valve cle HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 954 of 1395

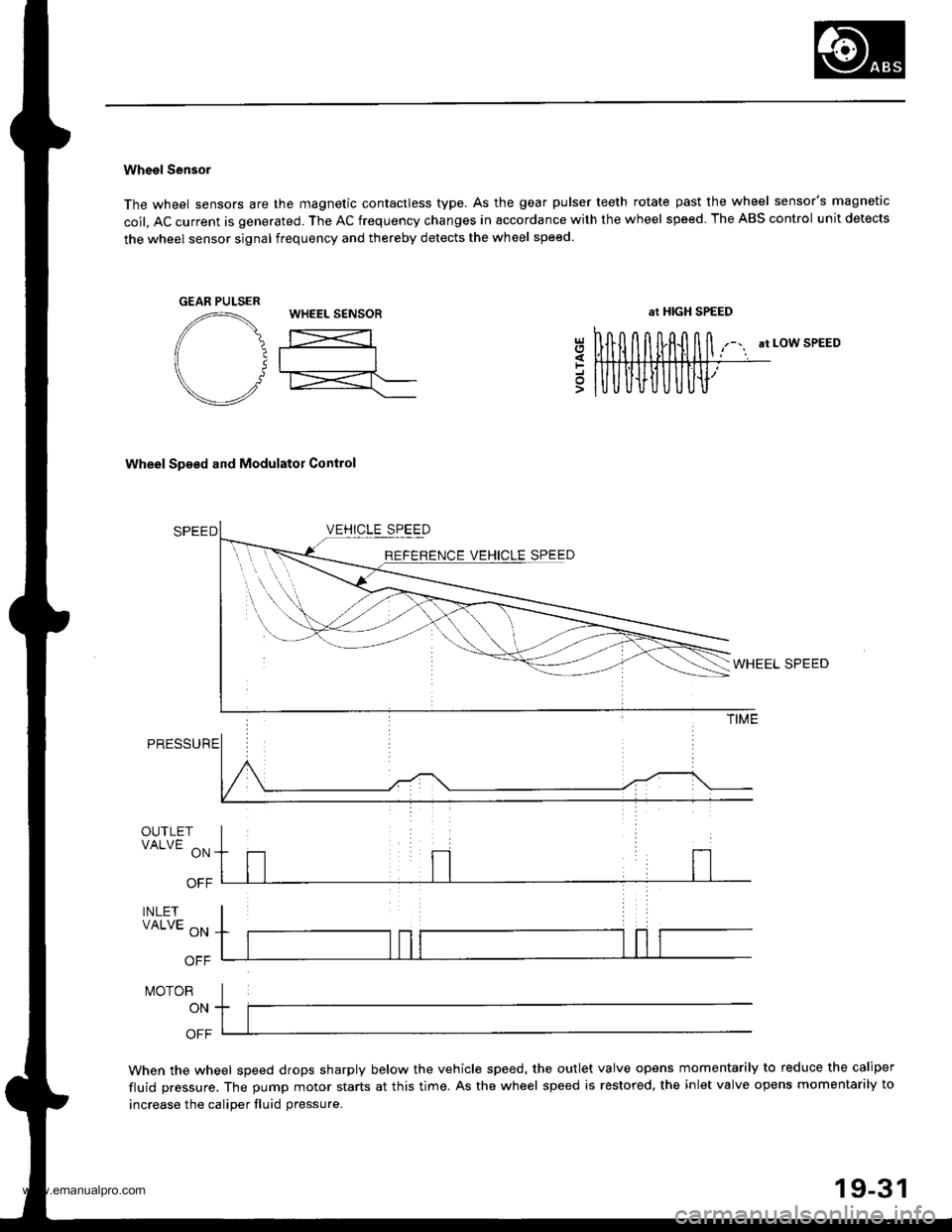

Wheel Sensor

The wheel sensors are the magnetic contactless type. As the gear pulser teeth rotate past the wheel sensor's magnetic

coil, AC current is generated. The AC frequency changes in accordance with the wheel speed. The ABS control unit detects

the wheel sensor signal frequency and thereby detects the wheel speed

at LOW SPEED

wheel Sp€od and Modulatot Control

VEHICLE SPEED

VEHICLE SPEED

WHEEL SPEED

PRESSU

OUTLETVALVE ON

OFF

INLETVALVE ON

OFF

MOTOR

ON

OFF

When the wheel speed drops sharply below the vehicle speed, the outlet valve opens momentarily to reduce the caliper

fluid pressure. The pump motor starts at this time. As the wheel speed is restored. the inlet valve opens momentarily to

increase the caliDer fluid oressure.

F

GEAR PULSER

19-31

www.emanualpro.com

Page 959 of 1395

Troubleshooting Precautions

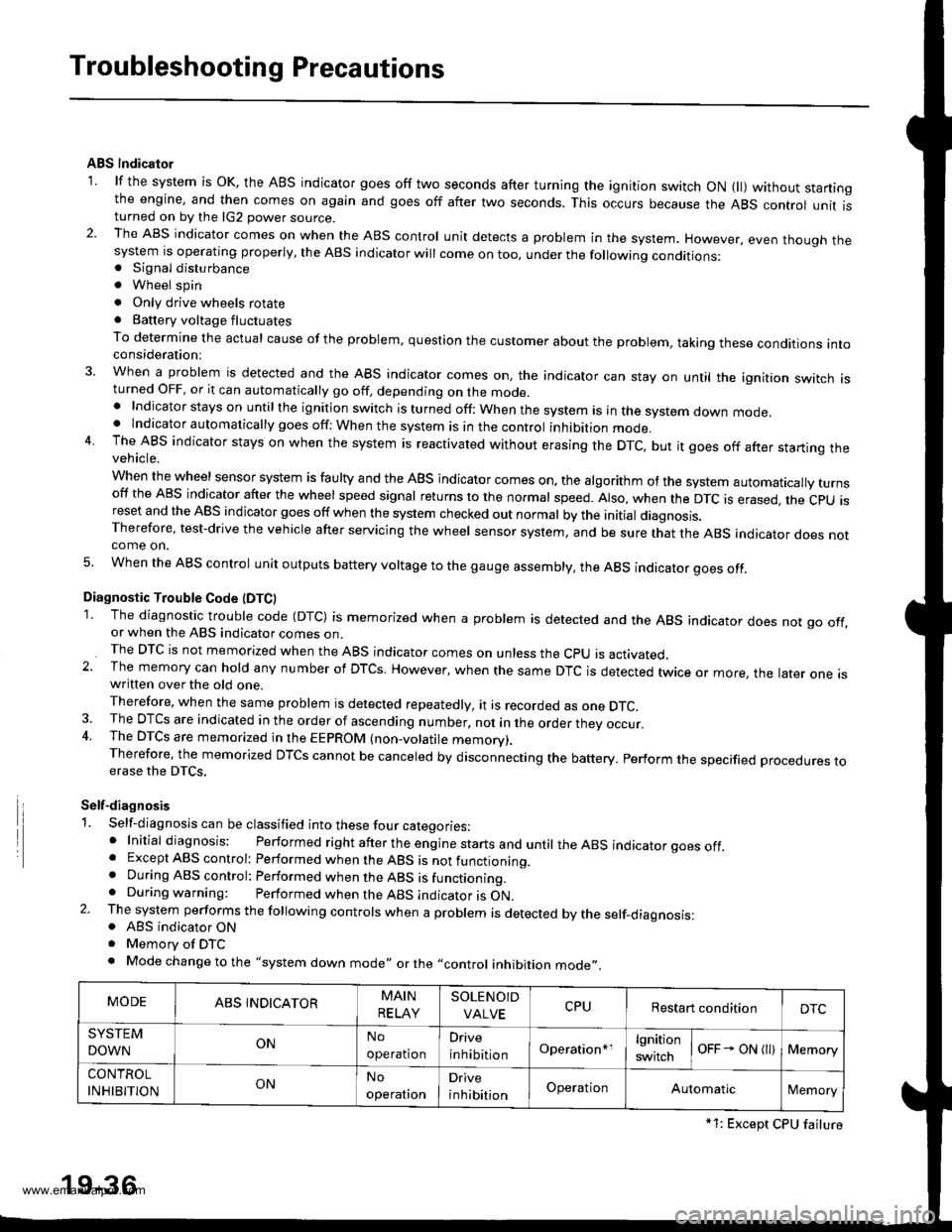

ABS lndicalor

1 lf the system is oK, the ABS indicator goes off two seconds after turning the ignition switch oN 1l) wathout staningthe engine, and then comes on again and goes off after two seconds. This occurs because the ABS control unit isturned on by the lG2 power source.2. The ABS indicator comes on when the ABS control unit detects a problem in the system. However, even thouoh thesystem is operating properly, the ABs indicator will come on too, under the following conditions:. Signal disturbance

. Wheel spin

. Only drive wheels rotate. Battery voltage fluctuates

To determine the actual cause of the problem, question the customer about the problem, taking these conditions intoconsideration:

3 When a problem is detected and the ABS indicator comes on, the indicator can stay on until the ignition switch isturned OFF, or it can automatically go off, depending on the mode.. Indicator stays on untilthe ignition switch is turned off: When the system is in the system down mode.. Indicator automatically goes off: When the system is in the control inhibition mode.4 The ABS indicator stays on when the system is reactivated without erasing the DTC, but it goes off after starting thevehicle.

When the wheel sensor system is faulty and the ABS indicator comes on. the algorithm of the system automatically turnsoff the ABS indicator after the wheel speed signal returns to the normal speed. Also, when the DTc is erased, the cpu isreset and the ABS indicator goes off when the system checked out normal by the initial diagnosis.Therefore, test-drive the vehicle after servicing the wheel sensor system. and be sure that the ABS indicator does notcome on.

5 When the ABS control unit outputs battery voltage to the gauge assembly, the ABS indicator ooes off.

Diagnostic Trouble Code (DTCI

1. The diagnostic trouble code (DTc) is memorized when a problem is detected and the ABS indicator does not go off,or when the ABS indicator comes on.The DTc is not memorized when the ABS indicator comes on unress the cpu is activated,2 The memory can hold any number of DTCs. However, when the same DTc is detected twice or more, the tater one iswritten over the old one.

Therefore, when the same problem is detected repeatedly, it is recorded as one DTC.3. The DTCs are indicated in the order of ascending number, not in the order they occur.4. The DTCS are memorized in the EEPROM (non-volatile memorv).Therefore, the memorized DTcs cannot be canceled by disconnecting the battery. perform the specified procedures toerase the DTCS.

Self-diagnosis

1. Self-diagnosis can be classified into these four categories:' Initial diagnosis: Performed right after the eng ine starts and untir theABS indicator goes off.. Except ABS control: Performed when the ABS is not functioning.. During ABS control: Performed when the ABS is functioning.. During warning: Performed when the ABS indicator is ON.2. The system performs the fo|owing contrors when a probrem is detected by the serf-diagnosis:. ABS indicator ON. Memorv of DTC. Mode changetothe "system down mode,, or the ,,control inhibition mode,,.

MODEABS INDICATORMAIN

RELAY

SOLENOID

VALVECPURestart conditionDTC

SYSTEM

DOWNONNo

operation

Drive

inhibitionOperation*rlgnition

switchoFF - ON l)Memory

CONTROL

INHIBITIONONNo

operal|on

Drive

inhibitionOperationAutomaticlMemory

*1: Except CPU failure

19-36

www.emanualpro.com

Page 960 of 1395

Kickback'1. The motor operates when the ABS is functioning. and the fluid in the reservoir is forced out to the master cylinder,

causing kickback at the brake pedal.

2. The ABS control unit operates the solenoid valve when the brake pedal is released after the initial diagnosis You may

hear the solenoid valve operate at this time, but it is normal

Pumo Motol

1. The pump motor operates when the ABS is functioning

2. The ABS control unit checks the pump motor operation during acceleration. You may hear the motor operate at this

time, but it is normal.

Brake Fluid Replacement/Ail Bleeding

L Brake fluid replacement and air bleeding procedures are the same as for vehicles without ABS To ease bleeding, start

with the front wheels.

Troubleshooting

1. The troubleshooting flowchart procedures assume that the cause of the problem is still present and the ABS indicator

is still on. Following the flowchart when the ABS indicator does not come on can result in incorrect diagnosis.

2. Ouestion the customer about the conditions when the problem occurred, and try to reproduce the same conditions

for troubleshooting.

Self-diagnosis is made at various times such as the initial diagnosis, except ABS control, during ABS control, during

acceleration, during the specified vehicle speed, etc. Therefore, the symptom canngt be checked unless the check

conditions match with the problem conditjons

3. When the ABS jndicator does not come on during the test-drive. but troubleshooting is performed based on the DTC,

check lor loose connectors, poor contact of the terminals, etc., before you start troubleshooting.

4. After troubleshooting, erase the DTC and test-drive the vehicle. Be sure the ABS indicator does not come on.

5. The connector illustratjons show the female terminals with a single outline and the male terminals with a double out-

l ne.

ABS Function Test

To simulate ABS operation and activate the solenoid valves and pump, use the Honda PGM Tester.

Connect the PGM Tester to the 16P Data Link Connector (DLC). When the System Select menu is displayed, select the ABS

Test Mode menu, and follow the tester's prompts.

19-37

www.emanualpro.com

Page 1097 of 1395

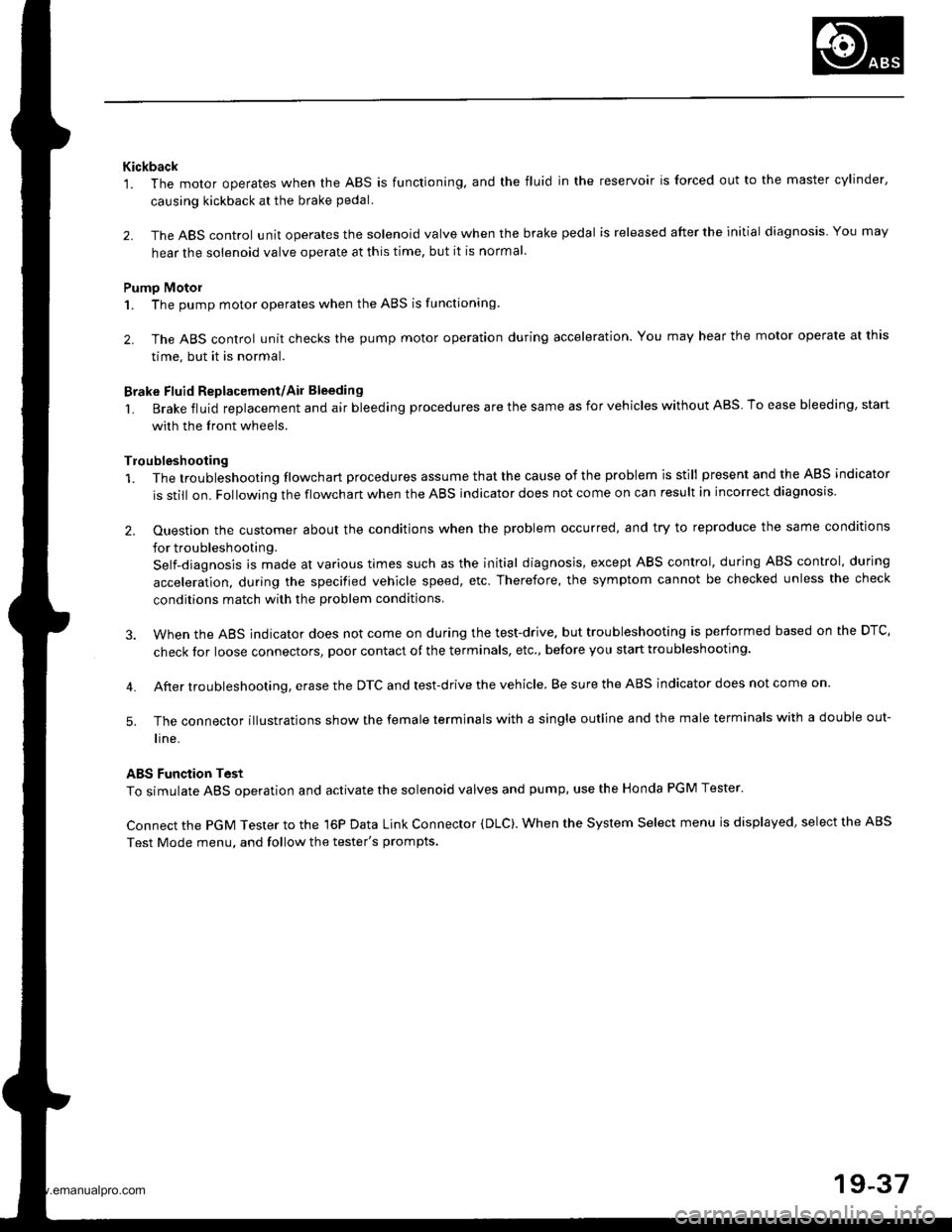

Description

The air conditioner system removes heat from the passenger compartment by circulating refrigerant through the systemas shown below.

High'temperature/ High-temperature/

high-pressure gas h igh-pressure liquid

Suction and compression Radiation of heat

High-temperature/

high-pressu re liq uidr raps oeons,

and removes

motsture

More liquidified

row-pressure vapor

EVAPoRAToR (-l EXPANSToN vAL

SUCTION LINEtLow-PRESSURE S|OEt

LIOUID LINE

CONDENSER

coMpREssoR Il- coruoerusenl* necetve

Less moisturized

low-pressure vapor

Absorption of heat

DISCHARGE LINEIHIGH.PRESSURE SIDEI

This vehicle uses HFC-I34a (R-l34a) refrigerant which does not contain chlorofluorocarbons. Pay attention to the follow-ing service items:

. Do not mix refrigerants CFC-12 (R-12) and HFC-l34a (R-134a). They are not compatible.. Use only the recommended polyalkyleneglycol (PAG) refrigerant oil (SP-10) designed for the R-134a compressor.Intermixing the recommended (PAG) refrigerant oil with any other refrigerant oil will result in compressor failure.. Afl Ay'C system parts (compressor, discharge line. suction line, evaporator, condenser. receiver/dryer, expansion valve,O-rings for joints) have to be proper for refrigerant R-134a. Do not confuse with R-12 parts.

. Use a halogen gas leak detector designed for refrigerant R-134a.. R-12 and R-134a refrigerant servicing equipment are not interchangeable. Use only a recovery/recycling/charging stationthat is U.L.iisted and is certified to meet the requirements of SAE J2210 to service R-134a air conditioning system.. Always recover the refrigerant R-134a with an approved recovery/recycling/charging station before disconnecting anylVC fitting.

EVAPORAYOR

22-7

www.emanualpro.com

Page 1141 of 1395

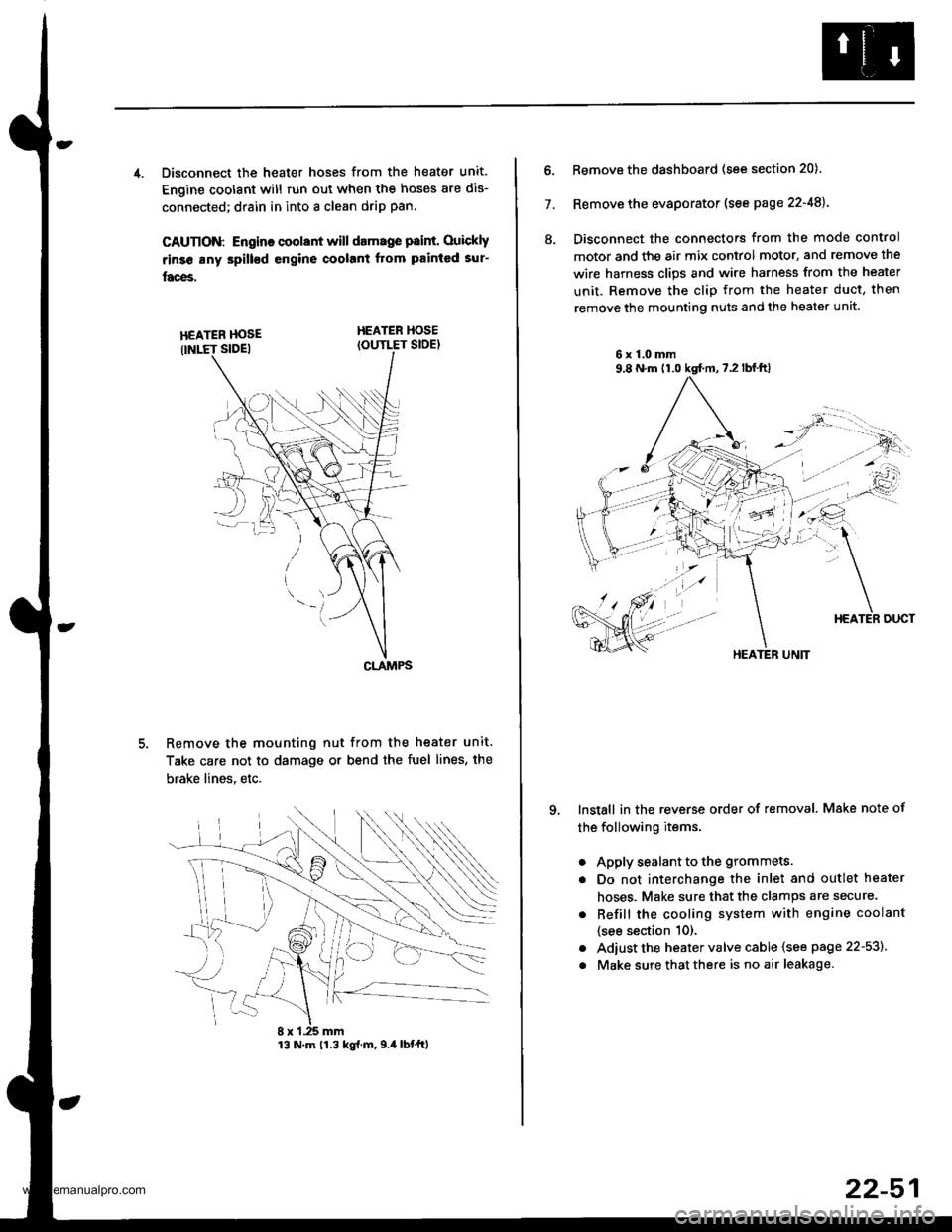

4. Disconnect the heater hoses from the heater unit.

Engine coolant will run out when the hoses are dis-

connected; drain in into a clean drip pan.

CAUTION: Engino coolant will damage p8int. Ouickly

rinse any spill€d engine coolant Itom painted sur-

faces.

HEATER HOSEIOUTLET SIDE)

Remove the mounting nut from the heater unit.

Take care not to damage or bend the fuel lines, the

brake lines. etc.

CLAMPS

13 N.m 11.3 kg{.m,9.4 lbtftl

22-51

7.

ll.

Remove the dashboard (see section 20).

Remove the evaporator (see page 22-48).

Disconnect the connectors from the mode control

motor and the air mix control motor, and remove the

wire harness clips and wire harness from the heater

unit. Remove the clip from the heater duct, then

remove the mounting nuts and the heater unit

6x1.0mm9,8 N.m (1.0 kgt m,7.2lblft)

qInstall in the reverse order of removal. Make note of

the following items.

a

a

a

a

Apply sealant to the grommets.

Do not interchange the inlet and outlet heater

hoses. Make sure that the clamps are secure.

Refill the cooling system with engine coolant

{see section 10).

Adiust the heater valve cable (see page 22-53).

Make sure that there is no air leakage.

HEATER UNIT

www.emanualpro.com

Page 1148 of 1395

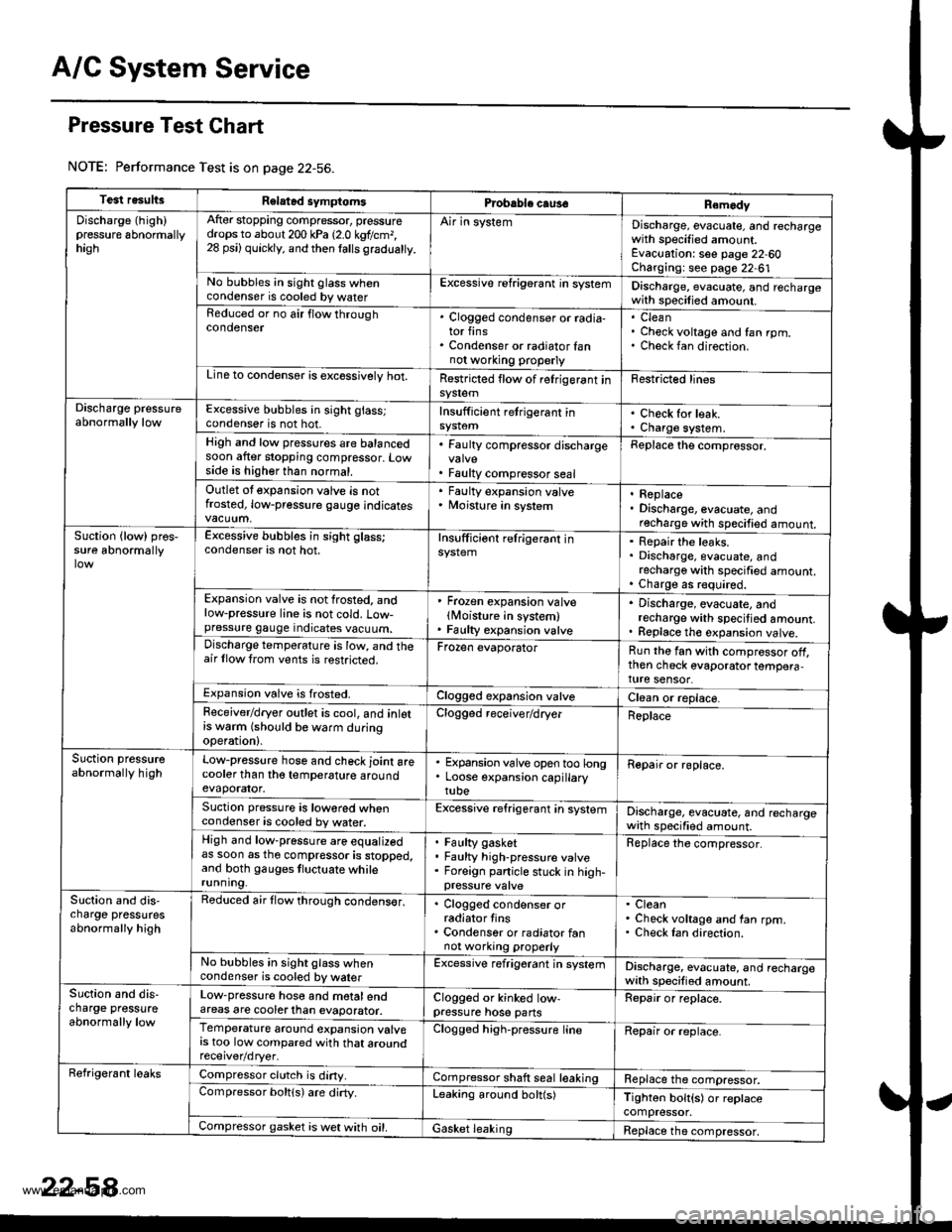

A/C System Service

Pressure Test Chart

NOTE: Performance Test is on page 22-56.

Test resultsRelatad symptomsPrcbable caus€Remody

Discharge (high)pressure 6bnormallyhagh

After stopping compressor, pressuredrops to about 200 kPa 12.0 kgtlcm,,28 psi) quickly, and then lalls gradualty.

Air in systemDischarge, evacuate, and rechargewith specified amount.Evacuation: see page 22-60Charging: see page 22-61No bubbles in sight glass whencondenser is cooled by waterExcessive refrigerant in systemDischarge, evacuate, and rechargewith specilied amount.Reduced or no air flow throughcondenser. Clogged condenser or radia-tor fins. Condenser or radiator fannot wo.king properly

CleanCheck voltage and fan rpm.Check fan direction.

Line to condensor is excossivelv hot.Restricted flow of relrigerant insy$emFestricted lines

Discharge pressureabnormally lowExcessive bubbles in sight glass;condenser is not hot.Insufficient retrigerant inCheck for leak.Charge system.High and low pressures are balancedsoon after stopping compressor. Lowside is higher than normal.

. Faulty compressor discharge

. Faulty compressor seal

Replace the comprossor.

Outlet ot expansion valve is notfrosted, low-pressure gauge indicates

' Faulty expansion valve. Moisture in system. Replace. Discharge, evacuate, andrecharge with specified amount.Suction {low) pros,sure abnormallyExcessive bubbles in sight glass;condenser is not hot.Insufficiont relrigerant inRepair the leaks.Discharge, evacuate, andrecharge with specified amount.Charge as r€quired.Expansion valve is not frosted, andlow-pressure line is not cold. Low-pressure gauge indicates vacuum.

' Frozen expansion valvelMoisture in system). Faulty expansion valve

. Discharge, evacuate, andrecharge with specitied amount.. Replace th€ expansion valve.Discharge temperature is low, and theair llow trom vents is restricted.Frozen evaporatorRun the fan with compressor off,then check evaporator tempera,ture sensor.Expansion valve is frosted.Clogged expansion valveClean or replace.Feceiver/dryer outlet is cool, and inlotrs w6rm (should be warm duringoperation).

Clogged receiver/dryerReplace

Suction pressureabnormally highLow-pressure hose and check joint arecooler than tho temperature aroundevaporator.

. Expansion valve open too long. Loose expansion capillarytube

Repair or roplace.

Suction pressure is lowored whencondenser is cooled by water.Excessive refrigerant in systemDischarge, evacuate, and rechargewath specified amount.High and low-pressure are equalizedas soon as tho compressor is stopped,and both gauges tluctuate whilerunning.

Faulty gasketFaulty high-pressure valveForeign panicle stuck in high-

Replace the compressor.

Slction and dis,charge pressutesabnormally high

Reduced air flow through condens€r,. Clogged condenser orradiator tins. Condenser or radiator fannot working properly

CleanCheck voltage and fan rpm.Check Ian direction.

No bubbles in sight glass whencondenser is cooled by walerExcessive refrigerant jn systemDischarge, evacuate, and rechargewith specified amount.Suction and dis-charge pressureabnormally low

Low-pressure hose and motalendareas are cooterlhan evaporator.Clogged or kinked low-pressure hose pansRepair or replace.

Temperature around expansion valvers too low compared with that aroundClogged high-pressure lineRepair or replace.

Refrigerant leaksCompressor clutch is diny.Compressor shaft seal leakingReplace the compressor.Compressor boltls) are dirty.Leaking around bolt(s)Tighton bolt{s) or replacecompressor.Compressor gasket is wet with oil.Gasket leakingReplace the compressor,

www.emanualpro.com

Page 1151 of 1395

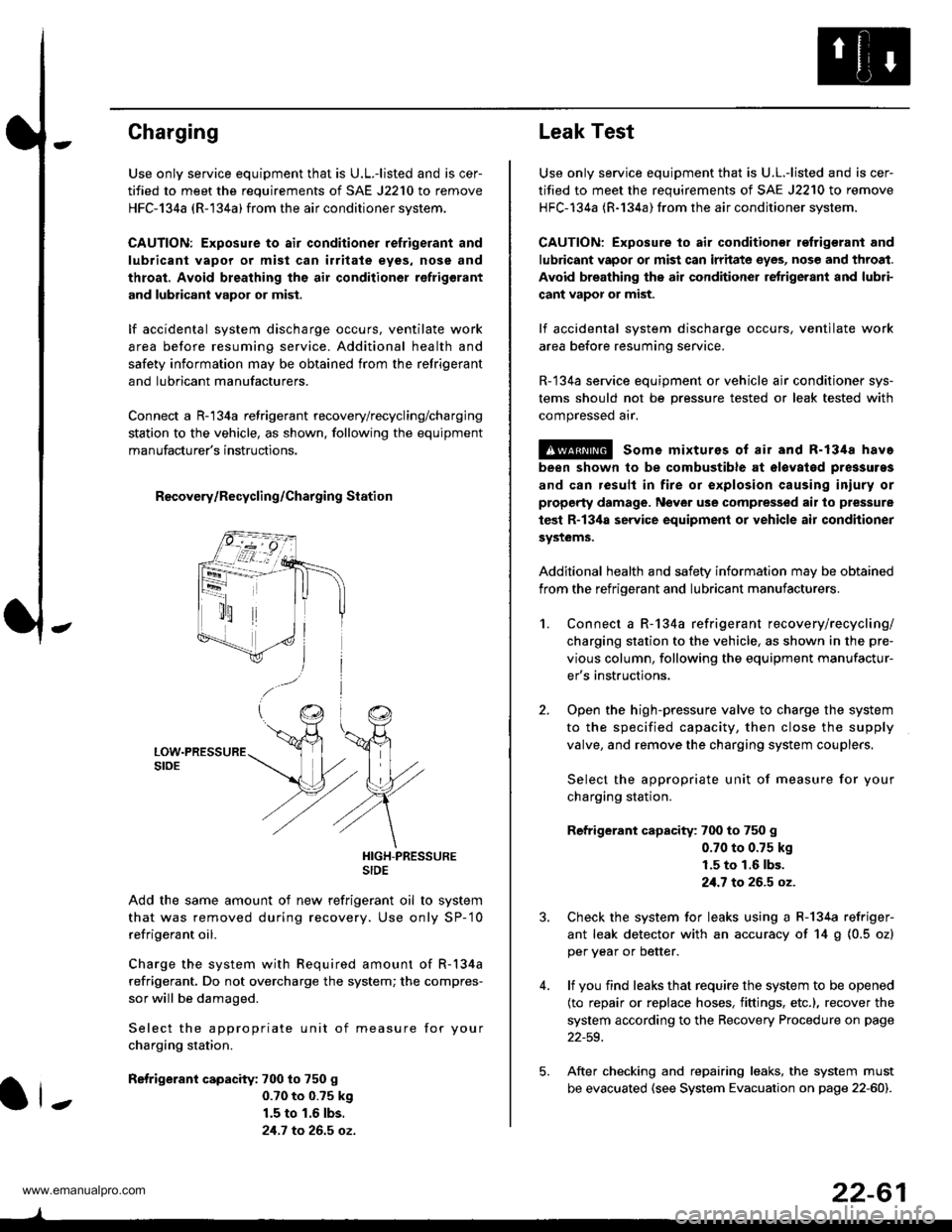

Charging

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant and

lubricant vapor or mist can irritate eyes, nose and

throat. Avoid breathing th€ air conditioner refrigerant

and lubricant vapor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming service. Additional health and

safety information may be obtained from the relrigerant

and lubricant manufacturers.

Connect a R-'134a refrigerant recovery/recycling/charging

station to the vehicle, as shown. following the equipment

manufacturer's instructions.

R€covery/Recycling/Charging Station

HIGH-PRESSURESIDE

Add the same amount of new refrigerant oil to system

that was removed during recovery. Use only SP-'10

refrigerant oil.

Charge the system with Required amount of R-134a

refrigerant. Do not overcharge the system; the compres-

sor will be damaged.

Select the appropriate unit of measure for your

charging station.

Refrigerant capacity: 700 to 750 g

0.70 to 0.?5 k9

1.5 to 1.6 lbs.

21.7 to 26.5 oz.

ll-

22-61

Leak Test

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditionor refrigerant and

lubricant vapor or mist can irritate eyes, nose and throat.

Avoid breathing the air conditioner retrigerant and lubri-

cant vapor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle ajr conditioner sys-

tems should not be pressure tested or leak tested with

compressed arr.

!@ some mixturos of air and R-1348 have

been shown to be combustible at olovatod pres3uras

and can result in fire or explosion causing iniury or

property damage. Never use comprelised air to pressure

test R-13ila service equipment or vehicle air conditioner

systems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

2.

1.Connect a R-134a refrigerant recove rylrecycling/

charging station to the vehicle, as shown in the pre-

vious column, following the equipment manufactur-

er's instructions.

Open the high-pressure valve to charge the system

to the specified capacity, then close the supply

valve, and remove the charging system couplers.

Select the appropriate unit of measure for your

charging station.

Refrigerant capacity: 700 to 750 g

0.70 to 0.75 kg

1.5 to 1.6 lbs.

21.7 to 26.5 oz.

Check the system for leaks using a R-134a refriger-

ant leak detector with an accuracy of 14 g (0.5 ozl

per year or better.

lf you find leaks that require the system to be opened

(to repair or replace hoses, fittings, etc.), recover the

system according to the Recovery Procedure on page

22-59.

After checking and repairing leaks, the system must

be evacuated (see System Evacuation on page 22-601.

5.

www.emanualpro.com

Page 1158 of 1395

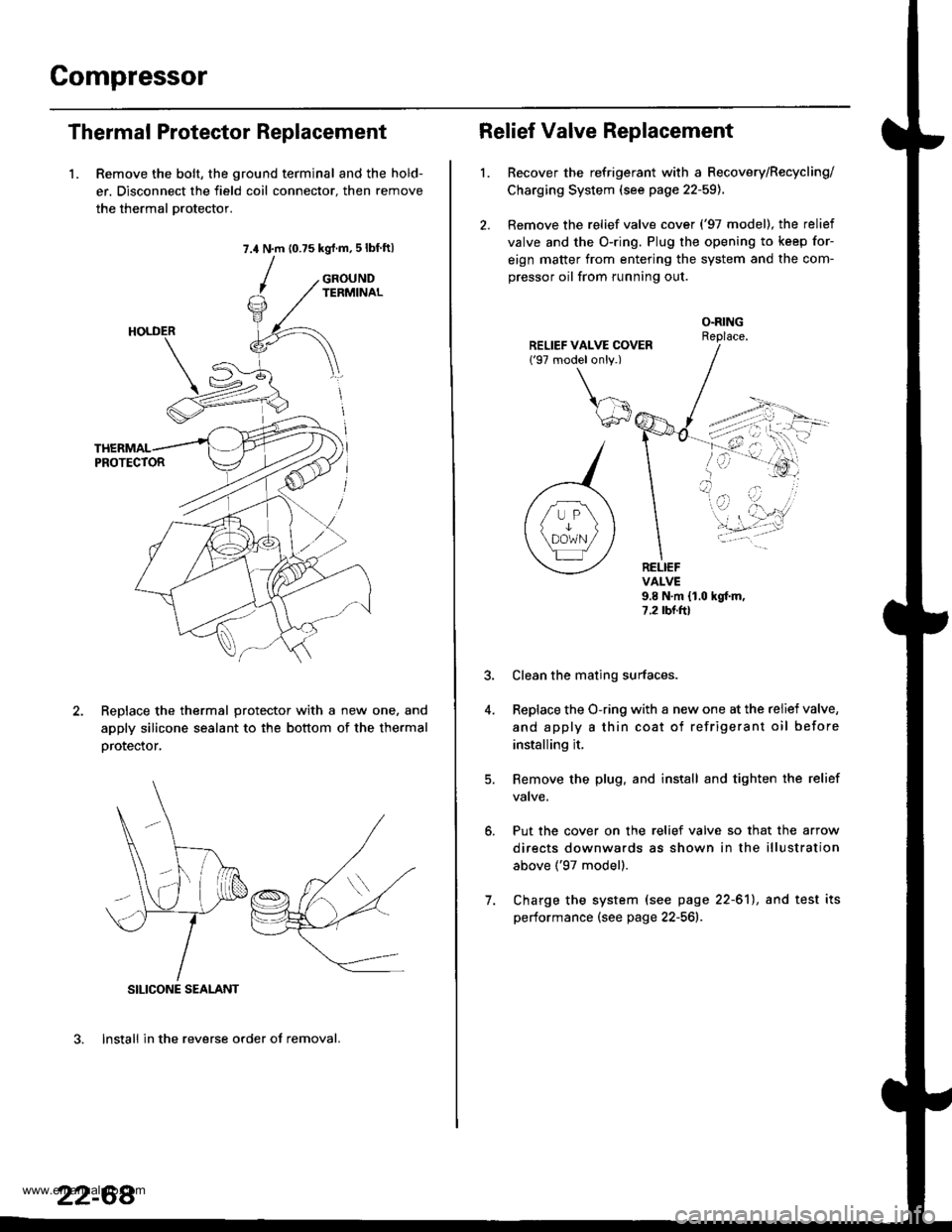

Compressor

Thermal Protector Replacement

1. Remove the bolt, the ground terminal and the hold-

er. Disconnect the field coil connector. then remove

the thermal Drotector.

7.4 N.m (0.75 kgrf.m,5lbf ftl

GROUNDTERMINAL

ReDlace the thermal protector with a new one, and

apply silicone sealant to the bottom of the thermal

orotector,

3. lnstall in the reverse order of removal.

SILICONE SEALANT

22-68

Relief Valve Replacement

l.Recover the refrigerant with a Recovery/Recycling/

Charging System (see page 22-59).

Remove the relief valve cover ('97 model), the relief

valve and the O-ring. Plug the opening to keep for-

eign matter from entering the system and the com-

pressor oil from running out.

O.RINGReplace.

RELIEFVALVE9.8 N.m {1.0 hgf.m,7.2 rbr.ftl

Put the cover on the relief valve so that the arrow

directs downwards as shown in the illustration

above ('97 model).

Clean the mating surfaces.

Replace the O-ring with a new one at the relief valve,

and apply a thin coat of refrigerant oil before

installing it.

Remove the plug. and install and tighten the relief

valve.

7. Charge the system (see page 22-61), and test its

performance (see page 22-561r.

www.emanualpro.com

Page 1174 of 1395

![HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1ll HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1ll](/img/13/5778/w960_5778-1173.png)

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1l'l

c112

c113

c't 14

cl16

cl16

c117

c118

c119

c120

c121

c't22

c't23

c't25

cl26

cl27

cr 28

cl29

c130

c131

c132

c 133

c134

c134

c135

c 136

10

6

1

2

1

2

1

10

20

31

16

22

l0

l0'14

14

1

Left side of engine compartment

Left side of engine compartment

Middle of engine

Middle of engine

Left side of engine compartment

Left side of engine compartment

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Right side of engine

Middle of engine

Behind right kick panel

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Right side of engine

Right side of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Left side of engine compartment

Middle of engine

Middle of engine

Main wire harness (C304)

Main wire harness (C305):'97 - 98 models

No. 1 fuel injector

Crankshaft speed fluctuation (CKF) sensor

Alternator

Alternator

Engine oil pressure switch

No.2 fuel injector

Evaporative emission (EVAP) purge

control solenoid valve

No. 3 fuel injector

No. 4 fuel injector

Primary heated oxygen sensor(Primary HO2S) (sensor 1)

Radiator fan switch

Coolant temperature sending unit

Engine coolant temperature (ECT) sensor

Mainshaft speed sensor

Lock-up control solenoid valve

Back-up light switch

Shift control solenoid valve

Linear solenoid valve

Countershaft speed sesnsor

Starter solenoid

Distributor

Junction connector

PCM

ECIWPCM

ECM/PCM

ECM/PCM

Main wire harness (C,|:}1)

IVT gear position switch

Vehicle speed sensor (VSS)

Throttle position (TP) sensor

MAP sensor

ldle air control (lAC)valve

lntake air temperature (lAT) sensor

Junction connector

Junction connector

Power steering pressure (PSP) switch

Junction connector

Knock sensor (KS)

A/r

USA

Canada

Alr

AlT

M/'r

Afi

'97mooel

'97 model'98 - 00

mooets

'99 - 00

models

T101

r102

Left side of en0ine companment

Right side of engine compartment

Alternator

Under-hood fuse/relay box

G101Middle of engineEngine ground, via engine wire harness

23-14

www.emanualpro.com