remove clutch HONDA CR-V 1999 RD1-RD3 / 1.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 814 of 1395

Rear Differential Assembly

Reassembly (cont'dl

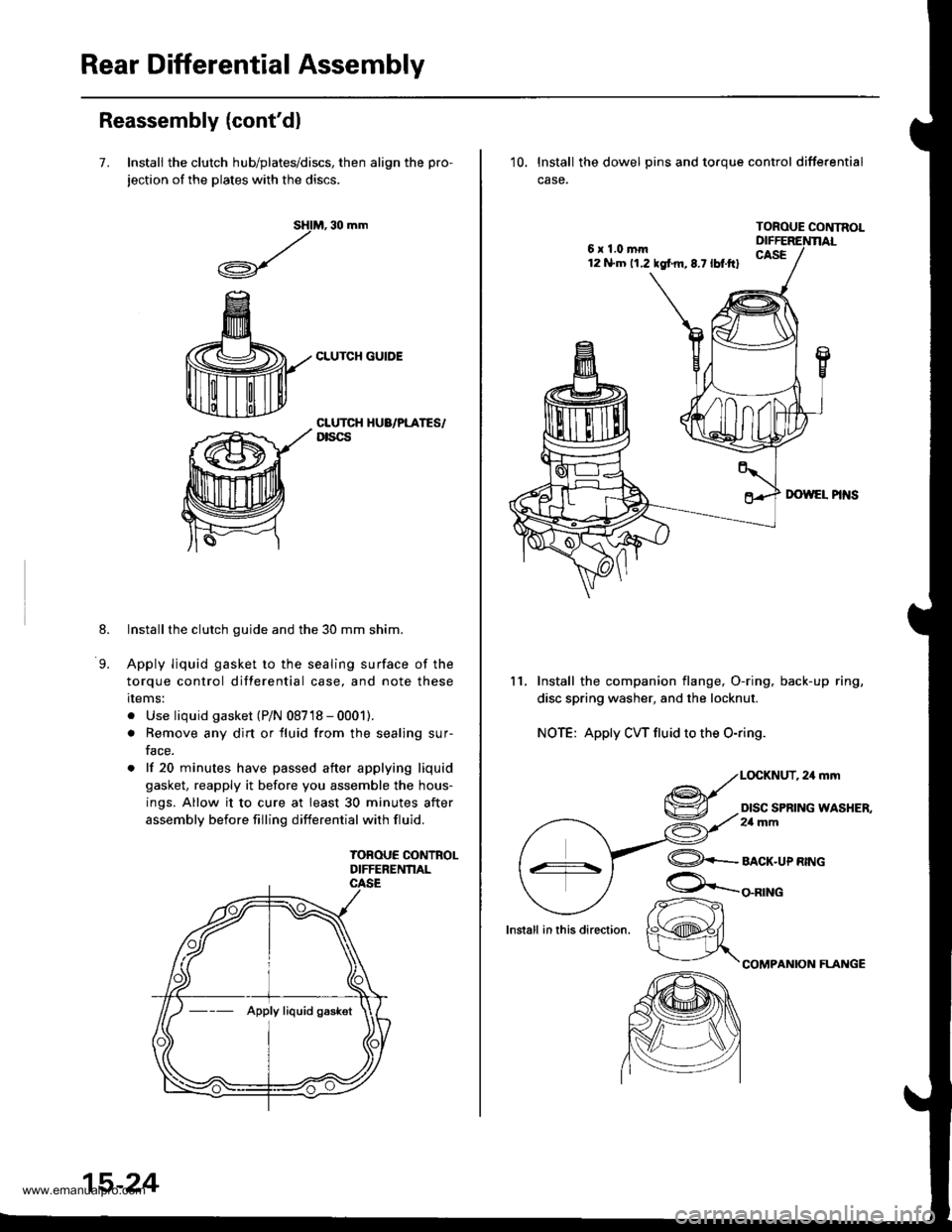

7. Install the clutch hub/plates/discs, then align the pro-

jection of the plates with the discs.

M, 30 mm

CLUTCH GUIDE

sHl

,/

.A-\,/r\-7

8.

9.

CLUTCH HUA/PLATES/Dtscs

Installthe clutch guide and the 30 mm shim.

Apply liquid gasket to the sealing surface of the

torque control differential case, and note these

rlems:

. Use liquid gasket (P/N 08718 - 0001).

. Remove any dirt or fluid from the sealing sur-

face.

. lf 20 minutes have passed after applying liquid

gasket, reapply it before you assemble the hous-

ings. Allow it to cure at least 30 minutes after

assembly before filling differential with fluid.

TOBOUE CONTROLDIFFERENNAL

--- Apply liquid gaskot

15-24

6x1.0mm12 N.m 11.2 tgf m,8.7lbt.ftl

10. lnstall the dowel pins and toroue control differential

case.

TOROUE CONTNOL

11. Install the companion flange, O-ring, back-up ring,

disc spring washer, and the locknut.

NOTE: Apply CW fluid to the O-ring.

,24mm

DISC SPRING WASHER,2a mm

lnstall in this direction.

@+-_alcr-upnwc

COMPANION FLAI{GE

/r-

K@#/

www.emanualpro.com

Page 1124 of 1395

Troubleshooting

To page 22-35

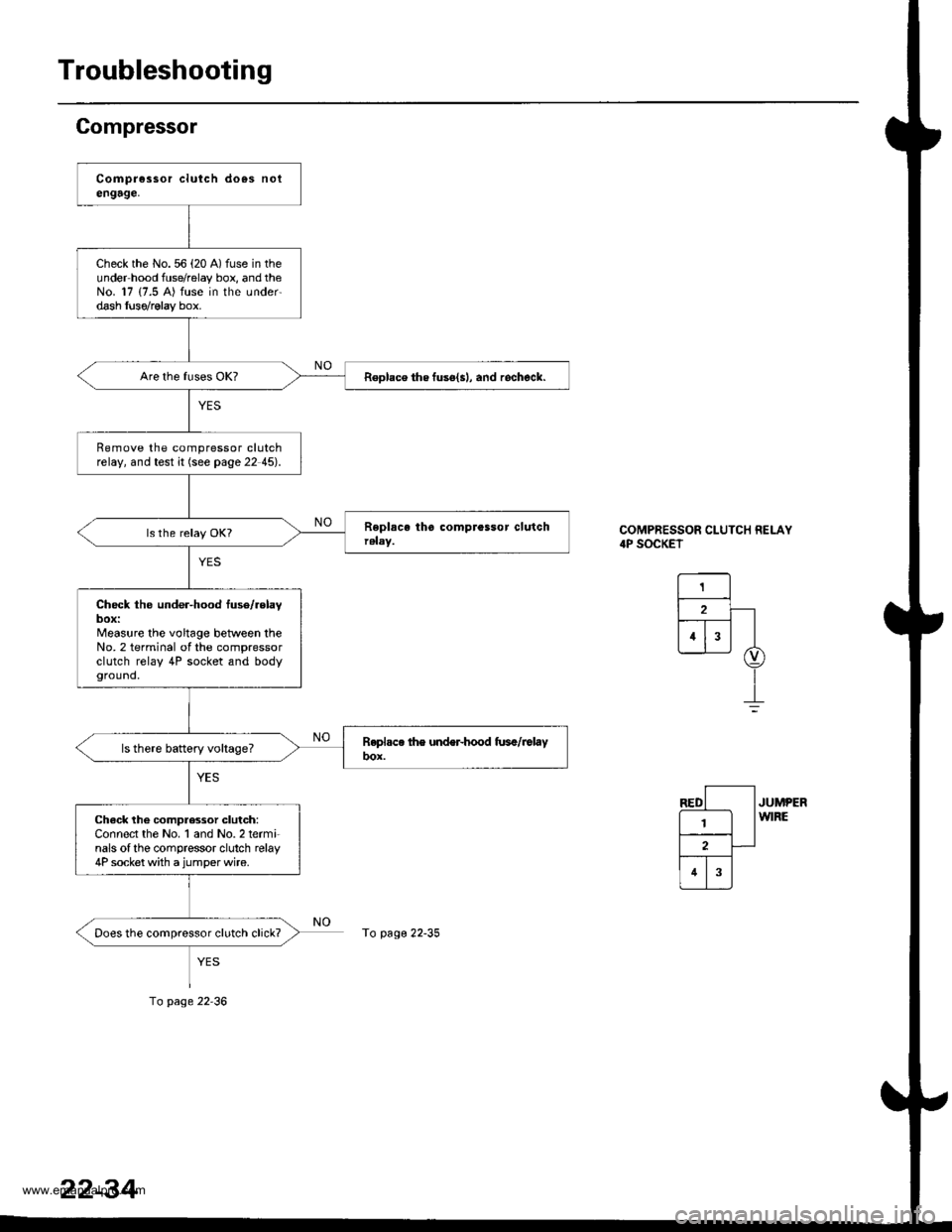

Check the No. 56 (20 A) fuse in theunder hood fuse/relay box, and theNo. 17 (7.5 A) fuse in the underdash luso/rglay box.

Replace the fuso(sl, and r6check.

Remove the compressor clutchrelay, and test it (see page 22 45).

Check the under-hood fuse/relayDOX:Measure the voltage between theNo. 2 terminal of the compressorclutch relay 4P socket and bodyground,

Chack lhe complessor clutch:Connect the No. 1 and No. 2 termi-nals ofthe comoressor clutch relav4P socket with a jumper wire.

Does the comprossor clutch click?

22-34

To page 22-36

www.emanualpro.com

Page 1152 of 1395

Compressor

Replacement

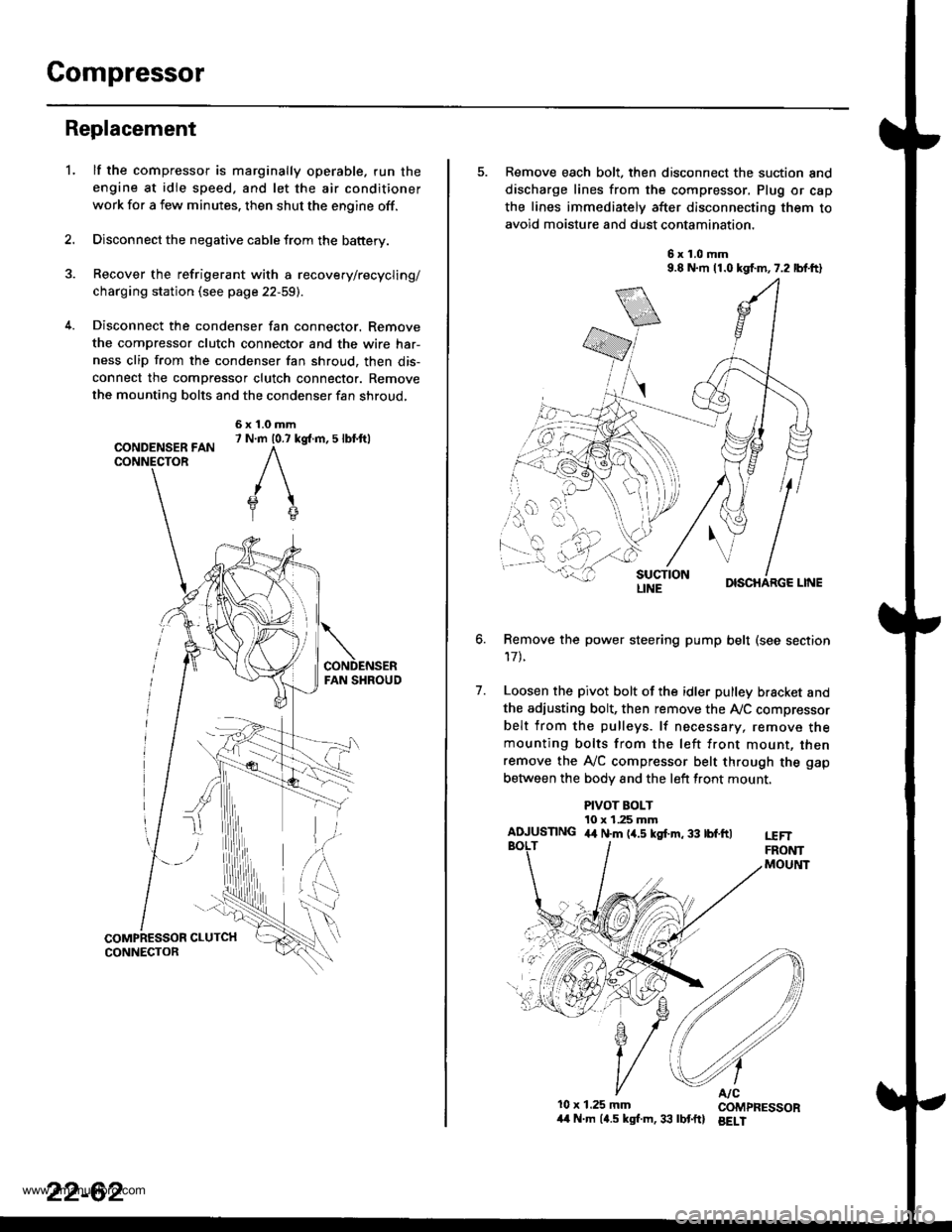

lf the compressor is marginally operable. run the

engine at idie speed, and let the air conditioner

work for a few minutes. then shut the engine off.

Disconnect the negative cable from the battery.

Recover the refrigerant with a recovery/recycling/

charging station (see page 22-59).

Disconnect the condenser fan connector. Remove

the compressor clutch connector and the wire har-

ness clip from the condenser fan shroud, then dis-

connect the compressor clutch connector. Remove

the mounting bolts and the condenser fan shroud,

CONDENSER FANCONNECTOR

6x1.0mm7 N.m 10.7 kg{.m, 5 lbl.ftl

'L

2.

5. Remove each bolt, then disconnect the suction and

discharge lines from the compressor. Plug or cap

the lines immediately after disconnecting them to

avoid moisture and dust contamination,

6x1.0mm9.8 N.m 11.0 kgf.m,7.2 lbf.ft)

DISCHARGE LINE

Remove the power steering pump belt (see section

17t.

Loosen the pivot bolt of the idler pulley bracket and

the adiusting bolt, then remove the Ay'C compressor

belt from the pulleys. lf necessary, remove themounting bolts from the left front mount, thenremove the A,/C compressor belt through the gap

between the bodv and the left front mount.

6.

7.

PIVOT BOLT10 x 1.25 mmAIUUSTING 4,t N.m (4.5 kgf.m, 33 tbf.ftlt€FTFRONTMOUltlT

10x 1.25 mm COMPRESSOR/t4 N.m (4.5 kgl.m,33 lbtftl BELI

LINE

www.emanualpro.com

Page 1155 of 1395

Clutch Inspection

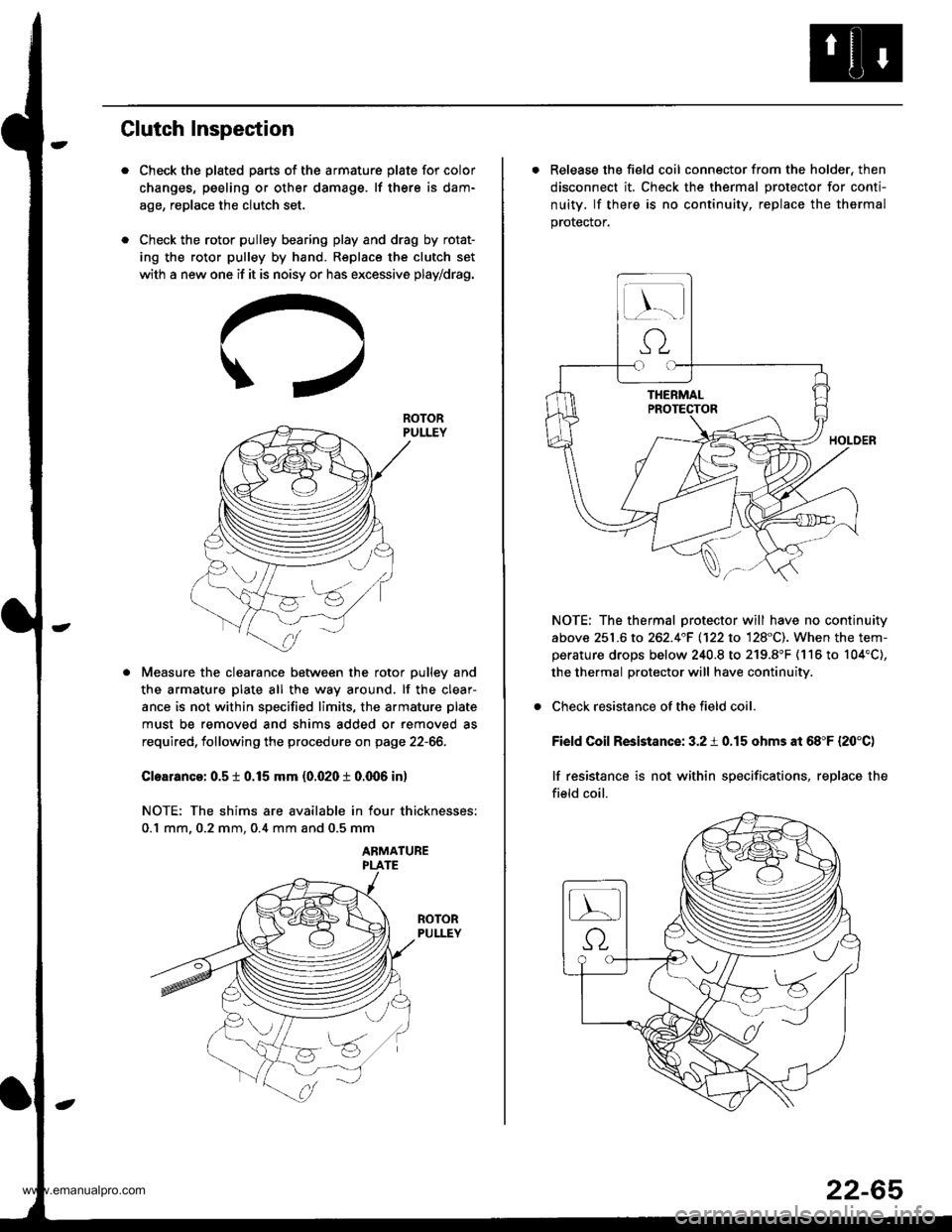

Check the plated parts of the armature plate for color

changes, peeling or other damage. lf there is dam-

age, replace the clutch set.

Check the rotor pulley bearing play and drag by rotat-

ing the rotor pulley by hand. Replace the clutch set

with a new one if it is noisy or has excessive play/drag.

Measure the clearance between the rotor pulley and

the armature plate all the way around. lf the clear-

ance is not within specified limits, the armature plate

must be removed and shims added or removed as

required, following the procedure on page 22-66.

Cloarance: 0.5 t 0.15 mm {0.020 t 0.q)6 in)

NOTE: The shims are available in four thicknesses:

0.1 mm. 0.2 mm. 0.4 mm and 0.5 mm

ABMATUBE

ROTOR

. Release the field coil connector from the holder, then

disconnect it. Check the thermal protector for conti-

nuity, lf there is no continuity, replace the thermal

prorecror.

NOTE: The thermal protector will have no continuity

above 251.6 to 262.4"F 1122 to 128"C). When the tem-perature drops below 240.8 to 219.8"F (116 to 104'C),

the thermal protector will have continuity.

Check resistance of the field coil.

Field Coil Resistance: 3.2 i 0.15 ohms at 68"F {20'C)

lf resistance is not within specifications, replace the

field coil.

22-65

www.emanualpro.com

Page 1156 of 1395

Compressor

Glutch Overhaul

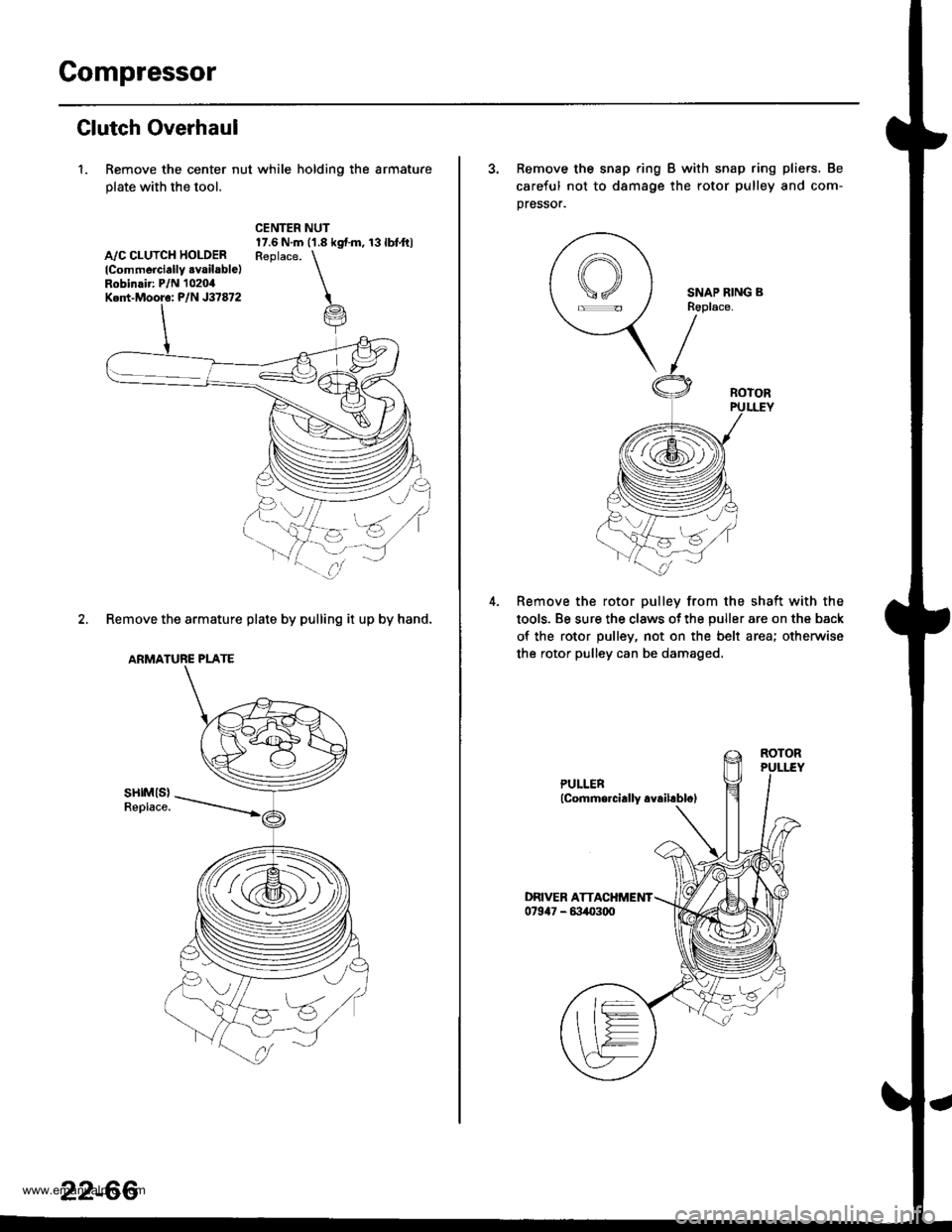

1. Remove the center nut while holding the armature

plate with the tool.

A,/C CLUTCH HOLOERlCommerciallY .vailable)Robinair: P/N 1020,0Ked-Mooro: P/N J37872

CENTER NUT17.6 N.m ('1.8 kgf.m, 13lbfft)Reolace. \

i

2. Remove the armature plate by pulling it up by hand.

ARMATURE PLATE

sHtMls)Replace.

za:s

(i@,

22-66

3. Remove the snap ring B with snap ring pliers. Be

careful not to d8mage the rotor pulley and com-

pressor.

SNAP RING BR6place.

Remove the rotor pulley from the shaft with the

tools. Be sure the claws ot the puller are on the back

of the rotor pulley, not on the belt area; otherwise

the rotor pulley can be damaged.

www.emanualpro.com

Page 1157 of 1395

l-

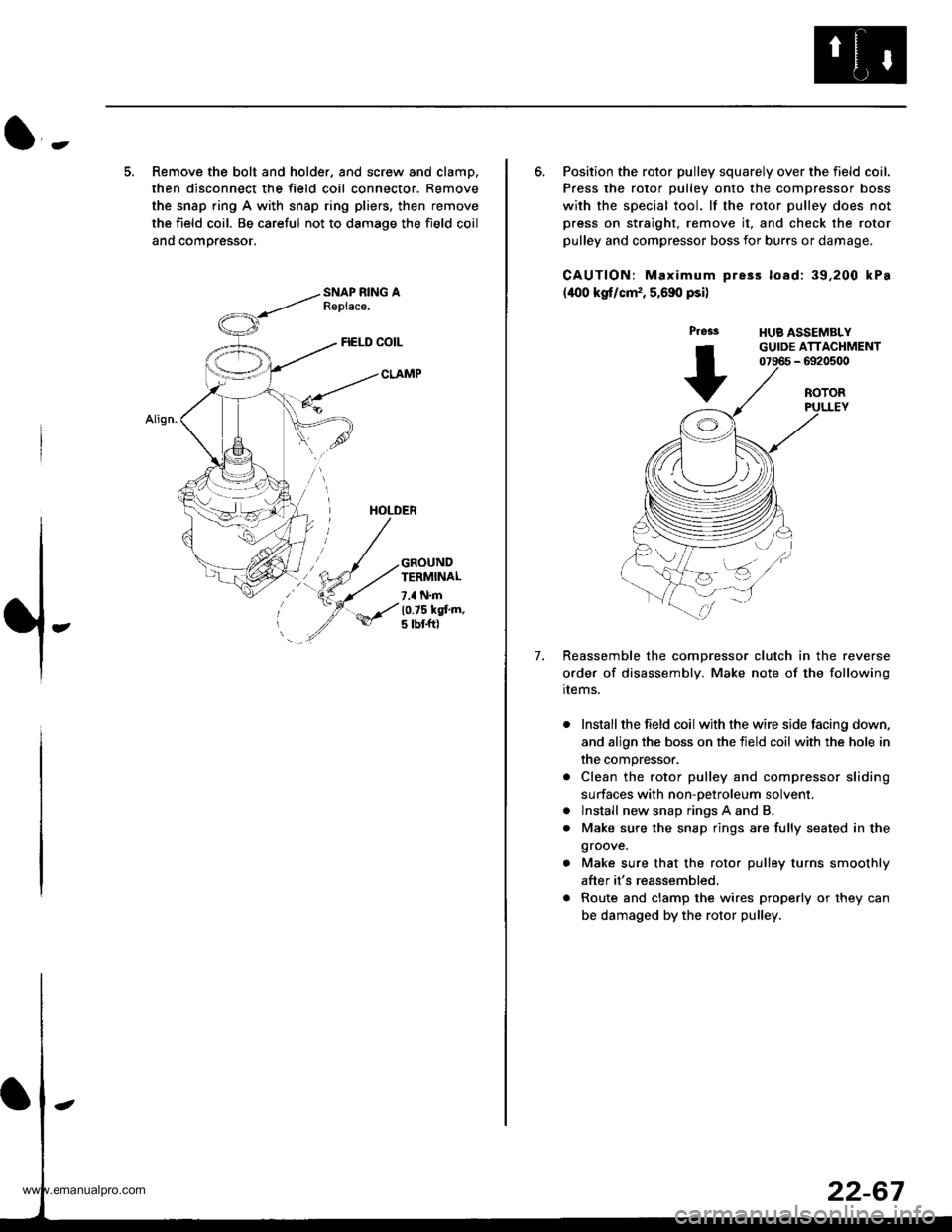

5. Remove the bolt and holder, and screw and clamp.

then disconnect the field coil connector. Remove

the snap ring A with snap ring pliers, then remove

the field coil. Be careful not to damage the field coil

and comoressor.

FIELD COIL

CLAMP

HOLDER

GROUNDTERMINAL

7,a N.m

10.75 kgt'm,5 tbt ftl

6. Position the rotor pulley squarely over the field coil.

Press the rotor pulley onto the compressor boss

with the special tool. lf the rotor pulley does not

press on straight, remove it, and check the rotor

pulley and compressor boss for burrs or damage.

CAUTION: Maximum pre3s load: 39,200 kPa

(400 kgf/cm,, 5,690 psi)

Press

+

HUB ASSEMBLYGUIDE ATTACHMENT07966 - 6920500

7.

ROTORPULLEY

Reassemble the comDressor clutch in the reverse

order of disassembly. Make note of the following

rrems.

Install the field coil with the wire side facing down,

and align the boss on the tield coil with the hole in

the compressor.

Clean the rotor pulley and compressor sliding

surfaces with non-oetroleum solvent.

lnstall new snap rings A and B.

Make sure the snap rings are fully seated in the

groove.

Make sure that the rotor pulley turns smoothly

after it's reassembled.

Route and clamp the wires properly or they can

be damaged by the rotor pulley.

a

a

www.emanualpro.com

Page 1234 of 1395

Integrated Control Unit

A1 --------> A7

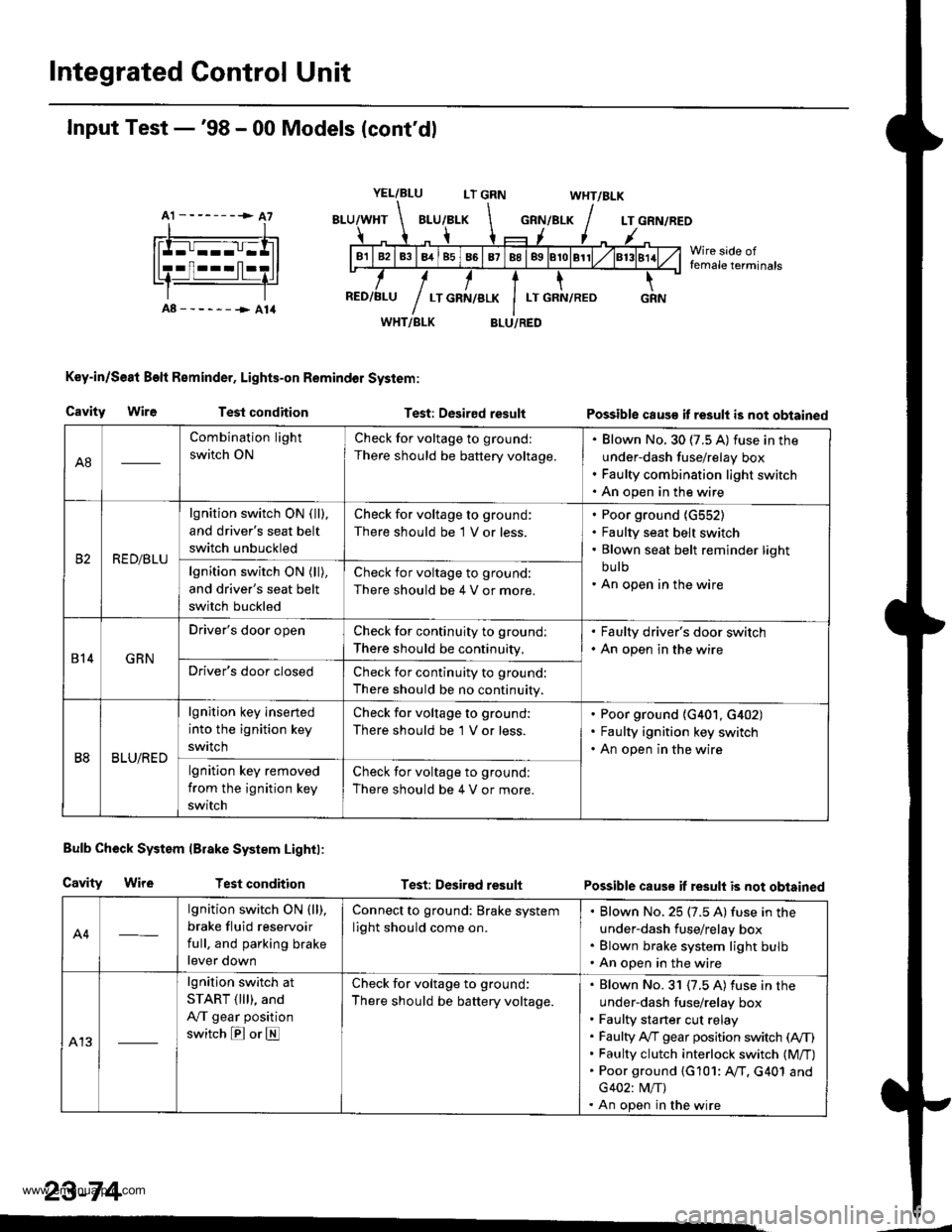

Input Test -'98 - 00 Models (cont'dl

YEL/BLULT GRNWHT/BLK

GRN/BLKLT GRN/REO

Wire side offemale terminals

A8------->A14WHT/BLK

Key-in/Se8t Beft Reminder, Lights-on Remindol System:

BLU/RED

Cavity WireTest conditionTest: Desired resultPossible caus€ it result is not obtained

Bulb Check System lBrake System Lightl:

Cavity WireTest conditionTest: Desired resultPossible caus€ if result is not obtained

A4

lgnition switch ON (ll),

brake fluid reservoir

full, and parking brake

lever down

Connect to ground: Brake system

light should come on.

Blown No. 25 (7.5 A) fuse in the

under-dash fuse/relay box

Blown brake system light bulb

An open in the wire

A13

lgnition switch at

START ( lll), and

A,/T gear position

switch E or E

Check for voltage to ground:

There should be battery voltage.

Blown No. 31 {7.5 A) fuse in the

under-dash fuse/relay box

Faulty sta rter cut relay

Faulty A,/T gear position switch (A,/T)

Faulty clutch interlock switch (M/T)

Poor ground {G101: AfI. G401 and

G402: M/T)

An open in the wire

23-74

A8

Combination light

switch ON

Check for voltage to ground:

There should be battery voltage.

Blown No. 30 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty combination light switch

An open in the wire

RED/BLU

lgnition switch ON ( ll),

and driver's seat belt

switch unbuckled

Check for voltage to ground:

There should be 1 V or less.

Poor ground {G552)

Faulty seat belt switch

Blown seat belt reminder light

bu lb

An open in the wirelgnition switch ON (ll),

and driver's seat belt

switch buckled

Check for voltage to ground:

There should be 4 V or more.

814GRN

Driver's door openCheck for continuity to ground:

There should be continuity,

. Faulty driver's door switch. An open in the wire

Driver's door closedCheck for continuity to ground:

There should be no continuity.

B8BLU/RED

lgnition key inserted

into the ignition key

swrtch

Check for voltage to ground:

There should be 'l V or less.

Poor ground (G401, G402)

Faulty ignition key switch

An open in the wire

lgnition key removed

from the ignition key

switch

Check for voltage to ground:

There should be 4 V or more.

www.emanualpro.com