Glass replacement HONDA CR-V 2000 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 995 of 1395

Doors

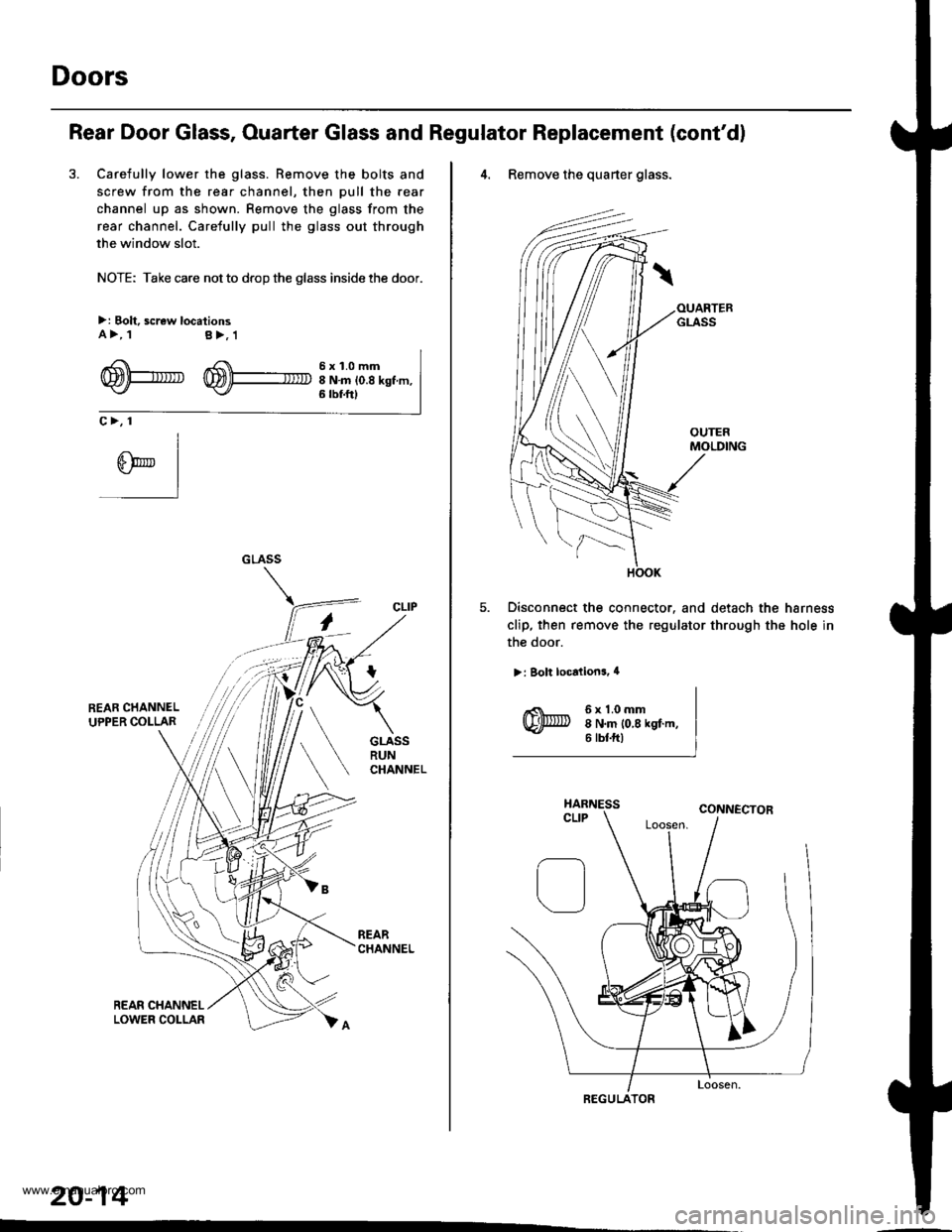

Rear Door Glass, Ouarter Glass and Regulator Replacement (cont'd)

3. Carefully lower the glass. Remove the bolts and

screw from the rear channel, then pull the rear

channel up as shown. Remove the glass from the

rear channel. Carefully pull the glass out through

the window slot.

NOTE: Take care not to drop the glass inside the door.

>: Bolt, screw locationsA>, tB>,1

-4 f 6 x 1.0 mmrTmtl-larR '^S\\\-.- -

WPU W)+ INmio.8ksf m,6 tbf.ftt

c>, 1

CLIP

20-14

''

4. Remove the quarter glass.

Disconnect the connector. and detach the harness

clip, then remove the regulator through the hole in

the door.

>: Bolt localions, 4

6x1.0mm8 N.m 10,8 kgf.m,6 tbtftl

REGULATOR

www.emanualpro.com

Page 999 of 1395

Doors

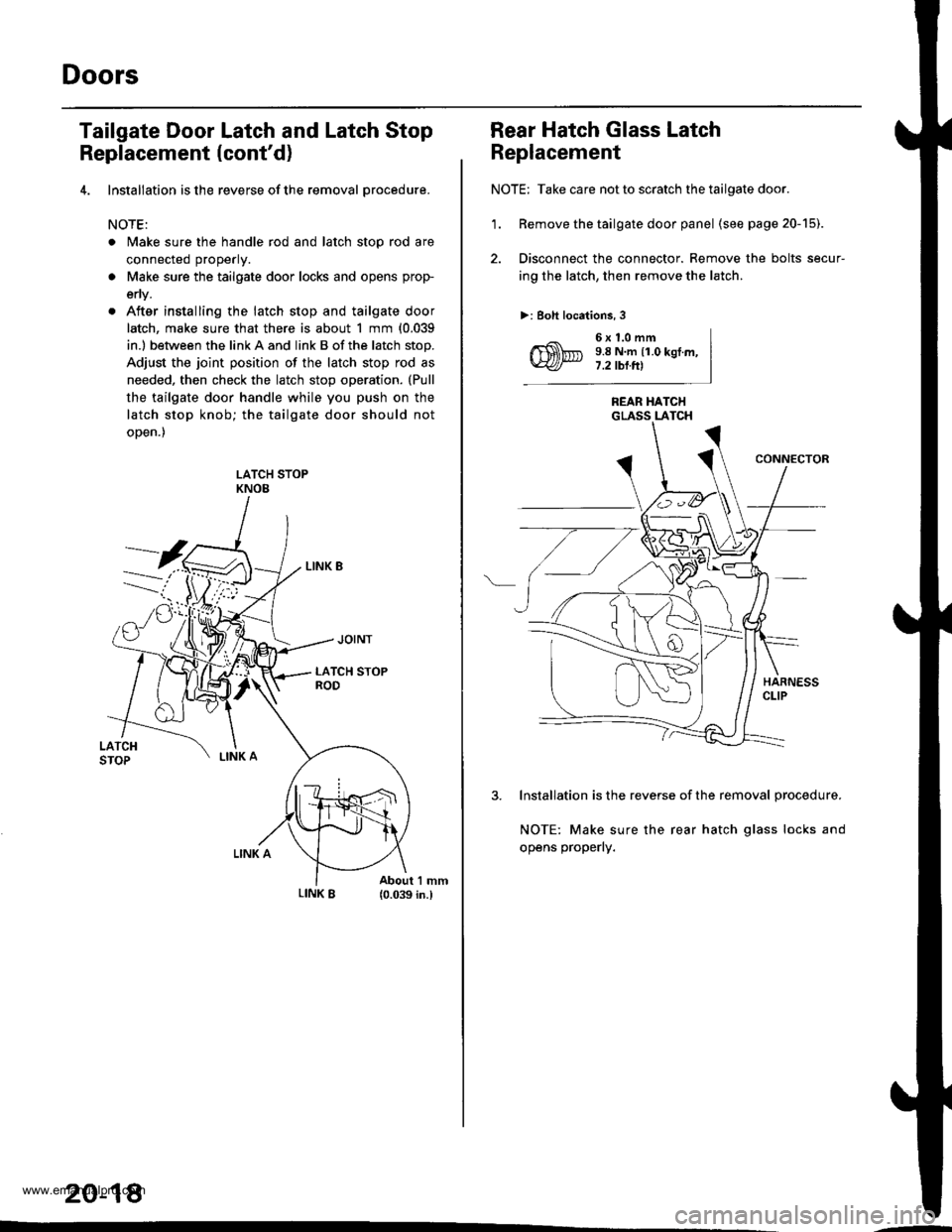

Tailgate Door Latch and Latch Stop

Replacement (cont'd)

4. lnstallation is the reverse of the removal orocedure.

NOTE:

. Make sure the handle rod and latch stop rod are

connected properly.

a Make sure the tailgate door locks and opens prop-

env.

. After installing the latch stop and tailgate door

latch, make sure that there is about 1 mm {0.039

in.l between the link A and link B of the latch stop.

Adjust the joint position of the latch stop rod as

needed, then check the latch stop operation. (Pull

the tailgate door handle while you push on the

latch stop knob; the tailgate door should not

oDen.)

LATCH STOPKNOE

20-18

Rear Hatch Glass Latch

Replacement

NOTE: Take care not to scratch the tailgate door.

'1. Remove the tailgate door panel (seepage20-15).

2. Disconnect the connector. Remove the bolts secur-

ing the latch, then remove the latch.

>: Boh locations, 3

6x1.0mm9.8 N.m {1.0 kgI.m,7.2 tbl.Itl

REAR HATCHGLASS LATCH

3. Installation is the reverse of the removal procedure.

NOTE: Make sure the rear hatch glass locks and

opens properly.

www.emanualpro.com

Page 1000 of 1395

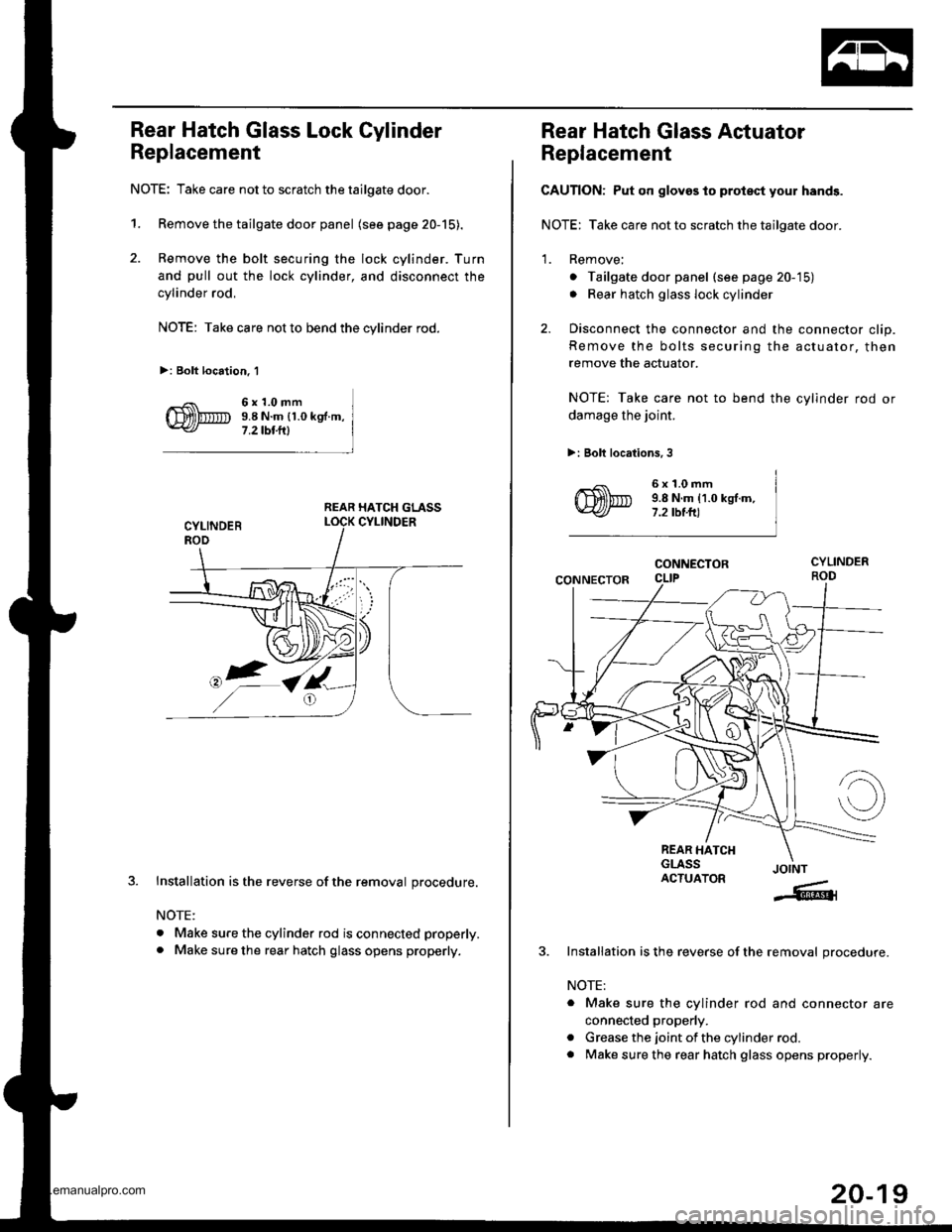

Rear Hatch Glass Lock Cylinder

Replacement

NOTE: Take care not to scratch the tailgate door.

1. Remove the tailgate door panel (see page 20-15).

2. Remove the bolt securing the lock cylinder. Turn

and pull out the lock cylinder, and disconnect the

cylinder rod,

NOTE: Take care not to bend the cylinder rod.

>: Bolt location. 1

6x1.0mm9.8 N.m {1.0 kg .m,

7 .2 tbt.lll

REAR HATCH GLASS

J.Installation is the reverse of the removal procedure.

NOTE:

. Make sure the cylinder rod is connected properly.

. Make sure the rear hatch glass opens properly.

Rear Hatch Glass Actuator

Replacement

CAUTION: Put on gloves to protsct your hands.

NOTE: Take care not to scratch the tailgate door.

1. Remove;

o Tailgate door panel (see page 20-'15)

. Rear hatch glass lock cylinder

2. Disconnect the connector and the connector clip.

Remove the bolts securing the actuator, then

remove the actuator.

NOTE: Take care not to bend the cylinder rod or

damage the joint.

>: Bolt locations, 3

6x1.0mm9.8 N.m 11.0 kgt.m,7.2 tbt.ft)

CONNECTOR

CONNECTOR

REAR HATCHGLASSACTUATORJOINT

-6{

Installation is the reverse of the removal procedure.

NOTE:

. Make sure the cylinder rod and connector are

connected properly.

. Grease the joint of the cylinder rod.

. Make sure the rear hatch glass opens properly.

20-19

www.emanualpro.com

Page 1001 of 1395

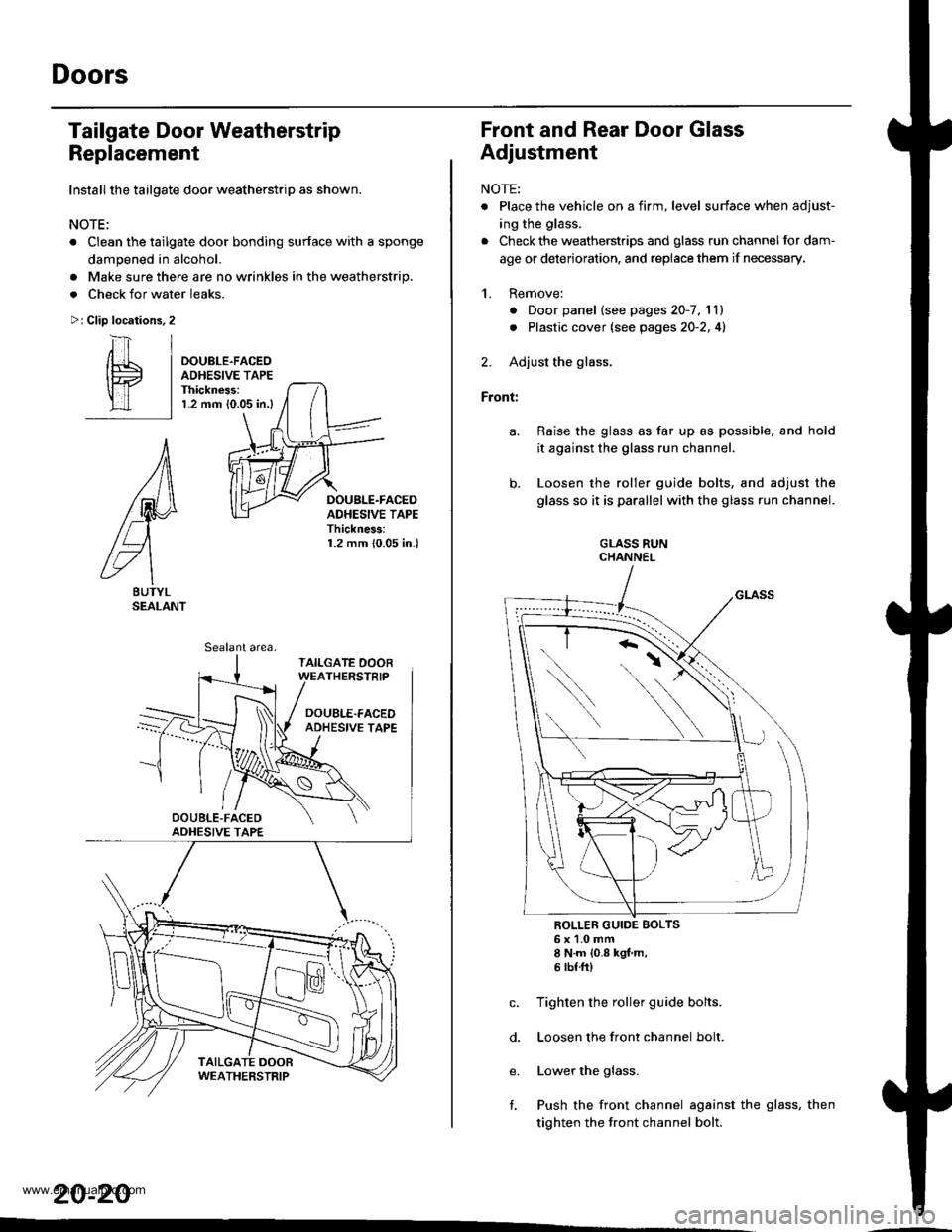

Doors

Tailgate Door Weatherstrip

Replacement

Install the tailgate door weatherstrip as shown.

NOTE;

. Clean the tailgate door bonding surface with a sponge

dampened in alcohol.

Make sure there are no wrinkles in the weatherstrip.

Check for water leaks.

Clip locations, 2

a

a

>:

i-t] |

/[L I oouere-rrceo

lE I aDHEsrvE rAPE

ll 1T I Thickness:

lll I r.2 mm lo.o5 in.)

A

lM

/L)

g\

BUTYLSEALANT

DOUBLE.FACEDADHESIVE TAPEThickne$:1.2 mm 10.05 in.)

Sealant area,

20-20

Front and Rear Door Glass

Adjustment

NOTE:

. Place the vehicle on a firm, level surface when adjust-

ing the glass.

. Check the weatherstrips and glass run channel for dam-

age or deterioration, and replace them if necessary,

1. Remove:

. Door panel (see pages20-7, lll

. Plastic cover (see pages2O-2,41

2. Adjust the glass.

Front:

Raise the glass as far up as possible. and hold

it against the glass run channel.

Loosen the roller guide bolts, and adjust the

glass so it is parallel with the glass run channel.

GLASS RUNCHANNEL

ROLLER GUIDE BOLTS6x1.0mm8 N.m {0.8 kgf.m,5 tbffi)

Tighten the roller guide bolts.

Loosen the front channel bolt.

Lower the glass.

Push the front channel against the glass, then

tighten the tront channel bolt.

e.

l.

www.emanualpro.com

Page 1008 of 1395

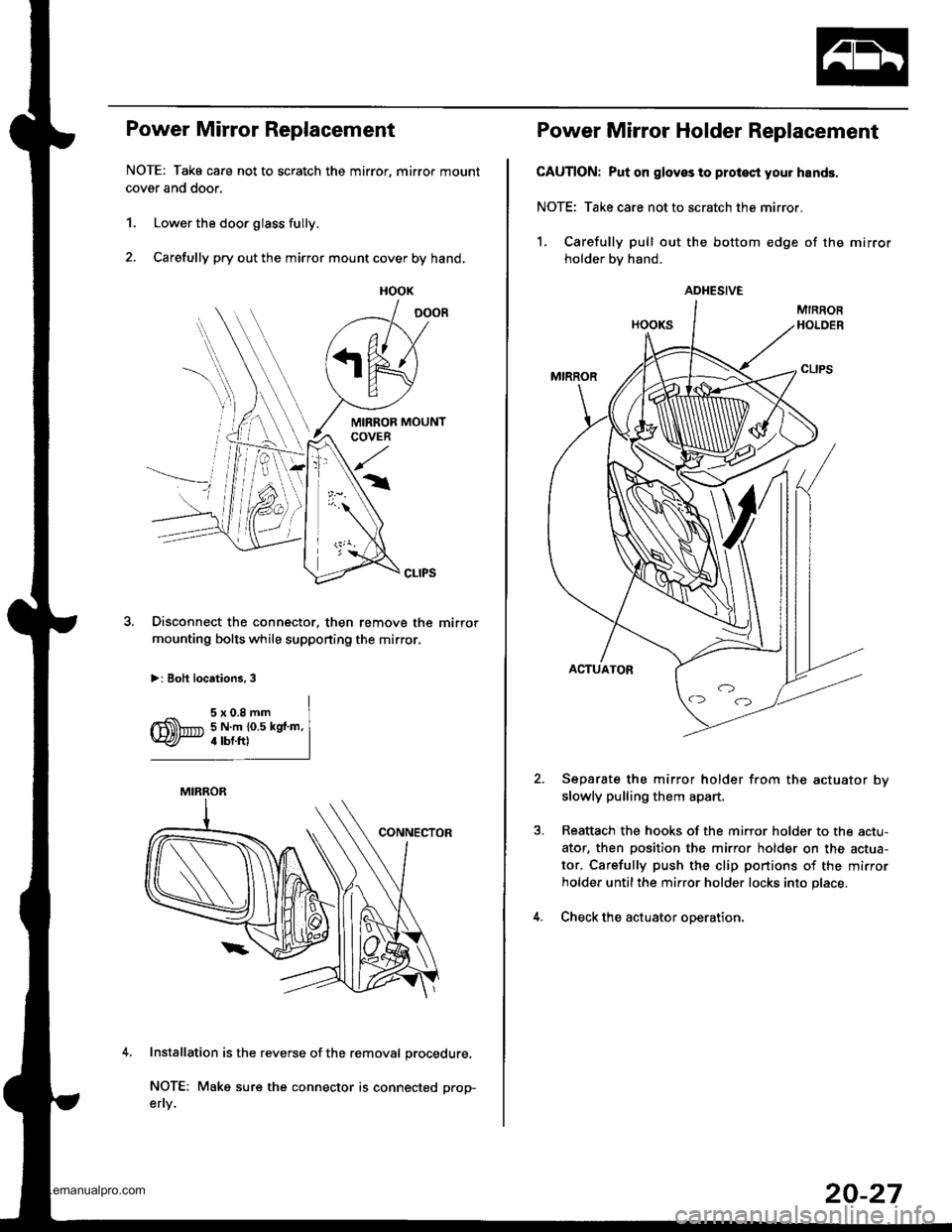

Power Mirror Replacement

NOTE: Tako care not to scratch the mirror, mirror mount

cover and door.

1. Lower the door glass fully.

2. Carefully pry out the mirror mount cover by hand,

,l

Disconnect the connector. then remove the mirror

mounting bolts while supponing the mirror,

>: Boh locations, 3

Installation is the reverse of the removal procedure,

NOTE: Make sure the connector is connected prop-

efly.

HOOK

MIRROR

Power Mirror Holder Replacement

CAUTION: Put on glovss to protest you. hands.

NOTE: Take care not to scratch the mirror.

1, Carefully pull out the bottom edge of the mirror

holder bv hand.

Separate the mirror holder from the actuator bv

slowly pulling them apart.

Reattach the hooks of the mirror holder to the actu-

ator, then Dosition the mirror holder on the actua-

tor. Carefully push the clip portions of the mirror

holder untilthe mirror holder locks into place.

Check the actuator ooeration.

ADHESIVE

20-27

www.emanualpro.com

Page 1010 of 1395

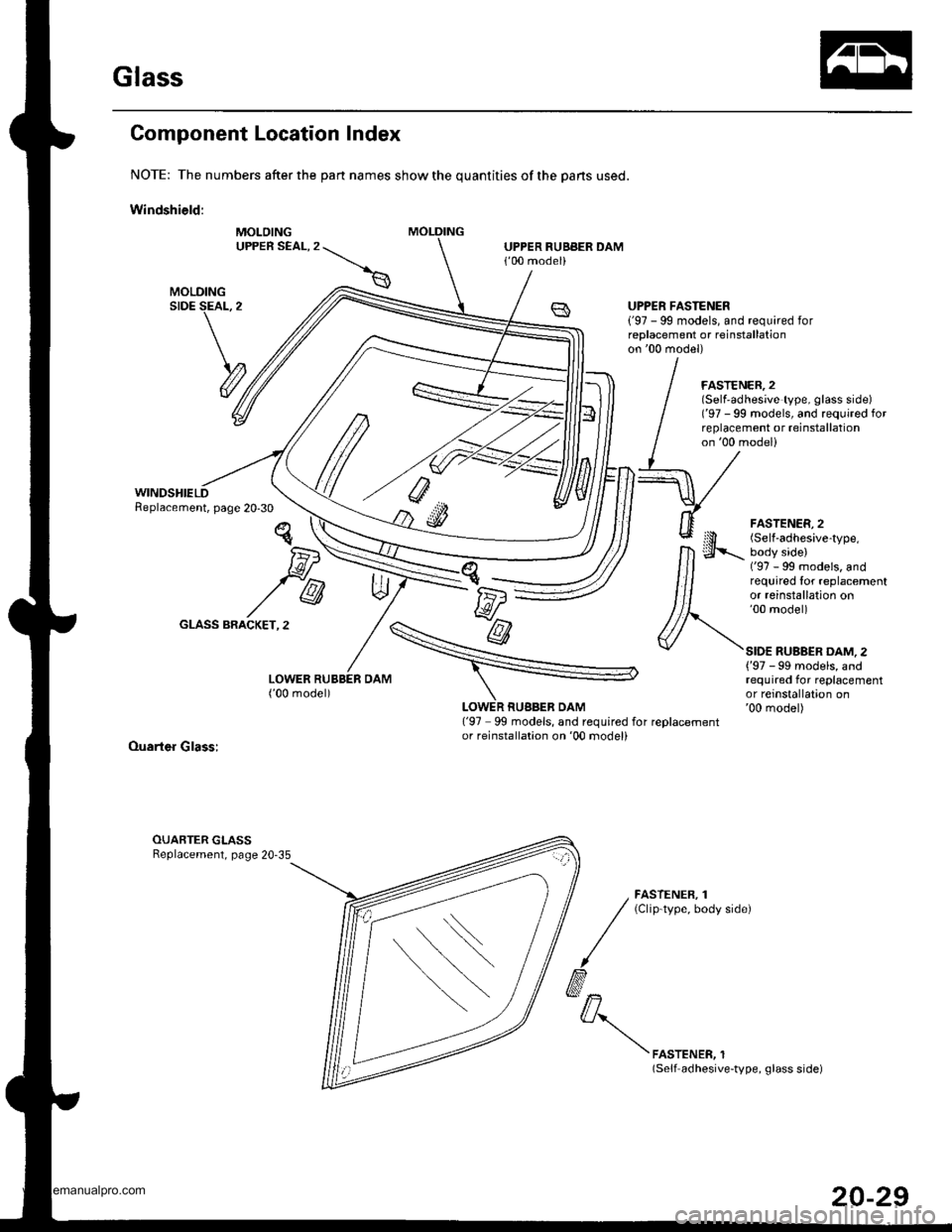

Glass

Component Location Index

NOTE: The numbers after the part names show the quantities of the pans used.

Windshield:

MOLOINGUPPER SEAL,2UPPER RUBBER DAM1'00 model)

WINDSHIELDReplacement, page 20-30

LOWER RUBBER DAM('00 model)

UPPER FASTENER('97 - 99 models, and required forreplacement or reinstallationon '00 model)

FASTENER,2(Self'adhesive type, glass side)('97 - 99 models, and required forreplacement or reinstallationon'00 model)

tE-r

*@

FASTENER,2(Self-adhesive-type,

body side)('97 - 99 models, andrequired lor replacementor reinstallation on'00 model)

SIDE RUBBER DAM, 2{'97 -99 models, andrequired for replacementor reinstallation on'00 model)LOWER RUBBER DAMl'97 99 models, and required for reDlacementor reinstallation on'00 modeliOuarter Glass:

OUABTER GLASSReplacement, page 20-35

FASTENER, 1(Clip-type, body side)

\,o,,.,.*,,,

(Self adhesive-type, glass side)

www.emanualpro.com

Page 1011 of 1395

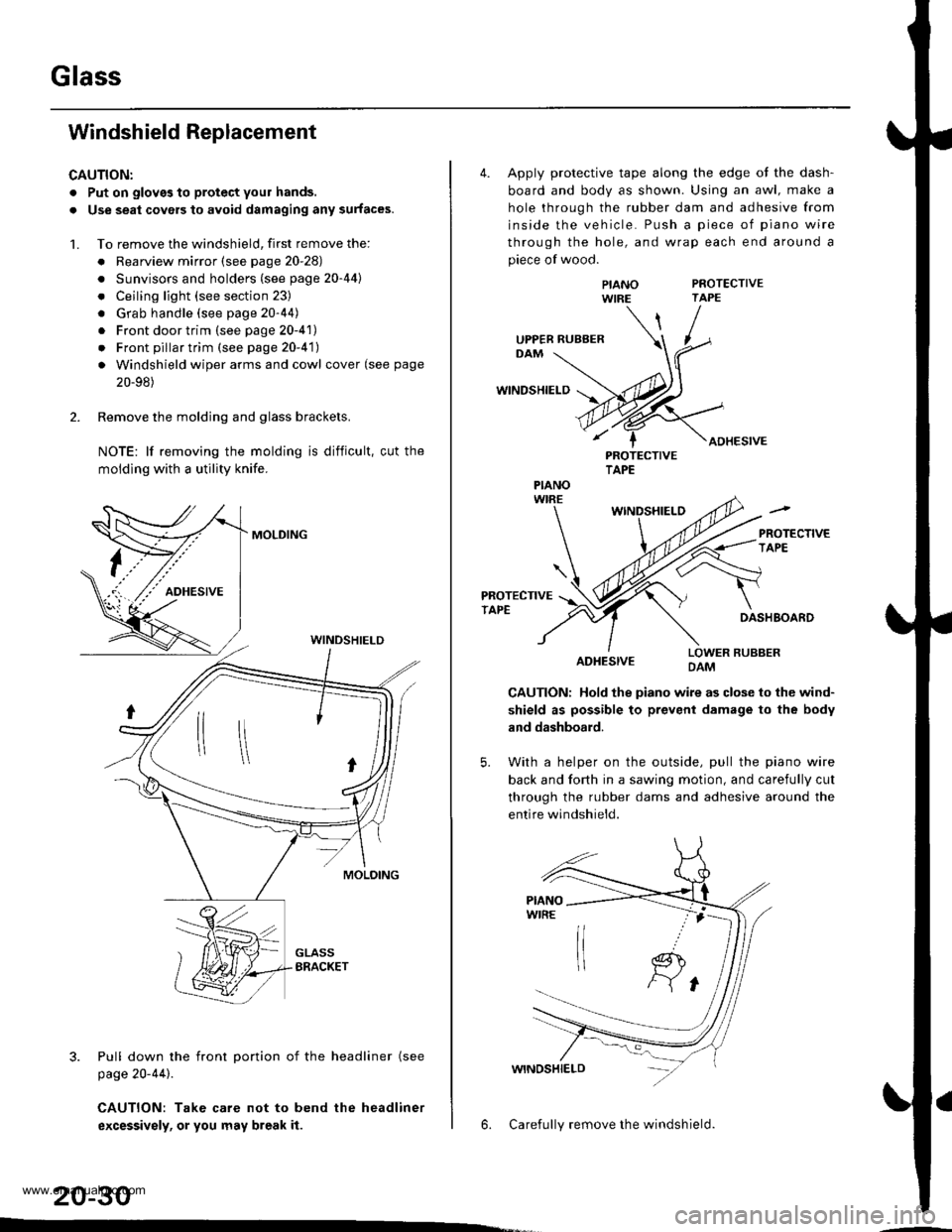

Glass

Windshield Replacement

CAUTION:

. Put on gloves to protect your hands.

. Use seat covers to avoid damaging any surfaces.

1. To remove the windshield, first remove the:

. Rearview mirror (see page 20-28)

. Sunvisors and holders (see page 20-44l'

. Ceiling light (see section 23)

. Grab handle (see page 20-44)

. Front door trim (see page 20-41)

. Front pillar trim (see page 20-41)

. Windshield wiper arms and cowl cover (see page

20-98)

2. Remove the molding and glass brackets.

NOTE: lf removing the molding is difficult, cut the

moldlng with a utility knife.

MOLDING

3. Pull down the front Dortion of the headliner (see

page 20-44).

CAUTION: Take care not to bend the headliner

excessivsly, or you may break it.

WINDSHIELD

20-30

4. Apply protective tape along the edge ot the dash-

board and body as shown. Using an awl, make a

hole through the rubber dam and adhesive from

inside the vehicle. Push a piece of piano wire

through the hole, and wrap each end around a

piece of wood.

PROTECTIVETAPE

WINDSHIELD

ADHESIVE

PIANOWIRE

PROTECTIVETAPE

WINDSHIELO

PROTECTIVETAPEDASHBOARD

ADHESIVELOWER RUBBERDAM

CAUTION: Hold the piano wire as close to the wind-

shield as possible to prevent damage to the body

and dashboard.

5. With a helper on the outside, pull the piano wire

back and fo(h in a sawing motion, and carefully cut

through the rubber dams and adhesive around the

entire windshield.

6. Carefully remove the windshield.

UPPER RUBBER

PIANO

www.emanualpro.com

Page 1013 of 1395

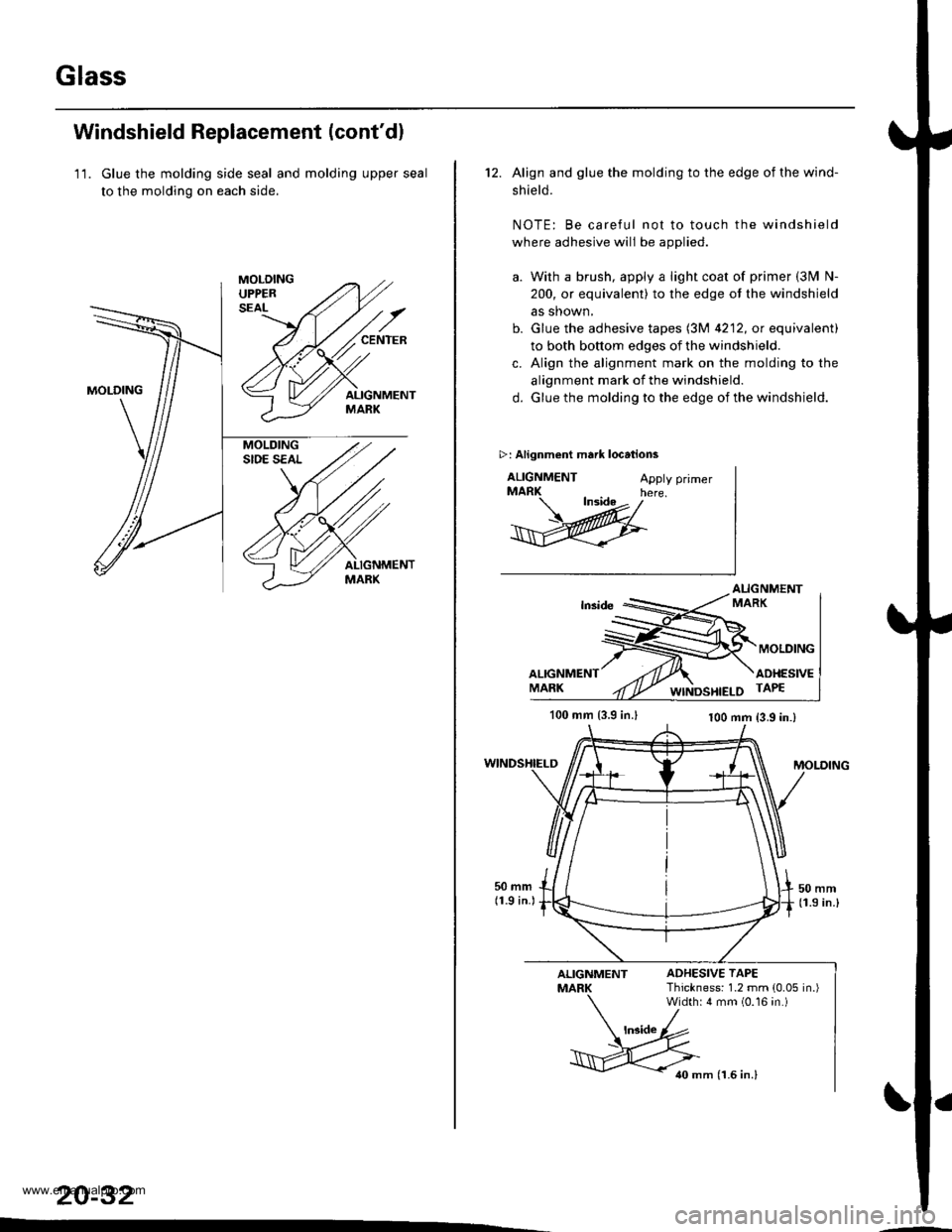

Glass

Windshield Replacement (cont'dl

11. Glue the molding side seal and molding upper seal

to the molding on each side.

20-32

12. Align and glue the molding to the edge of the wind-

shield.

NOTE: Be careful not to touch the windshield

where adhesive will be applied.

a. With a brush, apply a light coat of primer (3lvl N-

200, or equivalent) to the edge ot the windshield

as shown,

b. Glue the adhesive tapes l3M 4212, or equivalent)

to both bottom edges of the windshield.

c. Align the alignment mark on the molding to the

alignment mark of the windshield.

d. Glue the molding to the edge of the windshield.

>: Alignment mark locations

ALIGNMENTApply primerMARK here. ln3ide , /

@

100 mm {3.9 in.l100 mm {3.9 in.}

ADHESIVE TAPEThic*ness: 1.2 mm (0.05 in.)Widthr 4 mm (0.16 in.)

r0 mm (1.6 in.l

www.emanualpro.com

Page 1015 of 1395

Glass

Windshield Replacement (cont'dl

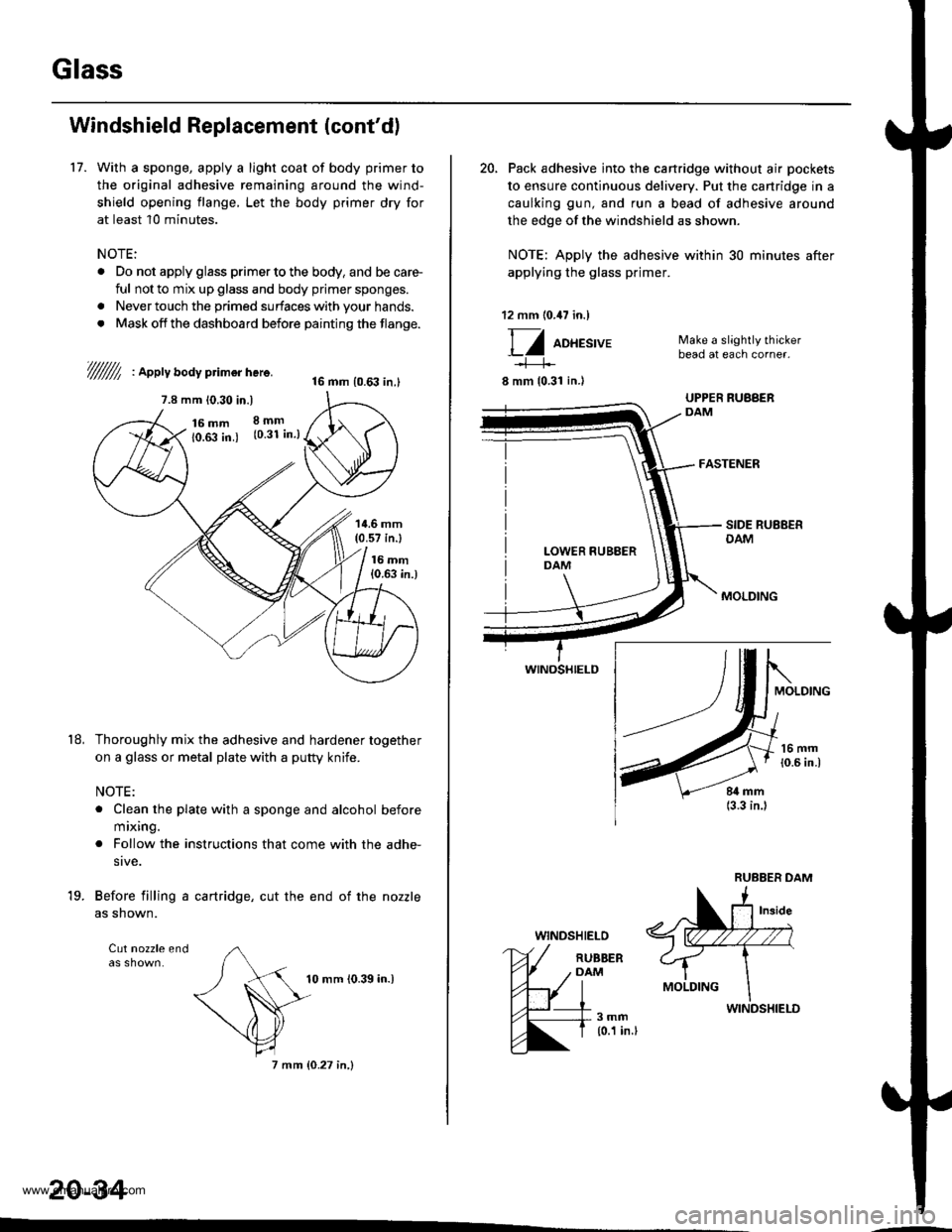

17. With a sponge, apply a light coat of body primer to

the original adhesive remaining around the wind-

shield opening flange, Let the body primer dry for

at least 10 minutes.

NOTE:

. Do not apply glass primer to the body, and be care-

ful not to mix up glass and body prjmer sponges.

. Never touch the primed surfaces with your hands.

. Mask off the dashboard before painting the flange.

///////l , apptv aoav primor here.16 mm {0.63 in.l

7.8 mm 10.30 in.)

16 mm10.fi in.)

8mm(0.31 in.)

't8,

14.6 mm(0.57 in.l

16 mm{0.63 in.)

Thoroughly mix the adhesive and hardener together

on a glass or metal plate with a putty knife.

NOTE:

. Clean the plate with a sponge and alcohol before

mixing.

. Follow the instructions that come with the adhe-

sive.

Before filling a cartridge, cut the end of the nozzle

as shown.

Cut nozzle end

'19.

10 mm {0.39 in.)

7 mm {0.27 in,}

20-34

20, Pack adhesive into the cartridge without air pockets

to ensure continuous delivery. Put the cartridge in a

caulking gun, and run a bead of adhesive around

the edge of the windshield as shown.

NOTE: Apply the adhesive within 30 minutes after

applying the glass primer.

12 mm (0.47 in.)

Ff oo*tt'u'

8 mm {0.31 in.l

WINOSHIELD

WINDSHIELO

Make a slightly thickerbead at each corner.

FASTENER

RUBBERDAM

3mm{0.1 in.l

www.emanualpro.com

Page 1016 of 1395

22.

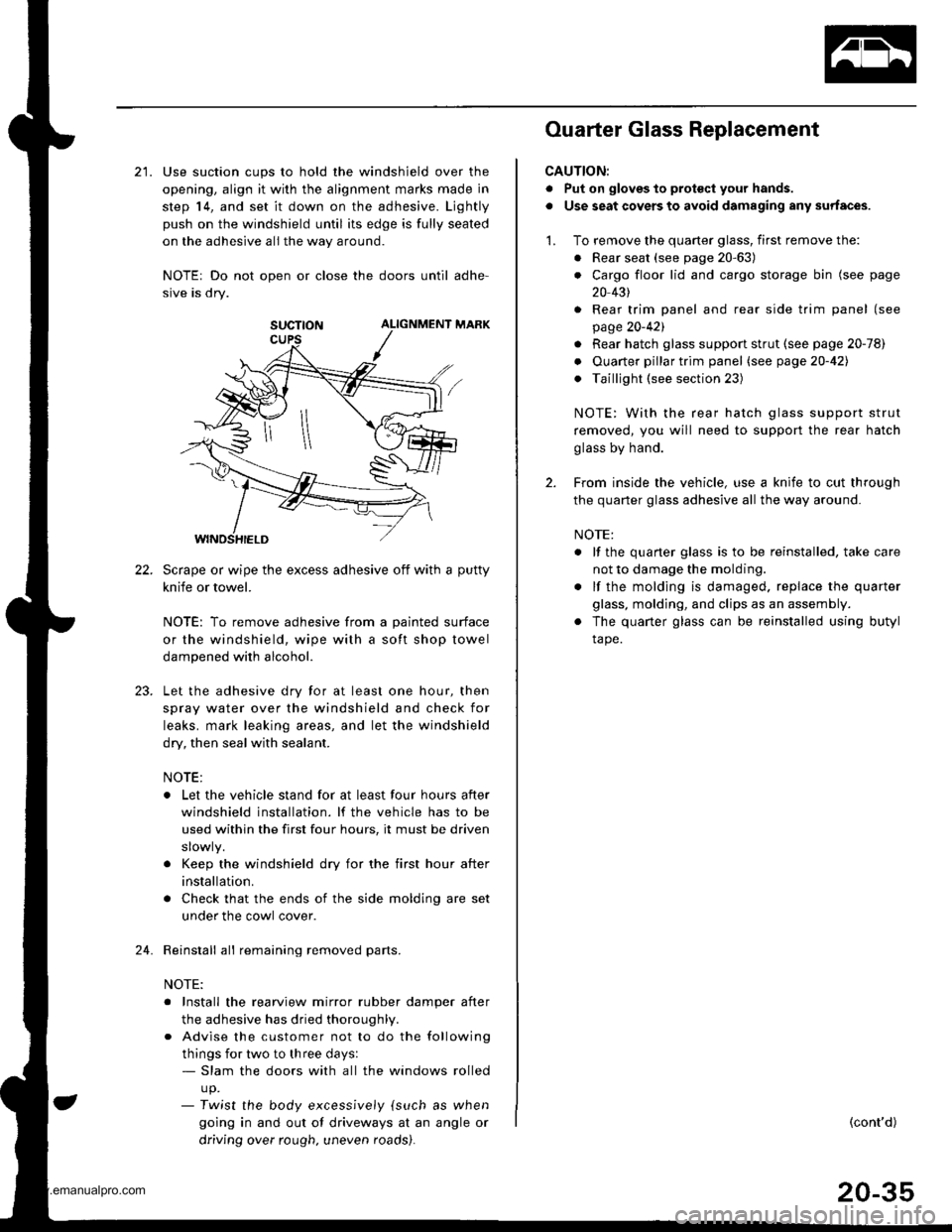

21. Use suction cups to hold the windshield over the

opening, align it with the alignment marks made in

step 14, and set it down on the adhesive. Ljghtly

push on the windshield until its edge is fully seated

on the adhesive all the way around.

NOTEr Do not open or close the doors until adhe-

sive is dry.

SUCTTON ALIGNMENT MARK

Scrape or wipe the excess adhesive off with a putty

knife or towel.

NOTE: To remove adhesive from a painted surface

or the windshield, wipe with a soft shop towel

dampened with alcohol.

Let the adhesive dry for at least one hour, then

spray water over the windshield and check for

leaks. mark leaking areas, and let the windshield

dry, then seal with sealant.

NOTE:

. Let the vehicle stand for at least four hours after

windshield installation. lf the vehicle has to be

used within the first four hours, it must be driven

. Keep the windshield dry for the first hour after

installation.

. Check that the ends of the side molding are set

under the cowl cover.

Reinstall all remaining removed parts.

NOTE:

. Install the rearview mirror rubber damper after

the adhesive has dried thoroughl,.

. Advise the customer not to do the following

things for two to three days:- Slam the doors with all the windows rolled

up.- Twist the body excess,vely {such as when

going in and out of driveways at an angle or

driving over rough. uneven roads).

24.

Ouarter Glass Replacement

CAUTION:

. Put on gloves to prot€ct your hands.

. Use seat covers to avoid damaging any surfaces.

1. To remove the quarter glass, first remove the:

. Rear seat (see page 20-63)

. Cargo floor lid and cargo storage bin (see page

20 431

. Rear trim panel and rear side trim panel (see

page 20-421

. Rear hatch glass support strut (see page 20-78)

. Ouarter pillar trim panel (see page20-421

. Taillight (see section 23)

NOTE: With the rear hatch glass support strut

removed, you will need to support the rear hatch

glass by hand.

2. From inside the vehicle, use a knife to cut through

the quarter glass adhesive all the way around.

NOTE:

. lf the quaner glass is to be reinstalled, take care

not to damage the molding.

. lf the molding is damaged. replace the quarter

glass, molding, and clips as an assembly.

. The quarter glass can be reinstalled using butyl

tape.

(cont'd)

20-35

www.emanualpro.com