speedsensor HONDA CR-V 2000 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 592 of 1395

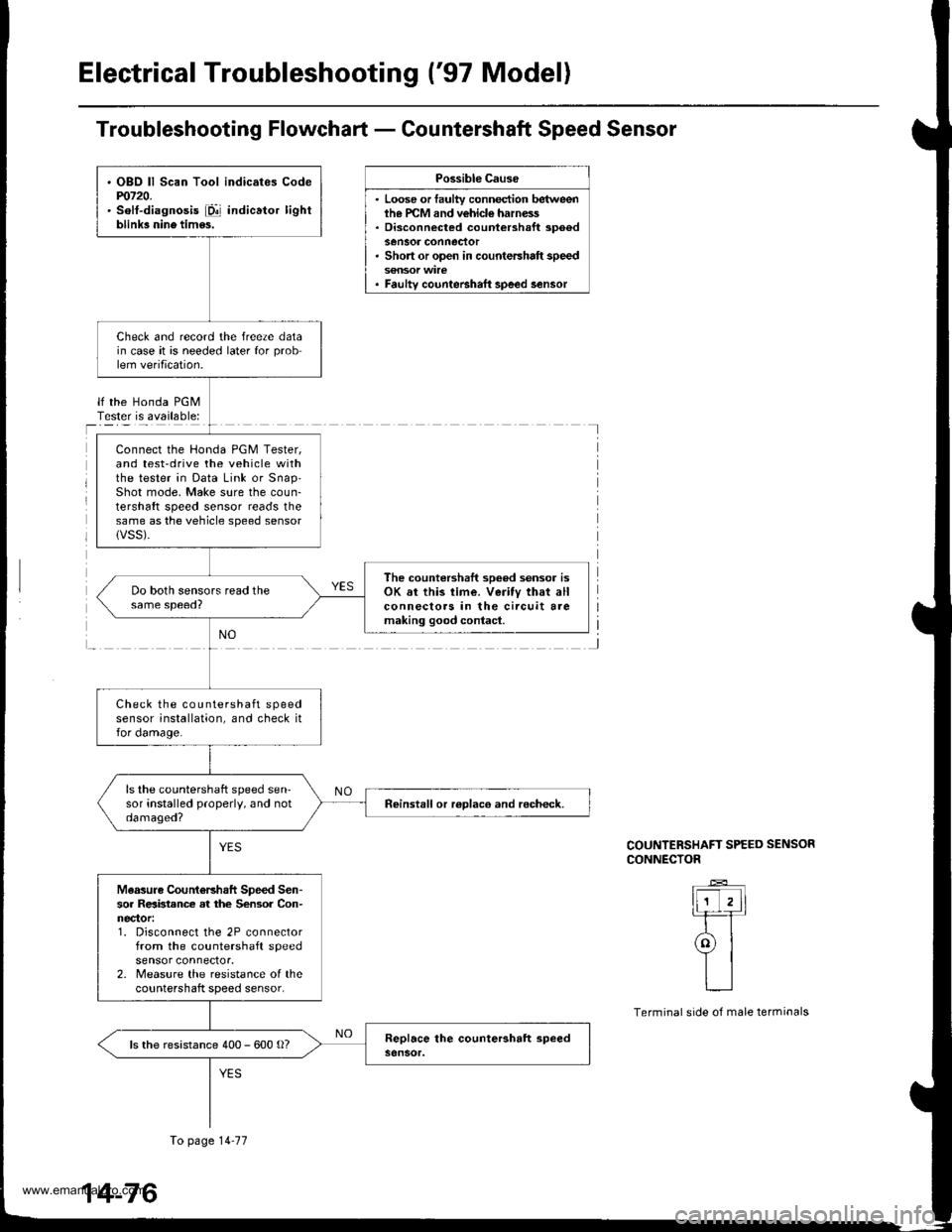

Electrical Troubleshooting ('97 Model)

Troubleshooting Flowchart - Countershaft Speed Sensor

Possible Cause

. Loose or faulty connection betweenih€ PCM and vehicle harness. Disconnected countershaft spoedsensor conneclor. Short or open in countershaft speed

. Faulty counteBhaft speed lensor

lf the Honda PGMTester is available:I

J

COUNTERSHAFT SPEED SENSOR

CONNECTOR

ll-'T,ll-rT

ral

YIL__l

Terminal side of male terminals

. OBO ll Scan Tool indicates Codem720.' solt-diagnosis iD!' indicator lightblink3 nine tim6s.

Check and record the freeze datain case it is needed later for problem verification.

Connect the Honda PGM Tester,and test-drive the vehicle withthe tester in Data Link or snap'Shot mode, Make sure the coun-tershaft speed sensor reads thesame as the vehicle speed sensorlVSS).

The countershaft sooed sensor isOK sr this time. Veritv that allconnecloas in the circuit aremaking good contacl.

Check the countershaft speedsensor installation, and check itfor damage.

ls the countershaft speed sen-sor installed properly, and notdamaged?neinstall or roDlaco and recheck.

Measuro CountoBhaft Speed Sen-sor Relbtance at the Sensor Con-nector:1. Disconnect the 2P connectorfrom the countershaft speedsensor connector.2. Measure the resistance of thecountershaft speed sensor.

ls the resistance 400 - 600 o?

To page 14-77

14-76

www.emanualpro.com

Page 595 of 1395

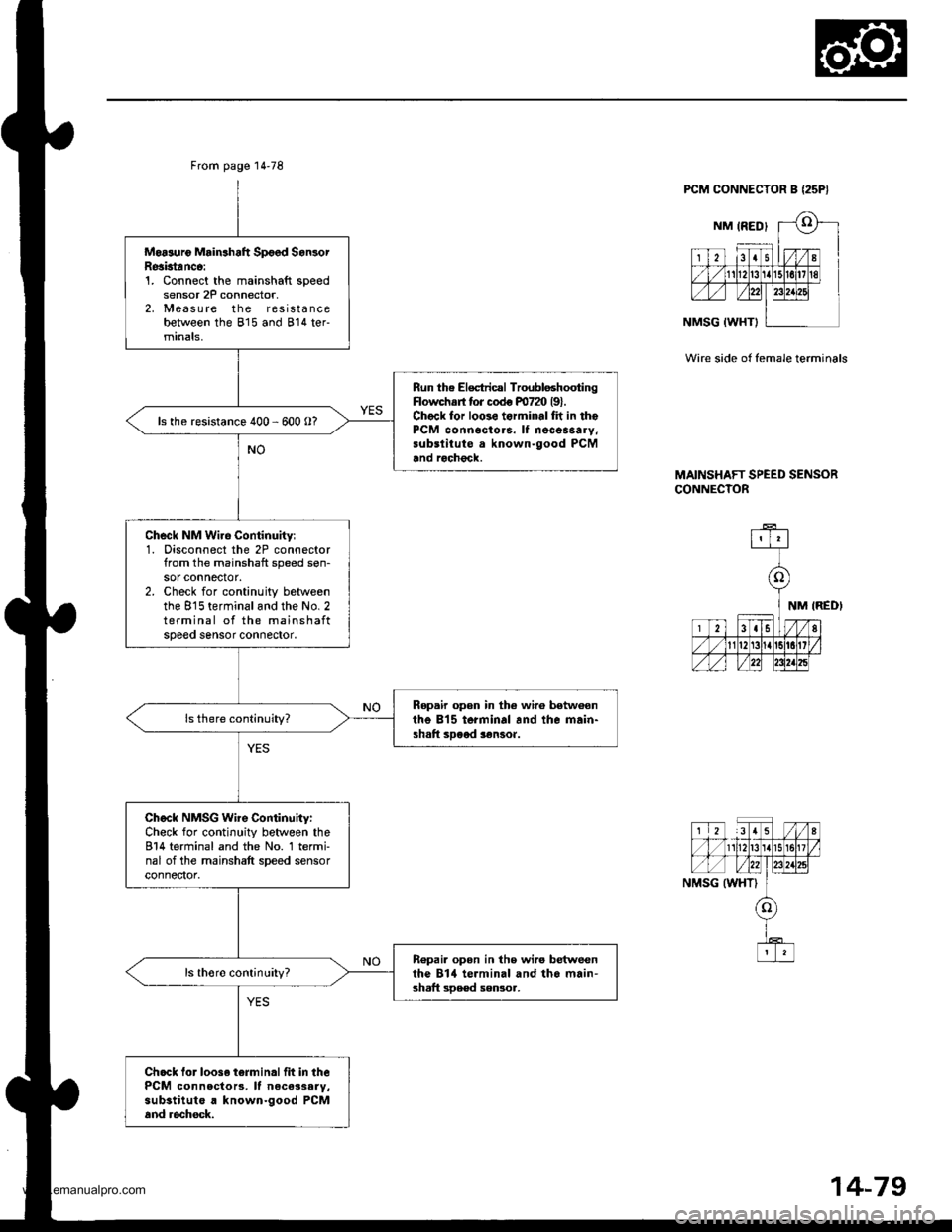

From page 14'78

Moasuro Mrin3haft Spoed SanlorResktanco:1. Connect the mainshaft speedsensor 2P connector,2, Measure the resistancebetween the 815 and 814 ter-minals,

Run the Electricrl TroubloshootingFlowchs tor codo m72O l9l.Chock for loo3e torminal fh in thePCM conn6cto.s. It necessarY,substitute a known-good PCMand rochgck.

ls the resistance 400 - 600 O?

Check NM Wiro Continuity:1. Disconnect the 2P connectorfrom the mainshaft speed sen-sor connector.2. Check for continuity betweenthe 815 terminaland the No.2terminal of the mainshaftspeeo sensor conneoor.

Ropair open in the wir6 betw€onthe 815 terminal and the main-shaft sDood $nsoa.

Check NMSG Wire Continuity:Check for continuity between the814 terminal and the No. 1 termi-nal of the mainshaft speed sensorconnector.

R€pai. opon in the wi.o betweenthe Bltl terminal and tho main'3haft sDe€d sensoa,

Ch.ck lor loos. t6rminallit in thePCM connecto13, lf neca3sary,substitute a known-good PCMand rochock.

PCM CONNECTOR B {25P}

Wir€ side of female terminals

MAINSHAFT SPEED SENSORCONNECTOR

14-79

www.emanualpro.com

Page 628 of 1395

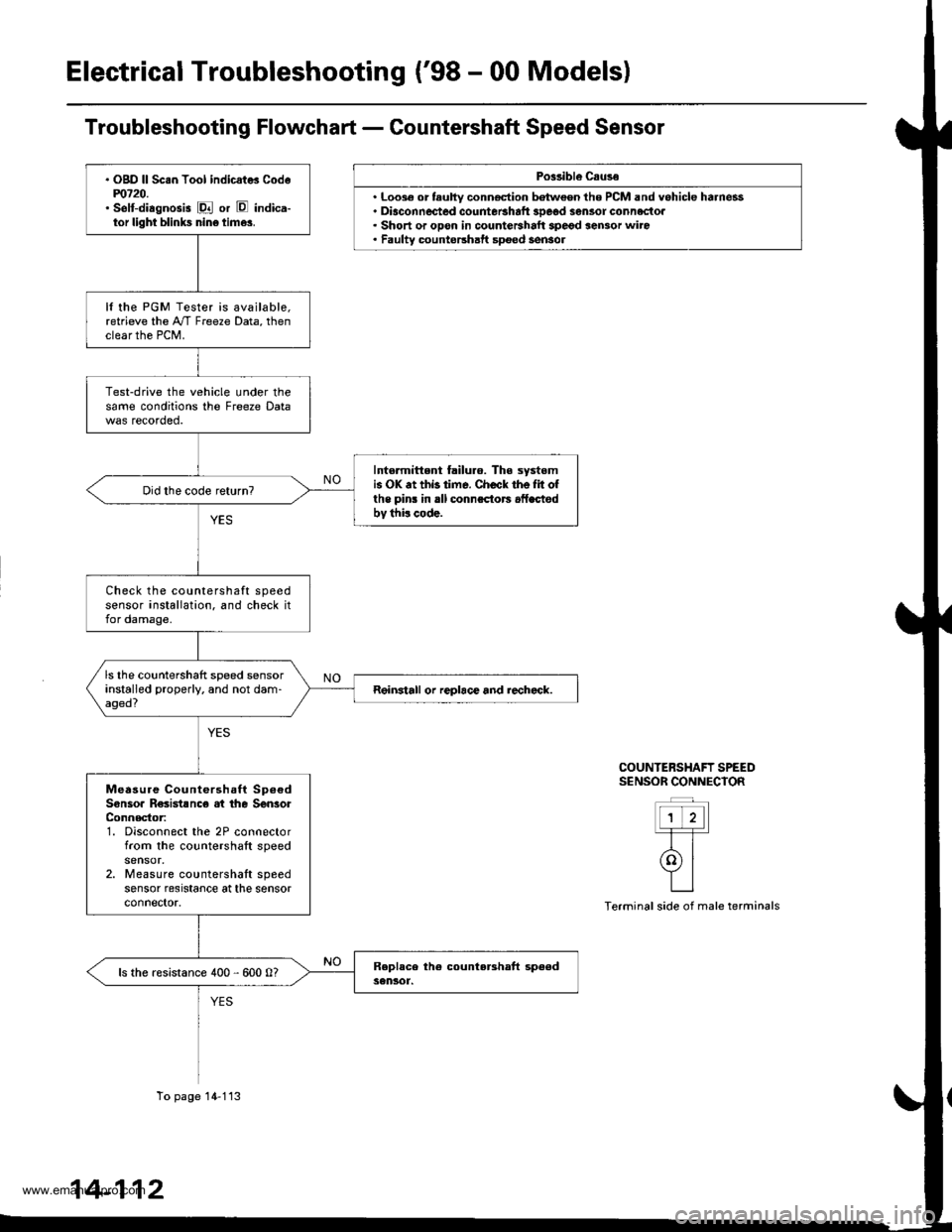

Electrical Troubleshooting ('98 - 00 Models)

Po$ibl€ Csuse

. Loo3€ or tauhy conn€ction batween the PCM and vehicle harness. Diaconnected countetshaft 3Deod sensor connectoa. Short or opon in countershalt spegd sensor wiro. Faulty countershatt spoed sensol

COUNTERSHAFT SPEEDS€NSOR CONNECIOR

ttt'l-T-T-

rolYILI

Terminal side of male terminals

. OgD ll Sc.n Tool indicat* Codem720.' selt-diagnosis E or E indica-tor light blinks nin6 time3.

It the PGM Tester is available,retrieve the A"/T Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freeze Data

Intormittent failuro. The systomis OK .t thb time. Check the Iit ofthe pins in rll connsctors .fLctodbv thi! code.

Check the countershaft speedsensor installation. and check itfor damage.

ls the countershaft speed sensorinstalled properly. and not dam-aged?Reinstall or replace and rechcck.

Measure Countershaft Sp6€dSonsoa R€sistsnc€ at the SenlorConnector:1. Disconnect the 2P connectorfrom the countershaft speed

2. Measure countershaft speedsensor resrstance at the sensorconnector.

ls the resistance 400 - 600 0?

To page 14-113

14-112

www.emanualpro.com

Page 630 of 1395

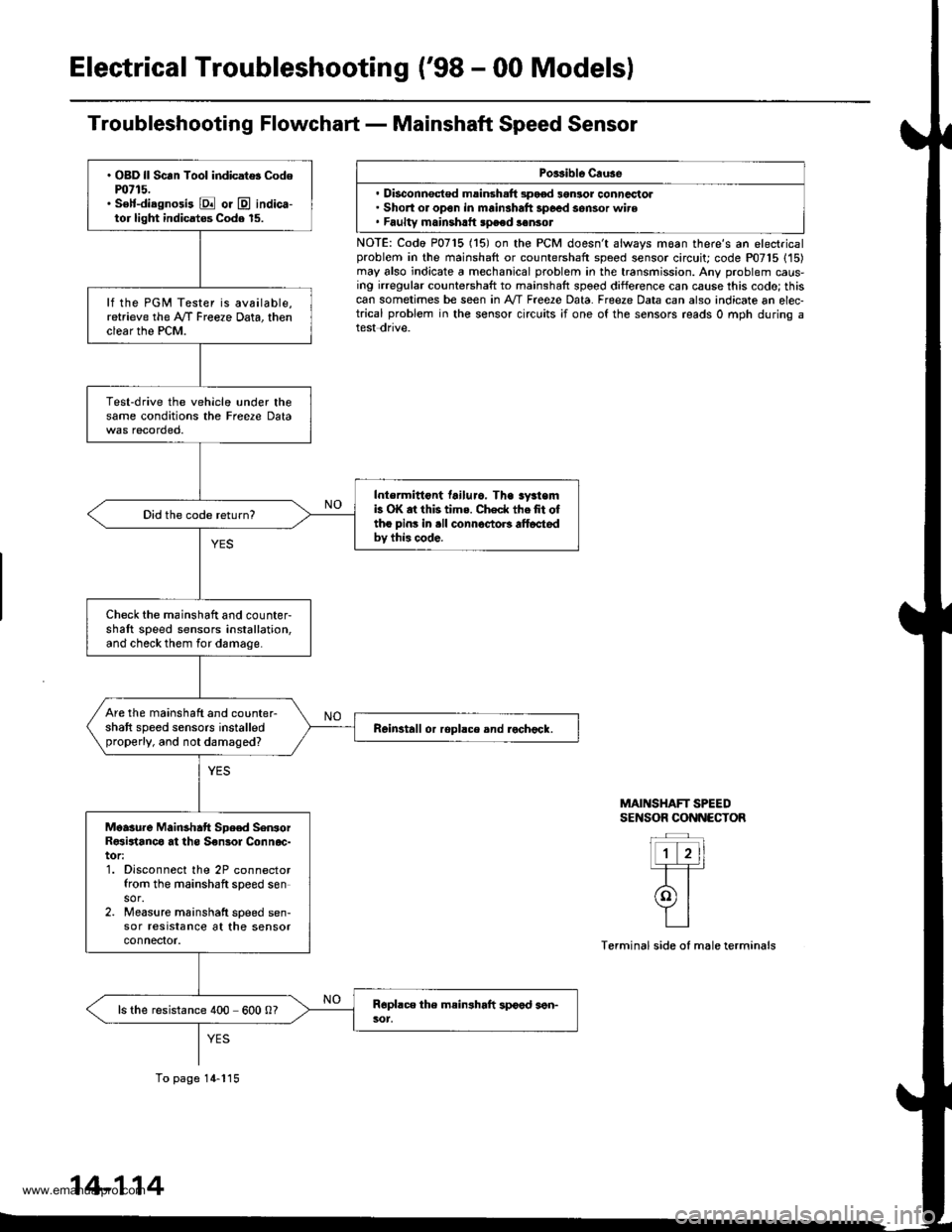

Electrical Troubleshooting ('98 - 00 Modelsl

Troubleshooting Flowchart - Mainshaft Speed Sensor

Porsible Cruse

. Disconnsct€d msinsh.ft 3pood 3gnlor conncctol. Short or open in mainshaft 3poed sensor wire. Faultv mainshrtt speed sonsot

NOTE: Codo P0715 (15) on the PCM doesn't always moan there's an electricalproblem in the mainshaft or countershaft speed sensor circuit; code P07'15 (15)may also indicate a mechanical problem in the transmission. Any problem caus-ing irregular countershaft to mainshaft spoed difference can cause this codo; thiscan sometimes be seen in A'/T Free2e Data. Freeze Data can also indicate an elec-trical problem in the sensor circuits ;f one of the sensors reads 0 mph during atest dnve.

MAINSHAFT SPEEDSENSOR CONNECTOR

Terminal side of male terminals

. OBD ll Scan Tool indicat$ Codem715.. S€lf-diagnosi3 E or @ indica-tor light indicatos Code 15.

lf the PGM Tester is available,retrieve the A/f Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freere Data

Intermittont tailuro. Tha sy3temb OK at this tims. Check thefit oftho pins in .ll connoctoB alt6ctedbv this code.

Did the code return?

Check the mainshaft and counter-shaft speed sensors installation,and check them for damage.

Are the mainshaft and counter-shaft speed sensors installedproperly, and not damaged?Reinstall or ropllce and rochock.

Moasure Mainshatt Spe€d SenrorR€sirtanco at ths S€nsol Connoc-tor:1. Disconnect the 2P connectorfrom the mainshaft speed sensor.2. Measure mainshatt speed sen-sor resrstance at the sensorconnefior.

ls the resistance 400 600 0?

To page 14-115

14-114

www.emanualpro.com

Page 631 of 1395

A {32P}

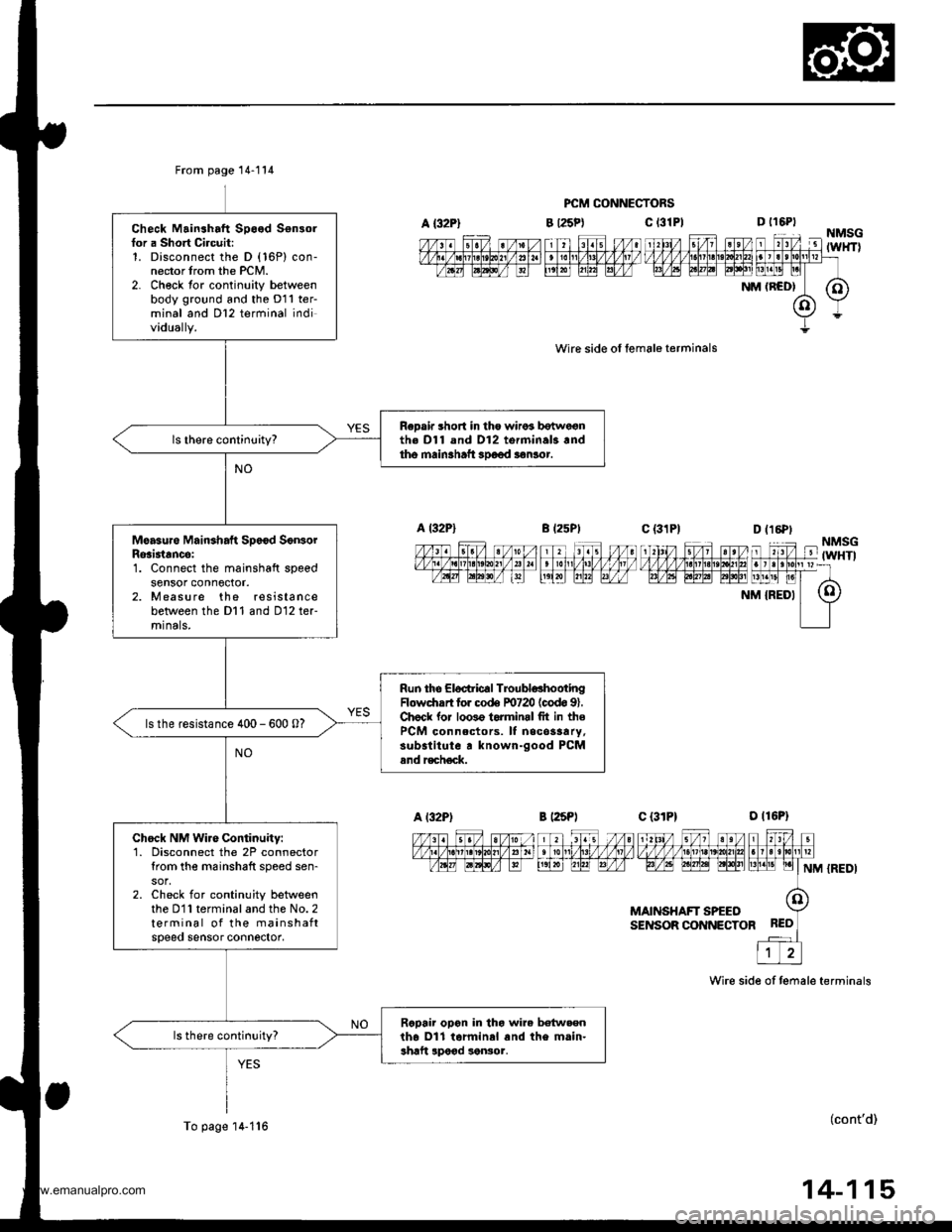

From page 14-114

Check Mainshaft Speed Sensorfor a Short Circuit:1. Disconnect the D (16P) con-nector trom the PCM.2- Ch€ck tor continuity betweenbody ground and the D11 ter-minal and Dl2 terminal individually.

ReDair short in tho wiros botwe€nth€ Dl1 and D12 torminal3.ndtho main3haft 3Doed aonlor.

Moasure Mainshaft Sp6€d SonsorRosi3tancei1. Connect the mainshaft speedsensor conn6ctor.2. Measure the resistancebetween the Dl1 and D12 ter-mrnals,

Run the Eloctric€l TroubldhootingFlowdrrrt for co& F0720 (codo 91.Chock lor loo3o torminrl fit in thePCM connectors. It necos3ary,substitute r known-good PCMand r€ch€ck.

ls the resistance 400 - 600 0?

Chock NM Wire Continuity:1. Disconnect the 2P connectortrom the m6inshaft speed sen-

2. Check for continuity betweenthe D11 terminal and the No. 2terminal of the mainshaftspeeo sensor connector,

Rcpair opon in tho wire betw.enth6 Dll tarminal and the main-shaft lpood sonsor.

To page'14-1'16

PCM CONNECTORS

c t3lPl

wire side ol female terminals

B l25Pt

D t16PtNMSG-'lTZ lit4'l Fl l'1til FTil ,'l unrv v v v v l.t1lLtLt?!/]|,1tut larrlrllllpr=rtavtq tptntat EElt [1!]t! pl

NM (RCD| (O)

(o)Y

Y=

c {31P1--_|--1\‰1,/ s/1 st/v,1zzfififinffiiFrF/l,6t FFF| LrLrEllNM {REDI

MAINSHAFT SPEEOSENSOR CONNECTOR

Wire side of temale terminals

(cont'd)

14-115

www.emanualpro.com

Page 632 of 1395

Electrical Troubleshooting ('98 - 00 Models)

Troubleshooting Flowchart - Mainshaft Speed Sensor (cont'd)

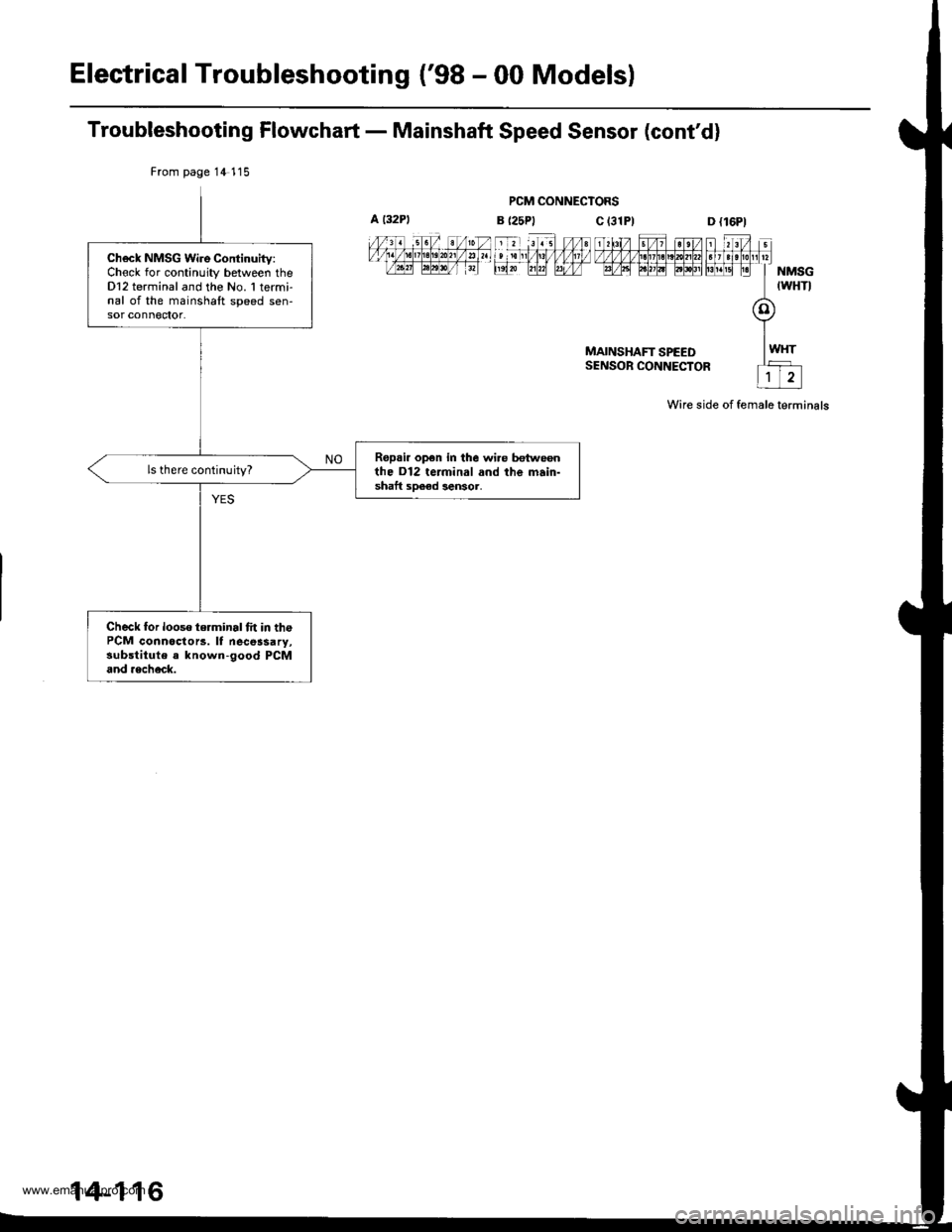

PCM CONNECTORS

MAINSHAFT SPEEDSENSOR CONNECTOR

Wire side of female terminals

From page 14 115

Ch6ck NMSG Wire Continuitv:Chock for continuity between theDl2 terminal and the No. 1 termi-nal of the mainshaft speed sen-sor conn€ctot.

Ropai. op€n in the wi.e hn eonthe D12 terminal and the main-shaft sDeed lensor,

ls there continuity?

Check for looso terminal fit in thePCM connoctorc. lf necessary,substitute a known-good PCMand aech6ck.

14-116

www.emanualpro.com

Page 685 of 1395

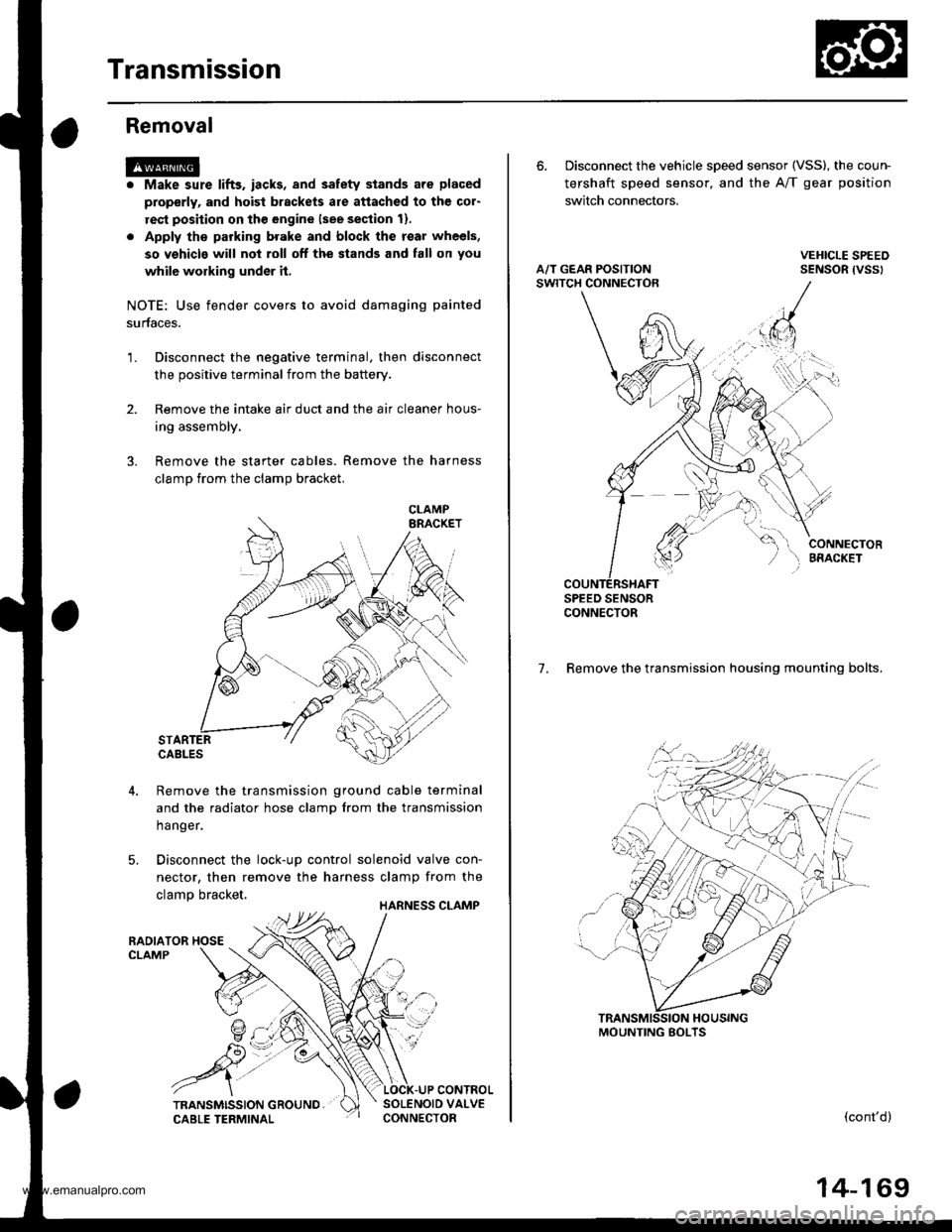

Transmission

Removal

@

2.

'1.

Make sure lifts. iacks, and safety stands aro placed

properly, and hoist brackets are attached to the col-

rest position on the engine lsee section 11.

Apply th€ parking brake and block the r€ar wheels,

so vehicls will noi roll off the stands and fall on you

while working under it.

NOTE: Use fender covers to avoid damaging painted

surfaces.

Disconnect the negative terminal, then disconnect

the positive terminal from the battery.

Remove the intake air duct and the air cleaner hous-

ing assembly,

Remove the starter cables. Remove the harness

clamp from the clamp bracket.

5.

STARTERCABLES

Remove the transmission ground cable terminal

and the radiator hose clamp lrom the transmission

hanger.

Disconnect the lock-up control solenoid valve con-

nector, then remove the harness clamp from the

clamp bracket.HARNESS CLAMP

RADIATOR HOSECLAMP

CONTROLSOLENOID VALVECONNECTOR

CLAMP

6. Disconnect the vehicle speed sensor (VSS), the coun-

tershaft speed sensor, and the A/T gear position

switch connectors.

A/T GEAR POSITIONSWITCH CONNECTOR

VEHICLE SPEEDSENSOR |VSS'

CONNECTORBfiACKET

SPEED SENSORCONNECTOR

7. Remove the transmission housing mounting bolts.

MOUNTING BOLTS

(cont'd)

14-169

www.emanualpro.com

Page 704 of 1395

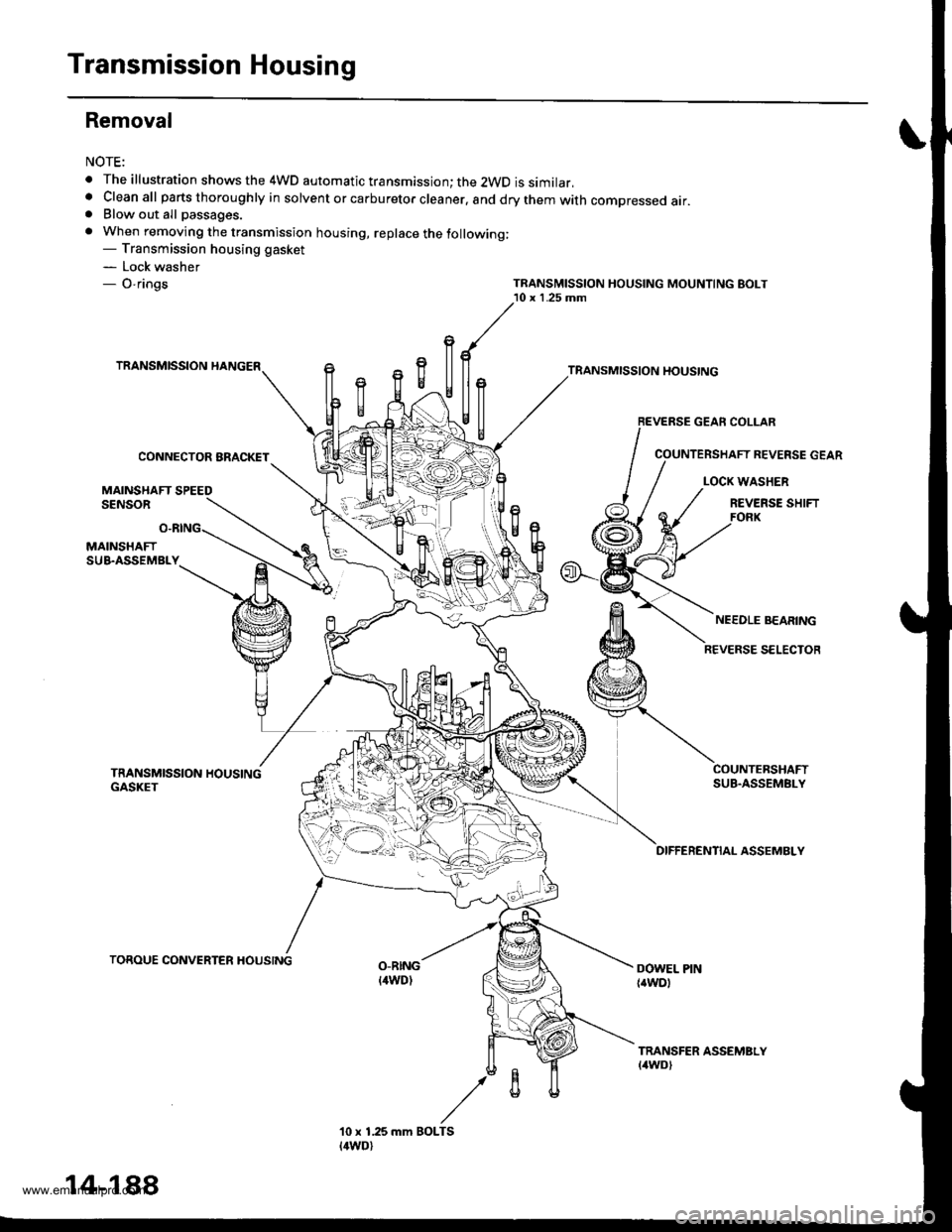

Transmission Housing

Removal

NOTE:

. The illustration shows the 4WD automatic transmission; the 2WD is similar,. Cleanall parts thoroughly in solvent or carburetor cleaner. and drythemwith compressed air.. Blow out all passages.

. When removing the transmission housing, replace the lollowing:- Transmission housing gasket- Lock washer- O-rings

TRANSMISSION HANGERTRANSMISSION HOUSING

REVERSE GEAN COLLAR

TRANSMISSION HOUSING MOUNTING EOLT

CONNECTOR BRACKET

MAINSHAFT SPEEDSENSOR

REVERSE GEAR

LOCK WASHER

REVERSE SHIFT

MAINSHAFTSUB.ASSEMBLY

TRANSMISSION HOUSINGGASKET

DIFFERENTIAL ASSEMBLY

TOROUE CONVERTER HOUSINGO-RINGt4wDl

TRANSFER ASSEMBLYt4wDt

10 x 1.25 mm

l4wo)

14-1 88

BOLTS

www.emanualpro.com