Drive shaft HONDA CR-V 2000 RD1-RD3 / 1.G Owners Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 758 of 1395

Transfer Assembly

Reassembly (cont'd)

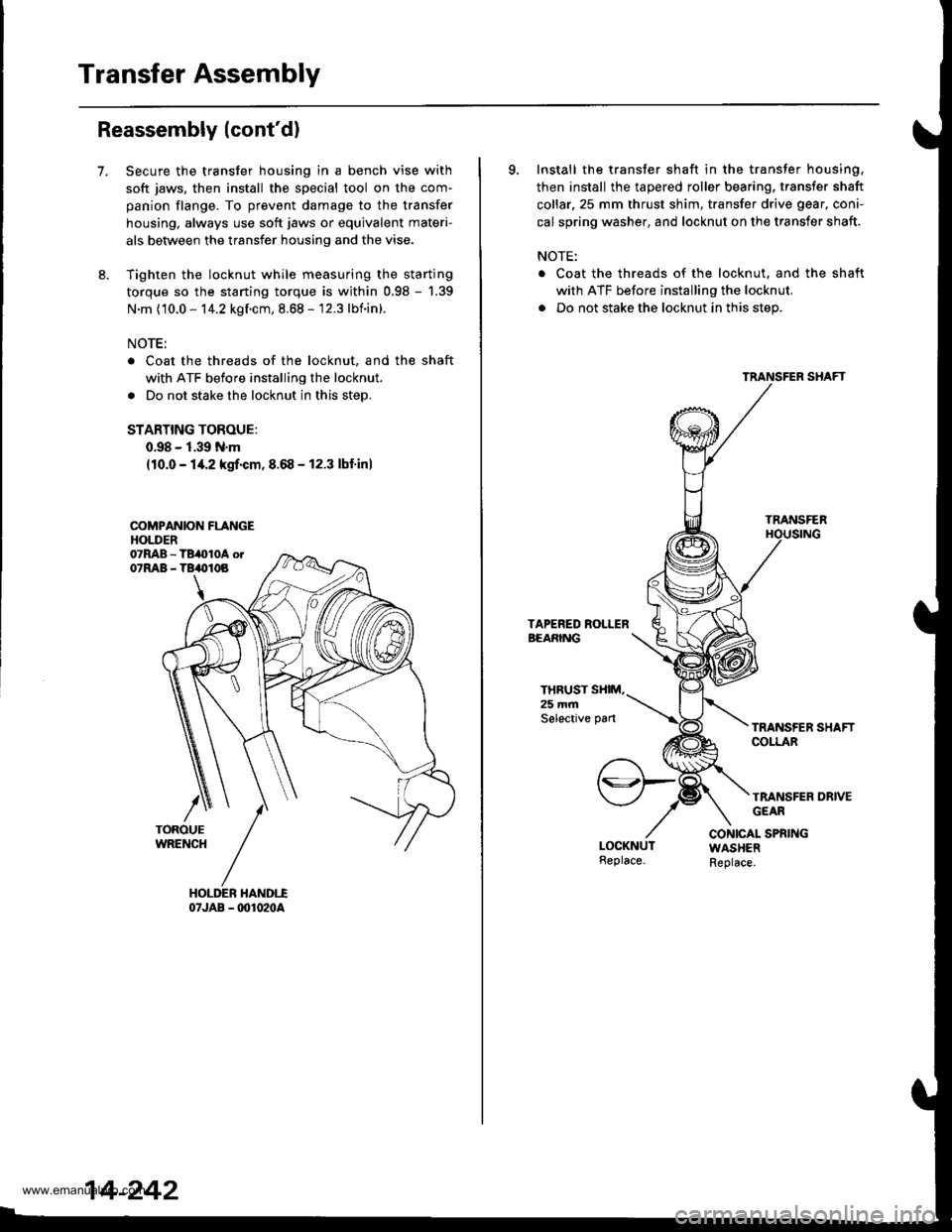

7.Secure the transfer housing in a bench vise with

soft jaws, then install the special tool on the com-

panion flange. To prevent damage to the transfer

housing, always use soft jaws or equivalent materi-

als between the transfer housing and the vise.

Tighten the locknut while measuring the starting

torque so the starting torque is within 0.98 - '1.39

N.m (10.0 - 14.2 kgf.cm, 8.68 - 12.3 lbnin).

NOTE:

Coat the threads of the locknut, and the shaft

with ATF before installing the locknut.

Do not stake the locknut in this step.

STARTING TOROUE:

0.98 - 1.39 N.m

{10.0 - 14.2 kgrf.cm,8.68 - 12.3 lbf'inl

COMPANION FLANGEHOLDER

07JAB - @1020A

14-242

9. Install the transfer shaft in the transfer housing,

then install the tapered roller bearing, transfer shaft

collar.25 mm thrust shim, transfer drive gear, coni-

cal spring washer, and locknut on the transfer shaft.

NOTE:

. Coat the threads of the locknut. and the shaft

with ATF before installing the locknut.

. Do not stake the locknut in this step.

TRANSFER

THRUST SXIM,25 mmSelective pan

TRANSFER DRIVEGEAR

CONICAL SPRINGWASHERReplace.

www.emanualpro.com

Page 760 of 1395

Transfer Assembly

18.

Reassembly (cont'dl

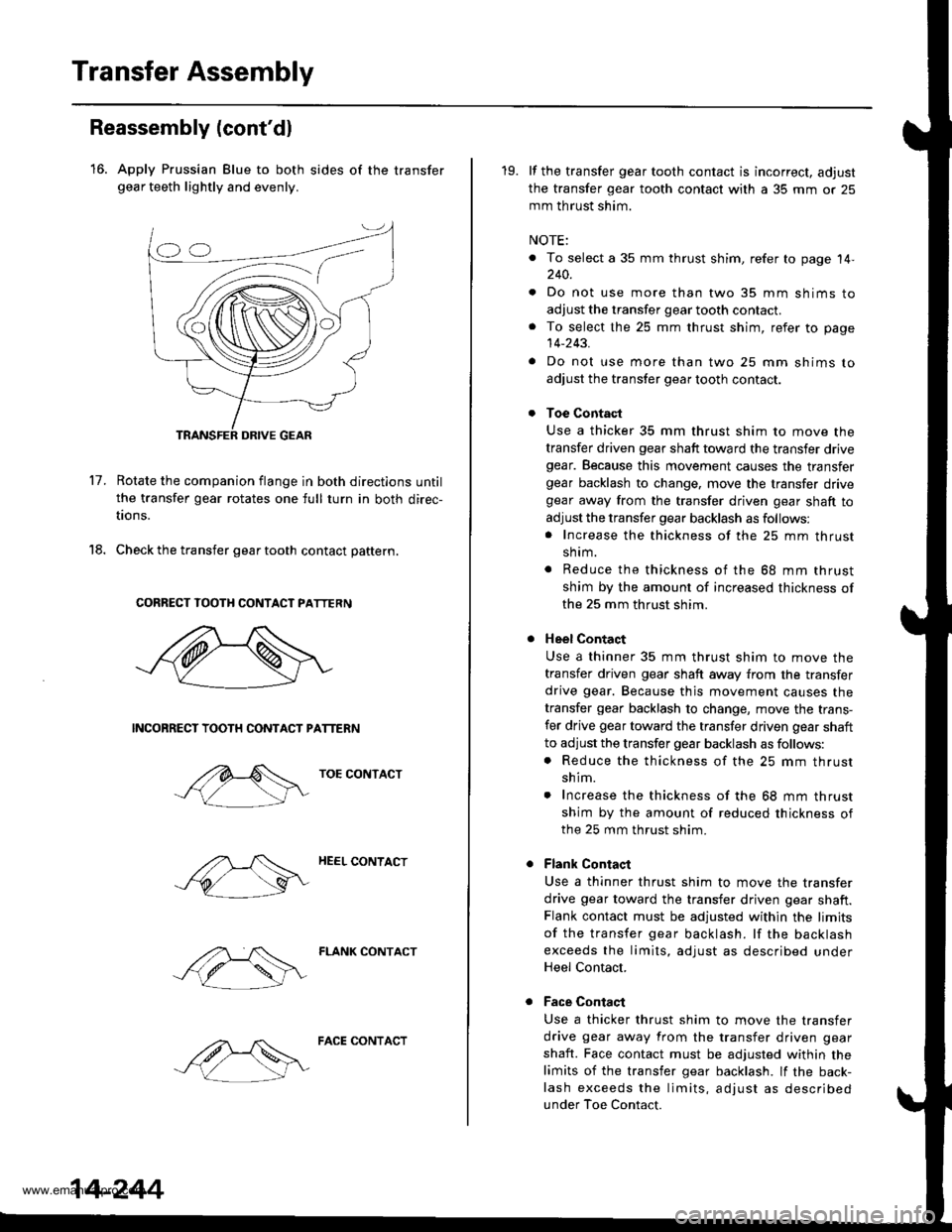

16. Apply Prussian Blue to both sides of the transfergear teeth lightly and evenly.

17.Rotate the companion flange in both directions until

the transfer gear rotates one full turn in both direc-

tions.

Check the transfer gear tooth contact pattern.

CORRECT TOOTH CONTACT PATTERN

NCONRECT TOOTH CONTACT PATTERN

TOE CONTACT

HEEL CONTACT

FLANK CONTACT

14-244

FACE CONTACT

19. lf the transfer gear tooth contact is incorrect, adjust

the transfer gear tooth contact with a 35 mm or 25

mm th rust shim.

NOTE:

. To select a 35 mm thrust shim, refer to page 14,240.

. Do not use more than two 35 mm shims to

adjust the transfer gear tooth contact.. To select the 25 mm thrust shim, refer to page

14-243.

. Do not use more than two 25 mm shims to

adjust the transfer gear tooth contact.

Toe Contact

Use a thicker 35 mm thrust shim to move the

transfer driven gear shaft toward the transfer drivegear. Because this movement causes the transfergear backlash to change, move the transfer drivegear away from the transfer driven gear shaft to

adjust the transfer gear backlash as follows:. Increase the thickness of the 25 mm thrust

shrm.

. Reduce the thickness of the 68 mm thrust

shim by the amount of increased thickness of

the 25 mm thrust shim.

Heel Contact

Use a thinner 35 mm thrust shim to move the

transfer driven gear shaft away from the transfer

drive gear. Because thjs movement causes the

transfer gear backlash to change, move the trans-

fer drive gear toward the transfer driven gear shaft

to adjust the transfer gear backlash as follows:. Reduce the thickness of the 25 mm thrust

shim.

. Increase the thickness of the 68 mm thrust

shim by the amount of reduced thickness ofthe 25 mm thrust shim.

Flank Contaqt

Use a thinner thrust shim to move the transfer

drive gear toward the transfer driven gear shaft.Flank contact must be adjusted within the limits

of the transfer gear backlash. lf the backlash

exceeds the limits, adjust as described underHeel Contact.

Face Contaqt

Use a thicker thrust shim to move the transfer

drive gear away from the transfer driven gear

shaft. Face contact must be adjusted within the

limits of the transfer gear backlash. lf the back-

lash exceeds the limits, adjust as described

under Toe Contact.

www.emanualpro.com

Page 761 of 1395

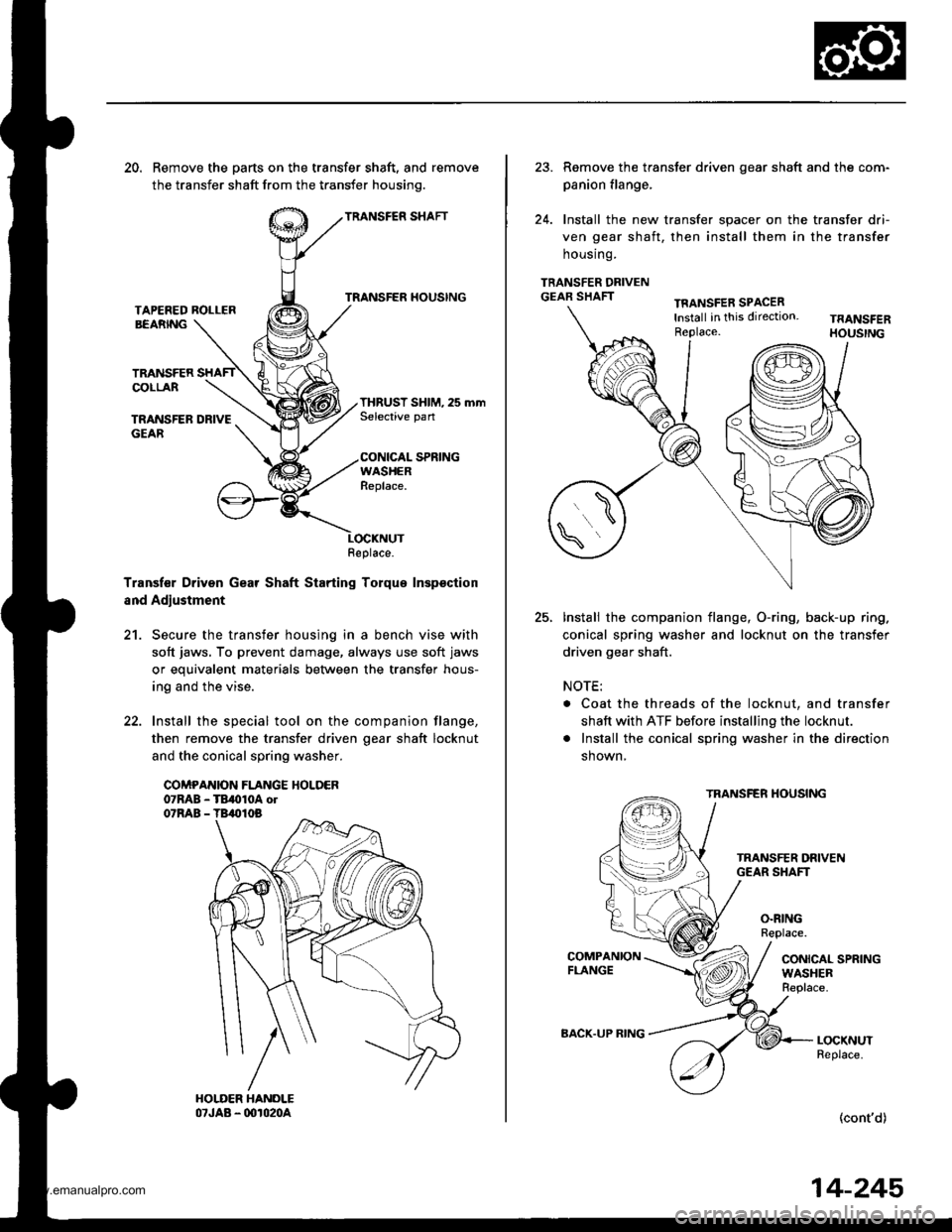

20. Remove the parts on the transfer shaft, and remove

the transfer shaft from the transfer housinq.

TRANSFER SHAFT

TRANSFER HOUSINGTAPEFED ROLLERBEARNG

TRANSFERCOLLAR

TRANSFER DRIVEGEAR

THRUST SHIM, 25 mmSelective pan

CONICAL SPRINGWASHERReplace.

Transf€r Driven Gear Shaft Starting Torque Inspsction

and Adjustment

21. Secure the transfer housing in a bench vise with

soft jaws, To prevent damage, always use soft jaws

or equivalent materials between the transfer hous-

ing and the vise.

22. Install the special tool on the companion flange,

then remove the transfer driven oear shaft locknut

and the conical spring washer.

COMPANION FLANGE HOLDER07RAB - TB,010A ol07RAB - TB,010B

Replace.

23. Remove the transter driven gear shaft and the com-

panion flange,

24. Install the new transfer spacer on the transfer dri-

ven gear shaft, then install them in the transfer

housrng.

TRANSFER DRIVENGEAR SHAFTTFANSFER SPACERlnstall in this direction.Replace.

25.Install the companion flange, O-ring, back-up ring.

conical spring washer and locknut on the transfer

driven gear shaft.

NOTE:

. Coat the threads of the locknut, and transfer

shaft with ATF before installing the locknut.

. Install the conical spring washer in the direction

shown,

TRANSFER HOUSING

O.RINGReplace.

CONICAL SPRINGWASHERReplace.

LOCKNUTReplace.

(cont'd)

BACK.UP RING

14-245

www.emanualpro.com

Page 762 of 1395

Transfer Assembly

Reassembly (cont'd)

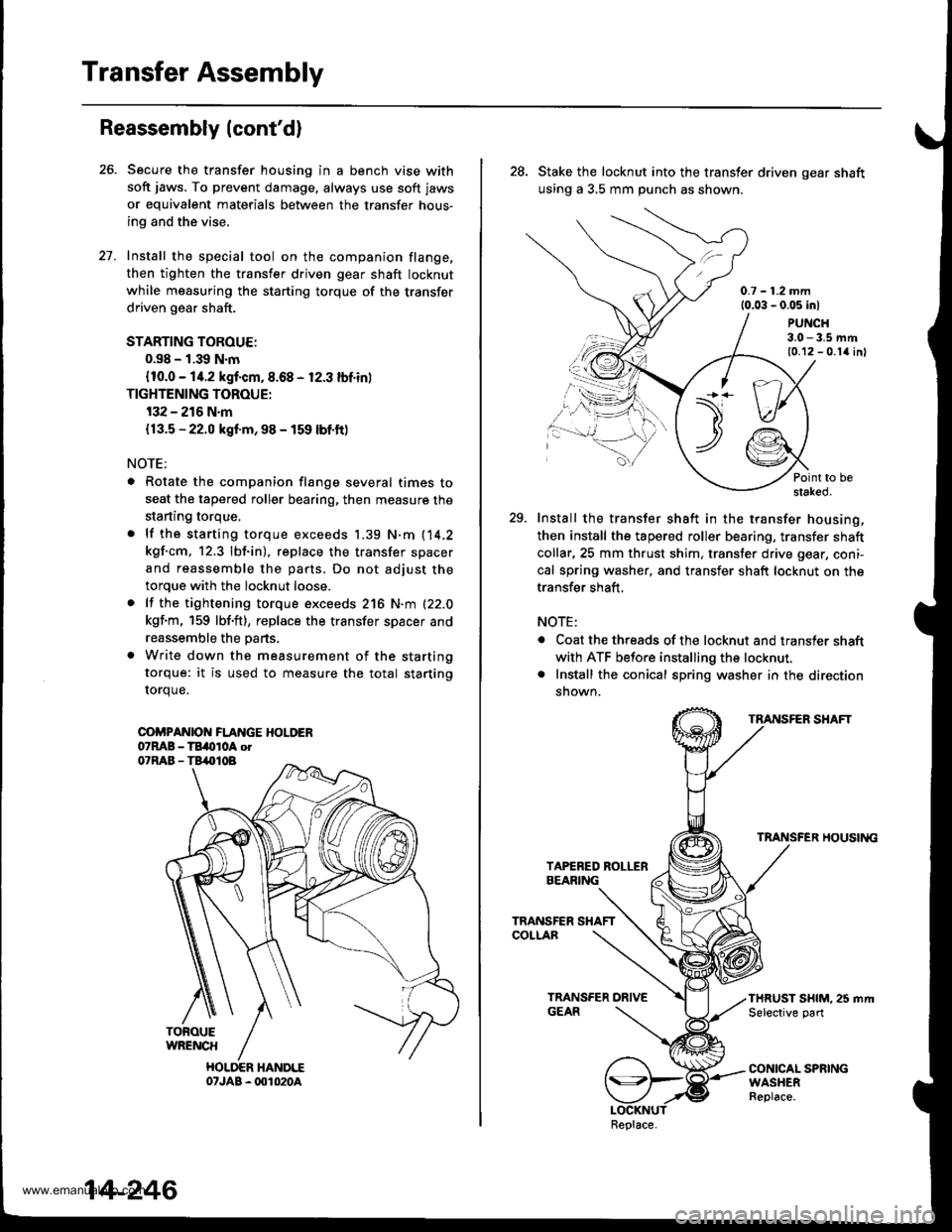

Secure the transfer housing in a bench vise with

soft jaws. To prevent damage, always use soft jaws

or equivalent materials between the transfer hous-

ing and the vise.

Install the special tool on the companion flange,

then tighten the transfer driven gear shaft locknut

while measuring the starting torque of the transfer

driven gear shaft.

STARTING TOROUE:

0.s8 - 1.39 N.m

{10.0 - 14.2 kgf.cm,8.68 - 12.3 lbf.in)

TIGHTENING TOROUE:

132 - 216 N.m

{13.5 - 22.0 kgf.m, 98 - 159 lbf.ft)

NOTE;

. Rotate the companion flange several times to

seat the tapered roller bearing, then measure the

starting torque,

. lf the starting torque exceeds 1.39 N.m (14,2

kgf.cm, 12.3 lbf.in), replace the transfer spacer

and reassemble the parts. Do not adjust the

torque with the locknut loose.

. lf the tightening torque exceeds 216 N.m (22.0

kgf.m, 159 lbf'ft), replace the transfer spacer and

reassemble the parts.

. Write down the measurement of the starting

torque: it is used to measure the total starting

rorque.

COi'PANIOI{ FLANGE HOLDER07MB - TBi(tloA otO'RAB - TB,.|}IOB

TOFOUEWRENCH

HOLDER HANDLE07JAB - 001020A

27.

14-246

28. Stake the locknut into the transfer driven gear shaft

using a 3,5 mm punch as shown.

0.7 - 1.2 mm{0.03 - 0.05 inl

PUNCH3.0 - 3.5 mm10.12 - 0.1{ inl

Point to bestaked.

29. Install the transfer shaft in the transfer housing,

then install the tapered roller bearing, transfer shaft

collar,25 mm thrust shim, transter drive gear, coni-

cal spring washer, and transfer shaft locknut on the

transfer shaft,

NOTE:

. Coat the threads of the locknut and transler shaft

with ATF before installing the locknut.. Install the conical spring washer in the direction

snown.

TRANSFER SHAFT

TRANSFER HOUSII{G

THRUST SHIM. 25 mrt|Selective part

CONICAL SPRINGWASHERReplace.

\t)t--/./

.,.-,.,\

Replace.

www.emanualpro.com

Page 763 of 1395

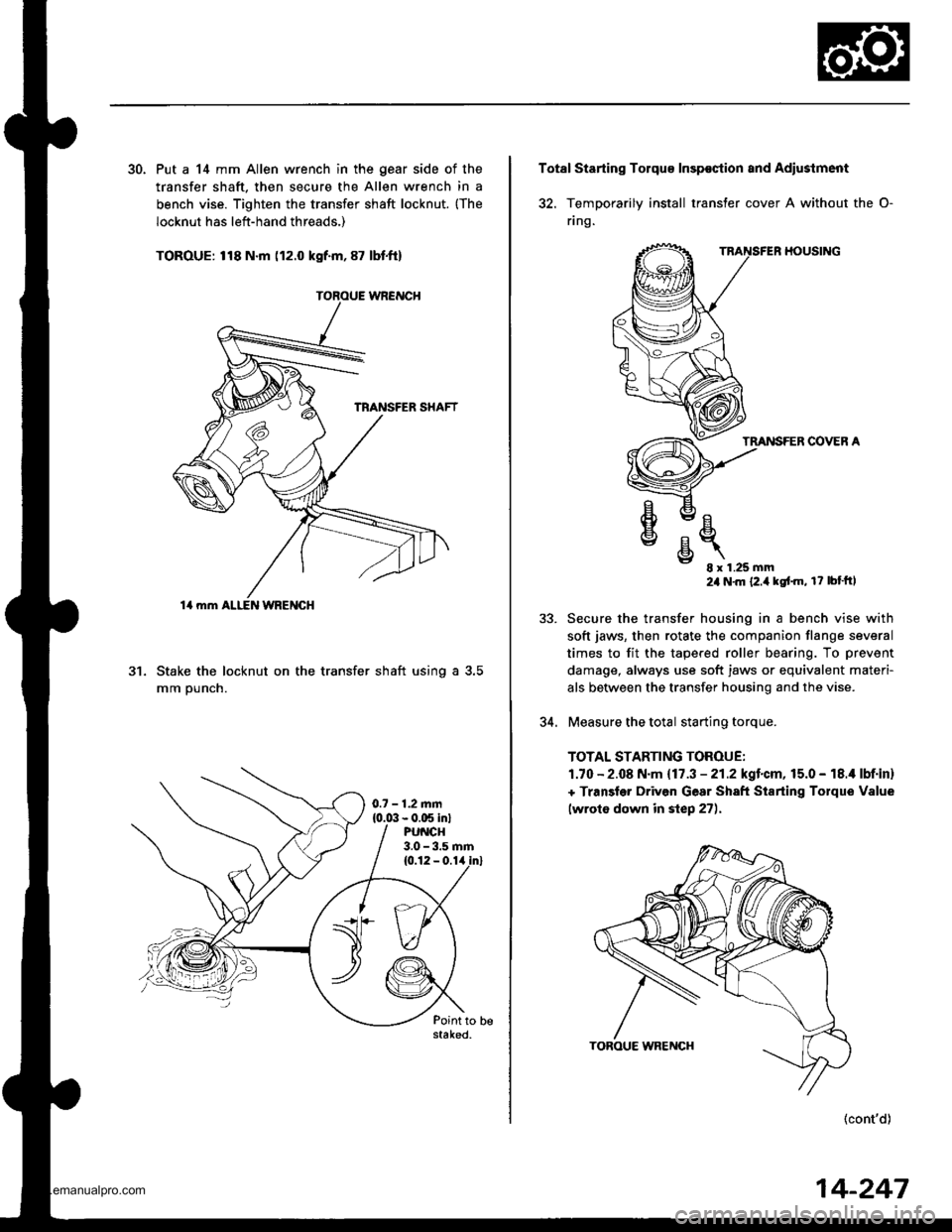

30. Put a 14 mm Allen wrench in the gear side of the

transfer shaft. then secure the Allen wrench in a

bench vise. Tighten the transfer shaft locknut. {The

locknut has left-hand threads,)

TOROUE: 118 N.m (12.0 kgf.m, 87 lbt.ft)

Stake the locknut on the transfer shaft using a 3.5

mm ounch.

al

14 mm ALI-EN WRENGH

0.7 - 1.2.nm{0.0:1- 0.C5 in}PU CH3.0 - 3.5 rnm

Total Starting Tolqu€ Insp€ction and Adiustment

32. TemDorarilv install transter cover A without the O-

flng.

HOUSING

TMNSFER COVER A

e

€

v

E- 8x1.25mm24 N'm {2.i1kgt'm, r? bt'ftl

Secure the transfer housing in a bench vise with

soft jaws, then rotate the companion flange several

times to fit the tapered roller bearing. To prevent

damage, always use soft jaws or equivalent materi-

als betlveen the transfer housing and the vise.

Measure the total starting torque.

TOTAL STARTING TOROUE:

1.70 - 2.08 N.m {17.3 - 21.2kgl.cm,15.0 - 18.i1 lbf.in}

+ Transler Driven Gear Sh8ft Starting Torque Value

lwroto down in step 27).

(cont'd)

5J.

34.

14-247

www.emanualpro.com

Page 766 of 1395

Transmission

Reassembly

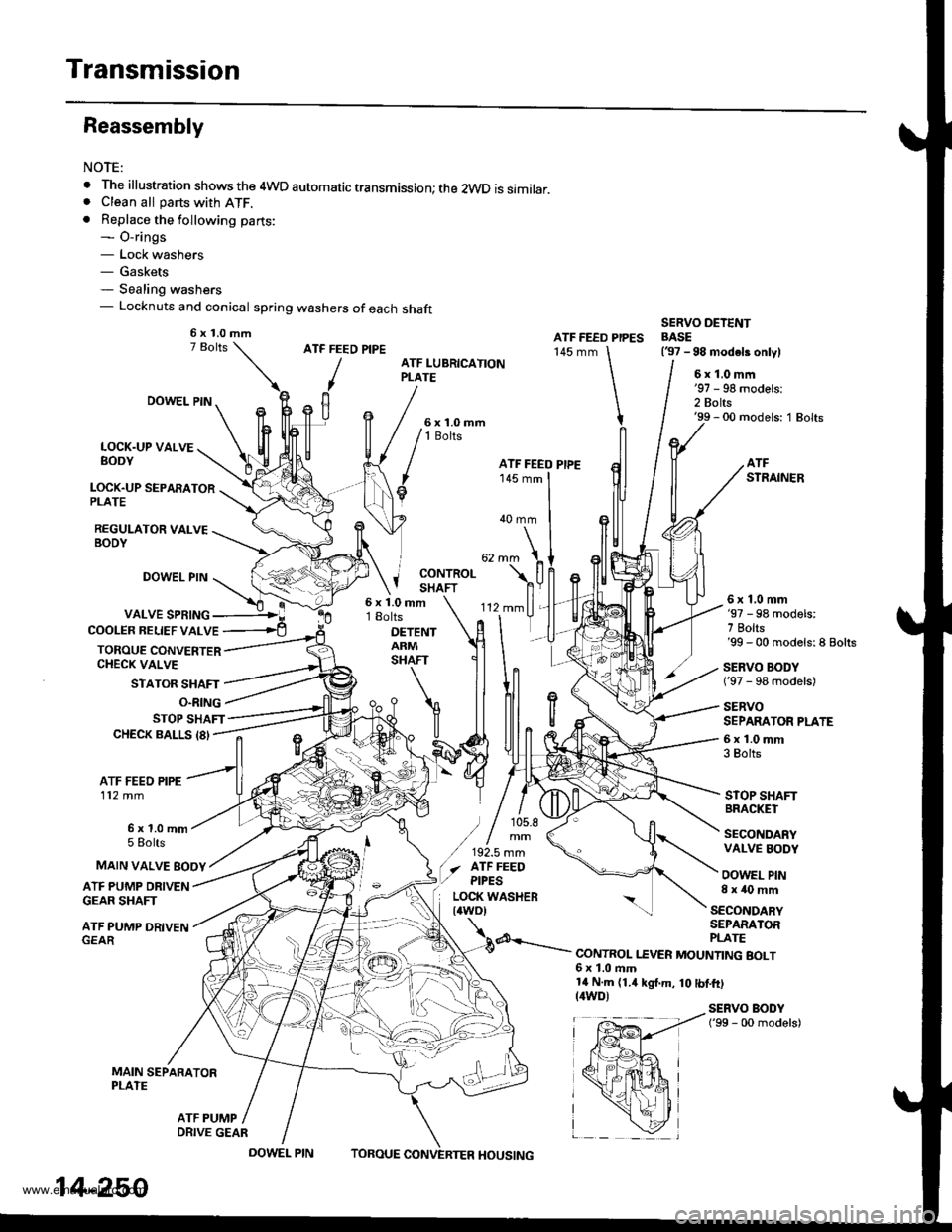

NOTE:

. The illustration shows the 4WD automatic transmission; the 2WD is similar.. Clean all parts with ATF.. Replace the following parts:- O-rings- Lock washers- Gaskets- Sealing washers- Locknuts and conical spring washers of each shaft

ATF FEED PIPE

/

ATF FEED PIPES145 mm

SERVO DETENTBASE(37 -98 modeb onlylATF LUBRICATIONPLATE6x1.0mm

2 Bolts'99 - 00 models: 1 Bolts

LOCK.UP VALVEBODY

LOCK.UP SEPARATORPLATE

REGULATOR VALVEBODY

DOWEL PIN

DOWEL PIN

VALVE SPRING

STATOR SHAFT

'-

'112mmll,

rlT

ATFSTRAINER

40 mm

j coNrRoLI SHAFT

COOLER BELIEF VALVE

TOROUE CONVERTERCHECK VALVE

6x1.0mm18olts

DETENTARMSHAFT

6x1,0mm'97 - 98 models:7 Bolts'99 - 00 models:8 Bolts

SERVO BODY('97 - 98 models)

SERVOSEPARATOR PLATE

6x1.0mm3 Bolts

STOP SHAFTBRACKET

SECONDARYVALVE BODY

OOWEL PIN8x40mm

O.RING

STOP SHAFTCHECK BALLS 18'

ATF FEED PIPE112 mm

6x1.0mm5 Eolts

ATF PUMP DRIVENGEAR SHAFT

ATF PUMP DRIVEN

MAIN SEPARATORPLATE

MAIN VALVE EOOY

SECONDARYSEPARATOR

d---.- PLATE--.- CONTROL I.EVER MOUNTING BOLT6x1.0ftm14 N.m (1.4 kgt.m, 10 tbf.ft)(4WD)SERVO BODY('99 - 00 models)

ATF PUMP

6x1.0mm

ATF FEEO PIPE

) / 105.8

/,,!.,::(./ afF FEEO,/ ptpEs

EP,---!ir{+*a r

fpffi4 i

x*hi

_ \zl

14-250

DRIVE GEAR

DOWEL PINTOBOUEHOUSING

www.emanualpro.com

Page 767 of 1395

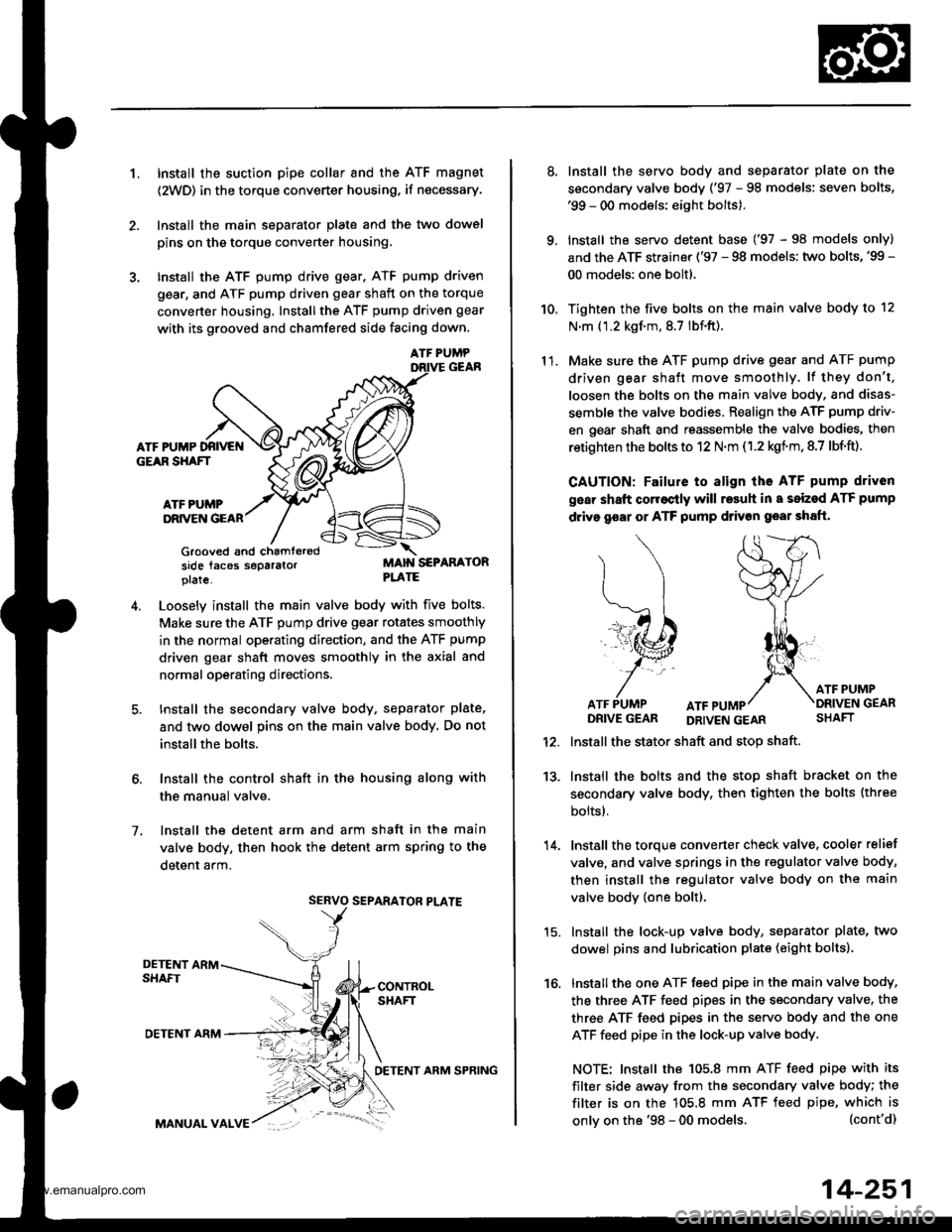

1.Install the suction pipe collar and the ATF magnet

{2WD) in the torque converter housing, if necessary.

lnstall the main seDarator Dlate and the two dowel

pins on the torque converter housing,

Install the ATF pump drive gear. ATF pump driven

gear, and ATF pump driven gear shaft on the torque

converter housing. Installthe ATF pump driven gear

with its grooved and chamfered side facing down.

ATF PUMPGEAR

ATF PUMP D{IVEf{GEAR SHAFT

ATF PUi'PORIVEN GEAR

Grooved and chamteredside faces separatorplate.

MAIN S€PAR/ATORPLATE

5.

o.

Loosely install the main valve body with five bolts.

Make sure the ATF pump drive gear rotates smoothly

in the normal operating direction, and the ATF pump

driven gear shaft moves smoothly in the axial and

normal operating directions.

Install the secondary valve body, separator plate,

and two dowel pins on the main valve body. Do not

installthe bolts.

Install the control shaft in the housing along with

the manual valve.

lnstall the detent arm and arm shaft in the main

valve body, then hook the detent arm spring to the

detent arm.

SEBVO SEPARATOR PLATE

7.

DETENT ARMSHAFT

OETENT ARM

CONTROLSHAFT

MANUAL VAIVE

OETENT ARM SPRING

onlv on the '98 - 00 models,

14-251

1l.

9.

8.

10.

Install the servo body and separator plate on the

secondary valve body ('97 - 98 models: seven bolts,'99 - 00 models: eight bolts).

lnstall the servo detent base ('97 - 98 models only)

and the ATF strainer ('97 - 98 models: two bolts,'99 -

00 models: one boltl.

Tighten the five bolts on the main valve body to 12

N'm (1.2 kgf.m, 8.7 lbf.ft).

Make sure the ATF pump drive gear and ATF pump

driven gear shaft move smoothly. lf they don't,

loosen the bolts on the main valve body, and disas-

semble the valve bodies. Realign the ATF pump driv-

en gear shaft and reassemble the valve bodies, then

retighten the bolts to 12 N.m (1.2 kgim, 8.7 lbf.ft).

CAUTION: Failure to align the ATF pump driven

gear shaft corroctly will rosult in a seizsd ATF pump

drive gear or ATF pump drivon gear shaft.

ATF PUMP ATFGEARDRIVE GEAR DBIVEN GEARSHAFT

Install the stator shaft and stop shaft

Install the bolts and the stop shaft bracket on the

secondary valve body, then tighten the bolts (three

bolts).

Install the torque converter check valve, cooler relief

valve, and valve springs in the regulator valve body,

then install the regulator valve body on the main

valve body {one boltl.

Install the lock-up valve body, separator plate, two

dowel pins and lubrication plate (eight bolts).

Installthe one ATF feed pipe in the main valve body,

the three ATF feed pipes in the secondary valve, the

three ATF feed pipes in the servo body and the one

ATF feed pipe in the lock-up valve body.

NOTE: lnstall the 105.8 mm ATF feed pipe with its

filter side away from the secondary valve body; the

filter is on the 105.8 mm ATF feed pipe, which is(cont'd)

13.

14.

15.

16.

www.emanualpro.com

Page 776 of 1395

Transmission

Installation (cont'dl

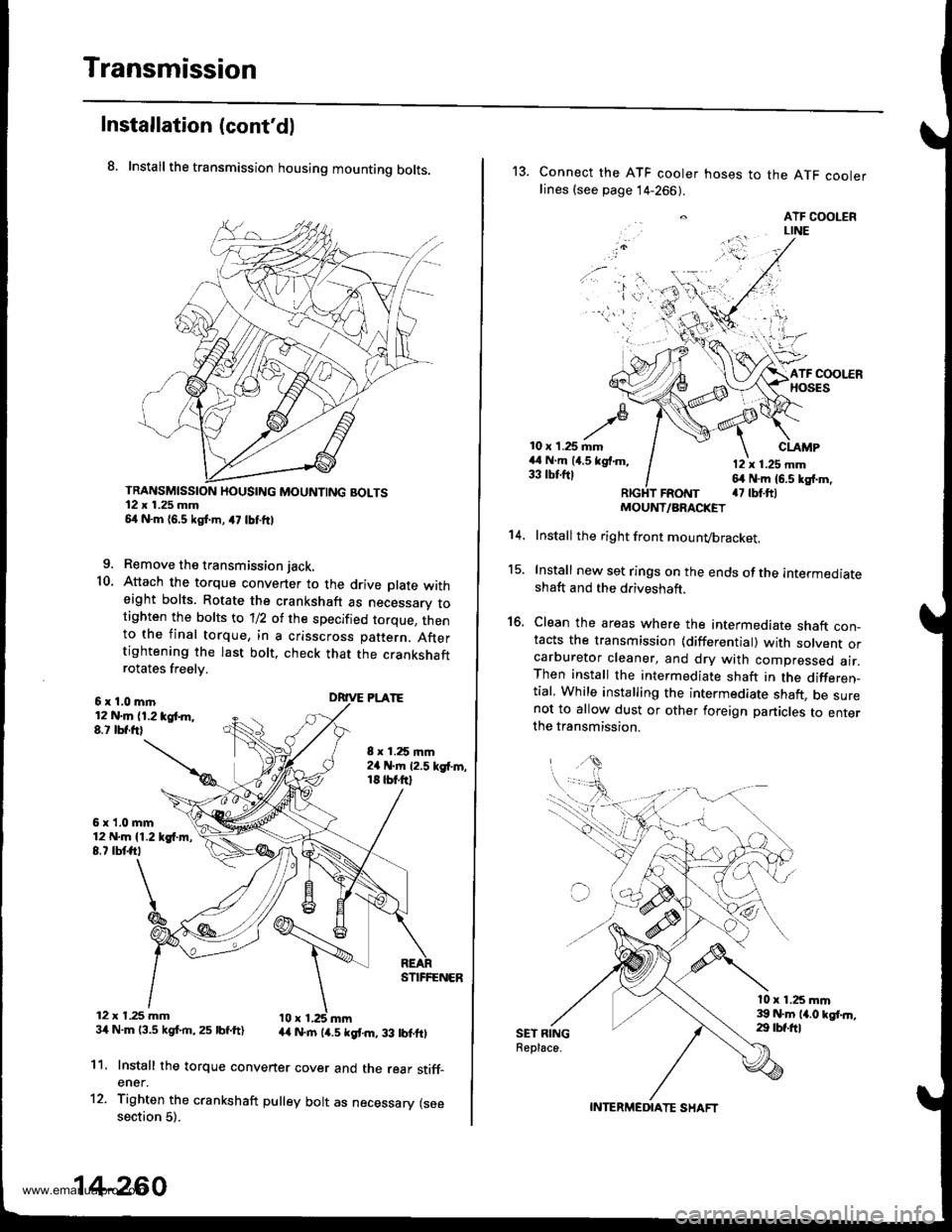

8. Install the transmission housing mounting bolts.

TRANSMISSION HOUSING MOUNTING BOLTS12 x 1.25 mm54 N.m 16,5 kgf.m, a7 lbtftl

9. Remove the transmission jack.

10. Attach the torque convener to the drive plate witheight bolts. Rotate the crankshaft as necessarv totighten the bolts to 'll2 of the specified torque, thento the final torque, in a crisscross pattern. Aftertightening the last bolt. check that the crankshaftrotates freelv.

6x1.0mln12 N.m (1.2 tgt m,8.t lbf.frl

6x1.0mm12 N.m {1.219{.m,8.7 tbtft,

12 x t.25 mm34 N.m 13.5 kgf.rn,25 lbf.ft)

8 x 1.25 mm2a N.m 12.5 kgf'm,18 tbt.ftl

DRIVE PLATE

STIFFENER

44 N.rn (4.5 kgt m, 33 lbtftl

11.

12.

Install the torque convener cover and the rear stiff_ener.

Tighten the crankshaft pulley bolt as necessary (seesection 5).

14-260

13. Connect the ATF cooler hoses to the ATF coolerlines (see page 14-266).

. ATF COOLERLINE

'i 'l'r',:,.) -

10 x 1.25 mm44 N.m (4.5 kgf.m,33 tbtftl

CLAMP

12 x 1.25 mm64 N.m 16.5 kg{.m,a7 tbt.ftlFRotrtT

15.

16.

't 4.

SET RINGReplace.

MOUNT/ARACKET

Install the right front mounvbracket.

Install new set rings on the ends of the intermediateshaft and the driveshaft.

Clean the areas where the intermediate shaft con_tacts the transmission {differential) with solvent orcarburetor cleaner, and dry with compressed air.Then install the intermediate shaft in the differen_tial, While installing the intermediate shaft, be surenot to allow dust or other foreign panicles to enterthe transmission.

l0 x 1.25 mm39 N.m 14.0 kgt.n,29 tbf.ftl

INTERMEDIATE SHAFT

www.emanualpro.com

Page 777 of 1395

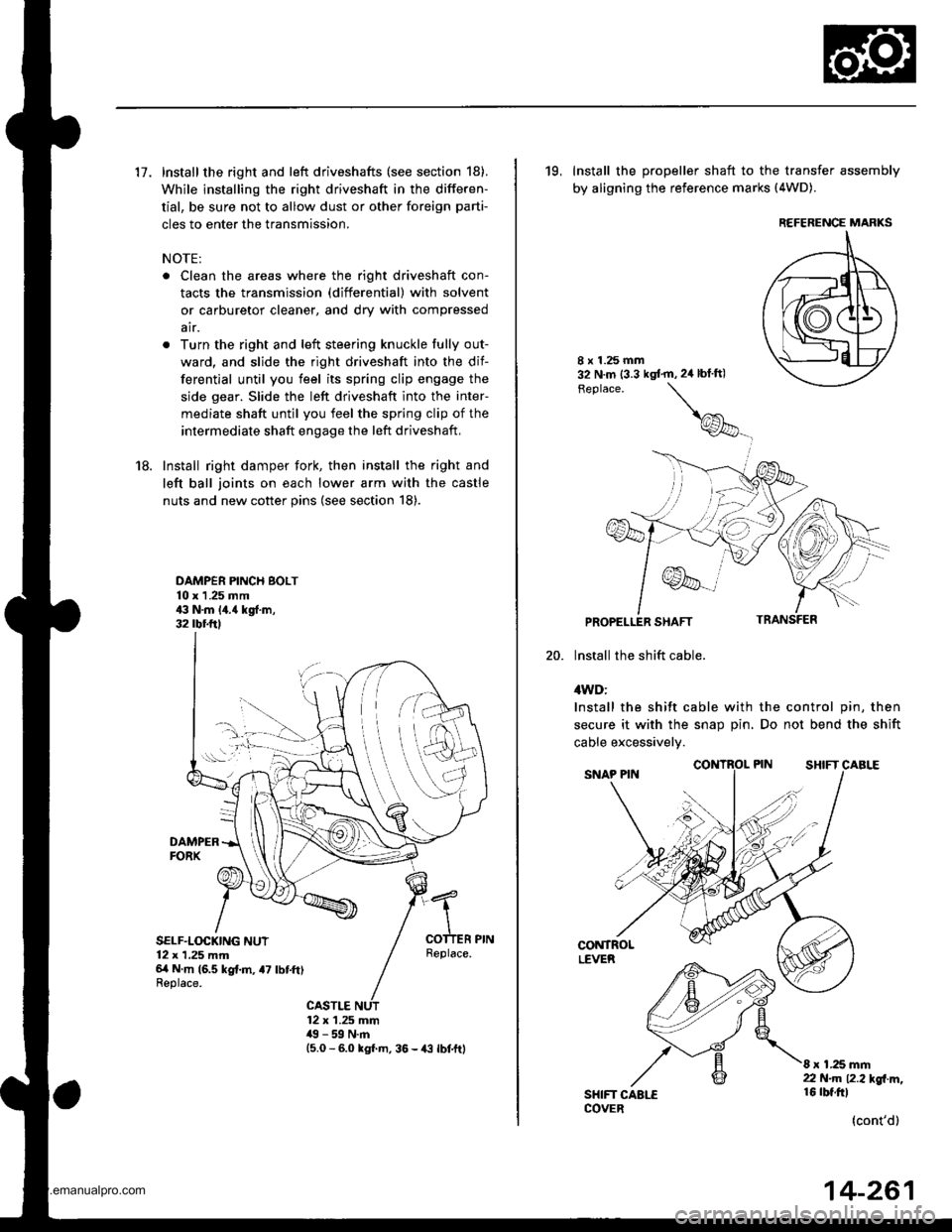

17. Install the right and left driveshafts (see section 18).

While installing the right driveshaft in the differen-

tial, be sure not to allow dust or other foreign parti-

cles to enter the transmission.

NOTE:

. Clean the areas where the right driveshaft con-

tacts the transmission (differential) with solvent

or carburetor cleaner, and dry with compressed

air.

. Turn the right and left steering knuckle fully out-

ward, and slide the right driveshaft into the dif-

ferential until you feel its spring clip engage the

side gear. Slide the left driveshaft into the inter-

mediate shaft until you feel the spring clip of the

intermediate shaft engage the left driveshaft,

18. Install right damper fork, then install the right and

left ball joints on each lower arm with the castle

nuts and new cotter pins (see section 18).

DAMPER PINCH BOLT10 x 1 .25 mm43 N.m 14.{ kgf.m,32 rbr.ftl

DAMPERFORX

SELF.LOCKING NUT12 x 1,25 mm6/t N m (6.5 kg{.m, a7 lbtft)Replace.

Replace.

CASTLE12 x 1.25 mm49 - 59 N.m15.0 - 6.0 kgl m, 36 - {3 lbtftl

19, Install the propeller shaft to the transfer assembly

by aligning the reference marks (4WD).

20.

8 x 1.25 mm32 N.m (3.3 kgt'm,2ir blft)

Feplace.

\

@_

PROPELLER SHAFT

lnstall the shift cable.

4WD:

Install the shift cable with the control pin, then

secure it with the snap Din. Do not bend the shift

cable excessivelv.

CONTROLLEVER

SHIFT CAALECOVER

8 x 1.25 mm22 N.m 12.2l'gl m,16 rbt.ftl

(cont'd)

REFERENCE MARKS

14-261

www.emanualpro.com

Page 794 of 1395

Description

Rear Differential

Outline

The Real-time 4WD-Dual Pump System model has a hydraulic clutch and a differential mechanism in the rear differential

assembly. Under normal conditions, the vehicle is driven by the front wheels. However, depending on to the driving force

of the front wheels and the road conditions. the system instantly transmits appropriate driving force to the rear wheels

without requiring the driver to switch between 2WD (tront wheel drive) and 4WD (four wheel drive). The switching mecha-

nism between 2WD and 4WD is integrated into the rear differential assembly to make the system light and compact.

ln addition, the dual-pump system switches off the rear-wheel-drive force when braking in a forward gear. This allows the

braking system to work properly on models equipped with an Anti-lock Braking System (ABS).

Construction

The rear differential assembly consists of the torque control differential case assembly and the rear differential carrier

assembly. The torque control differential case assembly consists of the differential clutch assembly, the companion

flange, and the oil pump body assembly. The rear differential carrier assembly consists of the differential mechanism. The

differential drive and driven gears are hypoid gears.

The oil pump body assembly consists of the front oil pump, the rear oil pump, the hydraulic control mechanism, and the

clutch piston. The clutch piston has a disc spring that constantly provides the differential clutch assembly with a preset

torque to Drevent abnormal sound.

The clutch guide in the differential clutch assembly is connected to the propeller shaft via the companion flange, and it

receives the driving force lrom the transfer assembly. The clutch guide rotates the clutch plate and the front oil pump in

the oil pump body.

The clutch hub in the differential clutch assembly has a clutch disc that is splined with the hypoid drive pinion gear. The

hypoid drive gear drives the rear oil pump.

The front and rear oil pumps are trochoidal pumps. The rear oil pump capacity is 2.5 percent larger that the front oil pump

to handle the rotation difference between the front and rear wheels caused by worn front tires and tight corner braking.

The oil pumps are designed so the fluid intake works as a fluid discharge when the oil pumps rotate in reverse. Genuine

Honda CVT fluid is used instead of differential fluid.

Operation

When there is a difference in rotation speed between the front wheels (clutch guide) and rear wheels (hypoid driven gear),

hydraulic pressure from the front and rear oil pumps engages the differential clutch, and drive force from the transler

assembly is applied to the rear wheels.

The hydraulic pressure control mechanism in the oil pump body selects 4WD mode when the vehicle is started abruptly,

or when accelerating in a forward or reverse gear (causing rotation difference between the front and rear wheels). or

when braking in reverse gear {when decelerating). lt switches to 2WD mode when the vehicle is driven at a constant speed

in forwar! or reverse gear (when there is no rotation difference between the front and rear wheels), or when braking in a

fo rwa rd gear (when decelerating).

To protect the system, the differential clutch assembly is lubricated by hydraulic pressure generated by the oil pumps in

both 4WD and 2WD modes. Also, the thermal switch relieves the hydraulic pressure on the clutch piston and cancels 4WD

mode if the temDerature of the differential fluid rises above normal.

www.emanualpro.com