check engine HONDA CR-V 2000 RD1-RD3 / 1.G Owners Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 371 of 1395

ldle Speed Setting

Inspoction/Adiustmont

37 modsl:

NOTE:

. Before setting the idle speed, check the following

items:- The MIL has not been reportsd on.- lgnition timing- Spark plugs

- Air cleaner- PCV system

. lcanada) Pull the parking brake lever up. Stan the

engine, then check that the headlights are off.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

Connect a tachometer or a Honda PGM Tester.

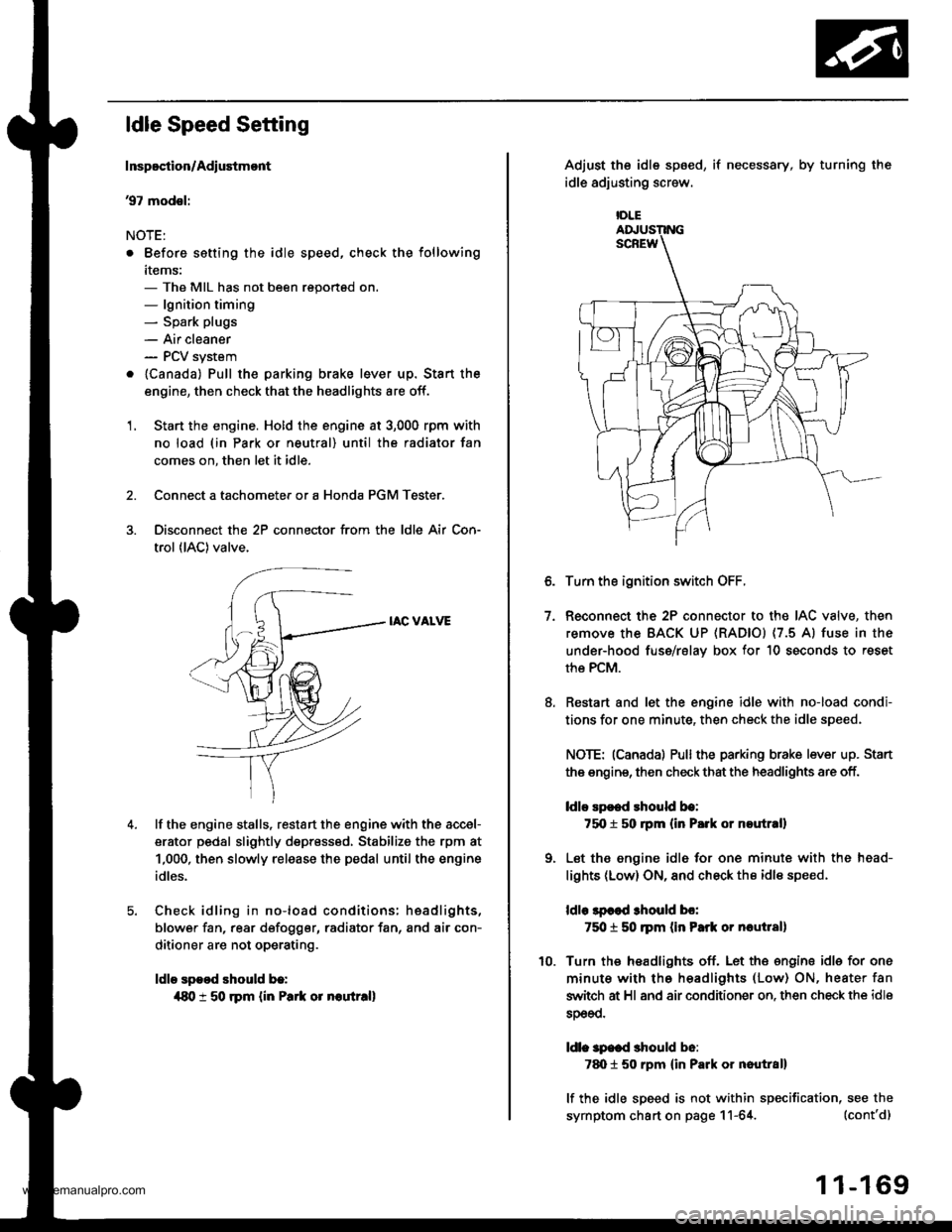

Disconnect the 2P connector from the ldle Air Con-

trol (lAC) valve.

IAC VALVE

lf the engine stalls, restart the engine with the accel-

erator pedal slightly depr6ss6d, Stabilize the rpm at

1,000, then slowly release the pedal until the engine

idles.

Check idling in no-load conditions: hsadlights,

blower fan, rear d€fogger, radiator fan, and air con-

ditioner are not operating.

ldle spood should b.:

{80 t 50 rpm {in Park or noutr.ll

IDLE

7.

Adjust the idle sp6ed,

idle adjusting screw.

if necessary, by turning the

Turn the ignition switch OFF.

Reconnect the 2P connector to the IAC valve, then

remove the BACK UP (RAD|Ol (7.5 Al fuse in the

under-hood fuse/rslav box for 10 seconds to reset

the PCM.

Restart and let the engine idle with no-load condi-

tions for one minute, then check the idle speed.

NOTE: (Canadal Pullthe parking brake lever up. Stan

the engine, then check that the headlights are off.

ldlo Ep€ed rhould be:

75O t 50 rpm (in P.rk or noutr.ll

Let the engine idl6 for one minute with the head-

lights (Low) ON, and check th€ idl€ speed.

ldle lpcod 3hould bo:

750 t 50 ]pm (in Park or nautlal)

Turn the headlights off. Let th€ engine idle for one

minute with the headlights (Low) ON, heater fan

switch at Hl and air conditioner on. then check the idle

sDeeo.

ldl. specd should b6:

7d) 1 50 rpm {in Park or nautral}

lf the idle speed is not within specification, see the

symptom chart on page 11-64. (cont'd)

1 1-169

www.emanualpro.com

Page 372 of 1395

ldle Control System

ldle Speed Setting (cont'd)

38 - 0O mod6l3:

NOTE: Before setting the idle speed, check the follow-

ing items:- The MIL has not been reported on.- lgnition timing- Spark plugs

- Air cleaner- PCV system

1. Start the engine. Hold the engine at 3.000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

Connect a tachometer.

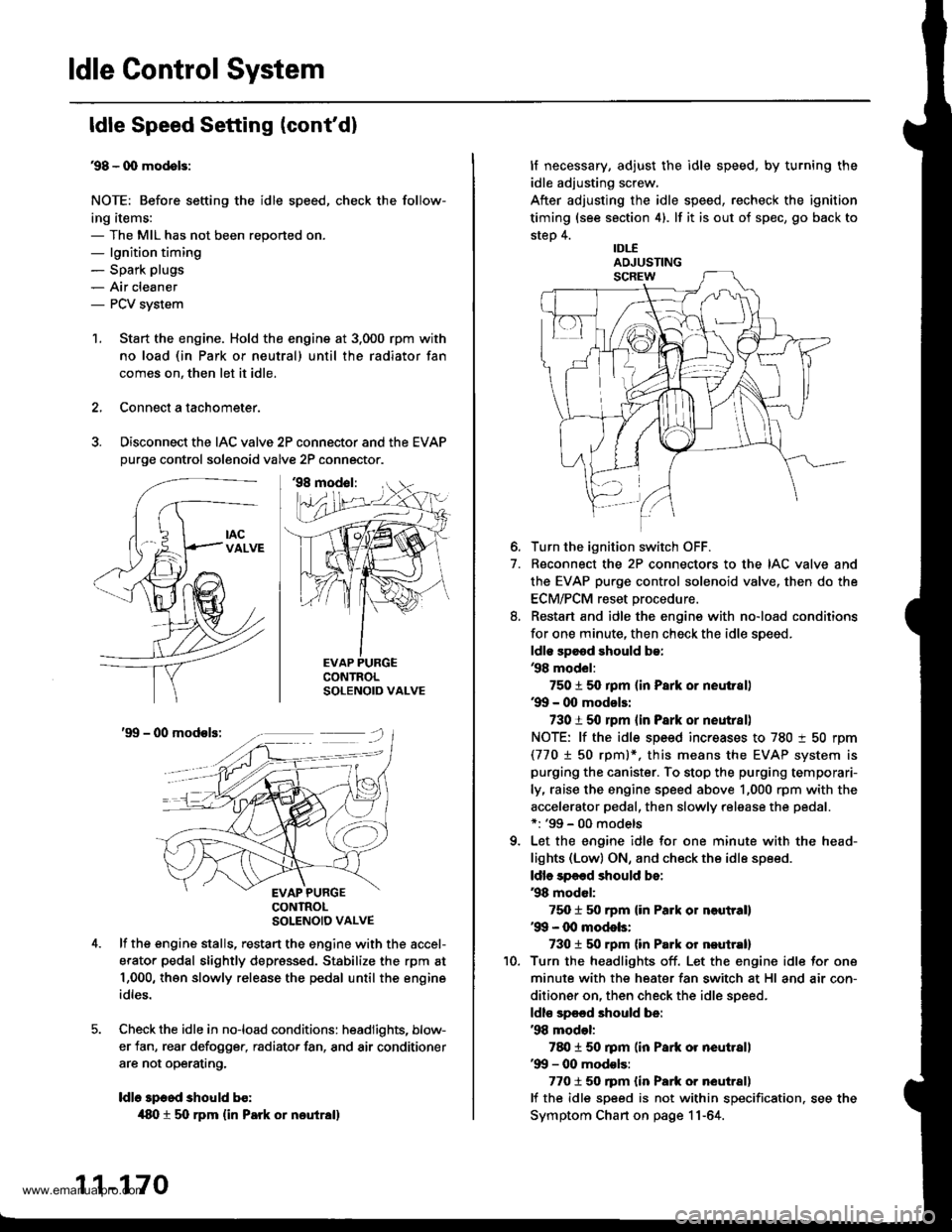

Disconnect the IAC valve 2P connector and the EVAP

purge control solenoid valve 2P connector.

CONTROLSOLENOID VALVE

SOLENOID VALVE

lf the engine stalls, restart the engine with the accel-

erato. pedal slightly depressed. Stabilize the rpm at

1,000, then slowly release the pedal until the engine

idles.

Che€k the idle in no-load conditions: headlights, blow-

er fan, rear defogger, radiator fan, and air conditioner

are not operating,

ldle speed should bo:

480 t 50 rpm {in PErk or noutrall

11-170

lf necessary, adjust the idle speed, by turning the

idle adjusting screw.

After adjusting the idle speed, recheck the ignition

timing (see section 4). lf it is out of spec, go back to

steo 4.tDt.E

6. Turn the ignition switch OFF.

7. Reconnect the 2P connectors to the IAC valve and

the EVAP purge control solenoid valve, then do the

ECM/PCM reset procedure.

8. Restart and idle the engine with no-load conditions

for one minute, then check the idle speed.

ldle speod should be:,98 model:

750 t 50 rpm tin Park or neutral)'9!l - 00 modsls:

730 i 50 lpm lin Psrk or neutral)

NOTE: lf the idle speed increases to 780 t 50 rpm(770 1 50 rpml*, this means the EVAP system is

purging the canister. To stop the purging temporari-

ly, raise the engine speed above 1,000 rpm with the

accelerator pedal, then slowly release the pedal.*: '99 - 00 models

9. Let the engine idle for one minute with the head-

lights (Low) ON, and check the idle speed.

ldle speed should be:

38 mod6l:

750 f 50 rpm (in Palk or neutrall'99 - 00 modols:

730 t 50 rpm (in Palk or neutral)

10. Turn the headlights off. Let the engine idle for one

minute with the heater fan switch at Hl and air con-

ditioner on, then check the idle speed.

ldls spqed should be:'98 model:

780 t 50 rpm (in Park or neutrall'99 - 00 mod€ls:

7701 50 rpm lin Park or neutral)

lf the idle speed is not within specification. see the

Symptom Chart on page 11-64.

ADJUSTING

www.emanualpro.com

Page 379 of 1395

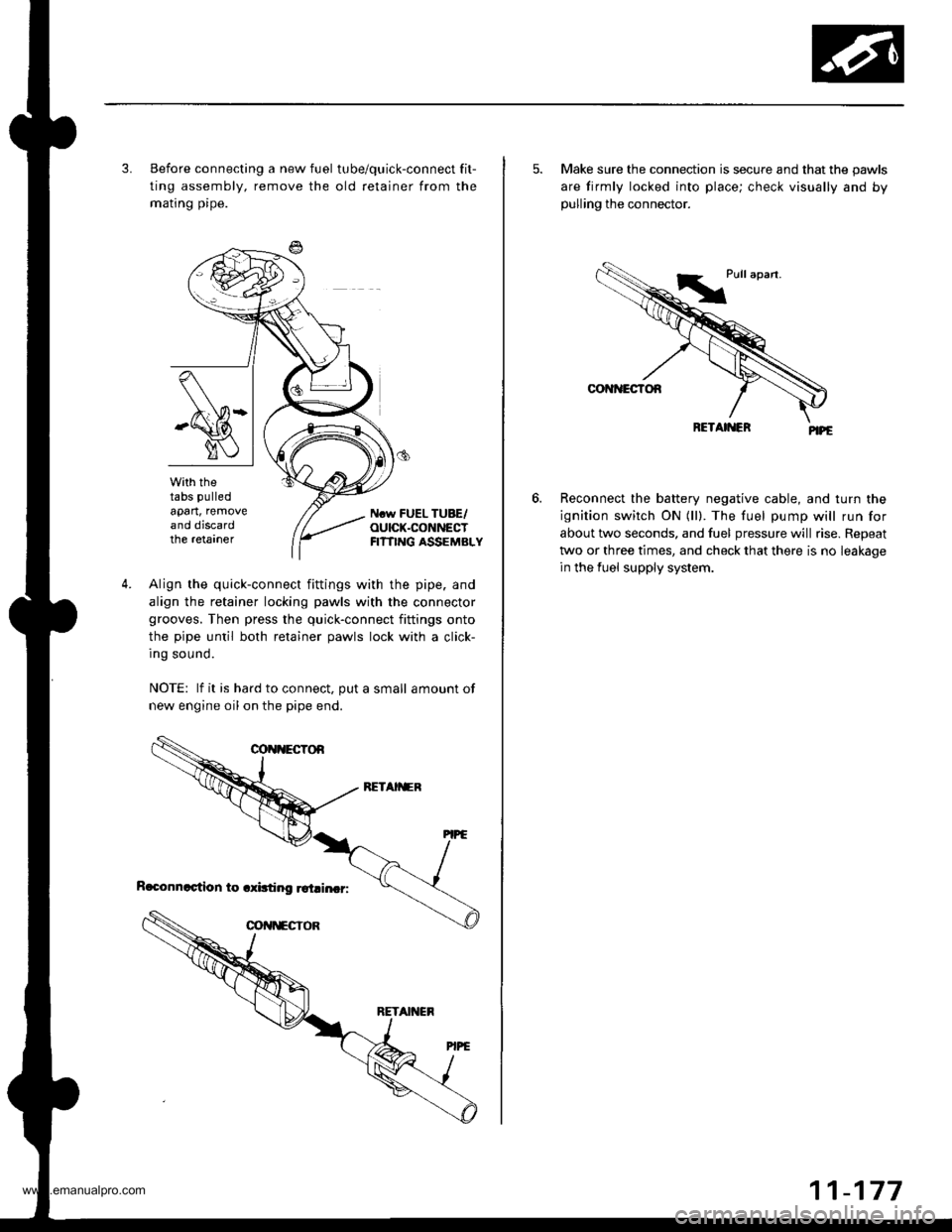

3. Before connecting a new fuel tube/quick-connect fit-

ting assembly, remove the old retainer from the

mating pipe.

with thetabs pulled

apart, removeand discardthe retarner

Ncw FUEL TUBE/OUICK.CONNECTFI?TING ASSEMBLY

4.Align the quick-connect fittings with the pipe. and

align the retainer locking pawls with the connector

grooves. Then press the quick-connect fittings onto

the pipe until both retainer pawls lock with a click-

Ing sound.

NOTE: lf it is hard to connect, put a small amount of

new engine oil on the pipe end.

5. Make sure the connection is secure and that the pawls

are firmly locked into place; check visually and bypulling the connector.

Reconnect the battery negative cable, and turn the

ignition switch ON (ll). The fuel pump will run for

about two seconds, and fuel pressure will rise. Repeat

two or three times, and check that there is no leakage

in the fuel supply system.

6.

www.emanualpro.com

Page 380 of 1395

Fuel Supply System

System Description

The fuel supply system consists of a fuel tank, in-tank

high-pressure fuel pump. PGM-Fl main relay, fuel filter,

fuel pressure regulator, fuel injectors, and fuel delivery

and return lines. This system delivers pressure-regulat-

ed fuel to the fuel injectors and cuts the fuel delivery

when the engine is not running.

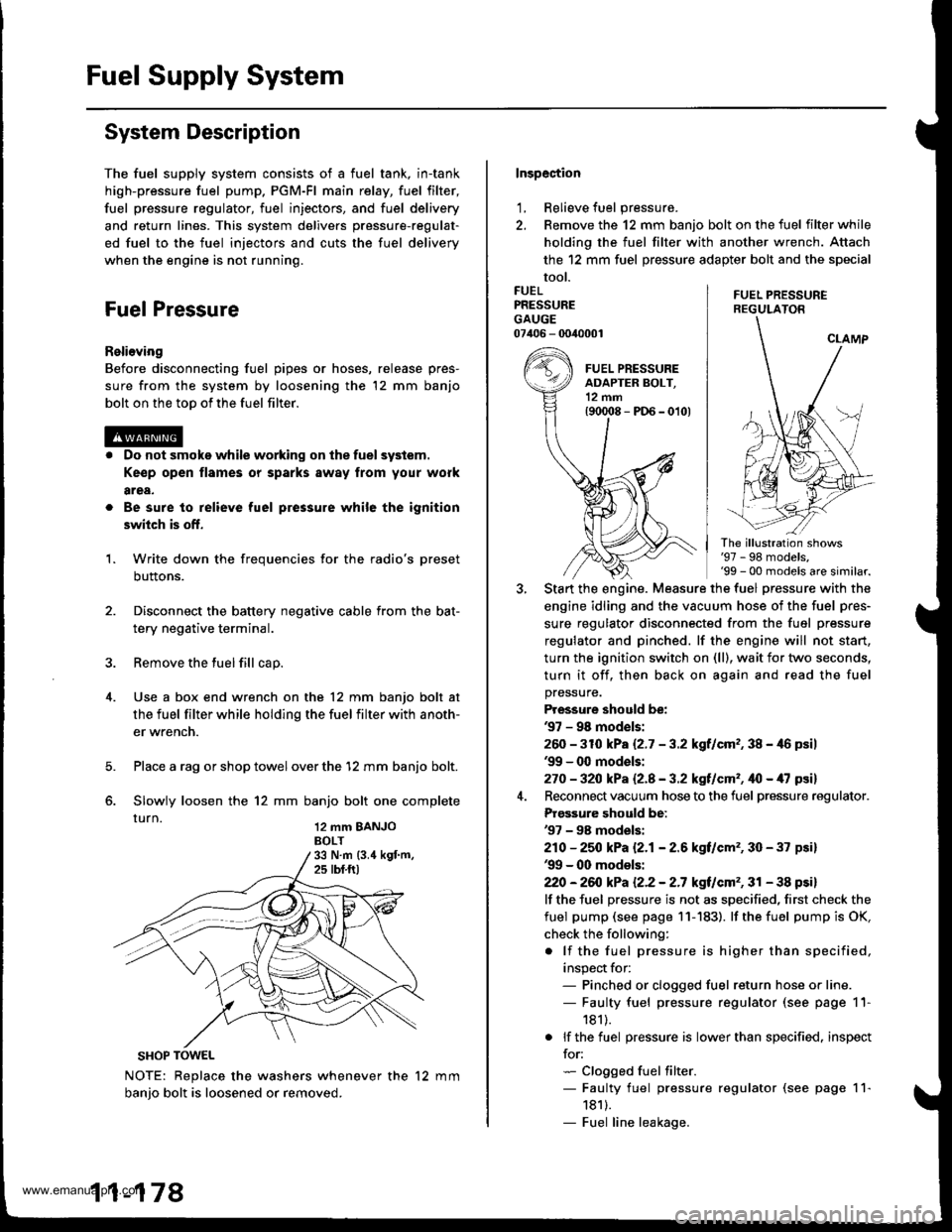

Fuel Pressure

Relieving

Before disconnecting fuel pipes or hoses, release pres-

sure from the system by loosening the 12 mm banjo

bolt on the too of the fuel filter.

Do not smoke while working on the fuel system.

Ke€p open flames or sparks away from your work

area,

Be sure to relieve fuel pressure while the ignition

switch is off.

Write down the frequencies for the radio's preset

buttons.

Disconnect the battery negative cable from the bat-

tery negative terminal.

Remove the fuel fill cap.

Use a box end wrench on the 12 mm banjo bolt at

the fuel filter while holding the fuel filter with anoth-

er wrench.

Place a rag or shop towel over the '12 mm banjo bolt.

Slowly loosen the 12 mm banjo bolt one complete

rurn 12 mm BANJoBOLT

1.

SHOP TOWEL

NOTE: Replace the washers whenever the 12 mm

banio bolt is loosened or removed.

11-178

Inspection

1, Relieve fuel pressure.

2. Remove the 12 mm banjo bolt on the fuel filter while

holding the fuel filter with another wrench. Attach

the 12 mm fuel pressure adapter bolt and the special

tool.

FUEL PRESSUREREGULATON

FUELPRESSUREGAUGE07406 - 0040001

The illustration shows'97 - 98 models,'99 - 00 models are similar.

Start the engine. Measure the fuel pressure with the

engine idling and the vacuum hose of the fuel pres-

sure regulator disconnected from the fuel pressure

regulator and pinched. lf the engine will not start,

turn the ignition switch on (ll), wait for two seconds,

turn it off, then back on again and read the fuel

pressure.

Pressure should be:'97 - 98 mod€ls:

260 -31O kPa 12.7 - 3.2 kgf/cm,, 38 - 46 psil'99 - 0O models:

270 - 32O kPa Q.A - 3.2 kgf/cm'�, ifo - /U psil

Reconnect vacuum hose to the fuel pressure regulator.

Prgs3ure should be:'97 - 98 models:

210 - 25O kPa 12.1- 2.6 kgf/cm'�, 30 - 37 psi)'99 - 00 models:

22O -26iJ kPa 12.2 - 2.7 kgt/cm'�, 31 - 38 psi)

lf the fuel pressure is not as specified, first check the

fuel pump (see page 11- 183). lf the fuel pump is OK,

check the following:

. lf the fuel pressure is higher than specified,

inspect for:- Pinched or clogged fuel return hose or line.- Faulty fuel pressure regulator (see page 11-

181).

. lf the fuel pressure is lower than specified. inspect

for:- Clogged fuel filter.- Faulty fuel pressure regulator (see page 11-

1811.- Fuel line leakage.

www.emanualpro.com

Page 382 of 1395

Fuel Supply System

Fuel Injectors {cont'dl

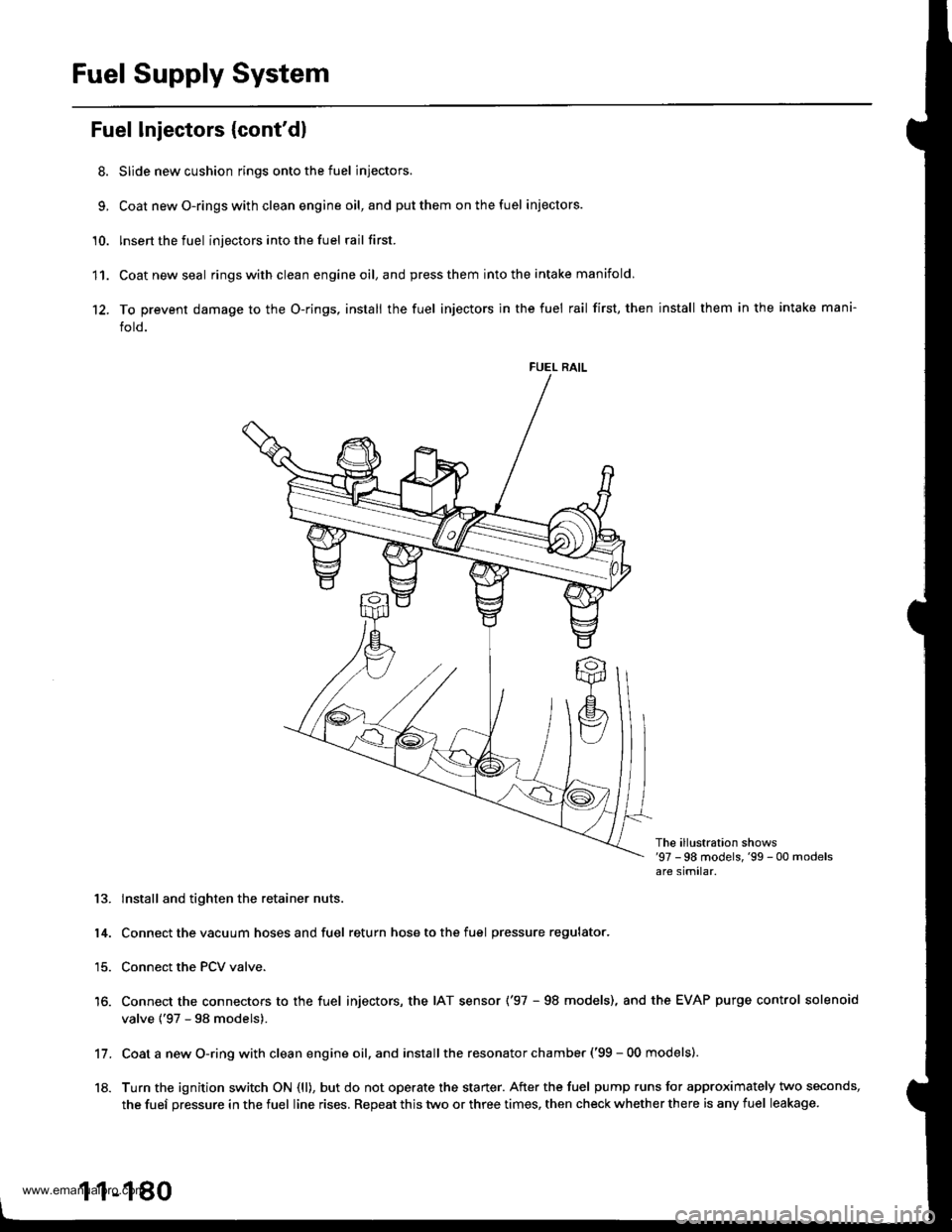

8. Slide new cushion rings onto the fuel injectors.

9, Coat newO-ringswith clean engine oil,and putthem onthefuel iniectors.

'10. lnsert the fuel injectors into the fuel rail first.

11. Coatnewseal ringswithclean engineoil,and press them into the intake manifold

12. To prevent damage to the O-rings, install the fuel injectors in the fuel rail first, then install them in the intake mani-

fold.

FUEL RAIL

The ill!stration shows'97 -98 models,'99 - 00 modelsare similar.

13. lnstall and tighten the retainer nuts.

14. Connect the vacuum hoses and fuel return hose to the fuel pressure regulator.

15. Connect the PCV valve.

16. Connect the connectors to the fuel injectors, the IAT sensor ('97 - 98 models), and the EVAP purge control solenoid

valve {'97 - 98 models).

Coat a new O-ring with clean engine oil, and install the resonator chamber ('99 - 00 models).

Turn the ignition switch ON (ll), but do not operate the starter. After the fuel pump runs for approximately two seconds,

the fuef pressure in the fuel line rises. Repeat this two or three times, then check whether there is any fuel leakage.

11.

18.

1 1-180

www.emanualpro.com

Page 383 of 1395

Fuel Pressure Regulator

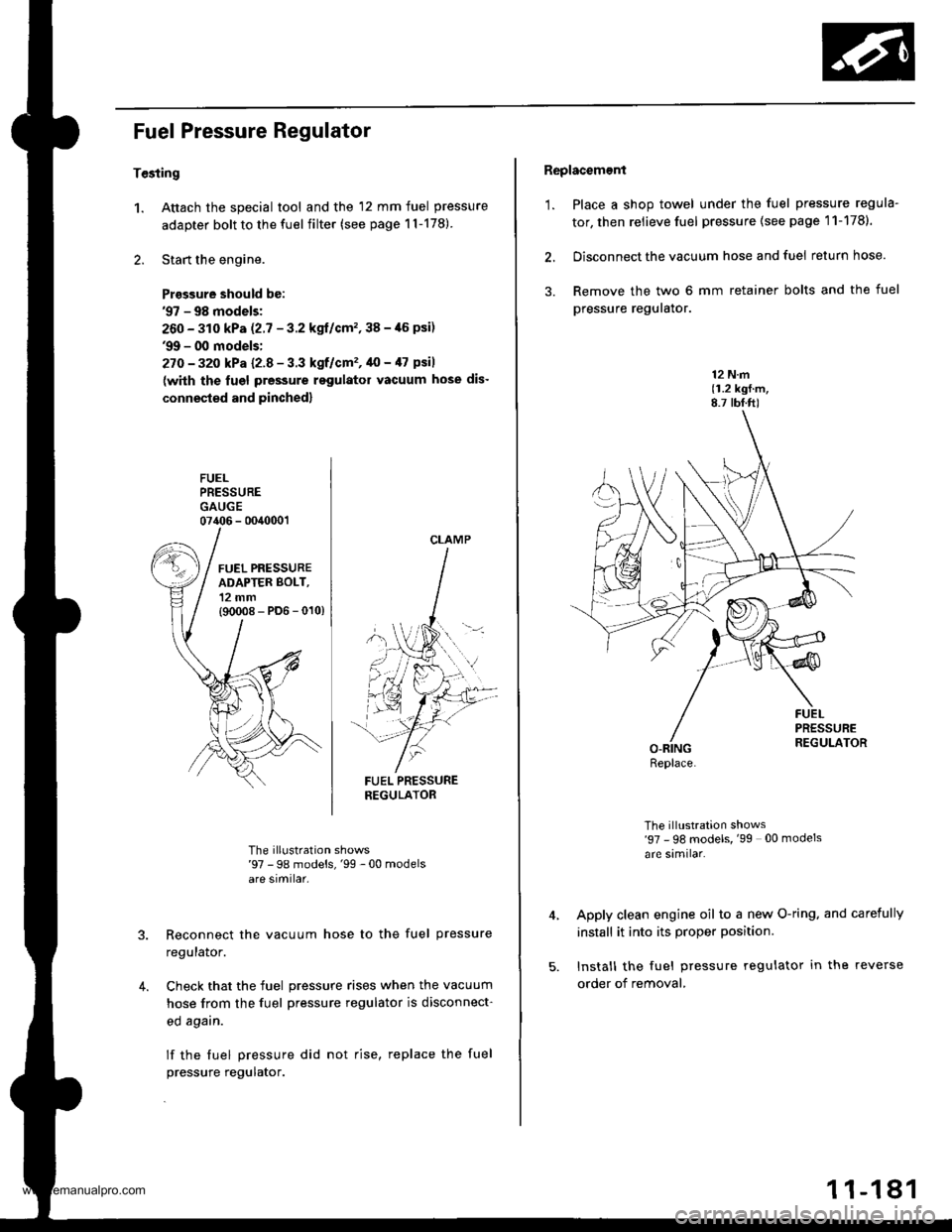

Tesiing

1. Attach the special tool and the 12 mm fuel pressure

adapter bolt to the fuel filter (see page 1l-178)

2. Start the engine.

Prasgure should be:'97 - 98 models;

260 - 310 kPa (2.7 - 3.2 kgl/cm'�,38 -,16 psi)'9!t - 00 models:

27O - 32o kPa l2-8 - 3.3 kgf/cm'�, 40 - /l7 psil

(with the lugl pressure rsgulator vacuum hose dis-

connested and pinched)

FUELPRESSUREGAUGE07406 - 0040001

FUEL PRESSURENEGULATOR

The illustration shows'97 - 98 models,'99 -00 modelsare similar.

Reconnect the vacuum hose to the fuel pressure

regulalor.

Check that the fuel pressure rises when the vacuum

hose from the fuel pressure regulator is disconnect-

ed agarn.

lf the fuel pressure did not rise, replace the fuel

pressure regulator.

4.

CLAMP

Replacement

'1. Place a shop towel under the fuel pressure regula-

tor, then relieve fuel pressure (see page 11-1781.

2. Disconnect the vacuum hose and fuel return hose.

3. Remove the two 6 mm retainer bolts and the fuel

pressure reguralor.

12 N.m(1.2 kgf.m,8.7 tbf.ft)

The illustration shows'97 - 98 models, '99 00 models

are similar.

Apply clean engine oil to a new O-ring. and carefully

install it into its proper position.

Install the fuel pressure regulator in the reverse

order of removal,

Replace.

1 1-181

www.emanualpro.com

Page 389 of 1395

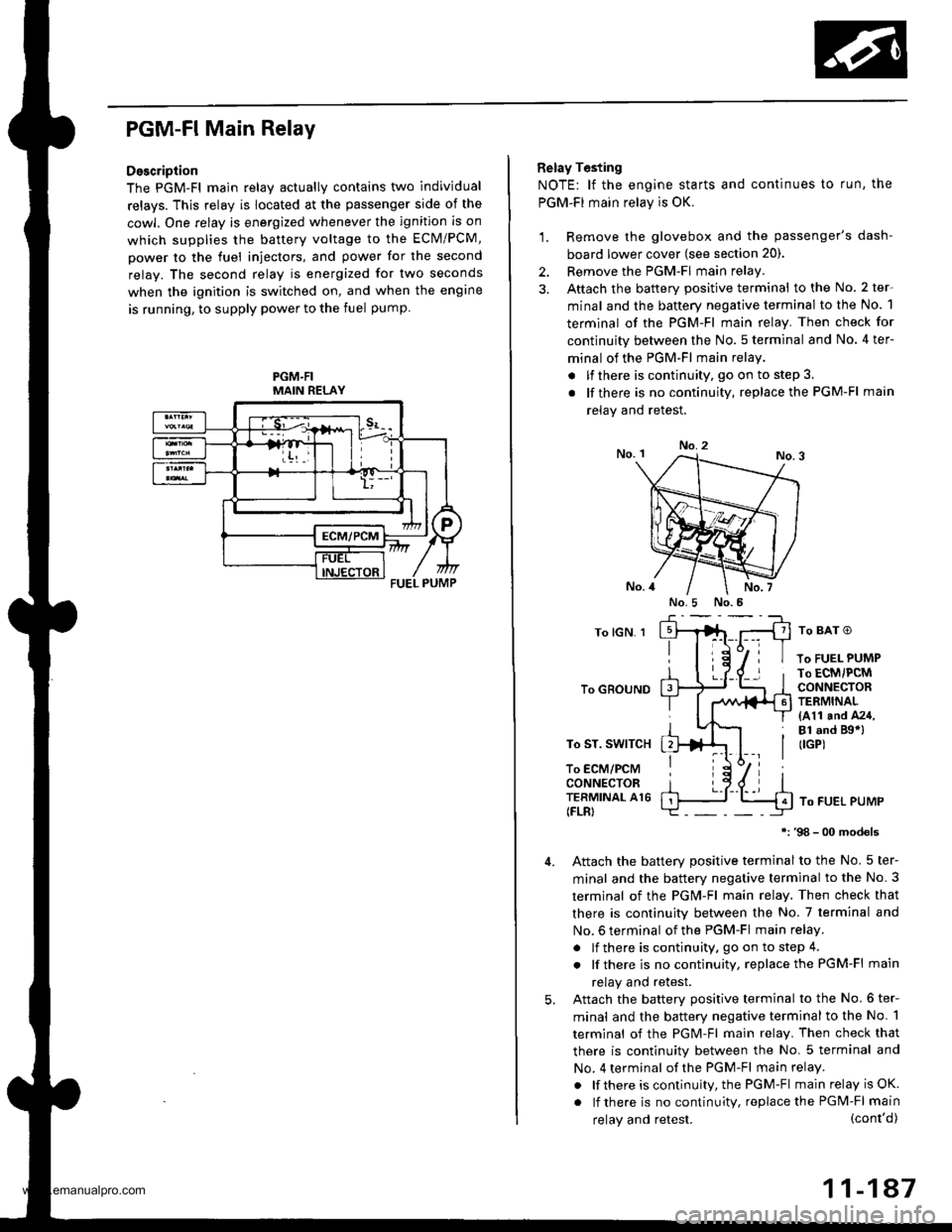

PGM-FI Main Relay

Description

The PGM-Fl main relav actuallv contains two individual

relays. This relay is located at the passenger side of the

cowl. One relay is energized whenever the ignition is on

which supplies the battery voltage to the ECM/PCM,

power to the fuel injectors, and power for the second

relay. The second relay is energized for two seconds

when the ignition is switched on, and when the engine

is running, to supply power to the fuel pump

PGM.FIMAIN RELAY

Belay Testing

NOTE: lf the engine starts and continues to run, the

PGM-FI main relay is OK.

1. Remove the glovebox and the passenger's dash-

board lower cover (see section 20).

2. Remove the PGM-FI main relay

3. Aftach the battery positive terminal to the No. 2 ter-

minal and the battery negative terminal to the No. 1

terminal of the PGM-Fl main relay. Then check for

continuity between the No. 5 terminal and No. 4 ter-

minal of the PGM-FI main relay

. lfthere is continuity, go on to step 3.

. lf there is nocontinuity, replacethe PGM-Fl main

relav and retest.

No.2

To lGN. 1

To GROUND

To ST. SWITCH

To ECM/PCMCONNECTORTERMINAL A16(FLR)

To BAT O

To FUEL PUMPTo ECM/PCMCONNECTORTERMINAL(411 and A24,Bl .nd Bgal(IGP)

To FUEL PUMP

98 - 00 models

Attach the batterv Dositive terminal to the No. 5 ter-

minal and the battery negative terminal to the No. 3

termjnal of the PGM-Fl main relay. Then check that

there is continuity between the No. 7 terminal and

No. 6 terminal of the PGM-FI main relay.

. lf there is continuity, go on to step 4.

. lf there is nocontinuity, replacethe PGM-Fl main

relay and retest.

Attach the batterv oositive terminal to the No.6 ter-

minal and the battery negative terminal to the No. 1

terminal of the PGM-Fl main relay. Then check that

there is continuitv between the No. 5 terminal and

No. 4 terminal of the PGM-Fl main relay.

. lf there is continuity, the PGM-Fl main relay is OK.

. lf there is nocontinuity, replacethe PGM-FI main

5.

(cont'd)

11-147

No.5 No.5

relay and retest.

www.emanualpro.com

Page 390 of 1395

![HONDA CR-V 2000 RD1-RD3 / 1.G Owners Manual

Fuel Supply System

PGM-FI Main Relay (contdl

Troubleshooting

lc(}21PGM.FI MAIN RELAY 7P CONNECTOR

GND

trTr]--Flq

FI,TilI A

Y

Wire side ot female terminals

- Engine will not start.- InsDection ol PG HONDA CR-V 2000 RD1-RD3 / 1.G Owners Manual

Fuel Supply System

PGM-FI Main Relay (contdl

Troubleshooting

lc(}21PGM.FI MAIN RELAY 7P CONNECTOR

GND

trTr]--Flq

FI,TilI A

Y

Wire side ot female terminals

- Engine will not start.- InsDection ol PG](/img/13/5778/w960_5778-389.png)

Fuel Supply System

PGM-FI Main Relay (cont'dl

Troubleshooting

lc(}21PGM.FI MAIN RELAY 7P CONNECTOR

GND

trTr]--Flq

FI,Til'I A

Y

Wire side ot female terminals

- Engine will not start.- InsDection ol PGM-FI mainrelay and relay harness,

Check fo. an open in the wireIGND linol:1. Turn the ignition switch OFF.2. Disconnect the PGM Fl mainrelay 7P connector.3. Check for continuity betweenthe PGM'FI main relay 7P con-nector terminal No. 3 and bodyground.

Repair opcn in th€ wire betweenthe PGM-FI main relav and G101.

Check tor an open or short in thewiro (BAT line):Measure voltage between thePGM'FI main relay 7P connectorterminal No. 7 and body ground.- Repai. open or short in lhewir6 belween the PGM-FImain relay and the Fl E/M (15Al fu3e.- Replace th6 FIE/M (15 Altus6in th€ under-hood fuse/.6lay

ls there baftery voltage?

Check lor an open or short in thewire (lGl line):L Turn the ignition switch ON (ll).2. Measure the voltage betweenthe PGM-FI main relay 7P connectorterminal No. 5 and bodyground.- Repair open or shorl in thewire between the FGM-FI mainrelay and the No. 13 FUELPUMP 115 A) tuse.- Replaco the No. 13 RJEL PUMP115 A) luse in the und6.-d$hfuso/ relav box.Check for an open or short in thewire {STS line):1. Turn the ignition switch to theSTART (lll) position.NOTE:. M/T: Clutch pedal must bedepressed.. A/T: Transmission in E orElposition.2. Measure the voltage betweenthe PGM-Fl main retay 7Pconnector terminal No. 2 andbody ground.- Repair open or short in thewire betwe€n the PIGM-FI m.inrclay and th€ No. 31 STARTERSlGllAL 17.5 A) tuse.- Repl.ce the No. 31 STARTERSIGNAL 17.5 Al tuse in theunder-dash tuse/relay box.('97 model: To page 11-189)('98 00models:To page 1l 190)

1 1-188

www.emanualpro.com

Page 396 of 1395

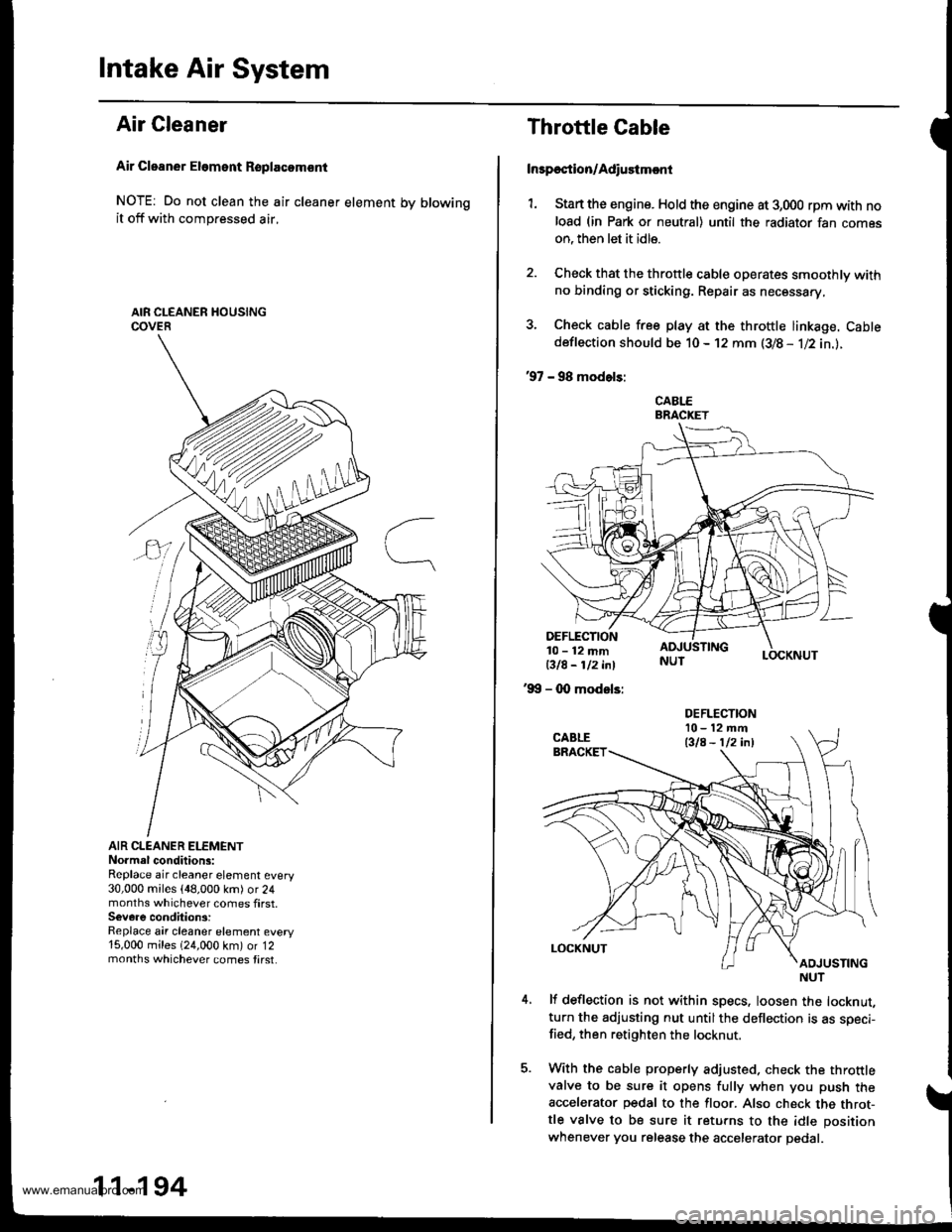

Intake Air System

Air Cleaner

Air Cleaner Eloment Rsplacomsnt

NOTE: Do not clean the air cleaner element by blowingit off with compressed air,

AIR CLEANER ELEMENTNo.mal conditions:Replace air cleaner element every30,000 miles {48,000 km) or 24months whichever comes first.Severe condition3:Replace air cleaner element every15,000 miles 124,000 km) or 12months whichever comes tirst.

m

11-194

Throttle Cable

Inrpection/Adiustmcnt

1. Stan the engine. Hold the engine at 3,000 rpm with noload (in Park or neutral) until the radiator fan comeson, then let it idle.

2. Check that the throttle cable operates smoothly withno binding or sticking. Repair as necessary,

3. Check cable free play at the throttle linkage. Cabtedeflection should be 10- 12 mm (3/8 - 1l2in.l.

'97 - 98 modols:

CABLEBRACKET

LOCKNUT

DEFLECTION10-12mmBIA- 112 i^l

'99 - 0O modsls:

lf deflection is not within specs, loosen the locknut,turn the adjusting nut untilthe deflection is as speci-fied, then retighten the locknut.

With the cable properly adjusted. check the throttlevalve to be sure it opens fully when you push theaccelerator pedal to the floor. Also check the throt-tle valve to be sure it returns to the idle position

whenever you release the accelerator pedal.

DEFLECTIONl0-12mft

Bla - 112 inl

NUT

www.emanualpro.com

Page 398 of 1395

Intake Air System

Throttle Body

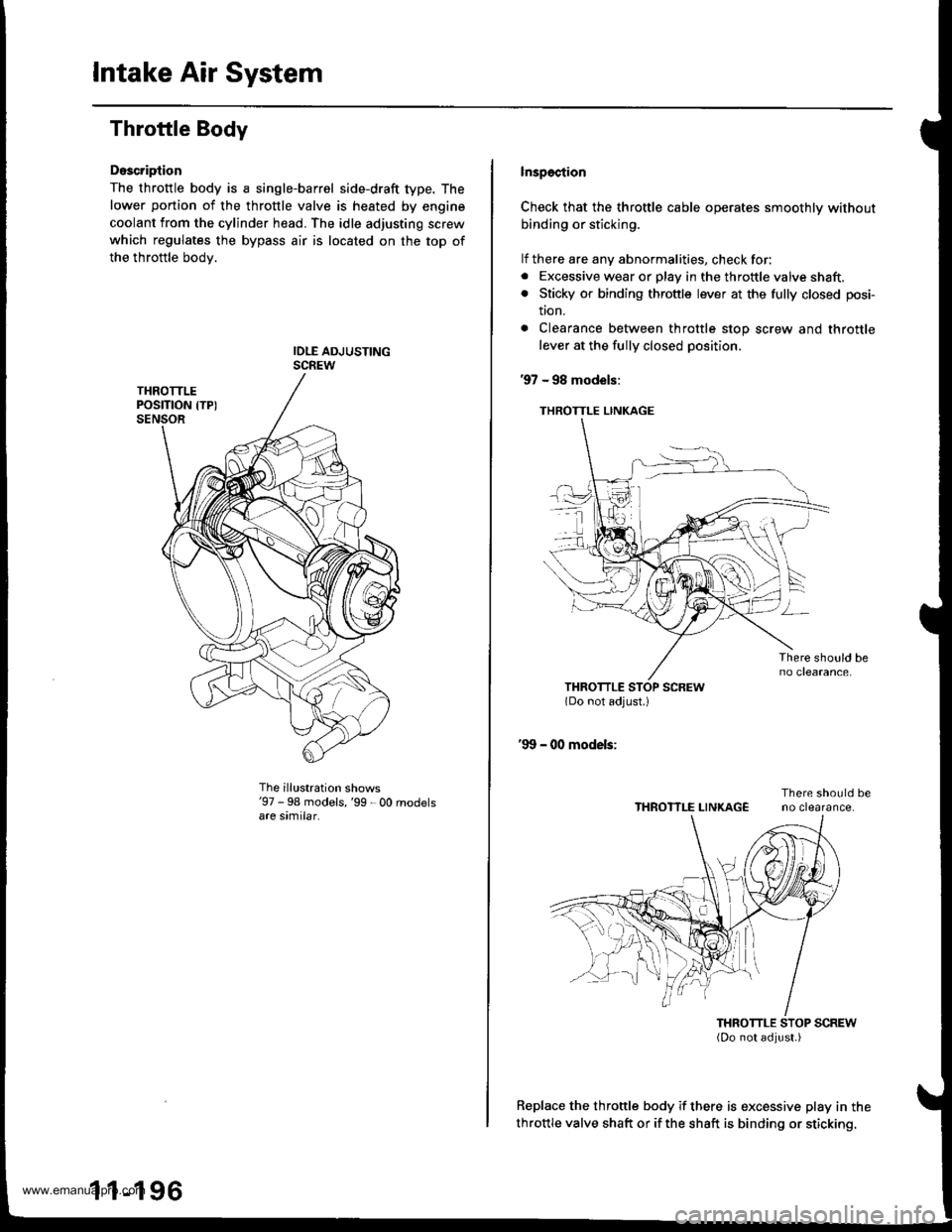

Doscription

The throttle body is a single-barrel side-draft type. The

lower portion of the throttle valve is heated by engine

coolant from the cylinder head. The idle adjusting screw

which regulates the bypass air is located on the top of

the throttle bodv.

The illustration shows'97 - 98 models,'99 - 00 rnodelsare similar.

1 1-196

lnspection

Check that the throttle cable operates smoothly without

binding or sticking.

lf there are any abnormalities, check for:. Excessive wear or play in the throftle valve shaft.. Sticky or binding throttle lever at the fully closed posi-

tton.

. Clearance between throttle stop screw and throttle

lever at the fully closed position.

97 - 98 models:

THROTTLE LINKAGE

Replace the throttle body if there is excessive play in the

throttle valve shaft or if the shaft is binding or sticking.

THROTTLE LINKAGE

www.emanualpro.com