HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

CR-V 2000 RD1-RD3 / 1.G

HONDA

HONDA

https://www.carmanualsonline.info/img/13/5778/w960_5778-0.png

HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

Trending: Oil pump ring, Locking, temp gauge stuck, width, quarter glass replacement, Quarter glass, Misfire

Page 1081 of 1395

Wiper/Washer

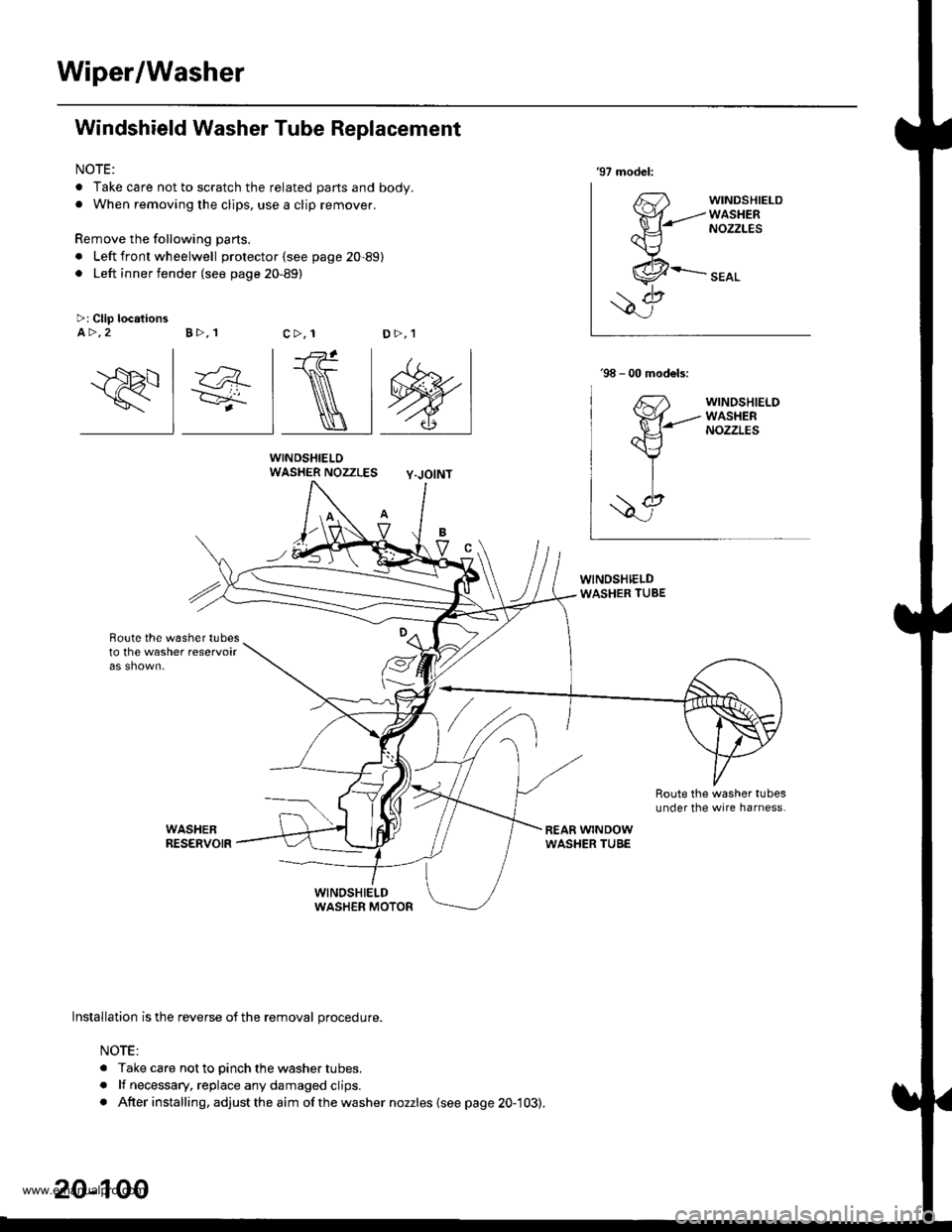

Windshield Washer Tube Replacement

NOTE:

. Take care not to scratch the related parts and body.. When removing the clips, use a clip remover.

Remove the following parts.

. Left front wheelwell protector (see page 20-89). Left inner fender (see page 20-89)

WINDSHIELOWASHER NOZZLES Y-JOINT

Boute the w6sher tubesto the washer reservoir

'97 model:

63'fr{-------

ax---\J

,.&--

\7>: Clip locationsA >,2 B >,1c>, 1D>,1

\

lnstallation is the reverse of the removal procedure.

NOTE:

. Take care not to pinch the washer tubes.

. lf necessary, replace any damaged clips.. After installing, adjust the aim ofthe washer nozzles (see page 20-103).

20-100

www.emanualpro.com

Page 1082 of 1395

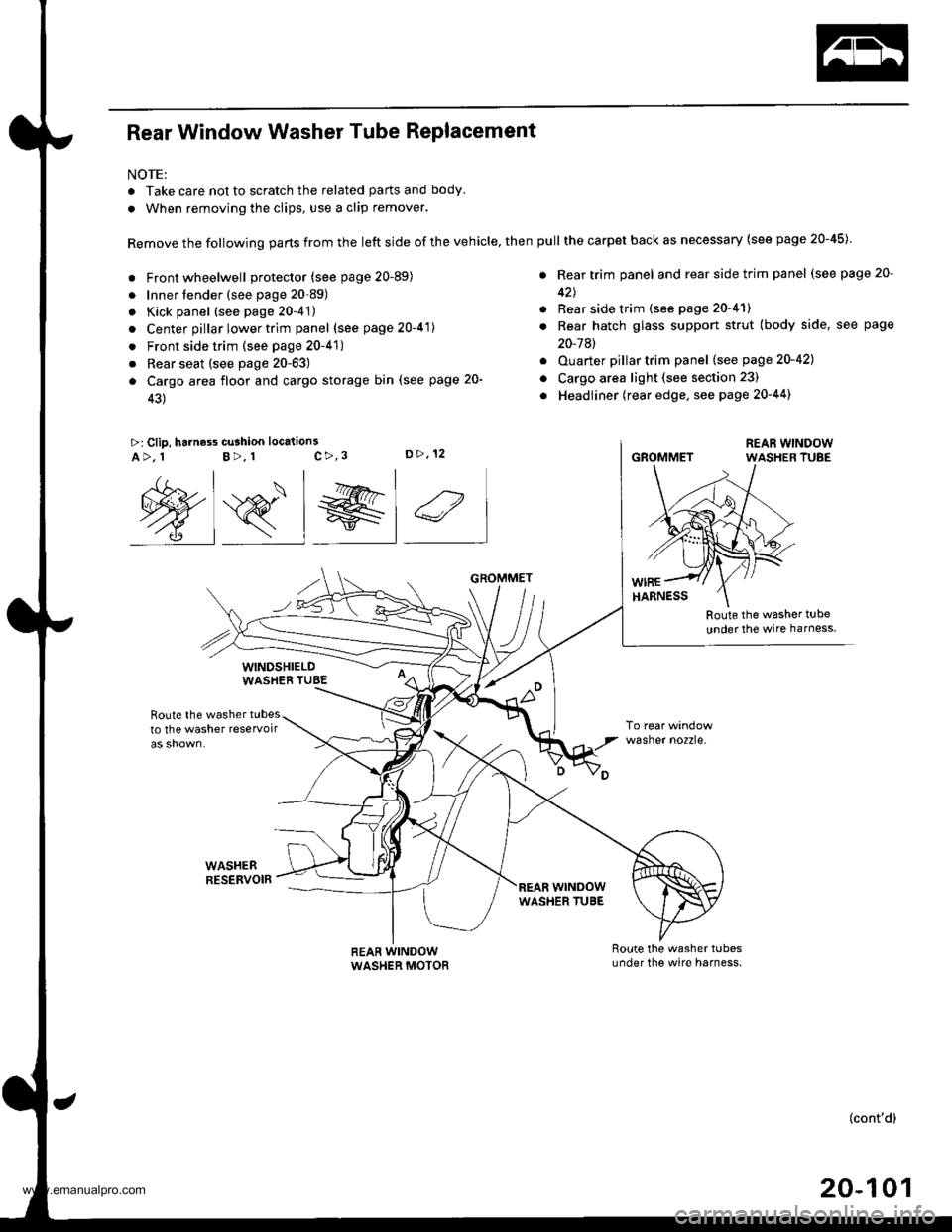

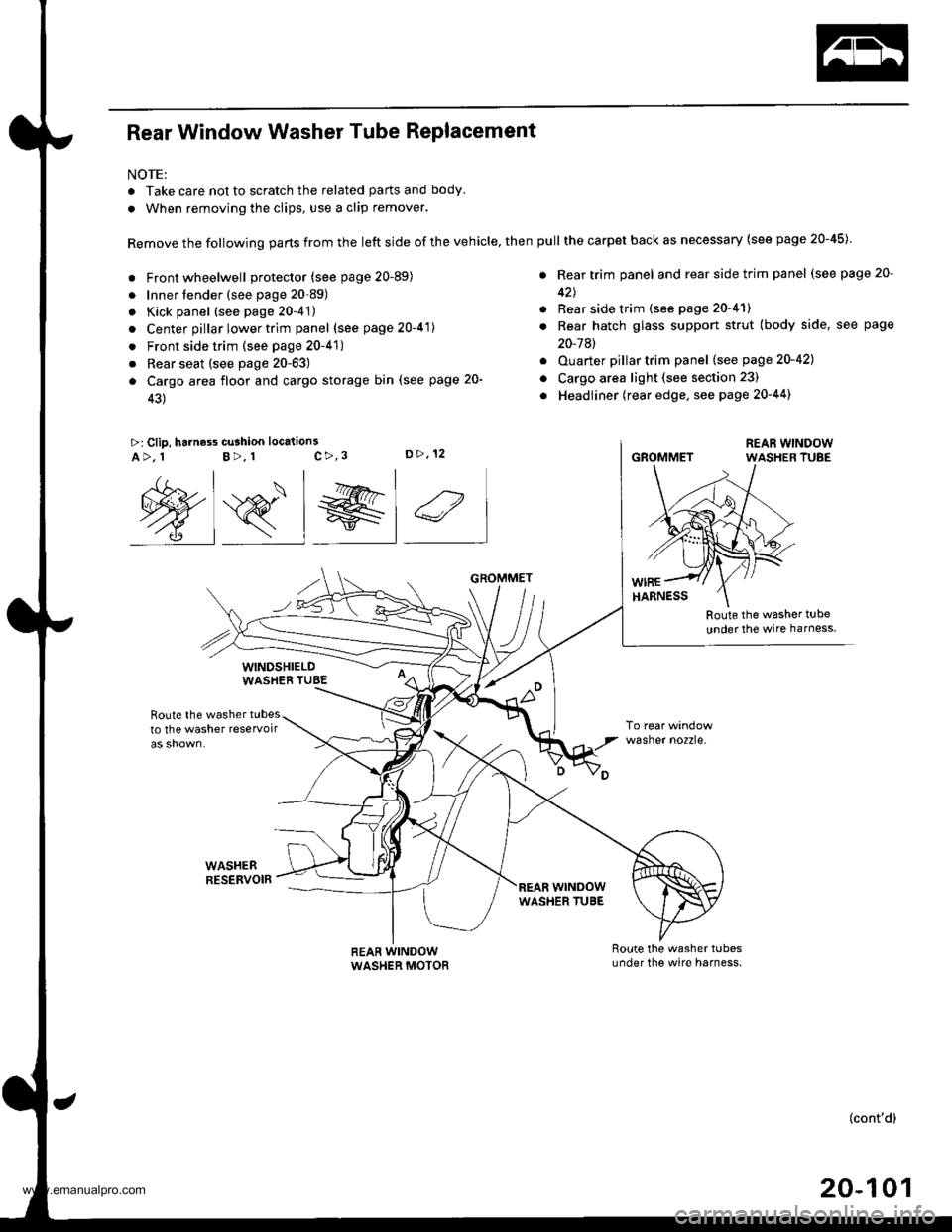

Rear Window Washer Tube Replacement

NOTE:

. Take care not to scratch the related parts and body.

. When removing the clips, use a clip remover.

Remove the following parts from the left side of the vehicle, then

. Front wheelwell protector (see page 20-89)

. Innertender (see page 20-89)

. Kick panel (see page 20-4't)

. Center pillar lower trim panel (see page 20-41)

. Front side trim (see page 20-41)

. Rear seat (see page 20-63)

a Cargo area floor and cargo storage bin (see page 20-

43)

>: Clip, harness cu3hion location3c>,3D>,12A>, 1B>, 1

Route the washer t!be

under the wire harness

Route the washer tubesto the washer reservoir

WASHEBRESERVOIR

wasner no2zre.

@s_l el 4

WINDSHIELDWASHEB TUBE

REAR WINDOWWASHER MOTOR

GROMMET

wrNoowWASHER TUBE

pull the carpet back as necessary (see page 20-45)

. Rear trim panel and rear side trim panel (see page 20-

42J

. Rear side trim (see page 20-41)

. Rear hatch glass support strut (body side, see page

20-7Al

. Ouarter pillartrim panel (see page 20-421

o Cargo area light (see section 23)

. Headliner (rear edge, see page 20-44)

GROMMET

(cont'd)

20-101

www.emanualpro.com

Page 1083 of 1395

Wiper/Washer

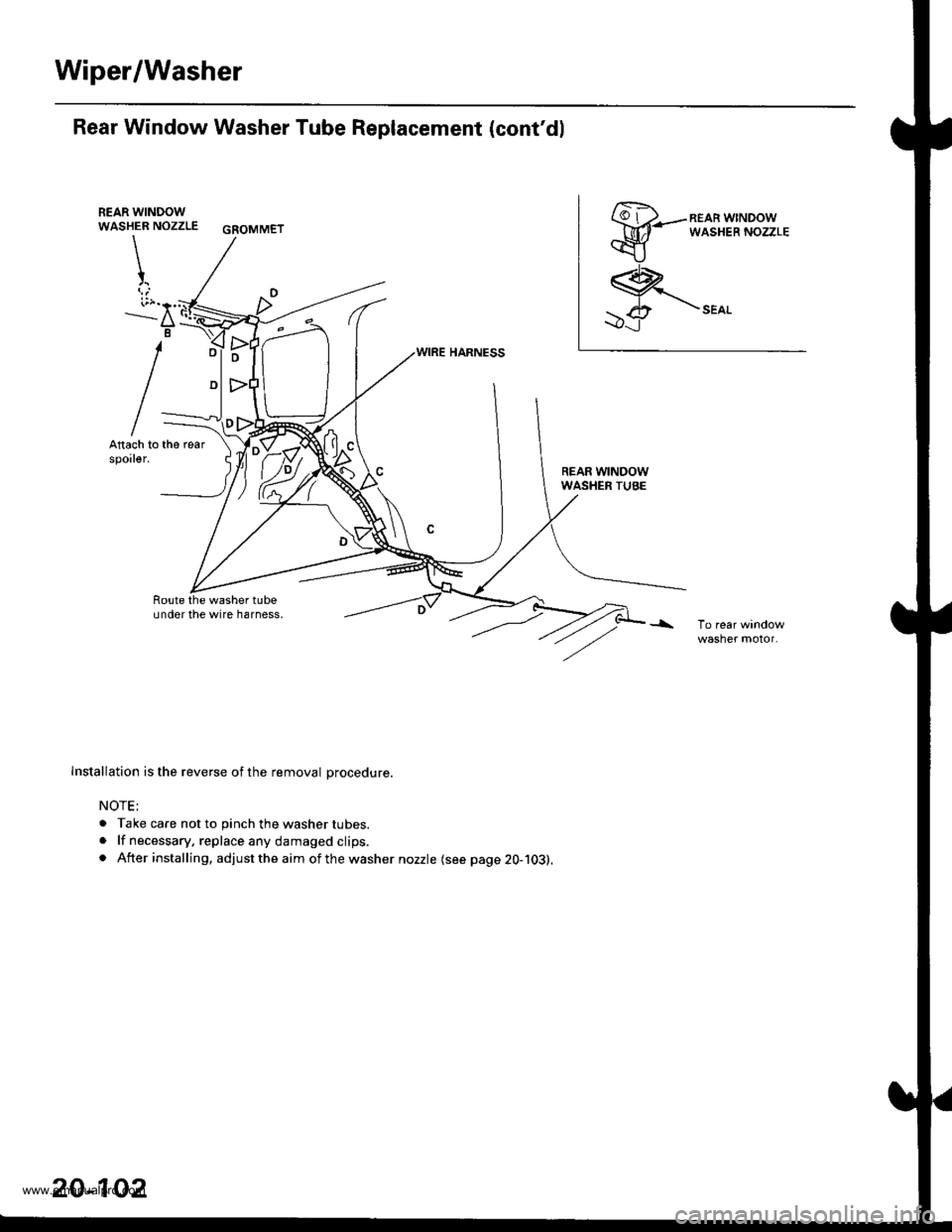

Rear Window Washer Tube Replacement (cont'dl

REAR WINDOWWASHER NOZZLE GSOMMET

\

t

i;r."'..--a

B

REAR WINDOWWASHER TUBE

Route the washer tubeundor the wire harness,

Installation is the reverse of the removal Drocedure.

NOTE;

. Take care not to pinch the washer tubes.. lf necessary, replace any damaged clips.. After installing, adjust the aim of the washer nozzle (see page 20-103).

20-102

www.emanualpro.com

Page 1084 of 1395

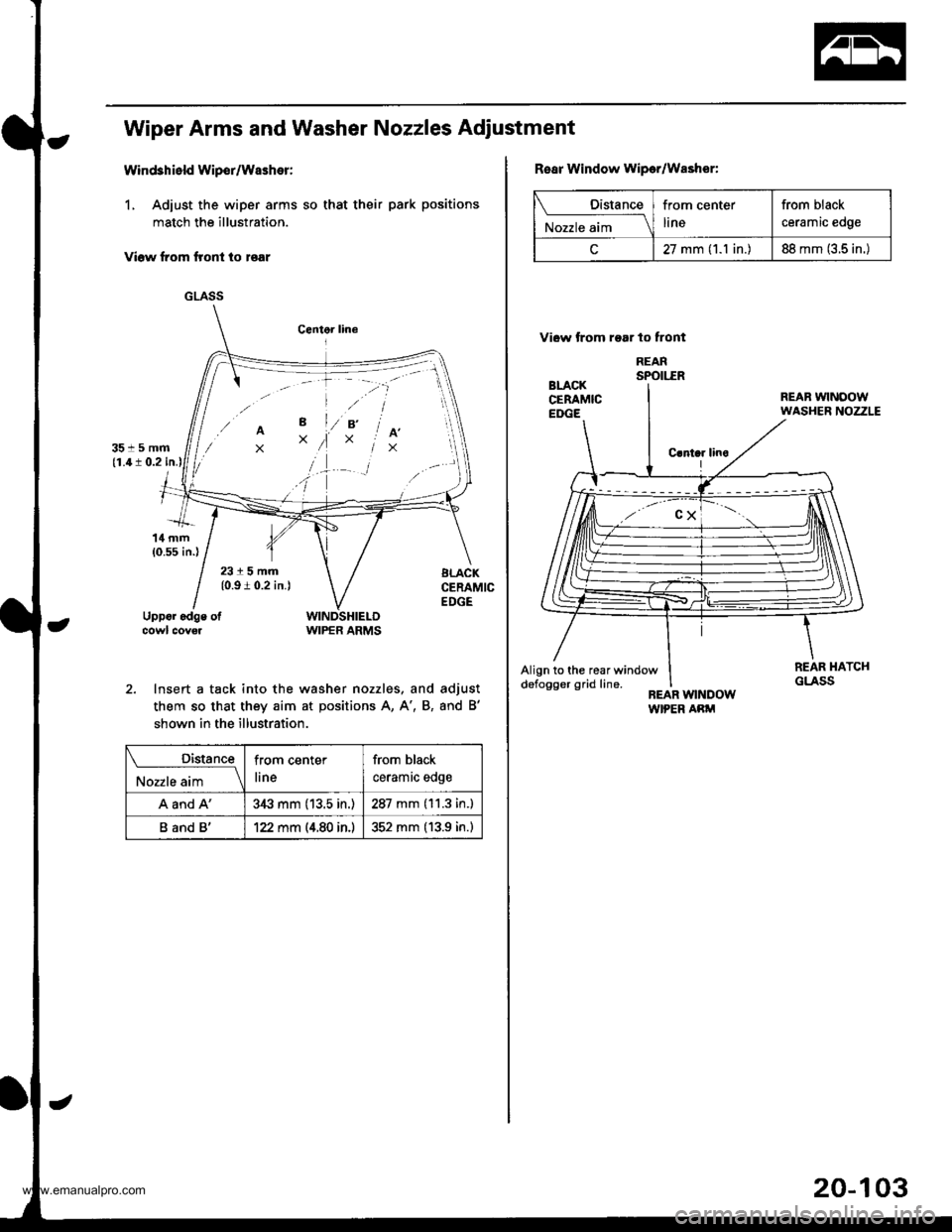

Wiper Arms and Washer Nozzles Adiustmenl

Wind3hield Wipor/Washer:

1, Adiust the wiper arms so that their park positions

match the illustration.

Viow from flont io roar

GLASS

2. Insert a tack into the washer nozzles. and

them so that they aim at positions A, A', B,

shown in the illustration.

adjust

and B'

Distance

^,J;-ll\

from center

line

from black

ceramic edge

A and A'3,$ mm (13.5 in.)287 mm (11.3 in.)

B and B'122 mm (4.80 in.)352 mm (13.9 in.)

Rear Window wipor/Washer:

Vi6w trom roar to lront

REARsPo[.-ER

C.nlar linoL

Align to the rear windowdefogger grid line.

Distance

ru"rrr. "i.

'_\from center

ltne

from black

ceramic edge

27 mm (1.1 in.)88 mm (3.5 in.)

20-103

www.emanualpro.com

Page 1085 of 1395

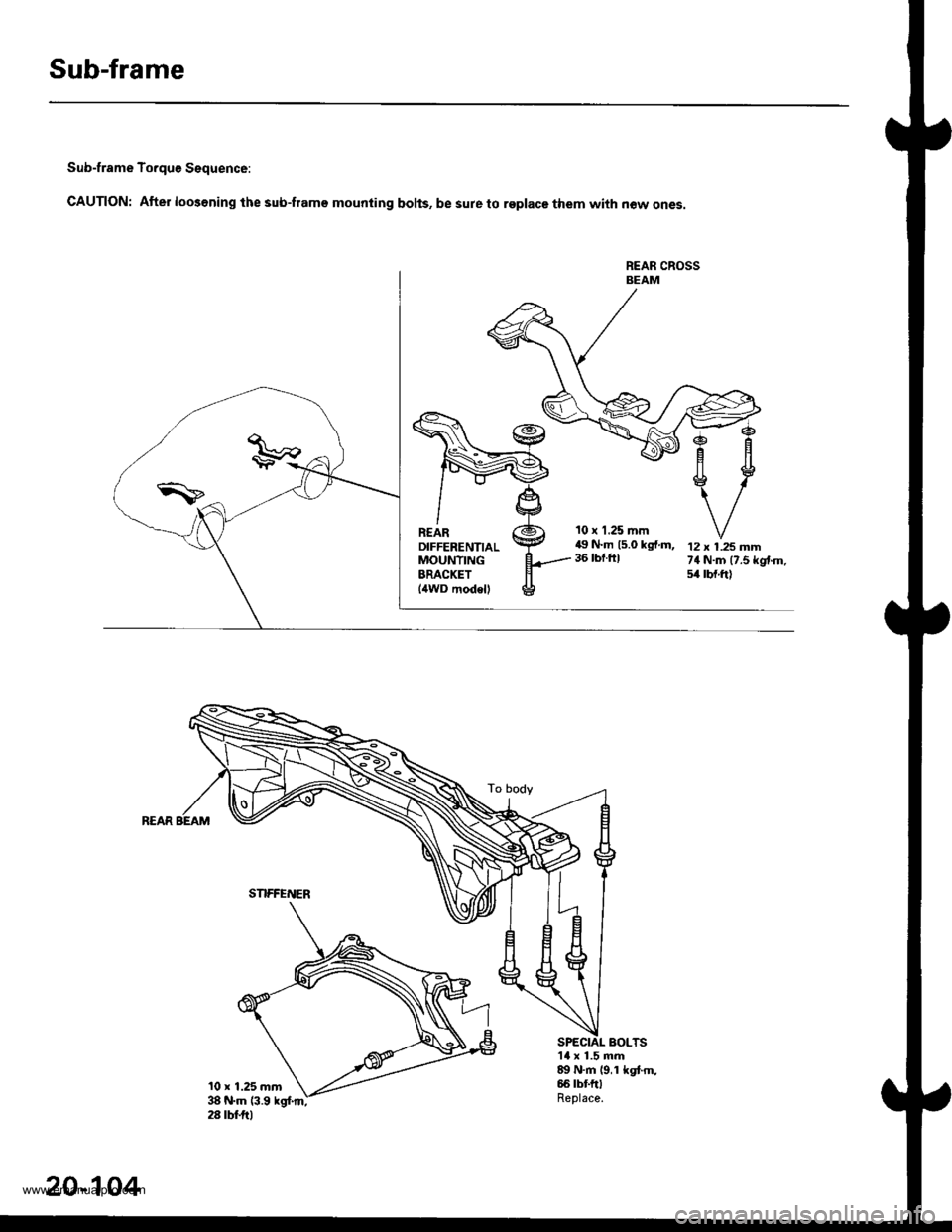

Sub-frame

Sub-frame To.que Sequence:

CAUTION: After loo3ening the sub-frame mounting bolts, be sure to replace them with now ones.

REAN CROSSBEAM

10 r 1.25 mm49 N.m 15.0 kg{.m,36 tbt.ftl12 x 1.25 mm74 N.m (7.5 kgtm.54 tbf.ft)

BOLTS1l x 1.5 mm89 N.m 19,1 kgt m,66 tbt ftlReplace.

SNFFENER

20-104

www.emanualpro.com

Page 1086 of 1395

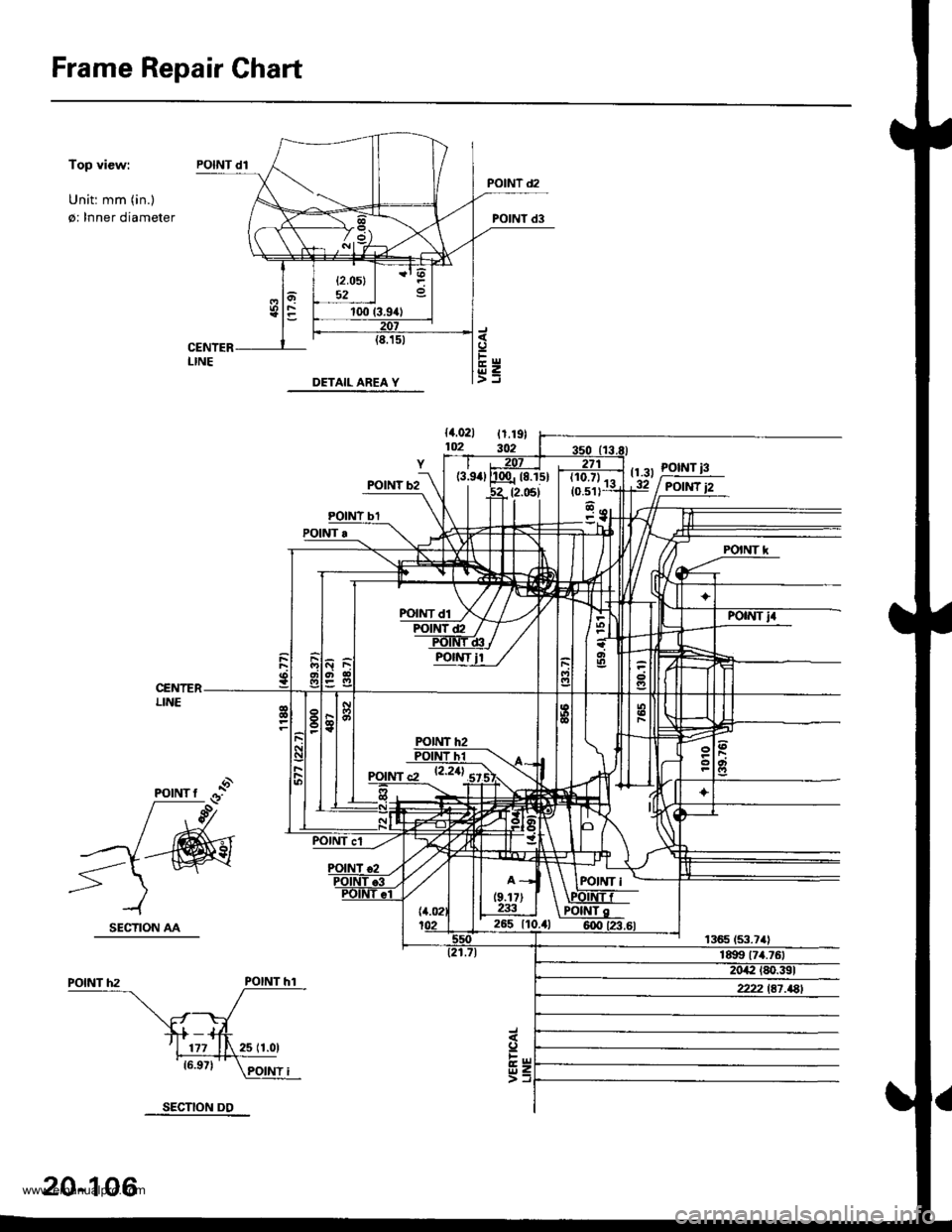

Frame Repair Chart

Top view:

Unit: mm (in.)

0: Inner diameter

{4.021 t1.19}lm 302

tr.rr !9$IPOtt{T

POINT'

POINT hl

20-106

SECTION DD

www.emanualpro.com

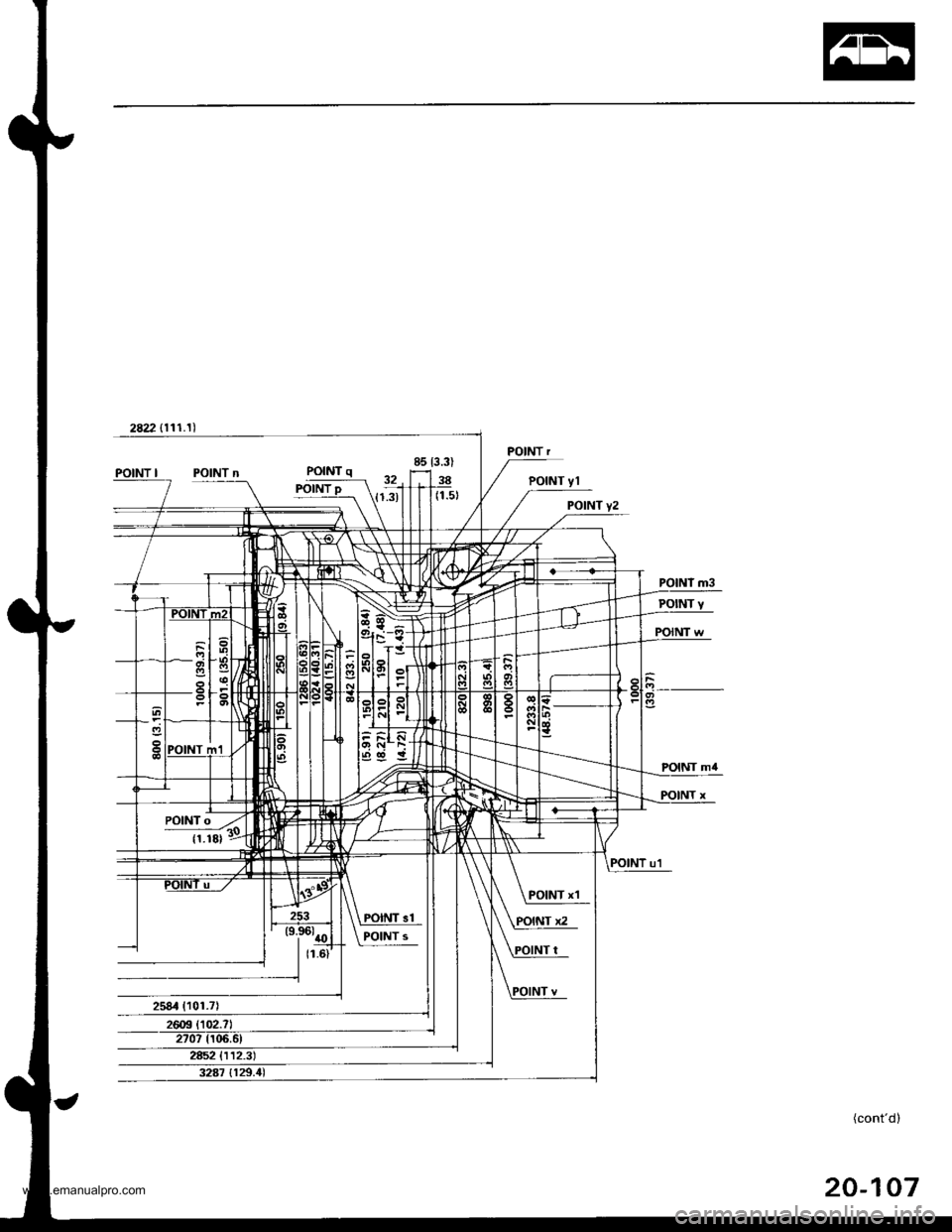

Page 1087 of 1395

2&2 t111.11

258,1{10r.7}

I POINT n

(cont'd)

20-107

32A7 1129.11

www.emanualpro.com

Page 1088 of 1395

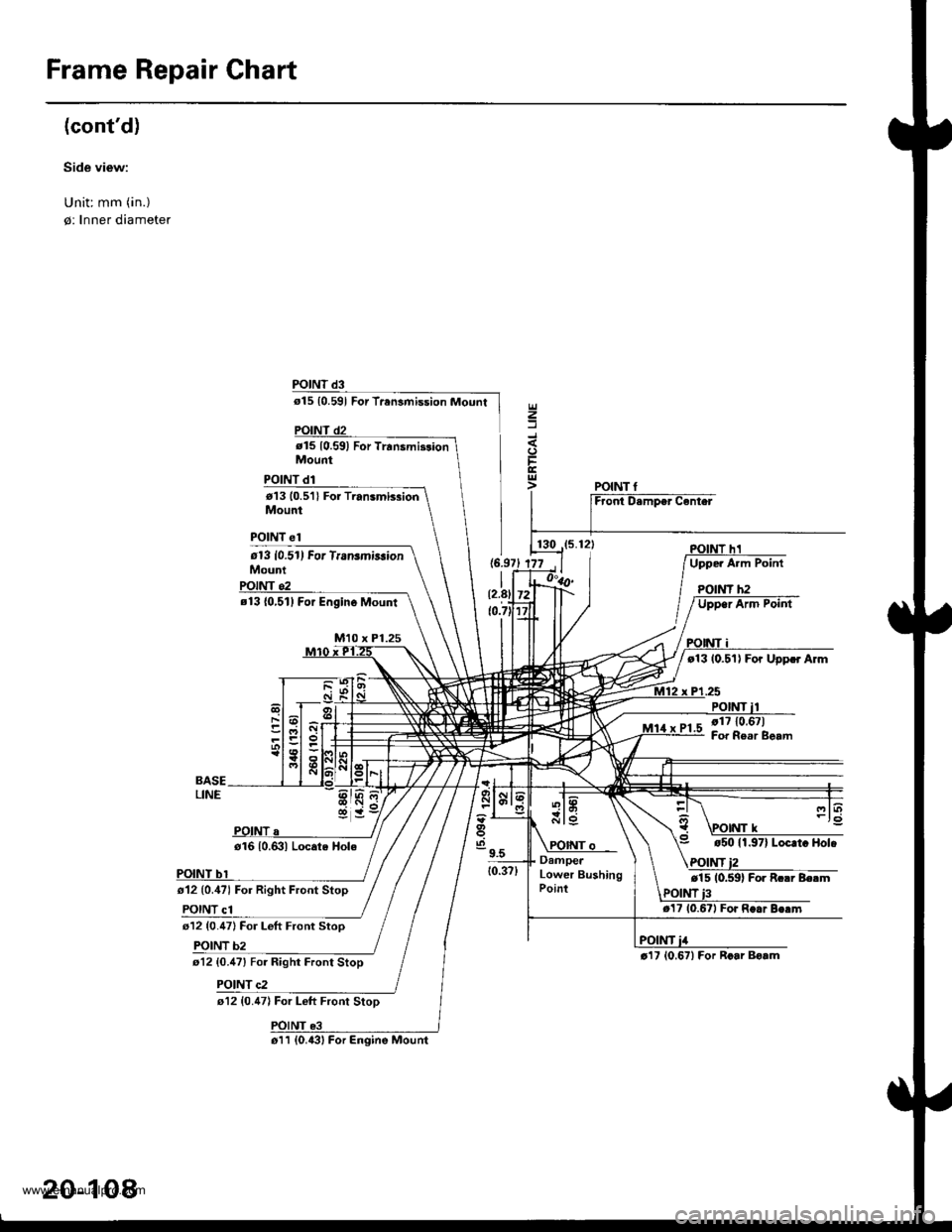

Frame Repair Chart

(cont'd)

Side view:

Unit: mm (in.)

0: Inner diamete.

POINT d3

o15 {0.591 For Trensmission Mount

d15 10.591 For Trrnsmi3donMount

POINT d1

t13 10.5'll For Transmb3ionMount

POINT el

613 10.51) For TransmirsionMouni

z

t13 {0,511 For Engin6 Mount

M10 x Pl.25

t13 10.51) For Uppcr Arm

.25

POINT,1710.67)Fof Re.r Beam

o12 (0.,171 For Right Front Stop

POINT c1

o16 10.631 Locate Hole

612 {0.47} For Left Front Stoo

b2

r12 {0.47) For Left Front StoD

t5011.97| Locrt. Hol.

POINT

t17 10.671 Fo. R..r

r'17 10.671 For Rcar Bo.mt12 {0.47} For Right Front Stop

POINT c2

130POINT h1

DamperLower BushingPoint

o11 (0.{31 For Engine Mount

20-108

www.emanualpro.com

Page 1089 of 1395

POlNTx.y / I

'sad

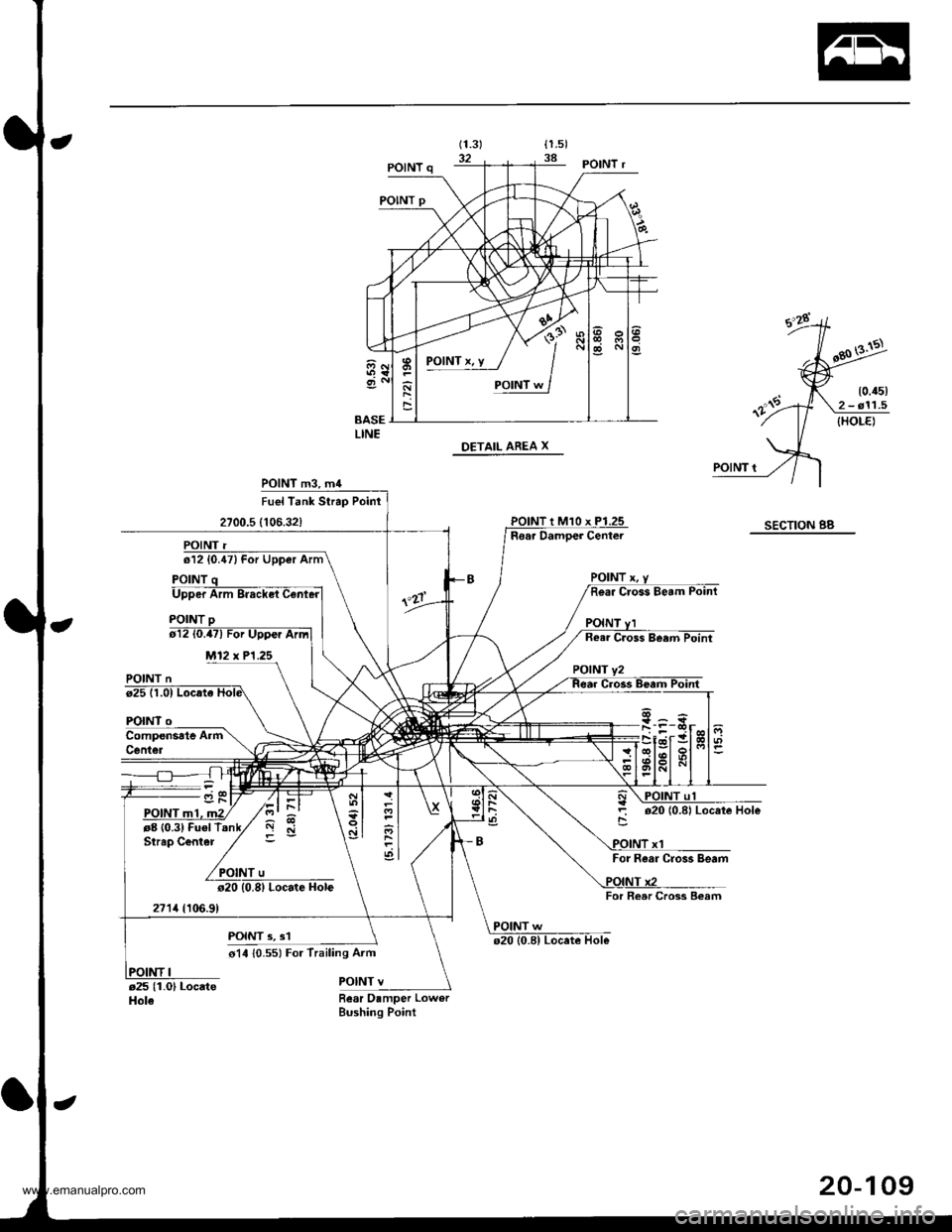

POINT m3, m4

Upper Arm

M12 x P1.25

Locate Hole

POINT 3, s1

o14 {0.551 For Trailing Aim

POINT v

Fuel Tank Strap Poinr

2700.5 (106.32)SECTION BBRear Damoer Center

POINT n

FOINT

rg (0.3) Fuel TStrap Center

271,1(10,6.9)

o2010.8| Locate Hole

For Rear Cros3 Beam

For Reer Cross Beam

POINT w

Bear Damper LowerBushing Point

I

\-

ql

ol

.df

20-109

www.emanualpro.com

Page 1090 of 1395

a

Heater and Air Conditioning

Heater ...........21

NOTE: Section 21 ("Heater") is included in section 22.

Air Conditioning ......'..'.. '.'22'1

SUPPLEMENTAL RESTRAINT SYSTEM (SRS}

This model has an SRS which includes a driver's airbag in the steering wheel hub, a passenger's airbag in the dashboard

above the glove box ('97,00 models). and seat belt tensioners in the seat belt retractors ('98 - 00 models). Information

necessary to safely service the SRS is included in this Service Manual. ltems marked with an asterisk (*) on the contents

page include. or are located near, SRS components. Servicing, disassembling or replacing these items will require special

precautions and tools, and should only be done by an authorized Honda dealer.

@. To avoid rendering the SRS inoperative, which could lead to personal iniury or death in the event of 8 severe frontal

collision, all SRS service work must be performed by an authotized Honda dealer.

lmproper service procedures, including incorrect removal and installation of the SRS, could lead to personal iniury

caused by unintentional deployment of the airbags ('97 - 00 models), and seat belt tensioners 138 - 00 models).

Do not bump the SRS unit. Otherwise, the system may fail in case of a collision, or the airbags may deploy when the

ignition switch is ON {lll.

SRS eleqtrical wiring harnesses are identified by yellow color coding. Related components are located in the steering

column, front console, dashboard, dashboard lower panel, and in the dashboard above the glove box. Do not use elec-

tricaltest equipment on thes€ cilcuils.

www.emanualpro.com

Trending: Air Intake, Component wiring, service, key battery, fuel cap release, Overheating, dash lights