34 shift valve HONDA CR-V 1999 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 672 of 1395

Symptom-to-Com ponent Chart

Hydraulic System (cont'd)

NOTES

See flushing procedure, page l4-264 and 265,

BSet idle rpm in gear to specified idle speed. lf still no good, adjust motor mounts as outlined in enginesection of this manual.

clf the large clutch piston O-ring is broken, inspect the piston groove for rough machining.

Dlf the clutch pack is seized or is excessively worn. inspect the other clutches fot wear, and check the orificecontrol valves, CPC valve, and linear solenoid for free movement.

lf the linear solenoid is stuck, inspect the clutches for wear.

lf the 1-2 shift valve is stuck closed. the transmission will not upshift. lf stuck open, the transmission hasno lst gear.

Hlf the 2nd orifice control valve is stuck, inspect the 2nd and 3rd clutch Dacks for wear.

lf the 3-4 orifice control valve is stuck, inspect the 3rd and 4th clutch packs for wear.

Jlf the clutch pressure control valve is stuck closed. the transmission will not shift out of lst gear.

Klmproper alignment of main valve body and torque converter housing may cause ATF pump seizure. Thesymptoms are mostly an rpm-related ticking noise or a high-pitched squeak.

Llf the ATF strainer is clogged with particles of steel or aluminum, inspect the ATF pump and differentialpinion shaft. lf both are OK and no cause for the contamination is found, replace the torque converter.

Mlf the lst clutch feed pipe guide in the end cover is scored by the mainshaft. inspect the ball bearing forexcessive movement in the transmission housing. lf oK, replace the end cover as it is dented. The o-rinounder the guide is probably worn.

N' Replace the mainshaft if the bushing for the 4th feed pipe is loose or damaged, lf the 4th feed pipe is darrFaged or out of round. replace the end cover.' Replace the mainshaft if the bushing for the l st feed pipe is loose or damaged. lf the 1st feed pipe is dam-aged or out of round, replace it.

oA worn or damaged sprag clutch is mostly a result of shifting the transmission in E!. E, or E positionwhile the wheels rotate in reverse. such as rocking the vehicle in snow.

PInspect the frame for collision damage.

lnspect for damage and wear:

l. Reverse selector gear teeth chamfers.

2. Engagement teeth chamfers of countershaft 4th and reverse gear.

3. Shift fork for scuff marks in center.

4. Differential pinion shaft for wear under pinion gears.

5. Bottom of 3rd clutch for swirl marks.

Replace items 1, 2, 3. and 4 if worn or damaged. lf transmission makes a clicking, grinding, or whirring noise,also replace mainshaft 4th gear, reverse idler gear, and countershaft 4th gear in addition to 1,2, 3, or 4.lf differential pinion shaft is worn, overhaul differential assembly, replace ATF strainer, and thoroughly cjeantransmission, flush torque converter. cooler, and lines,lf bottom of 3rd clutch is swirled and transmission makes gear noise. replace the countershaft and final drivenoear,

Be very careful not to damage the torque converter housing when replacing the main ball bearing. you

may also damage the ATF pump when you torque down the main valve body. This will result in ATF pumpseizure if not detected. Use the Drooer tools.

SInstall the main seal flush with the torque converter housing. lf you push it into the torque converterhousing until it bottoms out, it will block the fluid return passage and result in damage.

www.emanualpro.com

Page 674 of 1395

Road Test

(cont'd)

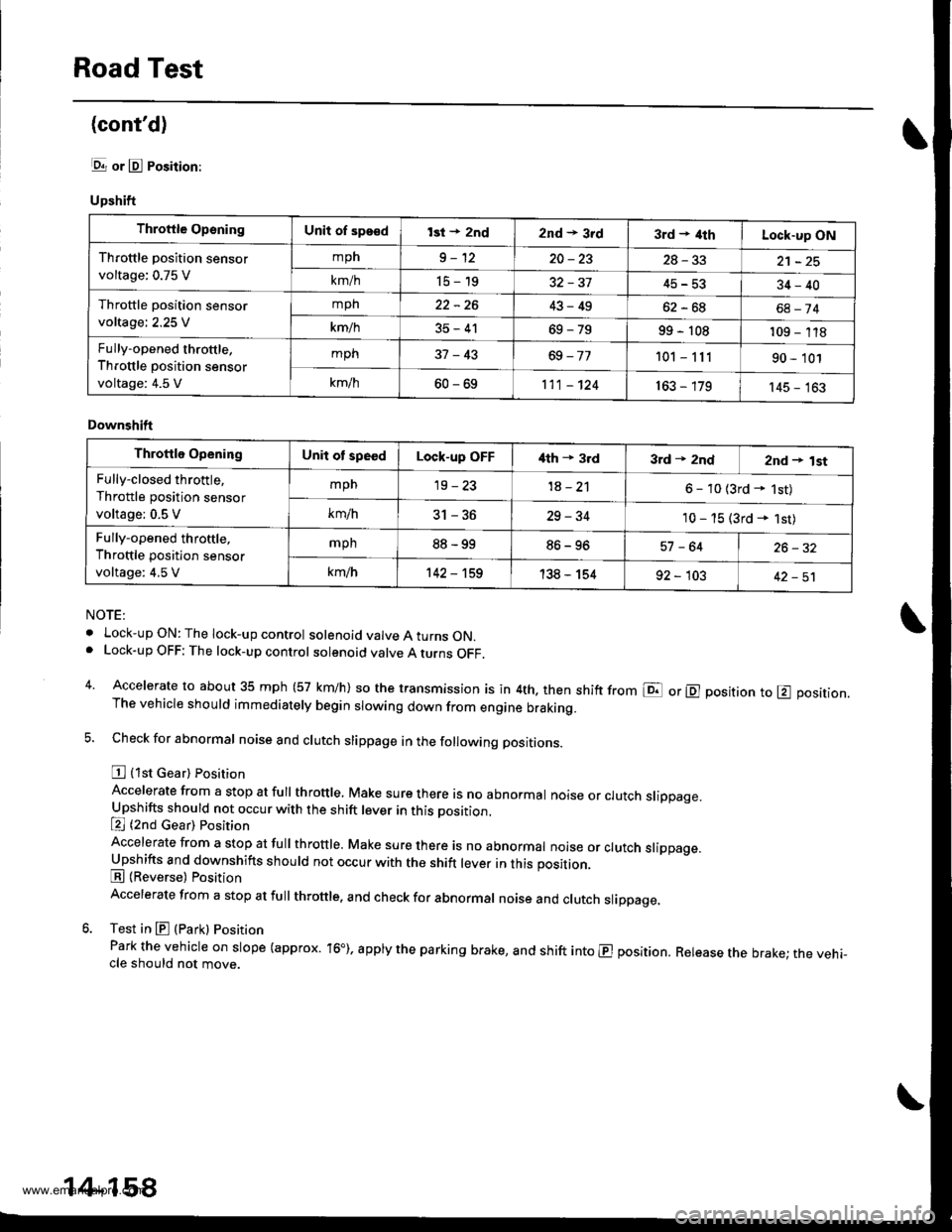

lgrr or E Position:

Upshift

NOTE:

. Lock-upON:The lock-up control solenoid valve A turns ON.. Lock-up OFF: The lock-up control solenoid valve A turns OFF.

4. Accelerate to about 35 mph (57 km/h) so the transmission is in 4th. then shift from E or E position to E position.The vehicle should immediately begin slowing down from engine braking.

5. Check for abnormal noise and clutch slippage in the following positions.

E {1st Gear) Position

Accelerate from a stop at full throttle, Make sure there is no abnormal noise or clutch slippage.Upshifts should not occur with the shift lever in this position.

E (2nd cear) Position

Accelerate from a stop at fuI throttre. Make sure there is no abnormar noise or crutch srippage.Upshifts and downshifts should not occur with the shift lever in this position.

E (Reverse) Position

Accelerate from a stop at full throttle. and check for abnormal noise and clutch slippage.

6. Test in E (Park) Position

Park the vehicle on slope (approx. 16"), apply the parking brake, and shift into E position. Release the brake; the vehi-cle should not move.

Throftle OpsningUnit of sps€dlsi + 2nd2nd * 3rd3rd + ilthLock-up ON

Throttle position sensor

voltage: 0.75 V

mph9-1220-2328-33

km/h15-1945-5334-40

Throttle position sensor

voltage; 2.25 V

mph22-2643-49oz - ott68-74

km/h35-4169-7999 - 108109 - 118

Fully-opened throttle,

Throttle position sensor

voltage: 4.5 V

mph37-43101 - 11190 - 101

k-/h60-69111 - 124163 - 179145 - 163

Downshift

Throttle OpeningUnit ot speedLock-up OFFi{th + 3rd3rd * 2ndznd + lst

Fully-closed throttle,

Throttle position sensor

voltage; 0.5 V

mpn19-231A - 2'l6 - 10 {3rd - 1st)

km/h5t-5D29-3410 - 15 (3rd * 1st)

Fully-opened throttle,

Throttle position sensor

voltage: 4,5 V

mph88-9986-9657 -6426-32

km/h142 - 't59138 - 15492 - 10342-51

14-158

www.emanualpro.com

Page 675 of 1395

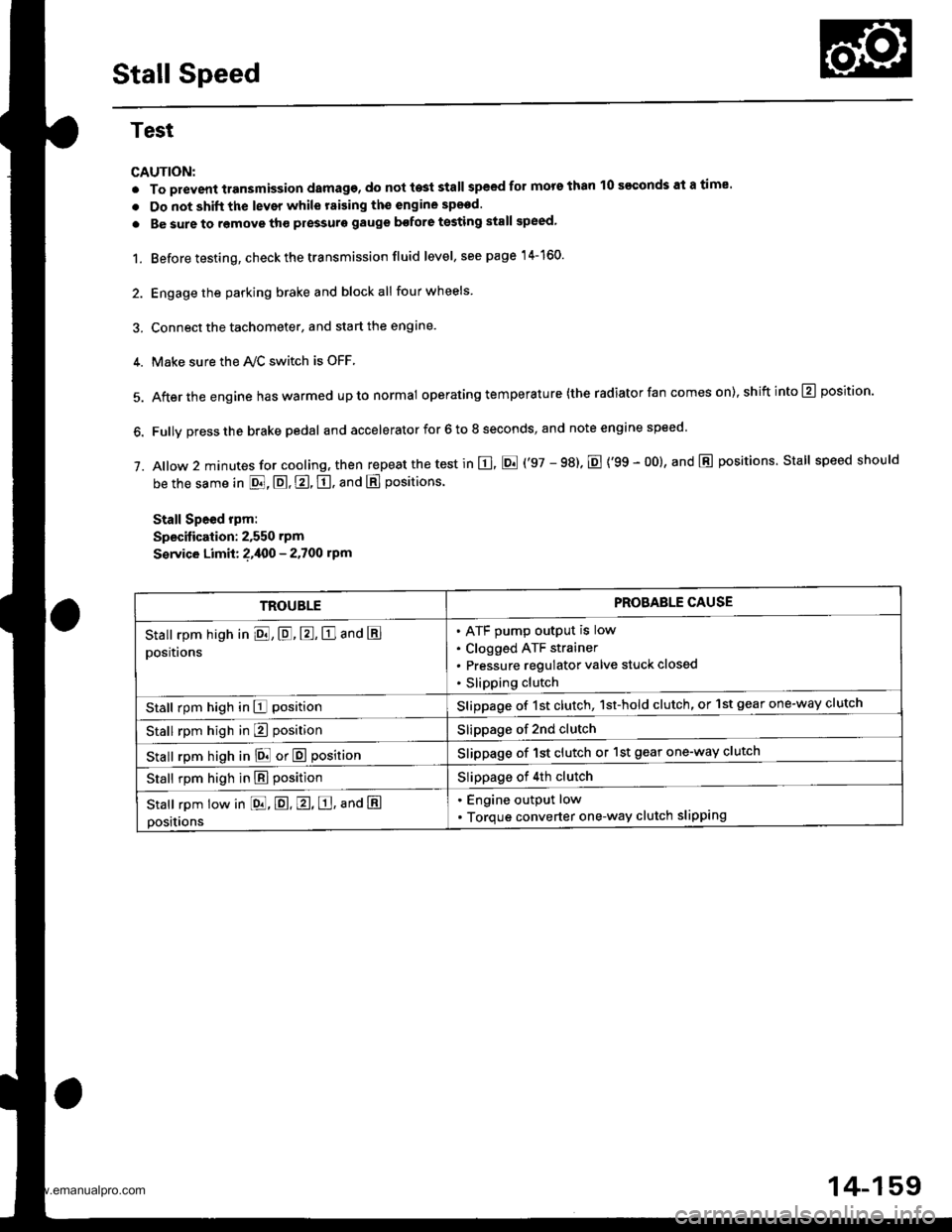

Stall Speed

Test

CAUTION:

. To prevent transmission damage, do not te3t stall speed for mors than 10 s€€onds at a time'

. Do not shift the lever while raising th€ engine spsed.

. Be sure to remove tho pressuro gauge bofore testing stall speed,

1. Before testing, check the transmission fluid level, s€e page 14-160.

2. Engage the parking brake and block all four wheels

3. Connect the tachometer, and start the engane.

4. Make sure the Ay'C switch is OFF

5. After the engine haswarmed upto normal operating temperature (the radiator fan comes on),shiftinto@ position.

6. Fully press the brake pedal and accelerator for 6 to 8 seconds, and note engine speed '

j. A|ow 2 minutes for cooling, then repeat the test in E, E ('97 - 98). E {'99 - 00}, and E positions. Stall speed should

be the same in E, E, E, tr. and E positions

Stall Speed rpm:

Specitication: 2,550 rpm

S€rvice Limit: ?,400 - 2.700 rpm

TROUBLEPROBAELE CAUSE

Stall rpm high in El, E, E, E and E

positions

ATF pump output is low

Clogged ATF strainer

Pressure regulator valve stuck closed

Slipping clutch

Stall rpm high in E positionSlippage of 1st clutch, 1st-hold clutch, or 1st gear one-way clutch

Stall rpm high in E positionSlippage of 2nd clutch

stall rpm high in E! or E positionSlippage of 1st clutch or 1st gear one-way clutch

Stall rpm high in E positionSlippage of 4th clutch

Stall rpm low in [dd, E. E, E, ana E

positions

. Engine output low

. Torque converter one-way clutch slipping

14-159

www.emanualpro.com

Page 678 of 1395

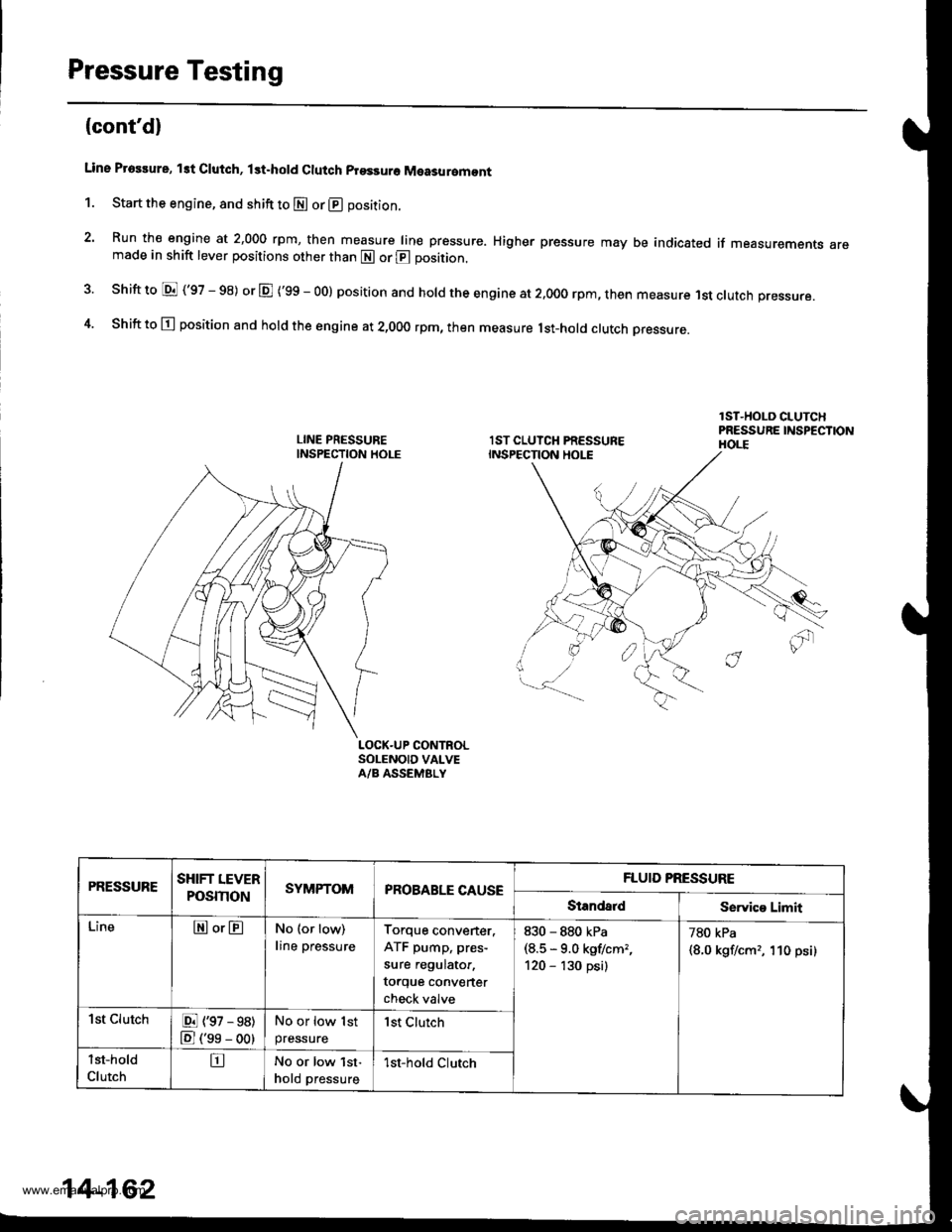

Pressure Testing

(cont'd)

Line Proslure, lst Clutch, lst.hold Clutch prsssuro Measuromont

1. Start the engine, and shift to E or @ position.

2. Run the engine at 2,000 rpm, then measure line pressure. Higher pressure may be indicated if measurements aremade in shift lever positions other than E or @ position.

shift to E ('97 - 98) or E ('99 - oo) position and hold the engine at 2.ooo rpm, then measure 1st clutch pressure.

Shift to E position and hold the engine at 2,000 rpm, then measure lst-hotd ctutch Dressure.

LOCK.UP CONTROLSOLENOID VALVEA/B ASSEMBLY

4.

PRESSURESHIFT LEVER

POSmONSYMPTOMPROBABLE CAUSEFLUID PRESSURE

StandaldService Limit

LineEor@No (or low)

line pressure

Torque converter.

ATF pump, pres-

sure regulator,

torque converter

check valve

830 - 880 kPa(8.5 * 9.0 kgflcm,,

120 - '130 psi)

780 kPa

{8.0 kgf/cm,, 'l10 psi)

1st ClutchE (97 - 98)

E ('se - oo)

No or low 1st

pressurelst Clurch

lst-hold

ClutchtrNo or low lst-

hold pressure1st-hold Clutch

14-162

www.emanualpro.com

Page 679 of 1395

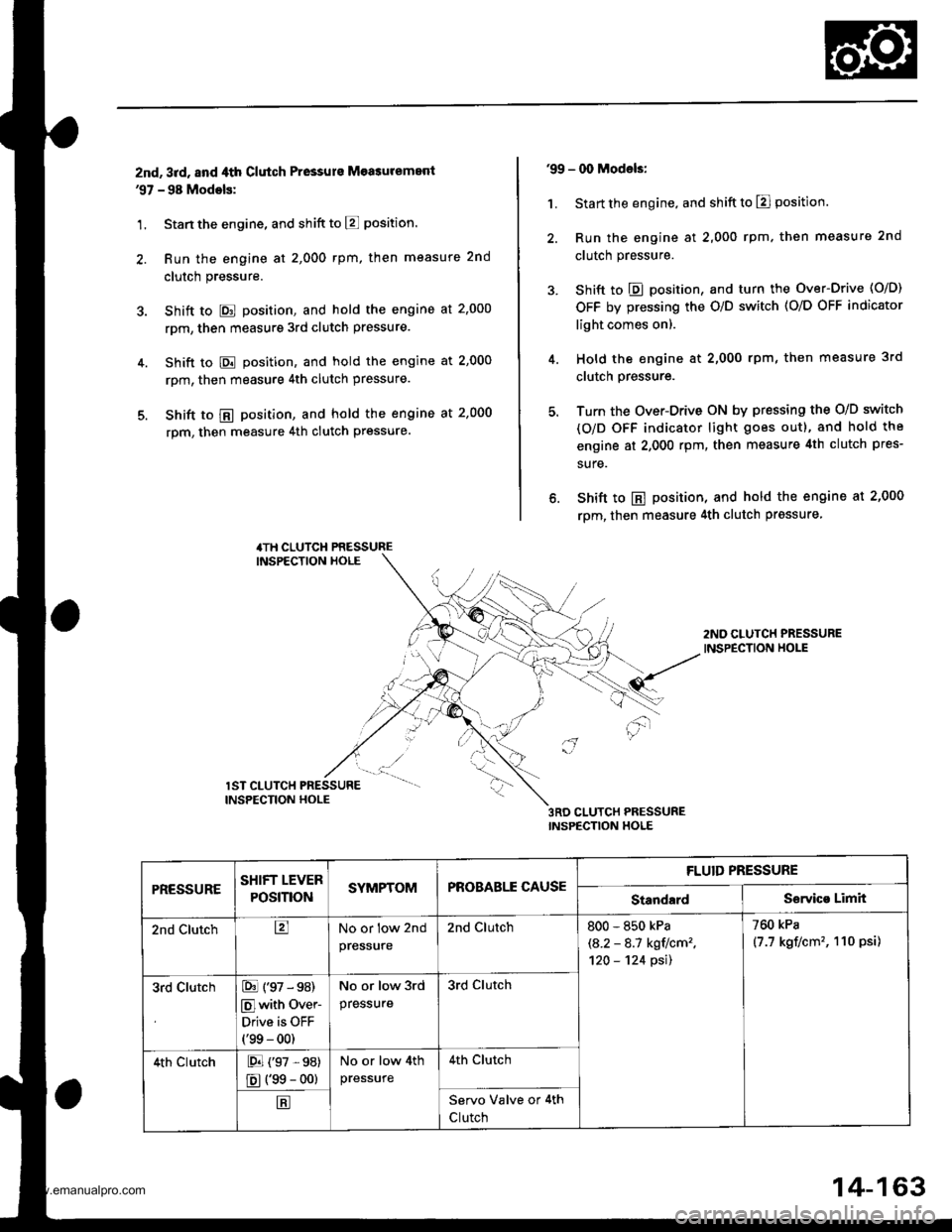

znd, 3rd, and ,lth Clutch Pressurs Measuremenl'97 - 98 Modols:

1. Stan the engine, and shift to E position.

2. Run the engine at 2,000 rpm, then measure 2nd

clutch pressure.

3. Shift to E position, and hold the engine at 2'000

rpm, then measure 3rd clutch pressure.

4. Shift to E position, and hold the engine at 2,000

rpm, then measure 4th clutch pressure.

5. Shift to @ position, and hold the engine at 2,000

rpm, then measure 4th clutch pressure.

4TH CLUTCH PRESSUREINSPECTION HOLE

'99 - 00 Models:

1. Start the engine, and shift to El position.

2. Run the engine at 2,000 rpm. then measure 2nd

clutch pressure.

3. Shift to E position, and turn the Over-Drive (O/D)

OFF by pressing the O/D switch (O/O OFF indicator

light comes on).

4. Hold the engine at 2,000 rpm, then measure 3rd

clutch Pressure.

5. Turn the Over-Drive ON by pressing the O/D switch

(O/D OFF indicator light goes out), and hold the

engine at 2,000 rpm, then measure 4th clutch pres-

sure.

6. Shift to E position, and hold the engine at 2,000

rpm, then measure 4th clutch prgssure

2ND CLUTCH PRESSUREINSPECTION HOLE

3RD CLUTCH PRESSUREINSPECTION HOLE

'"r.,-ur"" "..#

- -t"1' -.

INSPECTION HOLE

PRESSURESHIFT LEVER

POSmONSYMPTOMPROBABLE CAUSE

FLUID PRESSURE

StandardServico Limit

2nd ClutchtrNo or low 2nd

pres$ure

2nd Clutch800 - 850 kPa

\A.2 - 8.1 kgtlcm2,'120 - '124 psil

760 kPa

(7.7 kgf/cm'�, 110 psi)

3rd ClutchE (97 - s8)

Elwith Over-

Drive is OFF(99 - 00)

No or low 3rd

pressure

3rd clutch

4th clutchE (97 ,98)

E (99 - oo)

No or low 4th

pressure

4th Clutch

EServo Valve or 4th

Clutch

14-163

www.emanualpro.com

Page 686 of 1395

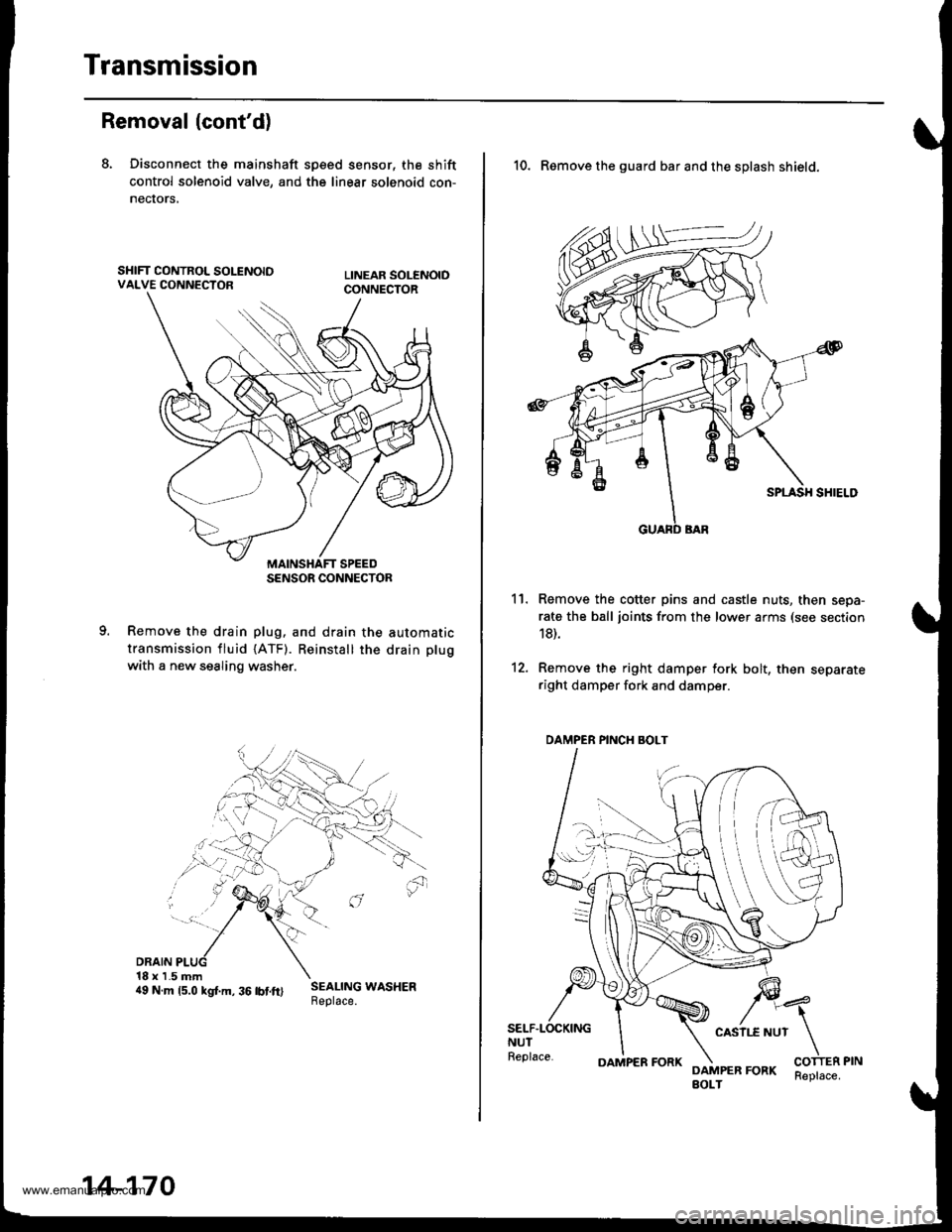

Transmission

Removal (cont'd)

8. Disconnect the mainshaft sp€ed sensor, the shift

control solenoid valve, and the linear solenoid con-

necrors,

Remove the drain plug. and drain the automatic

transmission fluid {ATF). Reinstall the drain plug

with a new sealing washer.

DRAIN18 x 1.5 mm4e N.m rs.o ksr.m. 36 rbrft) ;:i:$: *o"*."

SENSOR CONNECTOR

14-170

OAMPER FORKReplace.

10. Remove the guard bar and the splash shield.

Remove the cotter pins and castle nuts, then sepa-

rate the ball joints from the lower arms (see section

18).

Remove the right damper fork bolt, then separateright damper fork and damper.

11.

12.

SELF.LOCKINGNUTReplace.

CASII.E NUT

DAMPER FORKBOLT

DAMPER PINCH BOLT

www.emanualpro.com

Page 693 of 1395

![HONDA CR-V 1999 RD1-RD3 / 1.G Repair Manual

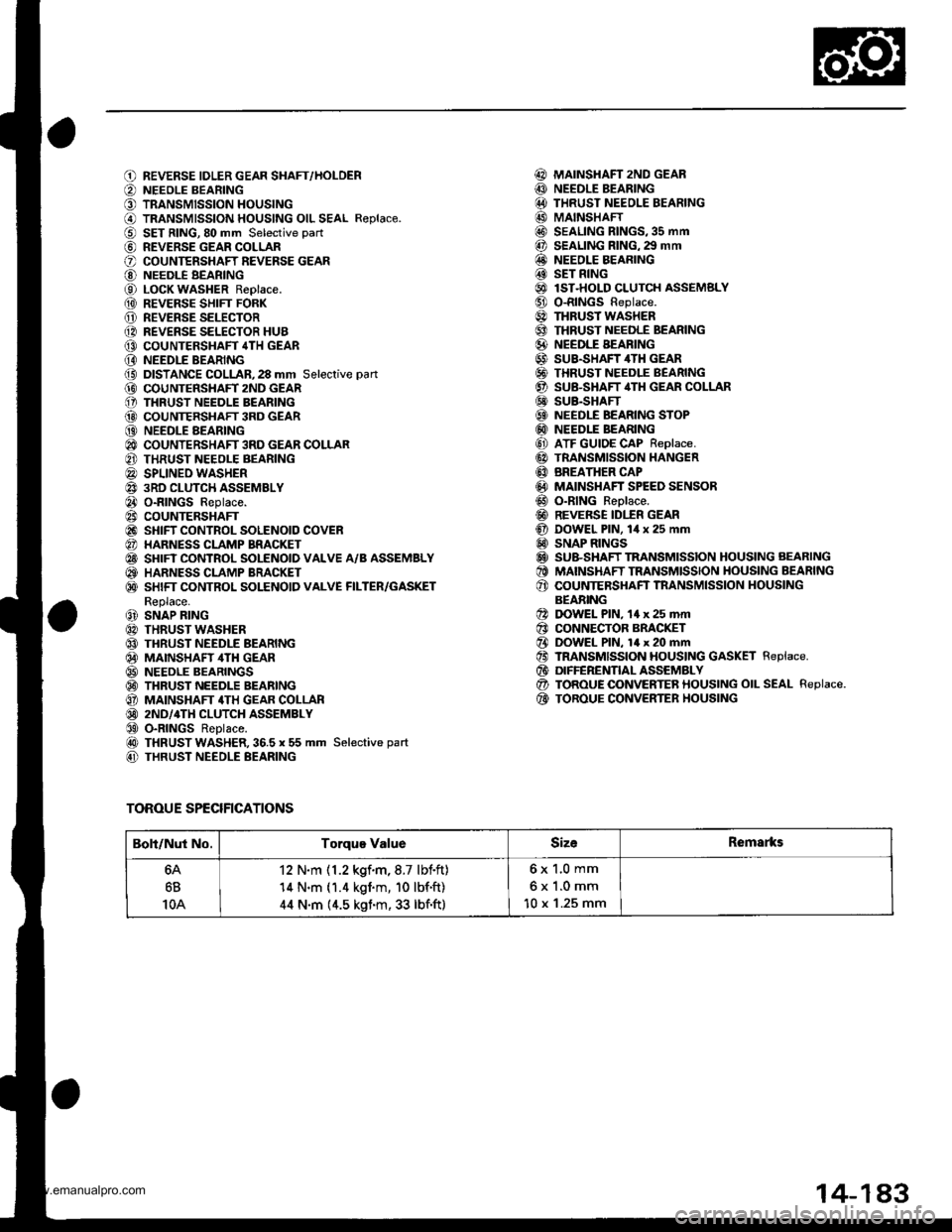

r] REVERSE IDLER GEAR SHAFT/HOLDERA N€EDLE BEARING

..] TRANSMISSION HOUSING

al TRANSMISSION HOUSING OIL SEAL Replace.g SET BING.80 mm Selecrive part

O REVERSE GEAR COLLABE couNTERSHAFT REVERSE GEA HONDA CR-V 1999 RD1-RD3 / 1.G Repair Manual

r] REVERSE IDLER GEAR SHAFT/HOLDERA N€EDLE BEARING

..] TRANSMISSION HOUSING

al TRANSMISSION HOUSING OIL SEAL Replace.g SET BING.80 mm Selecrive part

O REVERSE GEAR COLLABE couNTERSHAFT REVERSE GEA](/img/13/5778/w960_5778-692.png)

r] REVERSE IDLER GEAR SHAFT/HOLDER'A N€EDLE BEARING

..] TRANSMISSION HOUSING

al TRANSMISSION HOUSING OIL SEAL Replace.g SET BING.80 mm Selecrive part

O REVERSE GEAR COLLABE couNTERSHAFT REVERSE GEAB

.9,] NEEDLE BEARINGi9 LOCK WASHER Replace..1!i REVERSE SHIFT FORKO REVERSE SELECToRiJ. REVERSE SELECTOR HUBii' COUNTERSHAFT 4TH GEAR.14 NEEDLE BEARINGiD D|STANCE coLLAR,28 mm Selective part(i3 COUNTERSHAFT 2NO GEABi7-] THRUST NEEDLE BEARING(10 COUNTERSHAFT 3RD GEAR(9 NEEDLE BEARINGE9 COUNTERSHAFI3RD GEAB COLLAR.li THRUST NEEDLE BEARING.?) SPLINEO WASHER,,O 3RD CLUTCH ASSEMBLY

€1 O-RING Beplace.i23 COUNTERSHAFT

4i SHIFT CONTROL SOLENOID COVER

?Z] HARNESS CLAMP BRACKET

?9] SHIFT CONTROL SOLENOID VALVE A/B ASSEMBLY

8 HARNESS CLAMP BRACKET

GI SHIFT CONTROL SOLENOID VALVE FILTER/GASKET

(4 MAINSHAFT 2ND GEARi49 NEEDLE BEARING

@ THRUST NEEDLE BEARING(49 MAINSHAFT

@r SEAL|NG R|NG,35 mm

O SEALING RING,29 mm

@ NEEDLE BEARING

.49 SET RING

€) lST.HOLD CLUTCH ASSEMBLY

O o-RING Replace.6E THRUST WASHER

€9 THRUST NEEDLE BEARING

6' NEEDLE EEARING

€ir SUB-SHAFT 4TH GEAR

6 THRUST NEEDLE BEARING

@ SUB.SHAFT 4TH GEAR COLLAR@ sUB-sHAFf

6I NEEDI-E B€ARING STOP

@ NEEDLE BEARING(6t ATF GUIDE CAP Replace.(64 TRANSMISSION HANGEB

@ BREATHER CAP

i@ MAINSHAFT SPEED SENSOR

6i O-RING Replace.

6D REVERSE IDLER GEAR

@r DOWEL PlN, 14 x 25 mm.6d SNAP RINGS

QlI SUB.SHAFT TRANSMISSION HOUSING BEARING

E) MAINSHAFT TRANSMISSION HOUSING BEABING.2, COUNTERSHAFI TRANSMISSION HOUSINGBEARING

@[E

t,n9t0@)@),lD

04

@

@@:���������������.ro)

ai

Replace-SNAP RINGTHRUST WASHEBTHRUST NEEDLE BEARINGMAINSHAFT 4TH GEARNEEDLE BEARINGSTHRUST NEEDLE BEARINGMAINSHAFT 4TH GEAB COLLAR2NO/4TH CLUTCH ASSEMBLYO-RING Replace.THRUST WASHER,36.5 x 55 mm Selective partTHRUST NEEOLE BEARING

DOWEL PlN, 14 x 25 mmCONNECTOR BRACKETATF MAGNETDOWEL PlN, 14 x 20 mmTRANSMISSION HOUSING GASKET Replace.DIFFERENTIAL ASSEMBLYDOWEL PlN, 10 x 12 mmO-RING Replace.TRANSFER ASSEMBLYTOROUE CONVERTER HOUSING OIL SEAL Replace.TOROUE CONVERTER HOUSING

TOROUE SPECIFICATIONS

Bolt/Nut No.Torque ValueSizeRgmarks

6A

6B

10A

12 N.m (1.2 kgf.m,8.7 lbf.ft)

14 N.m (1.4 kgf.m, 10 lbift)

44 N.m (4.5 kgf.m,33 lbf.ft)

6x 1.0 mm

6x 1.0 mm

10 x 1.25 mm

14-177

www.emanualpro.com

Page 699 of 1395

oatl,6

@!.,

ao6l

@o@@@@@o@@@)@@@@@@@@@@)

@@@@)@@@@@@@

REVERSE IDLER GEAR SHAFT,/HOLDERNEEOLE BEARINGTRANSMISSION HOUSINGTRANSMISSION HOUSING OIL SEAL R€place.SET RING,80 mm Selective part

REVERSE GEAR COLLARCOUNTERSHAFT REVERSE GEARNEEDLE BEARINGLOCK WASHER Replace.REVERSE SHIFT FORKREVERSE SELECTORREVERSE SELECTOR HUBCOUNTERSHAFT 4TH GEARNEEDLE BEARINGDISTANCE COLLAR,28 mm Selective pan

COUNTERSIIAFT 2ND GEARTHRUST NEEDLE BEARINGCOUNTERSHAFT 3RD GEARNEEDLE AEARINGCOUNTERSHAFT 3RD GEAR COLLARTHRUST NEEOLE BEARINGSPLINEO WASHER3RD CLUTCH ASSEMBLYO-RINGS Replace.COUNTERSHAFTSHIFT CONTROL SOLENOID COVERHARNESS CLAMP BRACKETSHIFT CONTROL SOLENOID VALVE A/B ASSEMBLYHARNESS CLAMP BRACKETSHIFT CONTROL SOLENOID VALVE FILTER/GASKETReplace.SNAP RINGTHRUST WASHERTHRUST NEEDLE BEARINGMAINSHAF ,ITH GEARNEEDLE BEARINGSTHRUST NEEDLE BEARINGMAINSHAFT 4TH GEAR COLLAR2ND/4TH CLUTCH ASSEMBLYO-RINGS ReDlace.THRUST WASHER,36.5 x 55 mm Selective part

THRUST NEEDLE BEARING

MAINSHAFT 2ND GEARNEEDLE BEARINGTHRUST NEEOLE BEARINGMAINSHAFTSEALING RINGS,35 mmSEALING RING. 29 mmNEEDLE BEARINGSET RINGlST-HOLD CLUTCH ASSEMSLYO-RINGS Replace.THRUST WASHERTHRUST NEEDLE BEARINGNEEDLE BEARINGSUB.SHAFT 4TH GEARTHRUST NEEDLE BEARINGSU&SHAFT,ITH GEAR COLLARSUB.SHAFTNEEDLE BEARING STOPNEEDLE BEARINGATF GUIDE CAP Replace.TRANSMISSION HANGERBREATHER CAPMAINSHAFT SPEED SENSORO-RING Reolace.REVERSE IDI.fR GEARDOWEL PlN, lil x 25 mmSNAP RINGSSU&SHAFT TRANSMISSION HOUSING AEARINGMAINSHAFT TRANSMISSION HOUSING BEARINGCOUNTERSHAFT TNANSMISSION HOUSINGBEABINGDOWEL PlN, 14 x 25 mrnCONNECTOR BRACKETDOWEL PlN, 14 x 20 mmTRANSMISSION HOUSING GASKET Replace.DIFFERENTIAL ASSEMBLYTOROUE OONVERTER HOUSING OIL SEAL Replace.TOROUE CONVERTER HOUSING

@@@@@@@@@@@@@@@@@@@@@@@)@@@@@@@

@@@@@@@

TOROUE SPECIFICATIONS

Boli/Nut No.Torque ValueSizeRemarks

6B

10A

12 N.m (1.2 kgf.m,8.7 lbf.ft)'14 N.m (1.4 kgim, 10 lbf'ft)

44 N.m (4.5 kgim, 33 lbf.ft)

6x 1.0 mm

6x1.0mm

10 x '1.25 mm

14-1A3

www.emanualpro.com

Page 712 of 1395

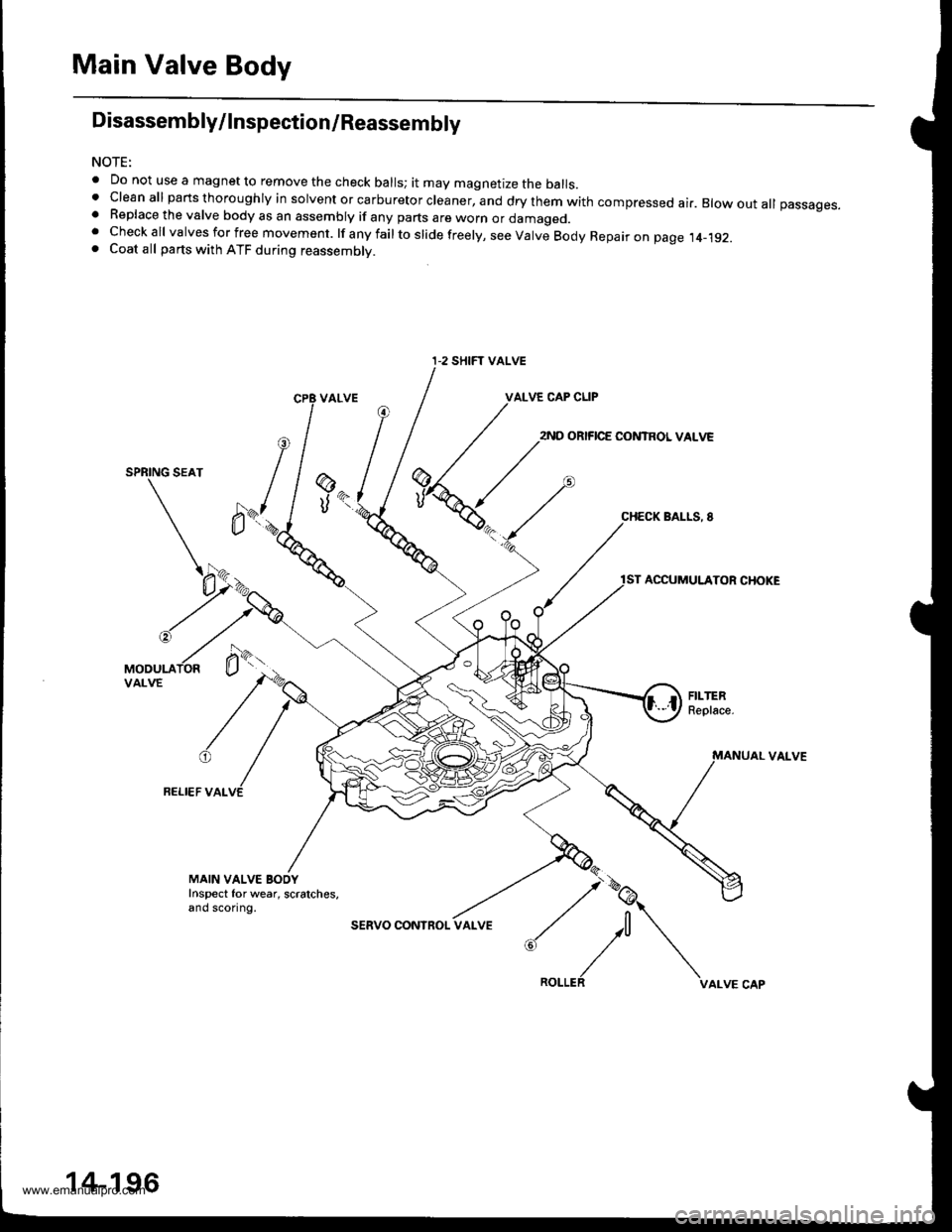

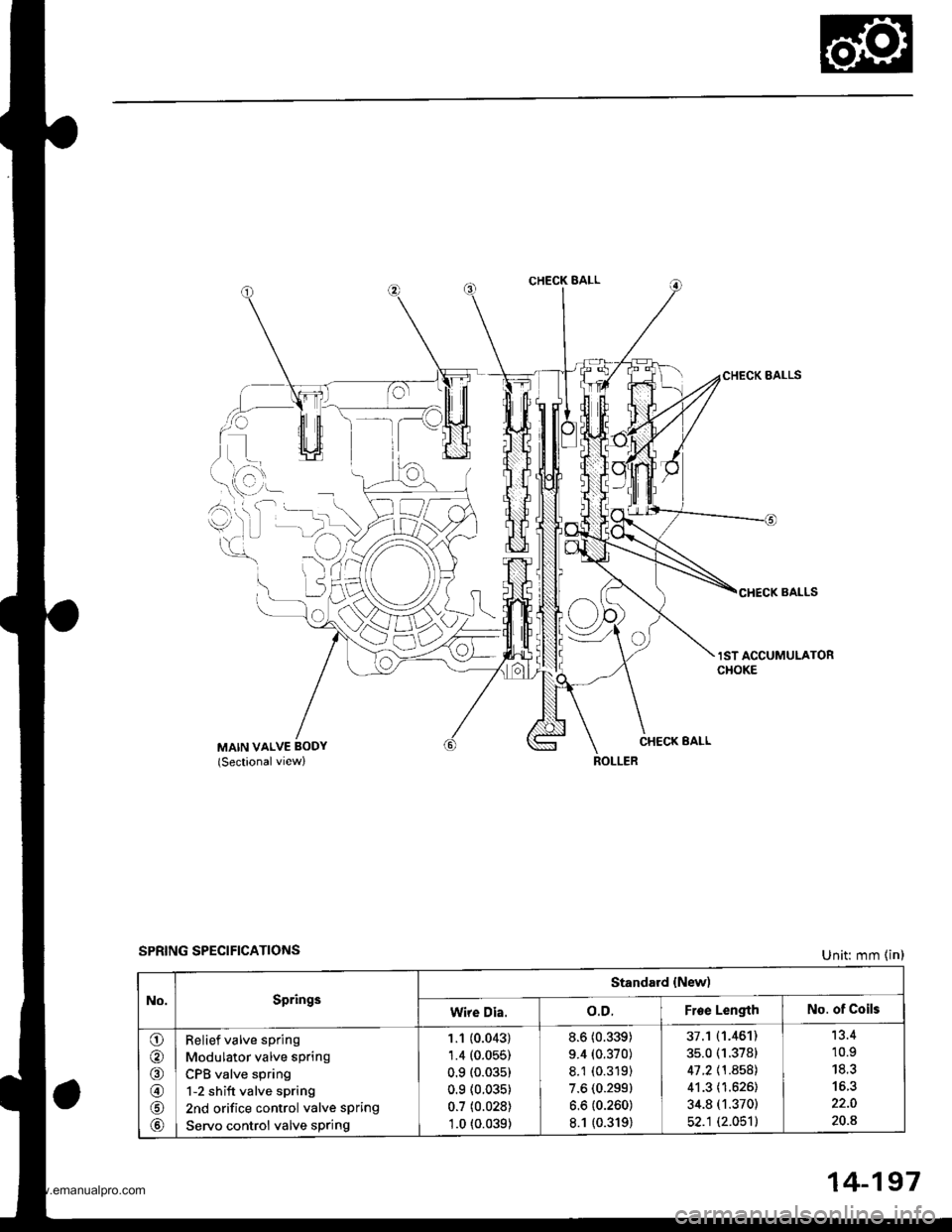

Main Valve Body

Disassembly/lnspection/Reassembly

NOTE:

. Do not use a magnet to remove the check balls; it may magnetize the balls.t clean all parts thoroughly in solvent or carburetor cleaner, and dry them with compressed ai.. Blow out all passages.. Replace the valve body as an assembly if any parts are worn or damageo.. Checkall valvesforfree movement. lfanyfailtoslidefreely,seeValveBodyRepaironpage.t4_192.. Coat all parts with ATF during reassembly.

VALVE CAP CLIP

2ND ORIFICE CONTROL VALVE

SPRING SEAT

BALLS, 8

ACCUMULATOR CHOKE

VAI-VE

FELI€F VALVE

@

UK

MAIN VALVE BOOYInspect for wear, scratches,and sconng.

sERVO CONInOL

:,/\^._.^,

I-2 SHIFT VALVE

14-196

www.emanualpro.com

Page 713 of 1395

CHECK BALL

i)L)

lo

CHECK BALLS

lST ACCUMULATORCHOKE

CHECK EALLMAIN VALVE BODY(Sectionalview)

SPRING SPECIFICATIONSUnit: mm (in)

No.Springs

Standard {New)

Wire Dia.o.D.Froe LengthNo. of Coils

o

@

@

@

Relief valve spring

Modulator valve spring

CPB valve spring

1-2 shift valve spring

2nd orifice control valve spring

Servo control valve sPring

1.1 (0.043)

1.4 (0.055)

0.9 (0.03s)

0.9 (0.035)

0.7 (0.028)

1.0 t0.039)

8.6 (0.339)

9.4 (0.370)

8.1 (0.319)

7.6 (0.299)

6.6 (0.260)

8.1 {0.319)

37.1 (1.461)

35.0 (1.3781

41 .2 \1 .8581

41.3 (1.626)

34.8 (1.370)

52.1 (2.051)

'13.4

10.9

20.8

14-197

www.emanualpro.com