Pgm- fi HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 204 of 1395

Fuel and Emissions

Special Tools ...................... 11-2

Component Locations

lndex ...................... ....,.... 11-3

Svstem Description

Vacuum Connections ...........,....,.,................. 1 1-9

Electrical Connections ................................... 1 1-15

System Connectors .,.,,.,............................,.,. 1 1-36

Troubleshooting

Troubleshooting Procedures,.,..................... 11-60

Engine Control Module/Powertrain ConttolModule Terminal Arrangement .............., 11-67

Diagnostic Trouble Code Chart .................... 1 t-75

How to Read Flowcharts .......,.....,.,............... I 1-79

PGM-Fl System

System Description .................,.,.,,,............... 1 1-80

Troubleshooting Flowcharts

Engine Control Module/PowertrainControl Module ........11-52

Manifold Absolute Pressure Sensor ............. 11-90

Intake Air Temperature Sensor .................... 1 1-95

Engine Coolant Temperature Sensor .,..,.,.... 1 1-99

Throttle Position Sensor ...........,.....,.,.,..,...... I 1'103

Primary Heated Orygen Sensor (Sensor 1) ... 11-110

Secondary Heated Oxygen Sensor{Sensor 2l .................. 1 1-117

Heated Oxygen Sensor Heater ..................... 11-121

Fuef Supply System ......11-124

Random Misfire ,....,.,..... 11-126

Mistire Detected in One Cylinder .....-........... 11-128

Knock Sensor ................ 11-130

CKP/TDC/CYP Sensor .................................... 1 1-131

Vehicle Speed Sensor ...............................,.... 1 1-135

Barometric Pressure Sensor .....,...,...,.,,........ 1 1-137

Electrical Load Detector ...,.,.......................... 1 1-138

CKF Sensor ................,.,, '11-112

ECM/PCM lnternaf Circuit ............................. 11'117

HO2S Replacement .,.,.,. 11-148

ldle Control System

System Description ............ 11-149

Troubleshooting Flowcharts

ldle Control System ...... 11-150

fdle Air Control Valve ......................,............. 11-152

Air Conditioning Signal ................................. I 1-155

Alternator FR Signal ...................................... 1 1-159

Starter Switch Si9na1 .................................... t l-161

Power Steering Pressure Switch Signal ...... 11-162

Brake Switch Si9na1 ...................................... 11-166

Fast ldle Thermo Valve .,.,.............................,.,.,. 11-168

ldle speed setting .............. 11-169

Fuel Supply System

Fuel Lines ............................ 11-171

Fuef Tube/Ouick-Conneci Fittings ..................... 11 -175

System Description ............ 11-178

Fuel Pressurg ...................... 11-178

Fuel Iniectors ................,..... 11-179

Fuel Pressure Re9u1ator .............................,.,...., f 1-181

Fuef Fifter ....,.,.,.,,,,.,............11-142

Fuel Pump ........................... 11-183

Fuel Gauge .......................... 11-184

Fuel Gauge Sending Unit ................................... I 1-185

Low Fuel Indicator System ...........,.,..,............... 1 1-185

PGM-FI Main Relay ............. 11-187

Fue|Tank................ ............. 11-191

Intake Air System

System Description ............ 11-193

Air Cleanel ,.,.,..................... 11-194

Throttle Cable ..................... 11-194

Throttle Body........ .............. 11-196

Emission Control System

System D$cription ...,....,.,. 11-199

Tailpipe Emission ............... 11-199

Three Way Catalytic Converter ..................,.,...,, 11-199

Positive Crankcase Ventilation System .,.,,,,.,.., 11-2O1

Evaporative Emission Controls .........,.,.,............ 11-203

www.emanualpro.com

Page 208 of 1395

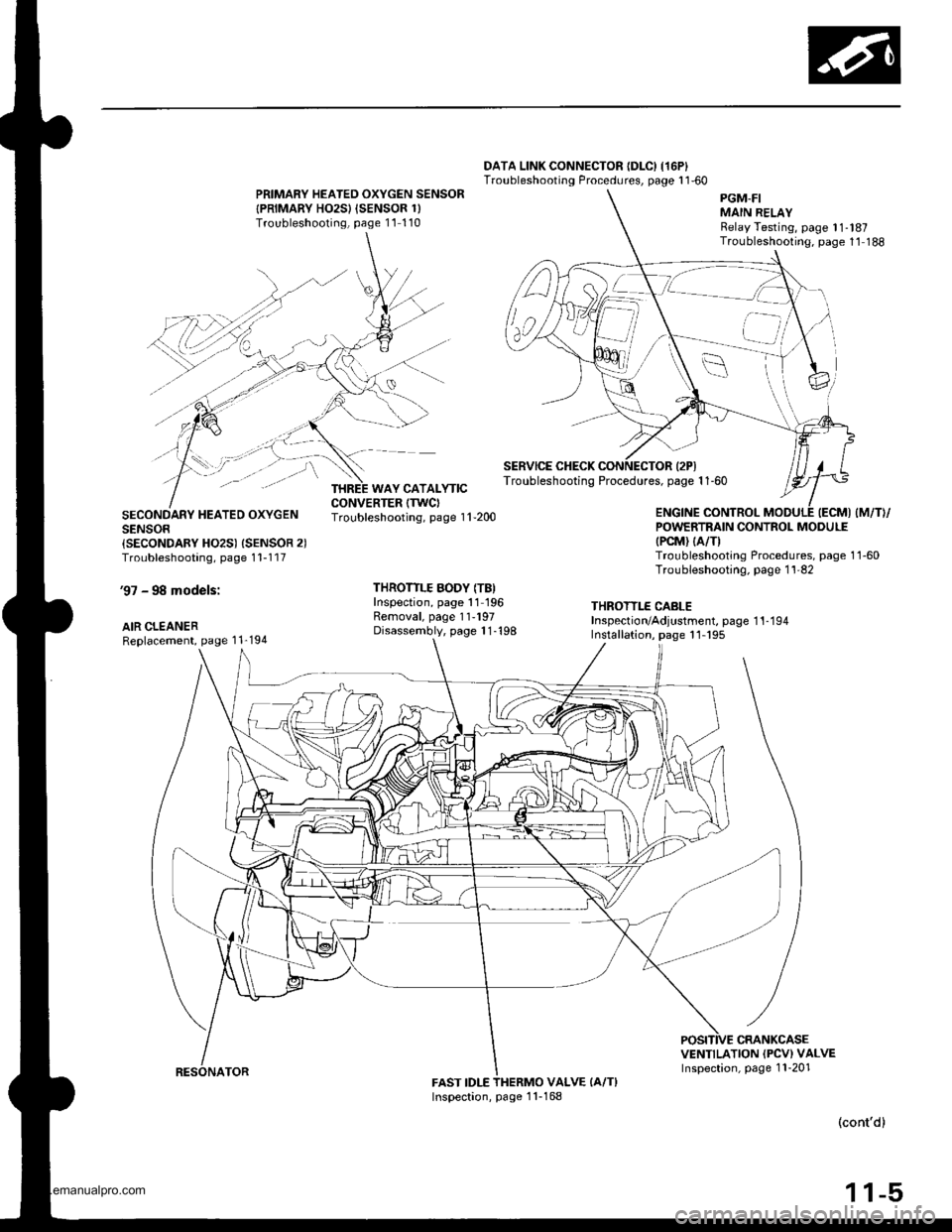

DATA LINK CONNECTOR {DLC) I16P}Troubleshooting Procedures, page 1 1'60PRIMARY HEATED OXYGEN SENSOR

{PRIMARY HO2SI {SENSOR 1)Troubleshooling, page 11 110

SECONDARY HEATED OXYGENSENSOR{SECONDARY HO2S) {SENSOR 2)Troubleshooting, page 1 1-1 17

'97 - 98 models:

AIR CLEANERReplacement, page 1 1'194

Troubleshooting, page 1 'l -200

THROTTLE BODY (TB)Inspection, page 11 196Removal, page 11-197Disassembly, page 1 1-'198

POWERTRAIN CONTROL MODULE(PCM) (A/TI

Troubleshooting Procedures, page 1 1-60Troubleshooting. page 1 1'82

THROTTLE CABLEInspection/Adjustment, page 1 1-1 94Installation, page 11- 195

VENTILATION (PCV) VALVEInspection, page 1 1-201FAST IDLEVALVE (A/T}

(cont'd)

1 1-5

PGM-FIMAIN RELAYRelay Testing, page 11-l87Troubleshooting. page 1'1 188

SERVICE CHECK CONNECTOR {2PITroubleshooting Procedures, page 1 1-60

,a'=_-_

WAY CATALYTIC

Inspection, page 1 1-168

www.emanualpro.com

Page 266 of 1395

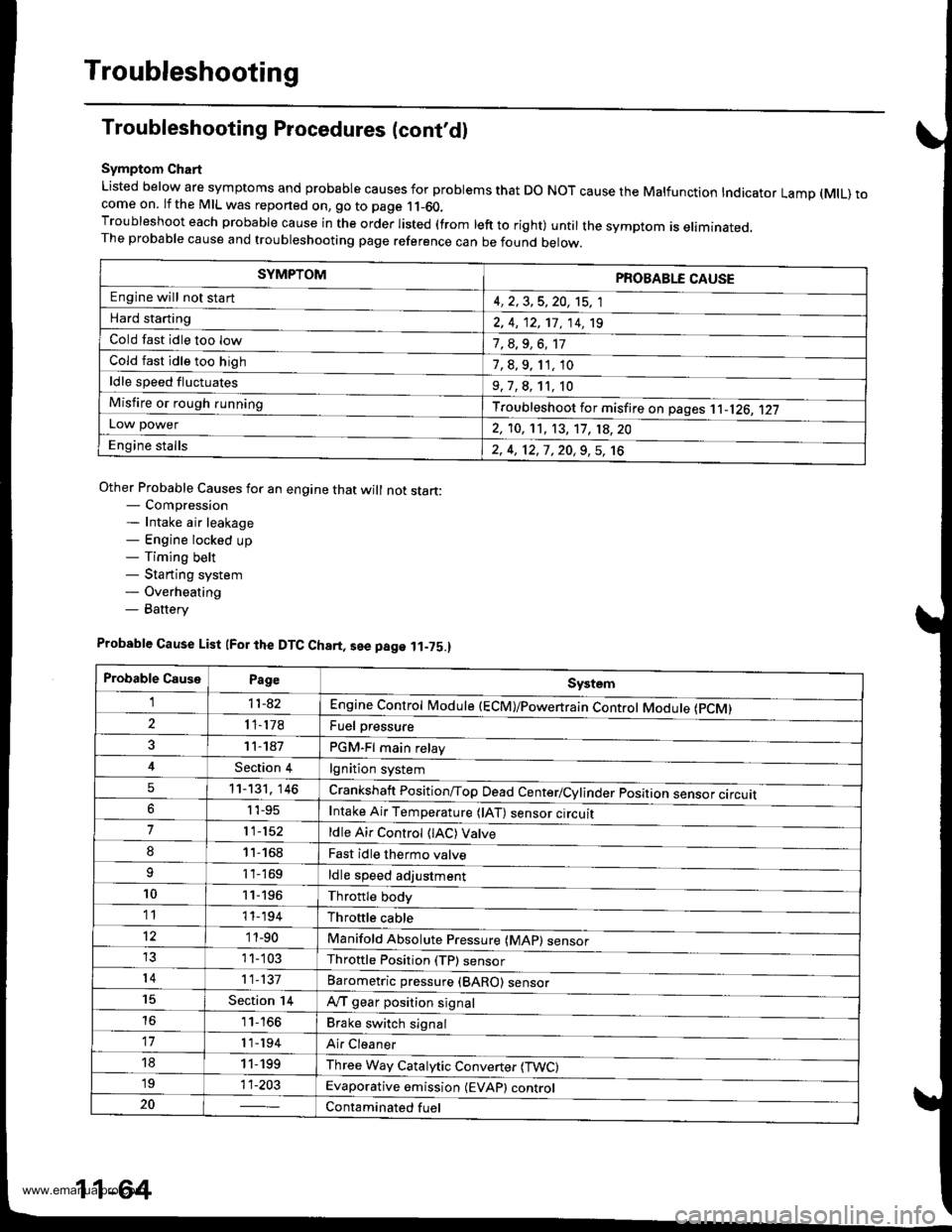

Troubleshooting

Troubleshooting Procedures (cont'dl

Symptom Chart

Listed below are symptoms and probable causes for problems that DO NOT cause the Malfunction Indicator Lamp (MlL) tocome on. lf the MIL was reported on, go to page 11-60.Troubleshoot each probable cause in the order listed (from left to right) until the symptom is eliminated,The probable cause and troubleshooting page reference can be found below.

Other Probable Causes for an engine that will not start:- Compression- Intake air leakage- Engine locked up- Timing belt- Starting system- Overheating- Battery

SYMPTOMPROBABLE CAUSE

Engine will not sta rt4, 2,3,5,20, 't5, 1

Hard starting2, 4, 12,17, 14, 't9

Cold fast idle too low7, a,9, 6, 17

Cold fast idle too high7,8,9,11,10

ldle speed fluctuates9,7,8, 't1, 10

Misfire or rough runningTroubleshoot for misfire on pages '11-126, 1|21LOl/\/ power2, 10,11, 13, '17, 18,20

Engine stalls2, 4, 12,1,20,9,5, 't6

Probable Cause List (For the DTC Ch8rt, see page ll-75.)

Probable CausePageSystem

Engine controt ruoaute (ecvtffi'I11-42

I 1-178Fuel oressure

PGM-Fl main relav

lgnition system

Crankshatt Position/Top Dead Center/Cylinder position sensor circuit

Intake Air Temperature (lAT) sensor ctrculr

ldle Air Control (lAC) Vatve

Fast idle thermo valve

ldle speed adjustment

Throttle body

Throftle cable

Manifold Absolute P."""rr"ffi

Throftle Position (TP) sensor

Barometric pressur" (gnno-

Ay'T gear position signal

Brake switch signal

Air Cleaner

Three Way Catalytic Converter (TWC)

Evaporative emission (EVAP) control

Contaminated fuel

1 1- 187

Section 4

5't1-'t31,146

6I '�t-95

711-152

81'l-168

1 1- 169

1011-196'1111-'194

12'1 'l -90

1 1- 103

1411-137

15Section 14

161 1- 166

17r 1-194

181 1,199'1911-203

20

11-64

www.emanualpro.com

Page 282 of 1395

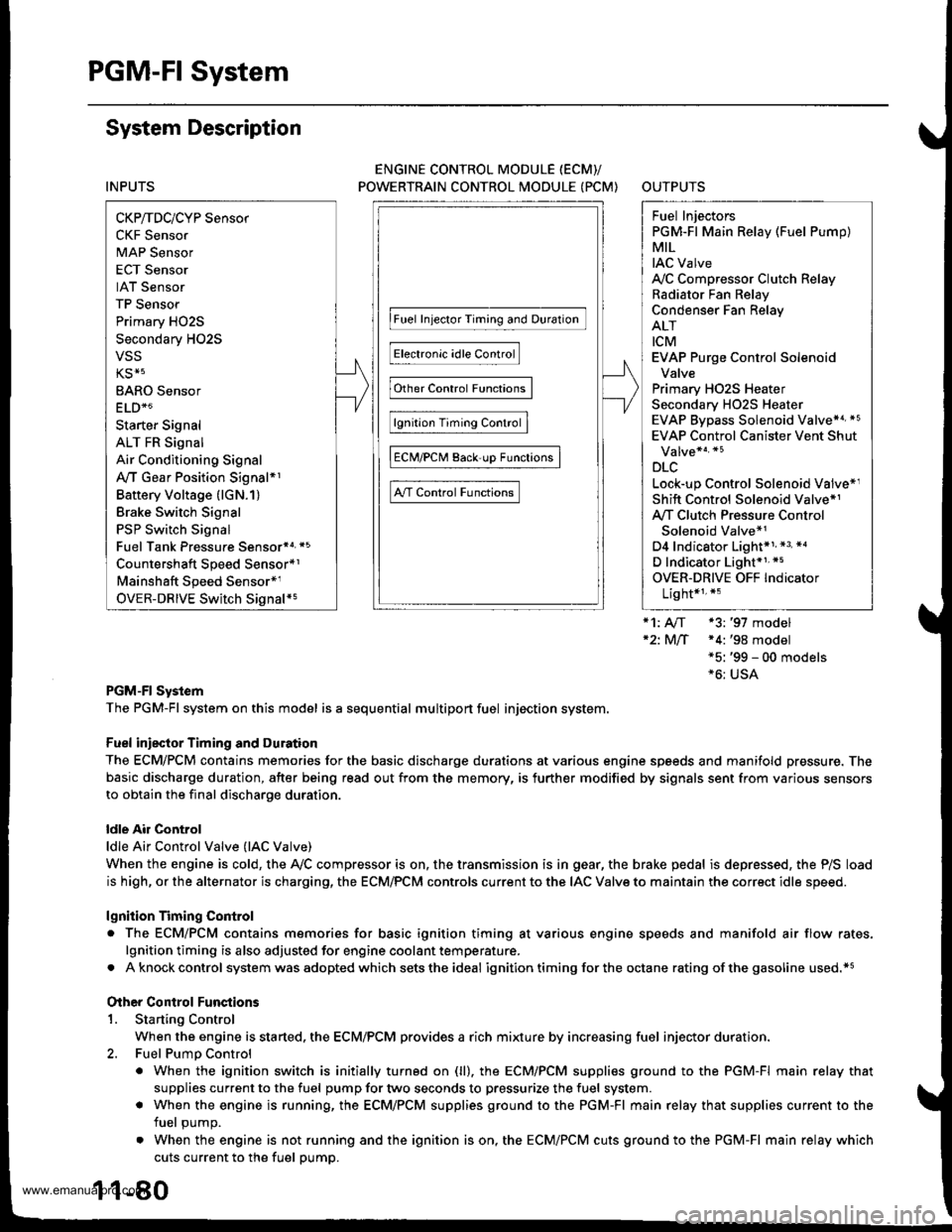

PGM-FI System

System Description

INPUTS

CKP/TDC/CYP Sensor

CKF Sensor

MAP Sensor

ECT Sensor

IAT Sensor

TP Sensor

Primary HO2S

Secondary H02S

vss

KS*5

BARO Sensor

ELD*6

Starter Signal

ALT FR Signal

Air Conditioning Signal

Ay'T Gear Position Signal*1

Baftery Voltage (lGN.1)

Brake Switch Signal

PSP Switch Signal

Fuel Tank Pressuae Sensor*4. *5

Countershaft Speed Sensor*1

Mainshaft Speed Sensor*r

OVER-DRIVE Switch Signal*s

ENGINE CONTROL MODULE (ECM)/

POWERTRAIN CONTROL MODULE (PCM) OUTPUTS

|iuel 1"j""- Th,rhg ""d Drrafr";-l

Et*-.nt"tdt"cont.orl

to,r*,c;;trffi;]

l.----.---:. .Lrgnrnon |lmrng Lonrror I

Ecir/PcM B*k',p Fr""il]

m;"t-ll-r*'io*l

Fuel Injectors

PGM-Fl Main Relay (Fuel Pump)

MIL

IAC Valve

Ay'C Compressor Clutch Relay

Radiator Fan Relay

Condenser Fan Relay

ALT

tcM

EVAP Purge Control Solenoid

Valve

Primary HO2S Heater

Secondary H02S HeaterEVAP Bypass Solenoid Valve*a *5

EVAP Control Canister Vent Shut

DLC

Lock-up Control Solenoid Valve*l

Shift Control Solenoid Valve*1

Ay'T Clutch Pressure Control

Solenoid Valve*1

D4 Indicator Light'1 *3, *a

D Indicator Light,l *5

OVER-DRIVE OFF Indicator

Lighl*t *:

*1: A/T {3:'97 model'2: M/f +4:'98 model*5: '99 - 00 models"6: USA

PGM-Fl System

The PGM-Fl system on this model is a sequential multiport fuel injection system.

Fuel iniecior Timing and Duration

The ECM/PCM contains memories for the basic discharge durations at various engine speeds and manifold pressure. The

basic discharge duration, after being read out from the memory, is further modified by signals sent from various sensors

to obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve (lAC Valve)

When the engine is cold, the Ay'C compressor is on, the transmission is in gear, the brake pedal is depressed, the P/S load

is high, or the alternator is charging, the ECM/PCM controls current to the IAC Valve to maintain the correct idle speed.

lgnition Timing Control

o The ECM/PCM contains memories for basic ionition timing at various engine speeds and manifold air flow rates.

lgnition timing is also adjusted for engine coolant temperature.

. A knock control system was adopted which sets the ideal ig nition timing for the octane rating of the gasoline used.*s

Other Control Funstions

1. Starting Control

When the engine is started. the ECM/PCM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

. When the ignition switch is initially turned on (ll). the ECMiPCM suppli€s ground to the PGM-FI main relay that

supplies current to the fuel pump for two seconds to pressurize the fuel system.

. When the engine is running, the ECM/PCM supplies ground to the PGM-FI main relay that supplies current to the

fuel oumo.

. When the engine is not running and the ignition is on, the ECM/PCM cuts ground to the PGM-FI main relay which

cuts current to the fuel pump.

1 1-80

www.emanualpro.com

Page 284 of 1395

PGM-FI System

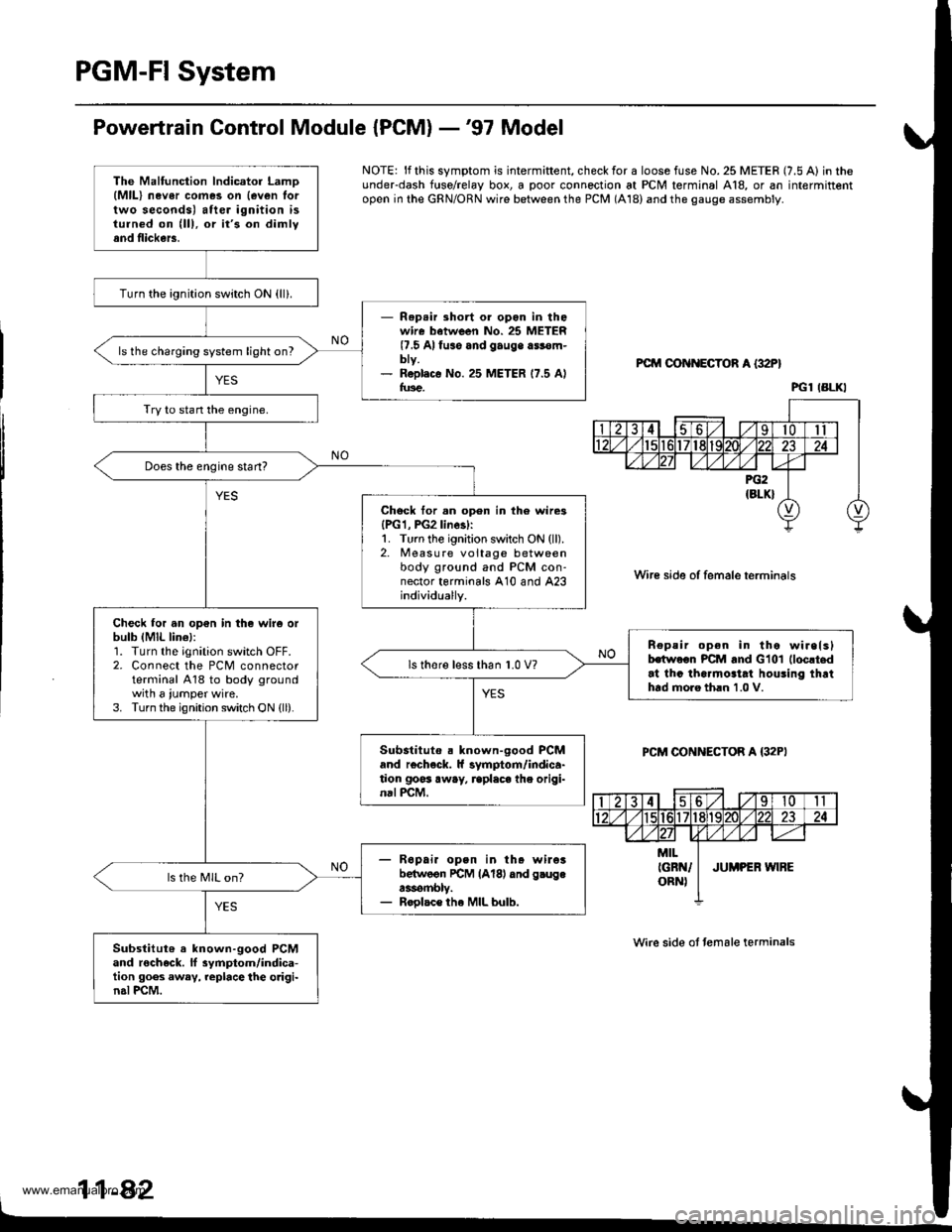

Powertrain Control Module {PCM} -'97 Model

NOTE: lf this symptom is intermiftent, check for a loose fuse No. 25 METER (7.5 A) in theunderdash f{rse/relay box, a poor connection at PCM terminal A18, or an intermittentopen in the GRN/ORN wire between the PCM (A18) and the gauge assembly.

PCM OON ECTOR A {32P}

Wire side of female terminals

PCM CONNECTOR A {32PI

Wire side ot temale terminals

11-42

The Malfunction lndicator LamD(MlL) nev6r comes on {even lortwo seconds) after ignition isturned on (lll, or it's on dimlyand flickers.

Turn the ignition switch ON {ll}.

- Rep.ir short or opon in thowire batween No. 25 METER(7.5 Alfuso and gauge a$€m-bty.- R6pl.c€ No. 25 METER 17.5 Alfus€.

ls the charging system light on?

Try to stan the engine.

Does the engine start?

Chock tor.n open in th6 wire3{PG1, PG2linesl:1. Turn the ignition switch ON (ll).2. Measure voltage betweenbody ground and PCM con-nector terminals A10 and A23individually.

Check for an op€n in the wir6 orbulb (MlL lin€l:1. Turn the ignition switch OFF.2. Connect the PCM connectorterminal A18 to body groundwith a iumper wire.3. Turn the ignition switch ON {ll).

n€peir open in tho wirelslhwoon PCM and Glol (loc!t.d

at thc tha.mo3tat houling thrthtd moro th.n 1.0 V.

ls thore l€ss than 1.0 V?

Substituto . known-good PCMand r€check. ll symptom/indica-tion goss away, rcplaca the origi-nal PCM.

- R6pai. open in th. wileibelwoon rcM lAl8l dnd g.ugea3rombly.- Roolac€ the MIL bulb.

ls the MIL on?

Substitut6 a known-good PCMand rocheck. ll 3ymptom/indica-tion goes away, replace the o.igi-n.l PCM.

PGl IBLKI

www.emanualpro.com

Page 285 of 1395

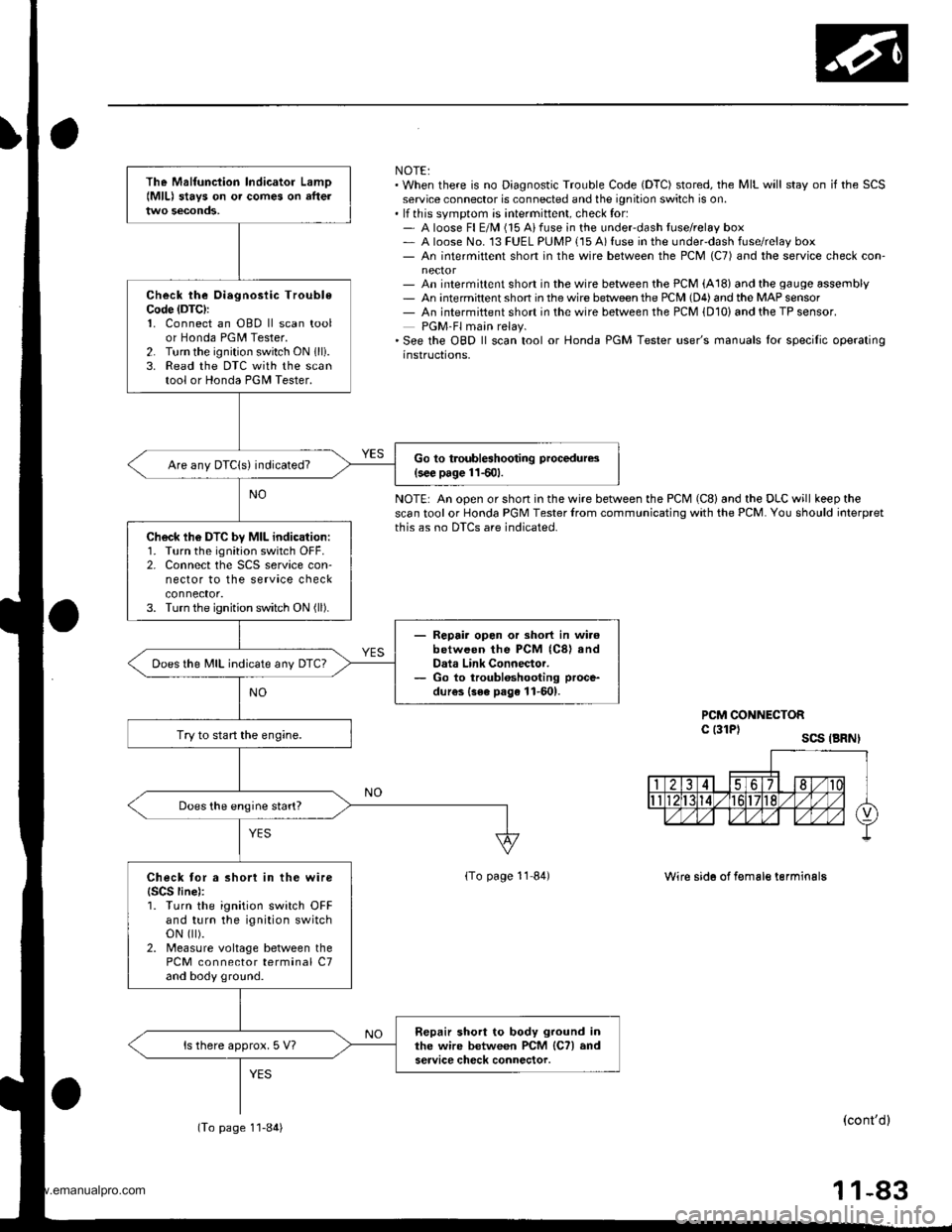

NOTE:. When there is no Diagnostic Trouble Code (DTC) stored, the MIL will stay on if the SCSservice connector is connected and the ignition switch is on.. lf this svmotom is intermittent, check for:- A loose Fl E/M (15 Aifuse in the underdash tuse/relay box- A loose No. 13 FUEL PUMP {15 A) fuse in the under-dash fuse/relay box- An intermittent short in the wire between the PCM (C7) and the service check con-

- An intermittent short in the wire between the PCM (A18) and the gauge assembly- An intermittent shon in the wire betlveen the PCM (D4) and the MAP sensor- An intermiftent short in the wire between the PCM {D10) and the TP sensor.PGM-Fl main relay.'See the OBD ll scan tool or Honda PGM Tester user's manuals lor specilic operatinginstructions,

NOTE: An open or short in the wire between the PCM (C8) and the DLC will keep thescan tool or Honda PGM Tester lrom communicating with the PCM. You should ioterpretthis as no DTCS are indicated.

PCM CONNECTORc l3lPl scs .BRNI

lTo page 11 84)Wire sid6 of f€male terminalg

(cont'dl

11-83

The Malfunciion lndicator Lamo{MlL) stavs on o. comes on afteltwo seconds,

Check the Oiegnosiic TroubleCode (DTC):

1. Connect an OBD ll scan toolor Honda PGM Tester.2. Turn the ignition switch ON 1lli.3. Read the DTC with the scantool or Honda PGII Tester.

Go to troubleshooting procedures(s€€ page 11501.Are any DTCIs) indicated?

Ch6ck lh6 DTC by MIL indication:1. Turn the ignition switch OFF.2. Connect the SCS service con-nector to the service checkconnector.3. Turn the ignition switch ON (ll).

- Repair opon or short in wi.6between the PCM (C8) andData Link Connector.- Go to troubloshooting proce-

dur€s {3ee page 11-601.

Does the MIL indicate any DTc?

Try to start the engine.

Does the engine start?

Check tor a short in the wire{SCS line):1. Turn the ignition switch OFFand turn the ignition switchoN flt).2. Measure voltage between thePCM connector terminal C7and body ground.

Repair short to body ground inthe wire between PCM lCTl andservice check connector.ls there approx. 5 V?

(To page 1'l-84)

www.emanualpro.com

Page 286 of 1395

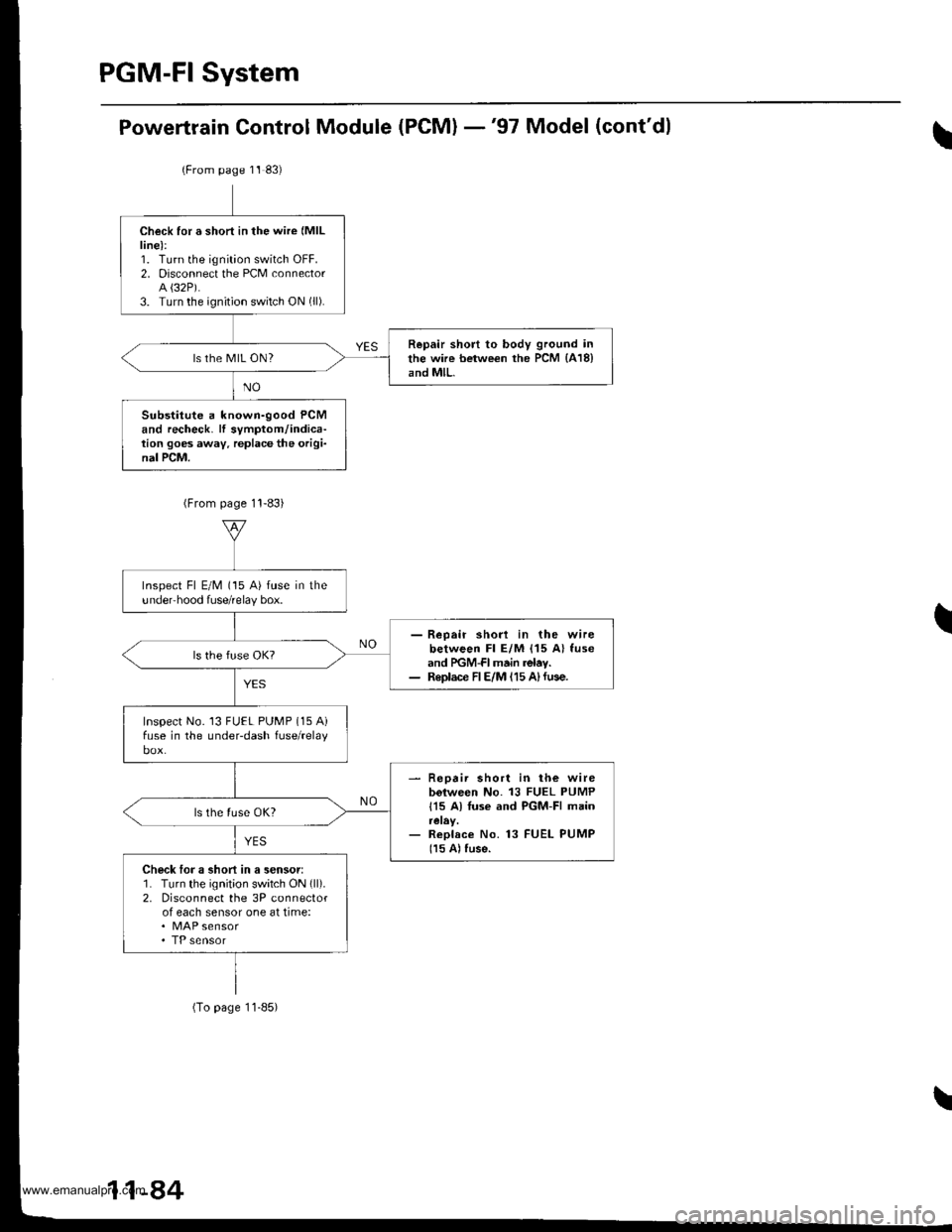

Powertrain Control Module (PCM) -'97 Model (cont'dl

(From page 11 83)

Check for a short in the wire (MlL

line):1. Turn the ignition switch OFF.2. Disconnect the PCM connectorA {32P).3. Turn the ignition switch ON (ll).

Repair short to body ground inthe wire between the PCM {418}and MlL.ls the MIL ON?

Substitute a known-good PCMand recheck. lf symptom/indica-tion goes away. replace the origi-nal PCM.

Inspect Fl E/M (15 A) fuse in theundeFhood fuse/relay box.

- Reoair shod in the wirebetween Fl E/M {15 A} fuseand PGM-FI main relav.- Replace FIE/M 115 A)fuse.

Inspect No. 13 FUEL PUMP (15 Aifuse in the underdash fuse/relay

- Repair short in lh€ wirebolween No. 13 FUEL PUMP

115 A) Iuse and PGM-FI main

- Replace No. 13 FUEL PUMP

115 A) fuse.

Check loJ a short in a sensor:1. Turn the ignit;on switch ON (ll).

2. Disconnect the 3P connectorof each sensor one at time:. MAP sensor

(To page 11-85)

11-84

www.emanualpro.com

Page 287 of 1395

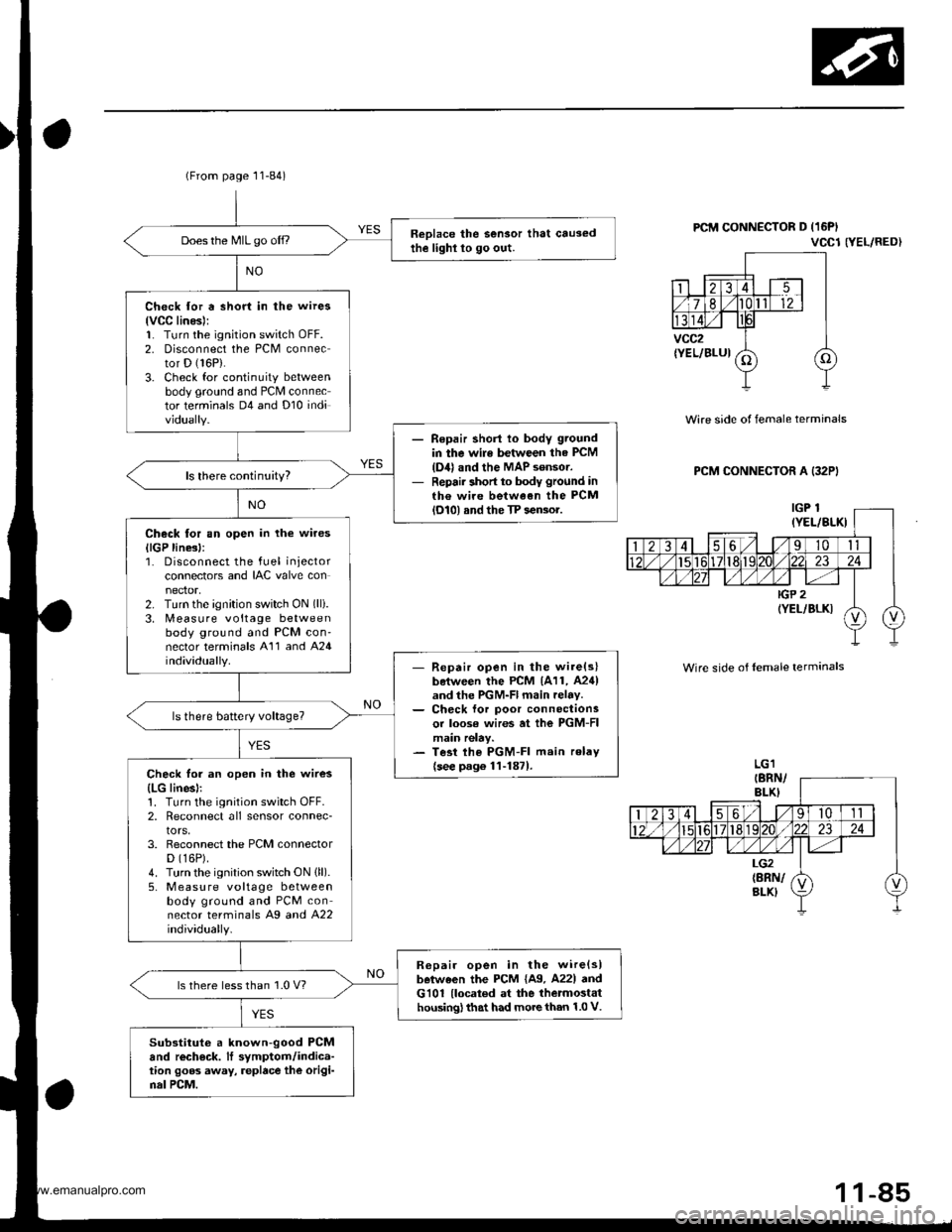

(From page 11-84)

Reolace the Sensor that causedthe lighl lo go out.Does the MIL go off.,

Check for a short in the wires

lvCC linesl:1. Turn the ignition switch oFF.2. Disconnect the PCM connector D (16P).

3. Check for continuity betweenbody ground and PCM connector terminals D4 and Dl0 individually.

Repair shorl lo body ground

in the wile between the PCM

{D4} and the MAP sensor.Repair short to body ground inth€ wire between the PCMlol0l and the TP sensor.

Check tor an open in the wires

llGP line3l:1. Disconnect the fuel injectorconnectors and IAC valve con

2. Turn the ignition switch ON (lli.

3. [,4easure voltage betweenbody ground and PCM con'nector terminals A'11 and A24individually.- Repair open in the wire(slboiween the PCM 1A11, A24)and the PGM-Fl main relav.- Ch€ck lor poor connectionsor loose wires at ihe PGM-FImain relay.- Tesi lhe PGM-FI main relav

{see p.g6 1l-1871.Check for an open in the wires

{LG linesl:1. Turn the ignition switch OFF.2, Reconnect all sensor connec-tors,3. Reconnect the PCM connectorD (16P).

4. Turn the ignition switch ON (ll).

5, M easu re voltage betweenbody ground and PCM connector terminals Ag a^d 422individually.

R6pair open in the wire{slbetween the PCM {A9. A22l andG101 {located at the thetmostathousing) that had more than 1.0 V.

ls there less than 1.0 V?

Substituto a known-good PCMand rech€ck. It symptom/indica-tion goos away, replace the origi-nal PCM.

PCM CONNECTOR D (16PI

VCCl NEL/RED}

Wire side of female terminals

PCM CONNECTOR A (32PI

Wire side of lemale terminals

1 1-85

www.emanualpro.com

Page 288 of 1395

PGM-FI System

Tho Maltunction Indicator Lamo(MlL) n6Yor como3 on leven lortwo laconds) rft6r tho ignhion isturnod ON {lll.

Turn th6 ignition switch ON (ll).

- Repair lhort or opcn in thowire between the No. 25METER 17.5 Al fu3e snd thegauge assembly.- Repl.co the No. 25 METER17.5 Al fus€.

ls the low oil pressure light on?

Try to start the engine.

Chock for an opsn in th€ wiro orbulb {MlL line,:1. Turn the ignition switch OFF.2. Connect the ECM/PCM con-nector terminal A18 to bodyground with a iumper wire.3. Turn the ignition switch ON (ll).

Rep.ir open in the wi.osbotween the ECM/FCM lA18land the gaugo rasombly.Roplece the MIL bulb.

ls th6 MIL on?

Substitute a known-good ECM/PCM and rochock. lf rymptom/indication goes eway, replacetho o gind ECM/PCM.

Turn the ignition switch OFF.Inspect the Fl E/M 115 A) tusein the undeFhood fuse/relaybox.

- Repair short in the wirebetween lhe Fl E/M (15 AlfusG and the PGM-Fl m.in.slay.- Roplsce th€ Fl E/M (15 Alfu3€.

Inspect the No. 13 FUEL PUMP(15 A) fuse in the under-dashfuse/relay box.

- Repair short in th6 wirebetween tho No. 13 FUELPUMP 115 A) luse and thePGM-FI main .elay.- ReDlace tho No. 13 FUELPUMP 115 Al tuse.

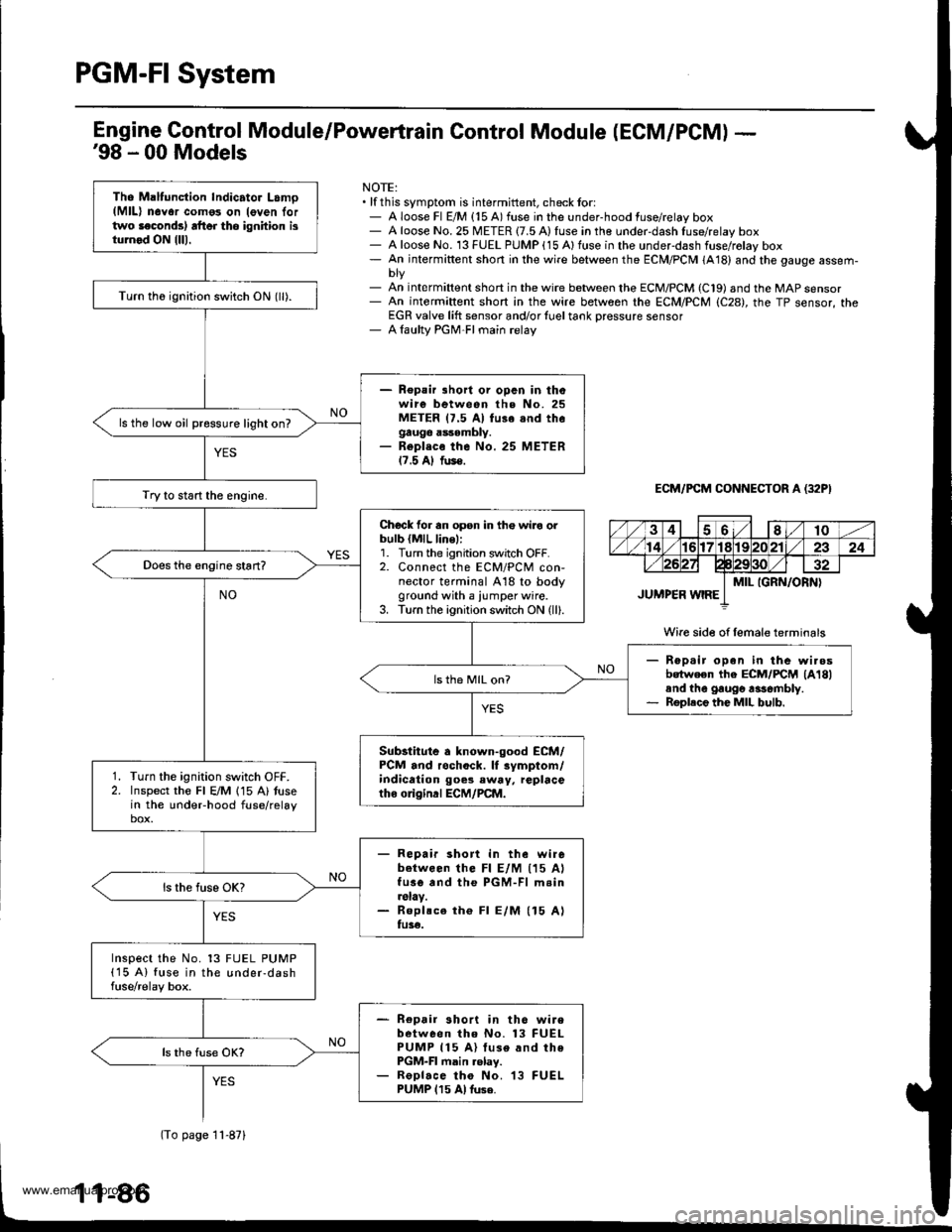

Engine Gontrol Module/Powertrain Control Module (ECM/PCM) -'98 - 00 Models

NOTE:. lf this symptom is intermittent, check tor:- A loose Fl E/M {15 A) fuse in the under-hood fuse/relay box- A loose No. 25 METER {7.5 A) fuse in the under-dash fuse/relay box- A loose No. 13 FUEL PUMP (15 Alfuse in the underdash fuse/rolay box- An intermiftent short in the wire between the ECM/PCM (A18) and the gauge assem-

- An int€rmiftent short in the wire between the ECM/PCM (C19) and the MAP sensor- An intermiftent short in the wire between rhe ECM/PCM (C28), the TP sensor, theEGR valve lift sensor and/or {uel tank Dressure sensor- A laulty PGM-FI main relay

ECM/PCM CONNECTOR A (32P}

Wire side of female terminals

(To page 11-871

www.emanualpro.com

Page 289 of 1395

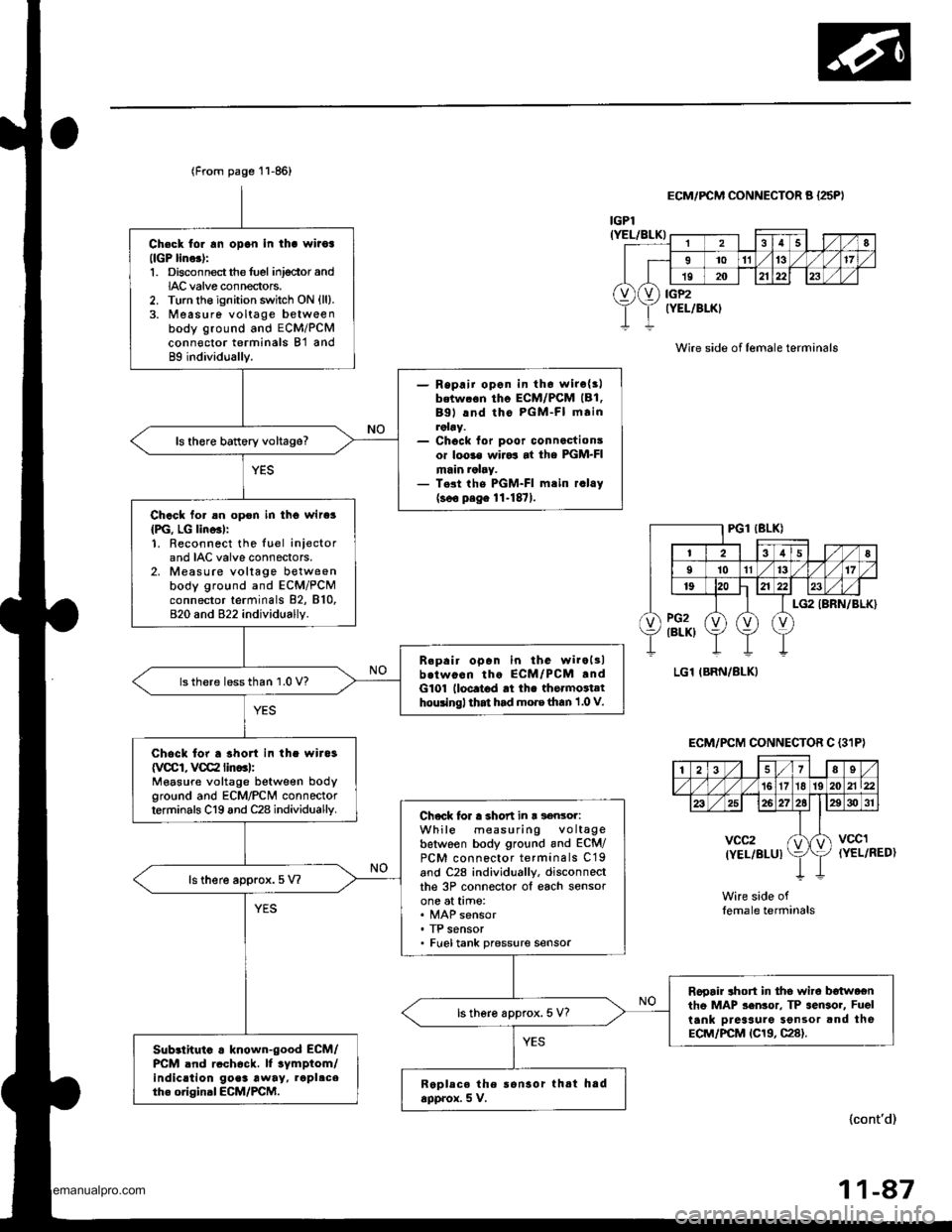

Ch€ck tor rn opon in tha wiioa(lGP lino.):1. Disconnectthe fuel inj€ctor andIAC valve connectors.2. Turn the ignition switch ON {ll}.3. Measure voltage betweenbody ground and ECM/PCMconn€ctor terminals B'l and89 individually.

- Repaii opon in th6 wirc{3lbetw.6n tho ECM/PCM (B1.

Bgl lnd tho PGM-FI mainroby.- Chock for poor connactionsor loo3€ wiJo3 at the PGM-FImain ralry.- T.st the PGM-FI mtin r.lay(soo p.ge 11-1871.

ls there battery voltage?

Chack for an opon in tho wire3

{PG, LG lino3l:1. Reconnect the luel iniectorand IAC valve connectors.2. Measure voltage betweenbody ground and ECM/PCMconnector terminals 82, 810,820 and 822 individually.

B.pair open in the wiroltlb.twocn tho ECM/PCM .ndG101 lloc.t6d rt th. thormoiathouingl that had mo.e than 1 .0 V.

lsthere lessthan 1.0 V?

Chock for a shon in the wira3

{VCCI, VCC2 lin..l:Measure voltage between bodyground and ECM/PCN4 connectorterminals C19 and C28 individuallv.Chock lor a short in r s€nsor:While measuring voltagebetwoen body ground and ECM/PCM connector terminals C19and C28 individually, disconneclthe 3P connector ol each sensorone at time:

. TP sensor. Fueltank pressure sensor

ls there approx.5 V?

Rooair ahort in tho wire b€twoentho MAP sen3or. TP sensor, Fuel

tank Dreaaure Sonsor and theECM/PCM tC19, C28).

ls there approx. 5 V?

Sub3lhuio . known-good ECM/PCM .nd rcch6ck. lf tymptom/indic.tion go.3 away, rapl.ceth. original ECM/PCM.Replece the ronsor thtt hadapprox. 5 V.

(From page 11-86)

lcont'd)

r

28

I1011't317

19202123

vXv) iiP2rELlBLK)

IGPl(YEL/BLK)

ECM/FCM CONNECTOR A {25PI

Wire side of lemale terminals

(YEL/RED)

Wire side oflemale terminals

ECM/PCM CONNECTOR C {3'IP}

| 2i37Es/'t61718 192021\22

26272elE30 31

vcc2(YEL/BLUIktvccl

11-47

www.emanualpro.com