11-187 HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 204 of 1395

Fuel and Emissions

Special Tools ...................... 11-2

Component Locations

lndex ...................... ....,.... 11-3

Svstem Description

Vacuum Connections ...........,....,.,................. 1 1-9

Electrical Connections ................................... 1 1-15

System Connectors .,.,,.,............................,.,. 1 1-36

Troubleshooting

Troubleshooting Procedures,.,..................... 11-60

Engine Control Module/Powertrain ConttolModule Terminal Arrangement .............., 11-67

Diagnostic Trouble Code Chart .................... 1 t-75

How to Read Flowcharts .......,.....,.,............... I 1-79

PGM-Fl System

System Description .................,.,.,,,............... 1 1-80

Troubleshooting Flowcharts

Engine Control Module/PowertrainControl Module ........11-52

Manifold Absolute Pressure Sensor ............. 11-90

Intake Air Temperature Sensor .................... 1 1-95

Engine Coolant Temperature Sensor .,..,.,.... 1 1-99

Throttle Position Sensor ...........,.....,.,.,..,...... I 1'103

Primary Heated Orygen Sensor (Sensor 1) ... 11-110

Secondary Heated Oxygen Sensor{Sensor 2l .................. 1 1-117

Heated Oxygen Sensor Heater ..................... 11-121

Fuef Supply System ......11-124

Random Misfire ,....,.,..... 11-126

Mistire Detected in One Cylinder .....-........... 11-128

Knock Sensor ................ 11-130

CKP/TDC/CYP Sensor .................................... 1 1-131

Vehicle Speed Sensor ...............................,.... 1 1-135

Barometric Pressure Sensor .....,...,...,.,,........ 1 1-137

Electrical Load Detector ...,.,.......................... 1 1-138

CKF Sensor ................,.,, '11-112

ECM/PCM lnternaf Circuit ............................. 11'117

HO2S Replacement .,.,.,. 11-148

ldle Control System

System Description ............ 11-149

Troubleshooting Flowcharts

ldle Control System ...... 11-150

fdle Air Control Valve ......................,............. 11-152

Air Conditioning Signal ................................. I 1-155

Alternator FR Signal ...................................... 1 1-159

Starter Switch Si9na1 .................................... t l-161

Power Steering Pressure Switch Signal ...... 11-162

Brake Switch Si9na1 ...................................... 11-166

Fast ldle Thermo Valve .,.,.............................,.,.,. 11-168

ldle speed setting .............. 11-169

Fuel Supply System

Fuel Lines ............................ 11-171

Fuef Tube/Ouick-Conneci Fittings ..................... 11 -175

System Description ............ 11-178

Fuel Pressurg ...................... 11-178

Fuel Iniectors ................,..... 11-179

Fuel Pressure Re9u1ator .............................,.,...., f 1-181

Fuef Fifter ....,.,.,.,,,,.,............11-142

Fuel Pump ........................... 11-183

Fuel Gauge .......................... 11-184

Fuel Gauge Sending Unit ................................... I 1-185

Low Fuel Indicator System ...........,.,..,............... 1 1-185

PGM-FI Main Relay ............. 11-187

Fue|Tank................ ............. 11-191

Intake Air System

System Description ............ 11-193

Air Cleanel ,.,.,..................... 11-194

Throttle Cable ..................... 11-194

Throttle Body........ .............. 11-196

Emission Control System

System D$cription ...,....,.,. 11-199

Tailpipe Emission ............... 11-199

Three Way Catalytic Converter ..................,.,...,, 11-199

Positive Crankcase Ventilation System .,.,,,,.,.., 11-2O1

Evaporative Emission Controls .........,.,.,............ 11-203

www.emanualpro.com

Page 289 of 1395

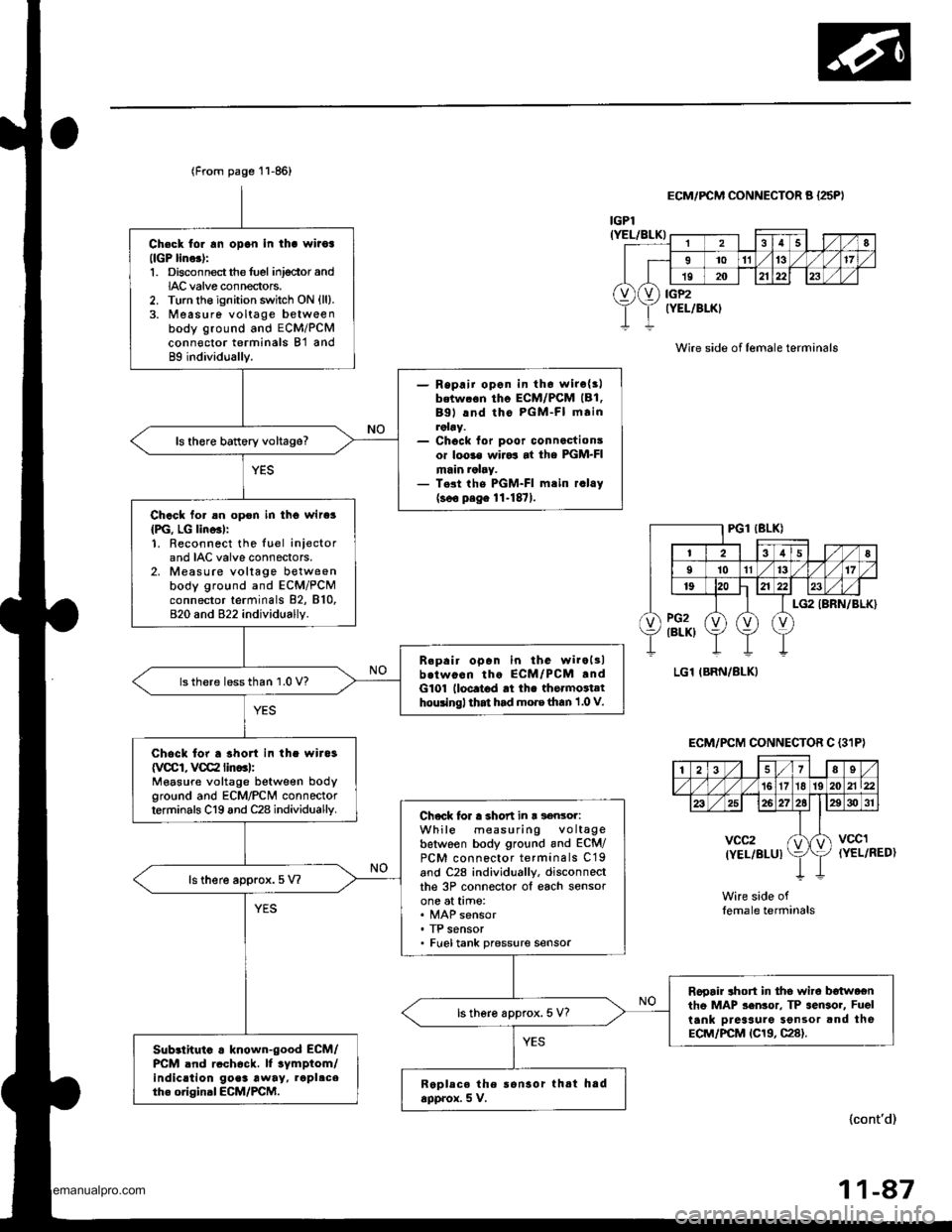

Ch€ck tor rn opon in tha wiioa(lGP lino.):1. Disconnectthe fuel inj€ctor andIAC valve connectors.2. Turn the ignition switch ON {ll}.3. Measure voltage betweenbody ground and ECM/PCMconn€ctor terminals B'l and89 individually.

- Repaii opon in th6 wirc{3lbetw.6n tho ECM/PCM (B1.

Bgl lnd tho PGM-FI mainroby.- Chock for poor connactionsor loo3€ wiJo3 at the PGM-FImain ralry.- T.st the PGM-FI mtin r.lay(soo p.ge 11-1871.

ls there battery voltage?

Chack for an opon in tho wire3

{PG, LG lino3l:1. Reconnect the luel iniectorand IAC valve connectors.2. Measure voltage betweenbody ground and ECM/PCMconnector terminals 82, 810,820 and 822 individually.

B.pair open in the wiroltlb.twocn tho ECM/PCM .ndG101 lloc.t6d rt th. thormoiathouingl that had mo.e than 1 .0 V.

lsthere lessthan 1.0 V?

Chock for a shon in the wira3

{VCCI, VCC2 lin..l:Measure voltage between bodyground and ECM/PCN4 connectorterminals C19 and C28 individuallv.Chock lor a short in r s€nsor:While measuring voltagebetwoen body ground and ECM/PCM connector terminals C19and C28 individually, disconneclthe 3P connector ol each sensorone at time:

. TP sensor. Fueltank pressure sensor

ls there approx.5 V?

Rooair ahort in tho wire b€twoentho MAP sen3or. TP sensor, Fuel

tank Dreaaure Sonsor and theECM/PCM tC19, C28).

ls there approx. 5 V?

Sub3lhuio . known-good ECM/PCM .nd rcch6ck. lf tymptom/indic.tion go.3 away, rapl.ceth. original ECM/PCM.Replece the ronsor thtt hadapprox. 5 V.

(From page 11-86)

lcont'd)

r

28

I1011't317

19202123

vXv) iiP2rELlBLK)

IGPl(YEL/BLK)

ECM/FCM CONNECTOR A {25PI

Wire side of lemale terminals

(YEL/RED)

Wire side oflemale terminals

ECM/PCM CONNECTOR C {3'IP}

| 2i37Es/'t61718 192021\22

26272elE30 31

vcc2(YEL/BLUIktvccl

11-47

www.emanualpro.com

Page 391 of 1395

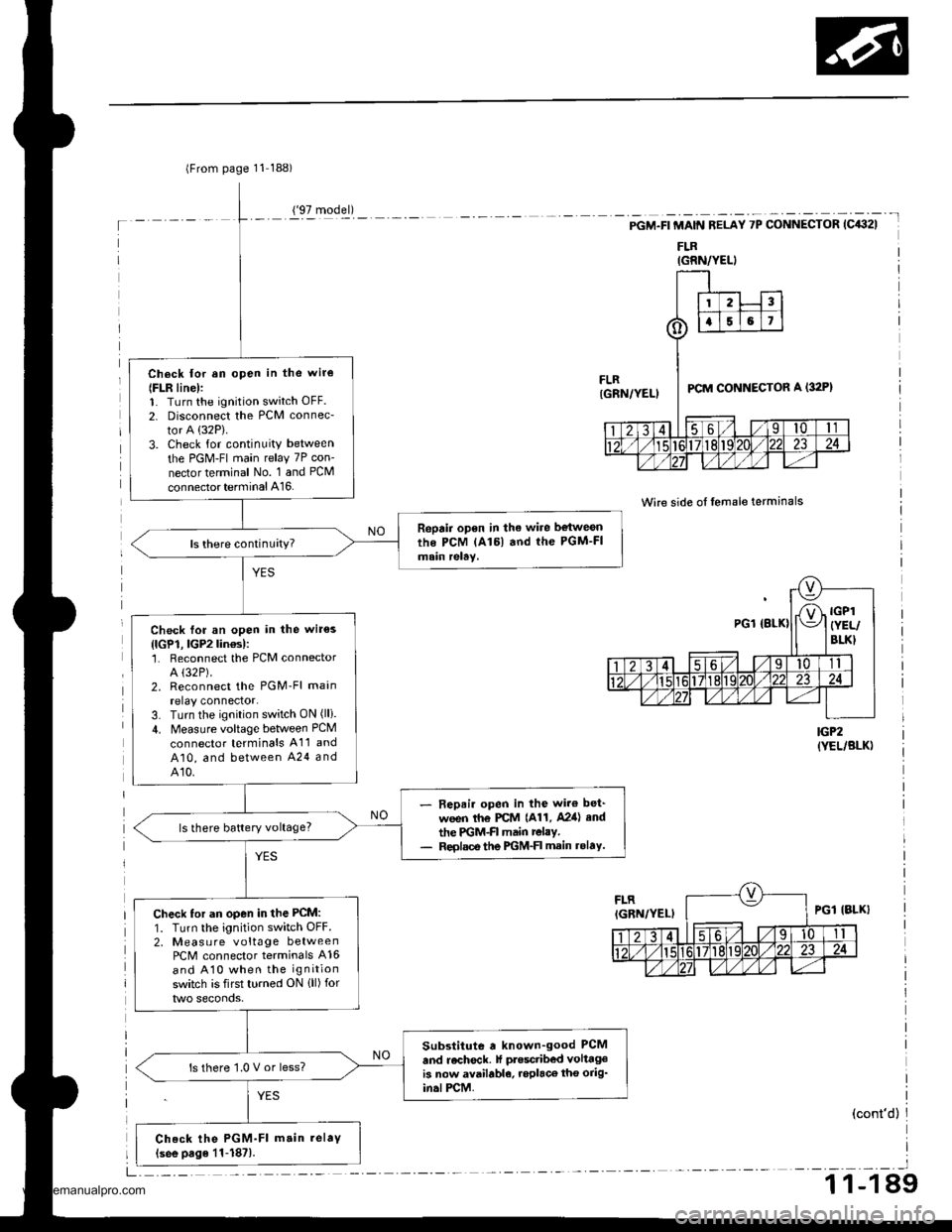

lFrom page 11 188)

Ch6ck lor an open in the wir€

{FLR line):1. Turn the ignition switch OFF.

2. Disconnect the PCM connec-

tor A (32P).

3. Check for continuity between

the PGM-FI main relay 7P con-

nector terminal No. 1 and PCM

connector terminal A16.

Repair open in the wire be{weonthe PCM lAl6l and the PGM-FImain relay.

Check for an open in the wir€s

{lGP1, lGP2lin€s):'1. Reconnect the PCM connectorA (32P).

2. Reconnect the PGM'Fl main

relay connector.3. Turn the ignition switch ON (lli.

4. Measure voltage between PCM

connector terminals A11 and

A10, and between A24 andA10.

- Repair open in the wir€ bet'

ween th€ PCM {A11, A2ia} end

the PGM-FI main relay.- Reolsce the PGM-FI main rolaY.

ls there battery voltage?

Check tor an open in the PCM:

1. Turn the ignition switch OFF.2, Measu re voltage betweenPCM connector terminals A16

and A10 when the ignition

switch is first turned ON {ll) for

Substitute a known-good PCM

and recheck. lf ptesctibed volttgeis now available, roplaco tho orig'in.lPCM.

ls there '1.0 V or less?

Check the PGM-Fl m.in.elaV(see page 11-187).

('97 model)

IGRN/YELI

-t

PGM.FI MAIN RELAY 7P CONNECTOR (C432I

FLR

Wire side of lemale terminals

IGP2(YEL/BLK)

(cont'd)

_l

1 1-1 89

www.emanualpro.com

Page 392 of 1395

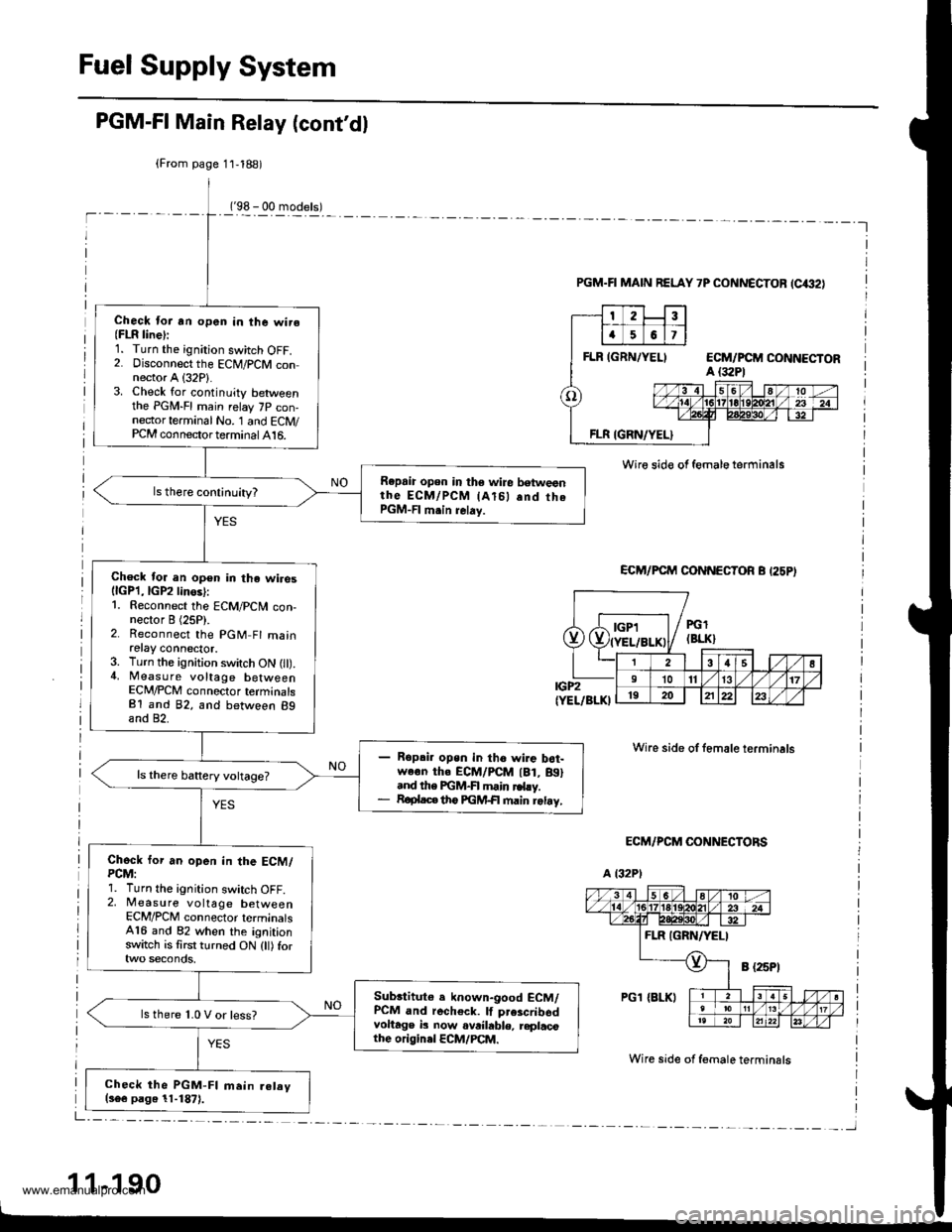

Fuel Supply System

PGM-FI Main Relay (cont'dl

('98 - 00 models)-l

(From page 11,188)

Check lor an open in the wire(FLR line):1. Turn the ignition switch OFF.2. Disconnect the ECM/PCM connector A (32P1.3. Check for continuity betweenthe PGM-FI main relay 7P con-nector terminal No. '1 and ECM/PCM connector terminal 416.

Repaia open in the wire betweenthe EcM/PcM lAl5l .nd thePGM-FI m.in relay.

Check for an open in the wiresllcPl,lGP2linos):1. Reconnect the ECM/PCN4 con-nector I (25P).2. Reconnect the PGM Fl mainretay connector.3. Turn the ignition switch ON l).4, Measure voltage betweenECM/PCM connector terminalsB1 and 82, and between 89and 82.

Ropai. open in tho wire b6t-we€n th. ECM/PCM lBt, Btl.nd the FGM-FI main rd.y.R€plac€ th6 FGM+| main retay,

Chock for an open in the ECM/PCM:1. Turn the ignition switch OFF.2, Measure voltage betweenECM/PCM connector terminals416 and 82 when the ignitionswitch is first turned ON (tl) for

Subrtitute e known-good ECM/PCM and recheck. lf prescribsdvoltage b now ovrihble, replacothe originel ECM/PCM.

ls there 1.0 V or less?

Check the PGM-FI main.elav(s6e page 11-1871.

PGM.FI MAIN RELAY 7P CONNECTOF (C€2)

Wire sid€ of female terminals

ECM/PCM CONNECTOR B I25PI

IGP2(YEL/BLKI

ECM/PCM CONNECTORS

a t32Pl

Wire side of female terminals

Wire side of f€male terminsls

1 1-190

Dde"Jt;;liL-F-T--

PGl(BLK}

38s l1011131719202122

www.emanualpro.com