lock HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 322, PDF Size: 4.64 MB

Page 215 of 322

Brak

e an d Clutc h Fluid , Powe r Steerin g

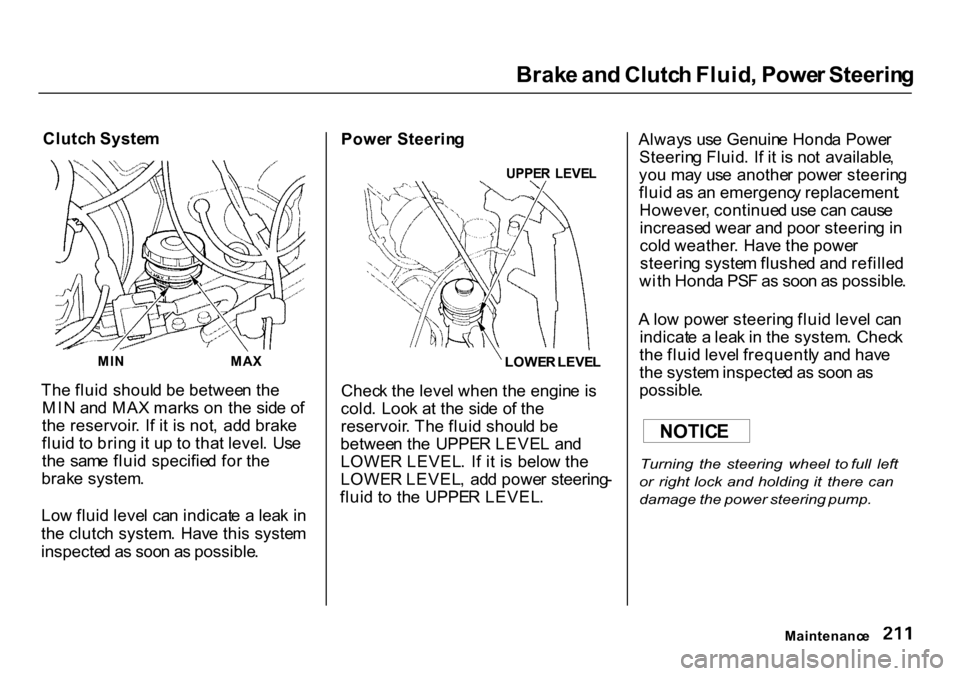

Clutc h Syste m

MI N

MAX

Th e flui d shoul d b e betwee n th e

MI N an d MA X mark s o n th e sid e o f

th e reservoir . I f i t i s not , ad d brak e

flui d t o brin g it u p t o tha t level . Us e

th e sam e flui d specifie d fo r th e

brak e system .

Lo w flui d leve l ca n indicat e a lea k i n

th e clutc h system . Hav e thi s syste m

inspecte d a s soo n a s possible . Powe

r Steerin g

UPPER LEVE L

LOWE R LEVE L

Chec k th e leve l whe n th e engin e i s

cold . Loo k a t th e sid e o f th e

reservoir . Th e flui d shoul d b e

betwee n th e UPPE R LEVE L an d

LOWE R LEVEL . I f i t i s belo w th e

LOWE R LEVEL , ad d powe r steering -

flui d t o th e UPPE R LEVEL . Alway

s us e Genuin e Hond a Powe r

Steerin g Fluid . I f i t i s no t available ,

yo u ma y us e anothe r powe r steerin g

flui d a s a n emergenc y replacement .

However , continue d us e ca n caus e

increase d wea r an d poo r steerin g in

col d weather . Hav e th e powe r

steerin g syste m flushe d an d refille d

wit h Hond a PS F a s soo n a s possible .

A lo w powe r steerin g flui d leve l ca n

indicat e a lea k in th e system . Chec k

th e flui d leve l frequentl y an d hav e

th e syste m inspecte d a s soo n a s

possible .

Turning the steering wheel to full left

or right lock and holding it there can

damage the power steering pump.

Maintenanc e

NOTIC

E

Page 222 of 322

Wipe

r Blade s

BLAD E

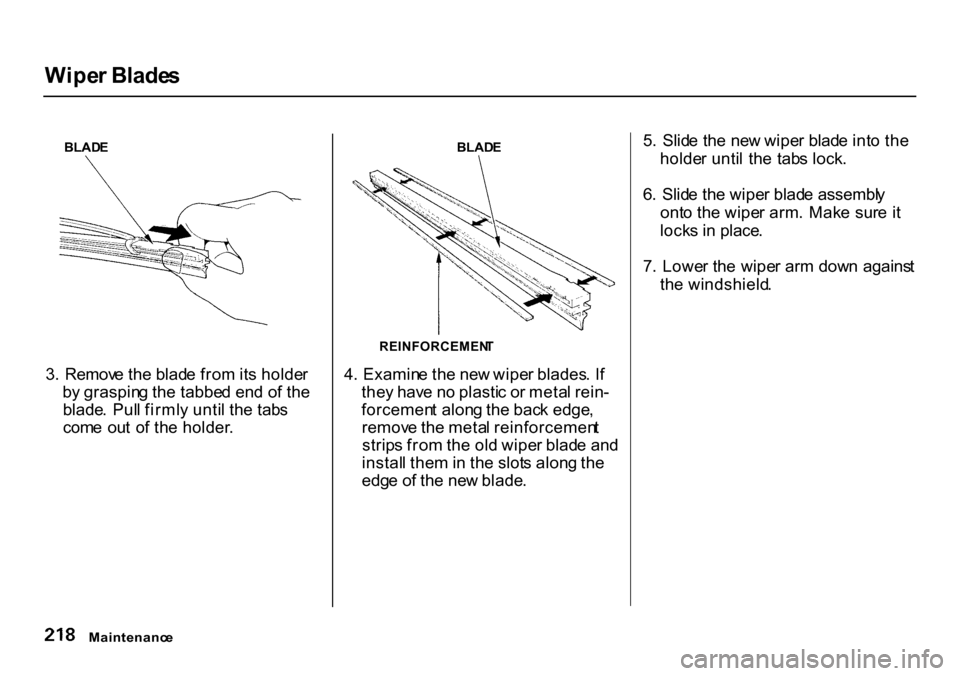

3 . Remov e th e blad e fro m it s holde r

b y graspin g th e tabbe d en d o f th e

blade . Pul l firml y unti l th e tab s

com e ou t o f th e holder .

BLAD

E

4 . Examin e th e ne w wipe r blades . I f

the y hav e n o plasti c o r meta l rein -

forcemen t alon g th e bac k edge ,

remov e th e meta l reinforcemen t

strip s fro m th e ol d wipe r blad e an d

instal l the m in th e slot s alon g th e

edg e o f th e ne w blade . 5

. Slid e th e ne w wipe r blad e int o th e

holde r unti l th e tab s lock .

6 . Slid e th e wipe r blad e assembl y

ont o th e wipe r arm . Mak e sur e i t

lock s i n place .

7 . Lowe r th e wipe r ar m dow n agains t

th e windshield .

Maintenanc e

REINFORCEMEN

T

Page 238 of 322

Light

s

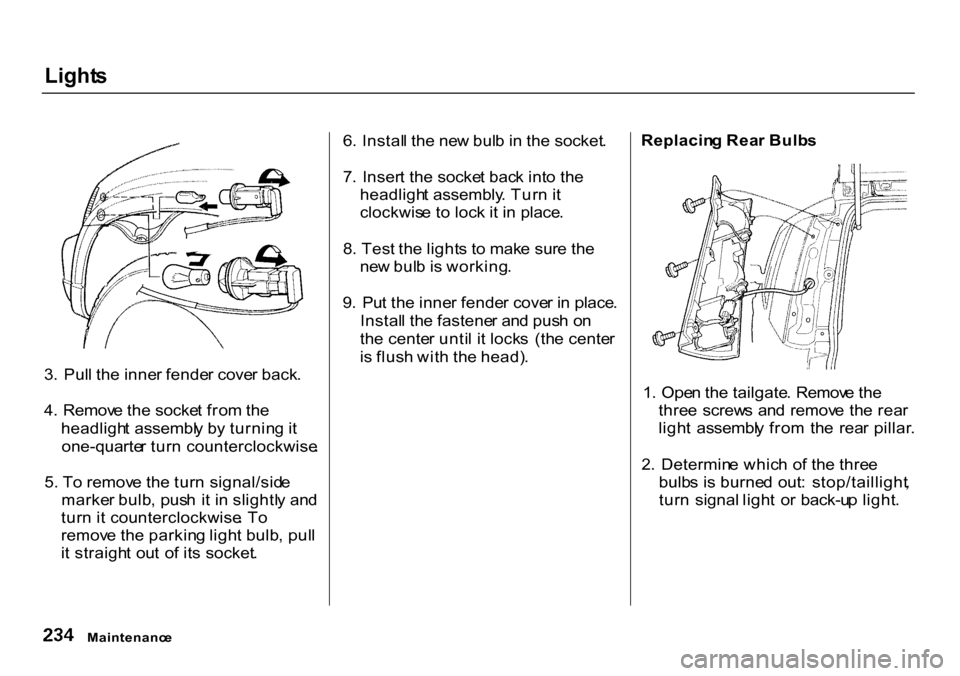

3 . Pul l th e inne r fende r cove r back .

4 . Remov e th e socke t fro m th e

headligh t assembl y b y turnin g it

one-quarte r tur n counterclockwise .

5 . T o remov e th e tur n signal/sid e

marke r bulb , pus h i t i n slightl y an d

tur n i t counterclockwise . T o

remov e th e parkin g ligh t bulb , pul l

i t straigh t ou t o f it s socket . 6

. Instal l th e ne w bul b in th e socket .

7 . Inser t th e socke t bac k int o th e

headligh t assembly . Tur n it

clockwis e t o loc k i t i n place .

8 . Tes t th e light s t o mak e sur e th e

ne w bul b is working .

9 . Pu t th e inne r fende r cove r i n place .

Instal l th e fastene r an d pus h o n

th e cente r unti l i t lock s (th e cente r

i s flus h wit h th e head) . Replacin

g Rea r Bulb s

1 . Ope n th e tailgate . Remov e th e

thre e screw s an d remov e th e rea r

ligh t assembl y fro m th e rea r pillar .

2 . Determin e whic h o f th e thre e

bulb s i s burne d out : stop/taillight ,

tur n signal light o r back-u p light .

Maintenanc e

Page 239 of 322

Light

s

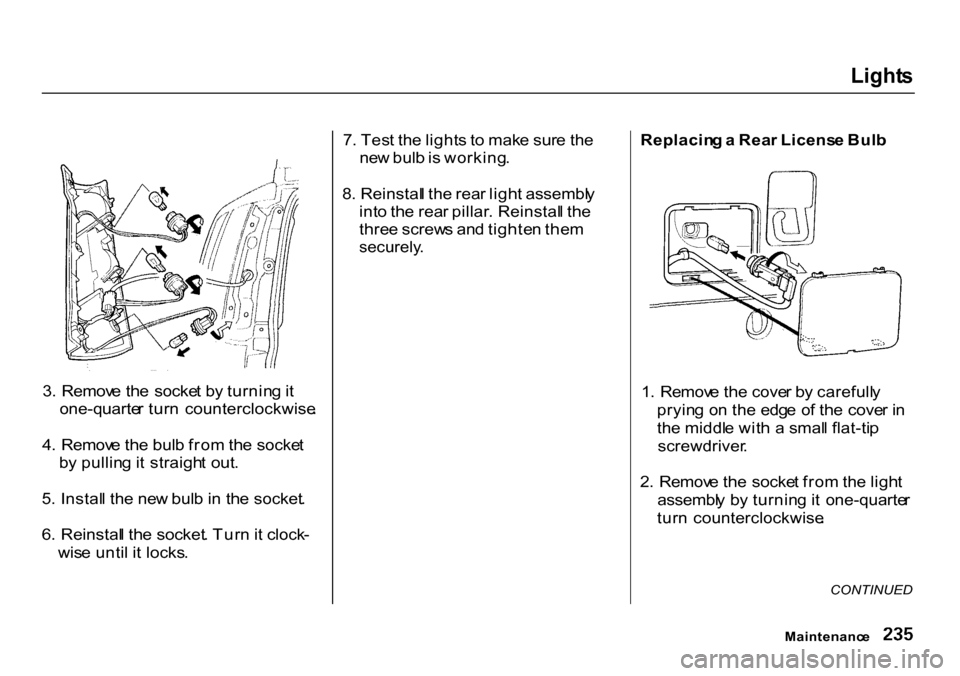

3 . Remov e th e socke t b y turnin g it

one-quarte r tur n counterclockwise .

4 . Remov e th e bul b fro m th e socke t

b y pullin g it straigh t out .

5 . Instal l th e ne w bul b in th e socket .

6 . Reinstal l th e socket . Tur n it clock -

wis e unti l i t locks . 7

. Tes t th e light s t o mak e sur e th e

ne w bul b is working .

8 . Reinstal l th e rea r ligh t assembl y

int o th e rea r pillar . Reinstal l th e

thre e screw s an d tighte n the m

securely .

Replacin

g a Rea r Licens e Bul b

1 . Remov e th e cove r b y carefull y

pryin g o n th e edg e o f th e cove r i n

th e middl e wit h a smal l flat-ti p

screwdriver .

2 . Remov e th e socke t fro m th e ligh t

assembl y b y turnin g it one-quarte r

tur n counterclockwise .

CONTINUED

Maintenanc e

Page 240 of 322

Light

s

3 . Pul l th e bul b straigh t ou t o f it s

socket . Pus h th e ne w bul b in unti l

i t bottom s in th e socket .

4 . Tur n o n th e parkin g light s an d

chec k tha t th e ne w bul b is

working .

5 . Reinstal l th e socket . Sna p th e

cove r bac k in place .

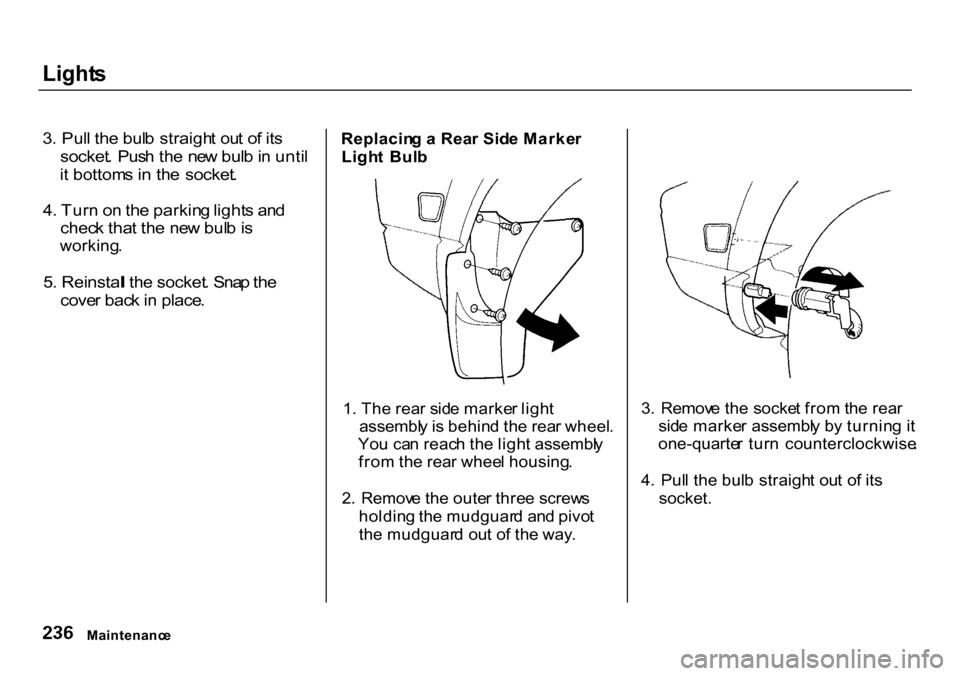

Replacin

g a Rea r Sid e Marke r

Ligh t Bul b

1 . Th e rea r sid e marke r ligh t

assembl y is behin d th e rea r wheel .

Yo u ca n reac h th e ligh t assembl y

fro m th e rea r whee l housing .

2 . Remov e th e oute r thre e screw s

holdin g th e mudguar d an d pivo t

th e mudguar d ou t o f th e way . 3

. Remov e th e socke t fro m th e rea r

sid e marke r assembl y b y turnin g i t

one-quarte r tur n counterclockwise .

4 . Pul l th e bul b straigh t ou t o f it s

socket.

Maintenanc e

Page 241 of 322

Light

s

5 . Instal l th e ne w bul b in th e socket.

6. Inser t th e socke t bac k int o th e

rea r sid e marke r ligh t assembly .

Tur n it clockwis e t o loc k i t i n place .

7 . Tes t th e light s t o mak e sur e th e

ne w bul b is working .

8 . Pu t th e mudguar d bac k i n plac e

an d secur e i t wit h th e thre e

screws .

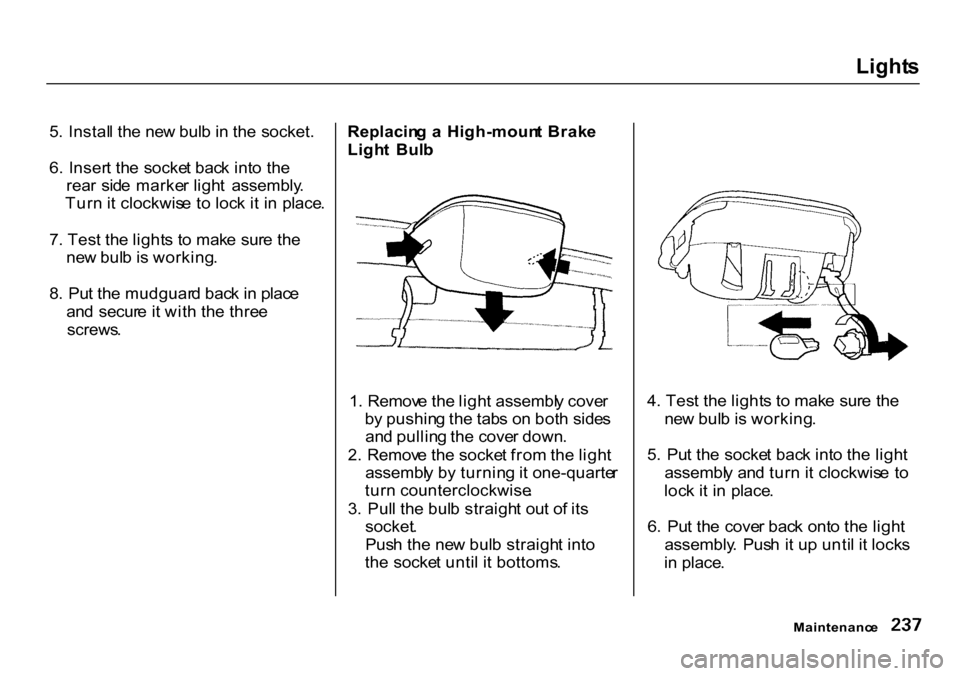

Replacin

g a High-moun t Brak e

Ligh t Bul b

1 . Remov e th e ligh t assembl y cove r

b y pushin g th e tab s o n bot h side s

an d pullin g th e cove r down .

2 . Remov e th e socke t fro m th e ligh t

assembl y b y turnin g it one-quarte r

tur n counterclockwise .

3 . Pul l th e bul b straigh t ou t o f it s

socket .

Pus h th e ne w bul b straigh t int o

th e socke t unti l i t bottoms . 4

. Tes t th e light s t o mak e sur e th e

ne w bul b is working .

5 . Pu t th e socke t bac k int o th e ligh t

assembl y an d tur n i t clockwis e t o

loc k i t i n place .

6 . Pu t th e cove r bac k ont o th e ligh t

assembly . Pus h i t u p unti l i t lock s

i n place .

Maintenanc e

Page 255 of 322

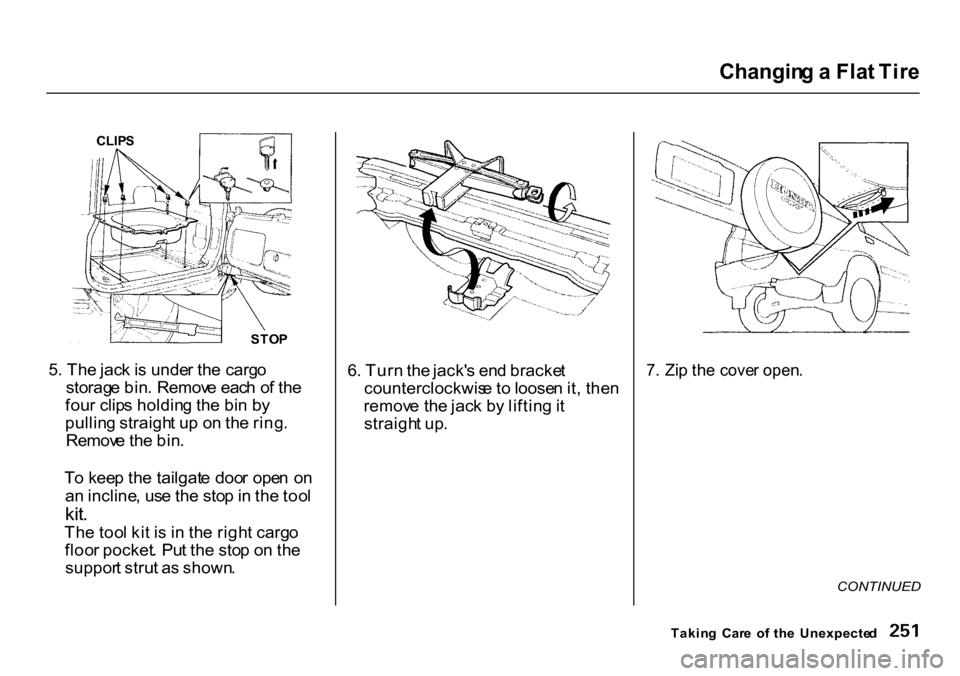

Changin

g a Fla t Tir e

CLIP S

STOP

5 . Th e jac k is unde r th e carg o

storag e bin . Remov e eac h o f th e

fou r clip s holdin g th e bi n b y

pullin g straigh t u p o n th e ring .

Remov e th e bin .

T o kee p th e tailgat e doo r ope n o n

a n incline , us e th e sto p in th e too l

kit .

Th e too l ki t i s i n th e righ t carg o

floo r pocket . Pu t th e sto p o n th e

suppor t stru t a s shown . 6

. Tur n th e jack' s en d bracke t

counterclockwis e to loose n it , the n

remov e th e jac k b y liftin g it

straigh t up .

7

. Zi p th e cove r open .

CONTINUED

Takin g Car e o f th e Unexpecte d

Page 257 of 322

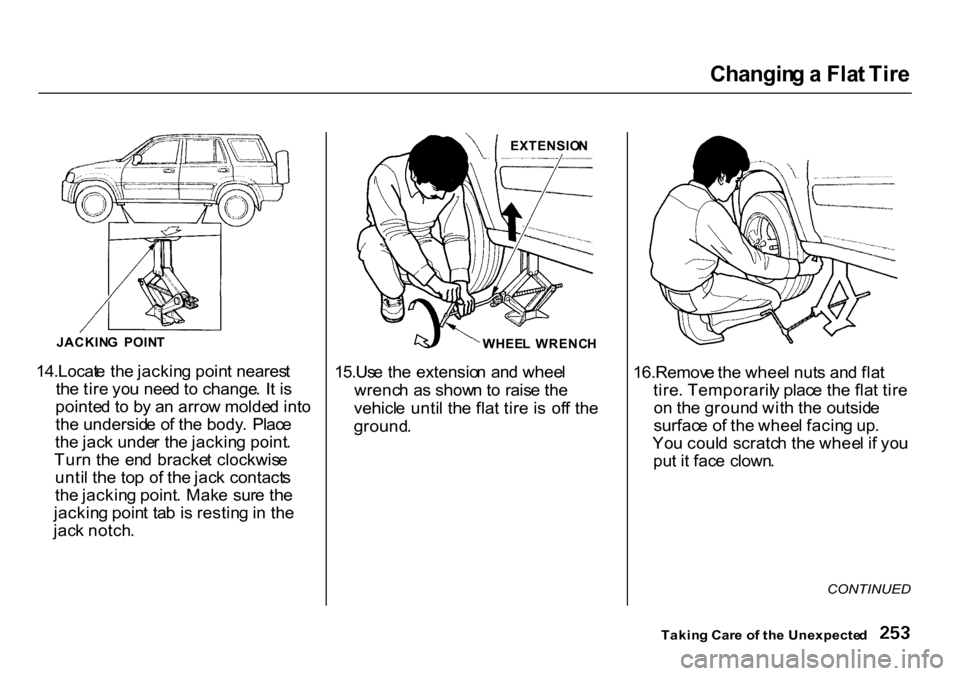

Changin

g a Fla t Tir e

JACKIN G POIN T

14.Locat e th e jackin g poin t neares t

th e tir e yo u nee d to change . I t i s

pointe d t o b y a n arro w molde d int o

th e undersid e o f th e body . Plac e

th e jac k unde r th e jackin g point .

Tur n th e en d bracke t clockwis e

unti l th e to p o f th e jac k contact s

th e jackin g point . Mak e sur e th e

jackin g poin t ta b is restin g in th e

jac k notch . EXTENSIO

N

WHEE L WRENC H

15.Us e th e extensio n an d whee l

wrenc h a s show n to rais e th e

vehicl e unti l th e fla t tir e i s of f th e

ground . 16.Remov

e th e whee l nut s an d fla t

tire . Temporaril y plac e th e fla t tir e

o n th e groun d wit h th e outsid e

surfac e o f th e whee l facin g up .

Yo u coul d scratc h th e whee l i f yo u

pu t i t fac e clown .

CONTINUED

Takin g Car e o f th e Unexpecte d

Page 262 of 322

I

f You r Engin e Won' t Star t

Diagnosin g wh y you r engin e won' t

star t fall s int o tw o areas , dependin g

o n wha t yo u hea r whe n yo u tur n th e

ke y t o STAR T (III) :

Yo u hea r nothing , o r almos t

nothing . Th e engine' s starte r

moto r doe s no t operat e a t all , o r

operate s ver y slowly .

Yo u ca n hea r th e starte r moto r

operatin g normally , o r th e starte r

moto r sound s lik e i t i s spinnin g

faste r tha n normal , bu t th e engin e

doe s no t star t u p an d run . Nothin

g Happen s o r th e Starte r

Moto r Operate s Ver y Slowl y

Whe n yo u tur n th e ignitio n switc h to

STAR T (III) , yo u d o no t hea r th e

norma l nois e o f th e engin e tryin g to

start . Yo u ma y hea r a clickin g soun d

o r serie s o f clicks , o r nothin g a t all .

Chec k thes e things :

Chec k th e transmissio n interlock .

I f yo u hav e a manua l transmission ,

th e clutc h peda l mus t b e pushe d

al l th e wa y t o th e floo r o r th e

starte r wil l no t operate . Wit h a n

automati c transmission , i t mus t b e

i n Par k o r Neutral . Tur

n th e ignitio n switc h t o O N (II) .

Tur n o n the headlight s an d chec k

thei r brightness . I f th e headlight s

ar e ver y di m o r don' t ligh t a t all ,

th e batter y is discharged . Se e

Jum p Startin g o n pag e 26 0 .

Tur n th e ignitio n switc h t o STAR T

(III) . I f th e headlight s d o no t dim ,

chec k th e conditio n o f th e fuses . I f

th e fuse s ar e OK , ther e is proba -

bl y somethin g wron g wit h th e

electrica l circui t fo r th e ignitio n

switc h o r starte r motor . Yo u wil l

nee d a qualifie d technicia n to

determin e th e problem . (Se e

Emergenc y Towin g o n pag e 27 3 . )

Takin g Car e o f th e Unexpecte d

Page 267 of 322

I

f You r Engin e Overheat s

6 . Loo k fo r an y obviou s coolan t leaks ,

suc h a s a spli t radiato r hose .

Everythin g i s stil l extremel y hot ,

s o us e caution . I f yo u fin d a leak , i t

mus t b e repaire d befor e yo u

continu e drivin g (se e Emergenc y

Towin g o n pag e 27 3 ) .

7 . I f yo u don' t fin d a n obviou s leak ,

chec k th e coolan t leve l i n th e

radiato r reserv e tan k (se e pag e

144 ). I f th e leve l i s belo w th e

MI N mark ,

ad

d coolan t t o halfwa y

betwee n th e MI N an d MA X marks .

8 . I f ther e wa s n o coolan t i n th e

reserv e tank , yo u ma y als o hav e t o

ad d coolan t t o th e radiator . Le t th e

engin e coo l dow n unti l th e pointe r

reache s th e middl e o f th e tempera -

tur e gauge , o r lower , befor e check -

in g th e radiator . 9

. Usin g glove s o r a larg e heav y

cloth , tur n th e radiato r ca p

counterclockwise , withou t pushin g

down , t o th e firs t stop . Thi s

release s an y remainin g pressur e i n

th e coolin g system . Afte r th e

pressur e releases , pus h dow n o n

th e ca p an d tur n i t unti l i t come s

off .

10

. Star t th e engin e an d se t th e

temperatur e contro l dia l t o

maximum . Ad d coolan t t o th e

radiato r u p t o th e bas e o f th e fille r

neck . I f yo u d o no t hav e th e

prope r coolan t mixtur e available ,

yo u ca n ad d plai n water .

Remembe r t o hav e th e coolin g

syste m draine d an d refille d wit h

th e prope r mixtur e a s soo n a s yo u

can .

11.Pu t th e radiato r ca p bac k o n

tightly . Ru n th e engin e an d watc h

th e temperatur e gauge . I f i t goe s

bac k t o th e re d mark , th e engin e

need s repair . (Se e Emergenc y

Towin g o n pag e 27 3 . )

12.I f th e temperatur e stay s normal ,

chec k th e coolan t leve l i n th e

radiato r reserv e tank . I f i t ha s

gon e down , ad d coolan t t o th e

MA X mark . Pu t th e ca p bac k o n

tightly .

Takin g Car e o f th e Unexpecte d

Removin

g th e radiato r ca p

whil e th e engin e is ho t ca n

caus e th e coolan t t o spra y out ,

seriousl y scaldin g you .

Alway s le t th e engin e an d

radiato r coo l dow n befor e

removin g th e radiato r cap .