steering rack HONDA CR-V 1999 RD1-RD3 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 896 of 1395

lnstallation

1. Before installing the gearbox, extend the rack all the

waY to right.

2. lnstall the mounting cushion on the steerlng gear-

box.

3. Pass the right side of the steering gearbox above

and through the right side of the rear beam. Be care-

ful not to bend or damage the two power steering

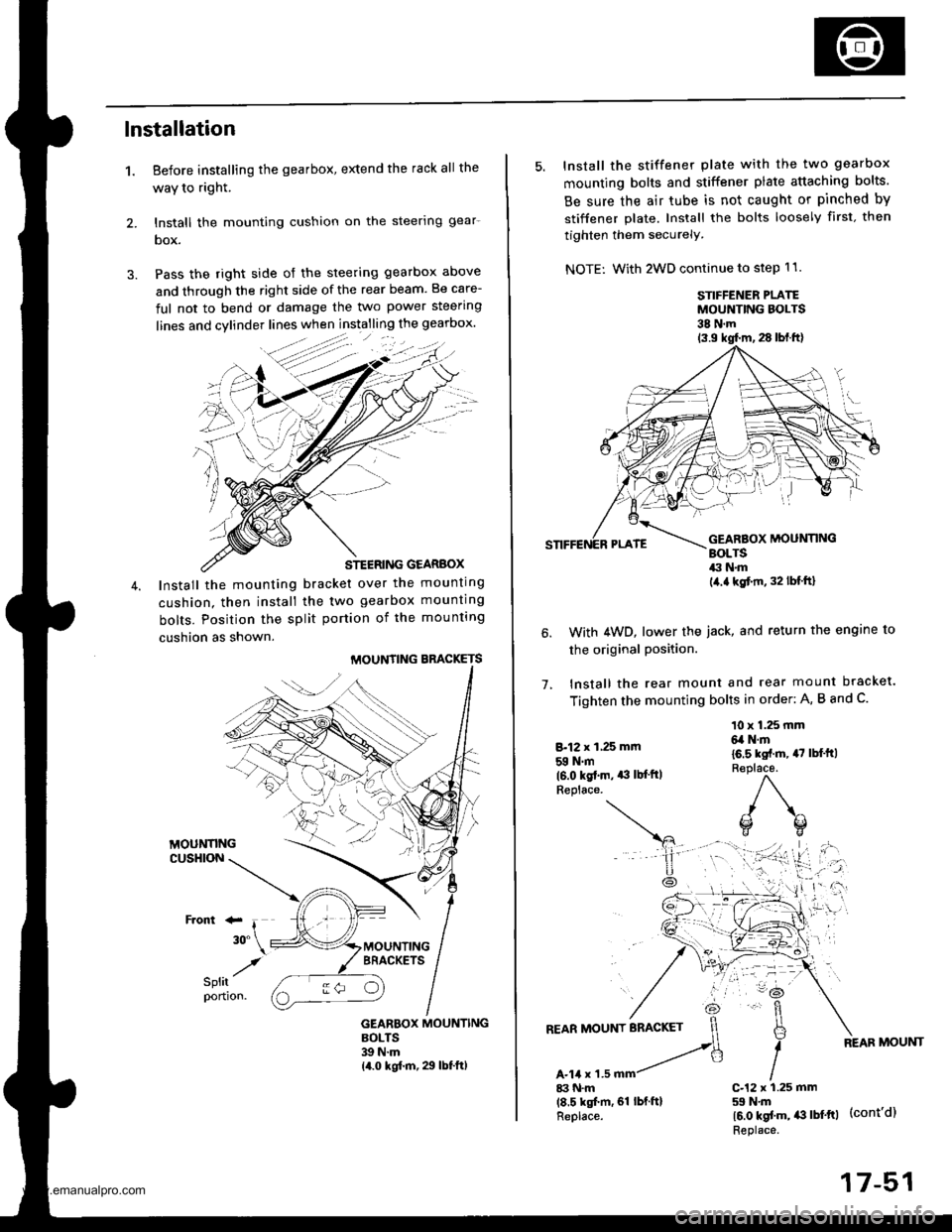

STEERING GEARBOX

Install the mounting bracket over the mounting

cushion. then install the two gearbox mounting

bolts. Position the split portion of the mounting

cushion as shown.

MOUNTING BBACKETS

GEARBOX MOUNTINGBOLTS39 N.m14.0 kgf.m, 29 lbf.ft)

:-

/

5. Install the stiffener plate with the two gearbox

mounting bolts and stiffener plate attaching bolts.

Be sure the air tube is not caught or pinched by

stiffener plate. Install the bolts loosely first. then

tighten them securely.

NOTE: With 2WD continue to step 11.

STIFFENER PLATEMOUNTING BOLTS38 N.m

1.

With 4WD, lower the iack, and return the engine to

the original Position.

lnstall the rear mount and rear mount bracket.

Tighten the mounting bolts in order: A, B and C.

8.12 x 1,25 mm

59 N.m(6.0 kgt.m. *l lb{'ftlReplace.

10 x 1.25 mm6,a N.m

16.5 kst.m, 47 lbl'ft)R€place.

)\^

o(]

17-51

www.emanualpro.com

Page 898 of 1395

't 4.

15.

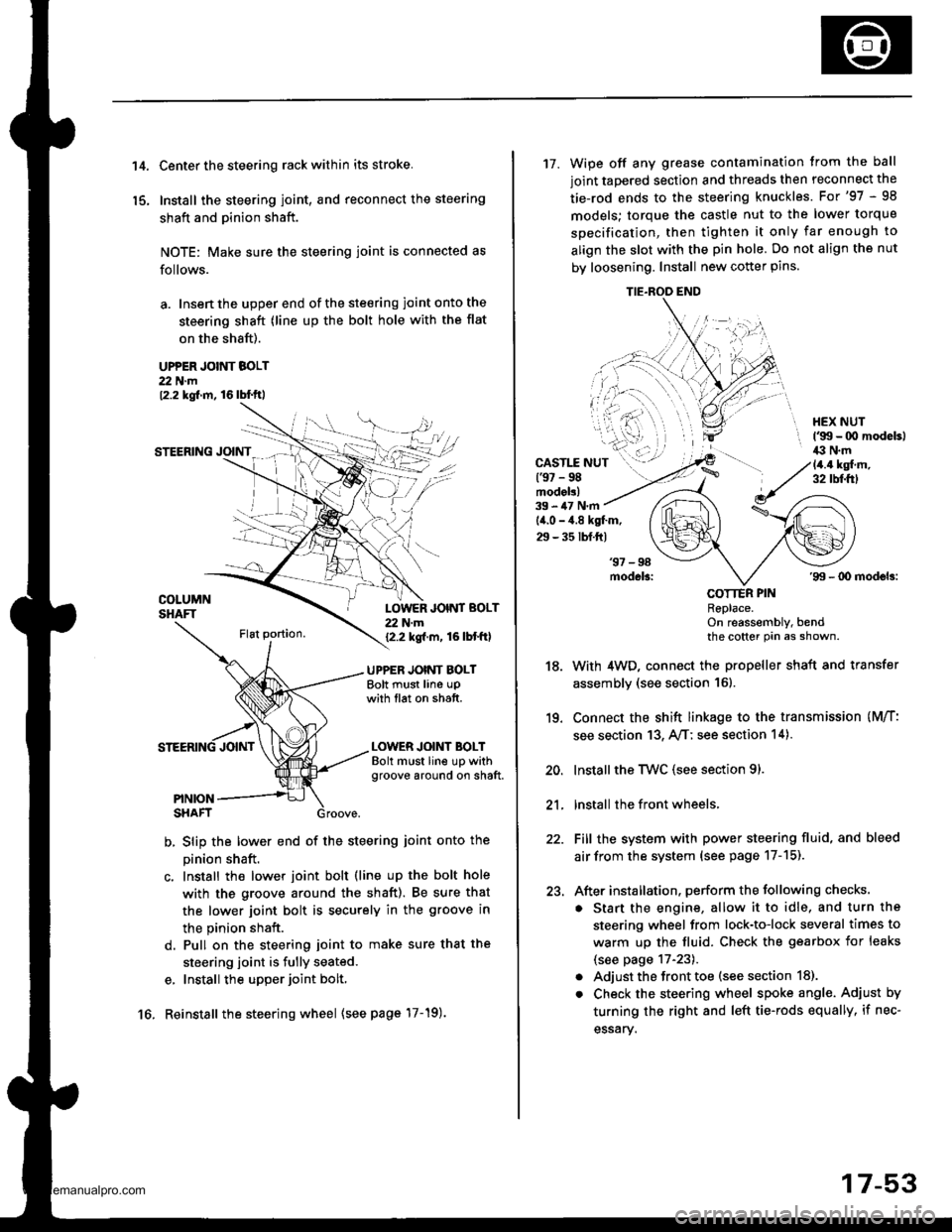

Center the steering rack within its stroke.

Install the steering joint, and reconnect the steering

shaft and pinion shaft.

NOTE: Make sure the steering joint is connected as

follows.

a. Insen the upper end of the steering joint onto the

steering shaft (line up the bolt hole with the flat

on the shaft).

UPPER JOINT BOLT22 N.m12.2 kgf.m, 16lbl.ft,

STEERING JOINT

COLUMNSHAFTLOWER JOINT BOLT22 N.m12.2 kgf.m, 16lbtftl

UPPER JOINT BOLTBolt must line upwith tlat on shatt.

LOWER JOINT BOLTBolt must line up withgroove around on shaft.

PINIONSHAFT

b, Slip the lower end of the steering ioint onto the

pinion shaft.

c. Install the lower joint bolt (line up the bolt hole

with ths groove around the shaft). Be sure that

the lower joint bolt is securely in the groove in

the pinion shaft.

d. Pull on the steering joint to make sure that the

steering joint is fully seated.

e, Install the upper joint bolt,

Reinstall the steering wheel {see page'17-19).16.

17-53

17. Wipe off any grease contamination trom the ball

joint tapered section and threads then reconnect the

tie-rod ends to the steering knuckles. For'97 - 98

models; torque the castle nut to the lower torque

specification, then tighten it only far enough to

align the slot with the pin hole. Do not align the nut

by loosening. Install new cotter pins.

CAST1T NUT(9t - 98modol!)

HEX NUTl'g!t - 00 modeb)il:l N.m14.4 ksl.m,32 tbf.f0

39 - iU N'm

lil.o - 4.8 kgl.m,

29 - 35 tbf.ftl

18.

19.

20.

21.

22.

23.

'99 - lD modeb:

COTTER PINRePlace.on reassembly, bendthe cotter Pin as shown.

With 4WD, connect the propeller shaft and transfer

assembly (see section 16).

Connect the shift linkage to the transmission (M/T:

see section 13, A,/T; see section 14).

Installthe Twc (see section 91.

lnstall the front wheels,

Fill the system with power steering fluid, and bleed

air from the system (see page 17-15).

After installation. perform the following checks.

. Start the engine, allow it to idle, and turn the

steering wheel from lock-to-lock several times to

warm up the fluid. Check the gearbox for leaks

(see page 17-23).

. Adjust the front toe (s€e section 18).

. Check the steering wheel spoke angl€. Adjust by

turning the right and left tie-rods equally, if nec-

essary.

TIE.ROO END

www.emanualpro.com

Page 1034 of 1395

Dashboard Removal and Installation

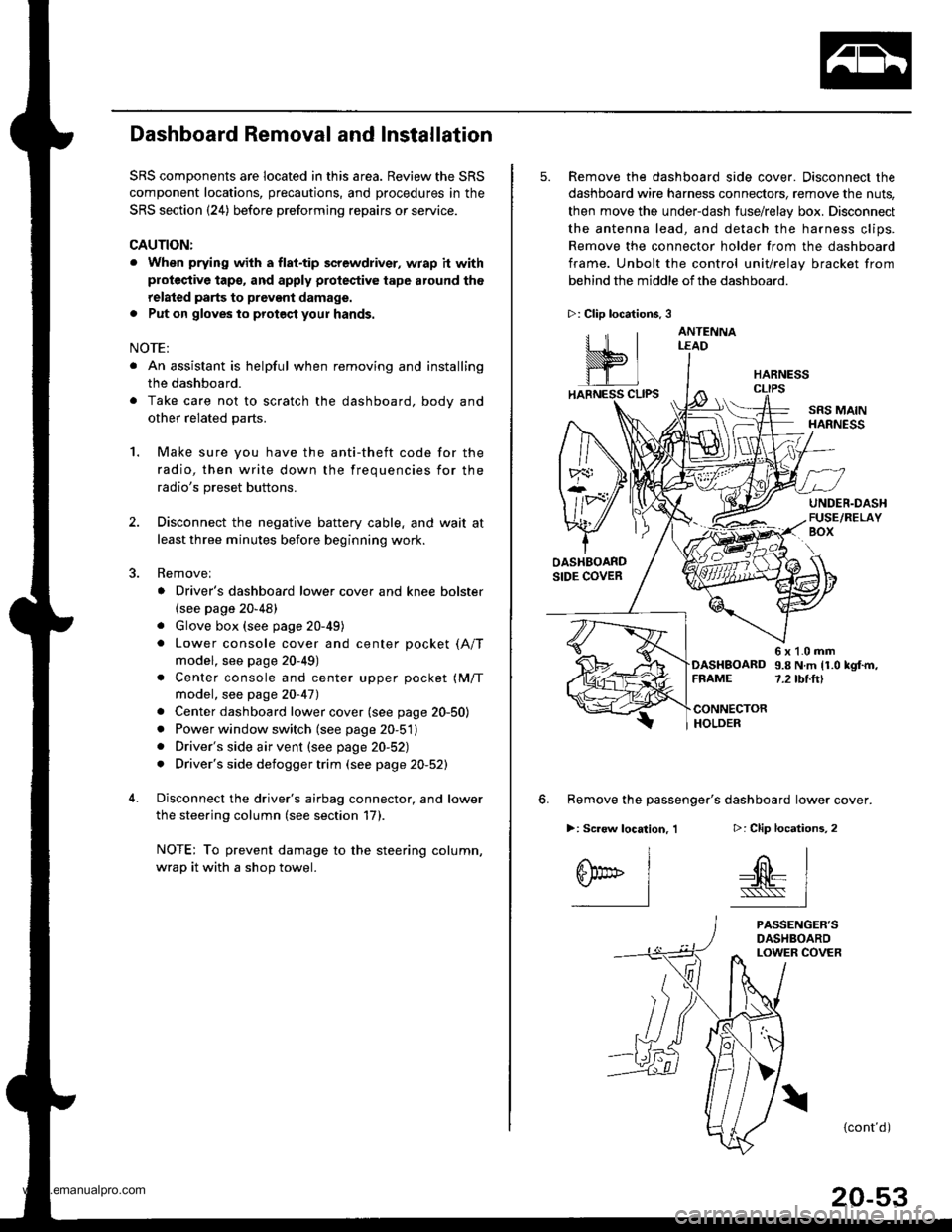

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section {24) before preforming repairs or service.

CAUTION:

. When prying with a flat-tip screwdriver, wrap h withprotective tap€, and apply protective tape around the

related parts to prevgnt damage.

. Put on gloves to prot€ct your hands.

NOTE:

. An assistant is helpful when removing and installing

the dashboard.

. Take care not to scratch the dashboard, bodv and

other related parts.

1.Make sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons.

Disconnect the negative battery cable. and wait at

least three minutes before beginning work.

Removei

a Driver's dashboard lower cover and knee bolster(see page 20-48)

. Glove box (see page 20-49)

. Lower console cover and center pocket (A/T

model, see page 20-49)

. Center console and center upper pocket (M/T

model, see page 20-47)

. Center dashboard lower cover (see page 20-50)

. Power window switch (see page 20-51)

. Driver's side air vent (see page 20-52)

. Driver's side defogger trim (see page 20-52)

Disconnect the driver's airbag connector, and lower

the steering column (see section 17)

NOTE: To prevent damage to the steering column,

wrap it with a shop towel.

2.

5. Remove the dashboard side cover. Disconnect the

dashboard wire harness connectors, remove the nuts,

then move the under-dash fuse/relay box. Disconnect

the antenna lead, and detach the harness clips.

Remove the connector holder from the dashboard

frame. Unbolt the control unit/relay bracket from

behind the middle of the dashboard.

HARNESS

6. Remove the passenger's dashboard lower cover.

D: Clip locations,

nl

-$t- Issj

I

ANTENNALEAD

>: Clip locations.

rttl

slllll

>: Scr€w location, 1

I

SF:oo I-l

SRS MAINHARNESS

UNDER.DASHFUSE/RELAYBOX

OASHBOARDSIDE COVER

6x1.0mm9.8Nm11.0kgf.m,7.2tbt.ftlDASHBOARDFFAME

CONNECTORHOLDER

PASSENGER'SDASHBOARDLOWER COVER

{cont'd)

www.emanualpro.com

Page 1152 of 1395

Compressor

Replacement

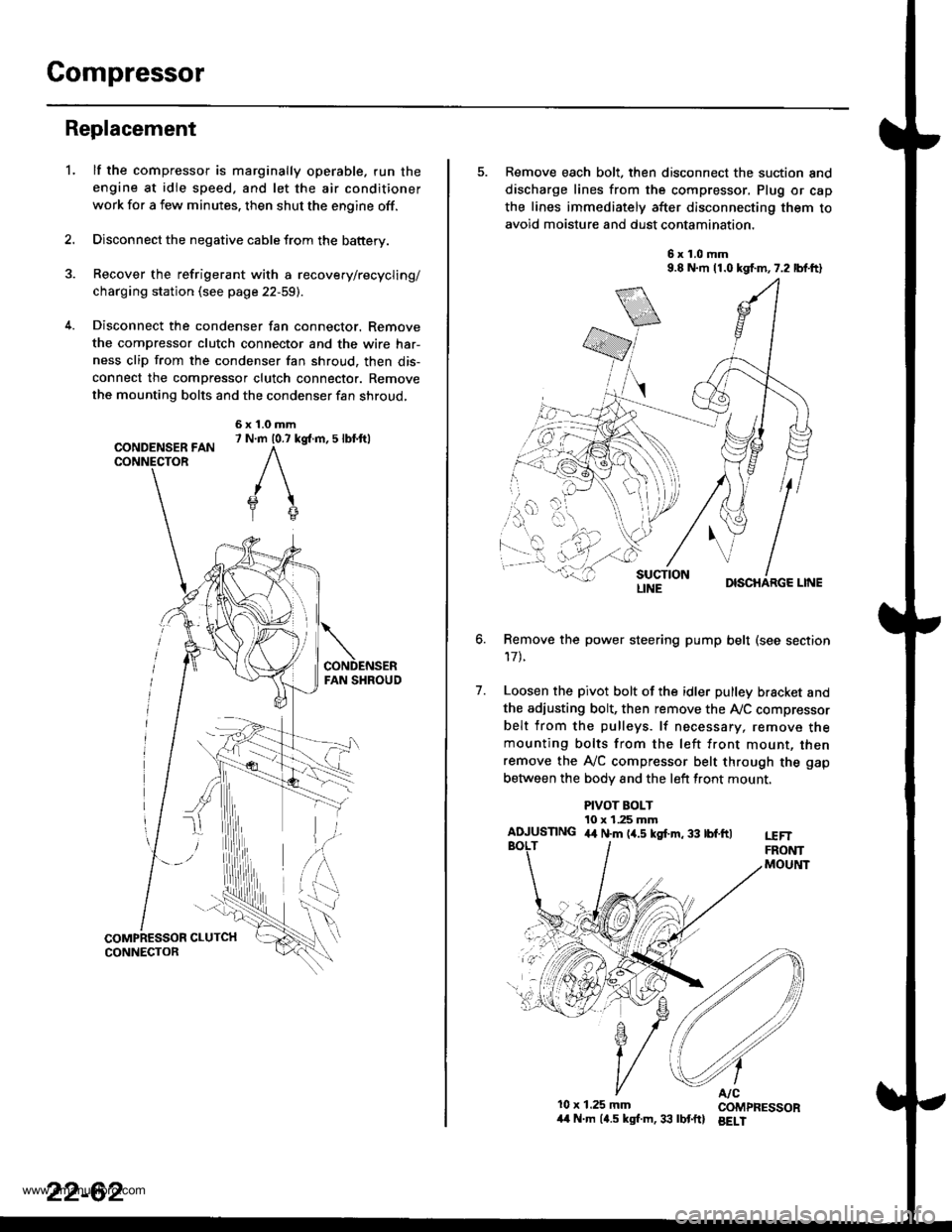

lf the compressor is marginally operable. run the

engine at idie speed, and let the air conditioner

work for a few minutes. then shut the engine off.

Disconnect the negative cable from the battery.

Recover the refrigerant with a recovery/recycling/

charging station (see page 22-59).

Disconnect the condenser fan connector. Remove

the compressor clutch connector and the wire har-

ness clip from the condenser fan shroud, then dis-

connect the compressor clutch connector. Remove

the mounting bolts and the condenser fan shroud,

CONDENSER FANCONNECTOR

6x1.0mm7 N.m 10.7 kg{.m, 5 lbl.ftl

'L

2.

5. Remove each bolt, then disconnect the suction and

discharge lines from the compressor. Plug or cap

the lines immediately after disconnecting them to

avoid moisture and dust contamination,

6x1.0mm9.8 N.m 11.0 kgf.m,7.2 lbf.ft)

DISCHARGE LINE

Remove the power steering pump belt (see section

17t.

Loosen the pivot bolt of the idler pulley bracket and

the adiusting bolt, then remove the Ay'C compressor

belt from the pulleys. lf necessary, remove themounting bolts from the left front mount, thenremove the A,/C compressor belt through the gap

between the bodv and the left front mount.

6.

7.

PIVOT BOLT10 x 1.25 mmAIUUSTING 4,t N.m (4.5 kgf.m, 33 tbf.ftlt€FTFRONTMOUltlT

10x 1.25 mm COMPRESSOR/t4 N.m (4.5 kgl.m,33 lbtftl BELI

LINE

www.emanualpro.com

Page 1153 of 1395

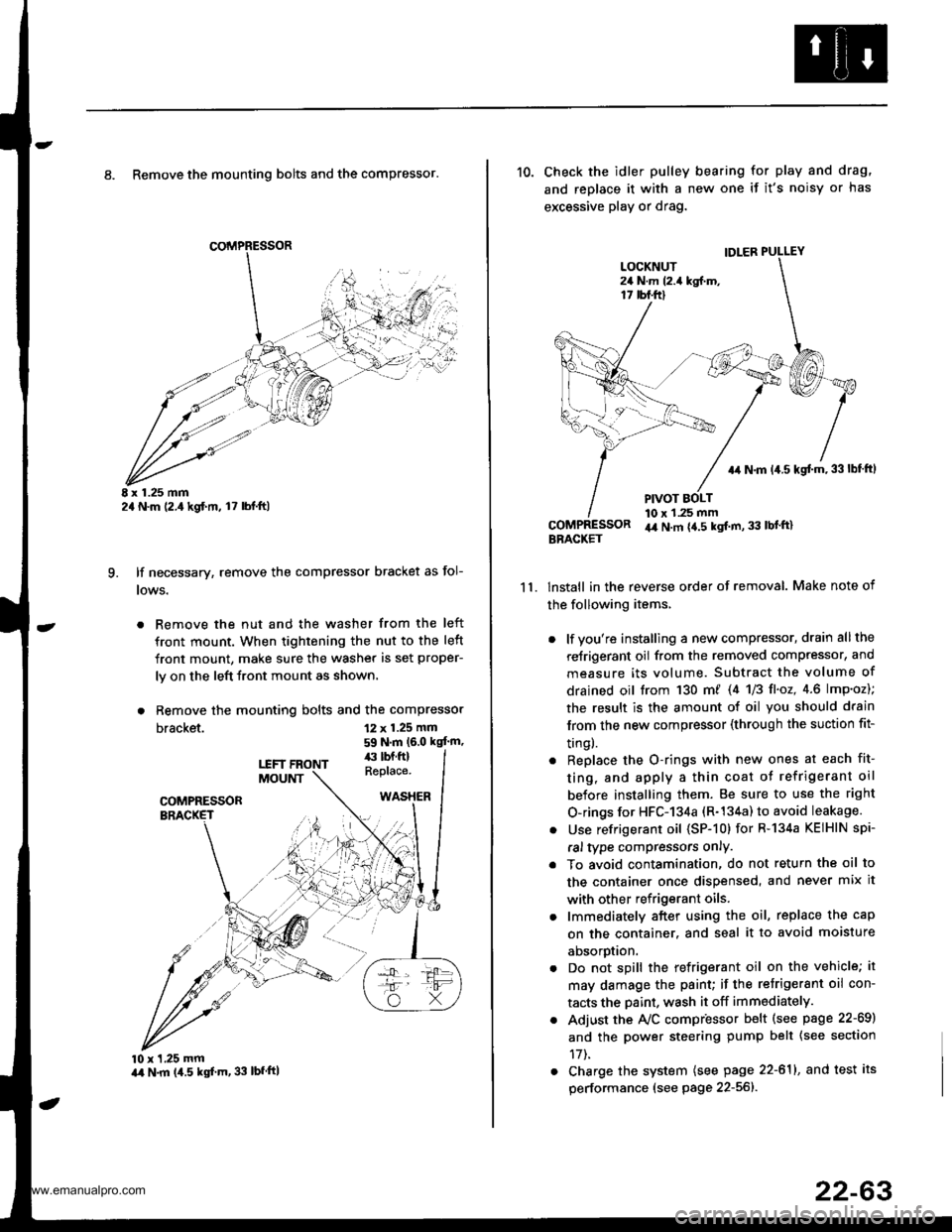

8. Remove the mounting bolts and the compressor.

E x 1.25 mm2a N.m (2.,1kgf.m, l7 lbl.ft)

lf necessary, remove the compressor bracket as fol-

lows.

. Remove the nut and the washer from the left

front mount. When tightening the nut to the left

front mount, make sure the washer is set proper-

ly on the left front mount as shown.

. Remove the mounting bolts and the compressor

bracket.

q

12 x 1.25 mm

59 N.m (6.0 kgt'm,

10 x 1,25 mmart N.m (4.5 kgf'm, 33 lbfftl

11.

10. Check the idler pulley bearing for play and drag,

and replace it with a new one if it's noisy or has

excessive play or drag.

lnstall in the reverse order of removal. Make note of

the following items,

. lf you're installing a new compressor, drain all the

reJrigerant oil from the removed compressor, and

measure its volume. Subtract the volume of

drained oil trom 130 m/ 14 U3 fl'o2,4.6 lmp'oz);

the result is the amount of oil you should drain

lrom the new compressor (through the suction fit-

trngl.

. Replace the O-rings with new ones at each fit-

ting, and apply a thin coat o{ refrigerant oil

before installing them. Be sure to use the right

O-rings for HFC-134a (R-134a) to avoid leakage.

. Use refrigerant oil (SP-10) for R-134a KEIHIN spi-

ral type compressors only.

. To avoid contamination, do not return the oil to

the container once dispensed, and never mix it

with other refrigerant oils.

. lmmediately after using the oil, replace the cap

on the container. and seal it to avoid moisture

aDsorprlon.

. Do not spill the refrigerant oil on the vehicle; it

may damage the paint; if the retrigerant oil con-

tacts the Daint, wash it off immediately.

. Adjust the Ay'C compr'essor b€lt (see psge 22-69)

and the power steering pump belt {see section

17t.

. Charge the system (see page 22-611, and test its

performance (see page 22-56]-.

IDLER PULLEY

+r N.m 14.5 kgt m,33lbf ftl

PIVOT BOLT10 x 1.25 mmir4 N.m {4.5 kgt m, 33 lbl'ft}BBACKET

www.emanualpro.com

Page 1172 of 1395

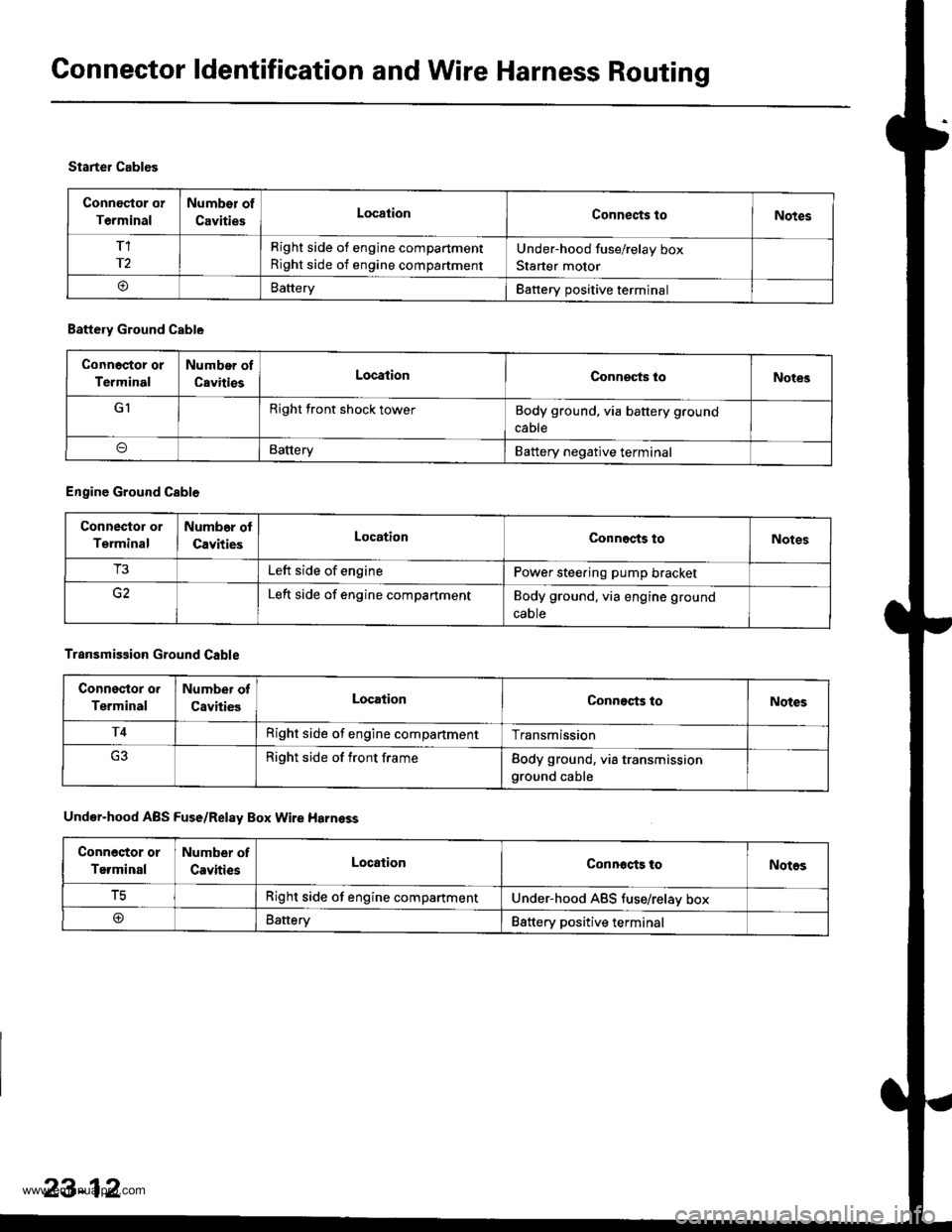

Connector ldentification and Wire Harness Routing

Connoctor or

Terminal

Number of

CavitiesLocationConnects toNotes

T1

r2

Right side of engine compartment

Right side of engine compartment

Under-hood fuse/relay box

Starter motor

oBatteryBattery positive terminal

Starter Cables

Battery Ground Cable

Connoctor or

Terminal

Number of

CavitiesLocationConneqts loNotes

GIRight front shock towerBody ground, via battery ground

cable

BatteryBattery negative terminal

Engine Ground Cable

Connector or

Terminal

Numb6r ol

CavitiesLocationConnects toNotes

T3Left side of enginePower steering pump bracket

Left side of engine compartmentBody ground. via engine ground

caote

Transmission Ground Cable

Connsstor o.

Terminal

Number of

CavitiesLocationConnects toNotes

T4Right side of engine compartmentTransmission

Right side of front frameBody ground, via transmissionground cable

Under-hood ABS Fuse/Relay Box Wire Harnsss

Conn6stor or

Terminal

Number of

CavitiesLocationConnocts toNotos

tcRight side of engine compartmentUnder-hood ABS tuse/relav box

@Battery88ttery positive terminal

23-12

www.emanualpro.com

Page 1316 of 1395

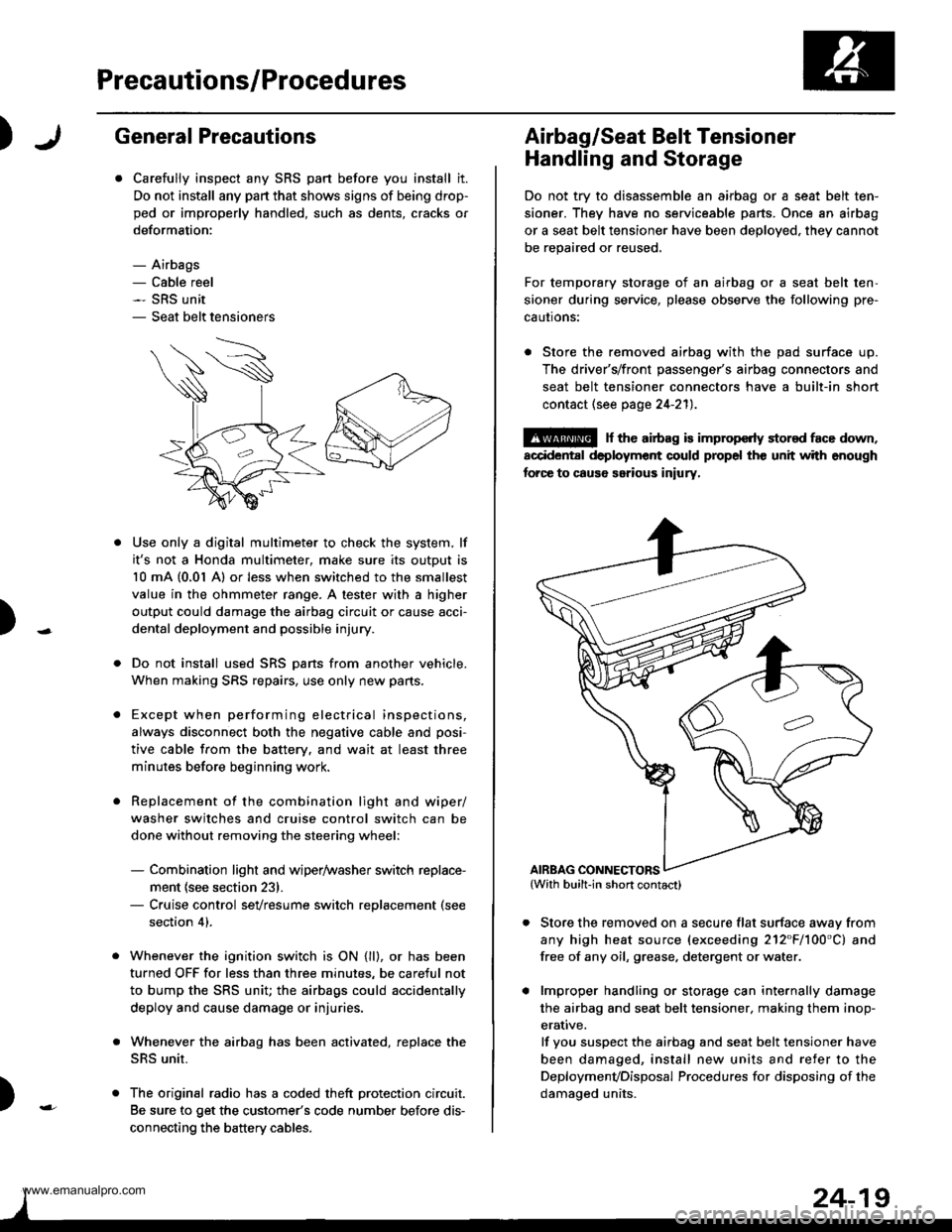

Precautions/Procedures

)General Precautions

Carefully inspect any SRS part before you install it.

Do not install any part that shows signs of being drop-

ped or improperly handled, such as dents, cracks or

deformation:

- Airbags- Cable reel- SRS unit- Seat belt tensioners

N

)-

Use only a digital multimeter to check the system, lf

it's not a Honda multimeter, make sure its output is

10 mA (0,01 A) or less when switched to the smallest

value in the ohmmeter range. A tester with a higher

output could damage the airbag circuit or cause acci-

dental deployment and possible injury.

Do not install used SRS Dans from another vehicle,

When making SRS repairs, use only new pans.

Except when performing electrical inspections,

always disconnect both the negative cable and posi-

tive cable from the batterv. and wait at least three

minutes before beginning work.

Replacement of the combination light and wiper/

washer switches and cruise control switch can be

done without removing the steering wheel:

- Combination light and wiper/washer switch replace-

ment {see section 231.- Cruise control sevresume switch replacement (see

section 41.

Whenever the ignition switch is ON {ll}, or has been

turned OFF for less than three minutes, be careful not

to bump the SRS unit; the airbags could accidentally

deploy and cause damage or injuries.

Whenever the airbag has been activated, replace the

SRS unit.

The original radio has a coded theft protection circuit.

Be sure to get the customer's code number before dis-

connecting the battery cables.

)

Airbag/Seat Belt Tensioner

Handling and Storage

Do not try to disassemble an airbag or a seat belt ten-

sioner. They have no serviceable parts. Once an airbag

or a seat belt tensioner have been deployed. they cannot

be repaired or reused.

For temporary storage of an airbag or a seat belt ten-

sioner during service, please observe the following pre-

cautons:

. Store the removed airbag with the pad surface up.

The driver's/front passenger's airbag connectors and

seat belt tensioner connectors have a built-in short

contact (see page 24-211.

@ r th€ airb.g is impropcrty stor€d face down,

accidental deployment could propel the unit with enough

forc€ to caus6 serious iniury,

Store the removed on a secure flat surface awav from

any high heat source (exceeding 212"F/100'C) and

free of any oil, grease. detergent or water.

lmproper handling or storage can internally damage

the airbag and seat belt tensioner. making them inop-

erative.

lf you suspect the airbag and seat belt tensioner have

been damaged, install new units and refer to the

Deploymenvoisposal Procedures for disposing of the

damaoed units.

AIRBAG CONNECTORS

www.emanualpro.com

Page 1384 of 1395

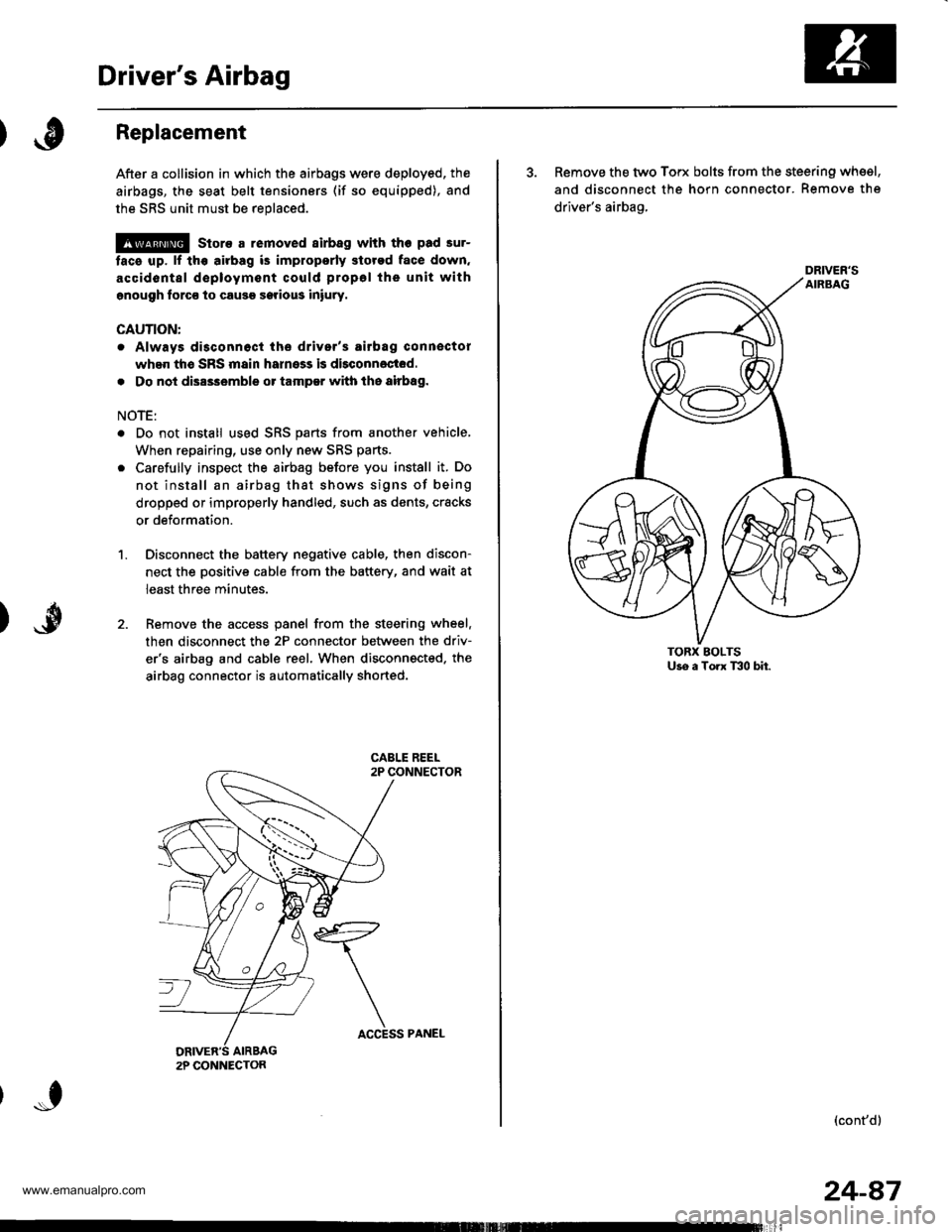

Driver's Airbag

1.

Replacement

After a collision in which the airbags were deployed, the

airbags, the seat belt tensioners (if so equipped), and

the SRS unit must be replaced.

@ Store a removed airbag with the pad su.-

tacs up, lf th€ airbag is improperly stored face down.

accidental deployment could propal the unit with

enough forc€ io causg serioug iniury.

CAUTION:

. Always disconnoct the drivor's airbag connector

when the SRS main harness is disconnactod.

. Do not disassemble or tamper with ihe airbag.

NOTE:

Do not install used SRS parts from another vehicle,

When repairing, use only new SRS parts.

Carefully inspect the airbag before you install it. Do

not install an airbag that shows signs of being

dropped or improperly handled, such as dents, cracks

or deformation.

Disconnect the battery negative cable, then discon-

nect the positive cable from the battery, and wait at

least three minutes.

Remove the access panel from the steering wheel.

then disconnect the 2P connector between the driv-

er'6 airbag and cable reel. When disconnected. the

airbag connector is automatically shorted.

2P CONNECTON

ACCESS PANEL

24-87

3. Remove the two Torx bolts from the steering whsel,

and disconnect the horn connector. Remove the

driver's airbag,

(cont'd)

DRIVER'S

www.emanualpro.com

Page 1388 of 1395

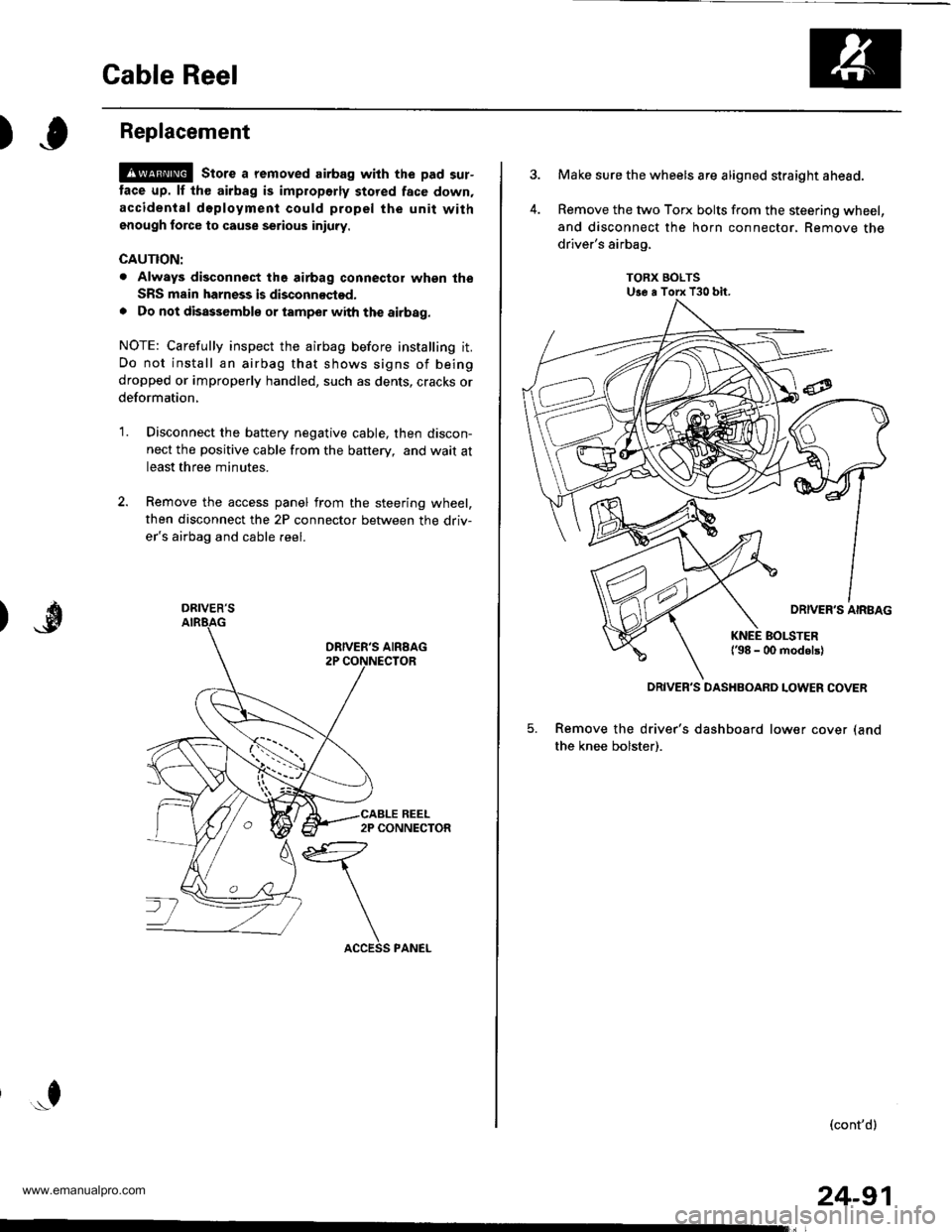

Cable Reel

)Replacement

@ stors a removed airbag with the pad sur-

tace up. lf th€ airbag is improperly stored face down,

accidental d6ployment could propel the unit withgnough force to cause serious iniuty.

CAUTION:

. Always disconnect the airbag connector whgn the

SRS msin harness is disconnoctod.

. Do not disassemblo or tamper with the airbag.

NOTE: Carefully inspect the airbag before installing it.

Do not install an airbag that shows signs of being

dropped or improperly handled, such as dents, cracks or

deformation,

'1.Disconnect the battery negative cable, then discon-

nect the positive cable from the battery, and wait at

least three minutes.

Remove the access panel from the steering wheel,

then disconnect the 2P connector between the driv-

er's airbag and cable reel.

*f

DRIVER'S

24-91

Make sure the wheels are aligned straight ahead.

Remove the two Torx bolts from the steering wheel,

and disconnect the horn connector, Remove the

driver's airbag,

TORX BOLTSUse a Torx T30 bit.

5. Remove the driver's dashboard lower cover (and

the knee bolster).

(cont'd)

DRIVER'S DASHBOARD LOWER COVER

www.emanualpro.com

Page 1392 of 1395

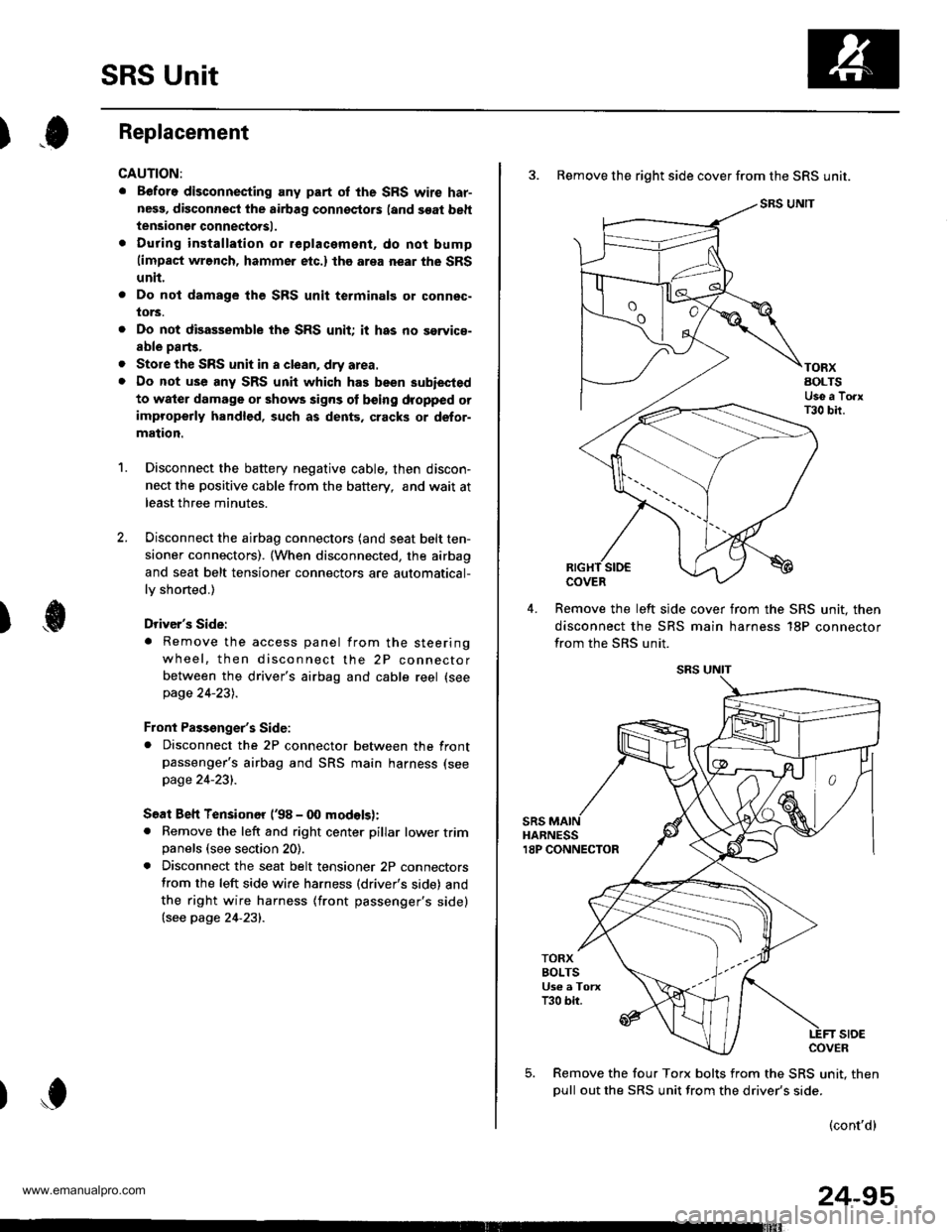

SRS Unit

).0Replacement

CAUTION:

. Before disconnecting any part of the SRS wire har-

nesg, disconnect the airbag connoctors (and soat beh

tensioner connectorsl.

. During installation or replacament, do not bump(impact wrench, hammer etc.) the area near the SRS

unit.

Do not damage the SFS unit terminalg or connsc-

lors.

Do not disassemble the SRS unit it has no saryice-

able parts,

Store the SRS unit in a clean, dry area.

Do not use any SRS unit which has been subiected

to water damage or shows signs ot being dropped orimproperly handlgd, such as dents, cracks or defor-

mation.

Disconnect the battery negative cable, then discon-

nect the positive cable from the battery, andwaitat

least three minutes.

Disconnect the airbag connectors (and seat belt ten-

sioner connectors). (When disconnected, the airbag

and seat belt tensioner connectors are automatical-

ly shorted.)

Driver's Side:

. Remove the access panel from the steering

wheel, then disconnect the 2P connector

between the driver's airbag and cable reel (see

page 24-231.

Front Passenger's Side:. Disconnect the 2P connector between the frontpassenger's airbag and SRS main harness (see

page 24-231.

Soat Beh Tensionor ('98 - 00 modelsr:. Remove the left and right center pillar lower trimpanels (see section 20).

. Disconnect the seat belt tensioner 2P connectors

from the left side wire harness (driver's side) and

the right wire harness (front passenger's side)(see page 24'231.

2.

a

a

'1.

)

)o

24-95

3. Remove the right side cover from the SRS unit.

SRS UNIT

TORXAOLTSUse a TorxT30 bir.

COVER

Remove the left slde cover from the SRS unit. then

disconnect the SRS main harness 18P connector

from the SRS unit.

sRsHARNESS18P CONNECTOR

TORXBOLTSUs€ a TorxT30 bir.

stoECOVER

Remove the four Torx bolts from the SRS unit. then

oull out the SRS unit from the driver's side.

(cont'd)

www.emanualpro.com