Throttle body HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 204 of 1395

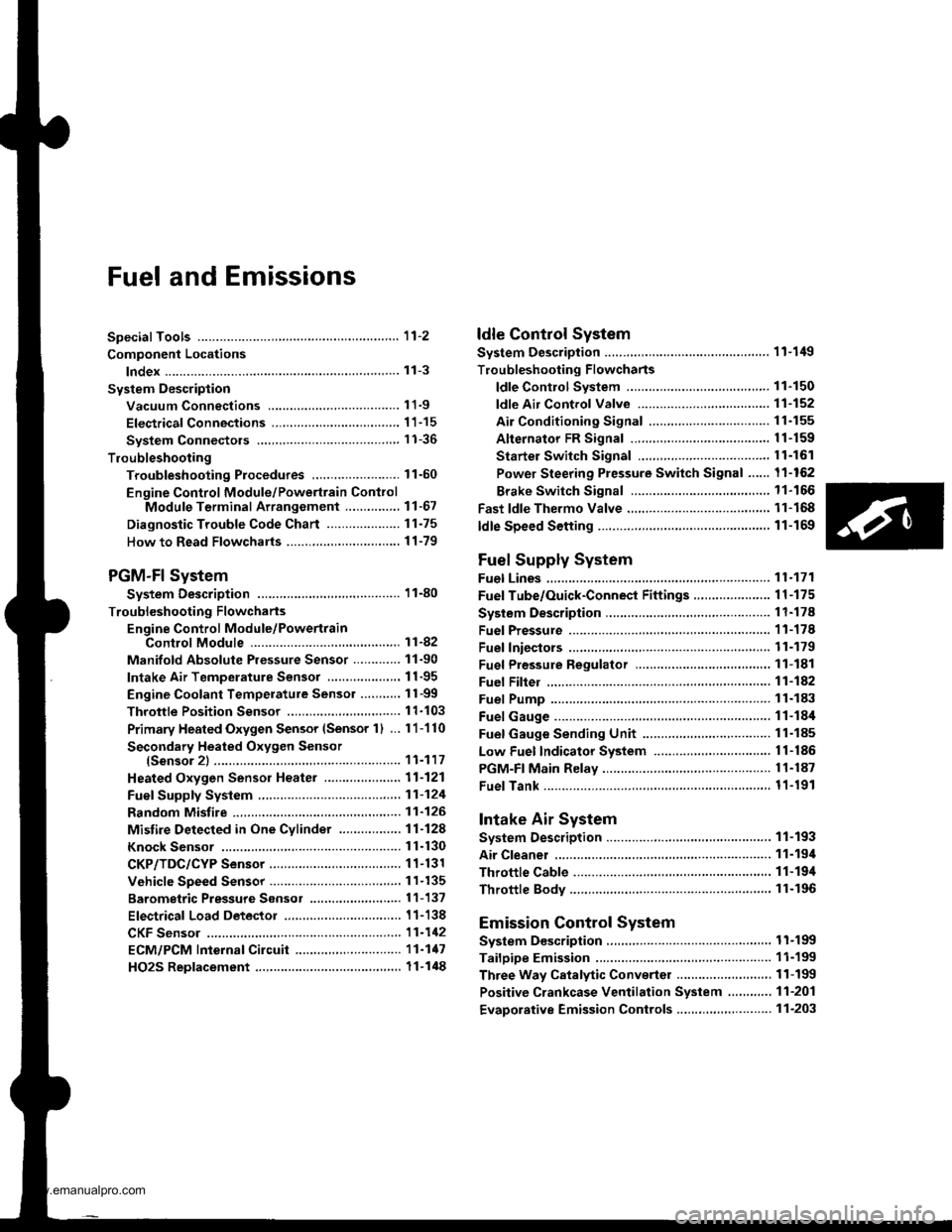

Fuel and Emissions

Special Tools ...................... 11-2

Component Locations

lndex ...................... ....,.... 11-3

Svstem Description

Vacuum Connections ...........,....,.,................. 1 1-9

Electrical Connections ................................... 1 1-15

System Connectors .,.,,.,............................,.,. 1 1-36

Troubleshooting

Troubleshooting Procedures,.,..................... 11-60

Engine Control Module/Powertrain ConttolModule Terminal Arrangement .............., 11-67

Diagnostic Trouble Code Chart .................... 1 t-75

How to Read Flowcharts .......,.....,.,............... I 1-79

PGM-Fl System

System Description .................,.,.,,,............... 1 1-80

Troubleshooting Flowcharts

Engine Control Module/PowertrainControl Module ........11-52

Manifold Absolute Pressure Sensor ............. 11-90

Intake Air Temperature Sensor .................... 1 1-95

Engine Coolant Temperature Sensor .,..,.,.... 1 1-99

Throttle Position Sensor ...........,.....,.,.,..,...... I 1'103

Primary Heated Orygen Sensor (Sensor 1) ... 11-110

Secondary Heated Oxygen Sensor{Sensor 2l .................. 1 1-117

Heated Oxygen Sensor Heater ..................... 11-121

Fuef Supply System ......11-124

Random Misfire ,....,.,..... 11-126

Mistire Detected in One Cylinder .....-........... 11-128

Knock Sensor ................ 11-130

CKP/TDC/CYP Sensor .................................... 1 1-131

Vehicle Speed Sensor ...............................,.... 1 1-135

Barometric Pressure Sensor .....,...,...,.,,........ 1 1-137

Electrical Load Detector ...,.,.......................... 1 1-138

CKF Sensor ................,.,, '11-112

ECM/PCM lnternaf Circuit ............................. 11'117

HO2S Replacement .,.,.,. 11-148

ldle Control System

System Description ............ 11-149

Troubleshooting Flowcharts

ldle Control System ...... 11-150

fdle Air Control Valve ......................,............. 11-152

Air Conditioning Signal ................................. I 1-155

Alternator FR Signal ...................................... 1 1-159

Starter Switch Si9na1 .................................... t l-161

Power Steering Pressure Switch Signal ...... 11-162

Brake Switch Si9na1 ...................................... 11-166

Fast ldle Thermo Valve .,.,.............................,.,.,. 11-168

ldle speed setting .............. 11-169

Fuel Supply System

Fuel Lines ............................ 11-171

Fuef Tube/Ouick-Conneci Fittings ..................... 11 -175

System Description ............ 11-178

Fuel Pressurg ...................... 11-178

Fuel Iniectors ................,..... 11-179

Fuel Pressure Re9u1ator .............................,.,...., f 1-181

Fuef Fifter ....,.,.,.,,,,.,............11-142

Fuel Pump ........................... 11-183

Fuel Gauge .......................... 11-184

Fuel Gauge Sending Unit ................................... I 1-185

Low Fuel Indicator System ...........,.,..,............... 1 1-185

PGM-FI Main Relay ............. 11-187

Fue|Tank................ ............. 11-191

Intake Air System

System Description ............ 11-193

Air Cleanel ,.,.,..................... 11-194

Throttle Cable ..................... 11-194

Throttle Body........ .............. 11-196

Emission Control System

System D$cription ...,....,.,. 11-199

Tailpipe Emission ............... 11-199

Three Way Catalytic Converter ..................,.,...,, 11-199

Positive Crankcase Ventilation System .,.,,,,.,.., 11-2O1

Evaporative Emission Controls .........,.,.,............ 11-203

www.emanualpro.com

Page 208 of 1395

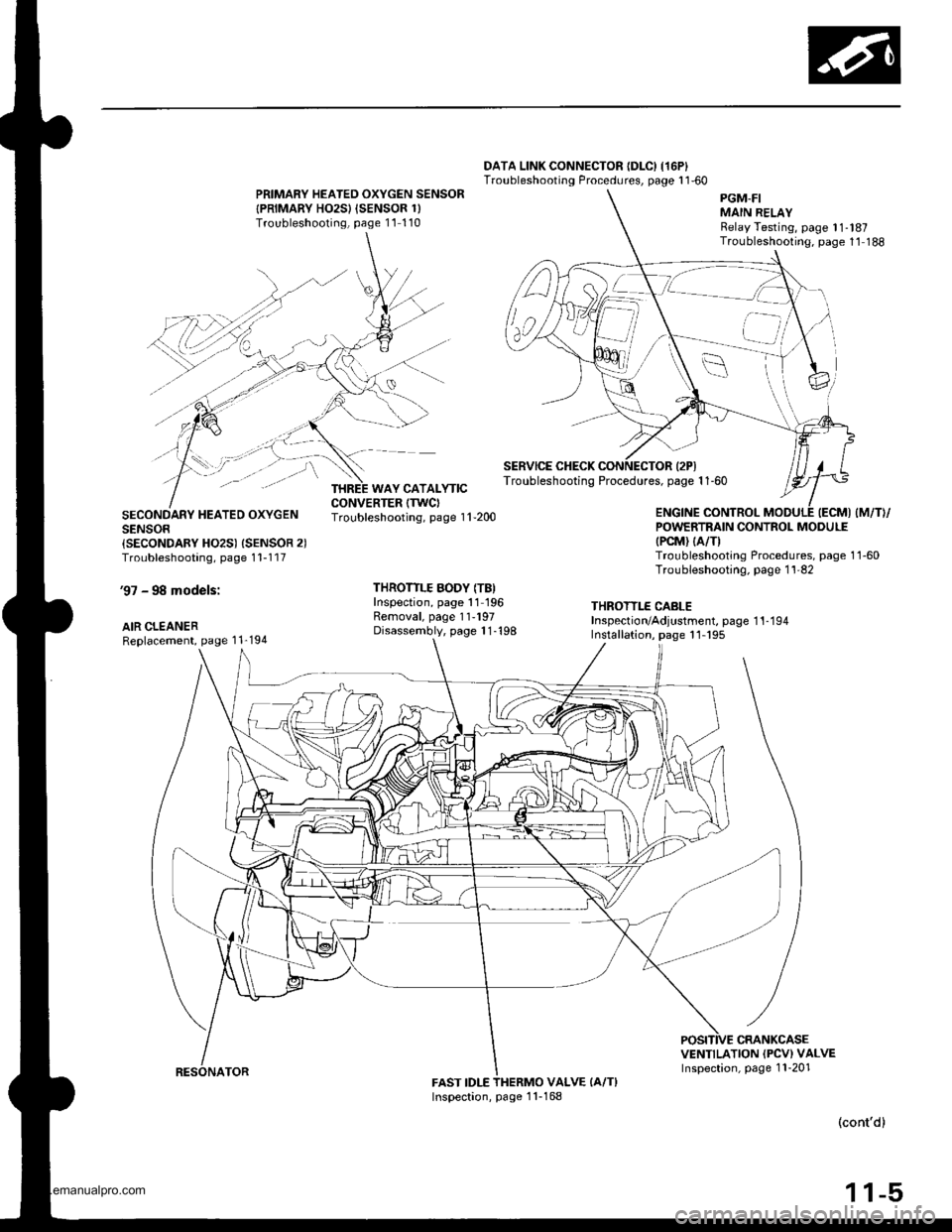

DATA LINK CONNECTOR {DLC) I16P}Troubleshooting Procedures, page 1 1'60PRIMARY HEATED OXYGEN SENSOR

{PRIMARY HO2SI {SENSOR 1)Troubleshooling, page 11 110

SECONDARY HEATED OXYGENSENSOR{SECONDARY HO2S) {SENSOR 2)Troubleshooting, page 1 1-1 17

'97 - 98 models:

AIR CLEANERReplacement, page 1 1'194

Troubleshooting, page 1 'l -200

THROTTLE BODY (TB)Inspection, page 11 196Removal, page 11-197Disassembly, page 1 1-'198

POWERTRAIN CONTROL MODULE(PCM) (A/TI

Troubleshooting Procedures, page 1 1-60Troubleshooting. page 1 1'82

THROTTLE CABLEInspection/Adjustment, page 1 1-1 94Installation, page 11- 195

VENTILATION (PCV) VALVEInspection, page 1 1-201FAST IDLEVALVE (A/T}

(cont'd)

1 1-5

PGM-FIMAIN RELAYRelay Testing, page 11-l87Troubleshooting. page 1'1 188

SERVICE CHECK CONNECTOR {2PITroubleshooting Procedures, page 1 1-60

,a'=_-_

WAY CATALYTIC

Inspection, page 1 1-168

www.emanualpro.com

Page 209 of 1395

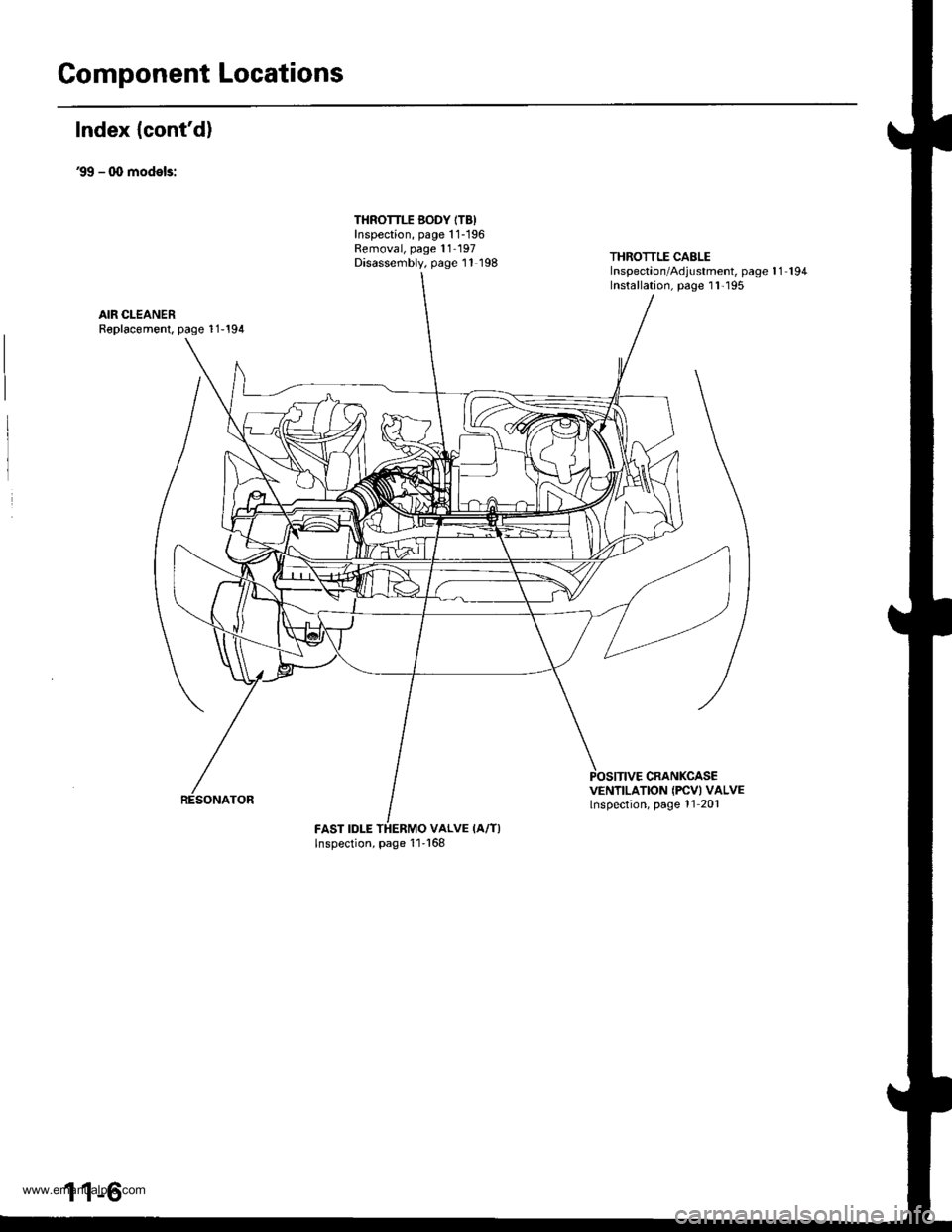

Component Locations

Index {cont'd)

39 - q, models:

THROTTLE BODY ITB)Inspection, page 1 1-196Removal, page 11- 197Disassembly, page 11 198THROTTLE CABLEInspectaon/Adjustment, page 1 1 194Installation, page I l'195

AIR CLEANERR€placomenl, page 1 1-194

CRANKCASEVENTILATION IFCVI VALVElnspection, page 11 201

FAST IDLE THERMO VALVE IA/T)Inspection, page 11'168

1 1-6

www.emanualpro.com

Page 215 of 1395

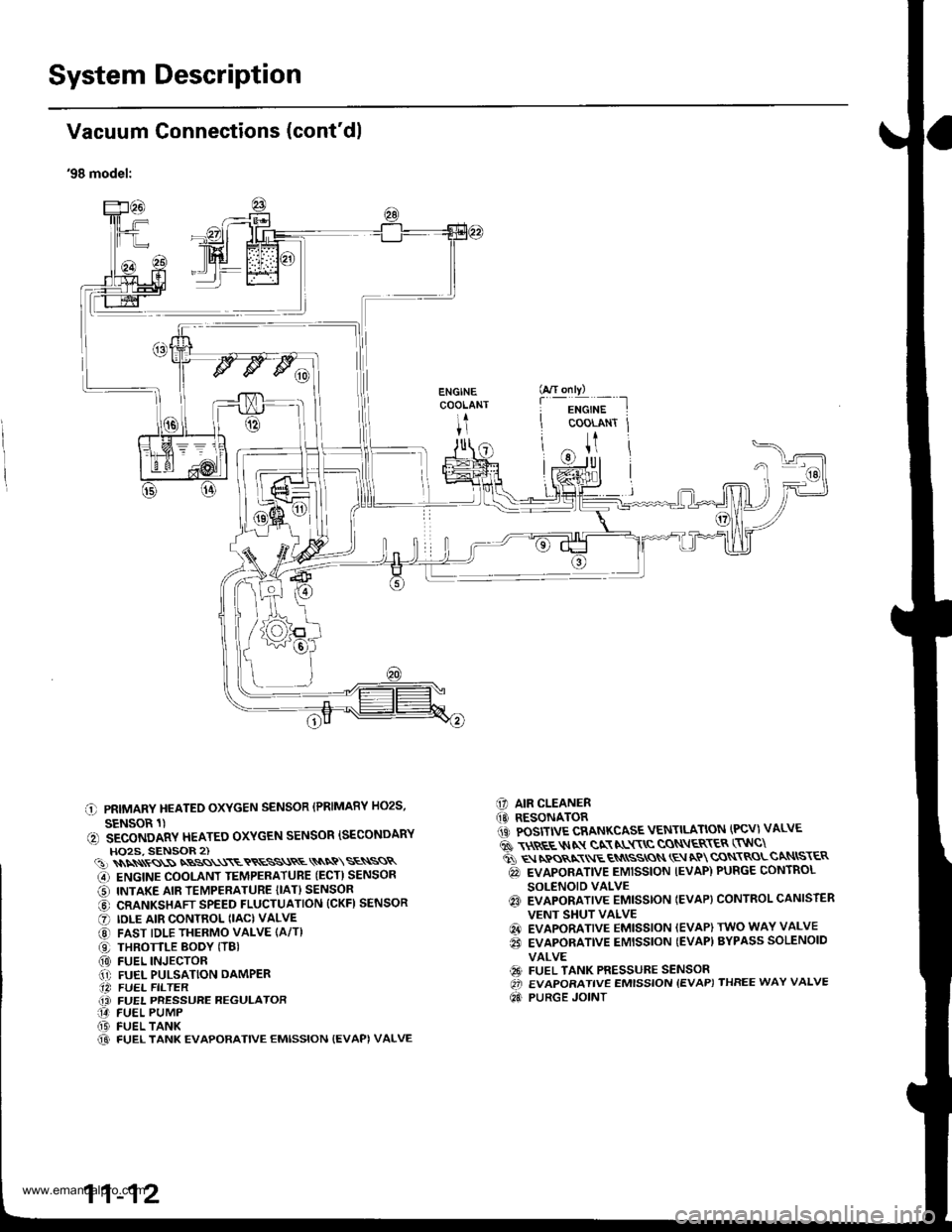

System Description

I

I

I

Vacuum Connections (cont'dl

'98 model:

C PRIMARY HEATEO OXYGEN SENSOR (PRIMARY HO2S,

SENSOR 1)(, SECONDARY HEATEO OXYGEN SENSOR ISECONDARYHO2S, SENSOR 2)(!)\\\\ss\SNBSS\\\ETRESS\RE\\NQ\SE\SSR

G) ENGINE COOLANT TEMPERATUBE (ECT) SENSOR

O INTAKE AIR TEMPERATURE {IAT} SENSOR

@ CRANKSHAFT SPEED FLUCTUATION (CKFI SENSOR

O IDLE AIR CONTROL (IAC) VALVE

@ FAST IDLE THERMO VALVE (A/T)

O THROTTLE BODY (TBI(0) FUEL INJECTOR.1' FUEL PULSATION DAMPER.14 FUEL FILTER(i FUEL PRESSURE REGULATOR14 FUEL PUMP(D FUEL TANK@ FUEL TANK EVAPORATIVE EMISSION {EVAPI VALVE

C] AIR CLEANER(O RESONATOR1iC POSITIVE CRANKCASE VENTILATION (PCV) VALVE

6 \$REE$IN gN NL$\C CON\ER\ER (TNC\

ti q rpos,xr E qN

ssros \E aP cqN\RoLcaNtsr€R

@ EVAPORATIVE EMISSION IEVAP) PURGE CONTROL

SOLENOID VALVEq3 EVAPORATIVE EMISSTON IEVAP} CONTROL CANISTER

VENT SHUT VALVE

@ EVAPORATIVE EMISSION (EVAP) TWO WAY VALVE

€i EVAPORATIVE EMISSION {EVAP) BYPASS SOLENOID

VALVE

€9 FUEL TANK PRESSURE SENSOROi EVAPORATIVE EMISSION {EVAP) THREE WAY VALVE

Qd PURGE JOINT

G/T only)

f

-i*'";-t

COOLANT Jt

U

11-12

www.emanualpro.com

Page 217 of 1395

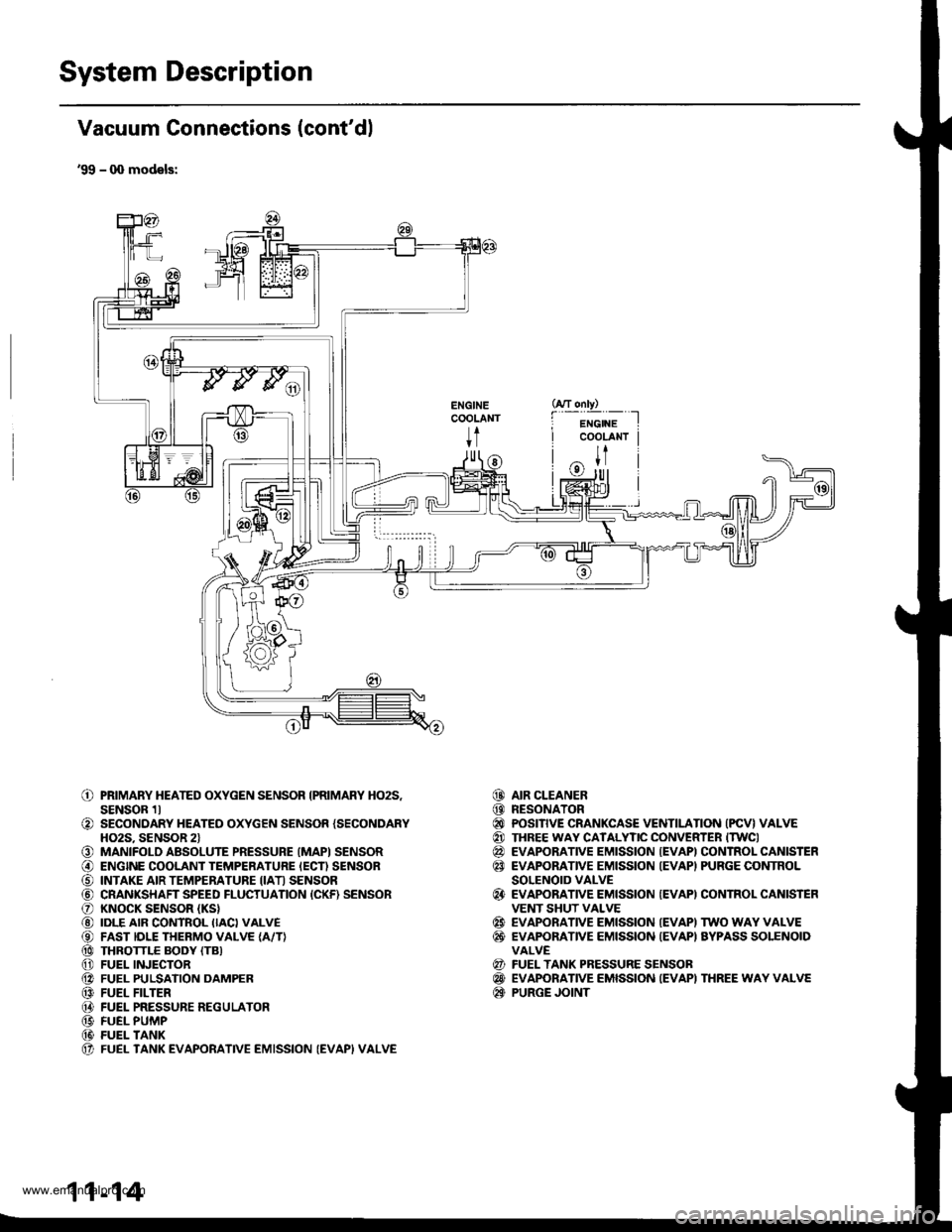

System Description

Vacuum Connections (cont'dl

'99 - q) models:

ENGINECOOLANT

t

o

o

o@

o@@@@@@@@@(t

PRIMARY HEATED OXYGEN SENSOR IPRIMARY HO2S,SENSOR 1lSECONDARY HEATED OXYGEN SENSOR {SECONDARYHO2S. SENSOR 2lMANIFOLD ABSOLUTE PRESSURE (MAPI SENSORENGINE COOLANT TEMPERATURE IECN SENSORINTAKE AIR TEMPERATURE IIATI SENSORCRANKSHAFT SPEED FLUCTUATION {CKF) SENSORKNOCK SENSOR (KS}

IDLE AIR CONTROL IIACI VALVEFAST IDLE THERMO VALVE {A/T}THROTTLE BODY (TB}

FUEL INJECTORFUEL PULSATION DAMPERFUEL FILTERFUEL PRESSURE REGULATORFUEL PUMPFUEL TANKFUEL TANK EVAPORATIVE EMISSION (EVAPI VALVE

AIR CLEANERRESONATORPOSITIVE CRANKCASE VENTILATION (PCV} VALVETHREE WAY CATALYTIC CONVERTER ITWCIEVAPORATIVE EMISSION {EVAPI CONTROL CANISTEREVAPORATIVE EMISSION IEVAPI PURGE CONTROLSOLENOID VALVEEVAPORATIVE EMISSION {EVAPI CONTROL CANISTEFVENT SHUT VALVEEVAPORATIVE EMISSION IEVAPI TWO WAY VALVEEVAPONANVE EMISSION {EVAPI AYPASS SOLENOIDVALVEFUEL TANK PRESSURE SENSOBEVAPORATIVE EMISSION IEVAPI THREE WAY VALVEPURGE JOINT

@@@@@@

@

@@

@@@

11-14

www.emanualpro.com

Page 266 of 1395

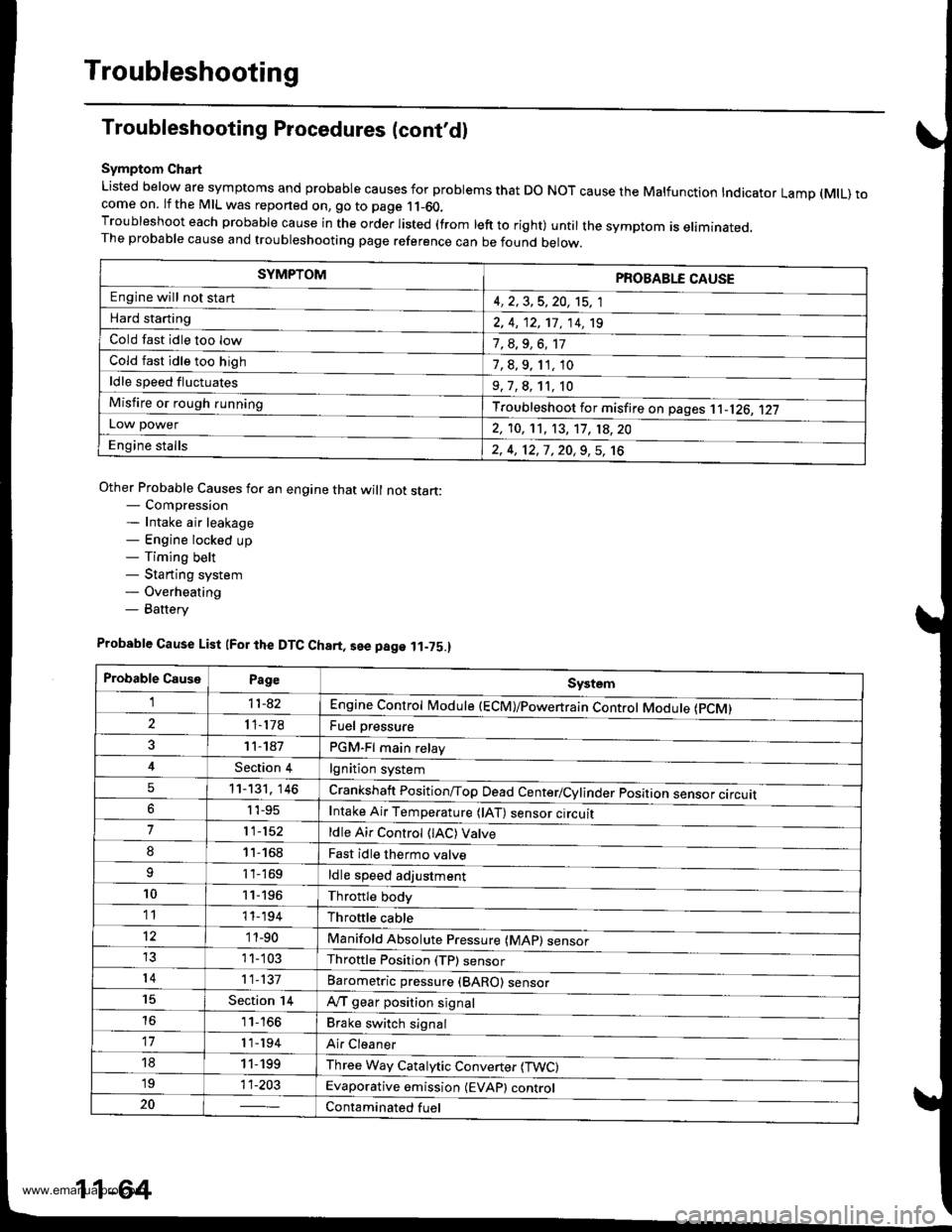

Troubleshooting

Troubleshooting Procedures (cont'dl

Symptom Chart

Listed below are symptoms and probable causes for problems that DO NOT cause the Malfunction Indicator Lamp (MlL) tocome on. lf the MIL was reported on, go to page 11-60.Troubleshoot each probable cause in the order listed (from left to right) until the symptom is eliminated,The probable cause and troubleshooting page reference can be found below.

Other Probable Causes for an engine that will not start:- Compression- Intake air leakage- Engine locked up- Timing belt- Starting system- Overheating- Battery

SYMPTOMPROBABLE CAUSE

Engine will not sta rt4, 2,3,5,20, 't5, 1

Hard starting2, 4, 12,17, 14, 't9

Cold fast idle too low7, a,9, 6, 17

Cold fast idle too high7,8,9,11,10

ldle speed fluctuates9,7,8, 't1, 10

Misfire or rough runningTroubleshoot for misfire on pages '11-126, 1|21LOl/\/ power2, 10,11, 13, '17, 18,20

Engine stalls2, 4, 12,1,20,9,5, 't6

Probable Cause List (For the DTC Ch8rt, see page ll-75.)

Probable CausePageSystem

Engine controt ruoaute (ecvtffi'I11-42

I 1-178Fuel oressure

PGM-Fl main relav

lgnition system

Crankshatt Position/Top Dead Center/Cylinder position sensor circuit

Intake Air Temperature (lAT) sensor ctrculr

ldle Air Control (lAC) Vatve

Fast idle thermo valve

ldle speed adjustment

Throttle body

Throftle cable

Manifold Absolute P."""rr"ffi

Throftle Position (TP) sensor

Barometric pressur" (gnno-

Ay'T gear position signal

Brake switch signal

Air Cleaner

Three Way Catalytic Converter (TWC)

Evaporative emission (EVAP) control

Contaminated fuel

1 1- 187

Section 4

5't1-'t31,146

6I '�t-95

711-152

81'l-168

1 1- 169

1011-196'1111-'194

12'1 'l -90

1 1- 103

1411-137

15Section 14

161 1- 166

17r 1-194

181 1,199'1911-203

20

11-64

www.emanualpro.com

Page 279 of 1395

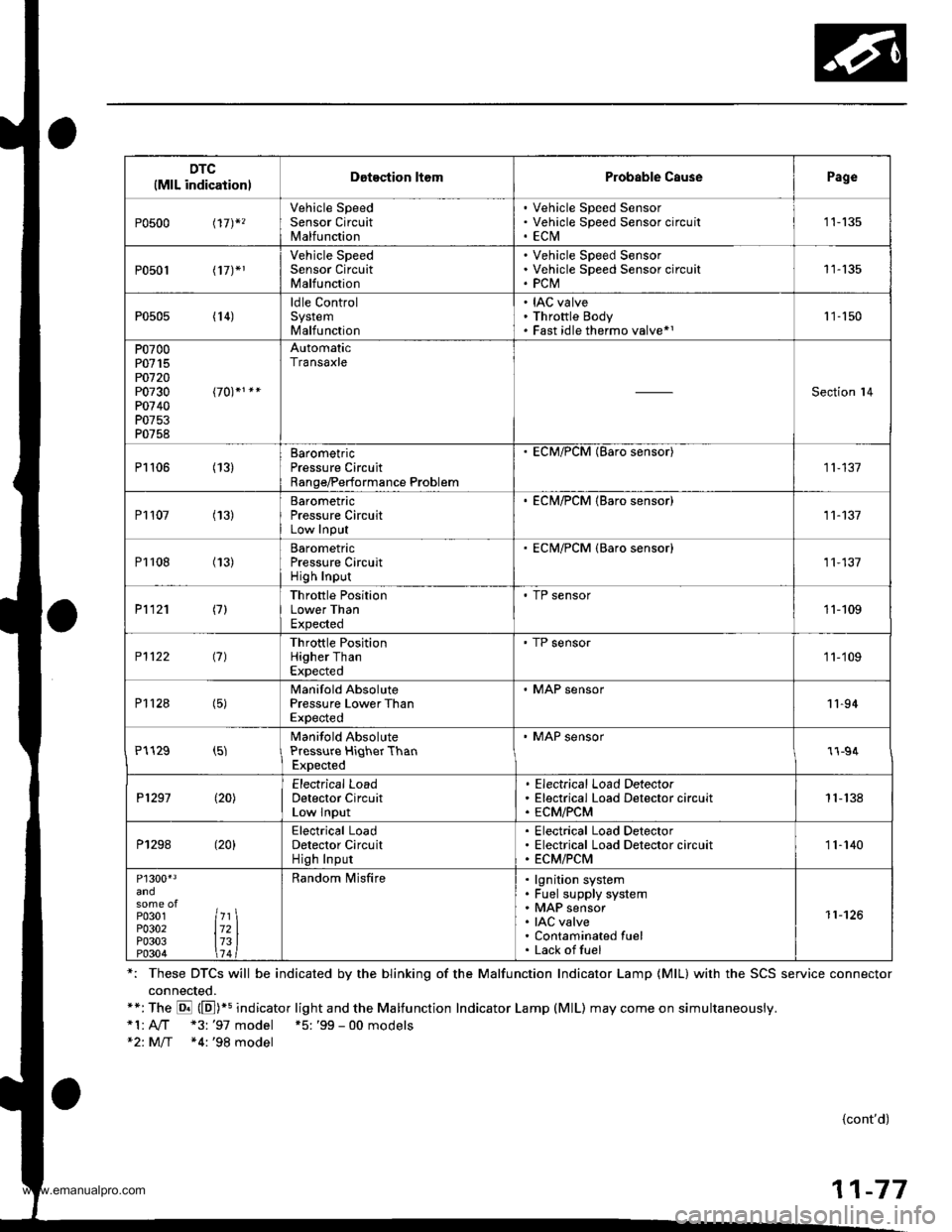

DTC(MlL indicationlDotection ltomProbable CausePage

P0500 t17)*,

Vehicle SpeedSensor CircuitMalfunction

Vehicle Speed SensorVehicle Speed Sensor circu itECtVI1 1-135

P0501 l17J*1

Vehicle SpeedSensor CircuitMalfunction

Vehicle Speed SensorVehicle Speed Sensor circuitPCM11-135

P0505 (14)ldle ControlSystemMalfunction

IAC valveThrottle BodyFast idle thermo valve*11 '�]- 150

P0700P0715PO720P0730P0740P0753P0758

AutomaticTransaxle

Section l4

P1106 (13)BarometricPressure CircuitRange/Performance Problem

ECM/PCM (Baro sensor)

11-137

P1107 (13)BarometricPressure CircuitLow InPut

. ECM/PCM {Baro sensor)11-137

P1108 (13)BarometricPressure CircuitHigh Inpur

ECM/PCM {Baro sensor)11,137

P1121 (7)Throttle PositionLower ThanExpected

. TP sensor11-109

P1122 (7)Throttle PositionHigher ThanExpected

' TP sensor1 1-'109

P112a (5)Manifold AbsolutePressure Lower ThanExpected

. MAP sensor11-94

P1129 (5)Manifold AbsolutePressure HiqherThanExpected

' MAP sensor1l-94

P1297 (20)Electrical LoadDetector CircuitLow Input

Electrical Load DetectorElectrical Load Detector circuitECM/PCM1 1- 138

P1298 (20)Electrical LoadDetector CircuitHigh Input

Electrical Load DetectorElectrical Load Detector circuitECM/PCM11-140

P1300'3

P0301P0302P0303P0304

7l721314

Random lvlisfirelgnition systemFuel supply systemMAP sensorIAC valveContaminated fuelLack offuel

11-126

*: These DTCS will be indicated by the blinking of the Malfunction Indicator Lamp {MlL} with the SCS service connector

connected.**:The E (E])+s indicator light and the Malfunction Indicator Lamp (MlL) may come on simultaneously.*1:A,./T "3: '97 model +5: '99 - 00 models*2: M/T *4:'98 model

{cont'd)

11-77

www.emanualpro.com

Page 314 of 1395

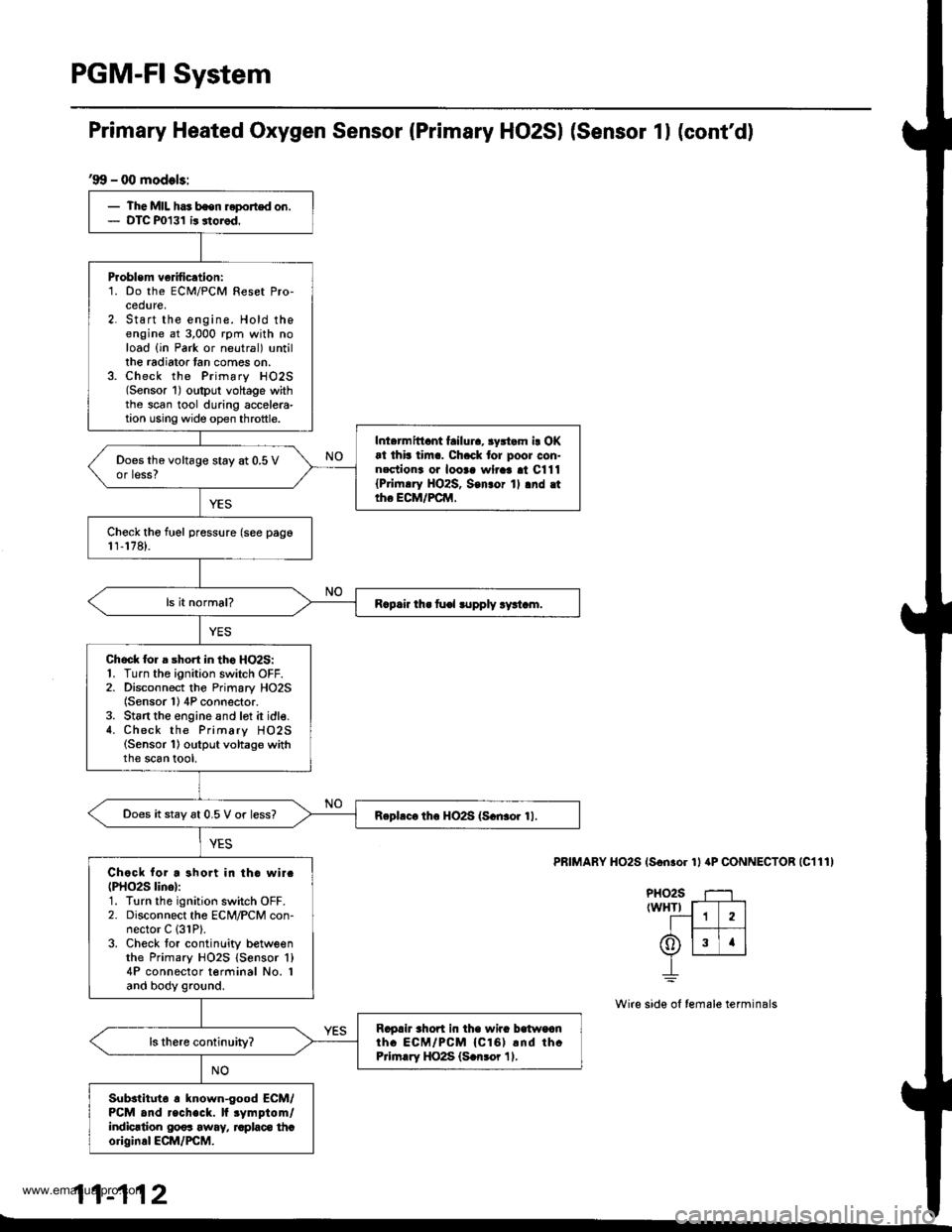

PGM-FI System

'99 - 00 models:

- The MIL has bsen reported on.- DTC P0131 ir storod.

Problem ve fication:1. Do the ECM/PCM Reset Pro-cedure,2. Start the engine. Hold theengine at 3,000 rpm with noload {in Park or neutral) untillhe radiator tan comes on.3. Check the Primary HO2S(Sensor 1) oltput voltage withthe scan tool during accelera-tion using wide op€n throttle.

Inl.rmittant failura, 3yrtam i! OKat thb tim.. Ch.ck tor poor con-nectiona oa looaa wlraa al C111{Pri|n.ry HO2S, Son3or 1l .nd .ttho ECM/FCM,

Does the voltage stay at 0.5 Vor less?

Check tho fuel pressure (see pago1r,178).

R.p.ir th. fu€l lupply ry!t.m.

Chock lor a short in tho HO2S:1. Turn the ignition switch OFF.2. Disconnect the Primary HO2S(Sensor 1) 4P connector.3. St6rt the engine and lot it idle.4. Check the Primary HO2S(Sensor 1) output voltage withthe scan tool,

Does it stay 6t 0.5 V or less?Rephc. th6 HO2S (S.n3or 11.

Chock for a short in tho wirc(PHO2S lino):1. Turn the ignition switch OFF.2. Disconnect the ECM/PCM con-nector C (31P).

3. Check tor continlity betweenthe Primary HO2S {Sensor 'l}

4P connector terminal No. Iand body ground.

Ragah rhort in tha wira balwoanth. ECM/PCM {Cl61 rnd thcPrirn.ry HO2S (S.n3or 11.

Substltut6 a known-good ECM/PCM and recheck. lf rymptom/indicrtion 00os away, raplaco thcoriginal ECM/PCM.

Primary Heated Oxygen Sensor (Primary HO2SI (Sensor 1l (cont'd)

PRIMARY HO2S (Son.or 1l aP CONNECTOR |C111)

PHO2S T--1rwHTr f-T---]

--1 1 2lI t--- 1t6)lslrlv L__r__J

_L

Wire side ol female terminals

11-112

www.emanualpro.com

Page 352 of 1395

ldle Control System

ldle Control System

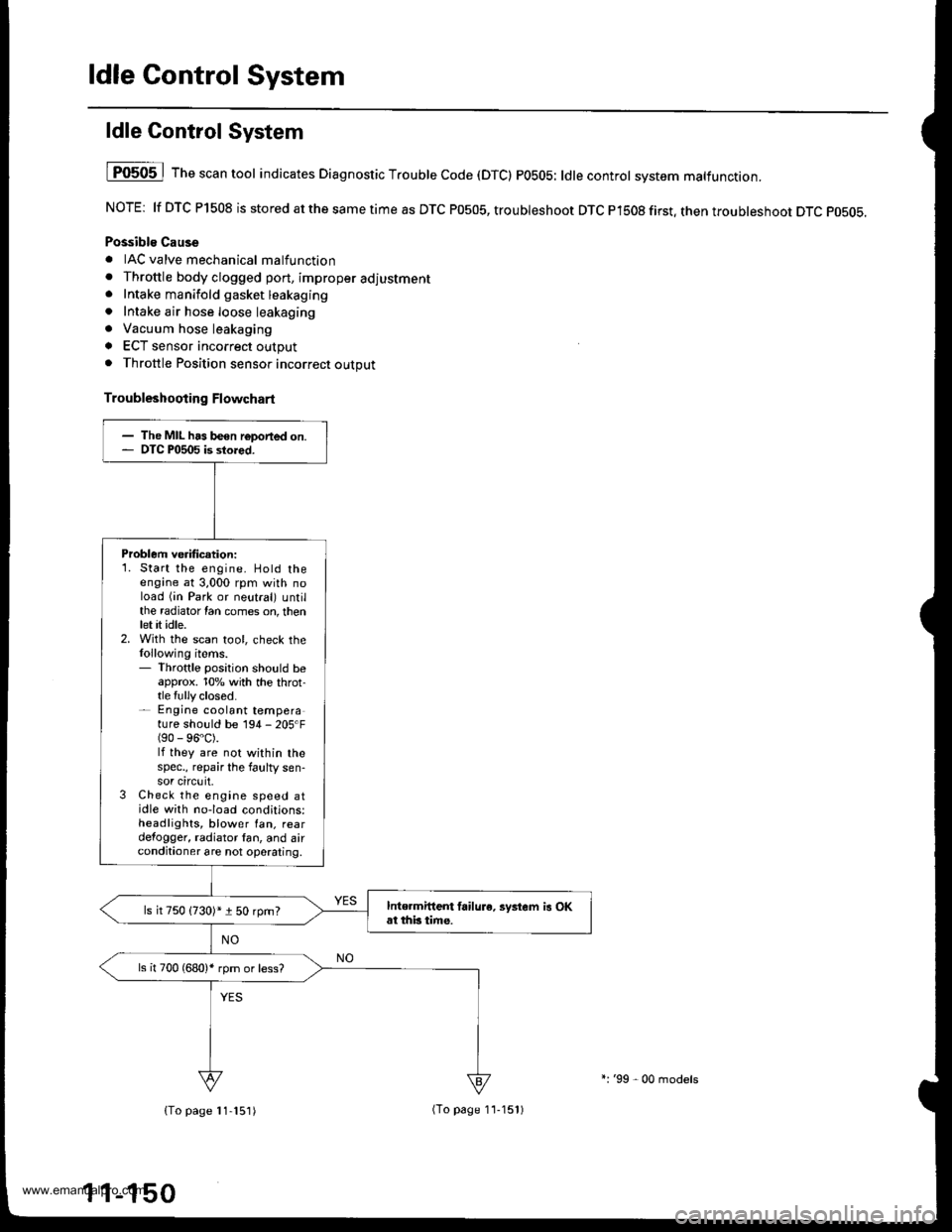

I P0505 | The scan tool indicates Diagnostic T.ouble Code (DTCI PO5O5: ldlecontrol svstem mattunction.

NOTE: lf DTC P1508 is stored at the same time as DTC P0505, troubleshoot DTC P1508 first. then troubleshoot DTC p0505.

Possibls Cause

. IAC valve mechanical malfunction. Throttle body clogged port, improper adlustment. Intake manifold gasket leakaging. Intake air hose loose leakaging. Vacuum hose leakaging

a ECT sensor incorrect output. Throttle Position sensor incorrect output

Troubleshooting Flowchart

The MIL has been reDorted on.DTC P0505 is sto.ed.

Problem verificationi1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator Ian comes on, thenlet it idle.2. With the scan tool, check thelollowing items.- Throttle position should beapprox. 10% with the throt-tle {ully closed.- Engine coolant temperature shorJld be 194 - 205'F(90 - 96"C).lf they are not within thespec., repair the faulty sen-sor circuit.3 Check the engine speed atidle with no-load conditions:headlights, blower fan. reardefogger, radiator lan, and airconditioner are not operaling,

Inte.mittent failure. syltem is OKat this time.ls it 750 {730)* i 50 rpm?

ls il 700 (680)' rpm or less?

{To page 11-151)(To page 1'l-151)

l:'99 - 00 models

www.emanualpro.com

Page 353 of 1395

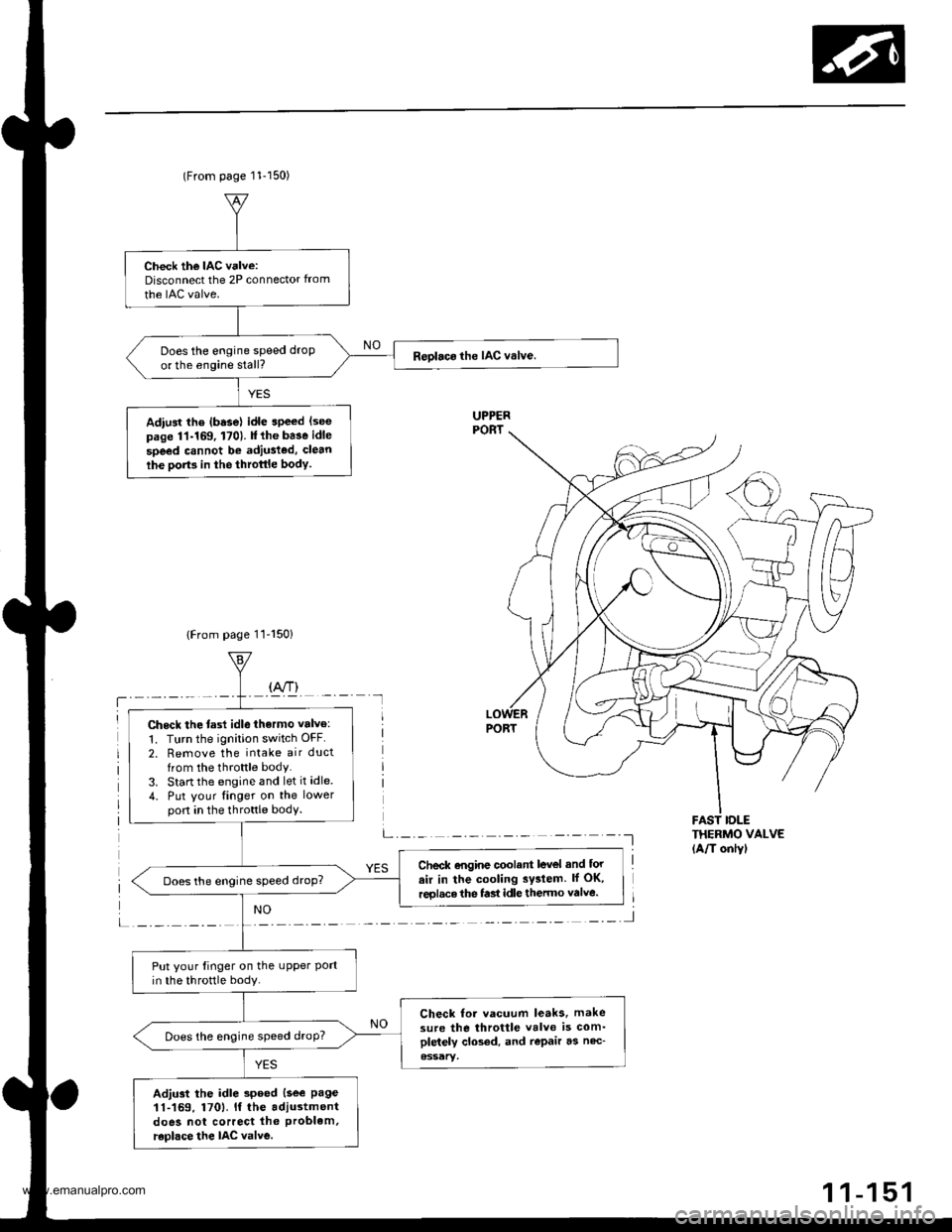

(From page 11-150)

{From page 11-150}

THERMO VALVE(A/T onlyl

Check the IAC valve:Disconnect the 2P connector from

the IAC valve.

Does the engine speed droP

or the engine stall?

Adiust the (basel idl€ speed lseepage 11-169, 1t0). Itihe ba3e idle

speed cannot be adiust€d, clean

the Dorts in the throttle body.

UPPER

Check the tast idle lhermo valve:

1. Turn the ignition switch OFF.

2. Remove the intake air ductfrom the throttle body.3. Start the engine and let it idle.

4. Put your finger on the lowerpon in the throttle body.

Check engine cool.nt level and for

air in the cooling sy3lem. lf OK,

reolace the f.st idle thermo valve.Does the engine speed drop?

Put your Iinger on the uPPer Portin the throttle body.

Check for vacuum leaks, make

sure the throttle valve is com'pletely clo3ed. and repair as nec-Does the engine speed droP?

Adjust the idle spoed lsee Page11-169. 1701. lf the adiustmentdoes not correct lhe problem,

r.olace the IAC valve.

www.emanualpro.com