Srs light HONDA CR-V 2000 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1207 of 1395

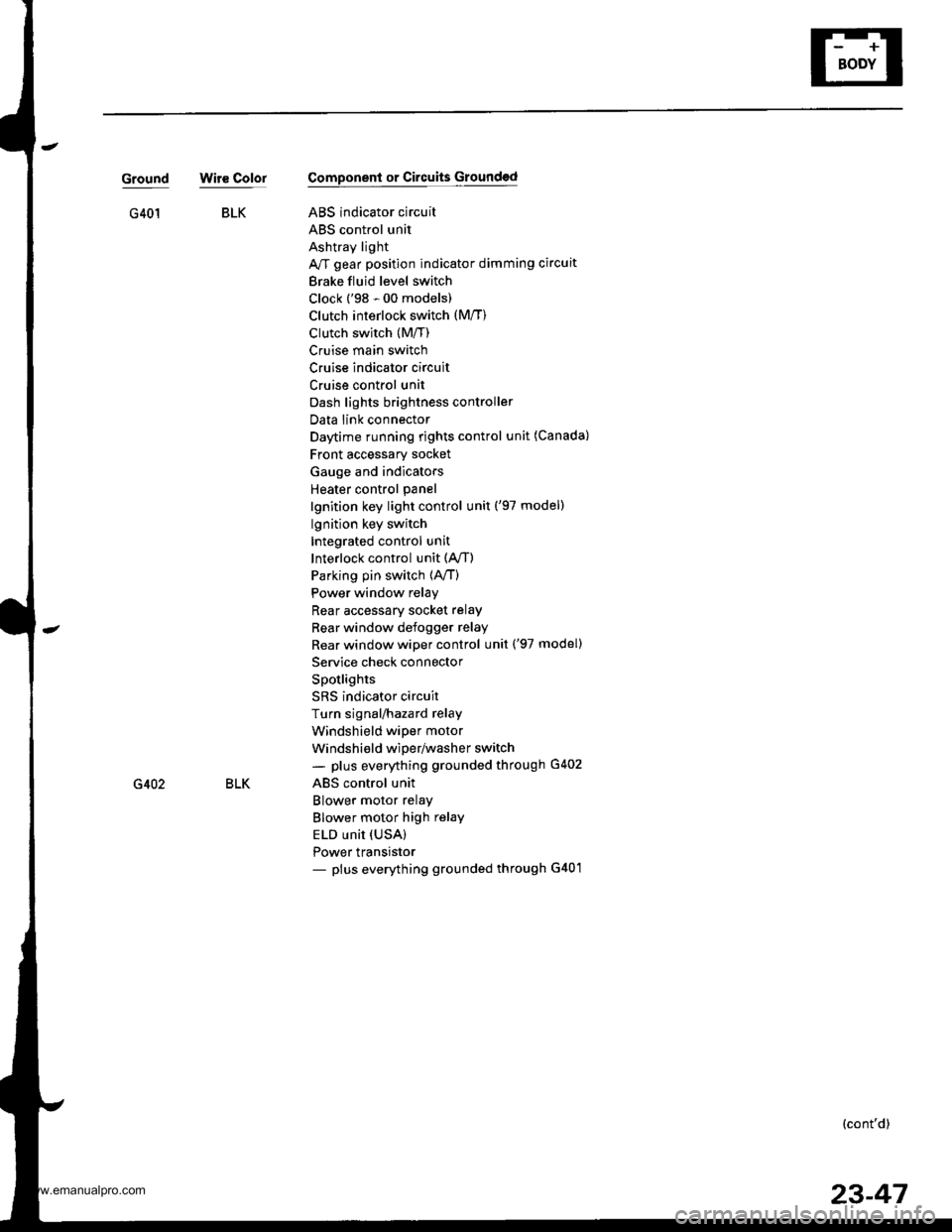

BLKG401

GroundWir€ ColorComponent or Circuits Grounded

ABS indicator circuit

ABS control unit

Ashtray light

A/T gear position indicator dimming circuit

Brake fluid level switch

Clock ('98 - 00 models)

Clutch inrerlock switch (M/T)

Clutch switch (Mff)

Cruise main switch

Cruise indicator circuit

Cruise control unit

Dash lights brightness controller

Data iink connector

Daytime running rights control unit (Canada)

Front accessary socket

Gauge and indicators

Heater control panel

lgnition key light control unit ('97 model)

lgnition key switch

Integrated control unit

Interlock control unit (Ay'T)

Parking pin switch {A,/T)

Power window relay

Rear accessary socket relay

Bear window defogger relay

Rear window wiper control unit ('97 model)

Service check connector

Spotlights

SRS indicator circuit

Turn signal/hazard relay

Windshield wiper motor

Windshield wiper/washer switch- plus everything grounded through G402

ABS control unit

Blower motor relay

Blower motor high relay

ELD unit (USA)

Power transistor- plus everything grounded through G401

BLKG402

{cont'd)

23-47

www.emanualpro.com

Page 1208 of 1395

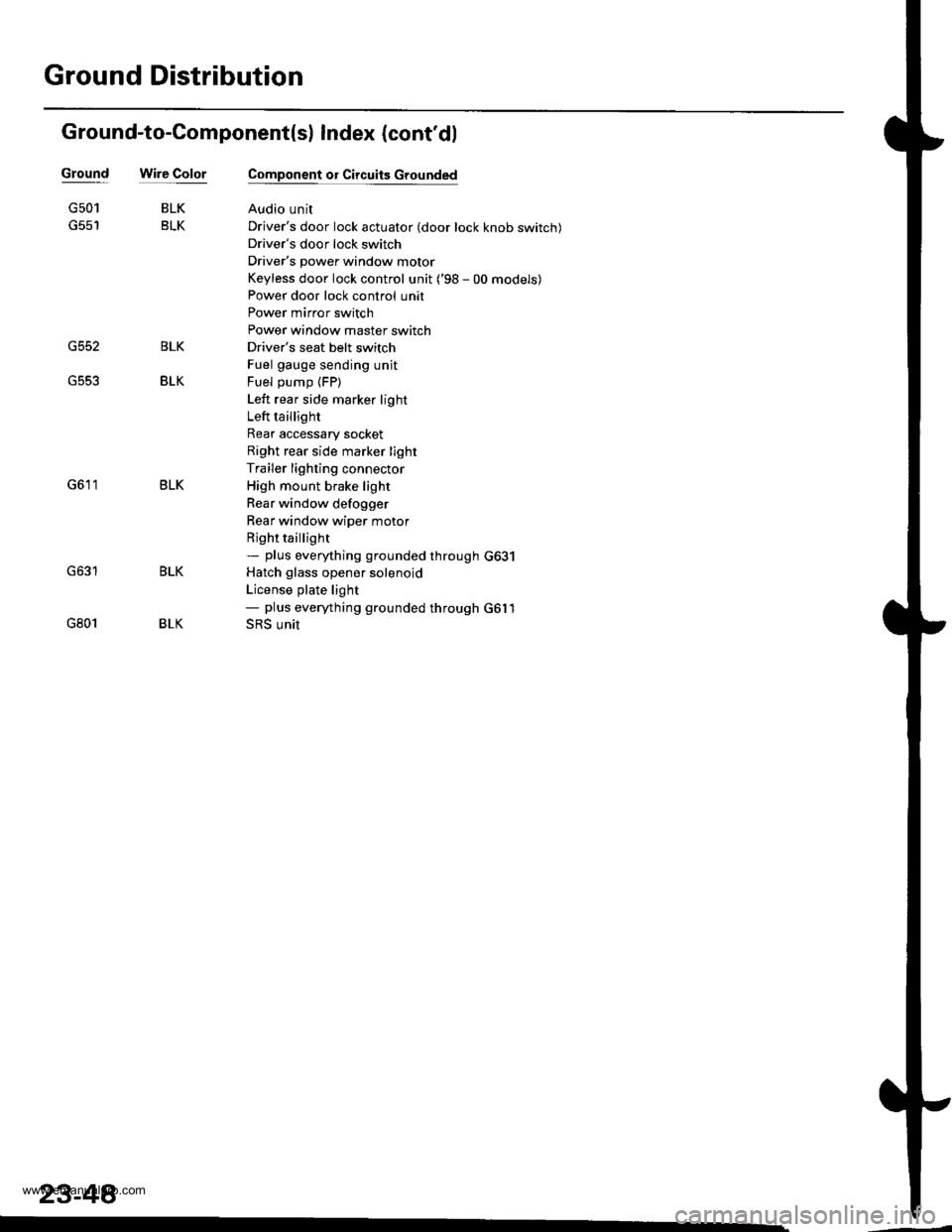

Ground Distribution

Ground-to-Component(sl Index (cont'dl

Wire ColorGround

G552

G501

G801

BLK

BLK

BLK

BLK

Component or Circuits Grounded

Audio unit

Driver's door lock actuator (door lock knob switch)

Driver's door lock switch

Driver's power window motor

Keyless door lock control unit ('98 - 00 models)

Power door lock control unit

Power mirror switch

Power window master switch

Driver's seat belt switch

Fuel gauge sending unit

Fuel pump (FP)

Left rear side marker light

Left taillight

Rear accessary socket

Right rear side marker light

Trailer lighting connector

High mount brake light

Rear window defogger

Rear window wiper motor

Rjght taillight- plus eveMhing grounded through G631

Hatch glass opener solenoid

License plate light- plus eveMhing grounded through G6l1

SRS unit

BLK

BLK

BLK

23-48�

www.emanualpro.com

Page 1217 of 1395

l-

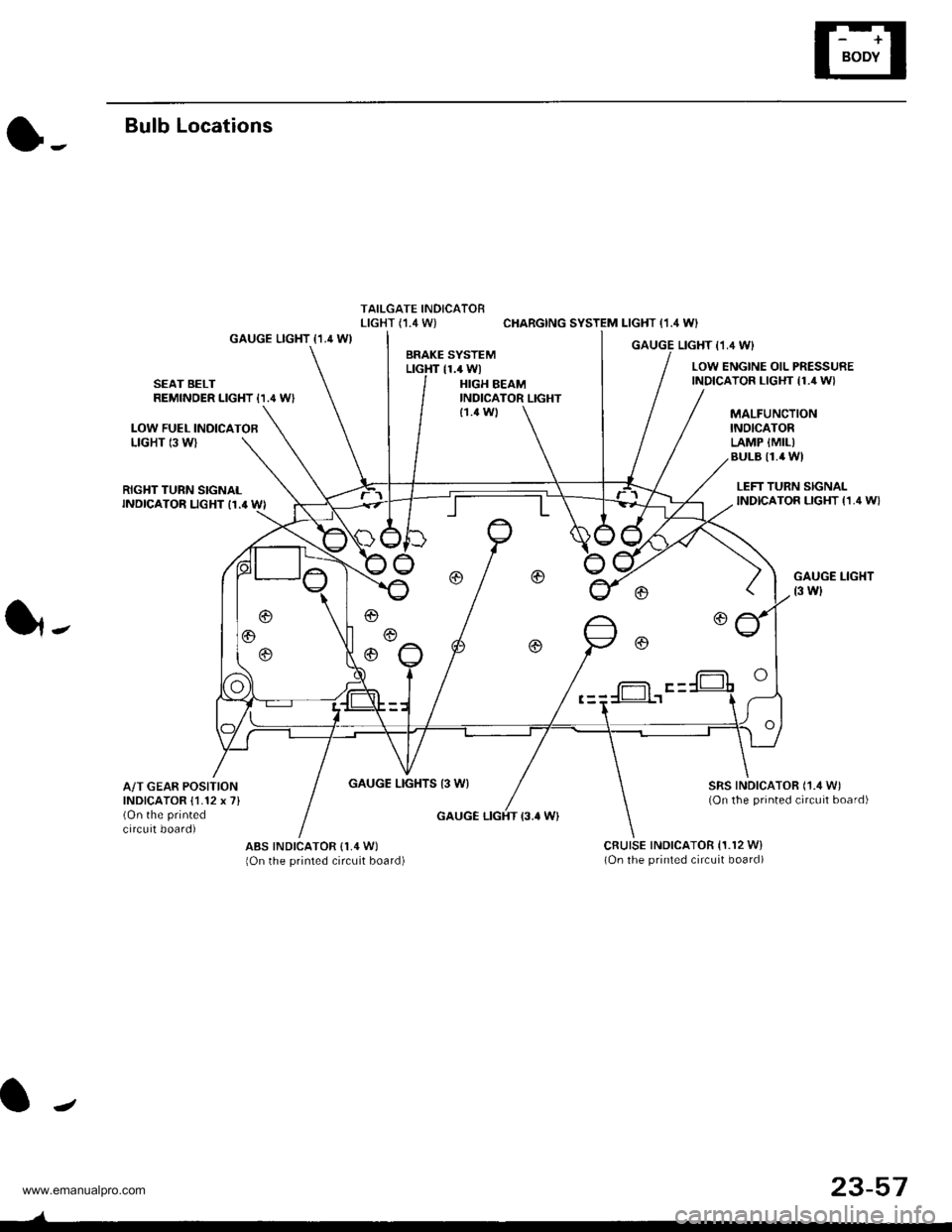

Bulb Locations

TAILGATE INDICATORLIGHT (,I.4 W) CHARGING SYSTEM LIGHT (1.4 WI

GAUGE LIGHT {1.4 WIGAUGE LIGHT I1,4 WIBRAKE SYSTEMLTGHT 11.4 WlLOW ENGINE OIL PRESSUREINDICATOR LIGHT {1./r W}SEAT BELTREMINDER LIGHT {1.' W'HIGH BEAMINDICATOR LIGHT

LOW FUEL INOICATOBLIGHT 13 WI

MALFUNCTIONINOICATORLAMP {MIL)BULB I1.4 WI

{1.4 Wl

RIGHT TURN SIGNALINDICATOR LIGHT I1.' WI

GAUGE LIGHTS 13 WI

LEFT TURN SIGNALINDICATOR LIGHT {1,4 W}

GAUGE LIGHT

t3 wl

SRS INDICATOR ('1./t W)(On the printed circuit board)

1,.

A/T GEAR POSITIONINDICATOR {1.12 x 7}(On the printed

circuit board)GAUGE LIGHT {3.' W}

ABS INDICATOR (1,4 W)

lOn the printed circuit board)cRutsE tNDtcAToR 11.r2 w)(On the printed circuit board)

f-= F -

J

23-57

www.emanualpro.com

Page 1218 of 1395

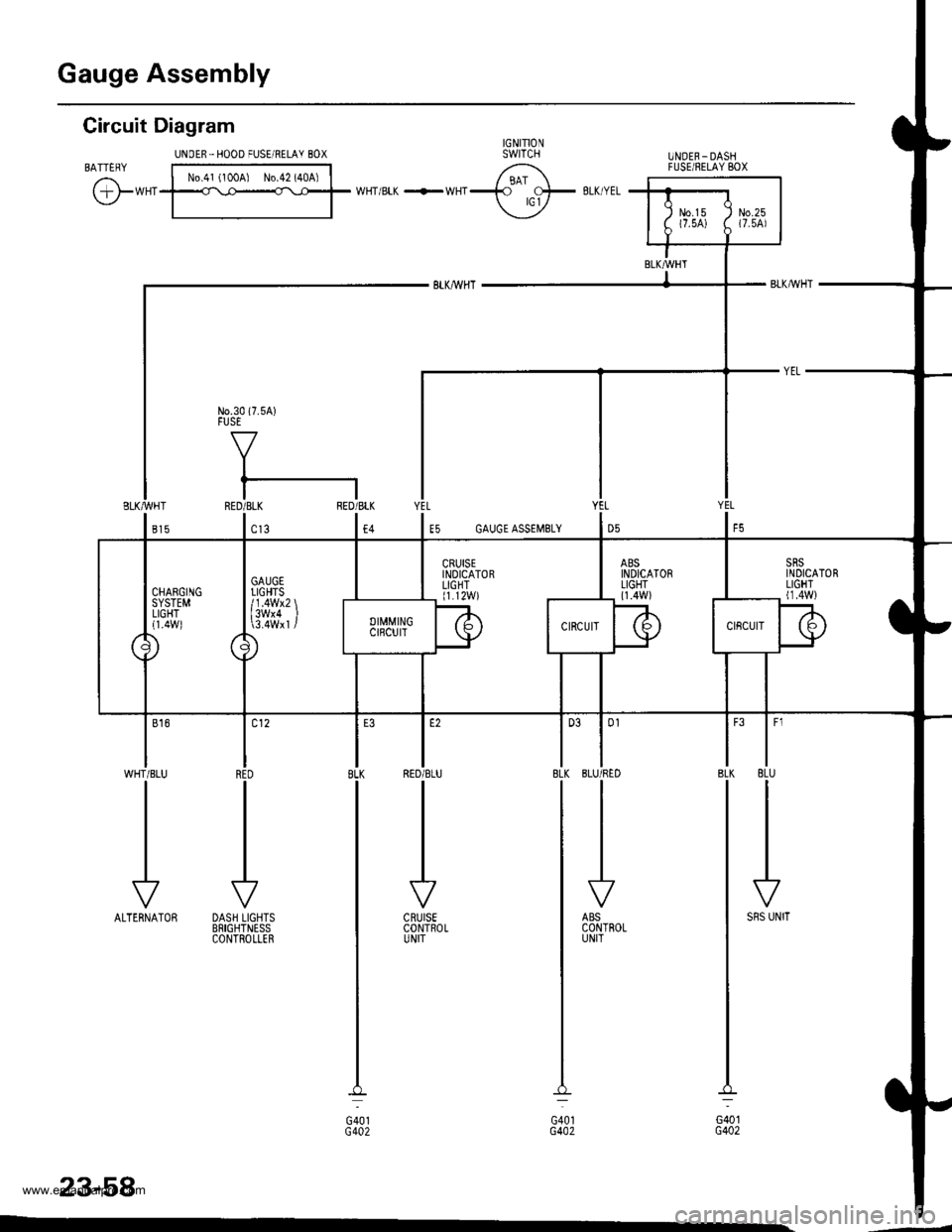

Gauge Assembly

Circuit Diagram

BATTERY

@*"

UNOER.IIOOD FUSE/RELAY 8OX

No.41 (100A) No.42 (40A)

UNOER_DASHFUSEiNELAY BOX

|

'''

IRED

-I

DASH LIGHTSBRIGHTNESSCONTROLLER

l-8LK

G401G4A2

CRUISECONTROLUNIT

23-58

JALTERNATOR

| 0l

IBLU/RED

-I

ABSCONTROLUNIT

JSRS UNIT

YEL

E5 GAUGE ASSEMSLY

www.emanualpro.com

Page 1239 of 1395

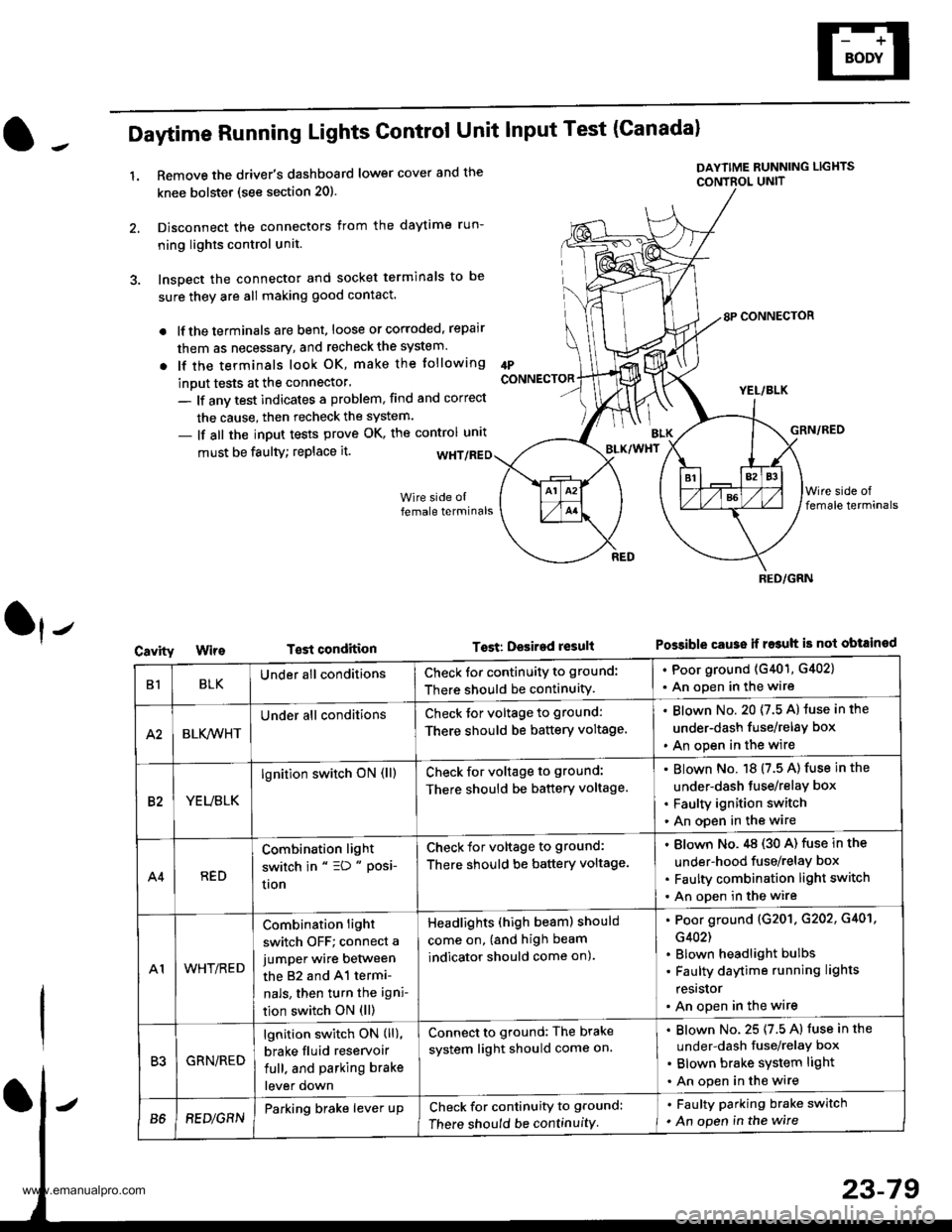

Daytime Running Lights Control Unit Input Test (Canadal

1.Remove the driver's dashboard lower cover and the

knee bolstet (see section 20).

Disconnect the connectors from the daytime run-

ning lights control unit.

Inspect the connector and socket terminals to be

sure they are all making good contact.

lf the terminals are bent, loose or corroded, repair

them as necessary, and recheck the system.

lf the terminals look OK, make the tollowing

inout tests at the connector'

- lf anv test indicates a problem, find and correct

the cause, then recheck the system.

- lf all the input tests prove OK, the control unrt

IPCONNECTOR

must be faulty; replace it.

T€st condition

DAYTIME RUNNING LIGHTS

CONTBOL UNIT

Tost: Desired result

8P CONNECTOR

YEL/BLK

GRN/RED

Possible cause ii r$uh is not obtained

BLK/WHT

Cavity

RED/GRN

B1BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G401, G402)

. An open in the wire

A2BLK,4iVHT

Under all conditionsCheck tor voltage to ground:

There should be battery voltage.

Blown No. 20 (7.5 A) luse in the

under-dash fuse/relay box

An open in the wire

82YEUBLK

lgnition switch oN (ll)Check for voltage to ground:

There should be battery voltage.

Blown No. 18 (7.5 A) fuse in the

under-dash tuse/relay box

Faulty ignition switch

An open in the wire

A4RED

Combination light

switch in " =D " Posi-

uon

Check for voltage to ground:

There should be battery voltage.

Blown No.,tg (30 A) fuse in the

under-hood fuse/relay box

Faulty combination light switch

An open in the wire

A1WHT/RED

Combination light

switch OFF; connect a

jumper wire between

the 82 and 41 termi-

nals, then turn the igni-

tion switch ON (ll)

Headlights (high beam) should

come on, (and high beam

indicator should come on).

Poor ground (G201. G202, G401,

G402)

Blown headlight bulbs

Faulty daytime running lights

resrslor

An open in the wire

R'IGRN/RED

lgnition switch ON (ll),

brake fluid reservoir

full. and parking brake

lever down

Connect to ground: The brake

system light should come on.

Blown No. 25 (7.5 A) fuse in the

under-dash fuse/relaY box

Blown brake system light

An open in the wire

B68EDlGRNParking brake lever upCheck for continuity to ground:

There should be continuity

. Faulty parking brake switch

. An open in the wire

www.emanualpro.com

Page 1246 of 1395

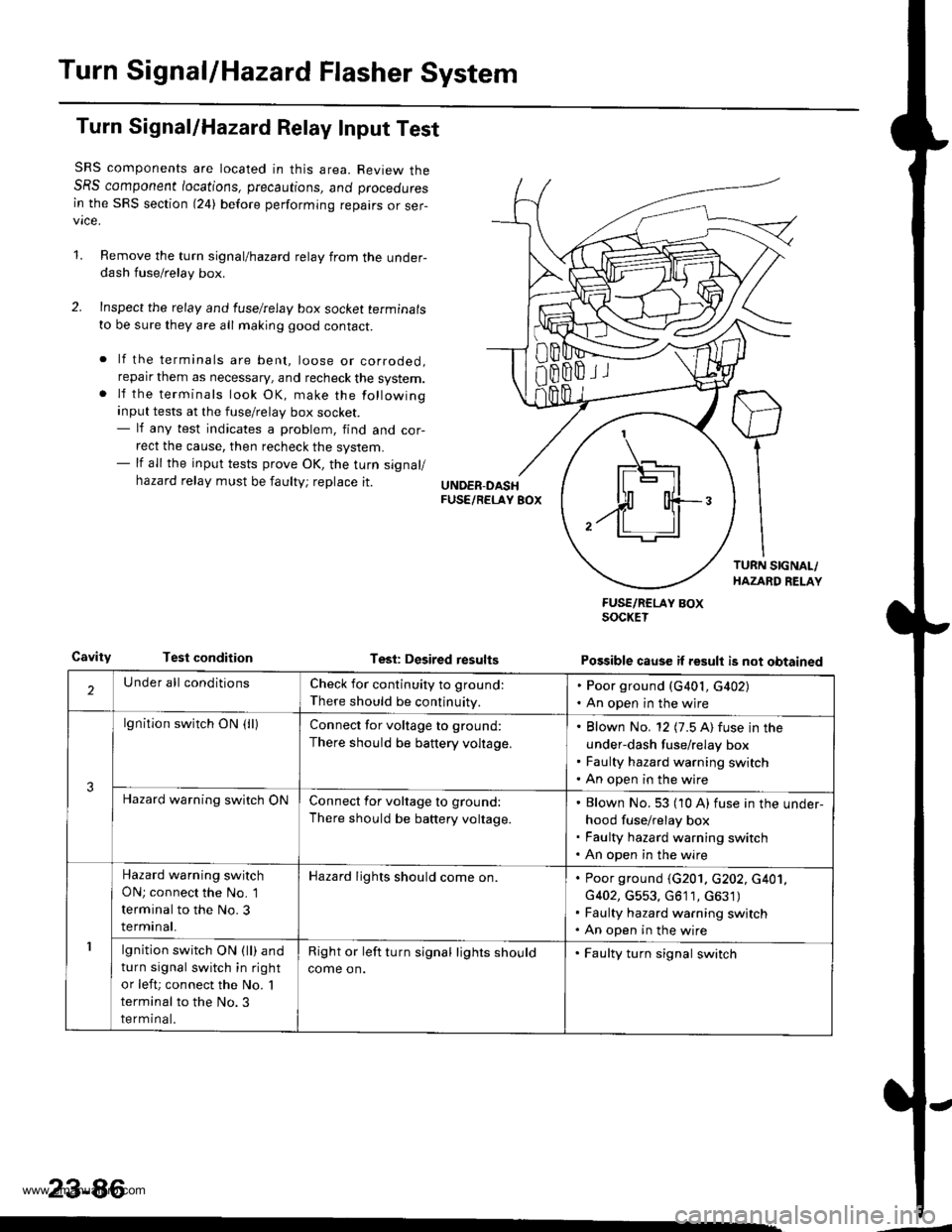

Turn SignallHazard Flasher System

Turn Signal/Hazard Relay Input Test

SRS components are located in this area. Review theSRS component /ocations, precautions, ano proceoures

in the SRS section (24) before performing repairs or ser-vice.

1.Remove the turn signal/hazard relay from the under-dash fuse/relay box.

Inspect the relay and luselrelay box socket terminals

to be sure they are all making good contact.

lf the terminals are bent, loose or corroded,reparr them as necessary, and recheck the system.lf the terminals look OK, make the following

input tests at the fuse/relay box socket.- lf any test indicates a problem, find and cor-

rect the cause, then recheck the system.- lf all the input tests prove OK, the turn signal/

hazard relay must be faulty; replace it.

CavityTest conditionTesl: Desired results

FUSE/RCLAY BOXSOCKET

Possible cause if result is not obtained

'1

IF\_-'l -]l

$ o{+-/ll ll

2Under all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G401, G402). An open in the wjre

3

lgnition switch ON (lllConnect for voltage to ground:

There should be battery voltage.

Blown No. 12 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty hazard warning switch

An open in the wire

Hazard warning switch ONConnect for voltage to ground:

There should be battery voltage.

Blown No. 53 (10 A) fuse in the under-

hood fuse/relay box

Faulty hazard warning switch

An open in the wire

1

Hazard warning switch

ON; connect the No. 1

terminal to the No. 3

terminal.

Hazard lights should come on.Poor ground (G201. c202, c401,

G402, G553, G611, c631)

Faulty hazard warning switch

An open in the wire

lgnition switch ON (ll) and

turn signal switch in right

or left; connect the No. 'l

terminal to the No.3

terminal.

Right or left turn signal lights should

come on.

. Faulty turn signal switch

23-86

www.emanualpro.com

Page 1266 of 1395

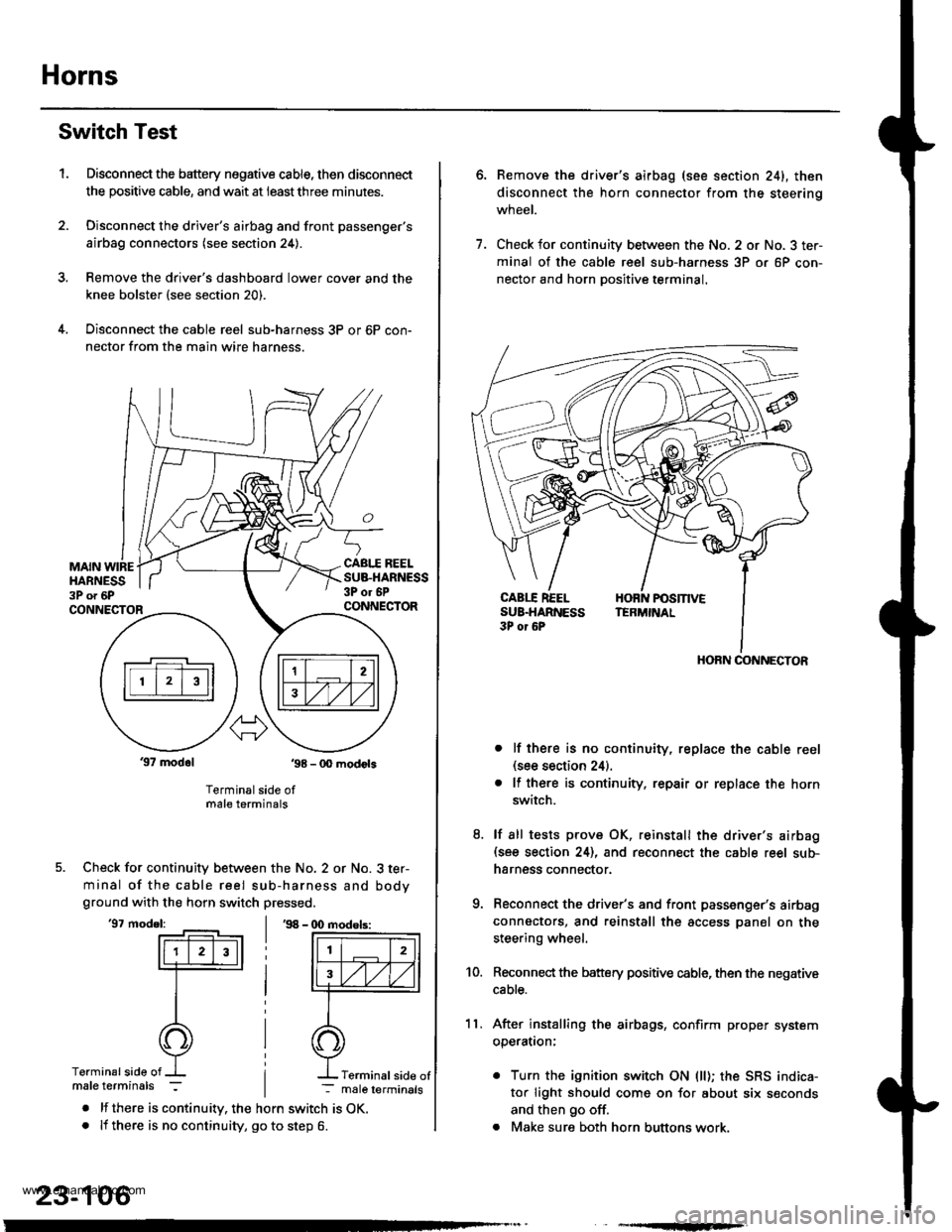

Horns

Switch Test

Disconnect the battery negative cable, then disconnect

the positive cable, and wait at ieastthree minutes.

Disconnect the driver's airbag and front passenger's

airbag connectors (see section 24).

Remove the drive.'s dashboard lower cover and the

knee bolster (see section 20).

Disconnect the cable reel sub-harness 3P or 6P con-

nector from the main wire harness.

1.

MAIN WIREHARNESS3P o. 6P

CABI.I REELSUB.HARNESS3P or 6PCONNECTORCONNECTOR

37 modol ,98 - 0O modots

Terminal side ofmale terminals

Check for continuity between the No. 2 or No. 3 ter-

minal of the cable reel sub-harness and bodyground with the horn switch pressed.

'97 model:'98 - (X) modols:

Terminalside of

. lf there is continuity. the horn switch is OK.. lf there is no continuity, go to step 6.

23-106

Terminal side of

6.Remove the driver's airbag (see section 241, then

disconnect the horn connector from the steerinq

wneet.

Check for continuity between the No. 2 or No. 3 ter-

minal of the cable reel sub-harness 3P or 6P con-

nector and horn Dositive terminal.

lf there is no continuity, replace the cable reel(see section 24).

lf there is continuity. repair or replace the horn

switch.

lf sll tests prove OK, reinstall the driver's airbag(see section 24), and reconnect the cable reel sub-

harness connector.

Reconnect the driver's and front passenger's airbag

connectors, and reinstall the access panel on the

steering wheel.

Reconnect the battery positive cable, then the negative

cable.

After installing the airbags, confirm proper system

operatron:

. Turn the ignition switch ON (ll); the SRS indica-

tor light should come on for about six seconds

and then go off.

. Make sure both horn buttons work.

7.

11.

8.

9.

10.

HORN CONNECTOR

www.emanualpro.com

Page 1310 of 1395

)

Supplemental Restraint System (SRS)

Special Tools .."....."" 24-14

Component/Wring Location

lndex - '97 model ..........'.." '.....""" 24-15

Component/Wiring Location

lndex - '98 - 00 models ..............." 24-16

Description .'.........."'.24'17

Circuit Diagram .........24'14

Precautions/Procedures

General Precautions ......".."'........... 24-19

Airbag/Seat Belt Tensioner

Handling and Stolage ....''........... 24-19

SRS Unit Precautions ...............'...... 24-20

lnspeciion After Deployment .......'.24'20

)

with Built-in Short Contact '...'....24-21

Spring-loaded Lock Connectors .."' 24-22

BackProbing SPring-loaded Lock

Conneetors ,.......24-22

Disconnecting the Airbag Connectors and

the Seat Beh Tensioner

Connectors ....'....24-23

Steering-lelated Precautions .......... 24-25

Troubleshooting

Self -diagnostic Procedures ............. 24-26

Reading the DTC .................. .....".."' 24'26

Erasing the DTC Memory ................24-28

Troubleshooting lntermittent

Faifures "'...........24'24

Diagnostic Trouble Gode {DTC}

Chart -'97 model ....""....... "......24-29

Diagnostic Trouble Gode (DTCI

Chart -'98 - 00 models ............. 24-31

SRS Indicator Light Wire

Connections ','," 24'33

Ff owcharts ....-........24'34

Driver's Airbag

Repf acement ..'......21'87

Front Passenger's Airbag

Repfacement .....'.',24'AS

Gable Reel

Replacement .......'.24-91

SRS Unit

Replacement .........24-95

Airbag/Seat Belt Tensioner

Disposaf .................24'97

)-e

www.emanualpro.com

Page 1312 of 1395

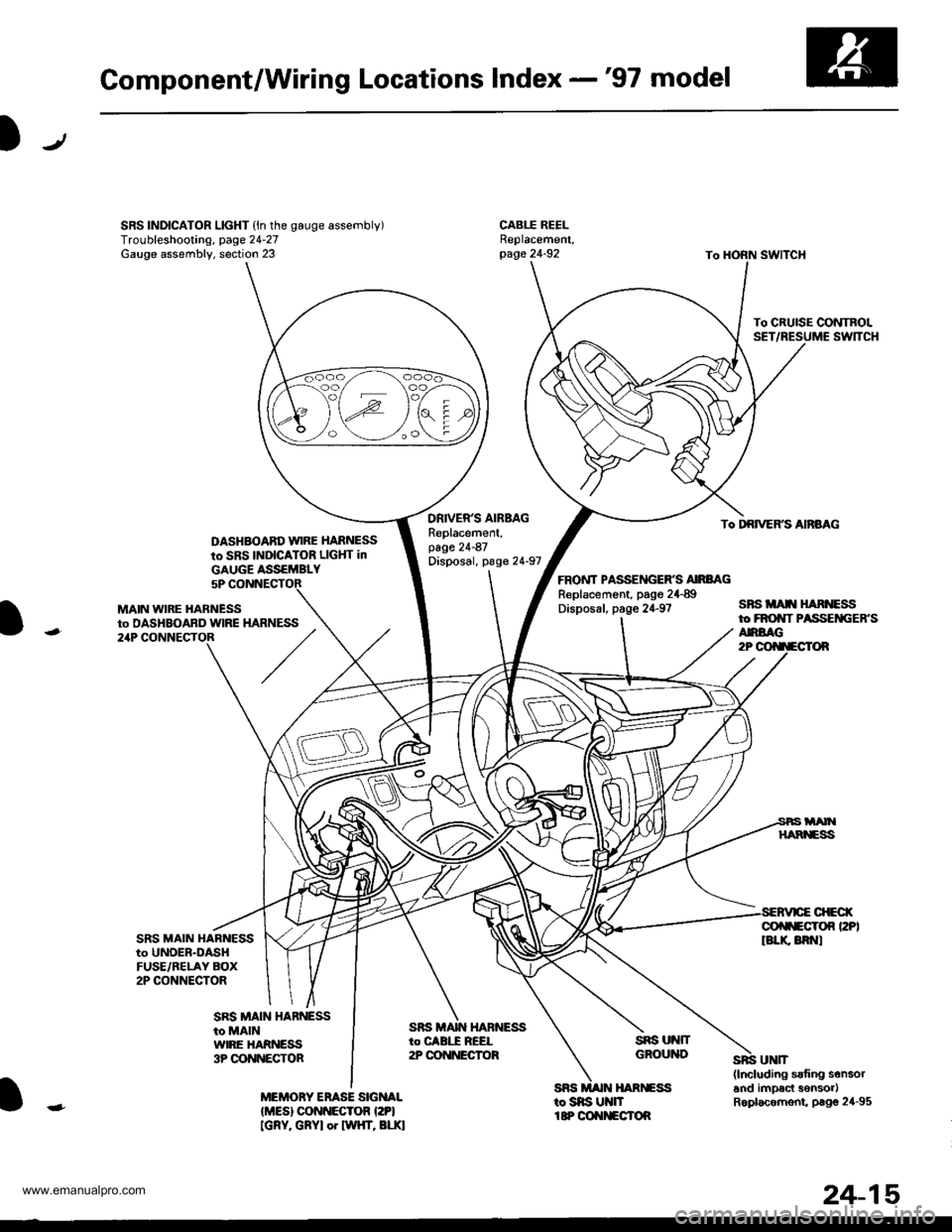

Component/Wiring Locations Index -'97 model

SRS INDICATOR LIGHT (ln the gauge assembly)Troubleshooting, page 24-27Gauge assembly, section 23

DASHBOABD w|RE HARNESS

to SBS INDICATOR LIGHT in

DRIVER'S AIBMGReplacement,page 21-87Disposal, page 24-97

To CRUISE CONTROLSET

To DRIVERS AnBAG

ANBAG2P

sBsitAr[ ] nNEssto FROI|T PASSEiIGEB.S

FRONT PASSEITGER'S AIRBAGReplacement, pago 24{9Disposal, page 24-97

sns ut{fTGROUND

SES MAIN HAR]GSStosns U nItP OOIIITECTOR

MAIN WIRE HABNESSto DASHBOABD wlRE21P

SRS MAIN HABNESSto UNOEB-DASHFUSE/BELAY BOX2P CONNECTOR

GOf$ECrOn PPIlBLr( 8R t

MEMORY ERASE SIGNALIMES) CONNECTOR I2PI[GRY. GRYI or twHT, BLr.l

GAUGE ASSEMBLY5P

HARNESS

SRS MAIN HARNESSto MAINWIRE HARNESS3P OONNECTOR

24-15

www.emanualpro.com

Page 1314 of 1395

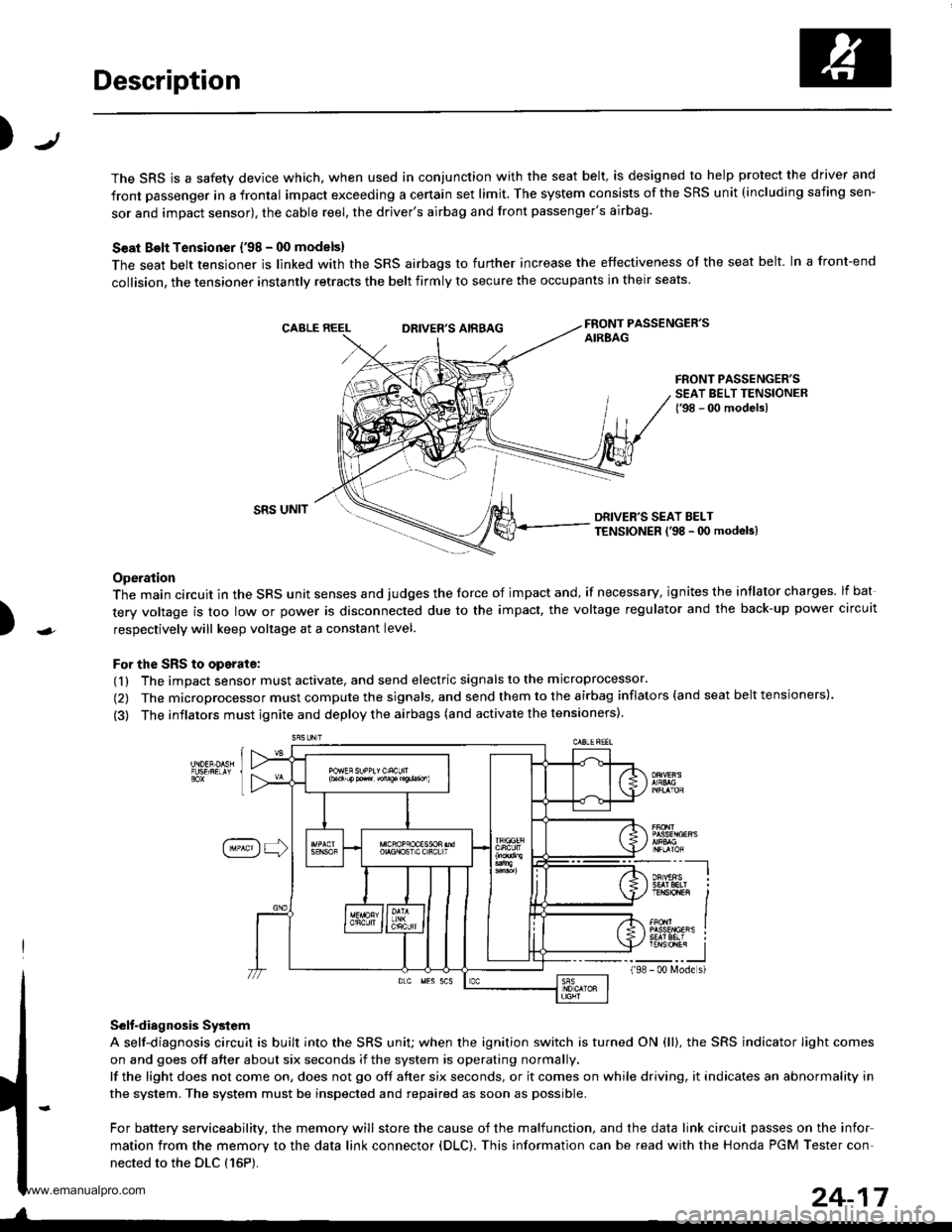

Description

J)

The SRS is a safety device which, when used in conjunction with the seat belt, is designed to help protect the driver and

front passenger in a frontal impact exceeding a certain set limit. The system consists of the SRS unit (including safing sen-

sor and impact sensor), the cable reel, the driver's airbag and front passenger's airbag.

Seat Bolt Tensioner {'98 - 00 models}

The seat belt tensioner is linked with the SRS airbags to further increase the effectiveness of the seat belt. In a front-end

collision, the tensioner instantly retracts the belt firmly to secure the occupants in their seats

FRONT PASSENGER'SAIREAGDRIVER'S AIRBAG

FRONT PASSENGER'SSEAT BELT TENSIONER{'98 - 00 modelsl

)

SRS UNITDRIVER'S SEAT BELTTENSIONER l'98 - 0O modeb)

Operation

The main circuit in the SRS unit senses and judges the force of impact and, if necessary, ignites the intlator charges. lf bat

tery voltage is too low or power is disconnected due to the impact, the voltage regulator and the back-up power circuit

respectively will keep voltage at a constant level.

For the SRS to operate:

(1) The impact sensor must activate, and send electric signals to the microprocessor.

(2) The microprocessor must compute the signals, and send them to the airbag inflators (and seat belt tensioners).

(3) The inflators must ignite and deploy the airbags (and activate the tensioners).

Selt-diagnosis System

A self-diagnosis circuit is built into the SRS uniU when the ignition switch is turned ON (ll), the SRS indicator Iight comes

on and goes off after about six seconds if the system is operating normally.

lf the light does not come on, does not go off after six seconds, or it comes on while driving, it indicates an abnormality in

the system. The system must be inspected and repaired as soon as possible.

For battery serviceability, the memory will store the cause of the malfunction, and the data link circuit passes on the infor

mation from the memory to the data link connector (DLC). This information can be read with the Honda PGM Tester con-

nected to the DLC {16P).

198

---__-l

TENSTO1En II

_-___J- 00 N4ode s)

24-17

www.emanualpro.com