crank pulley removal HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 114 of 1395

Cylinder Head/Valve Train

Speciaf Tools .............6-2

Valve Clearance

Adiustment ............6-3

Valve Seals

Replacement (cylinder head

removal not requiredl ................. 6-5

Crankshaft Pulley and Pulley Bolt

Replacement .........6-7

Timing Belt

I llustrated lndex ............................... 6-8

Inspection ............., 6-9

Tension Adjustment ........................ 6-9

Removal ...........,..... 6-10

lnstallation .............6-11

Crankshaft Speed Fluctuation (CKFI

Sensor

Replacement .........6-13

Cylinder Head

lllustrated lndex ............................... 6-14

Removal .................6-16

Warpage ................6-27

lnstallation ............. 6-30

Camshafts

lnspection ..............6-22

Valves, Valve Springs and Valve Seals

Removal ................, 6-23

lnstallation ............. 6-29

Valve Guides

Valve Movement ............,,,,.,............ 6-25

Replacement .........6-25

Reaming .................6-27

Valve Seats

Reconditioning ......6-28

www.emanualpro.com

Page 118 of 1395

Valve Seals

Replacement (cylinder head removal not required)

The procedure shown below applies when using the in-

car valve spring compressor (Snap-on YA8845 with

YA8845-2A 7/8" auachment). Use approved eye protec-

tion.

1. Turn the crankshaft so that the No. 1 and the No. 4

pistons are at top dead center (TDC).

2. Remove the cylinder head cover.

3. Remove the distributor.

4. Loosen and disconnect the timing belt from the

camshaft pulleys.

5. Remove the camshaft holder bolts. then remove the

camshaft holders, the camshafts and rocker arms.

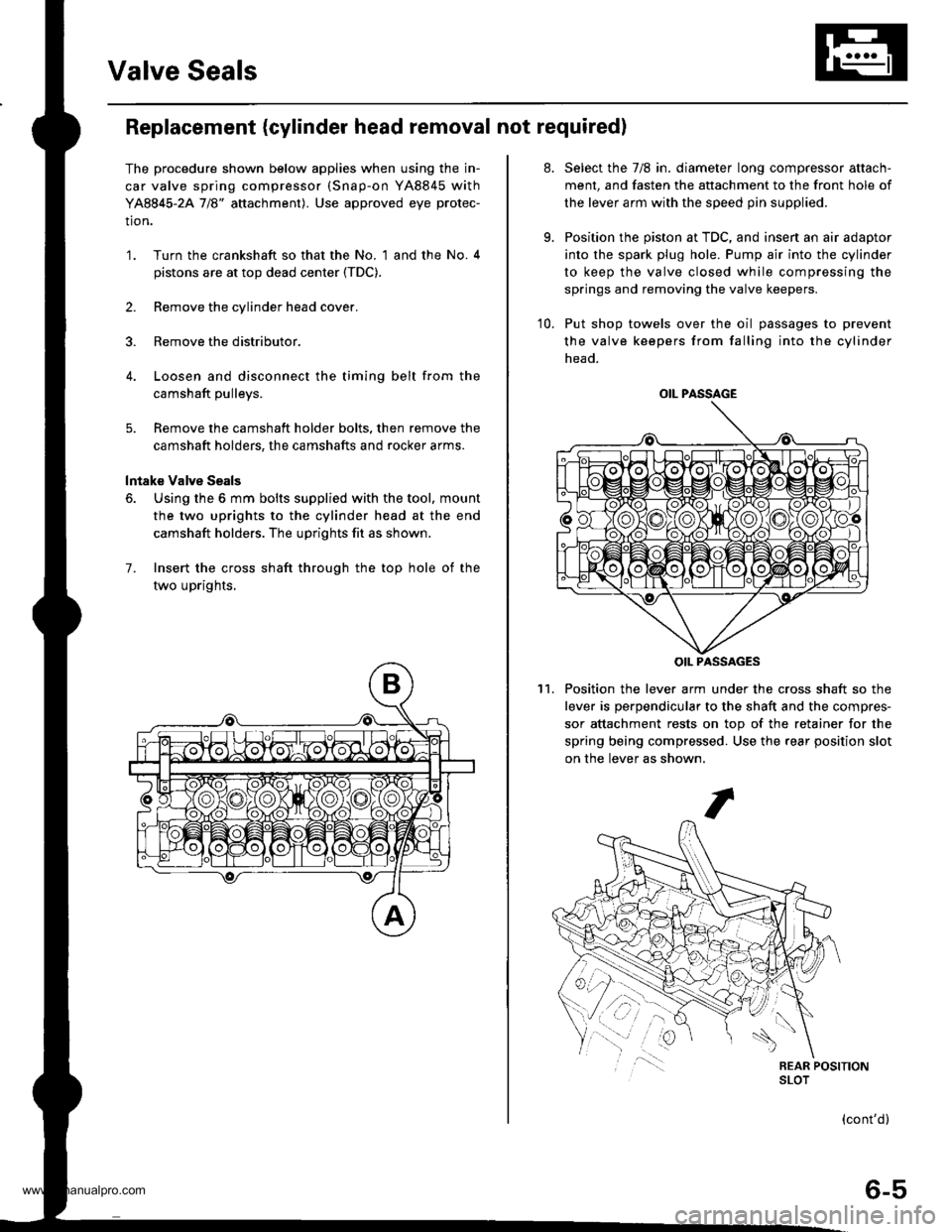

lntake Valve Seals

6. Using the 6 mm bolts supplied with the tool, mount

the two uprights to the cylinder head at the end

camshaft holders. The uprights fit as shown.

7. Insert the cross shaft through the top hole of the

two uprights,

at.

9.

Select the 7/8 in. diameter long compressor attach-

ment, and fasten the attachment to the front hole of

the lever arm with the speed pin supplied.

Position the piston at TDC, and insen an air adaptor

into the spark plug hole. Pump air into the cylinder

to keep the valve closed while compressing the

springs and removing the valve keepers.

10. Put shop towels over the oil passages to prevent

the valve keepers from falling into the cylinder

head.

Position the lever arm under the cross shaft so the

lever is perpendicular to the shaft and the compres-

sor attachment rests on top of the retainer for the

spring being compressed. Use the rear position slot

on the lever as shown,

't1.

OIL PASSAGE

OIL PASSAGES

(cont'd)

6-5

www.emanualpro.com

Page 121 of 1395

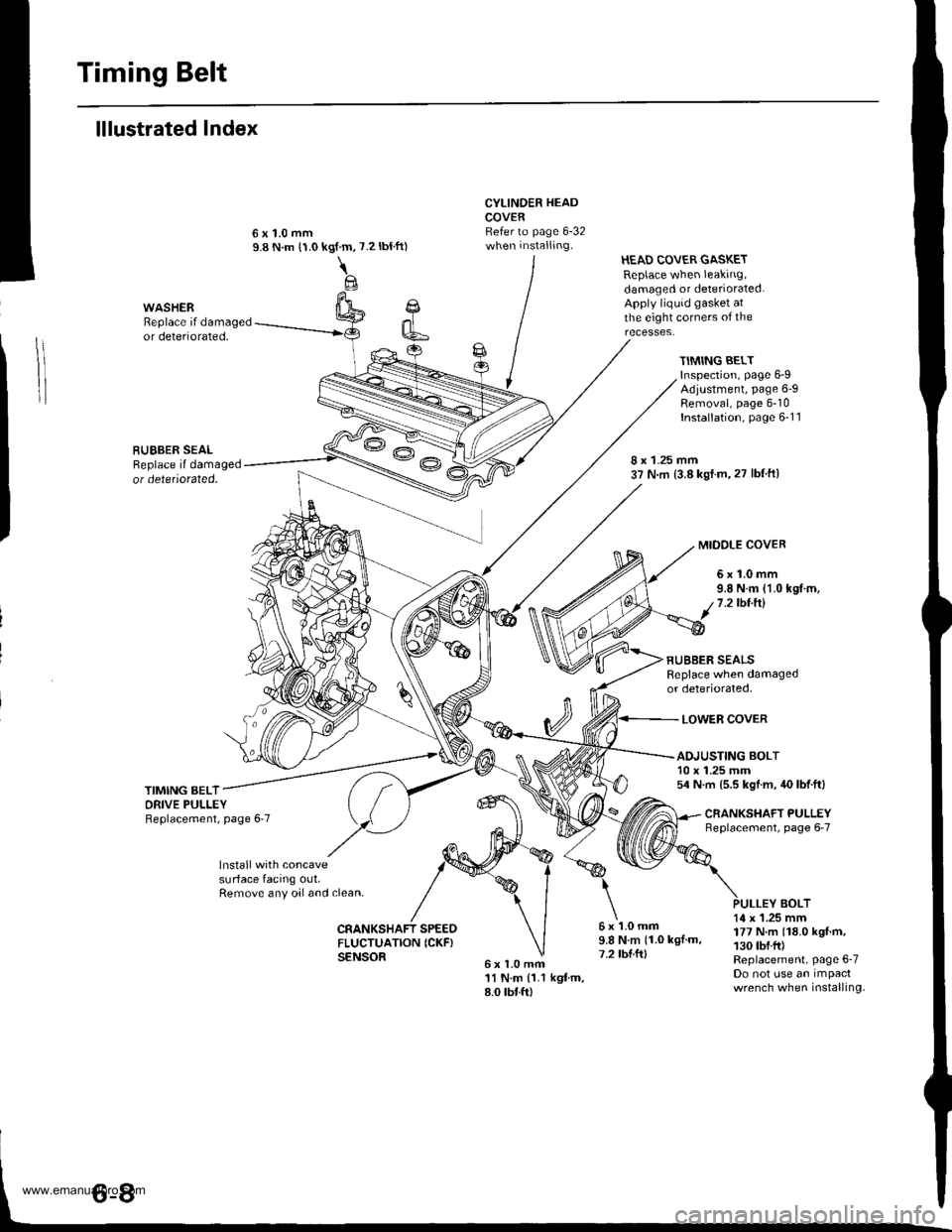

Timing Belt

lllustrated Index

Cl

k6

CYLINDER HEADCOVERRefer to page 6-32when installing.

6x1.0mfi11 N.m {1.1 kgtm,8.0 rbtft)

HEAD COVER GASKETReplace when leaking,damaged or deteriorated.Apply liquid gasket atthe eight corners of theWASHERReplace if damagedor deteriorated,

RUEBER SEALReplace il damagedot detetiorated.

kgf.m,

\@

7.2 tbtft)

TIMING BELTInspection, page 6-9Adjustment, page 6-9Removal, page 6-10Installation, page 6-1 1

8 x 1.25 mm37 N.m (3.8 kst.m,27 lbf ftl

MIDOLE COVER

6x1.0mm9.8 N.m {1.0 kgf.m,1.2lbt.ftl

RUBBER SEALSReplace when damagedor deteriorated,

LOWER COVER

TIMING BELTORIVE PULLEYReplacement, page 6'7

ADJUSTING BOLT10 x 1.25 mm54 N.m (5.5 kgl.m, 40 lbf.ft)

CNANKSHAFT PULLEYneplacement, page 6-7

lnstall with concavesurface facing out,Remove any oal and clean,BOLT

CRANKSHAFT SPEEOFLUCTUATION ICKF}SENSOR

6x1.0mm9.8Nm(1.0kgl.m,7.2 tbl.ft)

14 x 1.25 mm177 N.m (18.0 kgf'm,130 tbf.fr)Replacement, Page 6-7Do not use an impactwrench when installing.

www.emanualpro.com

Page 123 of 1395

Timing Belt

Removal

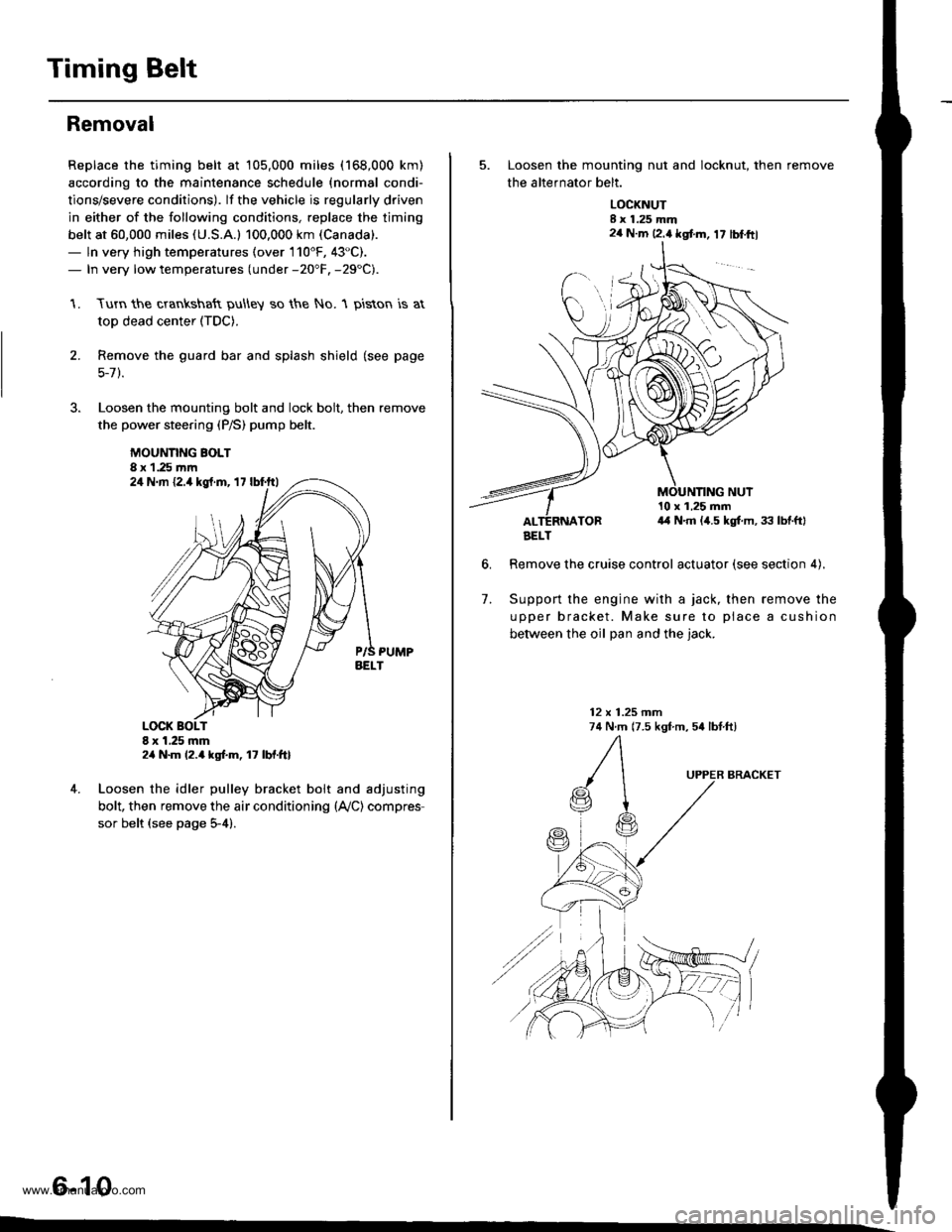

Replace the timing belt at 105,000 miles (168,000 km)

according to the maintenance schedule {normal condi-

tions/severe conditions). lf the vehicle is regularly driven

in either of the following conditions, replace the timing

belt at 60,000 miles (U.S.A.l 100.000 km (Canada).

- ln very high temperatures (over 110'F, 43"C).- In very low temperatures (under -20"F. -29"C).

Turn the crankshaft pu\ley so the No. 1 piston is at

top dead center (TDC).

Remove the guard bar and splash shield (see page

5-7 ).

Loosen the mounting bolt and lock bolt. then remove

the power steering (P/S) pump belt.

MOUNNNG BOLT8 x 1.25 rnm

1.

2.

,l

4. Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (lVC) compres

sor belt (see page 5-4).

6-10

24 N.m {2.4 kgt.m, 17 lbf.ftl

24 N.m 12.4 kgf.m, lt lbf.ftl

5. Loosen the mounting nut and locknut, then remove

the altefnator belt.

LOCKNUTI x 1.25 mm2a N.m 12.4 kgt m, 17 lblftl

6.

10 x 1,25 mm4,1 N.m (,1.5 kgt m, 33 lbtftl

Remove the cruise control actuator (see section 4).

Support the engine with a jack, then remove the

upper bracket. Make sure to place a cushion

between the oil Dan and the iack.

12 x 1.25 mm74 N.m (7.5 kgf m, 54 lbtftl

7.

BRACKET

AELT

www.emanualpro.com

Page 124 of 1395

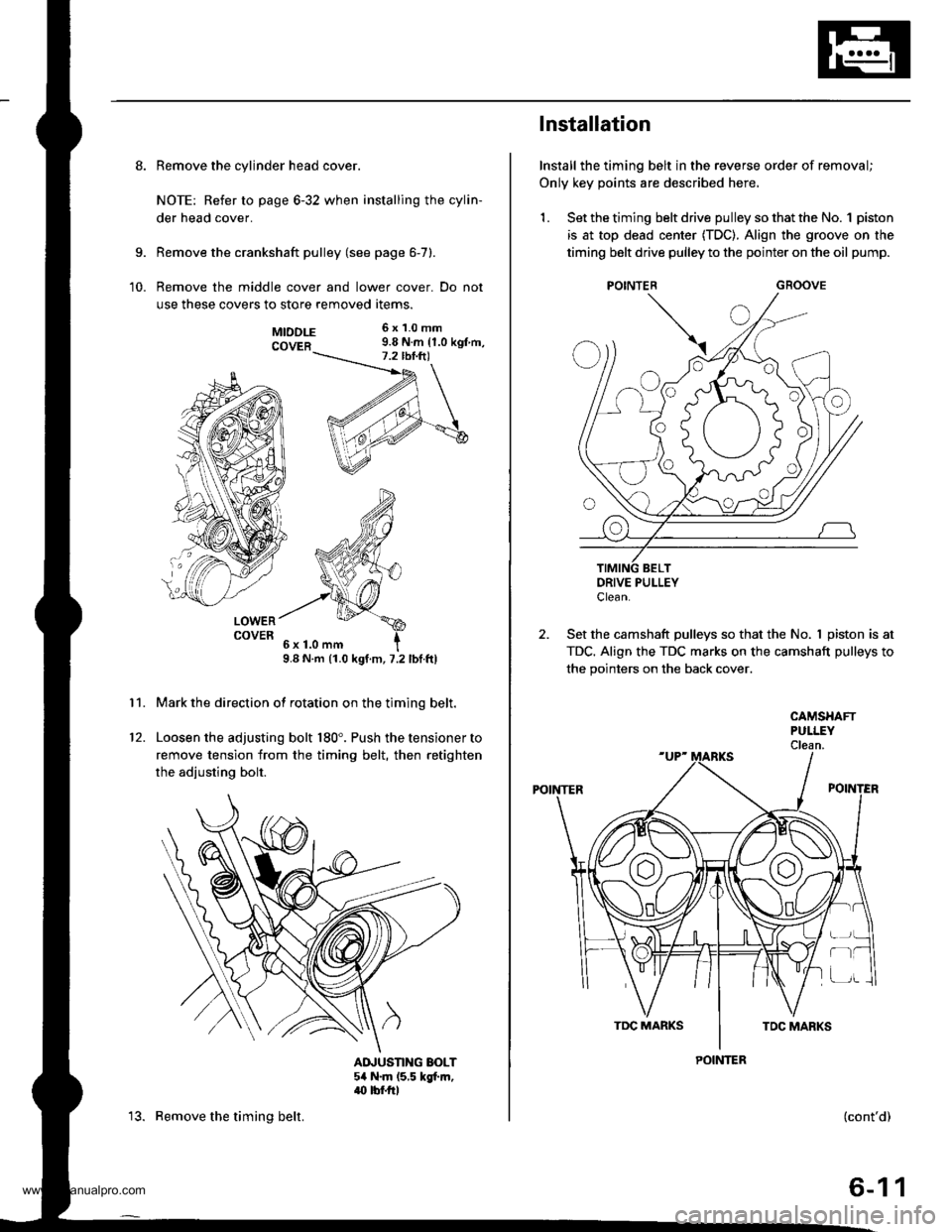

8. Remove the cylinder head cover.

NOTE: Refer to page 6-32 when installing the cylin-

der head cover.

Remove the crankshaft pulley (see page 6-7).

Remove the middle cover and lower cover. Do not

use these covers to store removed items.

9.

10.

11.

MTDDLE 6x1.0mm

COVER 9.8 N.m {1.0 kgt m,

LOWERCOVER

9.8 N.m (1.0 kgt.m, 7.2 lbf.ftl

Mark the direction of rotation on the timing belt.

Loosen the adjusting bolt 180'. Push the tensioner to

remove tension from the timing belt, then retighten

the adiusting bolt.

AINUSTING BOLT54 N.m (5,5 kgt m,.(} tbf.rrl

12.

13. Remove the timing belt.

Installation

Install the timing belt in the reverse order of removal;

Only key points are described here,

1. Set the timing belt drive pulley so that the No. 1 piston

is at top dead center (TDC). Align the groove on the

timing belt drive pulley to the pointer on the oil pump.

GROOVE

DRIVE PULLEYClean.

2. Set the camshaft pulleys so that the No. I piston is at

TDC. Align the TDC marks on the camshaft pulleys to

the pointers on the back cover.

POINTER

CAMSHAFTPULLEYClean.

POINTER

r-t

(cont'd)

6-11

www.emanualpro.com

Page 126 of 1395

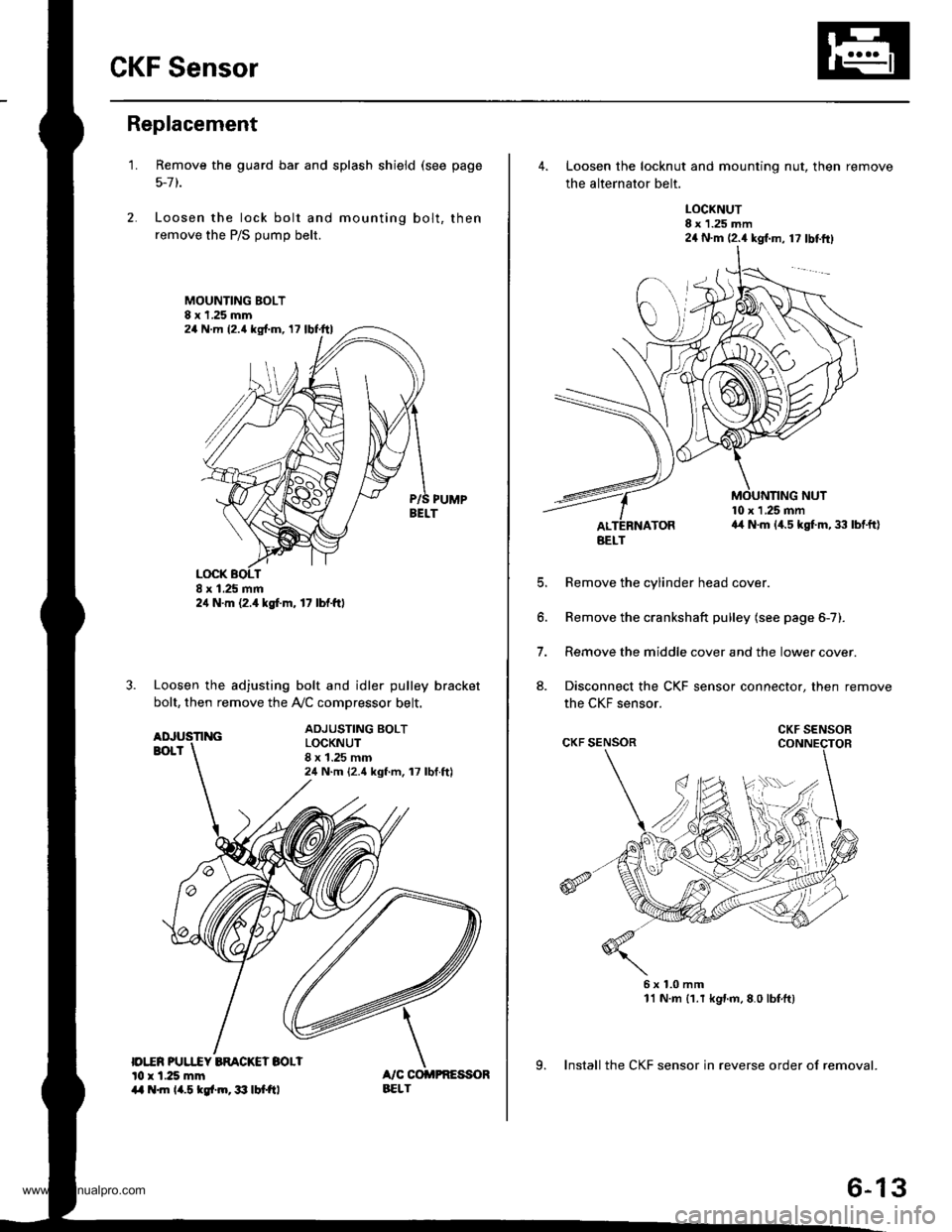

CKF Sensor

Replacement

1.

|o|'ln PUUCY BMCKET SOLIl0 r 1.25 mm14 .m 14.5 kgl.m,3:' lbtftl

Remove the guard bar and splash shield (see page

5-7 t.

Loosen the lock bolt and mounting bolt, then

remove the P/S pump belt.

MOUNTING BOLT8 x 1.25 mm

PUMPBELT

Loosen the adjusting bolt and idler pulley bracket

bolt, then remove the Ay'C comDressor belt.

ADJUSTING BOLTLOCKNUT8 x 1.25 mm24 N.m {2.4 kgf.m, 17 lbf.ft)

24 N.m (2.{ kgf.m, 17 lbf.ttl

24 N.m 12.4 lgf.m, 17 lbl.ftl

4. Loosen the locknut and mounting nut, then remove

the alternator belt.

LOCKNUT8 x 1.25 mm24 N.m (2.4 kgl.m, 17 lbtftl

10 x 1 .25 mma4 N.m (4.5 kgt m, 33 lbtft)

E

6.

7.

aJ.

Remove the cylinder head cover.

Remove the crankshaft pulley (see page 6-7).

Remove the middle cover and the lower cover.

Disconnect the CKF sensor connector, then remove

the CKF sensor.

6x1.0mm11 N.m {1.r kgnm,8.0 lbfft)

9. Install the CKF sensor in reverse order of removal.

BELT

CKF SENSOR

6-13

www.emanualpro.com

Page 688 of 1395

Transmission

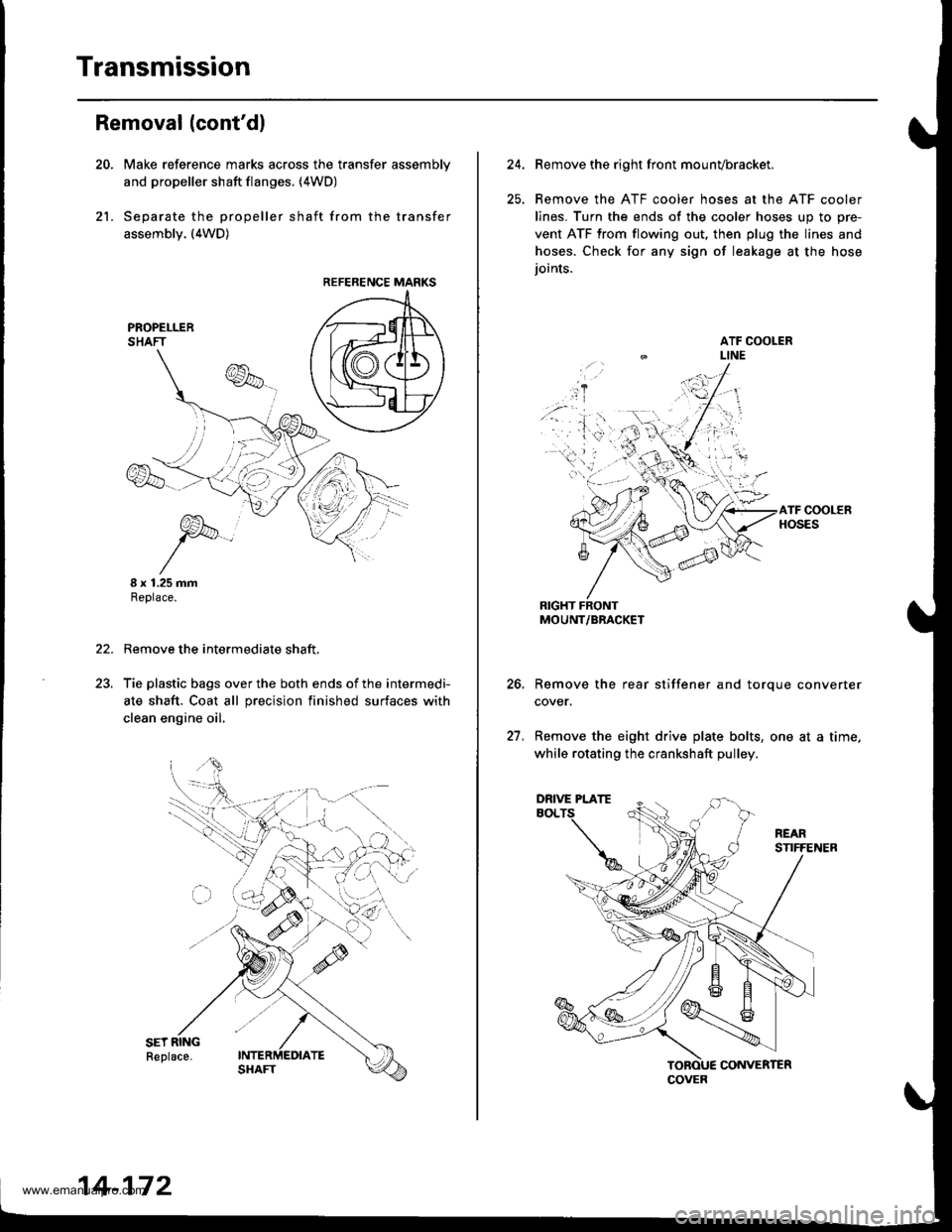

21.

Removal (cont'dl

Make reference marks across the transfer assemblv

and propeller shaft flanges. (4WD)

Separate the propeller shaft from the transfer

assembly. (4WD)

I x 1.25 mmReplace.

Remove the intermediate shaft,

Tie plastic bags over the both ends of the intermedi-

ate shaft. Coat all precision finished surfaces with

clean engine oil.

22.

REFERENCE MARKS

14-172

24.Remove the right front mounvbracket.

Remove the ATF cooler hoses at the ATF cooler

lines. Turn the ends of the cooler hoses uo to ore-

vent ATF from flowing out, then plug the lines and

hoses. Check for any sign of leakage at the hose

ioints.

RIGHT FRONTMOUNT/BRACKET

Remove the rear stiffener and torque converter

cover.

Remove the eight drive plate bolts, one at a time.

while rotating the crankshaft pulley.

27.

COVER

DRIVE PLATE

www.emanualpro.com