Ect HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 726 of 1395

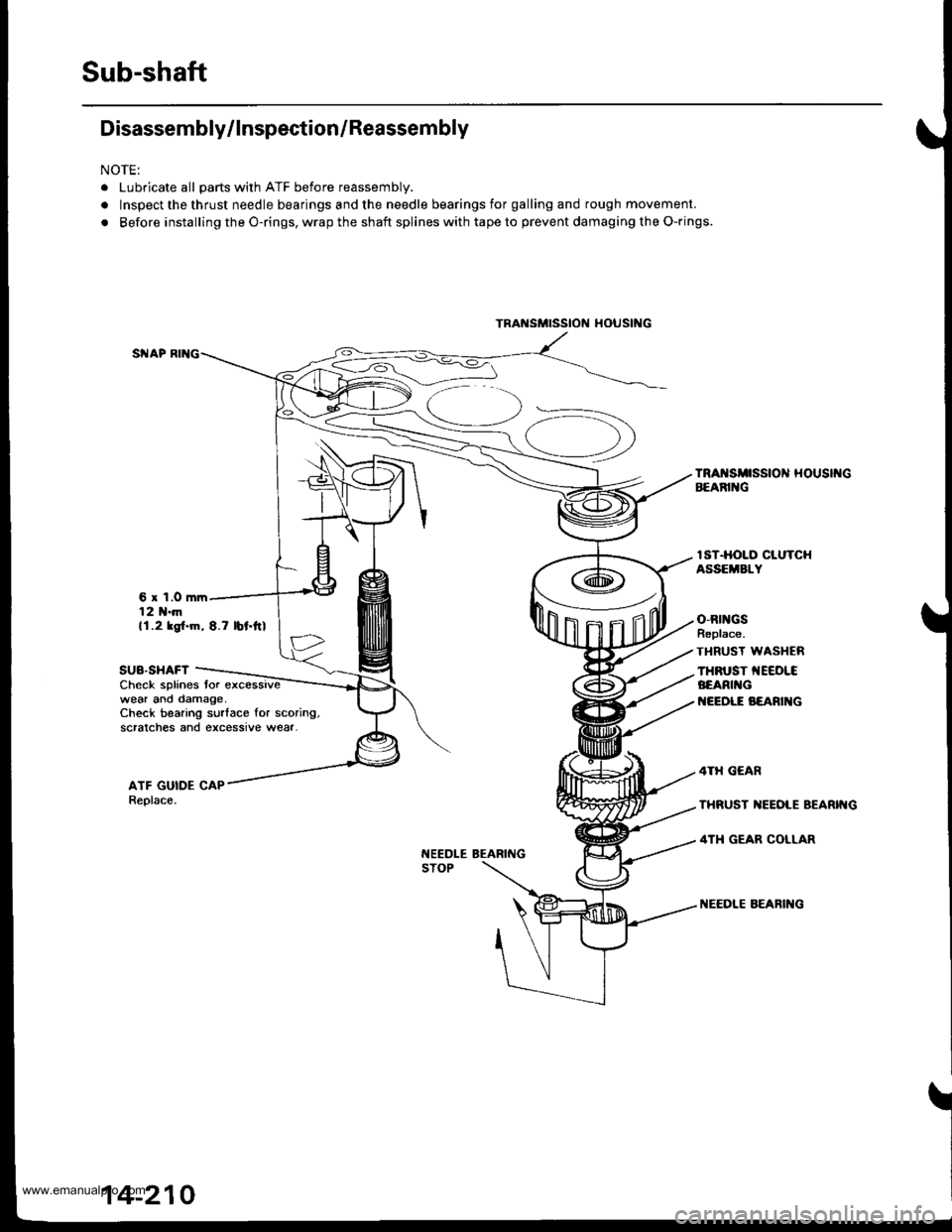

Sub-shaft

Disassembly/lnspection/Reassembly

NOTE:

. Lubricate all parts with ATF before reassembly.

. Inspect the thrust needle bearings and the needle bearings for galling and rough movement.

. Before installing the O-rings, wrap the shaft splines with tape to prevent damaging the O-rings.

6 x 1.0 mrr12 1{.mll.2 ksl.m, 8.7 lbt.ftl

SUB.SHAFTCheck splines tor excessivewear ano damage,Check bearing surlace for scoring,scralches and excessive wear-

t{EEDLE BEARINGSTOP

IST.HOLO CLUTCHASSEMBLY

o,Rtl{GSReplace.

TI{RUST WASI{ER

THFUST TEEOLCBEARI G

I{EEDLE B€ARI G

TRAi{SMTSStON tl()UStNG

14-210

www.emanualpro.com

Page 727 of 1395

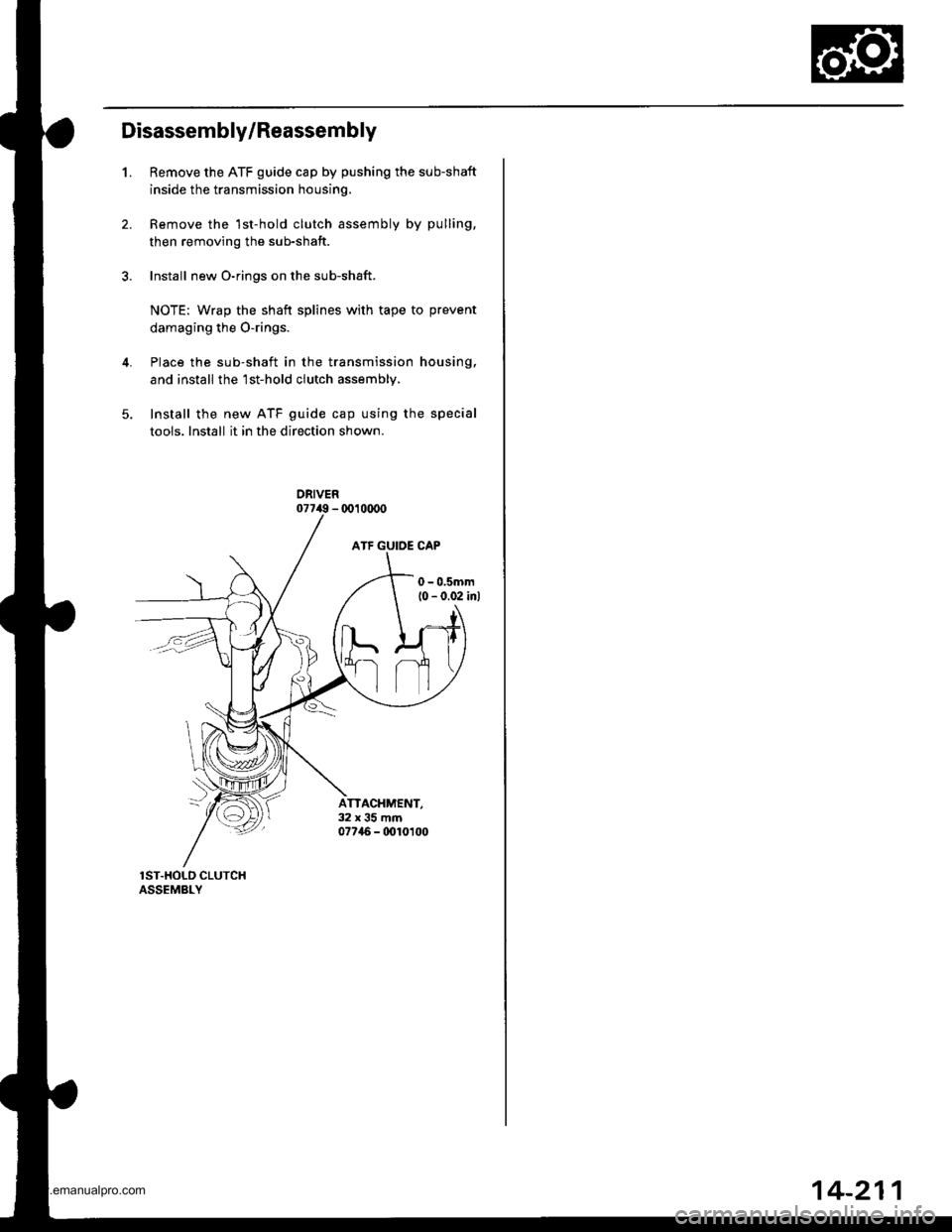

Disassembly/Reassembly

1.Remove the ATF guide cap by pushing the sub-shaft

inside the transmission housing.

Remove the 1st-hold clutch assembly by pulling,

then removing the sub-shaft.

Install new O-rings on the sub-shaft.

NOTE: Wrap the shaft splines with tape to prevent

damaging the O-rings.

Place the sub-shaft in the transmission housing,

and install the'lst-hold clutch assembly,

Install the new ATF guide cap using the special

tools. Install it in the direction shown.

ATTACHMENT,32x35mm07746 - 0010t00

14-211

www.emanualpro.com

Page 728 of 1395

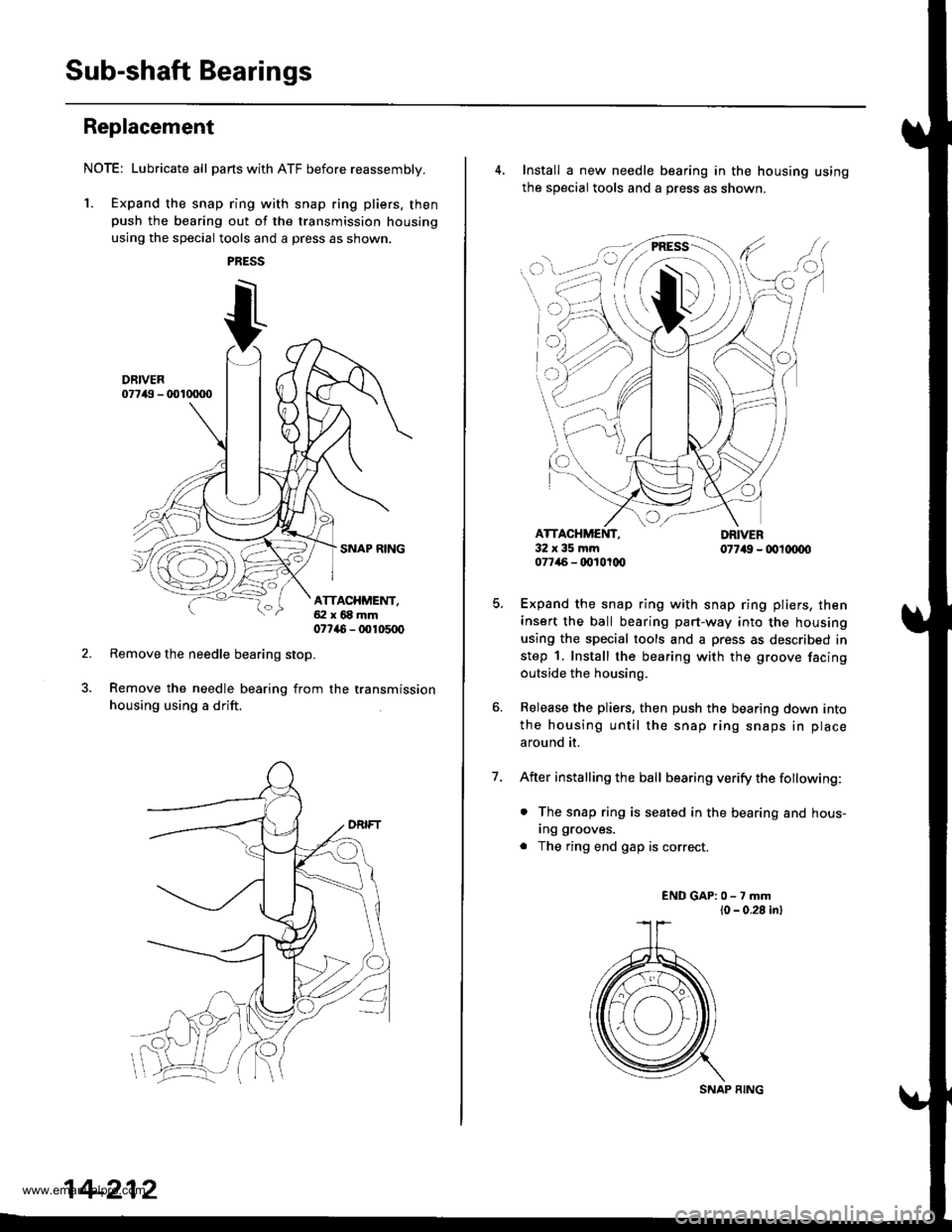

Sub-shaft Bearings

Replacement

NOTE: Lubricate all parts with ATF before reassembly.

1. Expand the snap ring with snap ring pliers. thenpush the bearing out of the transmission housing

using the special tools and a press as shown.

Remove the needle bearing stop.

Remove the needle bearing from the transmission

housing using a drift.

ATTACHMENT,ai:l x 68 mm07746 - 00105q)

14-212

SNAP RING

4. Install a new needle bearing in the housing using

the sOecial tools and a oress as shown.

7.

cI

32x35mm077/46 - qt10t(x,

Expand the snap ring with snap ring pliers, then

insert the ball bearing part-way into the housing

using the special tools and a press as described in

step 1. Install the bearing with the groove facing

outside the housing.

Release the pliers, then push the bearing down into

the housing until the snap ring snaps in place

around it.

After installing the ball bearing verify the fottowing:

. The snap ring is seated in the bearing and hous-

Ing grooves.

. The ring end gap is correct.

ENDGAP:0-7mml0 - 0.28 inl

www.emanualpro.com

Page 734 of 1395

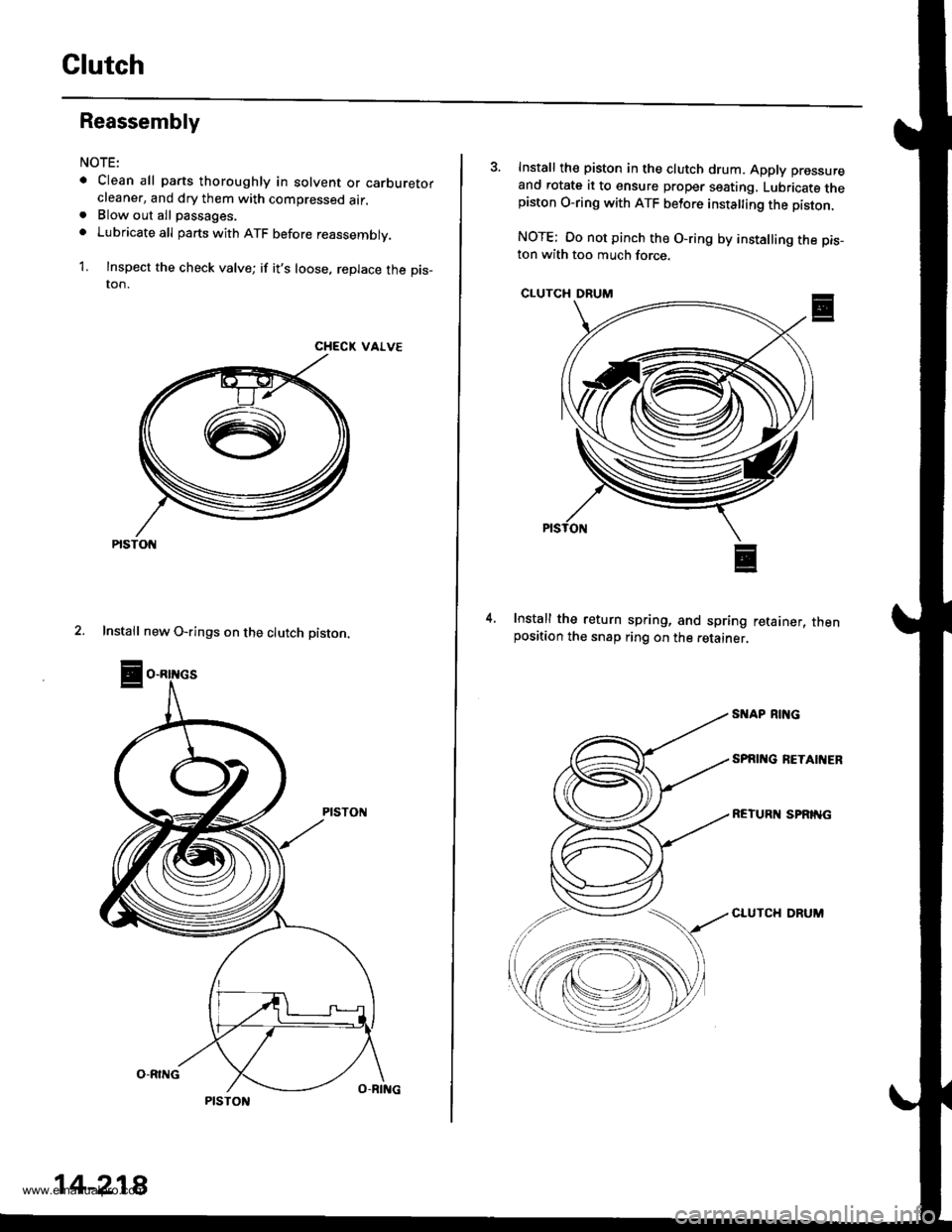

Glutch

Reassembly

NOTE:

. Clean all parts thoroughly in solvent or carburetorcleaner, and dry them with compressed air.. Blow out all passages.

o Lubricate all parts with ATF before reassembly.

1. Inspect the check valve; if it's loose, replace the pis_ton.

CHECK VALVE

2. Install new O-rings on the clutch piston.

PtsTot{

14-218

3. Install th€ piston in the clutch drum. Apply pressure

and rotate it to ensure proper seating, Lubricate thepiston O-ring with ATF betore insta ing the piston.

NOTE: Oo not pinch the O-ring by installing the pis_ton with too much force.

CLUTCH DRUM

Install the return spring, and spring retainer, thenposition the snap ring on the retainer.

4.

SI{AP RING

SPAI'{G RETAIIIER

REIURN SPRING

CLUTCH DRUM

www.emanualpro.com

Page 736 of 1395

Clutch

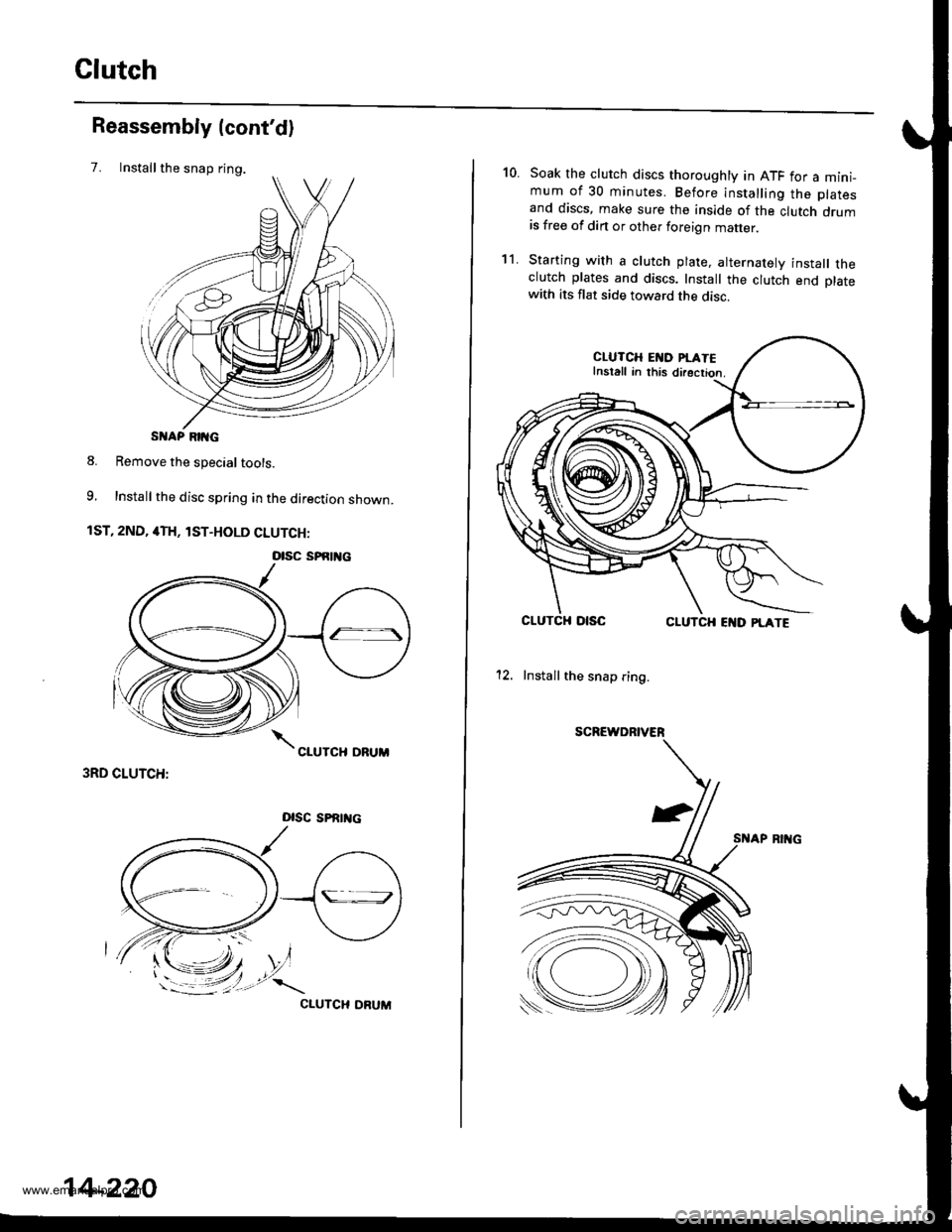

Installthe snap ring.

Reassembly (cont'd)

7.

S AP RIIG

8. Remove the special tools.

9, Install the disc spring in the direction shown.

1ST, 2ND, 4TH, lST-HOLD CLUTCH:

3RD CLUTCH:

Dlsc sPRrrtc

CIUTCH ORUM

otsc sPfitl{c

14-220

10.Soak the clutch discs thoroughly in ATF for a mini_mum of 30 minutes. Before installing the platesand discs, make sure the inside of the clutch drumis free of din or other foreign matter

Starting with a clutch plate, alternatelv install theclutch plates and discs. Install the clutch end platewith its flat side toward the disc.

CLUTCH EI{D PI.ATEInstall in this directior.

CLUTCHCLUTCH EI{D PLATE

12. Install the snap ring.

SCREWDRIVER

't1.

www.emanualpro.com

Page 737 of 1395

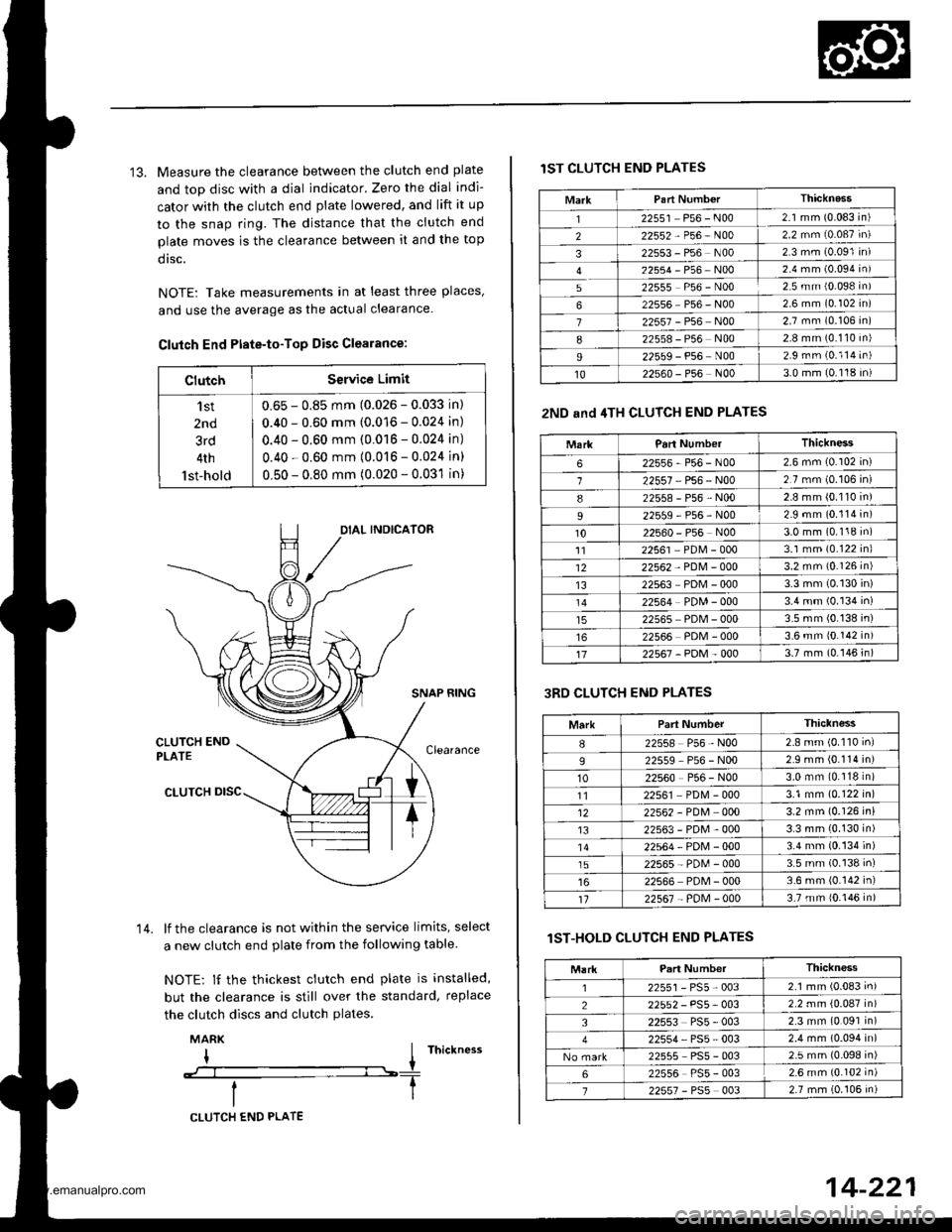

13. Measure the clearance between the clutch end plate

and top disc with a dial indicator. Zero the dial indi-

cator with the clutch end plate lowered, and lift it up

to the snap ring. The distance that the clutch end

plate moves is the clearance between it and the top

dtsc.

NOTE: Take measurements in at least three places'

and use the average as the actual clearance.

Clutch End Ptate-to-Top Disc Clearance:

ClutchService Limit

'l st

2nd

3rd

4th

lst-hold

0.65 - 0.85 mm (0.026 - 0.033 in)

0.40 - 0.60 mm (0.016 - 0.024 in)

0.40 - 0.60 mm (0.016 - 0.024 in)

0.40 - 0.60 mm (0.016 - 0.024 in)

0.50 - 0.80 mm (0.020 - 0.031 in)

SNAP RING

lf the clearance is not within the service limits, select

a new clutch end plate from the following table

NOTE: lf the thickest clutch end plate is installed,

but the clearance is still over the standard, replace

the clutch discs and clutch plates.

MARK

I I rnictness

--:--l----T

14.

CLUTCH END PLATE

14-221

lST CLUTCH END PLATES

2ND and 4TH CLUTCH END PLATES

3RD CLUTCH END PLATES

lST-HOLD CLUTCH END PLATES

MarkThicknass'I22551 P56 - N002.1 mm (0.083 in)

222552-P56-N002.2 mm (0.087 in)

322553 - P56 N002 3 mm (0.091 in)

22554-P56-NOo2.4 mm (0.094 in)

522555 P56 - N002.5 mm {0.098 in)

622556 P56 - N002 6 mm (0.102 in)

722557 - P56 N002.7 mm (0.106 in)

822558 - P56 N002.8 mm (0.110 in)

I22559 - P56 N002.9 rnm (0.114 in)

1022s60 - P56 N003.0 mm (0.118 in)

MarkParl NumberThickness

622556-P56-N002.6 mm (0.102 in)

122557 P56 - N002.7 mm (0.106 in)

822558-P56-N002.8 mm (0.110 in)

22559-P56-N002.9 mm (0.114 in)

1022560 - P56 N003.0 mm (0.118 in)'1122561 PDM - 0003.1 mm (0.122 inl

1222562 - PDM - 0003.2 mm {0.126 in)

1322563 PDM - 0003.3 mm (0.130 in)

22564 PDM - 0003.4 mm (0.134 in)

22565 PDM - 0003.5 mm (0.138 in)

22566 PDM - 0003.6 mm 10.142 in)

1722567-PDM-0003.7 mm (0.146 in)

MarkPart NumberThiclness

I22558 P56 - N002.8 mm (0.110 inl

922559 P56 - N002.9 mm (0.114 in)

1022560 P56 - N003.0 mm (0.118 in)

1122561 PD[4 - 0003.1 mm (0.122 in)

1222562 - PDM 0003.2 mm (0.126 in)

t322563-PDM-0003.3 mm (0.130 in)'1422564-PDN4-0003.4 mm (0.134 in)

1522565-PD[,l-0003.5 mm (0.138 in)

22566 PDM - 0003.6 mm (0.142 in)'t122567 - PoM - 0003.7 mm {0.146 in)

Thickness

2255r-PS5-0032.1 mm (0.083 in)

22552 - PS5- 0032.2 mm {0.087 in)

322553 PS5 - 0032.3 mm (0.091 in)

22554, PS5 - 0032.4 mm (0.094 in)

22555 PS5 - 0032.5 mm (0.098 in)

622556 PS5 - 0032.6 mm {0.102 in)

722557 - PSs 0032.7 mm (0.106 in)

www.emanualpro.com

Page 738 of 1395

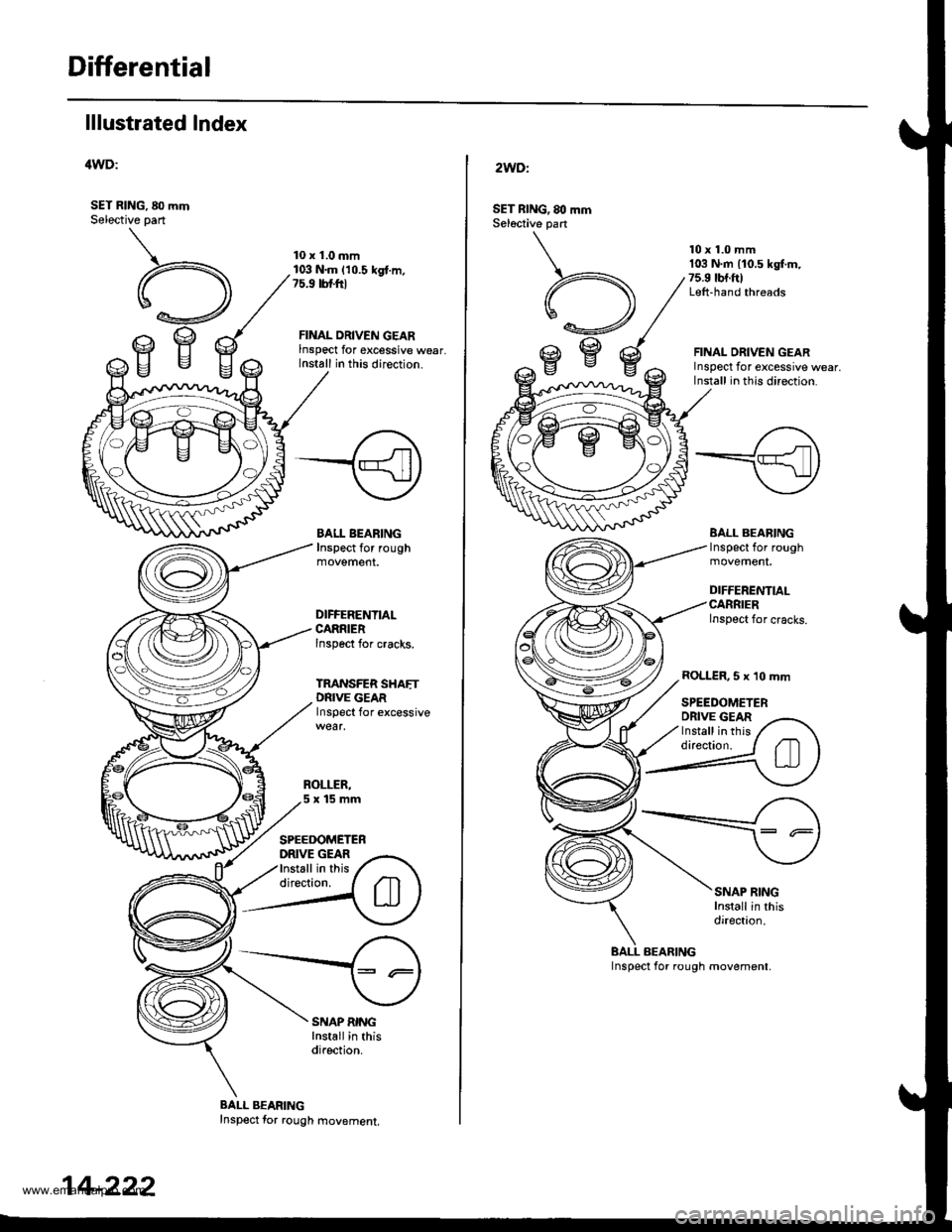

Differential

lllustrated Index

'lWD:

SET RING, 80 mmSelective part

10 x 1.0 mm103 N.m (10.5 kgt.m,?5.9 tbtftl

FINAL ORIVEN GEARlnspect for excessive wear,Install in this direction.

BALL BEARINGInspect for rough

DIFFERENTIAI.CARRIERlnspect for cracks.

TRANSFER SHAETDNlvE GEARInspect for excessive

SPEEDOMETERDRIVE GEARInstall in thisdirection.

SNAP RINGInstall in thisdirection.

BALL BEARINGInspect for rough movement,

14-222

2WDl

SET nlNG, 80 mmSel6ctive part

A,U

,gBc

10 x 1.0 mm103 N.m {10.5 kg[.m,75.9 tbt.ftlLeft-hand threads

FINAL ORIVEN GEARInspect for excessive wear,Install in thls direction.

BALL BEABINGInspect for rough

DIFFERENTIAI.CARRIERInspect for cracks.

ROLLER,5 x 10 mm

SPEEDOMETERDRIVE GEARInstall in thisdirection.

SNAP RINGInstall in thisdirection.

BALL BEARING

www.emanualpro.com

Page 739 of 1395

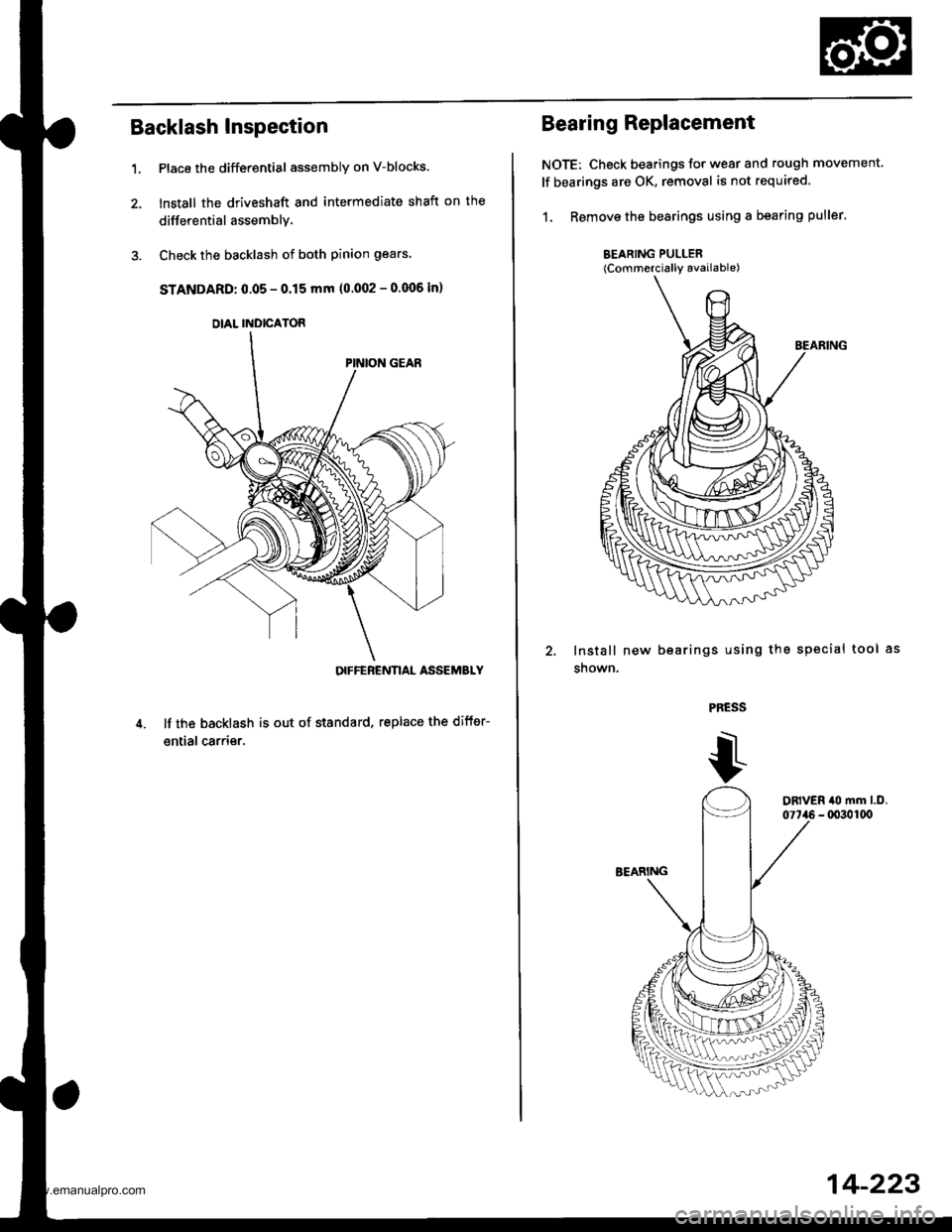

Backlash Inspection

Place the differential assembly on V-blocks.

lnstall the driveshaft and intermediate shaft on the

differential assemblY.

Check the backlash of both pinion gears.

STANDARD: 0.05 - 0.15 mm (0.002 - 0.006 in)

OIFFEBENNAL ASSEMBLY

It the backlash is out of standard, replace the difter-

ential carrier.

1.

DIAL INDICATOR

Bearing Replacement

NOTE: Check bearings for wear and rough movement.

lf bearings are OK, removal is not required.

1. Remove the bearings using a bearing puller.

BEARING PULLER(Commercially available)

lnstall new

snown.

bearings using the sPecial tool

PRESS

14-223

www.emanualpro.com

Page 740 of 1395

Differential

Differential Carrier Replacement

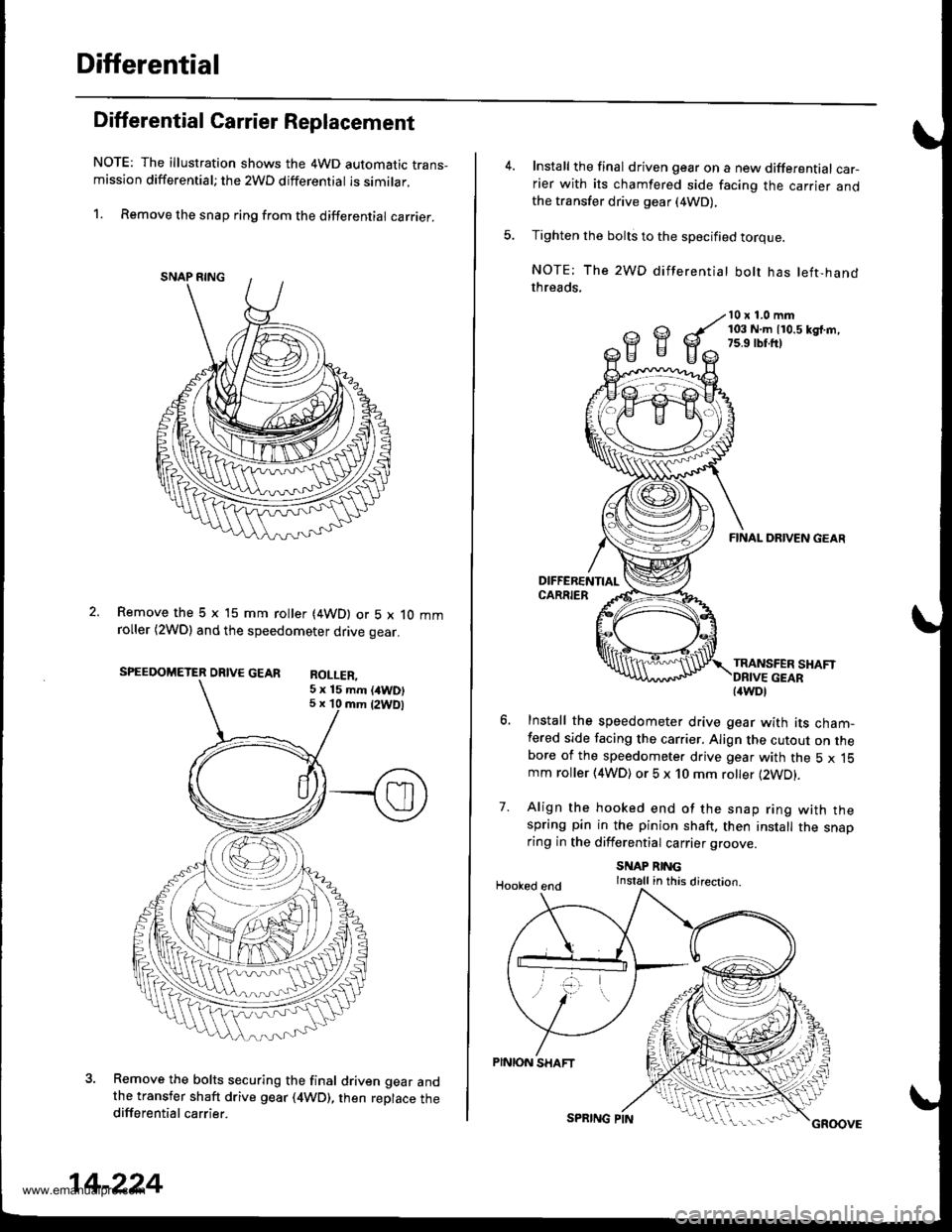

NOTE: The illustration shows the 4WD automatic trans-mission differential; the 2WD differential is similar.

1. Remove the snap ring from the differential carrier.

Remove the 5 x 15 mm roller (4WD) or 5 x 10 mmroller (2WDl and the speedometer drive gear.

SPEEDOMETER DRIVE GEAR RoI I FP

Remove the bolts securing the final driven gear andthe transfer shaft drive gear (4WD), then replace thedifferential carrier.

5 x 15 mm (/tWD)5 x 10 mm {2WDl

14-224

SPRING PINGROOVE

Install the final driven gear on a new differential car-rier with its chamfered side facing the carrier andthe transfer drive gear (4WD),

Tighten the bolts to the specified torque.

NOTE: The 2WD differentiat bolt has left-handthreads,

10 x 1.0 mm103 N.m 110.5 kd.m,7s.9 rbr.ft)

7.

FINAL DRIVEN GEAR

TRANSFER SHAFT

Install the speedometer drive gear with its cham-fered side facing the carrier. Align the cutout on thebore of the speedometer drive gear with the 5 x 15mm roller (4WD) or 5 x 10 mm roller (2WD).

Align the hooked end of the snap ring with thespring pin in the pinion shaft. then install the snaoring in the differential carrier groove

SNAP RINGInstall in this direction.Hooked end

PINION SHAFT

{4WDl

www.emanualpro.com

Page 742 of 1395

Differential

Side Clearance Inspection

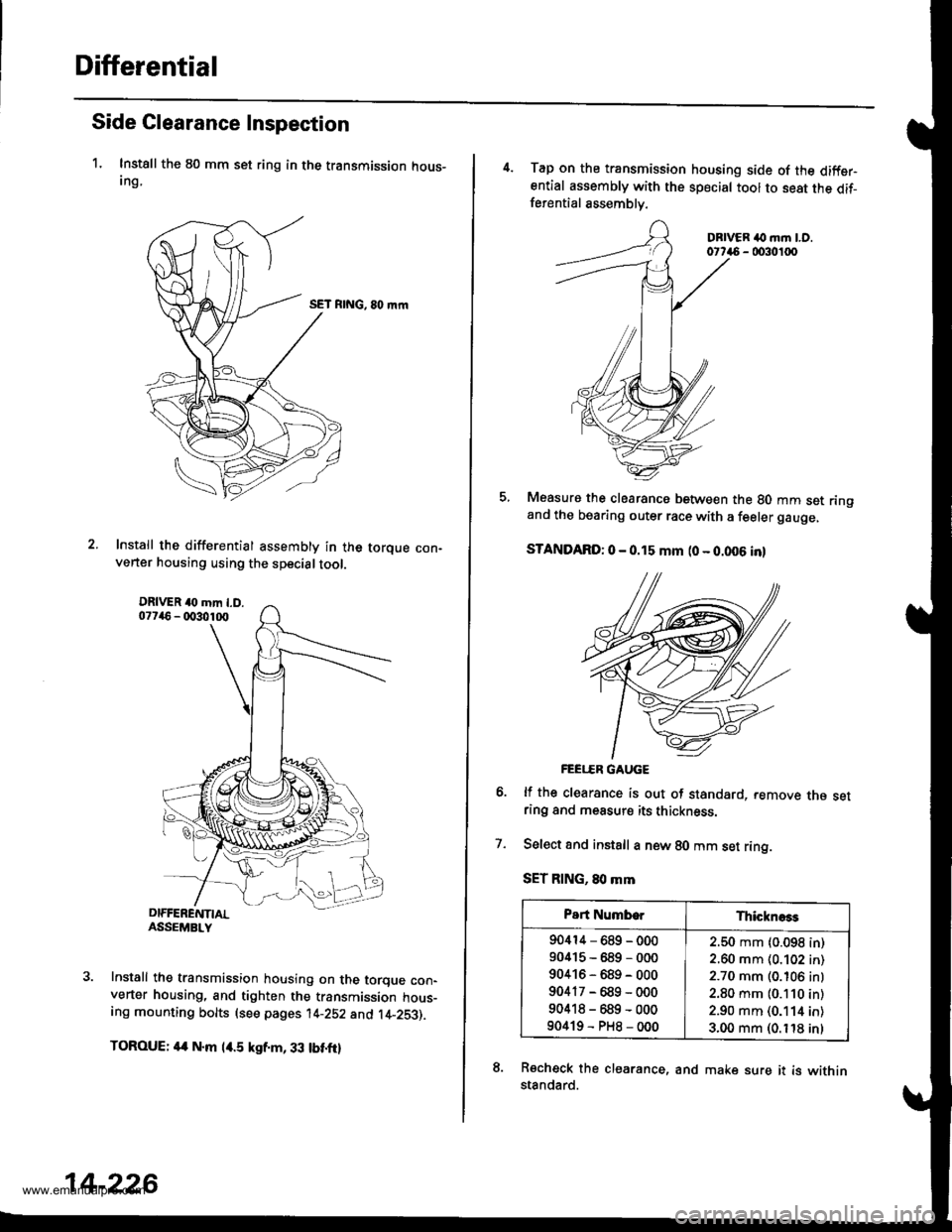

1. Instsll the 80 mm set ring in the transmission hous-Ing,

SET RING, 80 mrn

Install the differential assembly in the torque con-verter housing using the specialtool.

Install the transmission housing on the torque con-verter housing, and tighten the transmission hous-ing mounting bolts (see pages 14-252 and t4-253).

TOROUE: 4a N.m l/r.5 kgf.m, 33 tbt.ftl

14-226

4. Tap on the transmission housing side of the diffsrential assembly with the special tool to seat the dif-ferential assemblv.

DBIVER ilo m.n LO.0t746 - 0030100

Measure the clearancs between the 80 mm set ringand the bearing outer race with a feeler gauge,

STANDARD: 0 - 0.15 mm (0 - 0.006 inl

FEEI..ER GAUGE

lf the clearance is out of standard, remove rne setring and measurs its thickness.

Select and instsll a new 80 mm set ring.

SET RING, 80 mm

Recheck the clearance, and make sure it is withinstandard.

7.

Part NumborThicknoss

90414-689-000

90415-689-000

90416-689-000

90417-689-000

90418-689-000

90419-PH8-000

2.50 mm (0.098 in)

2.60 mm (0.102 in)

2.70 mm (0.106 inl

2.80 mm (0.110 in)

2.90 mm (0.114 in)

3.00 mm (0. t'18 inl

www.emanualpro.com