air idle intake valve HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 207 of 1395

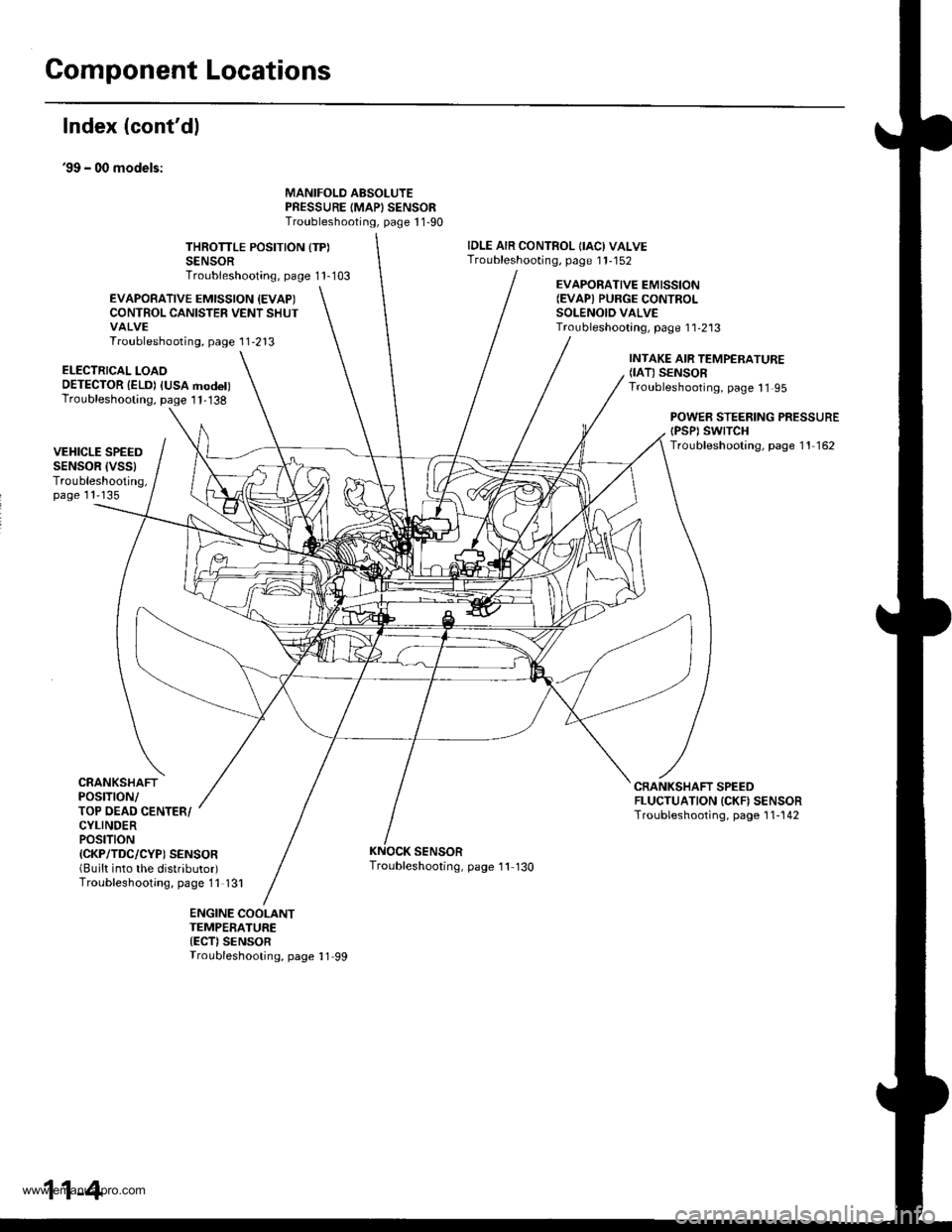

Component Locations

Index (cont'dl

39 - 00 models:

MANIFOLD ABSOLUTEPRESSURE IMAPISENSORTroubleshooting, page 1 1-90

THROTTLE POSITION {TP)SENSORTroubleshooting, page 1 1-103

IDLE AIR CONTROL OACI VALVETroubleshooting, page 1 1-152

EVAPOBATIVE EMISSION {EVAPICONTROL CANISTER VENT SHUTVALVETroubleshooting, page 1 1-213

EVAPORATIVE EMISSION(EVAPI PURGE CONTROI-SOLENOID VALVETroubleshootang, page 1 1-2'13

ELECTRICAL LOAOOETECTOR {ELD) IUSA modet)Troubleshooting, page I 1-138

INTAKE AIR TEMPERATURE(IAT) SENSORTroubleshooting, page 11 95

POWEB STEERING PRESSUREtPsPt swtTcHTroubleshooting, page 11 162VEHICLE SPEEDSENSOR IVSSITroubleshooting,page 11'135

CRANKSHAFTPOSTTTON/TOP OEAD CENTER/CYLINDERPOStTtON{CKP/TDC/CYP) SENSOR(Built into the distributor)Troubleshooting, page 11 131

CRANKSHAFT SPEEDFLUCTUATION ICKN SENSORTroubleshooting, page 1 1-142

SENSORTroubleshooting, page '11 130

ENGINE COOLANTTEMPERATURE{ECT)SENSORTroubleshooting, page 11 99

11-4

www.emanualpro.com

Page 213 of 1395

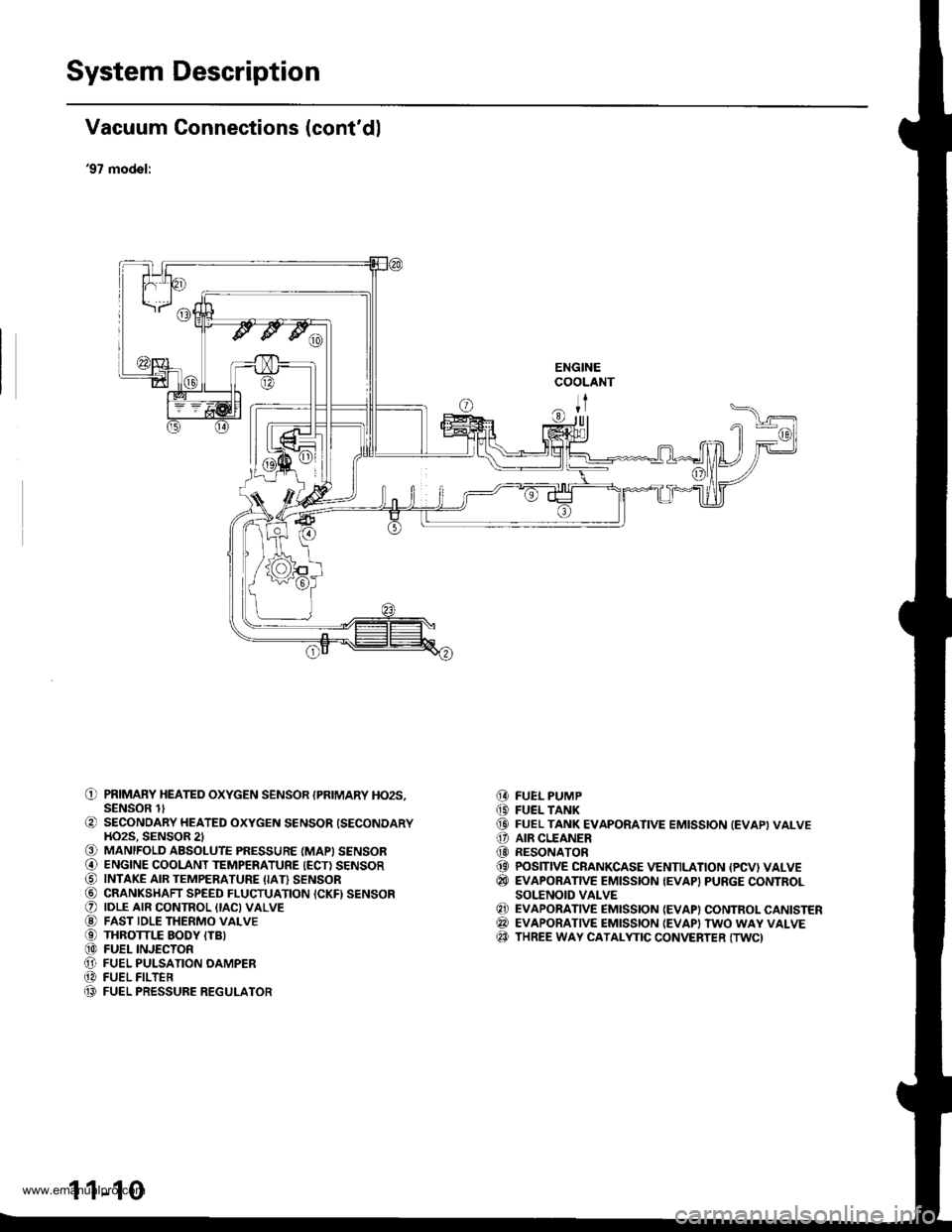

System Description

Vacuum Connections (cont'dl

'97 model:

ENGINECOOLANT

ITr|ll

O PRIMARY HEATED oxYGEN sENsoR {PRIMARY Ho2s,SENSOR lt

O SECONDARY HEATED oxYGEN sENsoR {SECoNDARYHO2S. SENSOR 2l€) MANIFOLD ABSOLUTE PRESSURE (MAPI SENSOR@ ENGINE cooLANT TEMPERATURE {EcT} sENsoRO INTAKE AIR TEMPERATURE (IAI} sENsoR@ CRANKSHAFT SPEED FLUCTUATION ICKFI SENSORO |DLE ArR coNTRoL {tAc)vALvE@ FAST IDLE THERMo vALvEO THRoTTLE EoDY ITB)@ FUEL INJEcTonO FUEL PULSATIoN oAMPER@ FUEL FILTEn(} FUEL PRESSURE REGULATOR

FUEL PUMPFUEL TANKFUEL TANK EVAPORATIVE EMISSION (EVAPIVALVEAIR CLEANERRESONATORPOSITIVE CRANKCASE VENTILATION {PCVI VALVEEVAPORATIVE EMISSION {EVAP} PURGE CONTROLSOI.'ENOID VALVEEVAPORATIVE EMISSION {EVAP) CONTROL CANISTEREVAPORATIVE EMISSION {EVAPI TWO WAY VALVETHREE WAY CATALYTIC CONVERTER (TWC)

@(D(D

o@(}

@

@@@

1 1-10

www.emanualpro.com

Page 215 of 1395

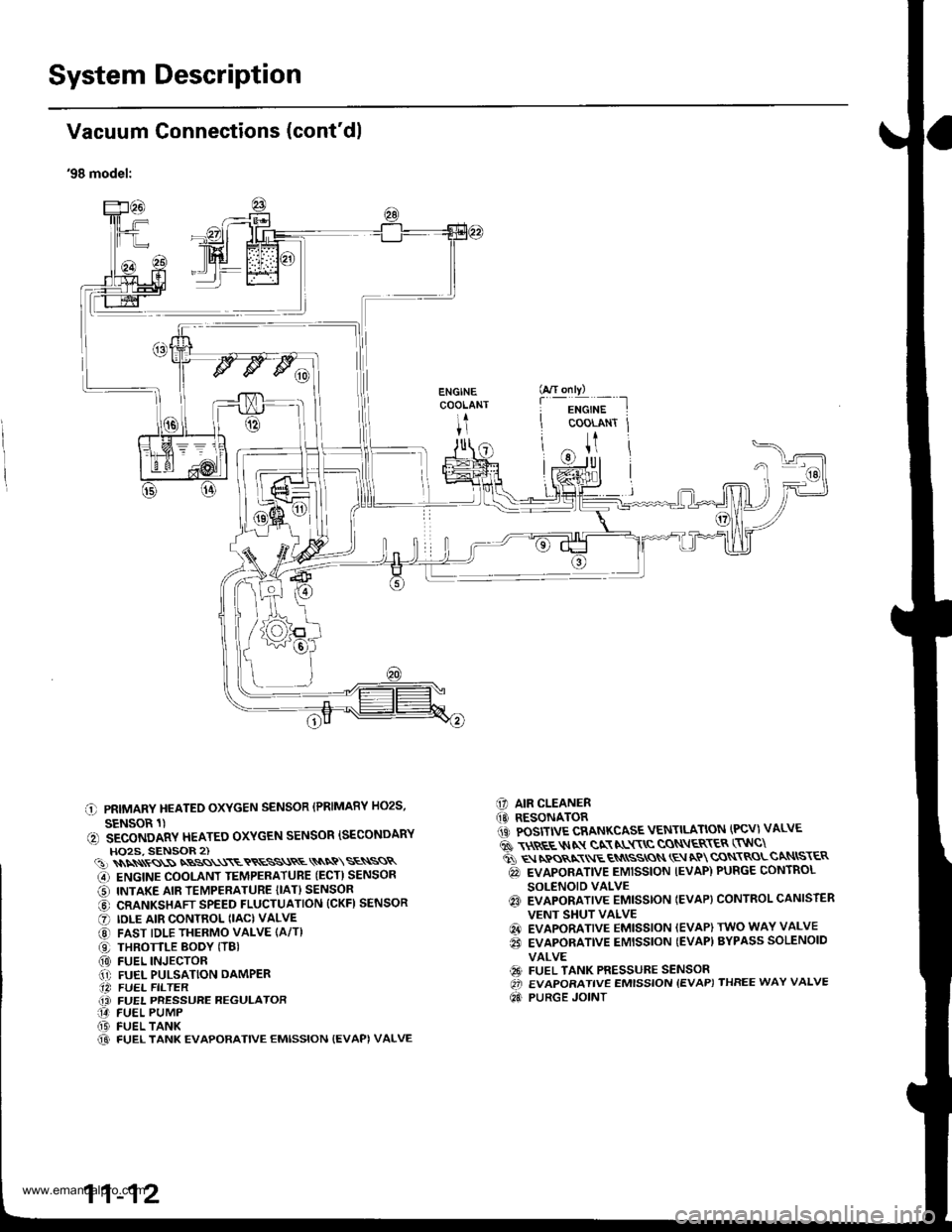

System Description

I

I

I

Vacuum Connections (cont'dl

'98 model:

C PRIMARY HEATEO OXYGEN SENSOR (PRIMARY HO2S,

SENSOR 1)(, SECONDARY HEATEO OXYGEN SENSOR ISECONDARYHO2S, SENSOR 2)(!)\\\\ss\SNBSS\\\ETRESS\RE\\NQ\SE\SSR

G) ENGINE COOLANT TEMPERATUBE (ECT) SENSOR

O INTAKE AIR TEMPERATURE {IAT} SENSOR

@ CRANKSHAFT SPEED FLUCTUATION (CKFI SENSOR

O IDLE AIR CONTROL (IAC) VALVE

@ FAST IDLE THERMO VALVE (A/T)

O THROTTLE BODY (TBI(0) FUEL INJECTOR.1' FUEL PULSATION DAMPER.14 FUEL FILTER(i FUEL PRESSURE REGULATOR14 FUEL PUMP(D FUEL TANK@ FUEL TANK EVAPORATIVE EMISSION {EVAPI VALVE

C] AIR CLEANER(O RESONATOR1iC POSITIVE CRANKCASE VENTILATION (PCV) VALVE

6 \$REE$IN gN NL$\C CON\ER\ER (TNC\

ti q rpos,xr E qN

ssros \E aP cqN\RoLcaNtsr€R

@ EVAPORATIVE EMISSION IEVAP) PURGE CONTROL

SOLENOID VALVEq3 EVAPORATIVE EMISSTON IEVAP} CONTROL CANISTER

VENT SHUT VALVE

@ EVAPORATIVE EMISSION (EVAP) TWO WAY VALVE

€i EVAPORATIVE EMISSION {EVAP) BYPASS SOLENOID

VALVE

€9 FUEL TANK PRESSURE SENSOROi EVAPORATIVE EMISSION {EVAP) THREE WAY VALVE

Qd PURGE JOINT

G/T only)

f

-i*'";-t

COOLANT Jt

U

11-12

www.emanualpro.com

Page 217 of 1395

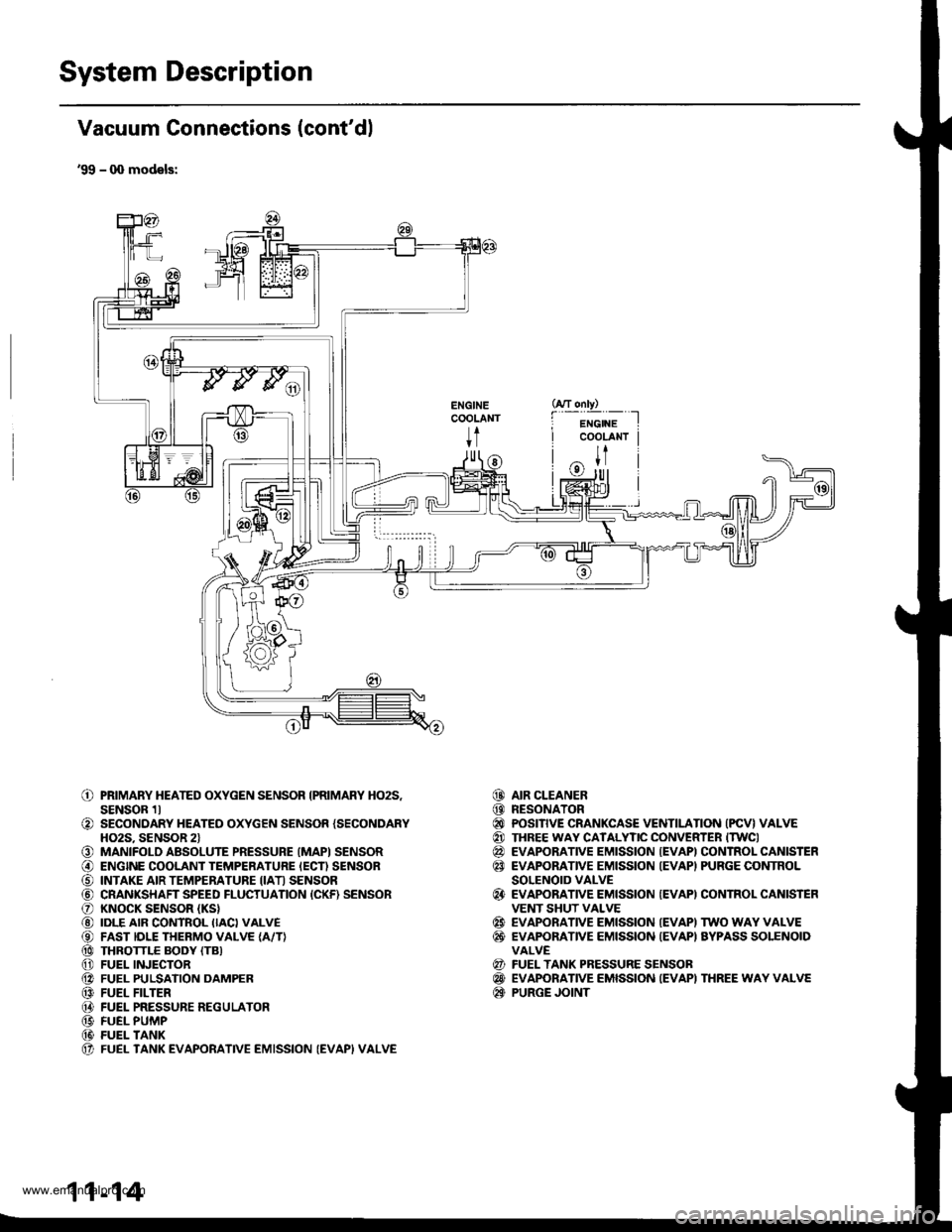

System Description

Vacuum Connections (cont'dl

'99 - q) models:

ENGINECOOLANT

t

o

o

o@

o@@@@@@@@@(t

PRIMARY HEATED OXYGEN SENSOR IPRIMARY HO2S,SENSOR 1lSECONDARY HEATED OXYGEN SENSOR {SECONDARYHO2S. SENSOR 2lMANIFOLD ABSOLUTE PRESSURE (MAPI SENSORENGINE COOLANT TEMPERATURE IECN SENSORINTAKE AIR TEMPERATURE IIATI SENSORCRANKSHAFT SPEED FLUCTUATION {CKF) SENSORKNOCK SENSOR (KS}

IDLE AIR CONTROL IIACI VALVEFAST IDLE THERMO VALVE {A/T}THROTTLE BODY (TB}

FUEL INJECTORFUEL PULSATION DAMPERFUEL FILTERFUEL PRESSURE REGULATORFUEL PUMPFUEL TANKFUEL TANK EVAPORATIVE EMISSION (EVAPI VALVE

AIR CLEANERRESONATORPOSITIVE CRANKCASE VENTILATION (PCV} VALVETHREE WAY CATALYTIC CONVERTER ITWCIEVAPORATIVE EMISSION {EVAPI CONTROL CANISTEREVAPORATIVE EMISSION IEVAPI PURGE CONTROLSOLENOID VALVEEVAPORATIVE EMISSION {EVAPI CONTROL CANISTEFVENT SHUT VALVEEVAPORATIVE EMISSION IEVAPI TWO WAY VALVEEVAPONANVE EMISSION {EVAPI AYPASS SOLENOIDVALVEFUEL TANK PRESSURE SENSOBEVAPORATIVE EMISSION IEVAPI THREE WAY VALVEPURGE JOINT

@@@@@@

@

@@

@@@

11-14

www.emanualpro.com

Page 266 of 1395

Troubleshooting

Troubleshooting Procedures (cont'dl

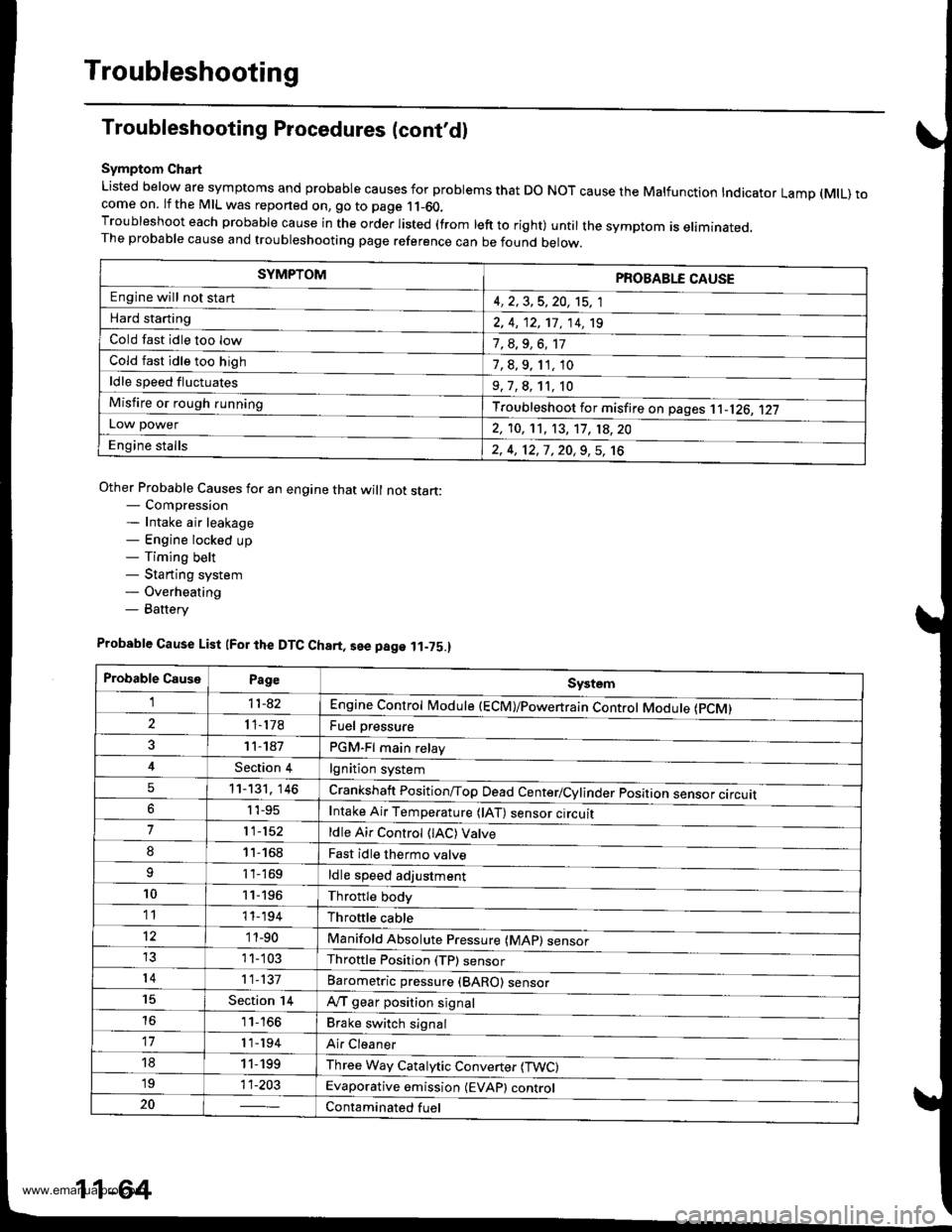

Symptom Chart

Listed below are symptoms and probable causes for problems that DO NOT cause the Malfunction Indicator Lamp (MlL) tocome on. lf the MIL was reported on, go to page 11-60.Troubleshoot each probable cause in the order listed (from left to right) until the symptom is eliminated,The probable cause and troubleshooting page reference can be found below.

Other Probable Causes for an engine that will not start:- Compression- Intake air leakage- Engine locked up- Timing belt- Starting system- Overheating- Battery

SYMPTOMPROBABLE CAUSE

Engine will not sta rt4, 2,3,5,20, 't5, 1

Hard starting2, 4, 12,17, 14, 't9

Cold fast idle too low7, a,9, 6, 17

Cold fast idle too high7,8,9,11,10

ldle speed fluctuates9,7,8, 't1, 10

Misfire or rough runningTroubleshoot for misfire on pages '11-126, 1|21LOl/\/ power2, 10,11, 13, '17, 18,20

Engine stalls2, 4, 12,1,20,9,5, 't6

Probable Cause List (For the DTC Ch8rt, see page ll-75.)

Probable CausePageSystem

Engine controt ruoaute (ecvtffi'I11-42

I 1-178Fuel oressure

PGM-Fl main relav

lgnition system

Crankshatt Position/Top Dead Center/Cylinder position sensor circuit

Intake Air Temperature (lAT) sensor ctrculr

ldle Air Control (lAC) Vatve

Fast idle thermo valve

ldle speed adjustment

Throttle body

Throftle cable

Manifold Absolute P."""rr"ffi

Throftle Position (TP) sensor

Barometric pressur" (gnno-

Ay'T gear position signal

Brake switch signal

Air Cleaner

Three Way Catalytic Converter (TWC)

Evaporative emission (EVAP) control

Contaminated fuel

1 1- 187

Section 4

5't1-'t31,146

6I '�t-95

711-152

81'l-168

1 1- 169

1011-196'1111-'194

12'1 'l -90

1 1- 103

1411-137

15Section 14

161 1- 166

17r 1-194

181 1,199'1911-203

20

11-64

www.emanualpro.com

Page 268 of 1395

Troubleshooting

Troubleshooting Procedures (cont'd)

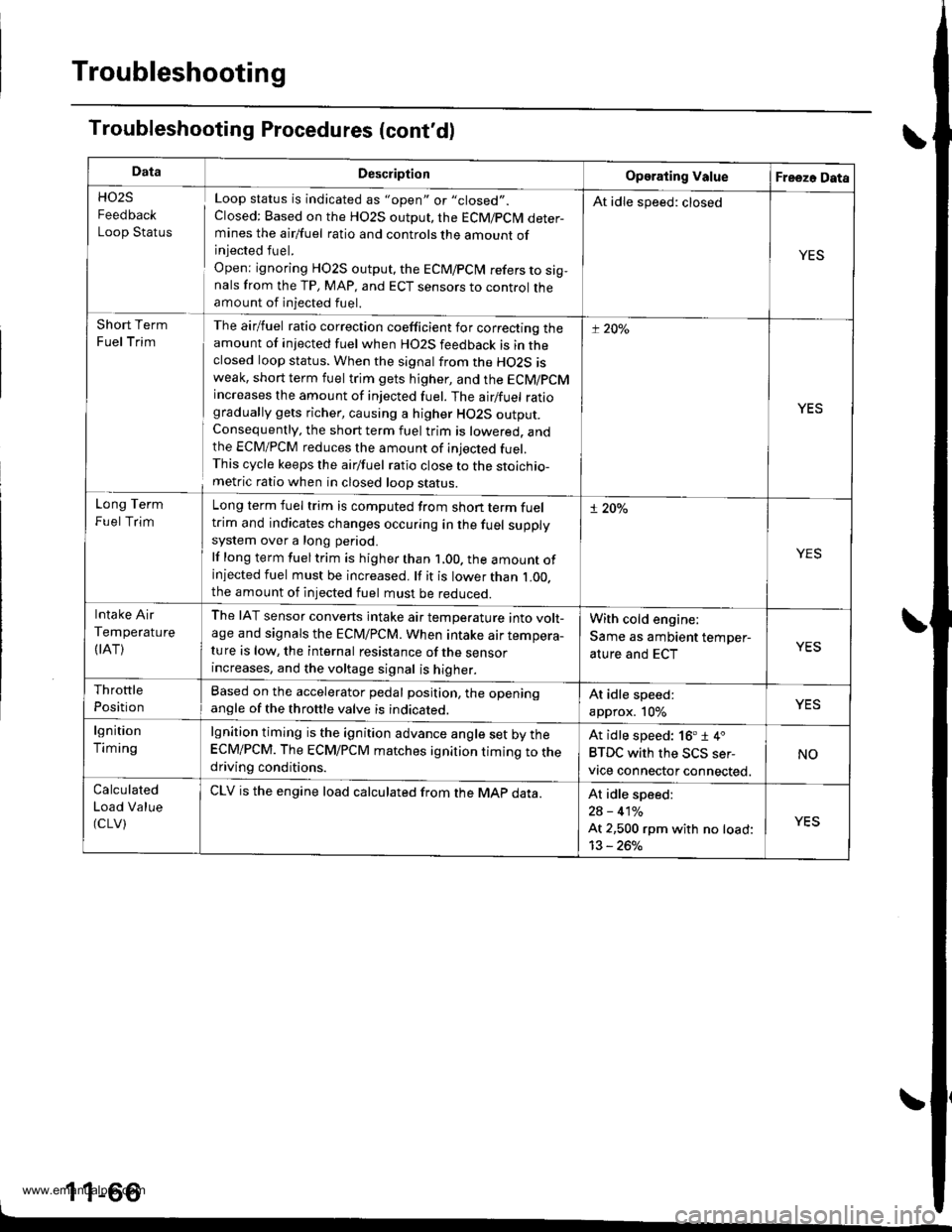

DataDescliptionOperating ValueFreezo Data

HO2S

Feedback

Loop Status

Loop status is indicated as "open" or "closed".

Closed: Based on the HO2S output, the ECM/pCM deter-mines the airlfuel ratio and controls the amount ofinjected fuel.

Open: ignoring HO2S output, the ECM/pCiM refers to sig,nals from the TP, MAP, and ECT sensors to control theamount of injected fuel.

At idle speed: closed

YES

Short Term

Fuel Trim

The airlfuel ratio correction coefficient for correcting theamount of injected fuel when HO2S feedback is in theclosed loop status. When the signal from the HO2S isweak, short term fuel trim gets higher, and the ECM/PCMincreases the amount of injected fuel. The airlfuel ratiogradually gets richer, causing a higher HO2S output.Consequently. the short term fuel trim is lowered. andthe ECM/PCM reduces the amount of injected fuel.This cycle keeps the airfuel ratio close to the stoichio-metric ratio when in closed looD status.

t:20y"

YES

Long Term

Fuel Trim

Long term fuel trim is computed from shon term fueltrim and indicates changes occuring in the fuel supplysystem over a long period.

lf long term fuel trim is higher than 1,00. the amount ofinjected fuel must be increased. lf it is lower than L00.the amount of injected fuel must be reduced.

! 20%

Intake Air

Temperature

(IAT)

The IAT sensor converts intake air temperature into volt-age and signals the ECrU/PCM. When intake air tempera-ture is low, the internal resistance of the sensorincreases, and the voltage signal is higher.

With cold engine:

Same as ambient temper-

ature and ECTYES

Throttle

Position

Based on the accelerator pedal position, the openingangle of the throttle valve is indicateo.At idle speed:

approx. 10%

lgnition

Timing

lgnition timing is the ignition advance angle set by theECM/PCM. The ECM/PCM matches ignition timing to thedriving conditions.

At idle speed: 16'1 4.

BTDC with the SCS ser-

vtce connector connected.

NO

Calculated

Load Value(cLV)

CLV is the engine load calculated from the MAp data.At idle speed:

2A - 410/o

At 2,500 rpm with no load:

13 - 260/o

YES

_

1 1_66

www.emanualpro.com

Page 351 of 1395

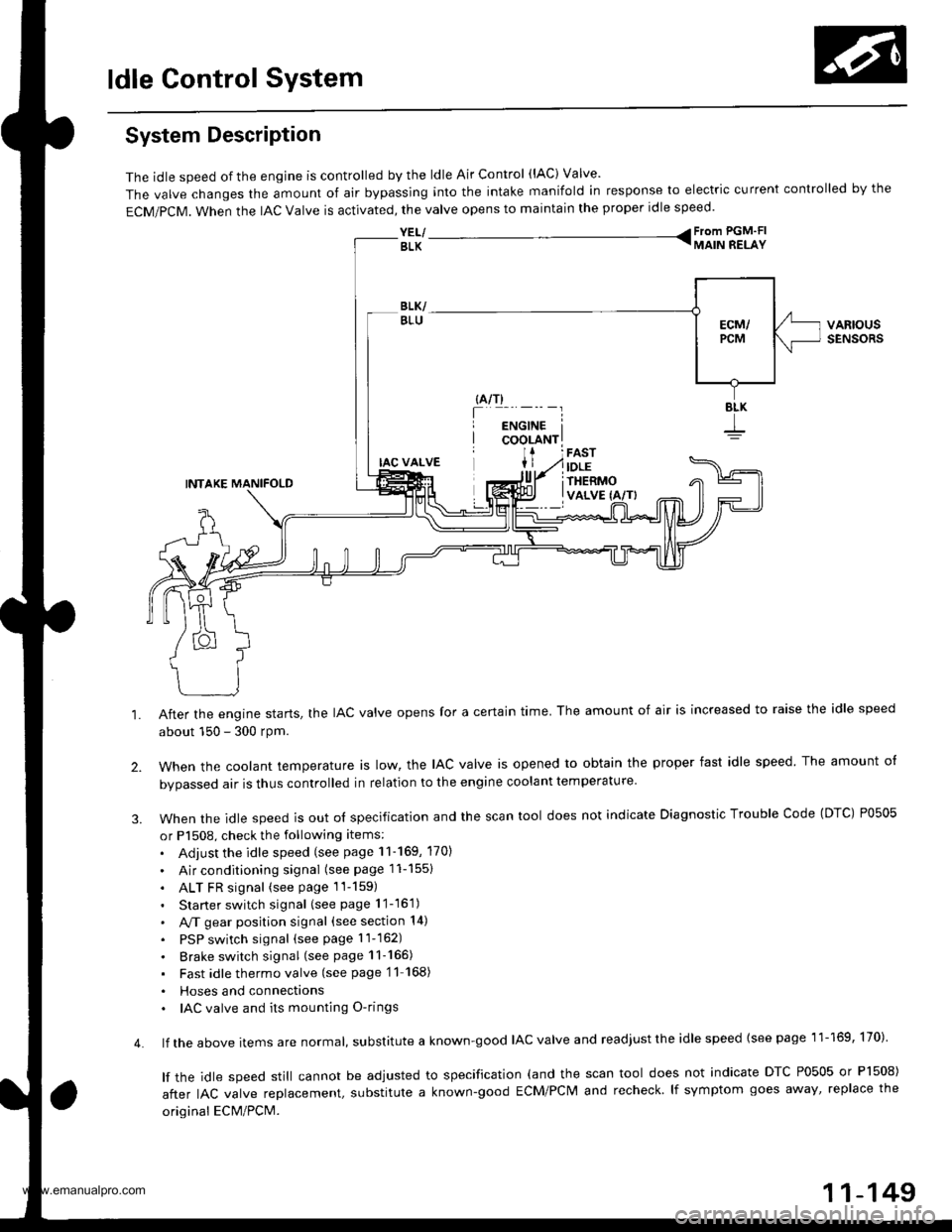

ldle Control System

System Description

The idle speed of the engjne is controlled by the ldle Air Control (lAC) Valve'

The valve changes the amount of air bypassing into the intake manifold in response to electric current controlled by the

ECM/PCM. When the lAc valve is activated, the valve opens to maintain the proper idle speed.

YEL/ From PGM'FI

BLK TMAIN RELAY

VARIOUSSENSORS

4.

IAC VALVE

INTAKE MANIFOLD

After the engine starts, the IAC valve opens for a certain time. The amount of air is increased to raise the idle speed

about 150 - 300 rpm.

when the cootant temperature ts row, the lAc valve is opened to obtain the proper fast idle speed The amount o{

bvoassed air is thus controlled in relation to the engine coolant temperature

When the idle speed is out o{ specification and the scan tool does not indicate Diagnostic Trouble Code (DTC) P0505

or P1508, check the following items:

. Adjust the idle speed (see page 11-169, 170)

. Air conditioning signal (seepagell-1551

. ALT FR signal (see page 1l-159)

. Starter switch signal (see page 11-16'1)

. A,/T gear position signal (see section 14)

. PSP switch signal (seepagell-162)

. Brake switch signal (see page 11-165)

. Fast idlethermovalve (see page'11 168)

. Hoses and connecttons. IAC valve and its mounting O-rings

lf the above items are normat, suDslitute a known-good IAC valve and readjust the idle speed {see page 11-169, 170)

lf the idle speed still cannot be adjusted to specification (and the scan tool does not indicate DTC P0505 or Pl508)

after IAC valve reolacement, substitute a known-good ECM/PCM and recheck lf symptom goes away' replace the

original ECM/PCM.

11-149

www.emanualpro.com

Page 352 of 1395

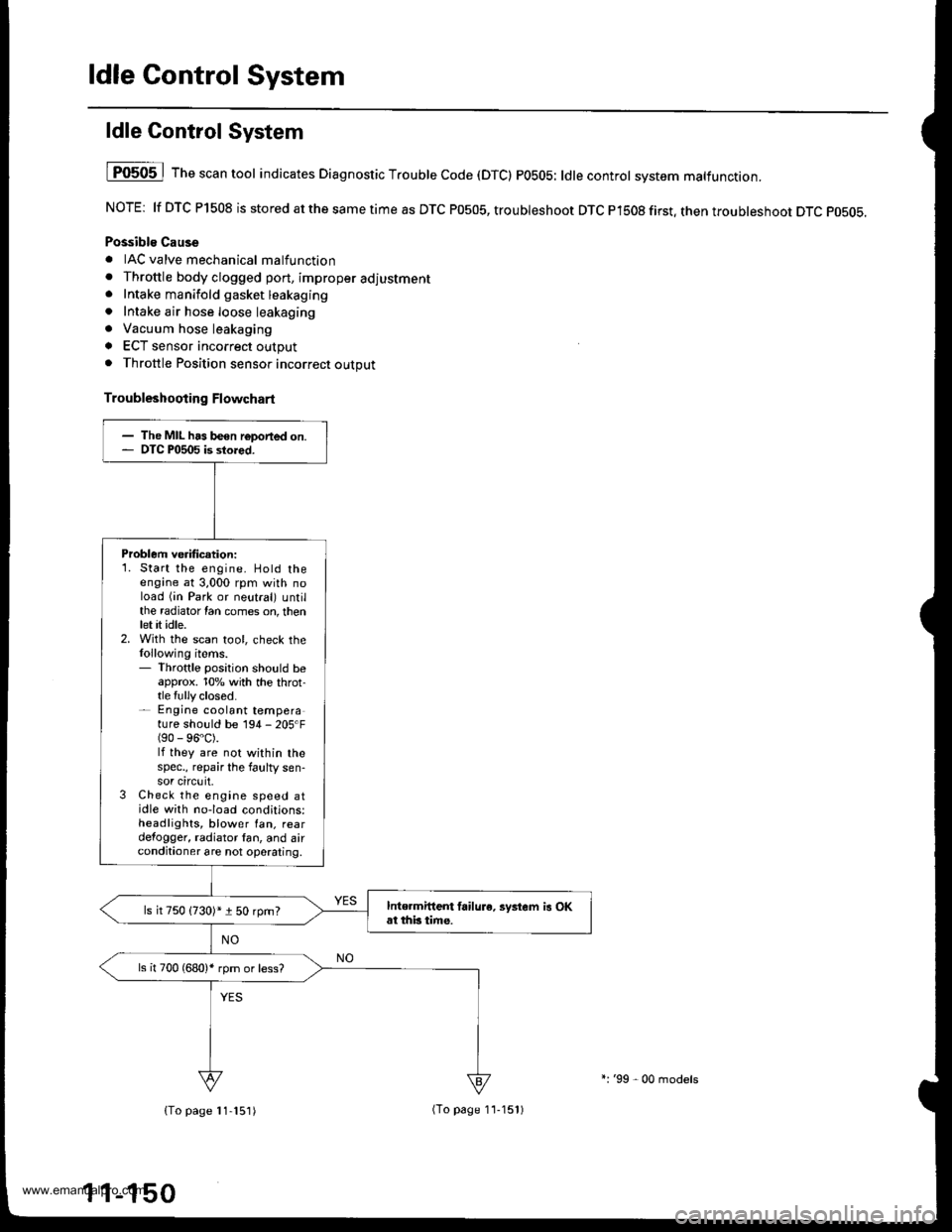

ldle Control System

ldle Control System

I P0505 | The scan tool indicates Diagnostic T.ouble Code (DTCI PO5O5: ldlecontrol svstem mattunction.

NOTE: lf DTC P1508 is stored at the same time as DTC P0505, troubleshoot DTC P1508 first. then troubleshoot DTC p0505.

Possibls Cause

. IAC valve mechanical malfunction. Throttle body clogged port, improper adlustment. Intake manifold gasket leakaging. Intake air hose loose leakaging. Vacuum hose leakaging

a ECT sensor incorrect output. Throttle Position sensor incorrect output

Troubleshooting Flowchart

The MIL has been reDorted on.DTC P0505 is sto.ed.

Problem verificationi1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator Ian comes on, thenlet it idle.2. With the scan tool, check thelollowing items.- Throttle position should beapprox. 10% with the throt-tle {ully closed.- Engine coolant temperature shorJld be 194 - 205'F(90 - 96"C).lf they are not within thespec., repair the faulty sen-sor circuit.3 Check the engine speed atidle with no-load conditions:headlights, blower fan. reardefogger, radiator lan, and airconditioner are not operaling,

Inte.mittent failure. syltem is OKat this time.ls it 750 {730)* i 50 rpm?

ls il 700 (680)' rpm or less?

{To page 11-151)(To page 1'l-151)

l:'99 - 00 models

www.emanualpro.com

Page 353 of 1395

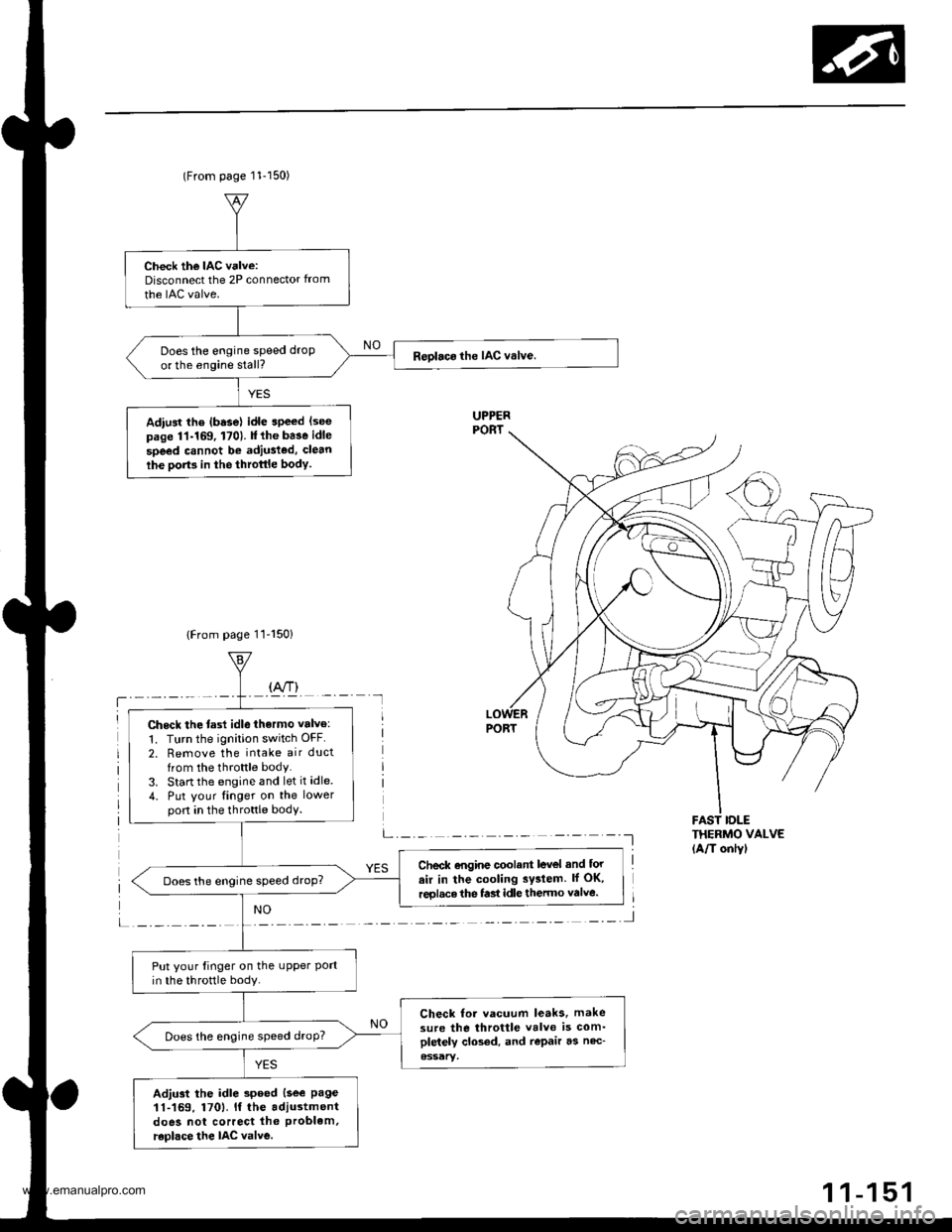

(From page 11-150)

{From page 11-150}

THERMO VALVE(A/T onlyl

Check the IAC valve:Disconnect the 2P connector from

the IAC valve.

Does the engine speed droP

or the engine stall?

Adiust the (basel idl€ speed lseepage 11-169, 1t0). Itihe ba3e idle

speed cannot be adiust€d, clean

the Dorts in the throttle body.

UPPER

Check the tast idle lhermo valve:

1. Turn the ignition switch OFF.

2. Remove the intake air ductfrom the throttle body.3. Start the engine and let it idle.

4. Put your finger on the lowerpon in the throttle body.

Check engine cool.nt level and for

air in the cooling sy3lem. lf OK,

reolace the f.st idle thermo valve.Does the engine speed drop?

Put your Iinger on the uPPer Portin the throttle body.

Check for vacuum leaks, make

sure the throttle valve is com'pletely clo3ed. and repair as nec-Does the engine speed droP?

Adjust the idle spoed lsee Page11-169. 1701. lf the adiustmentdoes not correct lhe problem,

r.olace the IAC valve.

www.emanualpro.com

Page 354 of 1395

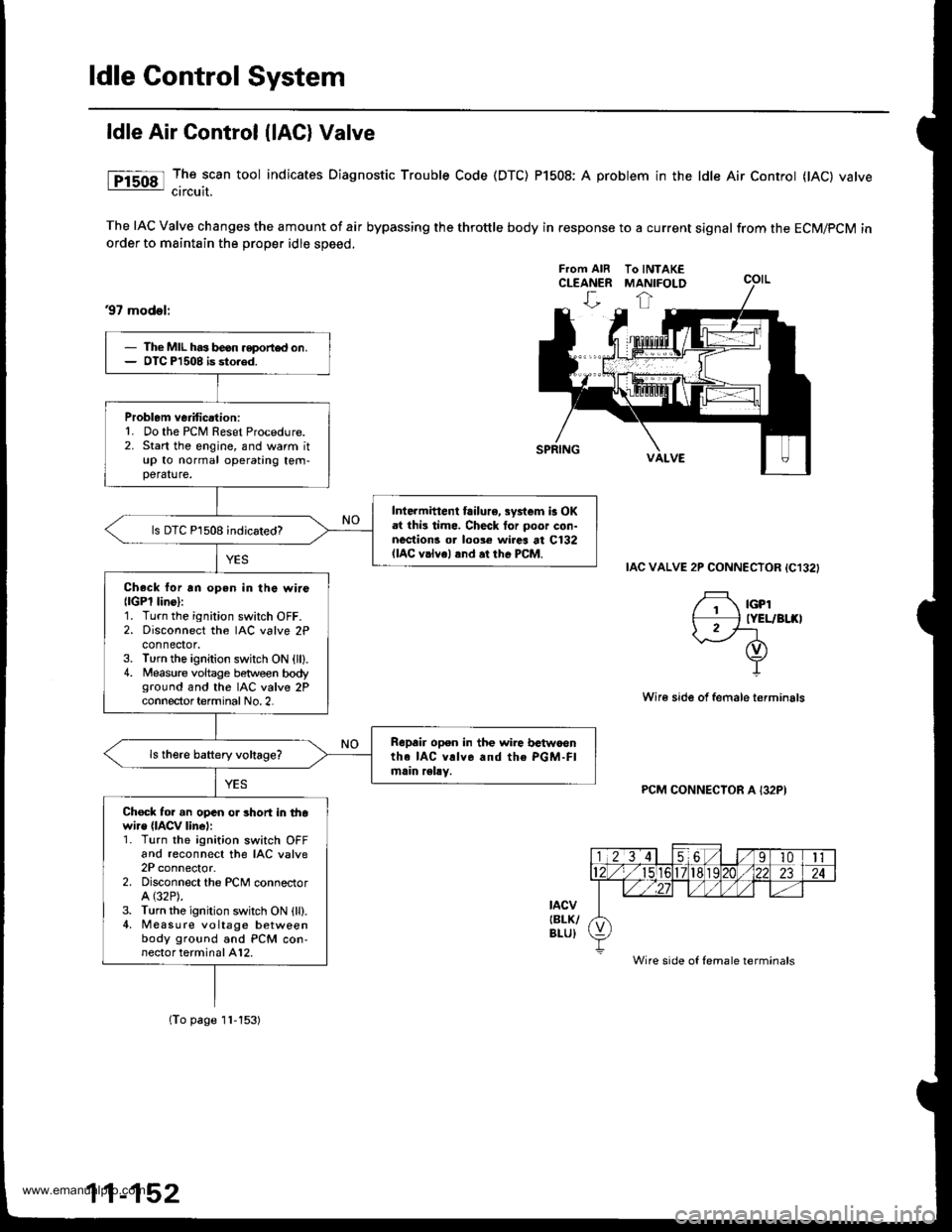

ldle Control System

ldle Air Control llAC) Valve

The scan tool indicates Diagnostic Trouble Code (DTC) Pl508: A probtem in the ldle Air Controt flAC) varvecircuit.

The IAC Valve changes the amount of air bypassing the throttle body in response to a current signal from the ECM/PCM inorder to maintain the proper idle speed.

37 model;

IAC VALVE 2P CONNECTOR {C132}

,f rcp'# IYEL/BI.(II2f-1-d)

Y

Wir€ side of female terminals

PCM CONNECTOR A I32PI

tacvIBLK/BLU)

From AIR To INTAKECLEANER MANIFOLD

Wire side of female terminals

The MIL has beon .eport€d on.OIC Pl508 is sto.ed.

Problem veiification:1. Do the PCM Reset Procedure.2. Start the engine, and warm itup to normal operating tem-perature.

Inte.mittent failure, systcm b OKat thi3 time. Check tor poo. con-nections or loose wircs at C132(lAC v.lvel and at the PCM.

ls DTC Pl508 indicated?

Check lor an open in the wir6{lGPl lins}:1. Turn the ignition switch OFF.2. Disconnect the IAC valve 2Pconnector.3. Turn the ignition switch ON {ll).4. Measure voltage between bodyground and the IAC valve 2Pconnector term inal No.2.

Repair open in the wire trctwoontha IAC v!lv6 and the PGM-Flmain relly.

Chock for an opan o. short in thowi.e (lACv linel:1. Turn the ignition switch OFFand reconnect the IAC valve2P connector.2. Disconnect the PCM conneclorA (32P).

3. Turn the ignition switch ON {ll).4, Measure voltage betweenbody ground and PCM con-nector terminal A12.

{To page 1l-153)

www.emanualpro.com