Intake manifold HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 96 of 1395

Engine

Engine RemovaUlnstallation ................ 5-1

Cylinder Head/Valve Train ................... 6-1

Engine Bfock .......... ...........7-1

Engine Lubrication ...........8-1

Intake Manifold/Exhaust System ........ 9-1

Cooling ......... 10-1

www.emanualpro.com

Page 132 of 1395

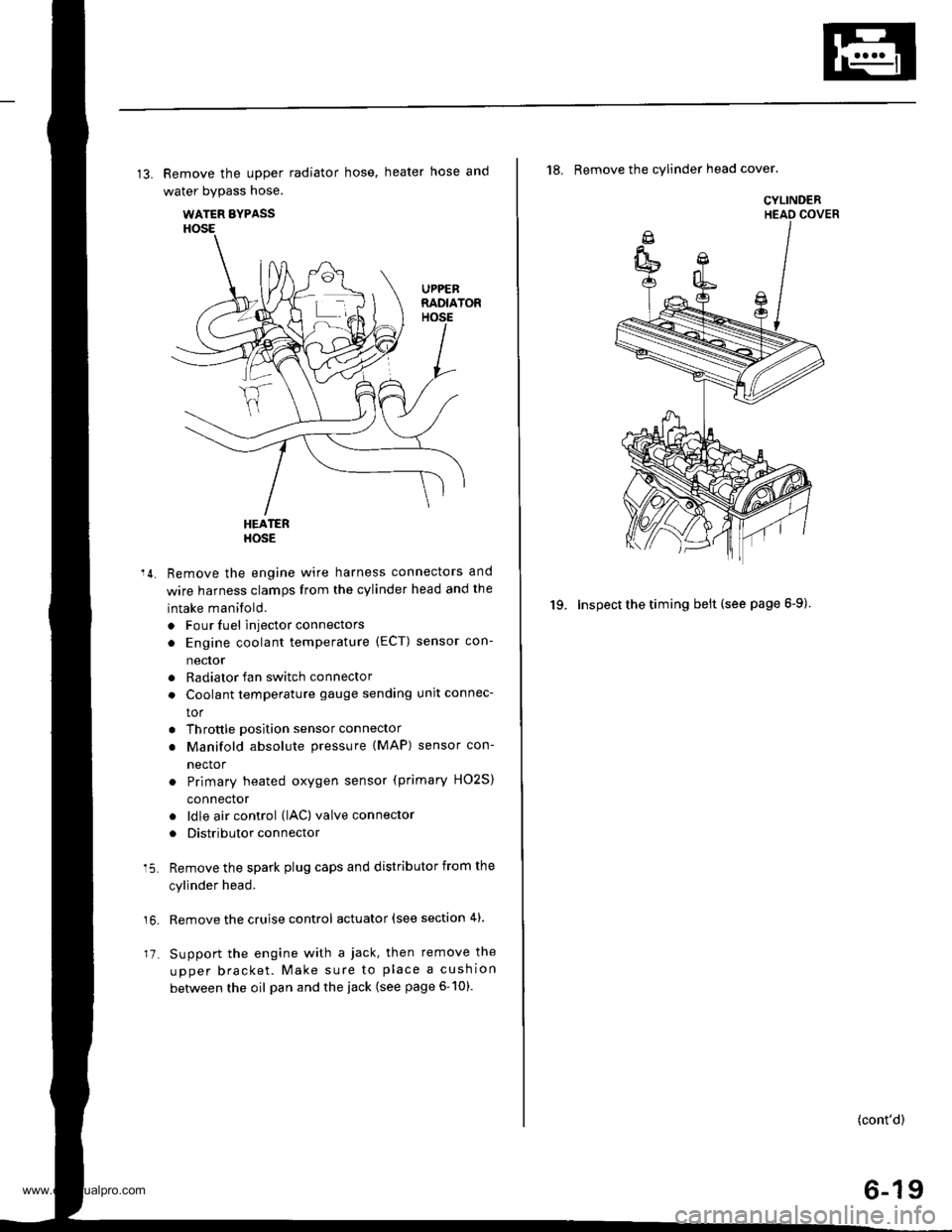

13. Remove the upper radiator hose, heater hose and

water bypass hose.

WATER BYPASS

UPPEBRADIATORHOSE

17

HEATERHOSE

Remove the engine wire harness connectors and

wire harness clamps from the cylinder head and the

intake manifold.

o Four fuel injector connectors

. Engine coolant temperature (ECT) sensor con-

neclor

. Radiator fan switch connector

. Coolant temperature gauge sendlng unlt connec-

tor

. Throttle position sensor connector

. Manifold absolute pressure {MAP) sensor con-

nector

Primary heated oxygen sensor (primary HO2S)

connector

ldle air control (lAC) valve connector

Distributor connector

Remove the spark plug caps and distributor from the

cylinder head.

Remove the cruise control actuator (see section 4).

Support the engine with a jack, then remove the

upper bracket. Make sure to place a cushion

between the oil pan and the iack (see page 6-10).

a

18. Remove the cylinder head cover.

19. Inspect the timing belt (see page 6-9).

CYLINDER

(cont'd)

6-19

www.emanualpro.com

Page 134 of 1395

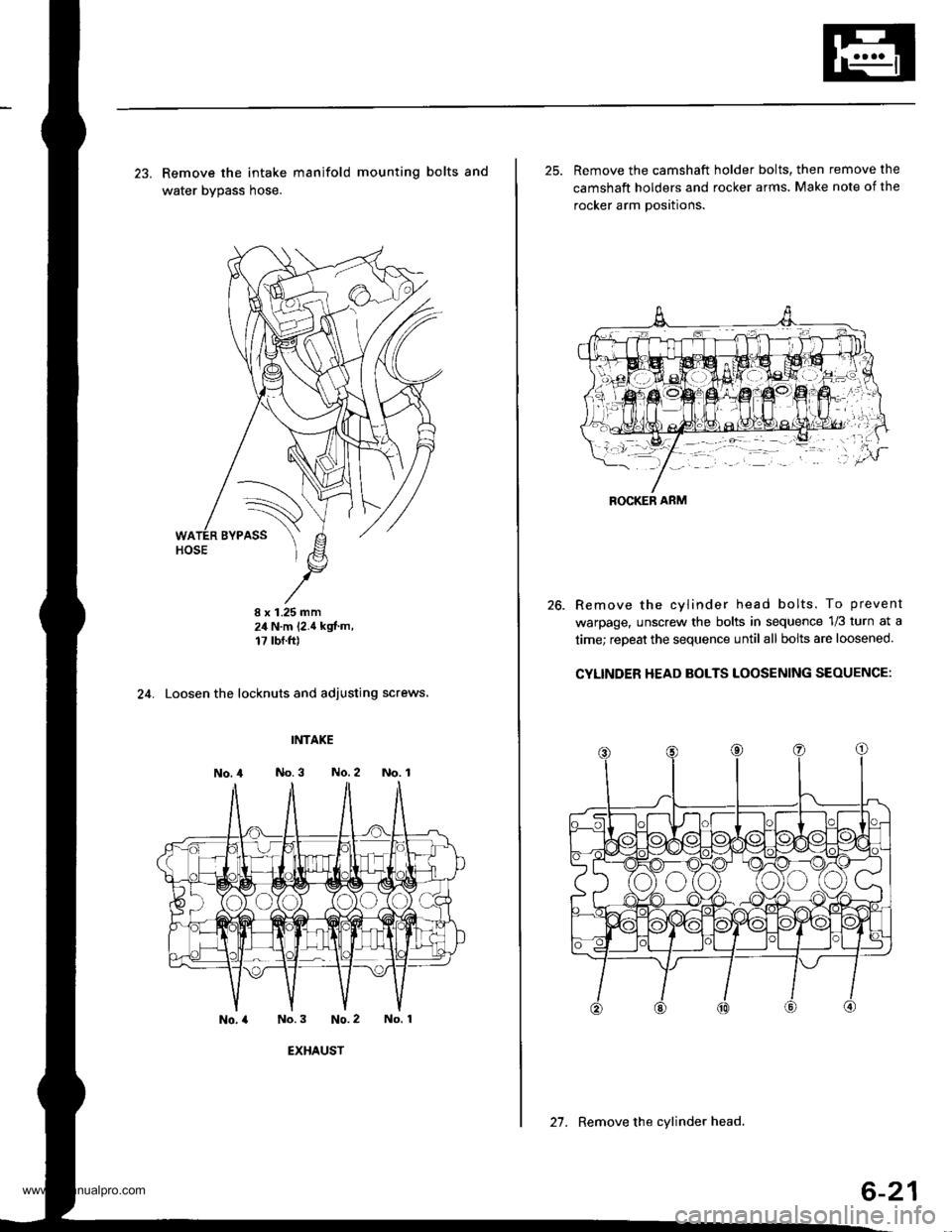

23. Remove the intake manifold mounting bolts and

water bvDass hose.

8 x 1.25 mm2,1 N.m 12.4 kgt.m,17 tbf.ft)

24. Loosen the locknuts and adjusting screws,

INTAKE

No.3 No.2 No. 1

No.3 No.2 No. 1

EXHAUST

No. 4

27. Remove the cylinder head.

6-21

25. Remove the camshaft holder bolts, then remove the

camshaft holders and rocker arms. Make note of the

rocker arm Dositions.

26. Remove the cylinder head bolts. To prevent

warpage, unscrew the bolts in sequence 1/3 turn at a

time; repeat the sequence until all bolts are loosened.

CYLINDER HEAD BOLTS LOOSENING SEOUENCE:

ROCKER ARM

www.emanualpro.com

Page 143 of 1395

Cylinder Head

Installation

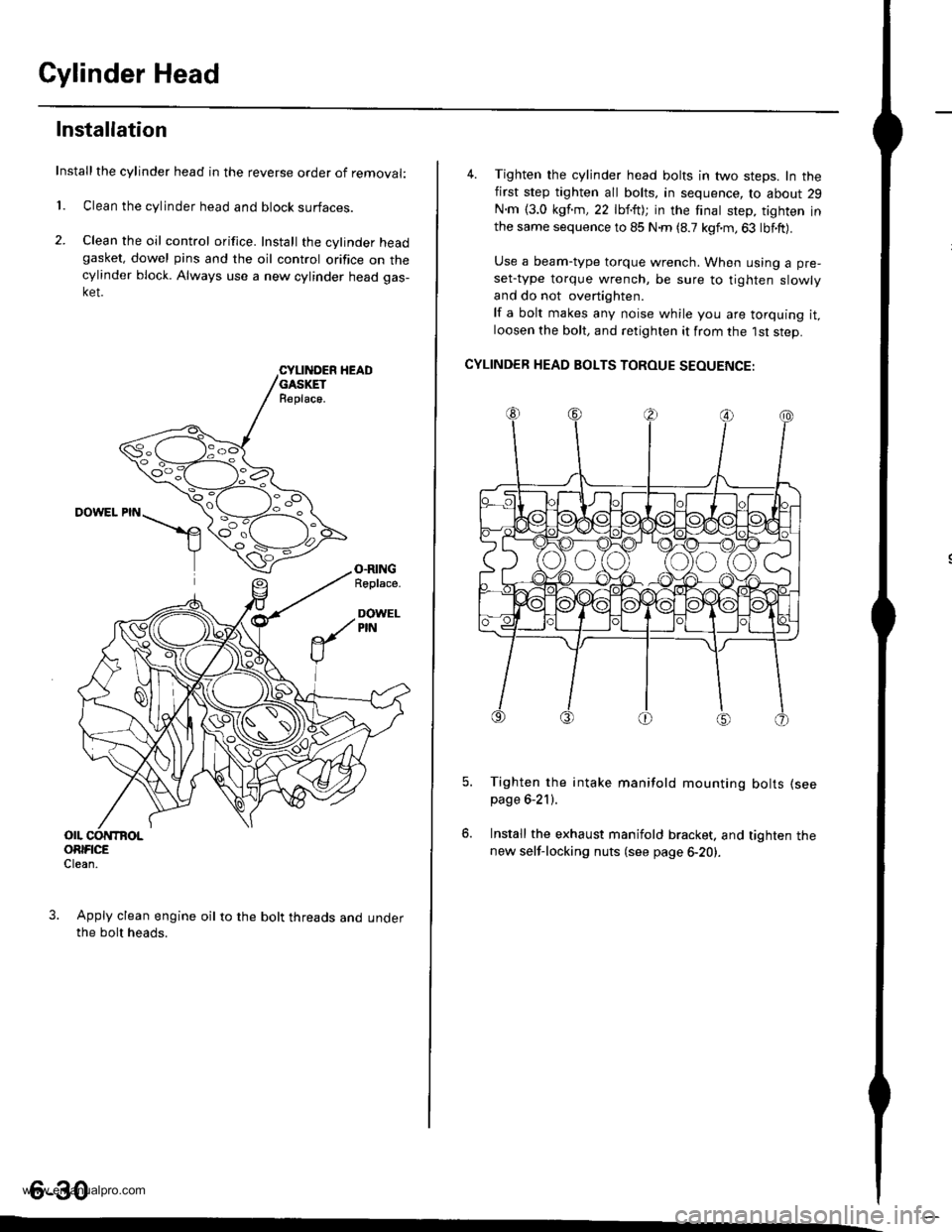

Installthe cylinder head in the reverse order of removal:

1. Clean the cylinder head and block surfaces.

2. Clean the oil control orifice. Install the cylinder headgasket, dowel pins and the oil control orifice on thecylinder block. Always use a new cylinder head gas-ket.

CYLII{DER HEADGASKETR€place.

DOWEL PIN

O.RINGRoplace.

DOWELPIN

OIL CONTBOLORIFICEClean.

Apply clean engine oil to the bolt threads and underthe bolt heads.

4. Tighten the cylinder head bolts in two steps. In thefirst step tighten all bolts, in sequence, to about 29

N.m {3.0 kgf.m,22 lbf.ft); in the finat step, tighten inthe same sequence to 85 N.m (8.7 kgf.m,63 lbf.ft).

Use a beam-type torque wrench. When using a pre-

set-type torque wrench, be sure to tighten slowly

and do not overtighten.

lf a bolt makes any noise while you are torquing it,loosen the bolt, and retighten it from the 1st step.

CYLINDER HEAD BOLTS TOROUE SEOUENCE:

Tighten the intake manifold mounting bolts (see

page 6-21).

Install the exhaust manifold bracket. and tighten thenew self-locking nuts (see page 6-20).

6-30

www.emanualpro.com

Page 182 of 1395

Intake Manifold/Exhaust System

Intake Manifold

Rep1acement ....................................... 9-2

Exhaust Manifold

Replacement ....................................... 9-4

Exhaust Pipe and Muffler

Replacement ....................................... 9-6

www.emanualpro.com

Page 183 of 1395

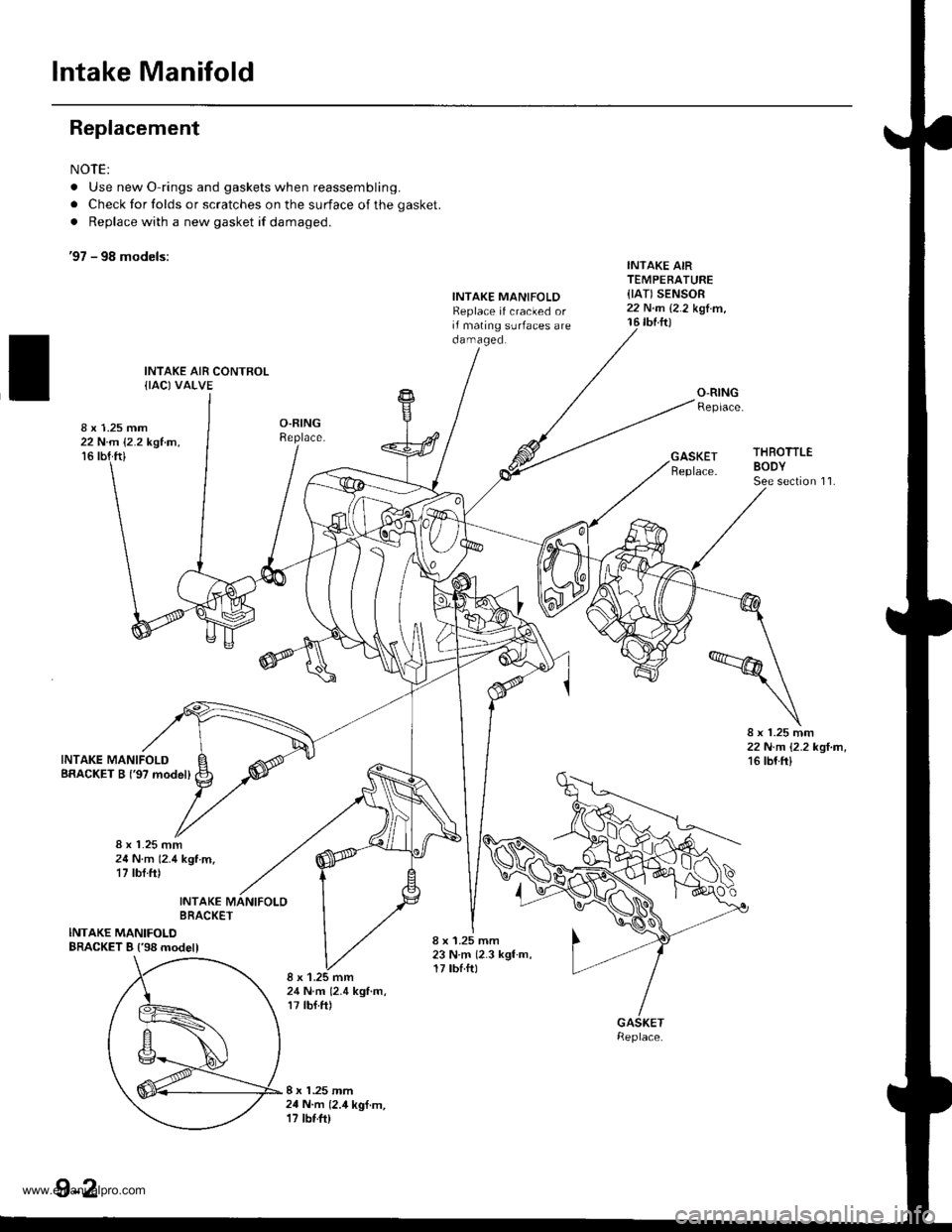

Intake Manifold

Replacement

NOTE:

. Use new O-rings and gaskets when reassembling.

. Check for folds or scratches on the surface of the gasket.

. Replace with a new gasket if damaged.

'97 - 98 models:

INTAK€ MANIFOLDReplace if cracked orif mating surfaces areoamageo,

INTAKE AIRTEMPERATURE

{IATI SENSOR22 N.n 12.2 kgl.m,16 rbf.ftl

8 x 1.25 mm22 N.m 12.2 kgtm.'t6 tbf ft)

8 x 1.25 mm22 N.m |.2.2 kgl.rn,'16 tbt ftl

I x 1.25 mm24 N m 12.4 kgf m.17 tbf.ft)

INTAKBRAC}

INTAKE MANIFOLOBRACKET B ('98 modell8 x 1.25 mm23 N m (2.3 kgt m,17 tbf.ftlI x 1.25 mm24 N.m 12.4 kgf.m,17 tbf.ft)

8 x 1.25 mm24 N.m (2.4 kgf.m,17 tbf.ft)

9-2

www.emanualpro.com

Page 184 of 1395

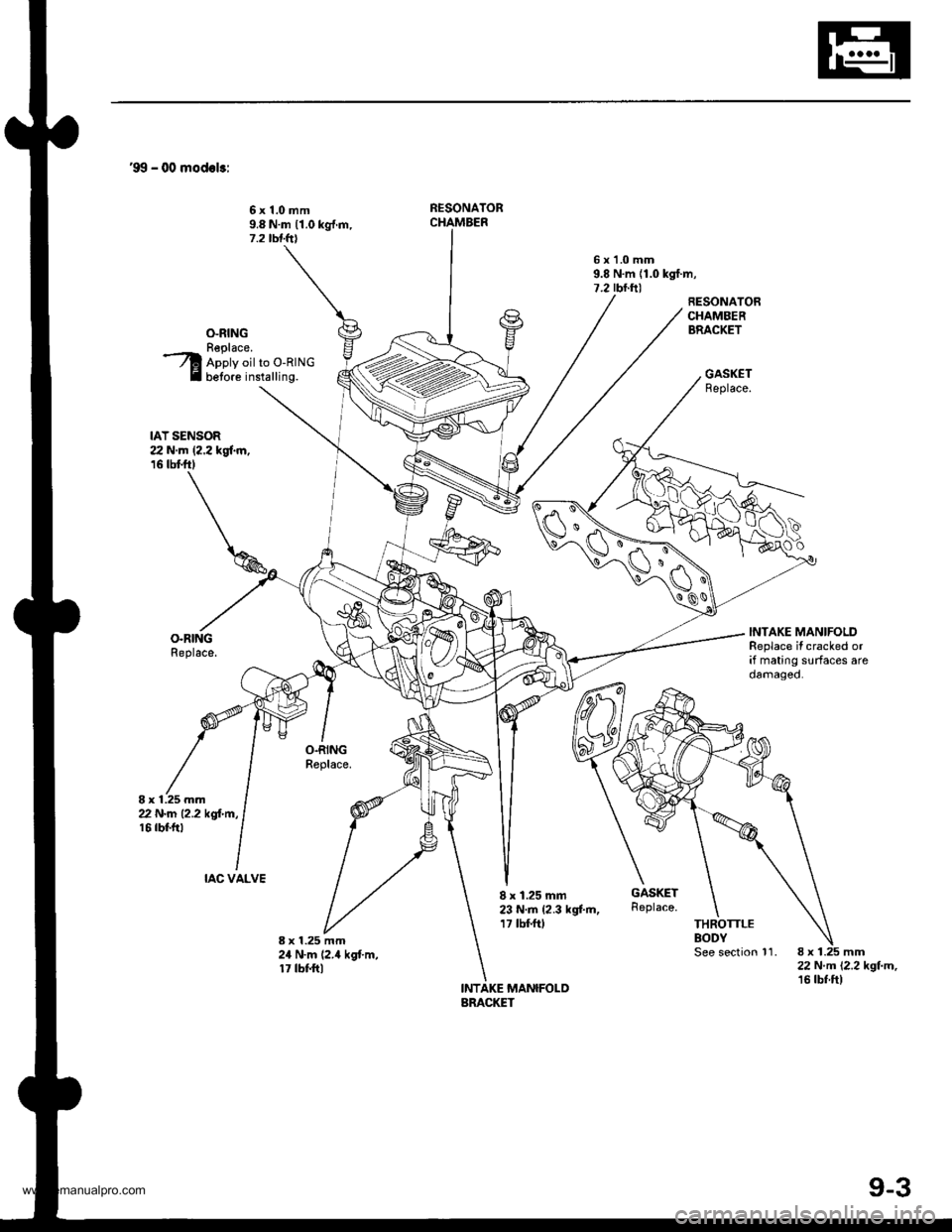

'99 - O0 modol3:

6x1.0mm9.8 N.m 11.0 kg{.m,7.2 tbtltl

NESONATOR

6x1.0mm9.8 N.m {1.0 kgf.m,7.2 rbr.ftt

O-RINGReplace.Apply oil to O-RINGbetore installing.

RESONATORCHAMBERBRACKET

GASKETReplace.

IAT SENSOR2:2N.m l2.2kgl.n,16 tbtftl

O.RINGReplace.

l

O.RINGReplace.

8 x 1.25 mm24 N.m 12.4 kgt m,17 tbt frl

INTAKE MANIFOLDReplace it cracked orif mating surfaces areoamageo.

8 x 1.25 mm22 N.m 12.2 kgl.m,16 rbf.ftt

IAC VALVE

8 x 1.25 mm23 N.m (2.3 kgf.m,17 tbf.ft,

INTAKE MANIFOLD

22 N.m 12,2 kgl.m,16 rbfftl

("\"- K\*}Gt

W\qu u

N,1\J 'n\

.a,,-\\J "

G)s

BRACKET

9-3

www.emanualpro.com

Page 204 of 1395

Fuel and Emissions

Special Tools ...................... 11-2

Component Locations

lndex ...................... ....,.... 11-3

Svstem Description

Vacuum Connections ...........,....,.,................. 1 1-9

Electrical Connections ................................... 1 1-15

System Connectors .,.,,.,............................,.,. 1 1-36

Troubleshooting

Troubleshooting Procedures,.,..................... 11-60

Engine Control Module/Powertrain ConttolModule Terminal Arrangement .............., 11-67

Diagnostic Trouble Code Chart .................... 1 t-75

How to Read Flowcharts .......,.....,.,............... I 1-79

PGM-Fl System

System Description .................,.,.,,,............... 1 1-80

Troubleshooting Flowcharts

Engine Control Module/PowertrainControl Module ........11-52

Manifold Absolute Pressure Sensor ............. 11-90

Intake Air Temperature Sensor .................... 1 1-95

Engine Coolant Temperature Sensor .,..,.,.... 1 1-99

Throttle Position Sensor ...........,.....,.,.,..,...... I 1'103

Primary Heated Orygen Sensor (Sensor 1) ... 11-110

Secondary Heated Oxygen Sensor{Sensor 2l .................. 1 1-117

Heated Oxygen Sensor Heater ..................... 11-121

Fuef Supply System ......11-124

Random Misfire ,....,.,..... 11-126

Mistire Detected in One Cylinder .....-........... 11-128

Knock Sensor ................ 11-130

CKP/TDC/CYP Sensor .................................... 1 1-131

Vehicle Speed Sensor ...............................,.... 1 1-135

Barometric Pressure Sensor .....,...,...,.,,........ 1 1-137

Electrical Load Detector ...,.,.......................... 1 1-138

CKF Sensor ................,.,, '11-112

ECM/PCM lnternaf Circuit ............................. 11'117

HO2S Replacement .,.,.,. 11-148

ldle Control System

System Description ............ 11-149

Troubleshooting Flowcharts

ldle Control System ...... 11-150

fdle Air Control Valve ......................,............. 11-152

Air Conditioning Signal ................................. I 1-155

Alternator FR Signal ...................................... 1 1-159

Starter Switch Si9na1 .................................... t l-161

Power Steering Pressure Switch Signal ...... 11-162

Brake Switch Si9na1 ...................................... 11-166

Fast ldle Thermo Valve .,.,.............................,.,.,. 11-168

ldle speed setting .............. 11-169

Fuel Supply System

Fuel Lines ............................ 11-171

Fuef Tube/Ouick-Conneci Fittings ..................... 11 -175

System Description ............ 11-178

Fuel Pressurg ...................... 11-178

Fuel Iniectors ................,..... 11-179

Fuel Pressure Re9u1ator .............................,.,...., f 1-181

Fuef Fifter ....,.,.,.,,,,.,............11-142

Fuel Pump ........................... 11-183

Fuel Gauge .......................... 11-184

Fuel Gauge Sending Unit ................................... I 1-185

Low Fuel Indicator System ...........,.,..,............... 1 1-185

PGM-FI Main Relay ............. 11-187

Fue|Tank................ ............. 11-191

Intake Air System

System Description ............ 11-193

Air Cleanel ,.,.,..................... 11-194

Throttle Cable ..................... 11-194

Throttle Body........ .............. 11-196

Emission Control System

System D$cription ...,....,.,. 11-199

Tailpipe Emission ............... 11-199

Three Way Catalytic Converter ..................,.,...,, 11-199

Positive Crankcase Ventilation System .,.,,,,.,.., 11-2O1

Evaporative Emission Controls .........,.,.,............ 11-203

www.emanualpro.com

Page 206 of 1395

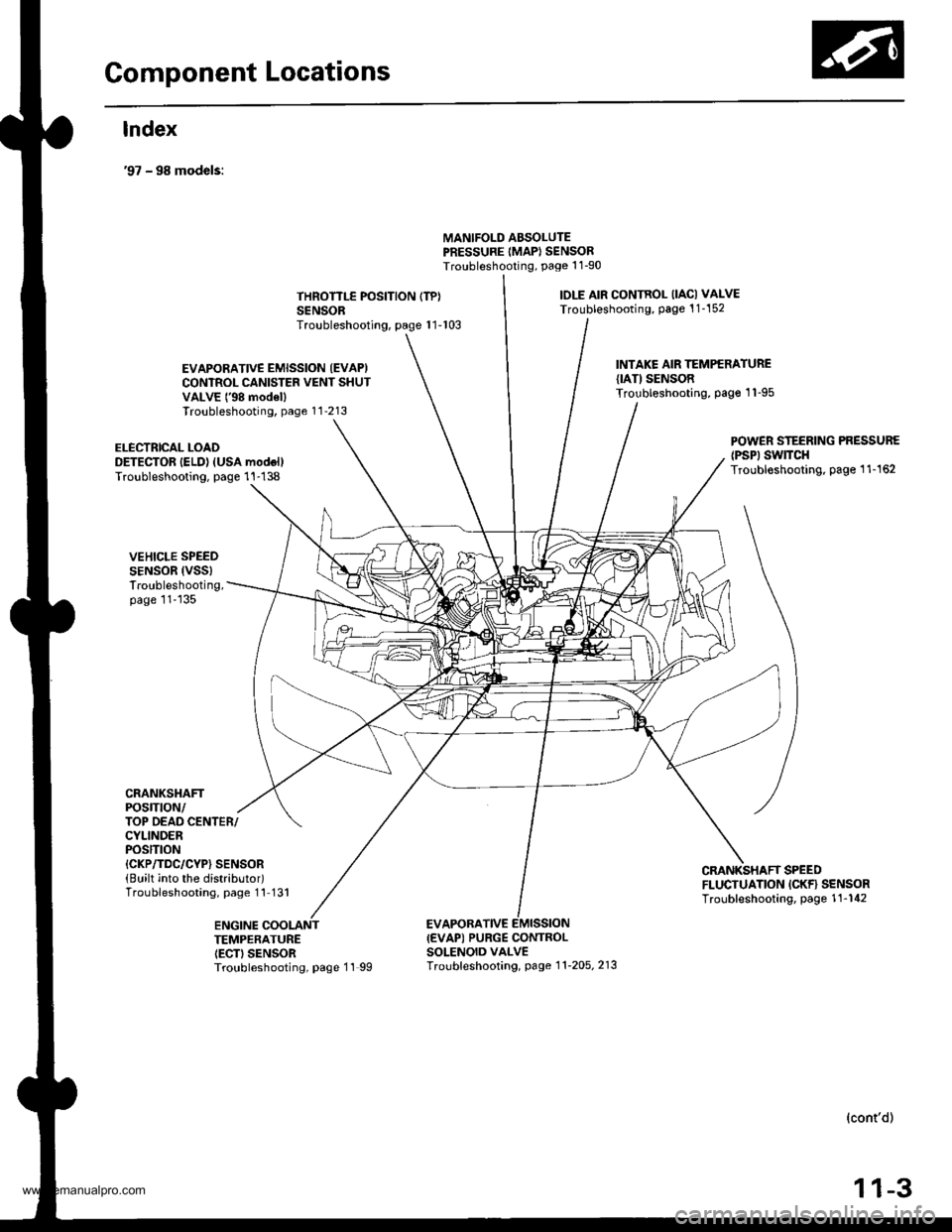

Component Locations

lndex

'97 - 98 models:

MANIFOLD ABSOLUTEPRESSURE IMAP} SENSORTroubleshooting, Page 1 1-90

THROTTLE POSITION (TP}

SENSORTroubleshooting, page 1 1-103

toLE AtR CONTROL llAcl VAI-VE

Troubleshooting, page 1 1-152

EVAPORATIVE EMISSION (EVAP)

CONTROL CANISTER VENT SHUTVALVE t'98 mod€llTroubleshooting, page 11'213

INTAKE AIR TEMPERATUREIIATI SENSORTroubleshooting. page 1 'l -95

ELECTRICAL LOADDETECTOR IELD) (USA modol)Troubleshooting, page 1 1-138

VEHICLE SPEEDSENSOR (VSS)

Troubleshooting,page 11'135

CRANKSHAFTPOSTTtON/

POWER STEERING PRESSURElPsPl swtrcHTroubloshooting, page 1 1-162

TOP OEAD CENTER/CYLINDERPOStTtON{CKP/TDC/CYP} SENSOR(Built into the distributor)Troubleshooting, page 1 l-131

CMNKSHAFT SPEEDFLUCTUATION ICKF} SENSORTroubleshooting. page 1'!-142

ENGINE COOLANTTEMPERATUREIECTI SENSORTroubleshooting, page 11 99

EVAPORATIVEI€VAP) PURGE CONTROLSOLENOID VALVETroubf eshooting, page 1 1'2o5, 213

(cont'd)

11-3

www.emanualpro.com

Page 207 of 1395

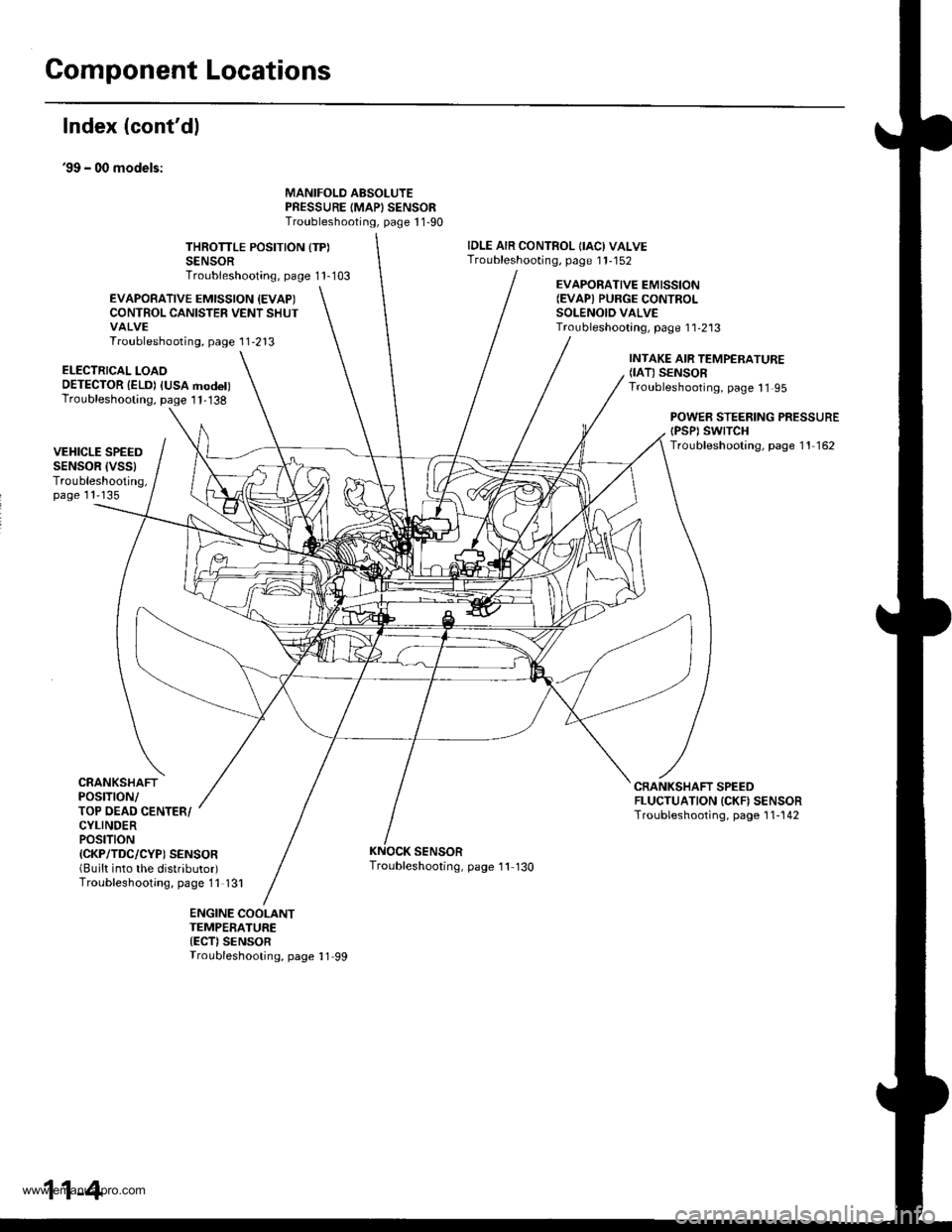

Component Locations

Index (cont'dl

39 - 00 models:

MANIFOLD ABSOLUTEPRESSURE IMAPISENSORTroubleshooting, page 1 1-90

THROTTLE POSITION {TP)SENSORTroubleshooting, page 1 1-103

IDLE AIR CONTROL OACI VALVETroubleshooting, page 1 1-152

EVAPOBATIVE EMISSION {EVAPICONTROL CANISTER VENT SHUTVALVETroubleshooting, page 1 1-213

EVAPORATIVE EMISSION(EVAPI PURGE CONTROI-SOLENOID VALVETroubleshootang, page 1 1-2'13

ELECTRICAL LOAOOETECTOR {ELD) IUSA modet)Troubleshooting, page I 1-138

INTAKE AIR TEMPERATURE(IAT) SENSORTroubleshooting, page 11 95

POWEB STEERING PRESSUREtPsPt swtTcHTroubleshooting, page 11 162VEHICLE SPEEDSENSOR IVSSITroubleshooting,page 11'135

CRANKSHAFTPOSTTTON/TOP OEAD CENTER/CYLINDERPOStTtON{CKP/TDC/CYP) SENSOR(Built into the distributor)Troubleshooting, page 11 131

CRANKSHAFT SPEEDFLUCTUATION ICKN SENSORTroubleshooting, page 1 1-142

SENSORTroubleshooting, page '11 130

ENGINE COOLANTTEMPERATURE{ECT)SENSORTroubleshooting, page 11 99

11-4

www.emanualpro.com