or below that one). and check clear-

ance again. lf the proper clearance cannot be

obtained by using the appropriate larger or smaller

bearings. replace the crankshaft and start over.

PLASTIGAGE

www.emanualpro.com

Page 160 of 1395

Piston PinsConnecting Rods

Assemble the Piston Pin Tools as shown.

PISTON BASE HEAO07HAF -PL20102

PISTON BASE07973 - 6570500

Adjust the length A of the piston pin dflver.

A: 49.70 mm 11.957 in)

PIN DRIVER HEAIPE00320

\

RIr1

nT---

u

ffi-"""-

u_ll

3. Place the piston on the piston base, and press the

pin out with a hydraulic press. Make sure that the

recessed portion of the piston aligns with the lips

on the collar.

7-14

Removal

1.

PISTON07973 -

PISTON PIN BASE INSERT07GAF - PH60300

PISTON PIN DRIVER SHAFT07973 - PEt 0310

PILOT COLLAR07LAF - PR30100Embossod mark facing up.

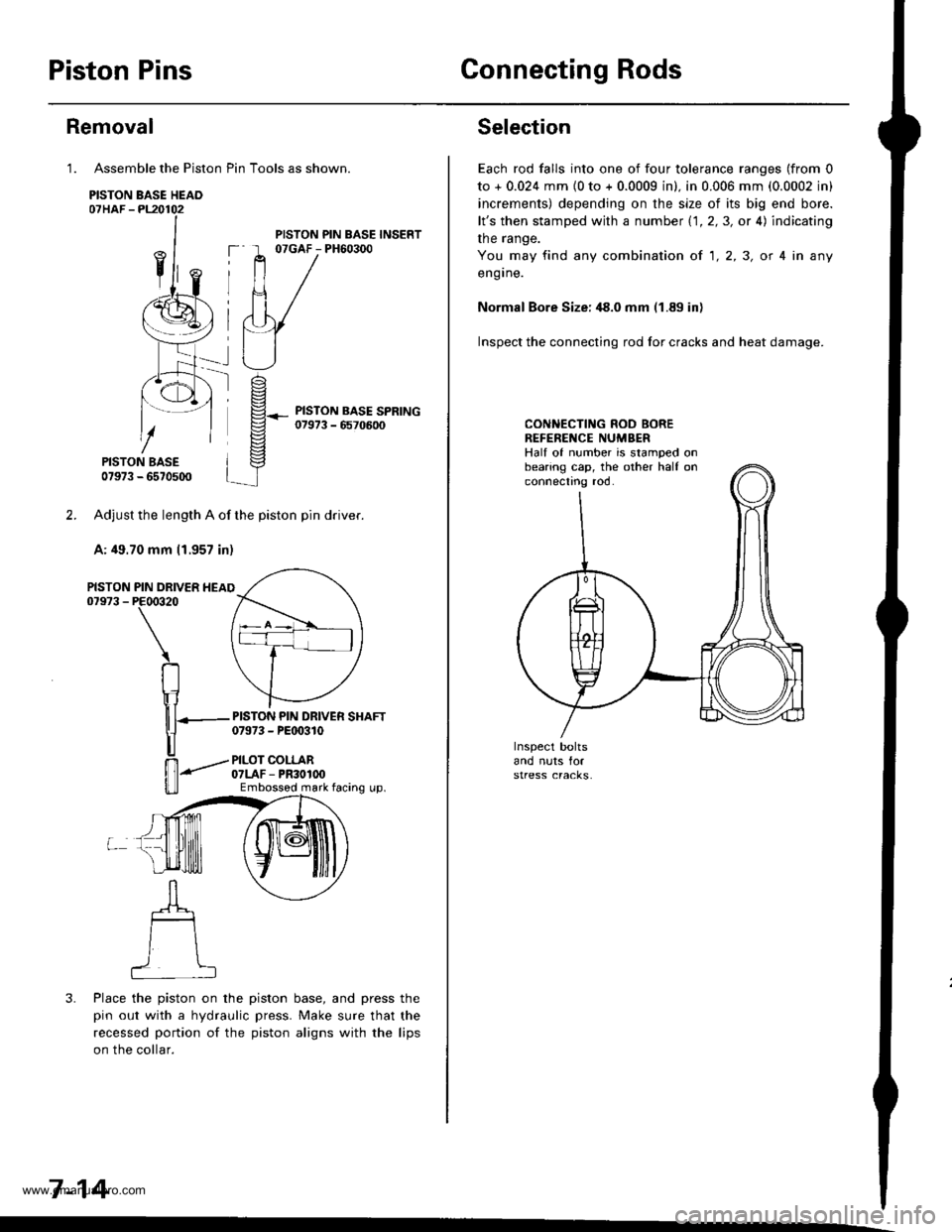

Selection

Each rod falls into one of four tolerance ranges (from 0

to + 0.024 mm {0 to + 0.0009 in). in 0.006 mm (0.0002 in)

increments) depending on the size of its big end bore.

lt's then stamped with a number 1.1.2,3, or 4) indicating

the range.

You may find any combination ot 1,2,3, or 4 in any

engrne.

Normal Bore Size: ,18.0 mm (1.89 in)

Inspect the connecting rod for cracks and heat damage.

CONNECTING ROD BOREREFENENCE NUMBERHalf of number is stamped onbearing cap, the other half onconnectno roo.

www.emanualpro.com