Gear position switch HONDA CR-V 1999 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 703 of 1395

1. Remove the A/T gear position switch harness

cramp.

Remove the y'VT gear position switch cover.

Remove the bolt securing the ly'T gear position switch

harness clamp on the end cover, then remove the A/T

gear position switch.

Remove the 12 bolts securing the end cover. then

remove the cover.

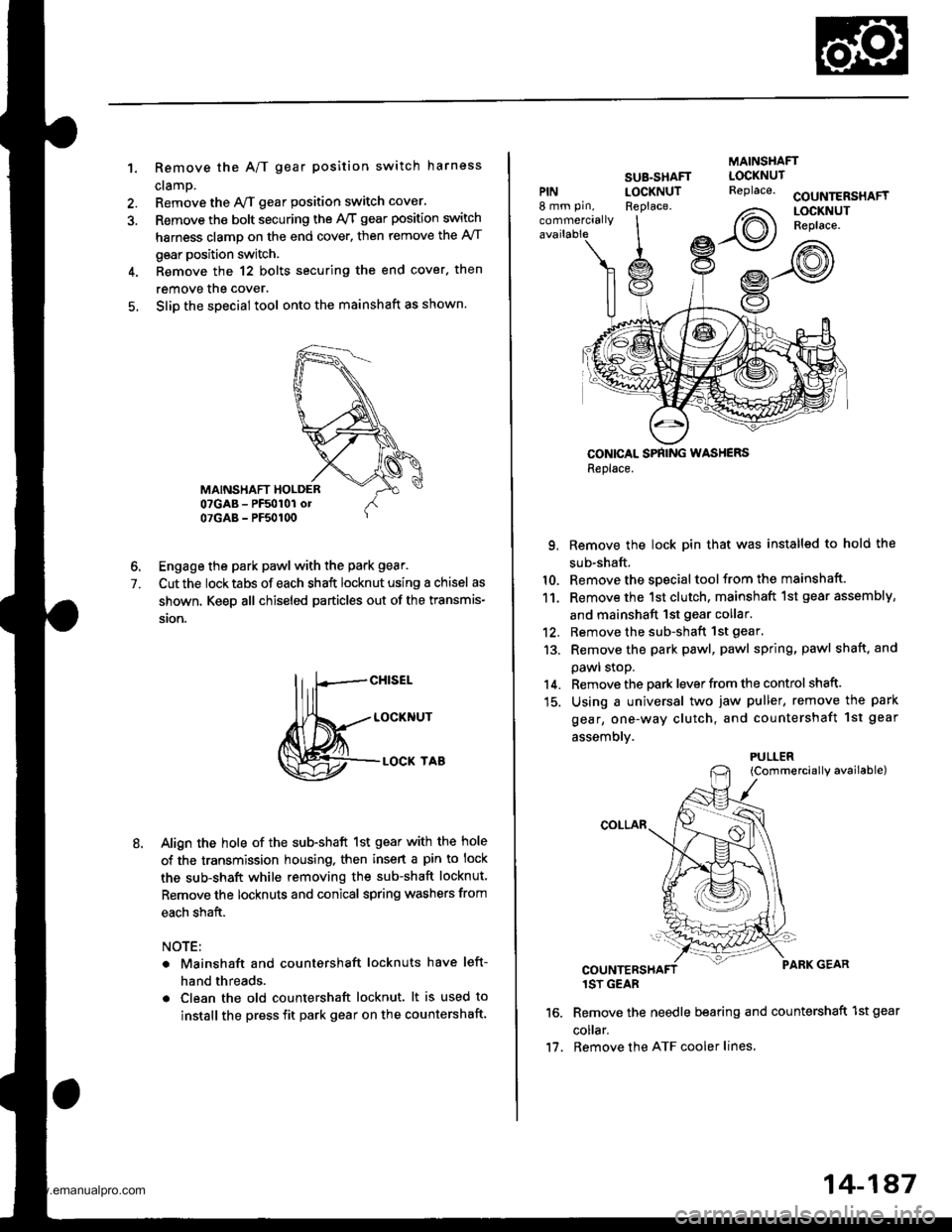

Slip the special tool onto the mainshaft as shown.

6. Engage the park pawl with the park gear.

7. Cut the locktabs of each shaft locknut using a chisel as

shown. Keep all chiseled particles out of the transmis-

ston.

M=tt"

Align the hole of the sub-shaft 1st gear with the hole

of the transmission housing. then insert a pin to lock

the sub-shaft while removing the sub-shaft locknut.

Remove the locknuts and conical spring washers from

each shaft.

NOTE:

Mainshaft and countershaft locknuts have left-

hand threads.

Clean the old countershaft locknut. lt is used to

install the press fit park gear on the countershaft.

MAINSHAFT

PIN8 mm pin,

commercially

SUB-SHAFTLOCKNUTReplace.COUNTERSHAFTLOCKNUTReplace.

CONICAL SPNING WASHERSReplace.

9. Remove the lock pin that was installed to hold the

sub-shaft.

10. Remove the special tool from the mainshaft.

11. Remove the 1st clutch, mainshaft 1st gear assembly,

and mainshaft 1st gear collar.'12. Remove the sub-shaft 1st gear.

13. Remove the park pawl, pawl spring, pawl shaft. and

pawl stoP.

14. Remove the park lever from the control shaft.

15. Using a universal two jaw puller, remove the park

gear, one-way clutch, and countershaft 1st geal

assemblv.

{Commercially available)

1SY GEAR

Remove the needle bearing and countershaft 1st gear

co ar.

Remove the ATF cooler lines,

LOCKNUTReplace.

2\

Irot)

PULLER

11.

14-187

www.emanualpro.com

Page 772 of 1395

Transmission

Reassembly lcont'd)

44.

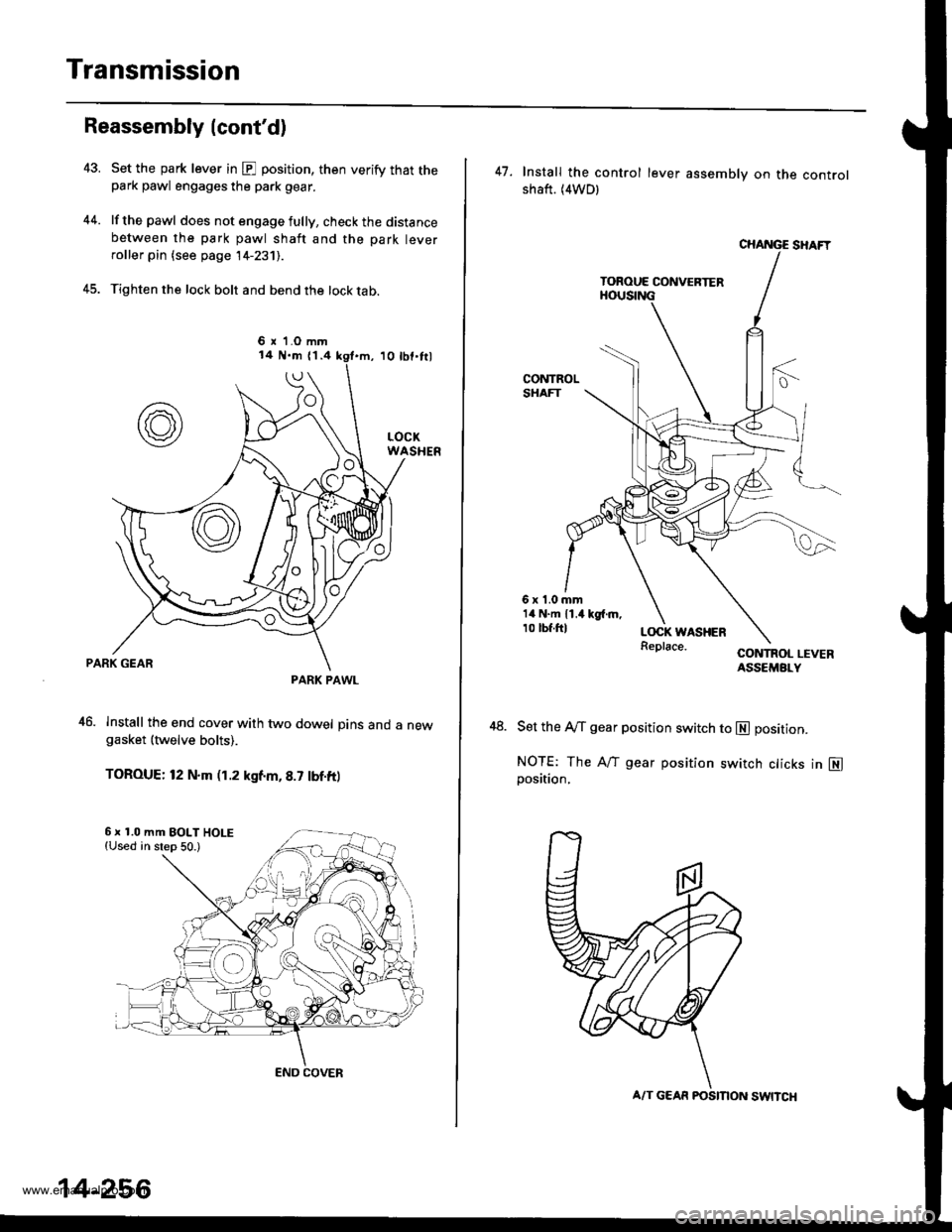

Set the park lever in @ position, then verify that thepark pawl engages the park gear.

lf the pawl does not engage fully, check the distancebetween the park pawl shaft and the park leverroller pin (see page 14-231).

Tighten the lock bolt and bend the lock tab.

1o tbf'frl

PARK GEAR

46. Install the end cover with two dowel pins and a newgasket {twelve bolts).

TOROUE: 12 N.m (1.2 kgf.m, 8.7 tbf.ft)

6 r 1.O mm

PARK PAWL

6 x 1.0 mm EOLT HOLE{Used in step 50.)

END COVER

14-256

A/T GEAR FOSMON SWNCH

47. Install the control lever assemblv on the controlshaft. (4WDl

6x1.0mm14 N.m 11.4 kg{.m,10 tbf.ftl

48.

CONTROL LEVERASSEMBLY

Set the A/f gear position switch to E] position.

NOTE: The Aff gear position switch cticks in N]position,

www.emanualpro.com

Page 773 of 1395

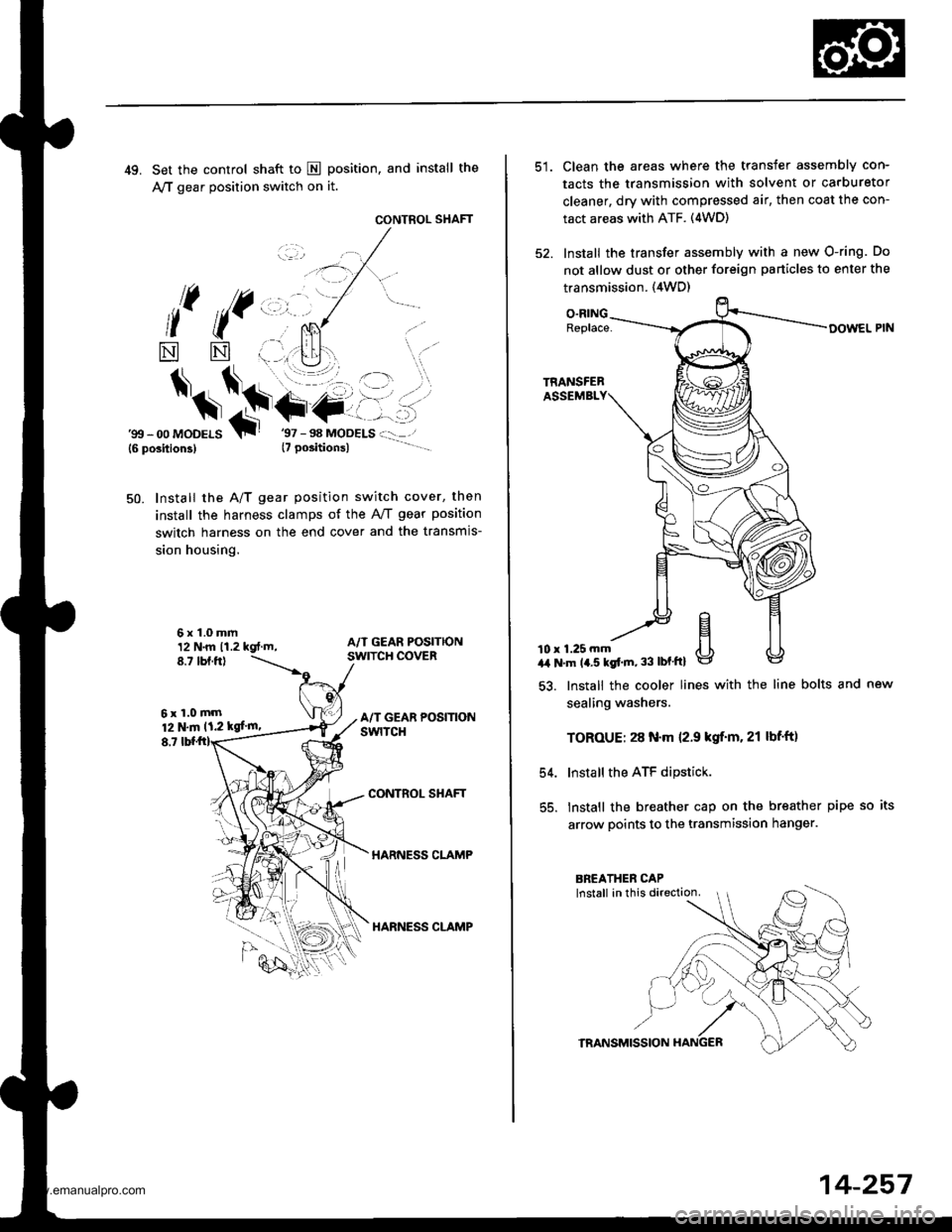

49. Set the control shaft to E position, and install the

A,/T gear position switch on it.

CONTROL SHAFT

l( ((,,, ,.

*

$*\.t+-

NN

6x1.0mm12 N.m 11.2 kgt.m,8.7 tbf.ftl

6xl.0mm12 N.m 11.2 kgf'm,

8,7

'gtt - 00 MoDELS{6 position3}T

Install the A/T gear position switch cover, then

install the harness clamps of the AviT gear position

switch harness on the end cover and the transmis-

sion housing.

50.

CONTROL SHAFT

HARNESS CLAMP

HARNESS CLAMP

Clean the areas where the transfer assembly con-

tacts the transmission with solvent or carburetor

cleaner, dry with compressed air, then coat the con-

tact areas with ATF. (4WD)

Install the transfer assembly with a new O-ring. Do

not allow dust or other foreign particles to enter the

transmission. {4WD)

O.RINGReplace-

10 r 1.25 mma,a N'm 14.5 kgt'm, 33 lbf'ftl

54.

55.

lnstall the cooler lines with the line bolts and new

sealing washers.

TOROUE: 28 N.m 12.9 kgif'm. 21 lbf'ft)

Install the ATF dipstick.

lnstall the breather cap on the breather pipe so its

arrow points to the transmission hanger.

TRANSMISSION

14-257

www.emanualpro.com

Page 779 of 1395

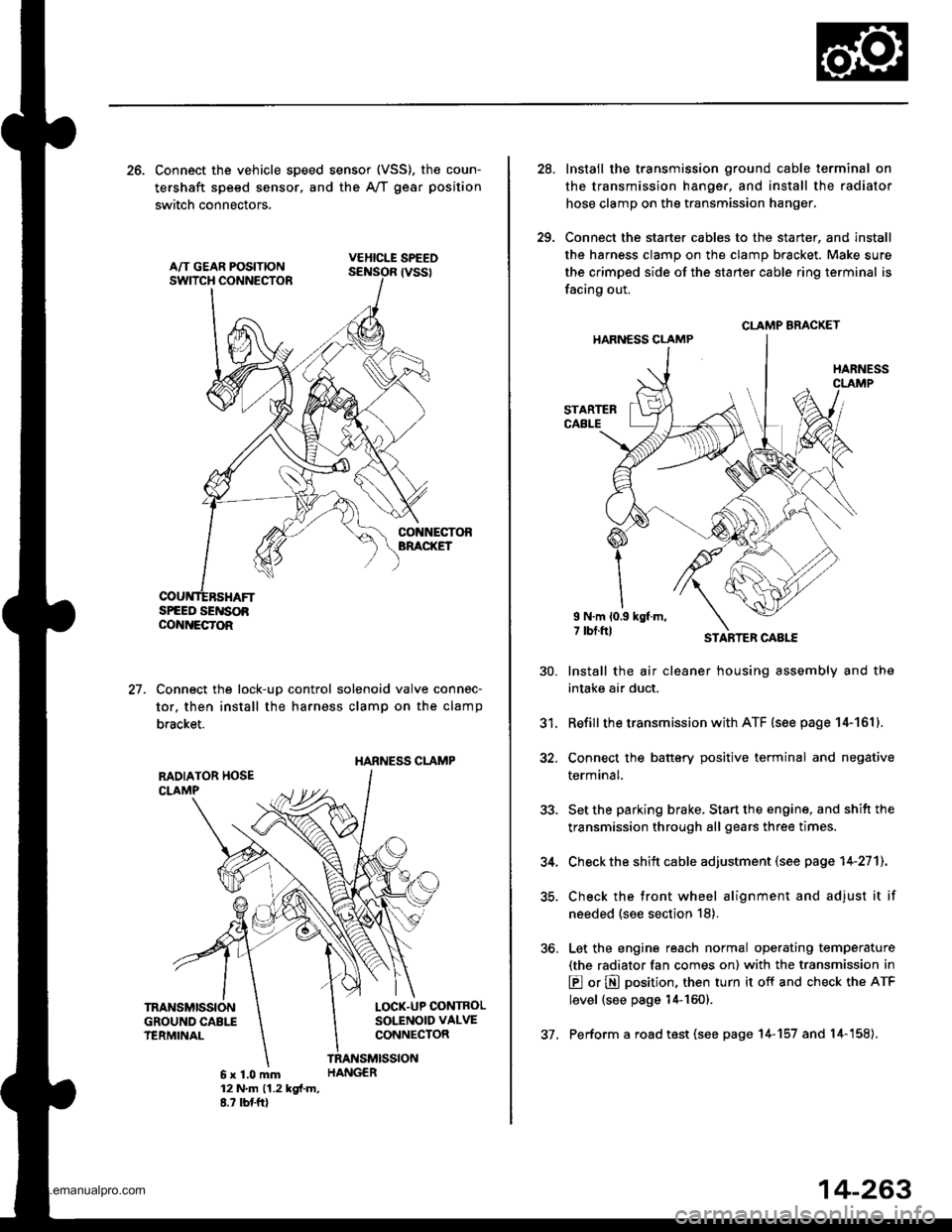

26. Connect the vehicle speed sensor (VSS). the coun-

tershaft speed sensor. and the A,/T gear position

switch connectors,

VEHICLE SPEEO

SPEED SENSOACO'{NECTOR

Connect the lock-up control solenoid valve connec-

tor, then install the harness clamp on the clamp

bracket.

HARNESS CI-AMP

27.

RADIATOR HOSECLAMP

TRANSMISSIONGROUND CAB1ITERMINAL

LOCK-UP OONTROLSOLENOID VALVECONNECTOR

6x1.0mm12 N'm (1.2 kgi.m,8.? tbtftl

28.

29.

Instail the transmission ground cable terminal on

the transmission hanger, and install the radiator

hose clamp on the transmission hanger,

Connect the starter cables to the starter, and install

the harness clamD on the clamD bracket. Make sure

the crimped side of the starter cable ring terminal is

facing out.

STARTEBCABLE

STARTER CAAtf,

Install the air cleaner housing assembly and the

intake air duct.

Refill the transmission with ATF (see page 14-161).

Connect the battery positive terminal and negative

terminal.

Set the parking brake, Start the engine, and shift the

transmission through all gears three times.

Check the shift cable adjustment (see page 14-271]-.

Check the tront wheel alignment and adjust it if

needed (see section 18).

Let the engine reach normal operating temperature

(the radiator fan comes on) with the transmission in

E or N position, then turn it off and check the ATF

level {see page 14-160).

Perform a road test (see page 14-157 and 14-158).

30.

31.

34.

CLAMP BRACKET

37.

14-263

www.emanualpro.com

Page 788 of 1395

Shift Gable

Adjustment

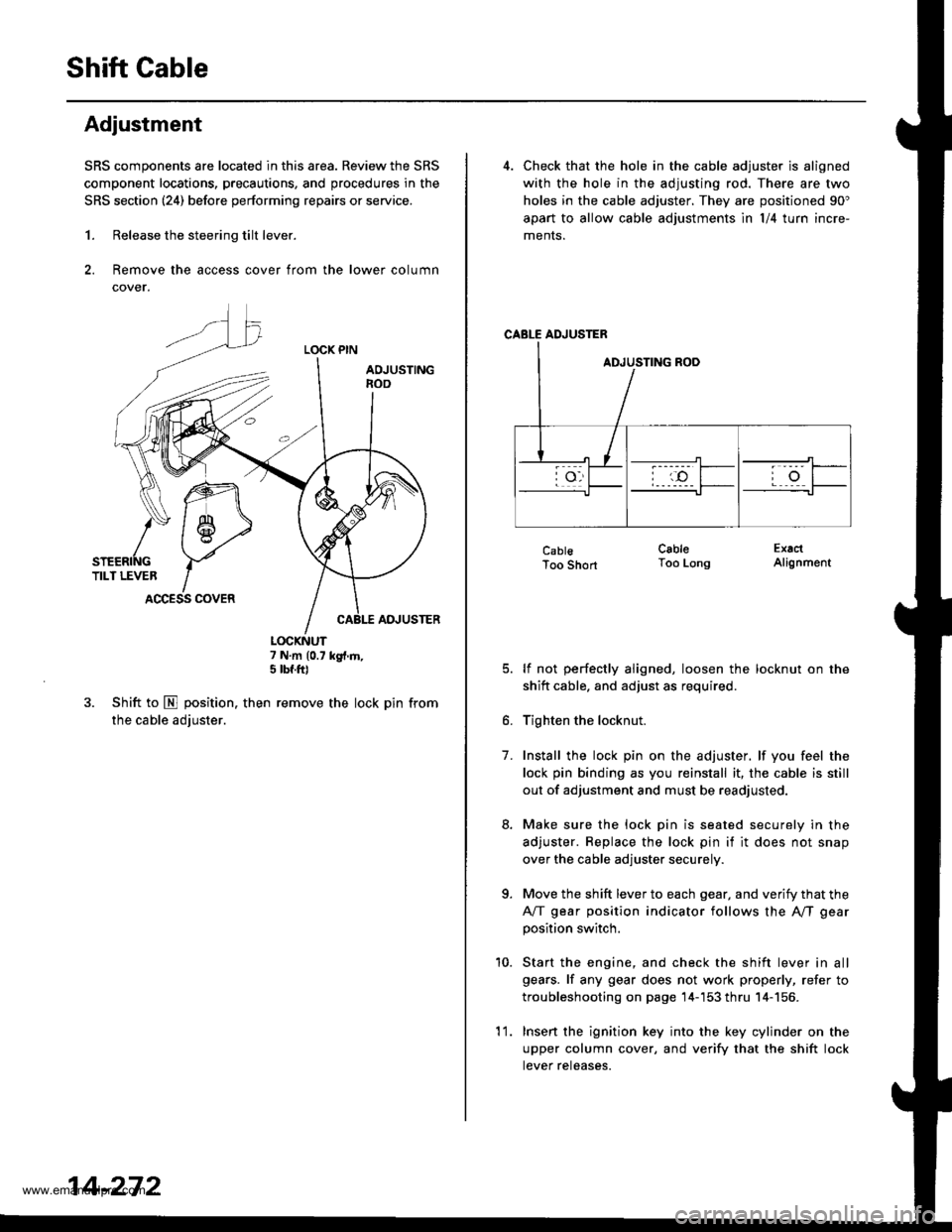

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section (241 before performing repairs or service.

1. Release the steering tilt lever.

2. Remove the access cover from the lower column

cover.

LOCK PIN

AOJUSTINGnoo

ADJUSTER

7 N.m (0.7 kg{.m,5 tbf.ft)

3. Shift to E position. then remove the lock pin from

the cable adjuster.

K\ffi

/* 1 6-,>

snenrftc YTILT LEVER IACCESS COVER

14-272

'l 1.

4. Check that the hole in the cable adjuster is aligned

with the hole in the adjusting rod. There are two

holes in the cable adjuster. They are positioned 90"

apart to allow cable adjustments ln l/4 turn incre-

ments.

CABLE ADJUSTER

CablsToo Short

lf not perfectly aligned, loosen the locknut on the

shitt cable. and adjust as required.

Tighten the locknut.

Install the lock pin on the adjuster. lf you feel the

lock pin binding as you reinstall it, the cable is still

out of adjustment and must be readjusted.

Make sure the lock pin is seated securely in the

adjuster. Replace the lock pin if it does not snap

over the cable adjuster securely.

Move the shift lever to each gear, and verify that the

A/T gear position indicator follows the A"/T gear

position switch.

Start the engine, and check the shift lever in all

gears. lf any gear does not work properly, refer to

troubleshooting on page 14-'153 thru 14-156.

Insert the ignition key into the key cylinder on the

upper column cover, and verify that the shift lock

tever reteases.

CableToo LongExactAlignment

7.

a

10.

www.emanualpro.com

Page 868 of 1395

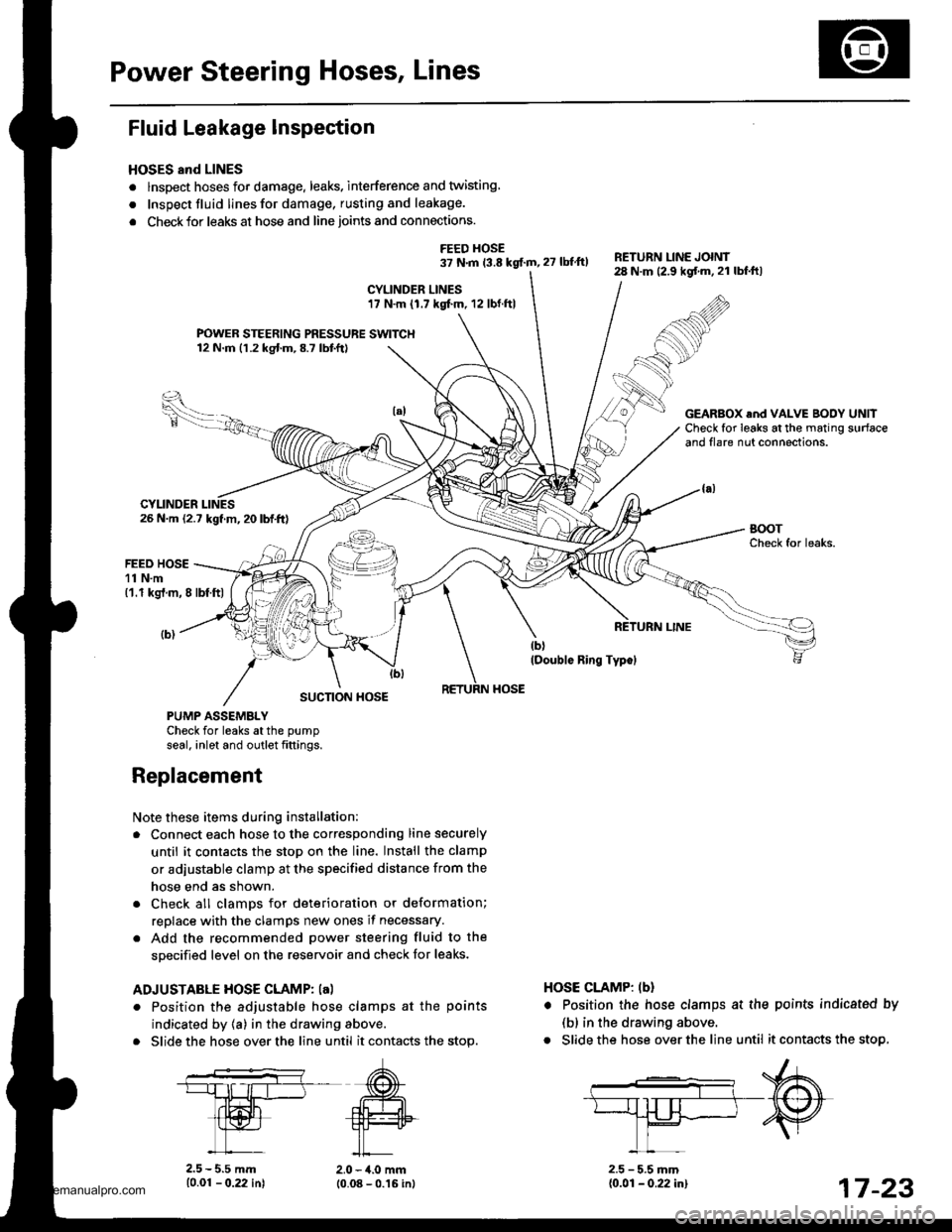

Power Steering Hoses, Lines

Fluid Leakage Inspection

HOSES and LINES

. lnspect hoses for damage. leaks. interference and twisting

. Inspect fluid linesfor damage, rusting and leakage.

. Check for leaks at hose and line joints and connections.

FEED HOSE37 N.m 13.8 kgf.m, 27 lbtft)RETURN LINE JOINT28 N.m (2.9 kgf.m.21 lbf.ftl

CYLINDER LINES17 N.m (1.7 kgf.m. 12 lbf.ftl

FOWER STEERING PRESSURE SWITCH12 N.m (1.2 kgf.m,8.7 lbtft)

26 N.m (2.7 kgf.m, 20 lbf.ft)

GEARBOX .nd VALVE BODY UNllCheck for leaks at the mating surfaceand flare nut connections.

CYLINDER

FEED HOSE11 N.m('1.1 kgt.m, 8 lbf.ftl

SUCTION HOSE

PUMP ASSEMBLYCheck for leaks atthe pump

seal. inlet and outlet fittings.

Note these items during installation:

. Connect each hose to the corresponding line securely

until it contacts the stop on the line. Install the clamp

or adjustable clamp at the specified distance from the

hose end as shown.

. Check all clamDs for deterioration or deformation;

replace with the clamps new ones if necessary.

. Add the recommended power steering fluid to the

specified level on the reservoir and check for leaks.

ADJUSTABLE HOSE CLAMP: la)

. Position the adjustable hose clamps at the points

indicated by (a) in the drawing above.

. Slide the hose over the line until it contacts the stop.

HOSE CLAMP: lbl

. Position the hose clamps at the

(b) in the drawing above.

. Slide the hose over the line until

Replacement

10.01 - 0.22 in)

points indicatsd by

it contacts the stop,

2.0 - 4.0 mm10.08 - 0.16 inl2.5 - 5.5 mm{0.01 - 0.22 in}17 -23

www.emanualpro.com

Page 1161 of 1395

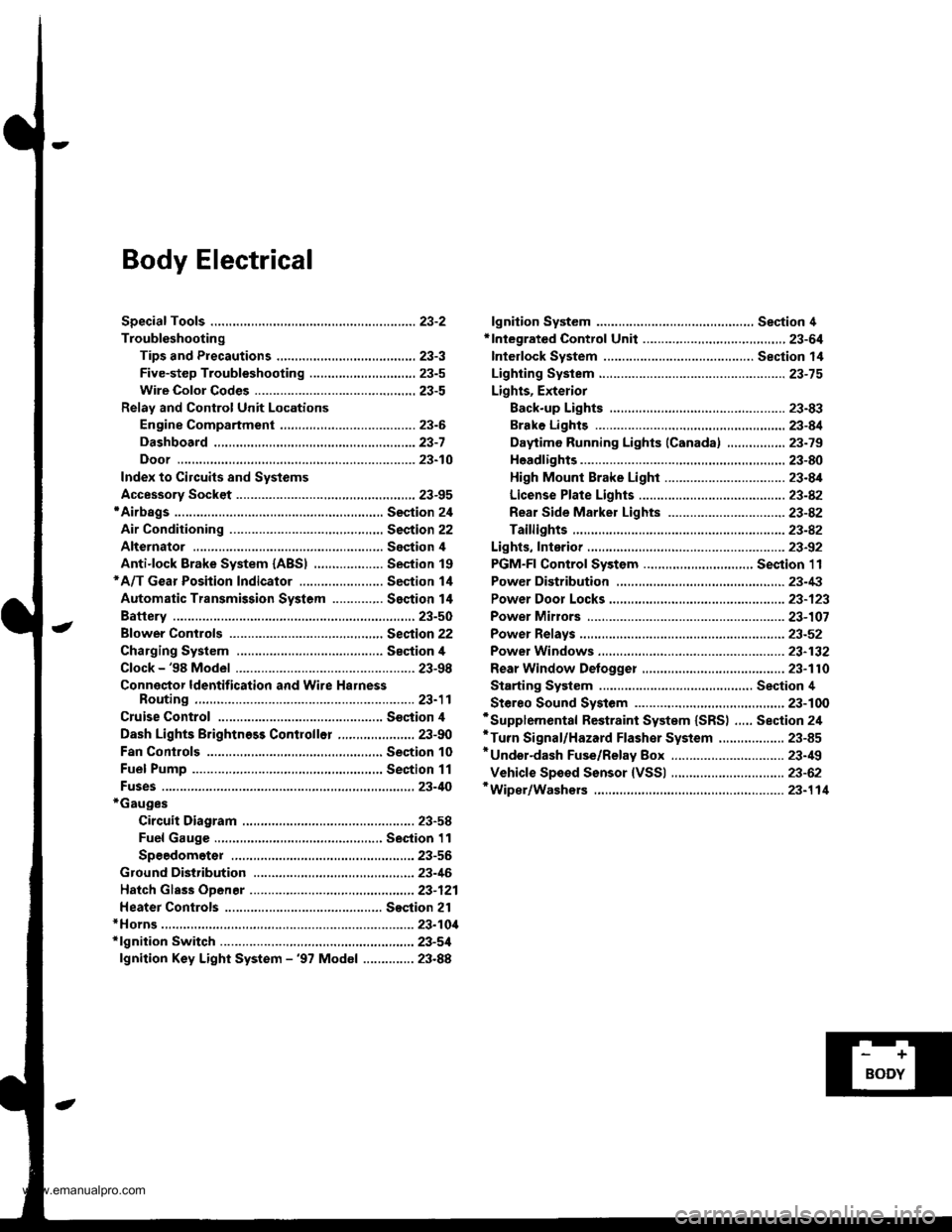

Body Electrical

Speciaf Toofs ,...,..,.............-.23-2

Troubleshooting

Tips and Precautions ......,.,..........,.................. 23-3

Five-step Troubleshooting ........,.,.,...,,.,......... 23-5

Wire Color Codes ...,....,.. 23-5

Relay and Control Unit Locations

Engine Compartment ..,.,......,......................... 23-6

Dashboard ,.,.,..............-.- 23-7

Door ....................... .........23-10

Index to Cilcuits and Sysiems

Accessory Socket .. ,....,.,..,.,. 23-95*Airbags ................ .,....,. Sestion 24

Air Conditioning ,.,.,.... Section 22

Alternator ................... Section 4

Anti-lock Brake System {ABSI ................... Section 19'A/T Gear Position Indicator ....................... Section 1,1

Automatic Transmission System ...........,.. Section 14

Battery ................... ..............23-50

Blower Controls .,...,.,, Section 22

Charging System ....... Seqtion il

Clock -'98 Model ................ 23-98

Connector ldentification and Wire HarnessRouting .................. ......... 23.11

Cruise Control ............ Ssction 4

Dash Lights Brightness Contlo||er ..................... 23-90

Fan Conlrols ...,......,.... Section 10

Fuel Pump ,..,.,...,....,.... Section 11

Fuses...................... .,,.,.,.,.,,.,23-40*Gauges

Circuit Diagram ......-....-..23-58

Fuel Gauge .....,.,..... Section 11

Speedometer ..,..........,... 23-56

Ground Distribution ,....,.,...23-46

Hatch Glsss ODenor .........................,.,.,.,.,..,.,.,.,,. 23-121

Heater Controls .-........ Soction 21*Horns.,...,..,.,.,....... ................23"104*fgnition Switch ,,.,.,..,.,.,,.,.,.,23-51

lgnition Key Light System -'97 Mod6l .............. 23.88

-+

BODY

www.emanualpro.com

Page 1174 of 1395

![HONDA CR-V 1999 RD1-RD3 / 1.G Repair Manual

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1ll HONDA CR-V 1999 RD1-RD3 / 1.G Repair Manual

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1ll](/img/13/5778/w960_5778-1173.png)

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1l'l

c112

c113

c't 14

cl16

cl16

c117

c118

c119

c120

c121

c't22

c't23

c't25

cl26

cl27

cr 28

cl29

c130

c131

c132

c 133

c134

c134

c135

c 136

10

6

1

2

1

2

1

10

20

31

16

22

l0

l0'14

14

1

Left side of engine compartment

Left side of engine compartment

Middle of engine

Middle of engine

Left side of engine compartment

Left side of engine compartment

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Right side of engine

Middle of engine

Behind right kick panel

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Right side of engine

Right side of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Left side of engine compartment

Middle of engine

Middle of engine

Main wire harness (C304)

Main wire harness (C305):'97 - 98 models

No. 1 fuel injector

Crankshaft speed fluctuation (CKF) sensor

Alternator

Alternator

Engine oil pressure switch

No.2 fuel injector

Evaporative emission (EVAP) purge

control solenoid valve

No. 3 fuel injector

No. 4 fuel injector

Primary heated oxygen sensor(Primary HO2S) (sensor 1)

Radiator fan switch

Coolant temperature sending unit

Engine coolant temperature (ECT) sensor

Mainshaft speed sensor

Lock-up control solenoid valve

Back-up light switch

Shift control solenoid valve

Linear solenoid valve

Countershaft speed sesnsor

Starter solenoid

Distributor

Junction connector

PCM

ECIWPCM

ECM/PCM

ECM/PCM

Main wire harness (C,|:}1)

IVT gear position switch

Vehicle speed sensor (VSS)

Throttle position (TP) sensor

MAP sensor

ldle air control (lAC)valve

lntake air temperature (lAT) sensor

Junction connector

Junction connector

Power steering pressure (PSP) switch

Junction connector

Knock sensor (KS)

A/r

USA

Canada

Alr

AlT

M/'r

Afi

'97mooel

'97 model'98 - 00

mooets

'99 - 00

models

T101

r102

Left side of en0ine companment

Right side of engine compartment

Alternator

Under-hood fuse/relay box

G101Middle of engineEngine ground, via engine wire harness

23-14

www.emanualpro.com

Page 1205 of 1395

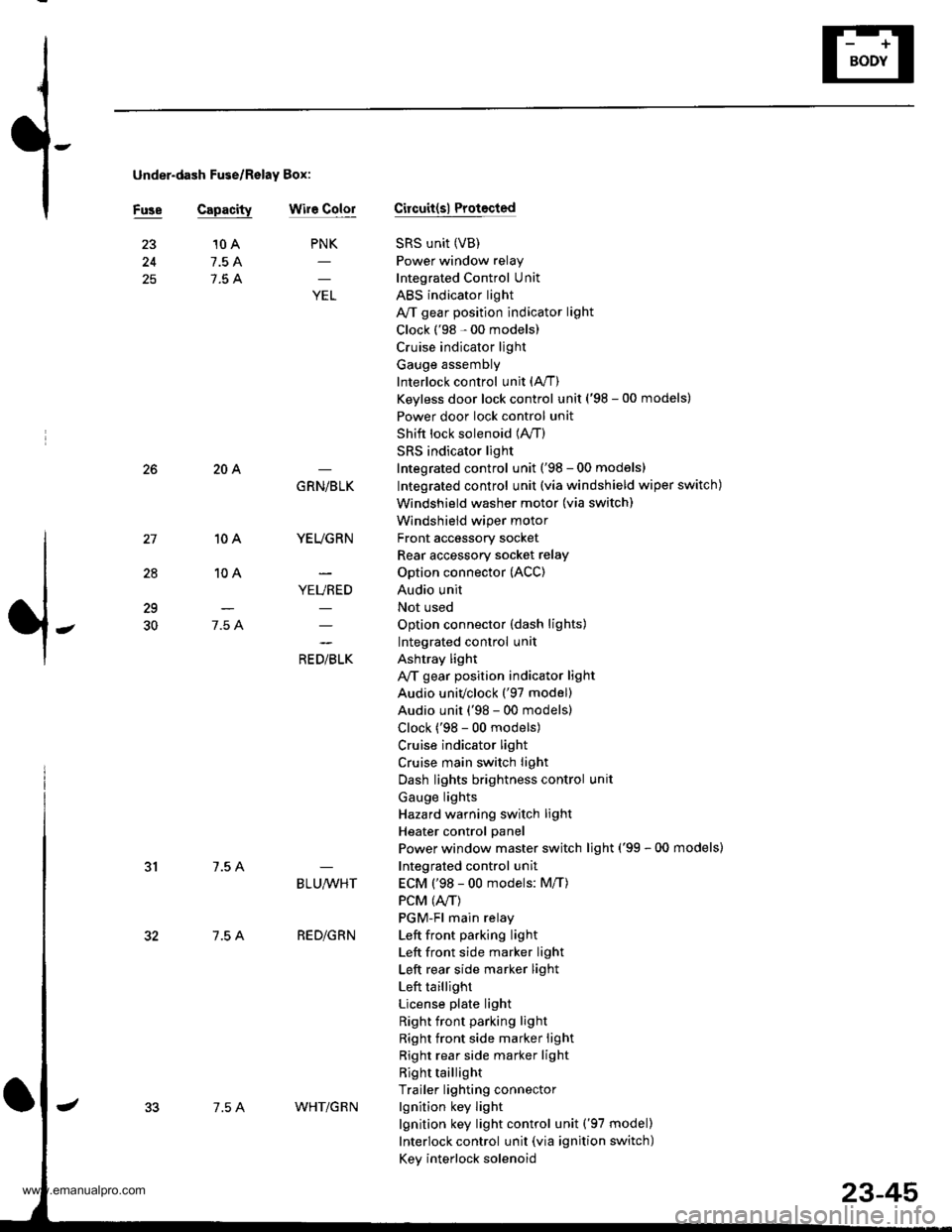

under-dash Fuse/Relay Box:

Fuse Capacitywir6 ColorCircuit(sl Protocted

SRS unit (VB)

Power window relay

Integrated Control Unit

ABS indicator light

A/T gear position indicator light

Clock ('98 - 00 models)

Cruise indicator light

Gauge assembly

Interlock control unit (A,/T)

Keyless door lock control unit ('98 - 00 models)

Power door lock control unit

Shift lock solenoid (lVT)

SRS indicator light

Integrated control unit ('98 - 00 models)

Integrated control unit (via windshield wiper switch)

Windshield washer motor (via switch)

Windshield wiper motor

Front accessory socket

Rear accessory socket relay

Option connector (ACC)

Audio unit

Not used

Option connector (dash lights)

Integrated control unit

Ashtray light

A,/T gear position indicator light

Audio univclock ('97 model)

Audio unit ('98 - 00 models)

Clock ('98 - 00 models)

Cruise indicator light

Cruise main switch light

Dash lights brightness control unit

Gauge lights

Hazard warning switch light

Heater control panel

Power window master switch light ('99 - 00 models)

Integrated control unit

ECM ('98 - 00 models: M/T)

PCM (4./T)

PGM-Fl main relay

Left front pa.king light

Left front side marker light

Left rear side marker light

Left taillight

License plate light

Right front parking light

Right front side marker light

Right rear side marker light

Right taillight

Trailer lighting connector

lgnition key light

lgnition key light control unit ('97 model)

Interlock control unit (via ignition switch)

Key interlock solenoid

25

PNK

;

10 A

7.5 A

7.5 A

28

10A

10A

7.5 A

204

7.5 A

7.5 A

GRN/BLK

YEUGRN

YEURED

a, olrL"

29

30

BLU,ryVHT

RED/GRN

7.5 AWHT/G R N

23-45

www.emanualpro.com

Page 1206 of 1395

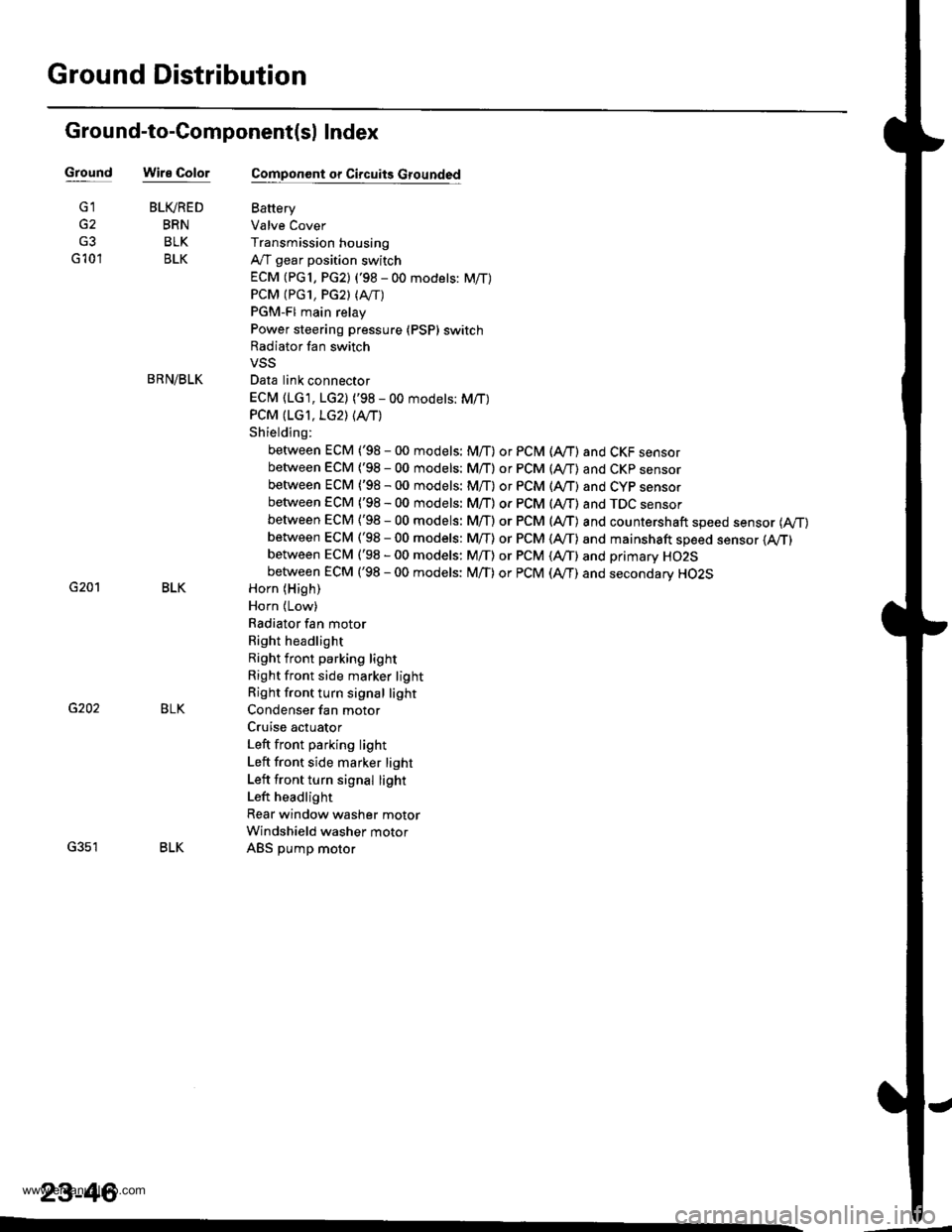

Ground Distribution

Ground-to-Component(sl Index

GroundWire Color

G2

G3

G 10'l

G201

G202

G351

BLIVRED

BRN

BLK

BLK

BRN/BLK

BLK

BLK

BLK

23-46

Component or Circuits Grounded

Battery

Valve Cover

Transmission housing

A,/T gear position switch

ECM (PG1, PG2) ('98 - 00 models: M/T)

PCM (PG1, PG2l (Avrr)

PGM-FI main relay

Power steering pressure (PSP) switch

Radiator fan switch

VSS

Data link connector

ECM (1G1, LG2) ('98 - 00 models: M/T)

PCM (LGI, LG2) (IVT)

Shielding:

between ECM ('98 - 00 models: M/T) or PCM (Ay'T) and CKF sensorbetween ECM {'98 - 00 modets: M/T} or pCM (Ay'T) and CKp sensorbetween ECM ('98 - 00 models: M/T) or PCM (rVT) and CYP sensorbetween ECM ('98 - 00 models: M/T) or PCM (Ay'T) and TDC sensorbetween ECM {'98 - 00 models: M/T) or PCM (ly'T) and countershaft speed sensor (Ay'T)

between ECM ('98 - 00 models: M/T) or PCM {A,,/T) and mainshaft sp€ed sensor {!VT)between ECM ('98 - 00 models: M/T) or PCM (A,/T) and primary HO2Sbetween ECM ('98 - 00 models: M/T) or PCM (Ay'T) and secondary HO2SHorn (High)

Horn {Low}

Radiator fan motor

Right headlight

Right front parking light

Right front side marker light

Right front turn signal light

Condenser fan motor

Cruise actuator

Left front parking light

Left front side marker light

Left front turn signal light

Left headlight

Rear window washer motor

Windshield washer motor

ABS pump motor

www.emanualpro.com