Door HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1294 of 1395

Power Windows

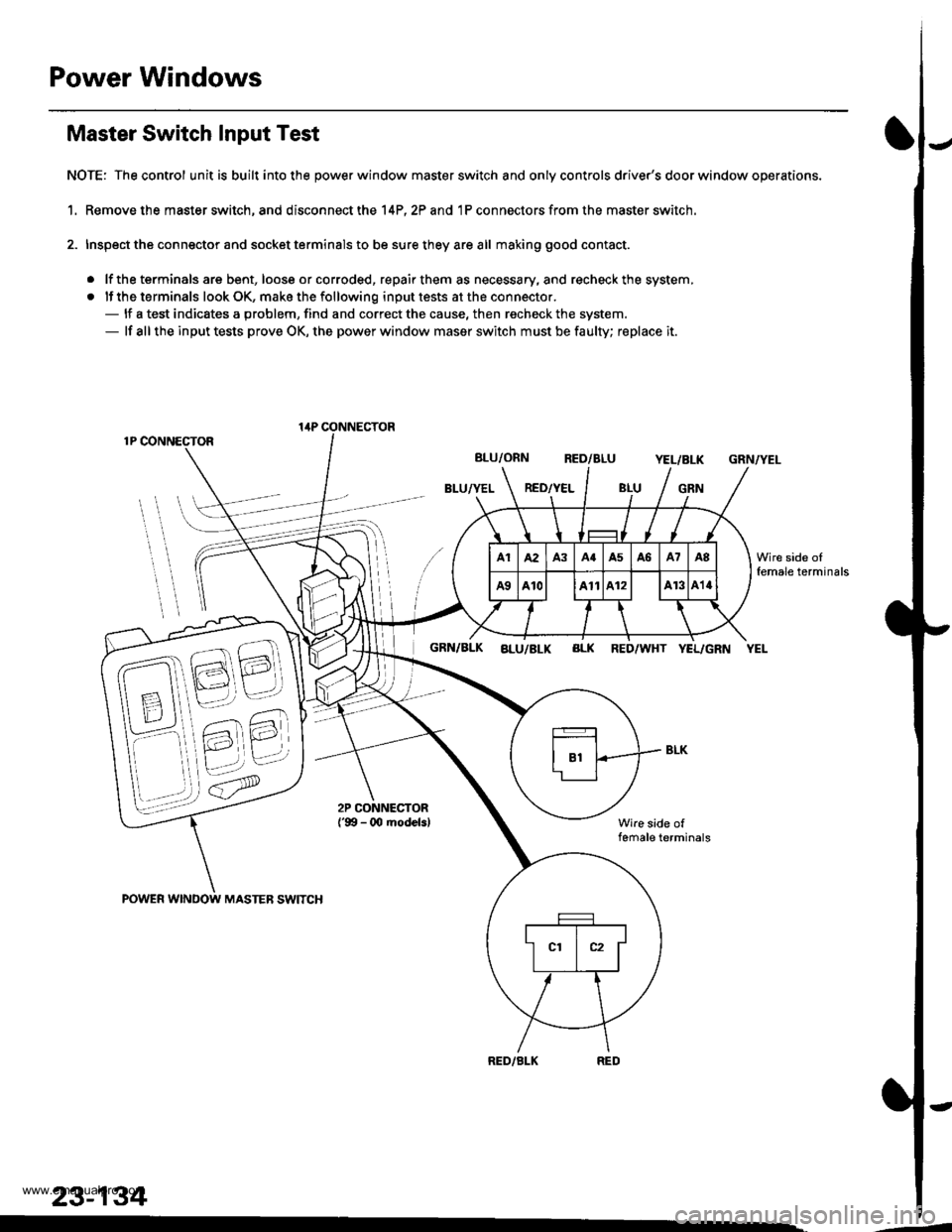

Master Switch Input Test

NOTE: The control unit is built into the power window master switch and only controls driver's door window operations.

1. Remove the master switch, and disconnect the 14P,2? and 1P connectors from the master switch.

2. Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose or corroded, repair them as necessary, and recheck the system,

. lf the terminals look OK, make the following input tests at the connector.- lf a test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, the power window maser switch must be faulty; replace it.

1P CONNECTOR

BLU/ORN RED/BLUYEL/BLK

BLU/YEL RED/YELGRN

GRN/YEL

POWER WINDOW MASTEB SWITCH

GRN/BLK aLu/BLK BLK RED/WHT YEL/GRN YEL

Wire side offemale terminals

RED/BLK

lirP CONNECTOR

23-134

Wire side oIfemale terminals

.-

www.emanualpro.com

Page 1297 of 1395

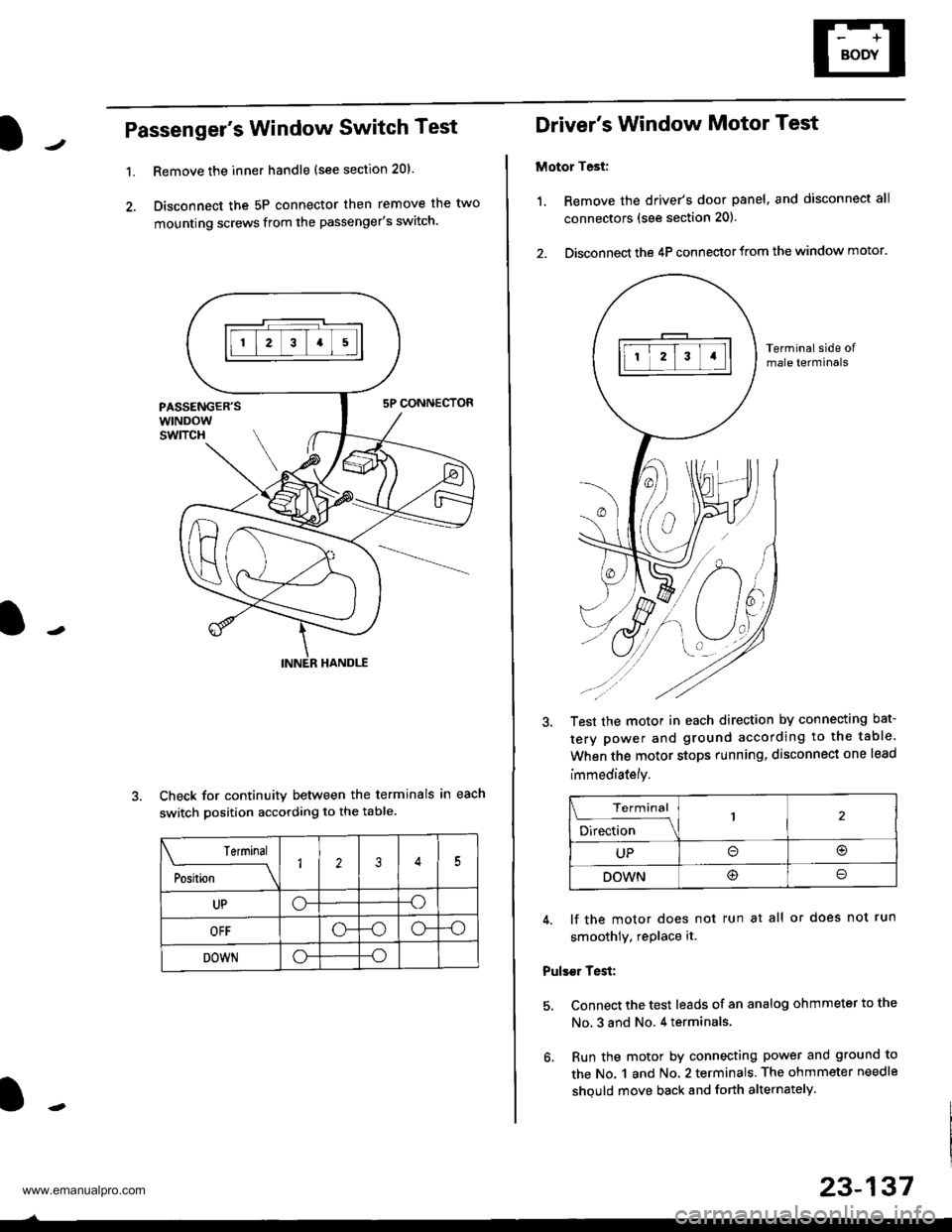

Passenger's Window Switch Test

1.Remove the inner handle (see section 20).

Disconnect the 5P connector then remove the two

mounting screws from the passenger's switch.

Check for continuity between the terminals in each

switch position according to the table

Terminal

;"rL-

__\1235

UPo--o

OFF-oo--o

DOWNo--o

Driver's Window Motor Test

Motor Test:

1. Remove the driver's door panel, and disconnect all

connectors (see section 201.

2. Disconnect the 4P connector from the window motor.

Terminal side ofmale terminals

Test the motor in each direction by connecting bat-

tery power and ground according to the table.

When the motor stops running. disconnect one lead

immediately.

Terminal

;;b"

-\

UPo(!r

DOWN@o

4. lf the motor does not run at all or does not run

smoothly. rePlace it.

Pulser Test:

5. Connect the test leads of an analog ohmmeter to the

No, 3 and No. 4 terminals.

6. Run the motor by connecting power and ground to

the No. 1 and No. 2 terminals. The ohmmeter needle

shquld move back and forth alternately.

23-137

www.emanualpro.com

Page 1298 of 1395

Power Windows

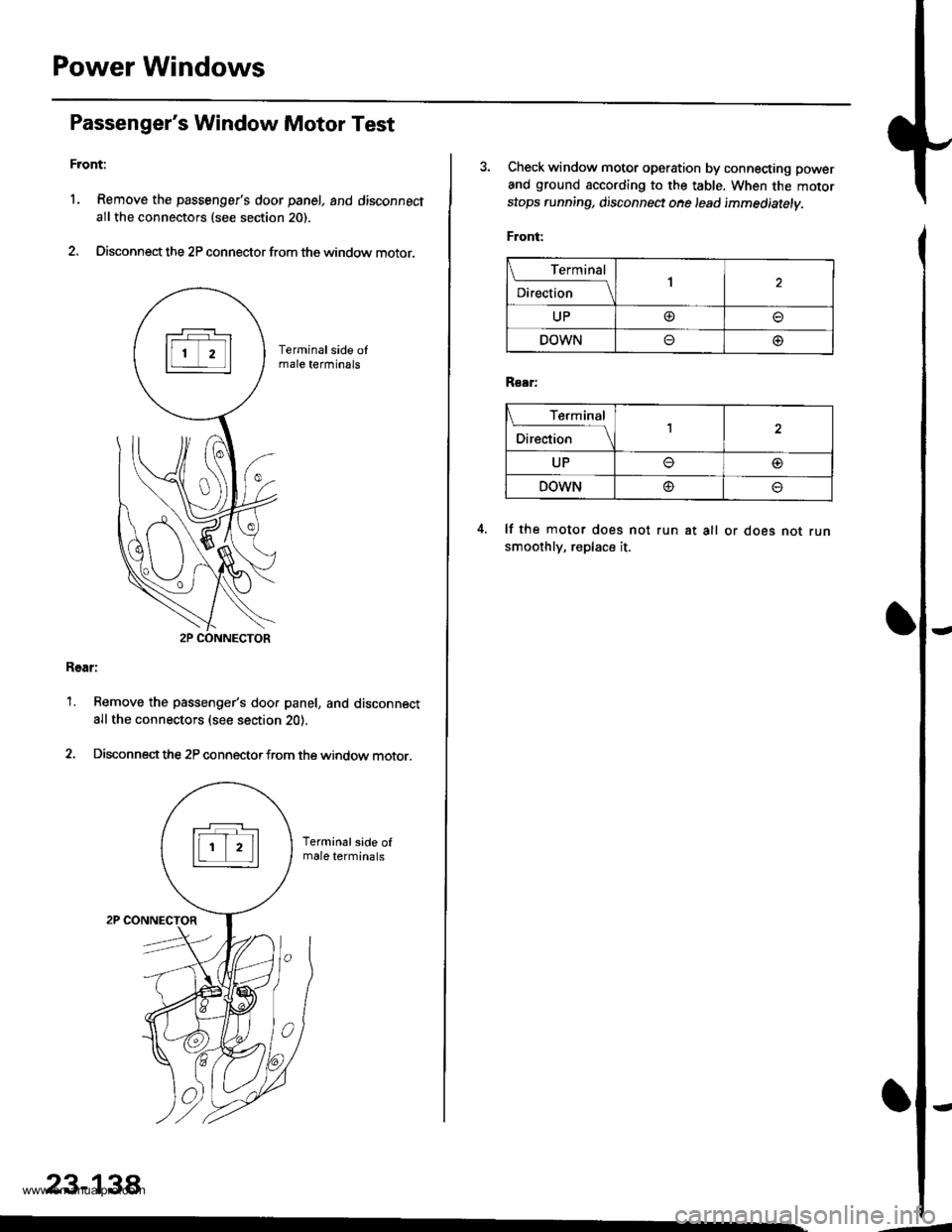

Passenger's Window Motor Test

Front:

l. Remove the passenger's door panel, and disconnect

allthe connectors (see section 20).

2. Disconnect the 2P connector from the window motor.

Rear:

1. Remove the passenger's doo. panel, and disconnect

allthe connectors (see section 20).

2. Disconnectthe 2P connectorfrom the window motor.

23-138

3. Check window motor operation by connecting power

and ground according to the table. When the motor

stops running, disconnect ohe lead immediatelv.

Front:

Terminal

;."b"

.l\

UP@

DOWNo@

R€ar:

I Terminal

;*r*

-l\

UPo@

DOWN@o

lf the motor does not run at all or does not runsmoothly, replace it.

www.emanualpro.com

Page 1395 of 1395

Airbag/Seat Belt Tensioner

1.

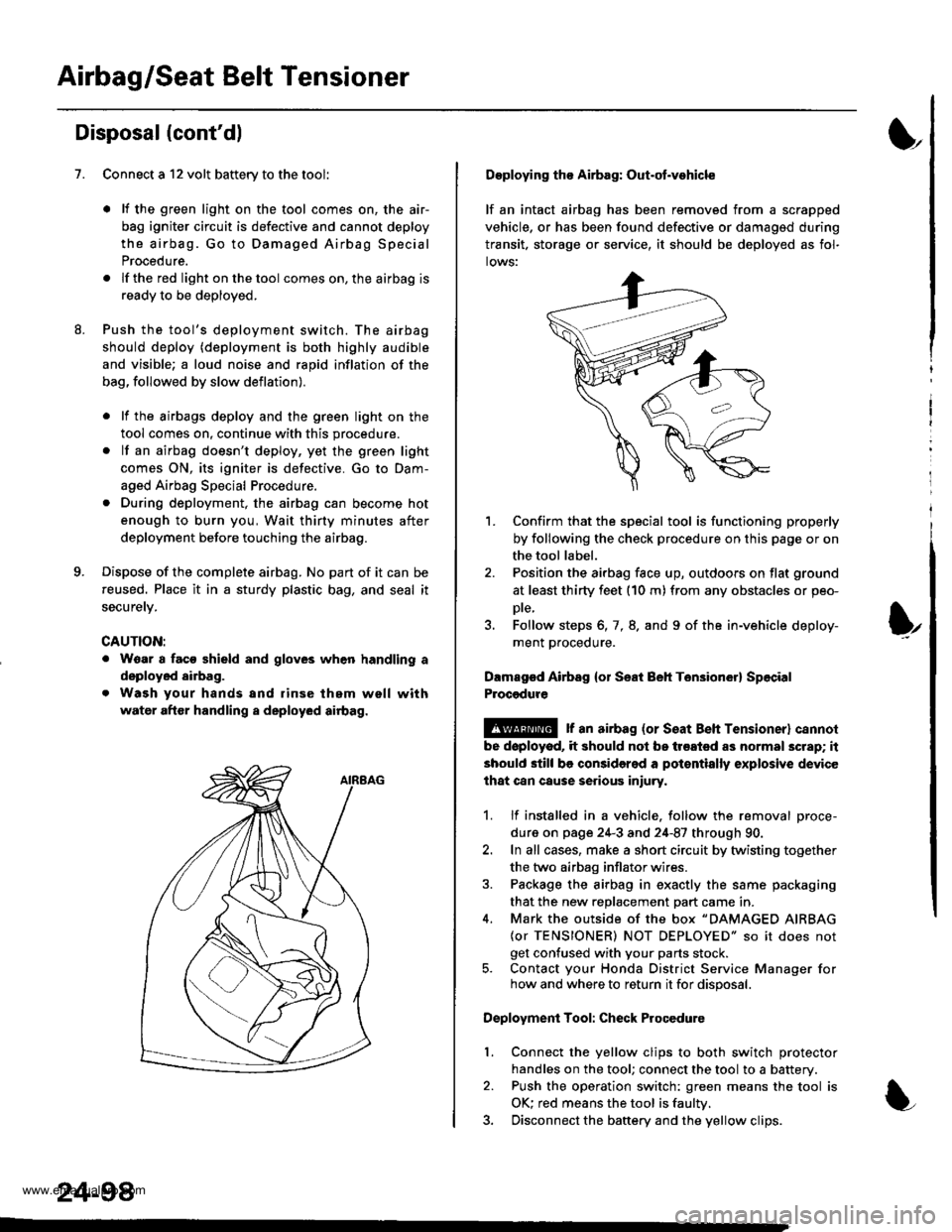

Disposal (cont'dl

Connect a 12 volt battery to the tool'

. It the green light on the tool comes on, the air-

bag igniter circuit is defective and cannot deploy

the airbag. Go to Damaged Airbag Special

Procedure.

.lftheredlightonthetool comes on, the airbag is

ready to be deployed.

Push the tool's deployment switch. The airbag

should deploy (deployment is both highly audible

and visible; a loud noise and rapid inflation of the

bag, followed by slow deflation).

. lf the airbags deploy and the green light on the

tool comes on, continue with this procedure.

. lf an airbag doesn't deploy, yet the green light

comes ON, its igniter is defective. Go to Dam-

aged Airbag Special Procedure.

. During deployment, the airbag can become hot

enough to burn you, Wait thirty minutes after

deployment before touching the airbag.

Dispose of the complete airbag. No part of it can be

reused. Place it in a sturdy plastic bag, and seal it

securety.

CAUTION:

. Wear a faco shield and gloves when handling a

deployed airbag.

. Wash your hands and rinse them well with

water after handling a deployed airbag.

24-98

Deploying tho Airbag: Out-ot.vohicle

lf an intact airbag has been removed from a scrapped

vehicle, or has been found defective or damagsd during

transit. storage or seryice, it should be deployed as fol-

lows:

'L Confirm that the special tool is functioning properly

by following the check procedure on this page or on

the tool label.

2. Position the airbag face up, outdoors on flat ground

at least thirty feet (10 m) from any obstacles or peo-

Dte,

3. Follow steps 6, 7, 8. and 9 of the in-vehicle deploy-

ment proceoure.

Dlmaged Airbsg {or Seat Beh Ten3ion6r} Sp6cial

Procgdure

!@ r an airbag {or seat Beh rensioner} cannol

be doployod, it should not be treated as normal scrap; it

should still be considered a pot€ntially explosive device

lhat can cause serious iniury.

1. lf installed in a vehicle. follow the removal proce-

dure on page 24-3 and 24-87 through 90.

2. In all cases, make a short circuit by twisting together

the two airbag inflator wires.

3. Package the airbag in exactly the same packaging

that the new reDlacement Dart came in.

4. Mark the outside of the box "DAMAGED AIRBAG

{or TENSIONER) NOT DEPLOYED" so it does not

get confused with your parts stock.5. Contact your Honda District Service Manager forhow and where to return it for disposal.

Deployment Tool: Check Procedure

Connect the yellow clips to both switch protector

handles on the tool; connect the tool to a battery.

Push the operation switch: green means the tool is

OK: red means the tool is faultv.

Disconnect the baftery and the yellow clips.

I

t

l.

www.emanualpro.com