body HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1070 of 1395

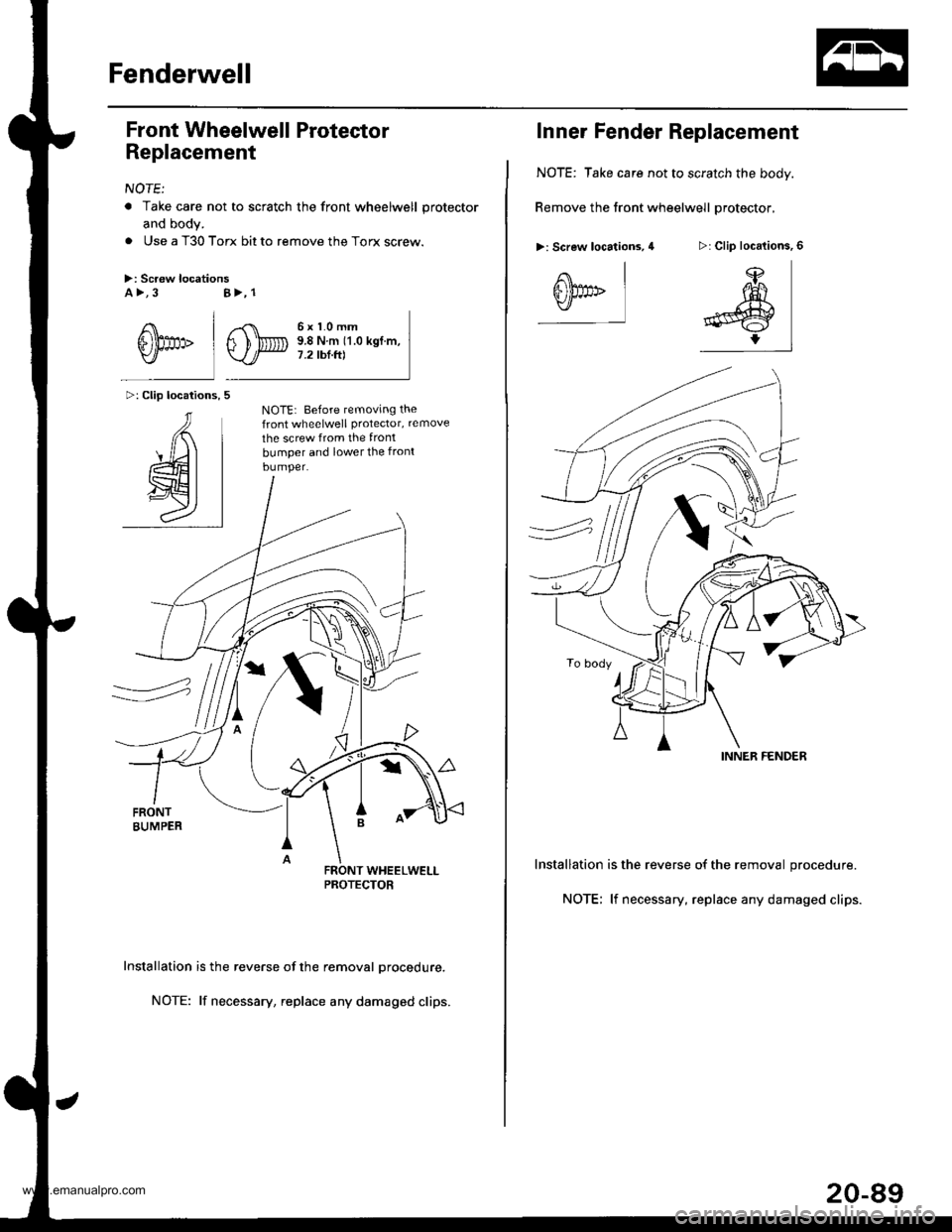

Fenderwell

Front Wheelwell Protector

Replacement

NOTE:

a Take care not to scratch the front wheelwell protector

and body.

. Use a T30 Torx bit to remove the Torx screw.

>: Screw locationsa >,3

/\l

6'thp IY/

>: Clip locations,

AI

4t I

wt I

al

B>, 1

,,-C\

s)Dv.l/

6x1.0mm9.8Nm(1.0kgf.m,7.2 tbf.ft)

NOTE: Before temoving thefront wheelwell Protector, remove

the screw from the front

bumper and lower the front

bumper.

Installation is the reverse of the removal Drocedure.

NOTE: lf necessary, replace any damaged clips.

Inner Fender Replacement

NOTE: Take care not to scratch the body.

Remove the front wheelwell protector,

>: Screw locations, 4

Installation is the reverse of the removal procedure.

NOTE; lf necessary, replace any damaged clips.

>: Clip locations,

ffi)fl(

l#:rl

A\

s))pp>Y]

INNER FENDER

20-89

www.emanualpro.com

Page 1071 of 1395

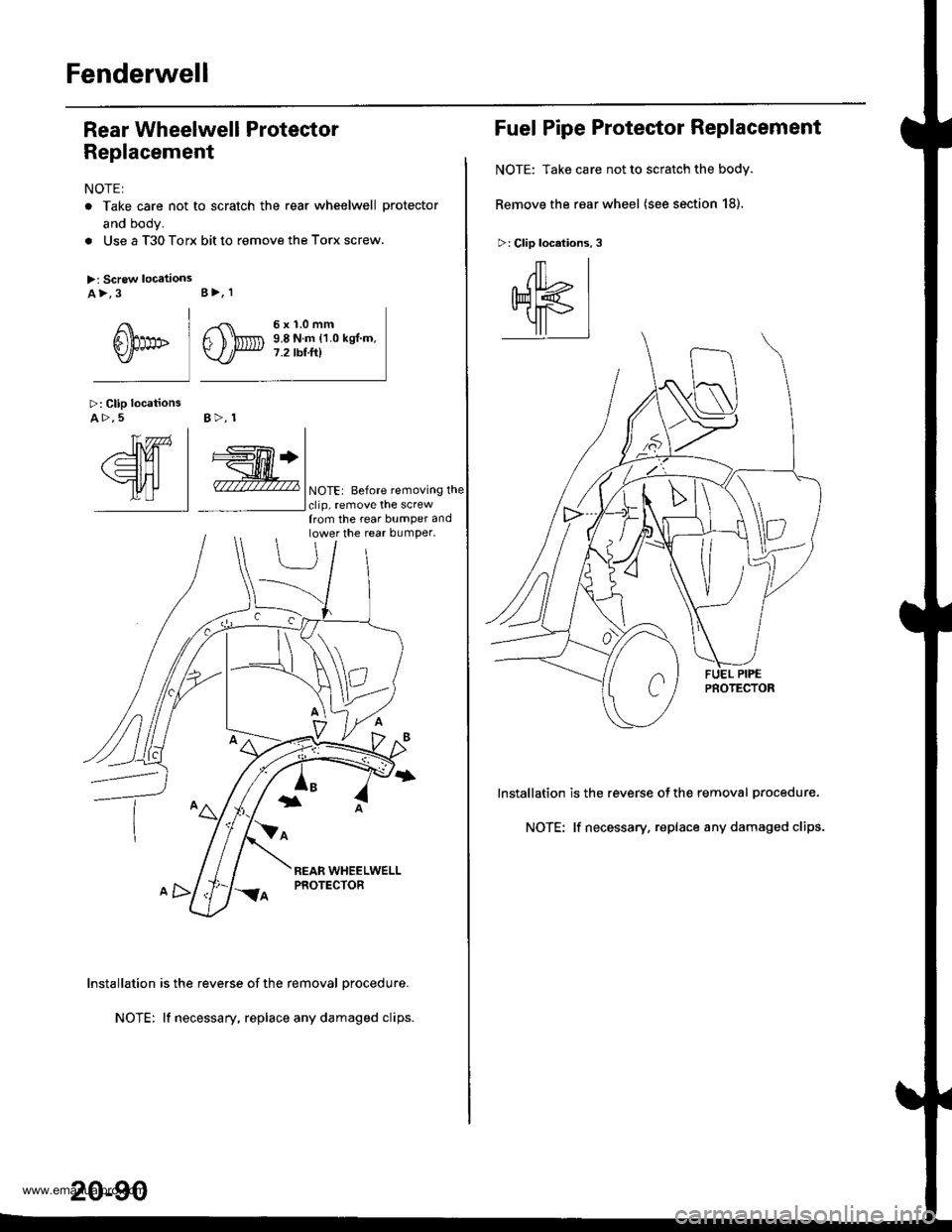

Fenderwell

Rear Wheelwell Protector

Replacement

NOTE:

. Take care not to scratch the rear wheelwell protector

and body.

. Use a T30 Torx bit to remove the Torx screw.

>: Screw locationsa>,3

I

6him" lY/

>: Clip locationsA >,5 B>, 1

B>, I

,.{\

F ),@Y-./

6x1.0mm9.8 N.m {1.0 kgl.m.7.2 rbtft)

YnTn | |

/'d)Ul | +['Tl+l

\=lHl | _H_l

tlrflJ | - INoTE: Before removinsthe- | lclip. remove the screw

lnstallation is the reverse of the removal procedure.

NOTE: lf necessary, replace any damaged clips.

from the rear bumper andlower the rear bumper,

20-90

Fuel Pipe Protector Replacement

NOTE: Take care not to scratch the body.

Remove the rear wheel (see section 18).

>: Clip locations,3

/ll

qK

1l

lnstallation is the reverse of the removal Drocedure.

NOTE: lf necessary. replace any damaged clips.

www.emanualpro.com

Page 1072 of 1395

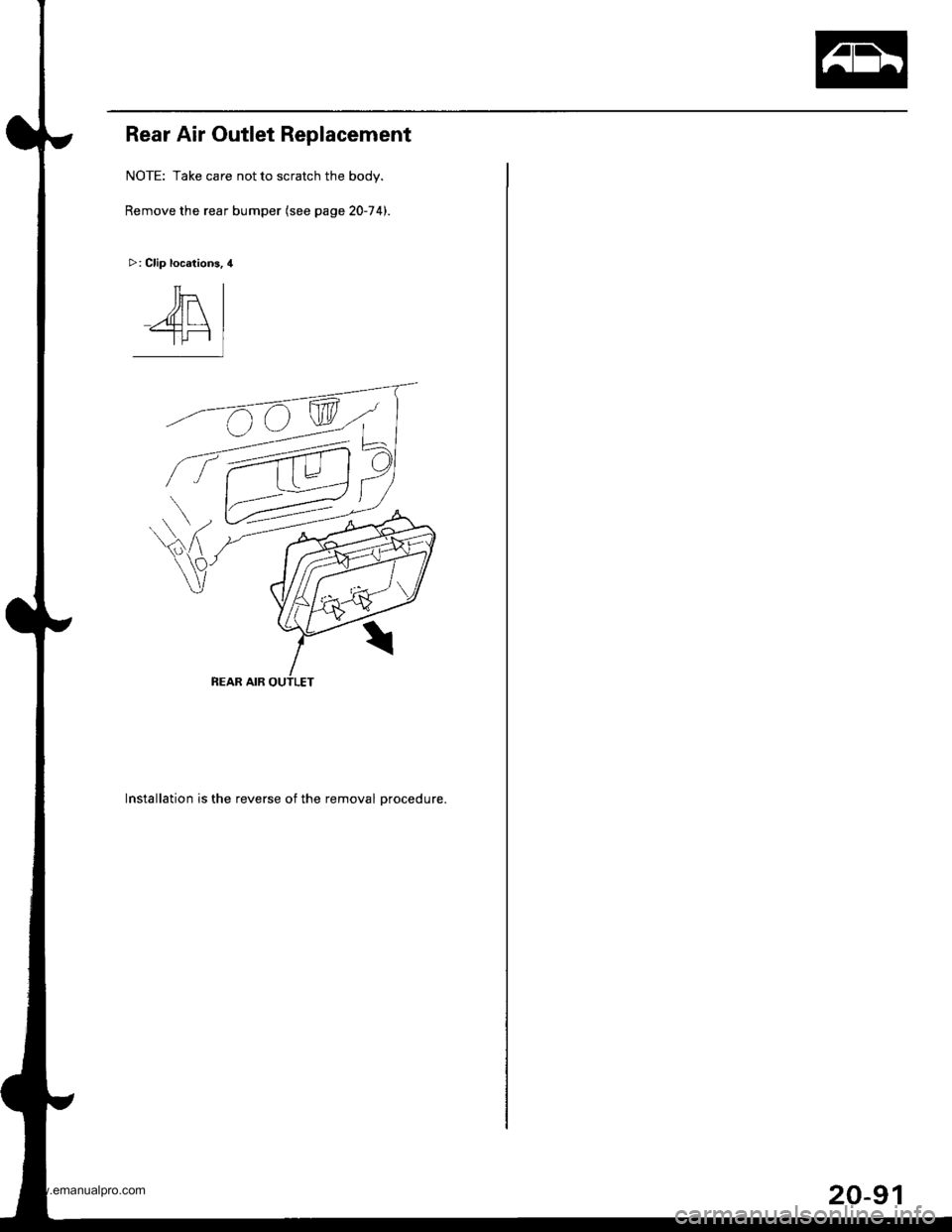

Rear Air Outlet Replacement

NOTE: Take care not to scratch the body.

Remove the rear bumper (see page 20-74).

>: Clip locations, 4

Installation is the reverse of the removal Drocedure.

Tt-

A\-T[-r

20-91

www.emanualpro.com

Page 1074 of 1395

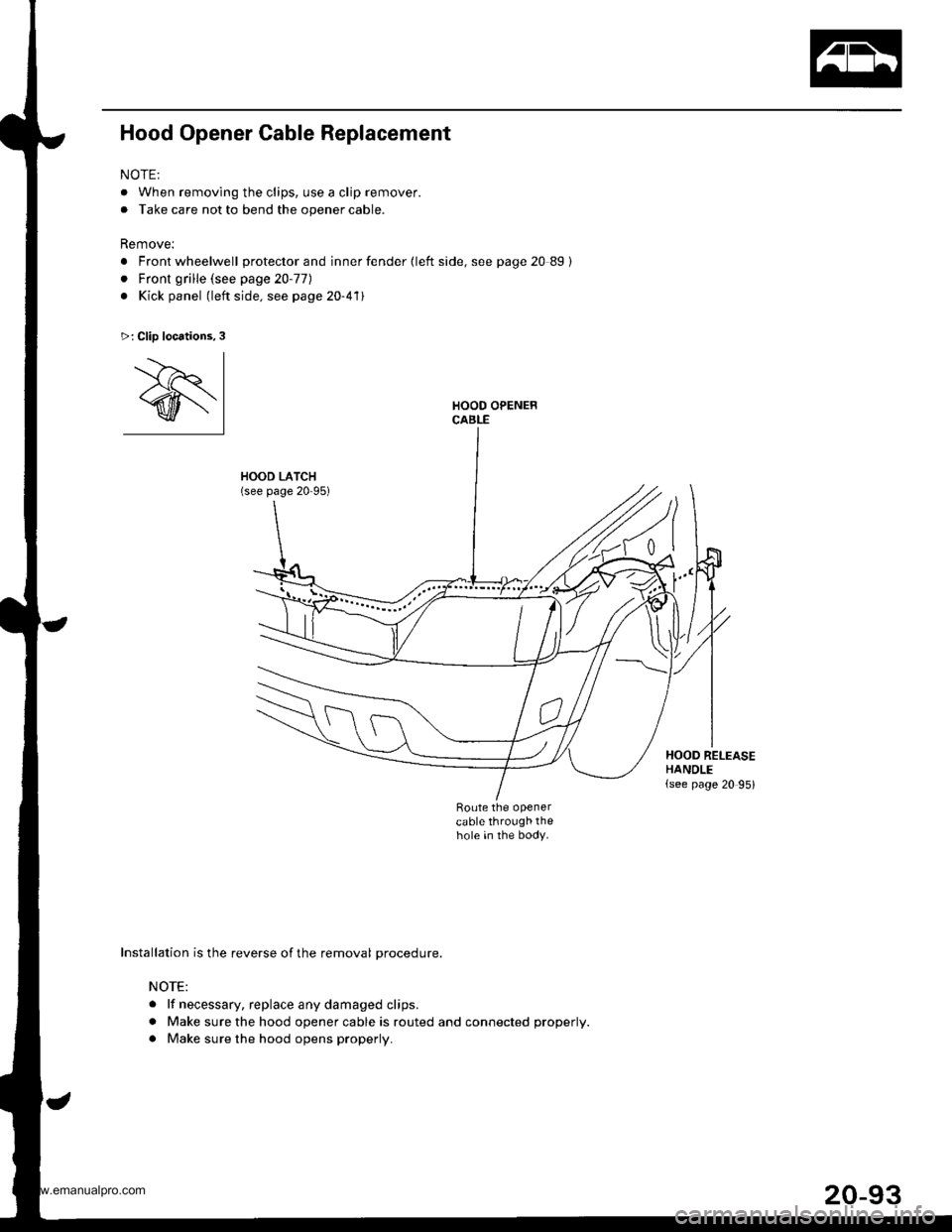

Hood Opener Cable Replacement

NOTE:

. When removing the clips, use a clip remover.

. Take care not to bend the opener cable.

Remove:

. Front wheelwell protector and inner fender {left side, see page 20 89}

. Front grille (see page 20-77)

. Kick panel (left side. see page 20-411

HOOD LATCH(see page 20-95)

Route the openercable through thehole in the body.

>: Clip locations,3

'.--)r I

@l

Installation is the reverse of the removal procedure.

NOTE:

. lf necessary. replace any damaged clips.

. Make sure the hood opener cable is routed and connected properly.

. Make sure the hood opens properly.

t"

HOOD RELEASEHANDLE(see page 20 95)

www.emanualpro.com

Page 1077 of 1395

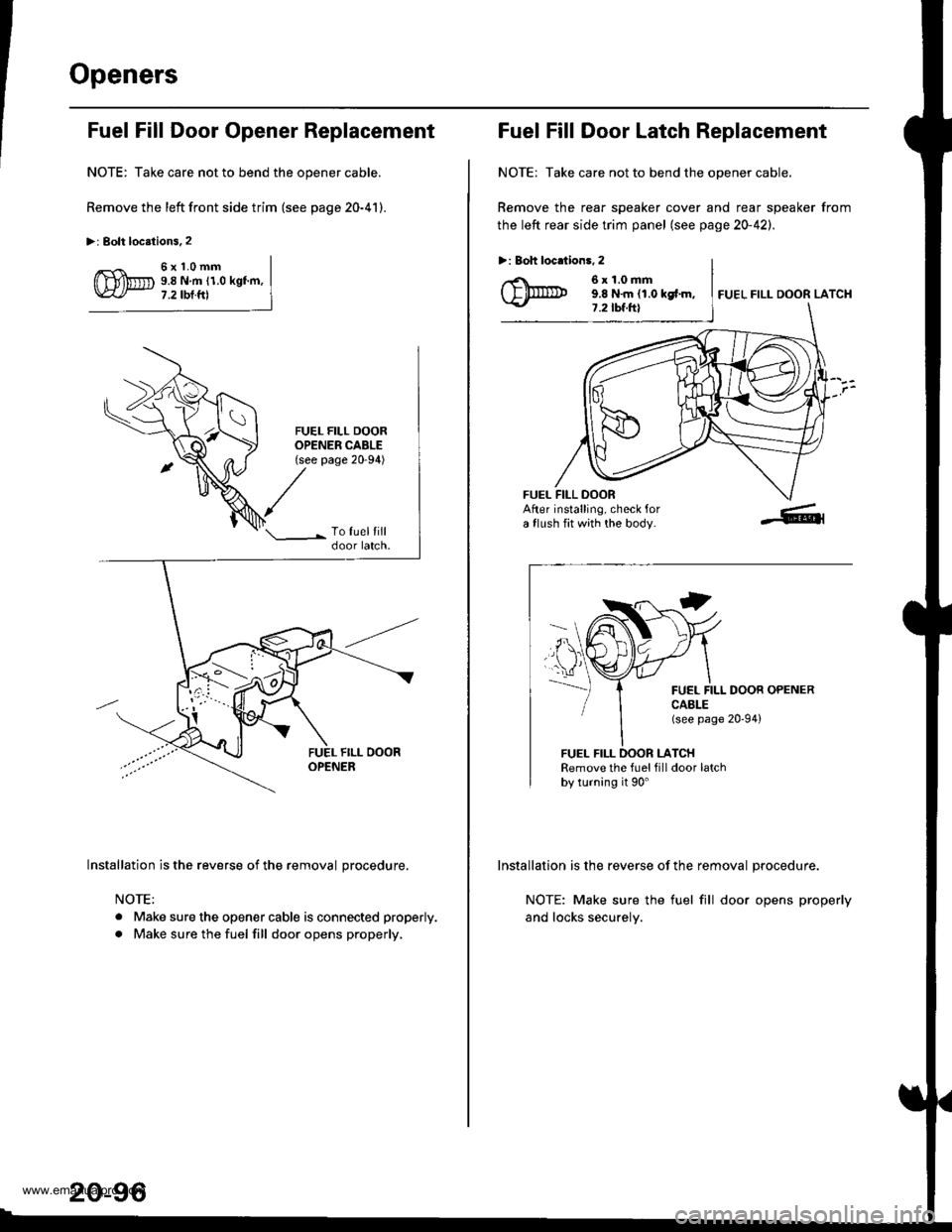

Openers

Fuel Fill Door Opener Replacement

NOTE: Take care not to bend the opener cable.

Remove the left front side trim (see page 20-41).

>: Bolt locstions.2

5x1.0mm9.8 N.m (1.0 kgf.m,7.2 tbt.ftl

FUEL FILL DOOROPENER CABLE(see page 20-94)

Installation is the reverse of the removal procedure.

NOTE:

. Make sure the opener cable is connected properly.

. Make sure the fuel fill door opens properly,

20-96

Fuel Fill Door Latch Reolacement

NOTE: Take care not to bend the opener cable.

Remove the rear speaker cover and rear speaker from

the left rear side trim panel (see page 20-42).

>: Boh locdions, 2

6x1.0mm9.8 N.m (1.0 kgf.m,7.2 tbf.ft)FUEL FILL DOOR LATCH

FUEL FILL DOORAfter installing, check fora flush fit with the body.

CAELE(see Page

LATCH

DOOR OPENER

20,94)

FUEL

FUEL FILLRemove the fuel fill door latchby turning it 90'

Installation is the reverse of the removal procedure.

NOTE: Make sure the fuel fill door opens properly

and locks securely.

www.emanualpro.com

Page 1079 of 1395

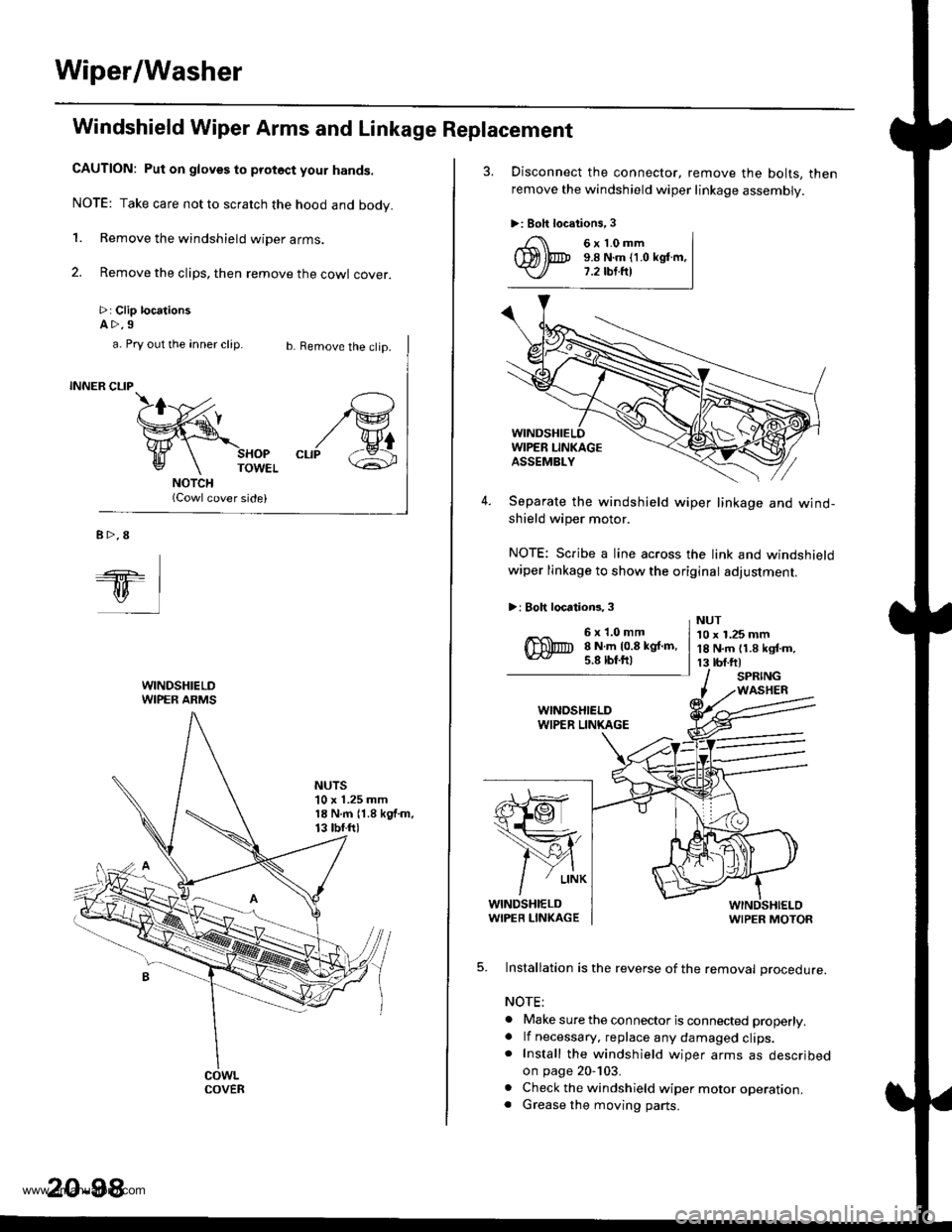

Wiper/Washer

Windshield Wiper Arms and Linkage Replacement

CAUTION: Put on gloves to protoct your hands.

NOTE: Take care not to scratch the hood and body.

1. Remove the windshield wiper arms.

2. Remove the clips, then remove the cowl cover.

>: Clip locationsA>.9

b. Remove the clip.

SHOPTOWEL

(Cowl cover side)

/G

"rr/ &

a. Pry out the anner clip.

INNER CLIP

B>.8

ql

WINDSHIELDWIPER ARMS

NUTS'10 x 1.25 mm18 N.m 11.8 kgf.m.13 tbf.ftl

COVER

20-98

3. Disconnect the connector, remove the bolts, then

remove the windshield wiper linkage assembly.

>: Boh locations,3

4. Separate the windshield wiper linkage and wind-shield wiper motor.

NOTE: Scribe a line across the link and windshieldwiper linkage to show the original adjustment.

>: Boh locations, 3

s}@

1ffi,

/Y{

/

' L|NK

WINDSHIELDWIPER LIN(AGEWIPER MOTOR

5. Installation is the reverse of the removal procedure.

NOTE:

. Make sure the connector is connected properly.. lf necessary. replace any damaged clips.. Install the windshield wiper arms as describedon page 20-103.

. Check the windshield wiper motor operation.. Grease the moving parts.

6x1.0mm9.8 N.m (1.0 kglm,7.2 tbt.fr)

6x1.0mm8 N.m 10.8 kgf.m,5.8 lbf.ftl

NUT10 x 1.25 mm18 N.m 11.8 kgf.m,13 tbf.ftlSPRINGWASHER

www.emanualpro.com

Page 1081 of 1395

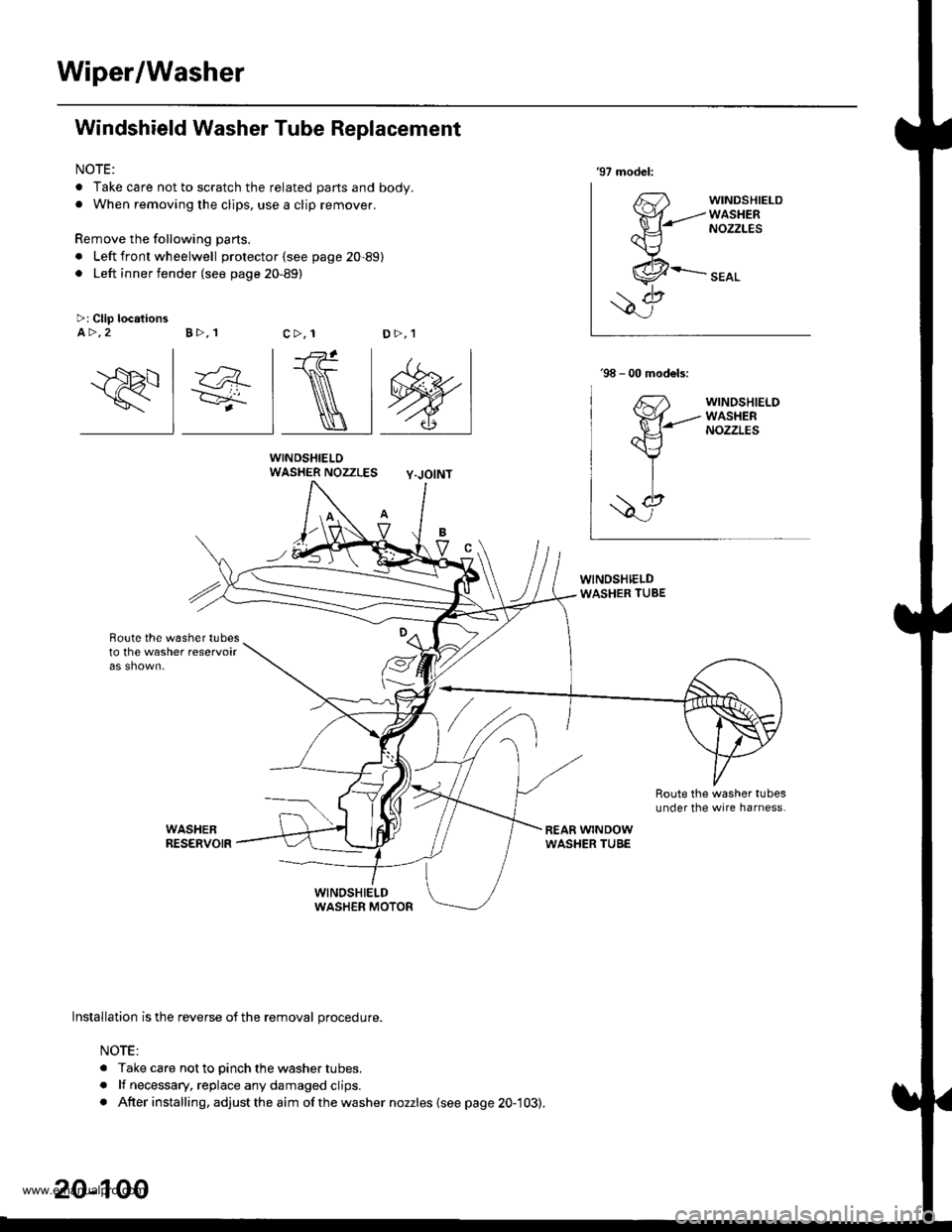

Wiper/Washer

Windshield Washer Tube Replacement

NOTE:

. Take care not to scratch the related parts and body.. When removing the clips, use a clip remover.

Remove the following parts.

. Left front wheelwell protector (see page 20-89). Left inner fender (see page 20-89)

WINDSHIELOWASHER NOZZLES Y-JOINT

Boute the w6sher tubesto the washer reservoir

'97 model:

63'fr{-------

ax---\J

,.&--

\7>: Clip locationsA >,2 B >,1c>, 1D>,1

\

lnstallation is the reverse of the removal procedure.

NOTE:

. Take care not to pinch the washer tubes.

. lf necessary, replace any damaged clips.. After installing, adjust the aim ofthe washer nozzles (see page 20-103).

20-100

www.emanualpro.com

Page 1082 of 1395

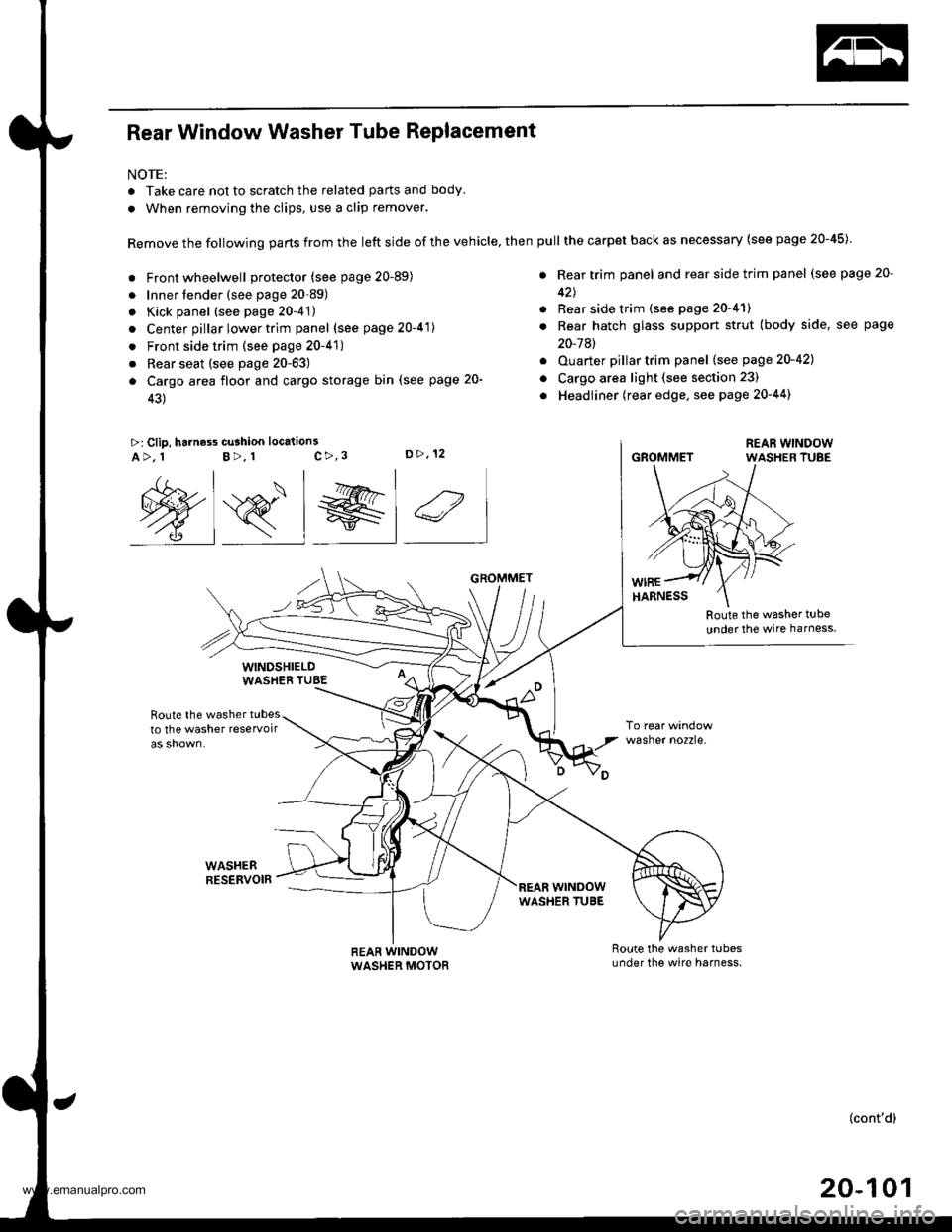

Rear Window Washer Tube Replacement

NOTE:

. Take care not to scratch the related parts and body.

. When removing the clips, use a clip remover.

Remove the following parts from the left side of the vehicle, then

. Front wheelwell protector (see page 20-89)

. Innertender (see page 20-89)

. Kick panel (see page 20-4't)

. Center pillar lower trim panel (see page 20-41)

. Front side trim (see page 20-41)

. Rear seat (see page 20-63)

a Cargo area floor and cargo storage bin (see page 20-

43)

>: Clip, harness cu3hion location3c>,3D>,12A>, 1B>, 1

Route the washer t!be

under the wire harness

Route the washer tubesto the washer reservoir

WASHEBRESERVOIR

wasner no2zre.

@s_l el 4

WINDSHIELDWASHEB TUBE

REAR WINDOWWASHER MOTOR

GROMMET

wrNoowWASHER TUBE

pull the carpet back as necessary (see page 20-45)

. Rear trim panel and rear side trim panel (see page 20-

42J

. Rear side trim (see page 20-41)

. Rear hatch glass support strut (body side, see page

20-7Al

. Ouarter pillartrim panel (see page 20-421

o Cargo area light (see section 23)

. Headliner (rear edge, see page 20-44)

GROMMET

(cont'd)

20-101

www.emanualpro.com

Page 1102 of 1395

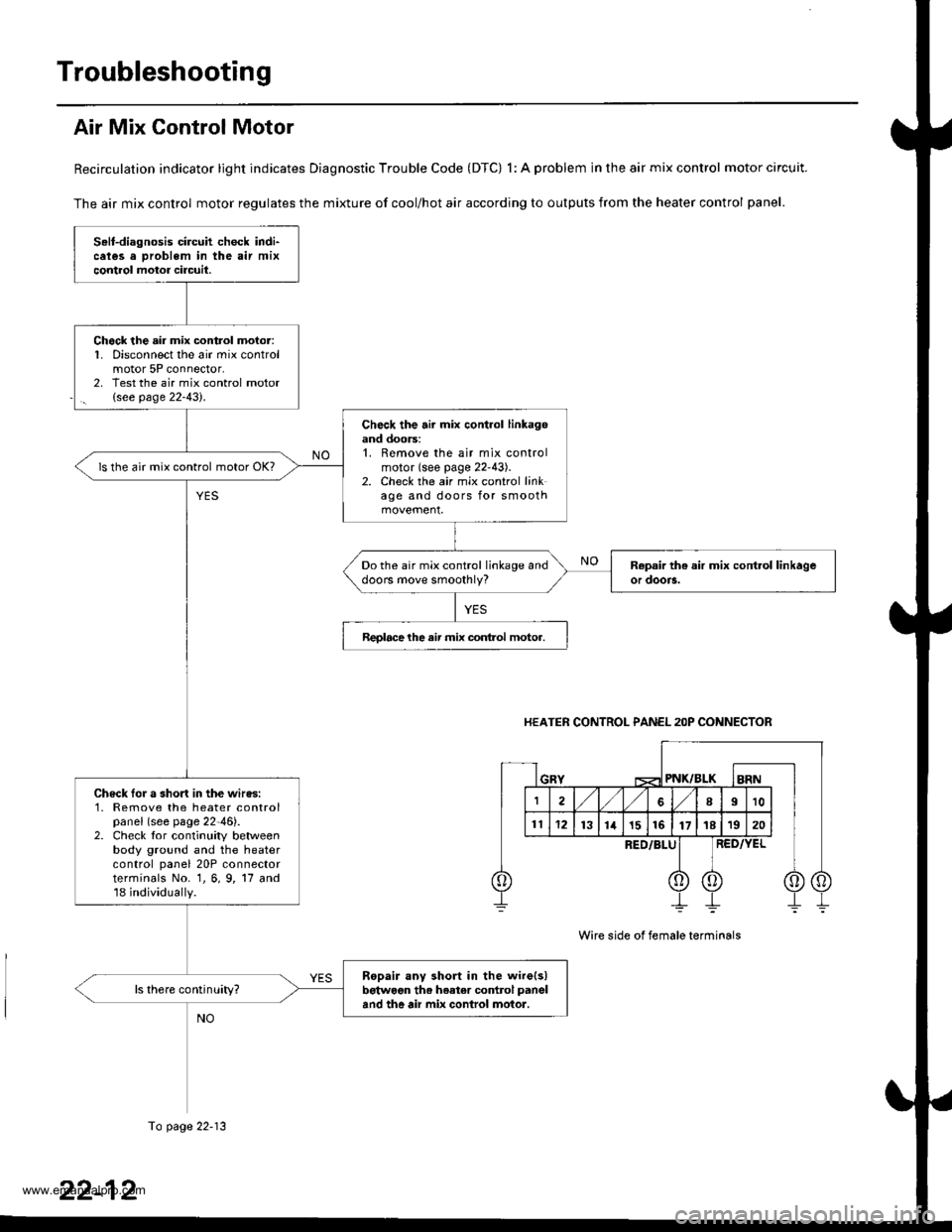

Troubleshooting

Air Mix Control Motor

Recirculation indicator light indicates Diagnostic Trouble Code (DTC) 1: A problem in the air mix control motor circuit.

The air mix control motor regulates the mixture of cool/hot air according to outputs from the heater control panel.

Selt-diagnosis circuit check indi-cates a Droblem in the air mixcontrol motor circuil.

Chock the air mix control moior:1. Disconnect the air mix controlmotor 5P connector,2, Test the air mix control motor(see page 22-43).

Check the air mix control linkagoand doors:1. Remove the air mix controlmotor (see page 22'43).2. Check the air mix control linkage and doors for smooth

ls the air mix control motor OK?

Do the air mix control linkage anddoors move smoothly?

Reolacelhe air mix conlrol motor.

Check Ior a short in the wires:1- Remove the heater controlpanel (see page 22-46).2. Check tor continuity betweenbody ground and the heatercontrol panel 20P connectorterminals No. 1, 6, 9, 17 and18 individually.

Ropair any short in the wire(s)betwoon th. heater co.rtrol panel

and the air mix conlrol motor.

HEATER CONTROL PANEL 2OP CONNECTOR

PNK/BLK

RED/BLU

Wire side of female terminals

To page 22-13

www.emanualpro.com

Page 1104 of 1395

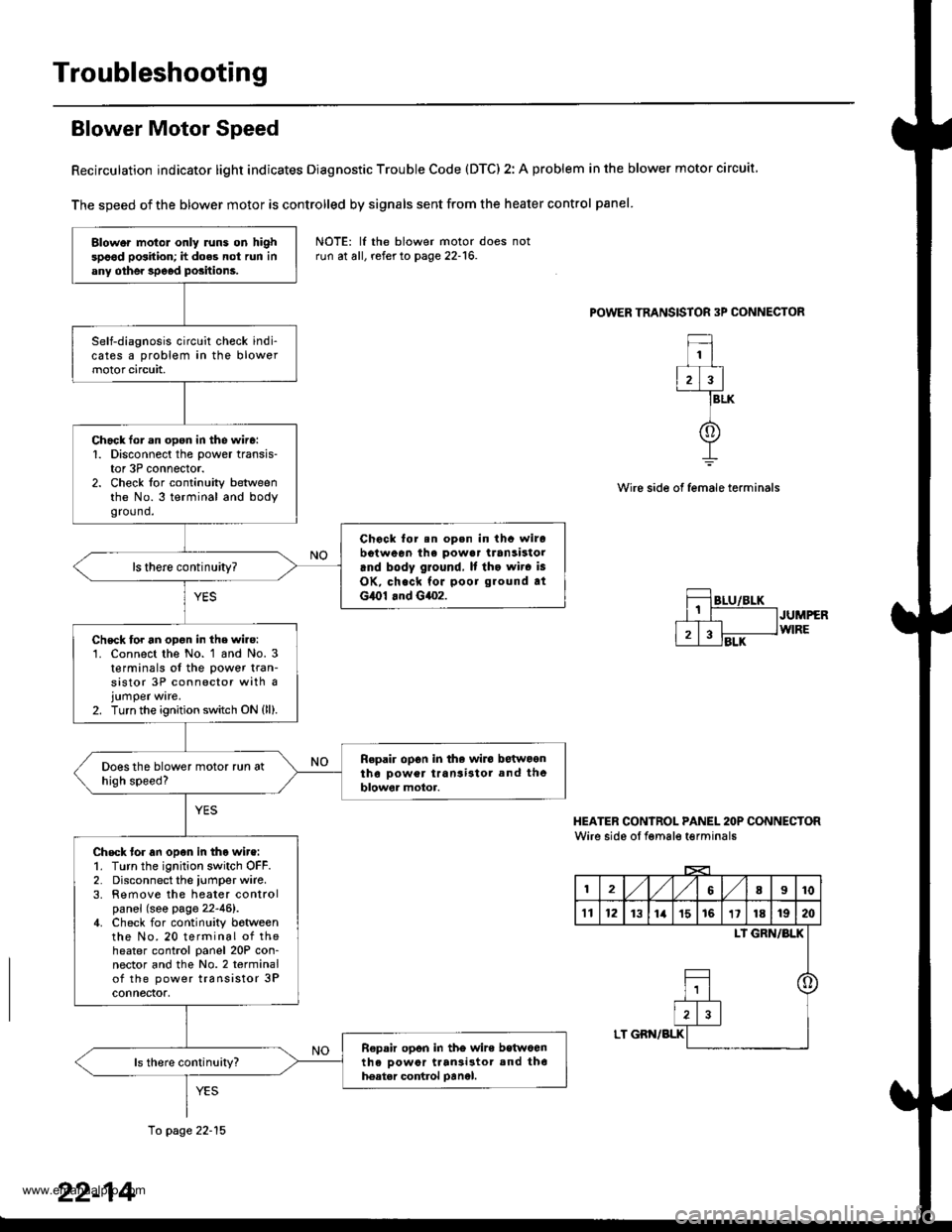

Troubleshooting

Blower Motor Speed

Recirculation indicator light indicates Diagnostic Trouble Code (DTC) 2: A problem in the blower motor circuit

The speed of the blower motor is controlled by signals sent from the heater control panel

POWER TRANSISTOR 3P CONNECTOR

1

2)3

f

BLK

Wire side of female terminals

JUMPERWIRE

HEATER CONIROL PANEL 2OP CONNECTORWire side oI fgmale t€rminals

12,/1,/68I10

't112131ia't51611181920

LI GRN/BLK

o

LT GBN/BLK

Blower motol only runs on highspood position; h does not run inany othe. speod positions.

Self-diagnosis circuit check indi-cates a problem in the blowermotor circuit,

Chack lor.n open in the wire:1. Disconnect the power transis-tor 3P connector.2. Check for continuity betweenthe No.3 terminal and bodygro(1nd.

Chock for.n op.n in thc wirobotween ihe powa. transistorrnd body ground, It tho wir. is

OK, check for poor ground atG,O1 .nd G4o2.

ls there continuity?

Chsck for an opon in the wire:'1. Connect the No. 1 and No. 3t€rminals of the power tran-sistor 3P connector with ajumper ware.2. Turn the ignition switch ON {ll).

Repair op6n in the wiro betwoontho Dower transi3tol and theblowor motor.

Check tor an open in tho wire:1. Turn the ignition switch OFF.2. Disconnect the iumper wire.3. Remove the heater controlpanel (see page 22-46).4. Check for continuity botweenthe No. 20 terminal of theheater control panel 20P con-nector and the No.2 terminalof the power transistor 3Pconnectof,

R€pair opon in tho wire betwoenth6 oowor ttan3i3tor and th6hoatar control oanel.

NOTE: lf the blower motor doesrun at all, refer to page 22-16.

10 page 22-15

22-14

www.emanualpro.com