Fluid HONDA CR-V 2000 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 543 of 1395

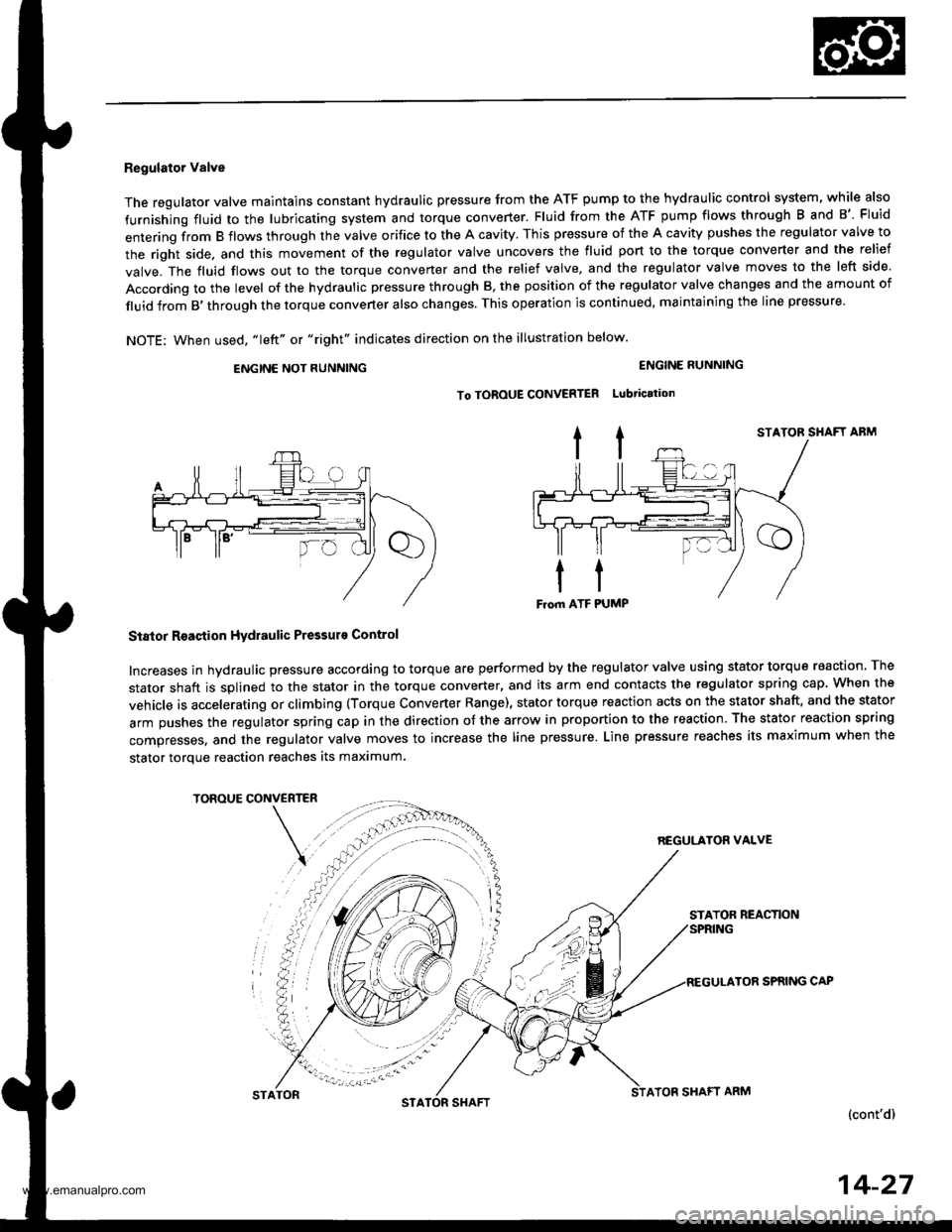

Regulator Valve

The regulator valve maintains constant hydraulic pressure from the ATF pump to the hydraullc control system, while also

furnishing fluid to the lubricating system and torque converter. Fluid from the ATF pump flows through B and B'. Fluid

entering from B flows through the valve orifice to the A cavity. This pressure of the A cavity pushes the regulator valve to

the right side. and this movement of the regulator valve uncovers the fluid port to the torque converter and the relief

valve. The fluid flows out to the torque converter and the relief valve, and the regulator valve moves to the left side.

According to the level of the hydraulic pressure through B, the position of the regulator valve changes and the amount of

fluid from B,through the torque converter also changes. This operation is continued, maintaining the line pressure.

NOTE; When used, "|eft" or "right" indicates direction on the illustration below.

ENGINE NOT RUNNING

STATOR SHAFT ABM

Stator Reaction Hydraulic Pressurs Control

Increases in hydraulic pressure according to torque are performed by the regulator valve using stator torque reaction. The

stator shaft is splined to the stator in the torque converter, and its arm end contacts the regulator spring cap When the

vehicle is accelerating or climbing (Torque Converter Range), stator torque reaction acts on the stator shaft, and the stator

arm pushes the regulator spring cap in the direction of the arrow in proportion to the reaction. The stator reaction spring

compresses, and the regulator valve moves to increase the line pressure. Line pressure reaches its maximum when the

stator torque reaction reaches its maximum.

TOROUE CONVERTER

REGULATON VALVE

STATOR REACTION

TOR SPRING CAP

(cont'd)

ENGINE RUNNING

To TOROUE CONVERTER Lubtication

STATONSTASHAFTATOF SHAFT ARM

14-27

www.emanualpro.com

Page 546 of 1395

Description

Hydraulic Flow (cont'dl

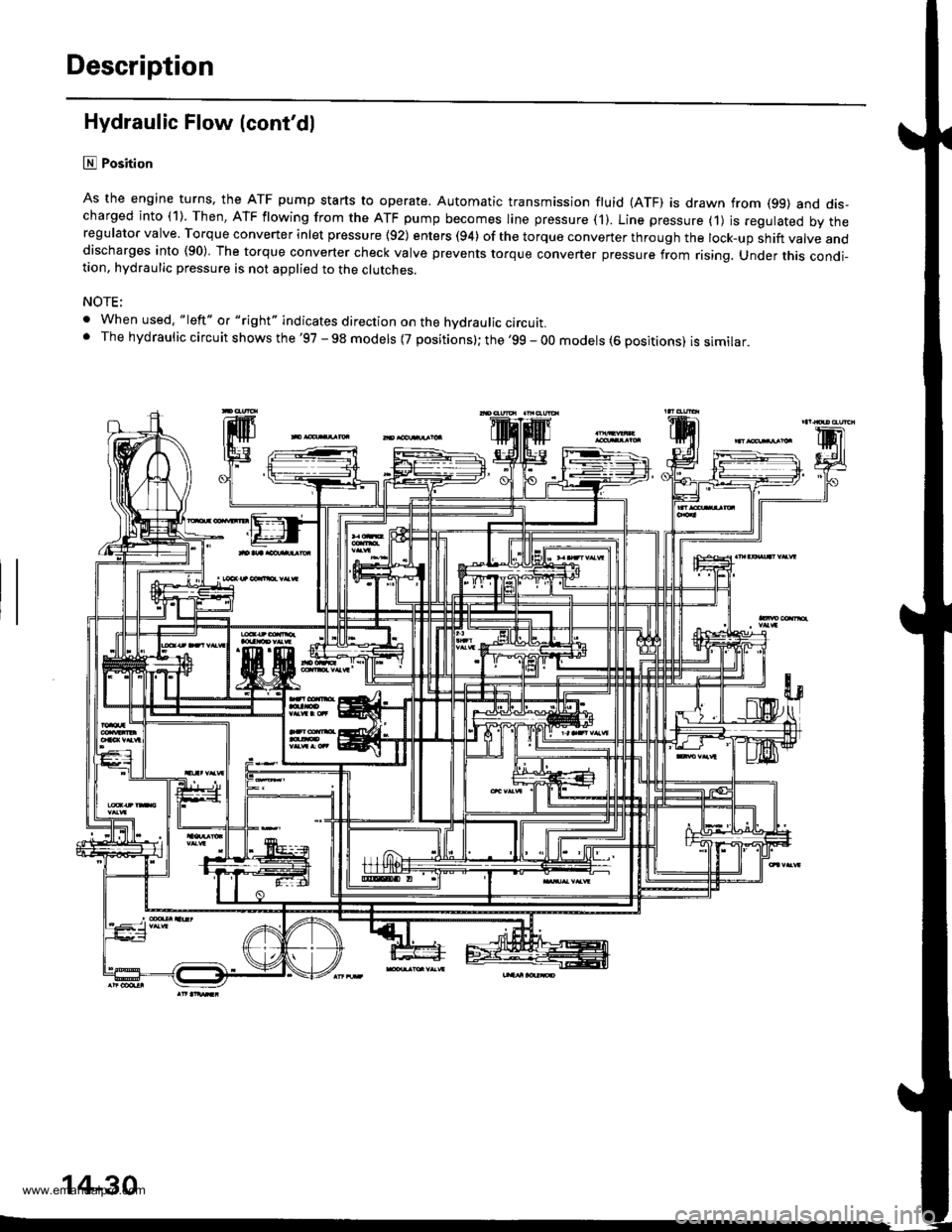

lll Position

As the engine turns, the ATF pump starts to operate. Automatic transmission fluid (ATF) is drawn from (99) and dis-charged into (1). Then, ATF flowing from the ATF pump becomes line pressure ('l). Line pressure (1) js regulated by theregulator valve. Torque converter inlet pressure {92) enters (94) of the torque conveTter through the lock-up shift valve anddischarges into (90) The torque converter check valve prevents torque converter pressure from rising. Under this condi-tion, hydraulic pressure is not applied to the clutches.

NOTE;

. When used. "|eft" o. "right" indicates direction on the hvdraulic circutt.. The hydraulic circuit shows the '97 - 98 models {7 positions}; the '99 - 00 models (6 positions) is similar.

'lF'.j.l

14-30

www.emanualpro.com

Page 549 of 1395

![HONDA CR-V 2000 RD1-RD3 / 1.G Owners Manual

E] or E Position (97 - 98 Models), and D Position (99 - 00 Modelsl

1. lst Gear

Fluid flow through the torque converter circuit is the same as in E] position. Line pressure flows to the manual valve HONDA CR-V 2000 RD1-RD3 / 1.G Owners Manual

E] or E Position (97 - 98 Models), and D Position (99 - 00 Modelsl

1. lst Gear

Fluid flow through the torque converter circuit is the same as in E] position. Line pressure flows to the manual valve](/img/13/5778/w960_5778-548.png)

E] or E Position ('97 - 98 Models), and D Position ('99 - 00 Modelsl

1. lst Gear

Fluid flow through the torque converter circuit is the same as in E] position. Line pressure flows to the manual valve

and the modulator valve. Line pressure changes to modulator pressure (6) at the modulator valve and to line pressure

{4) at the manual valve. Modulator pressure (6) flows to the left end of the 1-2 shift valve and the 3-4 shift valve

because shift control solenoid valve A is turned oFF and B is turned oN by the PcM. The 1-2 shift valve is moved to

the right side. Line pressure {4) changes to 'lst clutch pressure (10} at the 1-2 shift valve and the orifice The 1st clutch

pressure (10) is applied to the 1st clutch and the 1st accumulator; the vehicle will move as the engine power is trans-

mitted.

NOTE:

. When used, "left" or "right" indicates direction on the hydraulic circuit.

. The hvd rau lic circuit shows th e '97 - 98 models (7 positions); the '99 - 00 models {6 positions) issimilar.

(cont'dl

14-33

www.emanualpro.com

Page 550 of 1395

Description

Hydraulic Flow (cont'dl

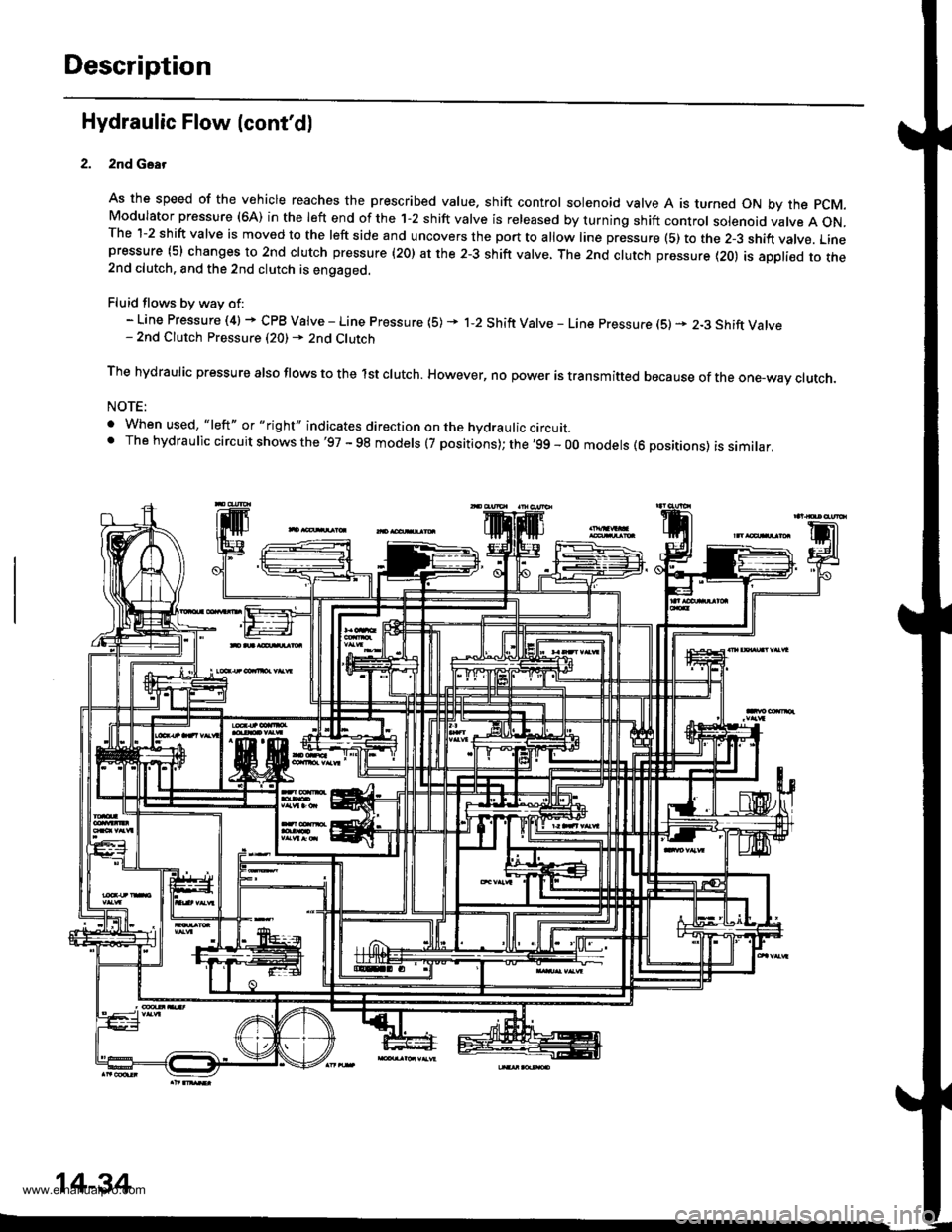

2nd Gsar

As the speed of the vehicle reaches the prescribed value. shift control solenoid valve A is turned ON by the pCM.Modulator pressure (6A) in the left end of the 1-2 shift valve is released by turning shift control solenoid valve A ON.The 1-2 shift valve is moved to the left side and uncovers the port to allow line pressure (5) to the 2-3 shift vatve. Linepressure (5) changes to 2nd clutch pressure (20) at the 2-3 shift valve, The 2nd clutch pressure {20) is appli€d to the2nd clutch. and the 2nd clutch is engaged.

Fluid flows by way of:- Line Pressure (4) + CPB Valve - Line Pressure (5) * 1-2 Shift Valve - Line pressure (S) * 2-3 Shift Valve- 2nd Clutch Pressure (20) - 2nd Clutch

The hydraulic pressure also flows to the lst clutch. However, no power is transmitted because of the one-wav ctutch.

NOTE:

. When used, "|eft" or "right" indicates direction on the hydraulic circurr_' The hydraulic circuit shows the'97 - 98 models (7 positions); the '99 - 00 models (6 positions) is similar,

14-34

www.emanualpro.com

Page 551 of 1395

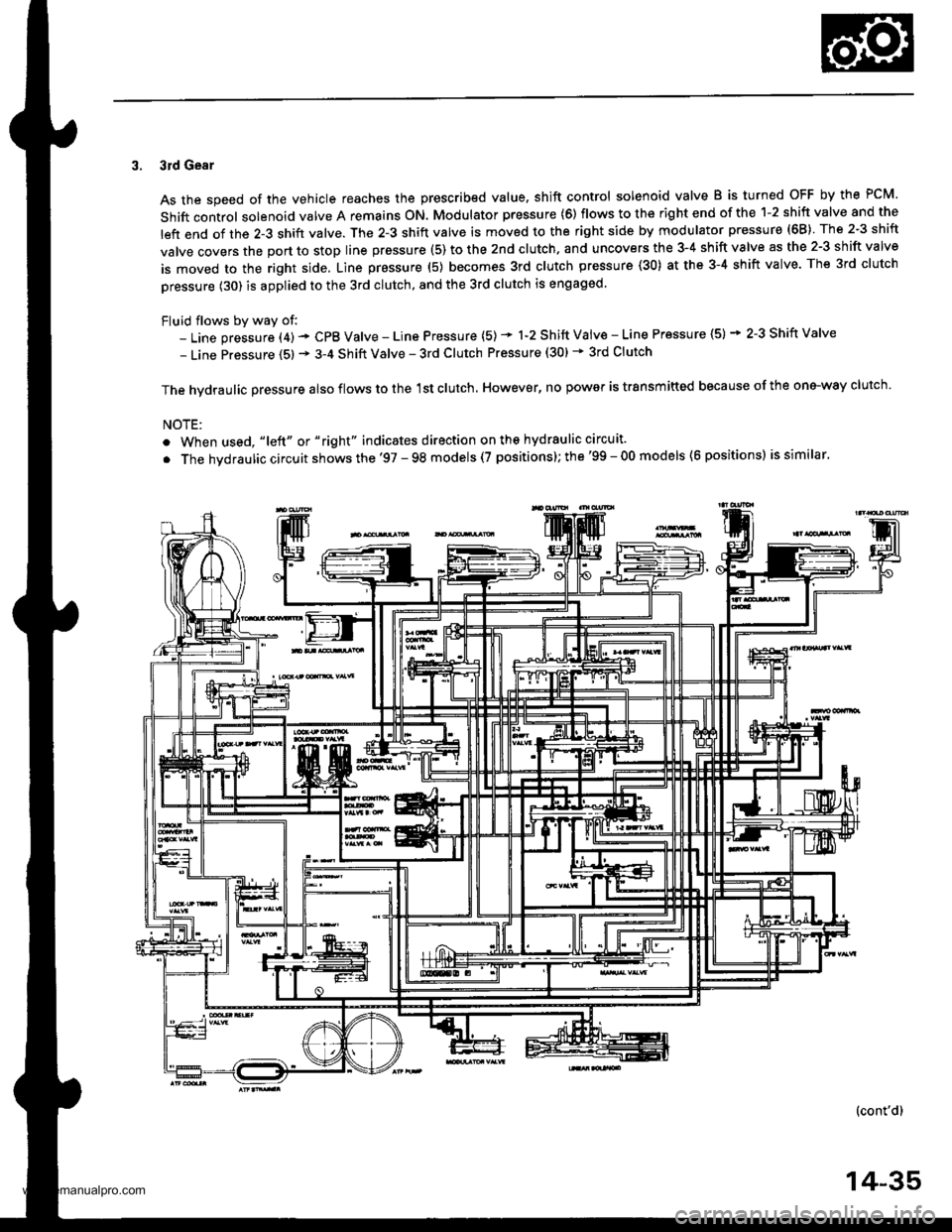

3. 3rd Gear

As the speed of the vehicle reaches the prescribed value. shift control solenoid valve B is turned OFF by the PCM.

Shift control solenoid valve A remains ON. Modulator pressure (6) flows to the right end of the 1-2 shift valve and the

left end of the 2-3 shift valve. The 2-3 shift valve is moved to the right side by modulator pressure (68) The 2-3 shift

valve covers the port to stop line prsssure (5) to the 2nd clutch. and uncovers the 3-4 shift valve as the 2-3 shift valve

is moved to the right side, Line pressure (5) becomes 3rd clutch pressure (30) at the 3-4 shift valve. The 3rd clutch

pressure (30) is applied to the 3rd clutch, and the 3rd clutch is engaged.

Fluid flows by way of:- Line pressure (4) - CPB Valve - Line Pressure (5) * 1-2 Shift Vaiv€ - Line Pressure (5) * 2-3 Shift Valve

- Line Pressure (5) * 3-4 Shift Valve - 3rd Clutch Pressure (30) * 3rd Clutch

The hvdraulic Dressure also flows to the 1st clutch. However, no power is trsnsmitted because of the one-way clutch.

NOTE:

. When used, "|eft" or "right" indicates direction on ths hydraulic circuit.

. The hvdraulic circuit shows the '97 - 98 models (7 positions); the'99 - 00 models (6 positions) is similar.

(cont'd)

14-35

www.emanualpro.com

Page 552 of 1395

Description

Hydraulic Flow (cont'd)

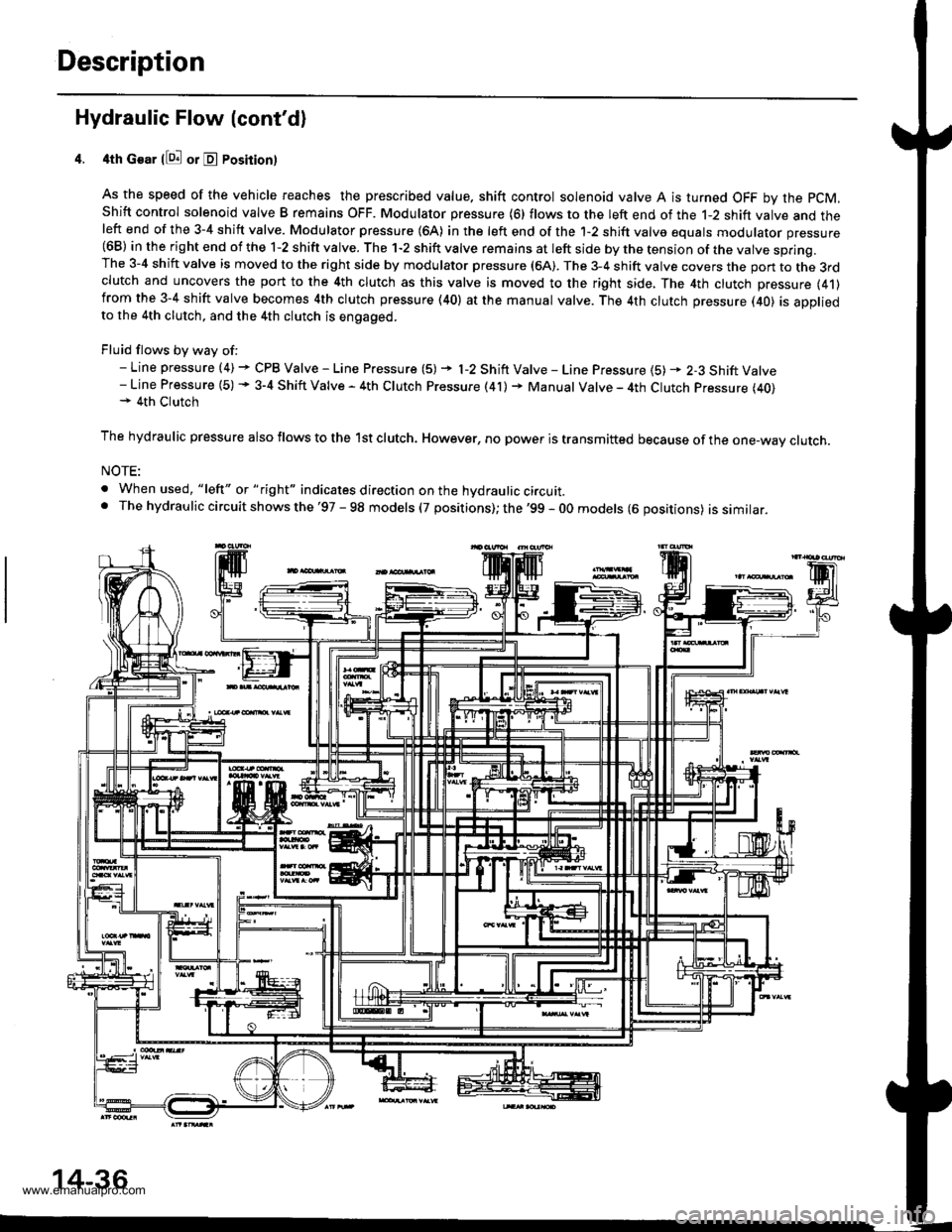

4th Gear llQ! or E Posirion)

As the speed of the vehicle reaches the prescribed value. shift control solenoid valve A is turned OFF by the pCM,

Shift control solenoid valve B remains OFF. Modulator pressure (6) flows to the left end of the 1-2 shift valve and theleft end of the 3-4 shift valve. Modulator pressure (64) in the left end of the 1-2 shift valve equals modulator pressure(68) in the right end of the 1-2 shift valve. The 1-2 shift valve remains at left side by the tension of the valve spring.The 3-4 shift valve is moved to the right side by modulator pressure (6A). The 3-4 shift valve covers the pon to the 3rdclutch and uncovers the port to the 4th clutch as this valve is moved to the right side, The 4th clutch pressure (41)from the 3-4 shift valve becomes 4th clutch pressure (40) at the manual valve. The 4th clutch pressure (40) is appliedto the 4th clutch, and the 4th clutch is engaged.

Fluid flows by way of:- Line pressure (4) + CPB Valve - Line Pressure (5) + l-2 Shift Valve - Line Pressure {5) * 2-3 Shift Valve- Line Pressure (5) + 3-4 Shift Valve - 4th Clutch Pressure (41) + Manual Valve - 4th Clutch Pressure (40)+ 4th Clutch

The hydraulic pressure also flows to the lst clutch. However, no power is transmitted because of the one-wav clutch.

NOTE:

. When used, "lelt" or " tight" indicates direction on the hydraulic circuit.. The hydrau lic circuit shows the '97 - 98 models (7 positions); the '99 - 0O models (6 oositions) issimilar.

14-36

www.emanualpro.com

Page 553 of 1395

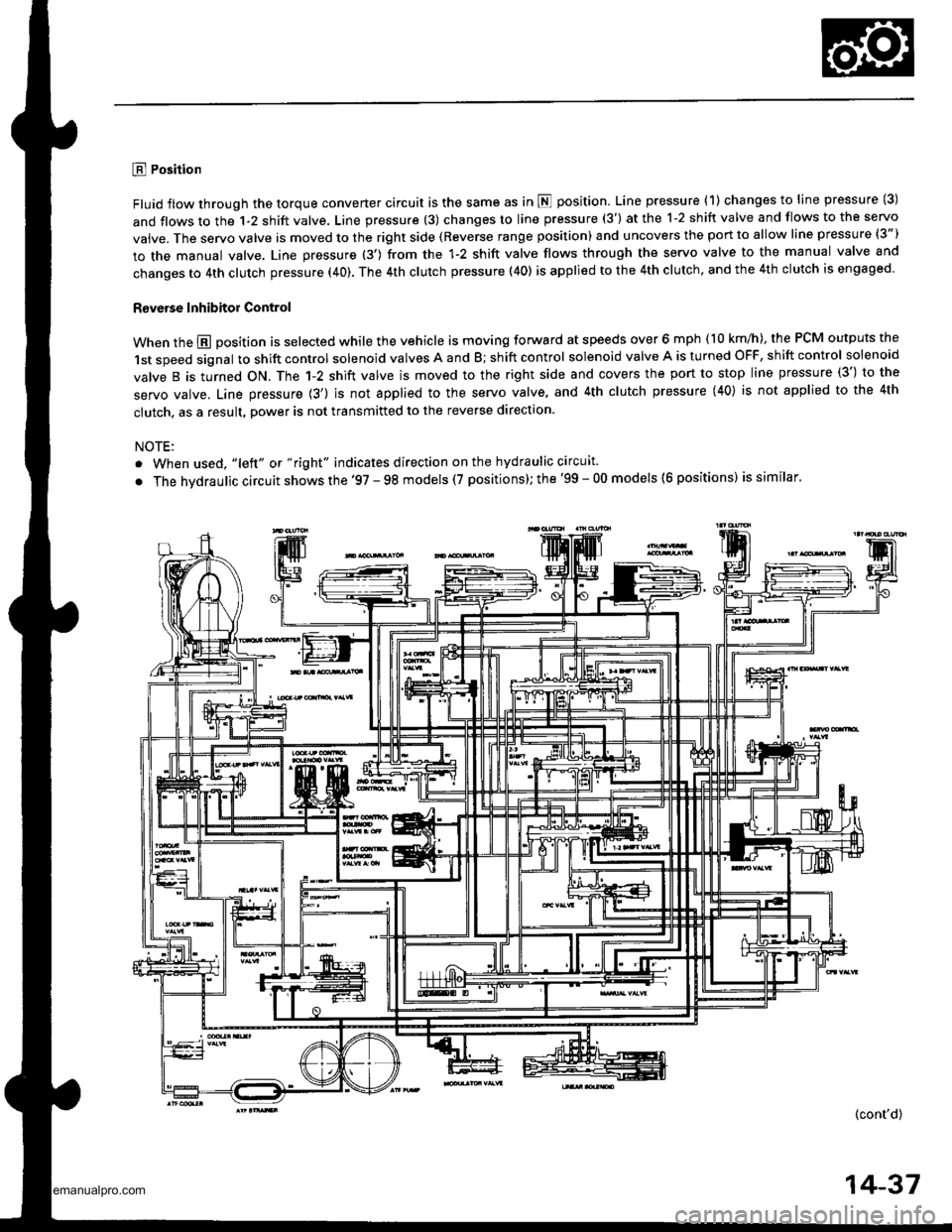

E Position

Fluid flow through the torque converter circuit is the same as in N position. Line pressure (1) changes to line pressure (3)

and flows to the 1-2 shift valve. Line pressure (3) changes to line pressure (3') at the 1-2 shift valve and flows to the servo

vaive. The servo valve is moved to the right side (Reverse range position) and uncovers the port to allow line pressure (3")

to the manual valve. Line pressure (3') from the 1-2 shift valve flows through the servo valve to the manual valve and

changes to 4th clutch pressure (40). The 4th clutch pressure (40) is applied to the 4th clutch, and the 4th clutch is engaged.

R€verse Inhibitor Control

When the @ position is selected while the vehicle is moving forward at speeds over 6 mph (10 km/h), the PCM outputs the

1st speed signal to shift control solenoid valves A and B; shift control solenoid valve A is turned OFF, shift control solenoid

valve B is turned ON. The 1-2 shift valve is moved to the right side and covers the port to stop line pressure (3') to the

servo valve. Line pressure {3') is not applied to the servo valve, and 4th clutch pressure (40} is not applied to the 4th

clutch, as a result, power is not transmitted to the reverse direction.

NOTE:

. When used, "lelt" ot " right" indicates direction on the hydraulic circuit.

. The hvdraulic circuit shows the '97 - 98 models (7 positions); the '99 - 00 models (6 positions) is similar'

(cont'd)

14-37

www.emanualpro.com

Page 554 of 1395

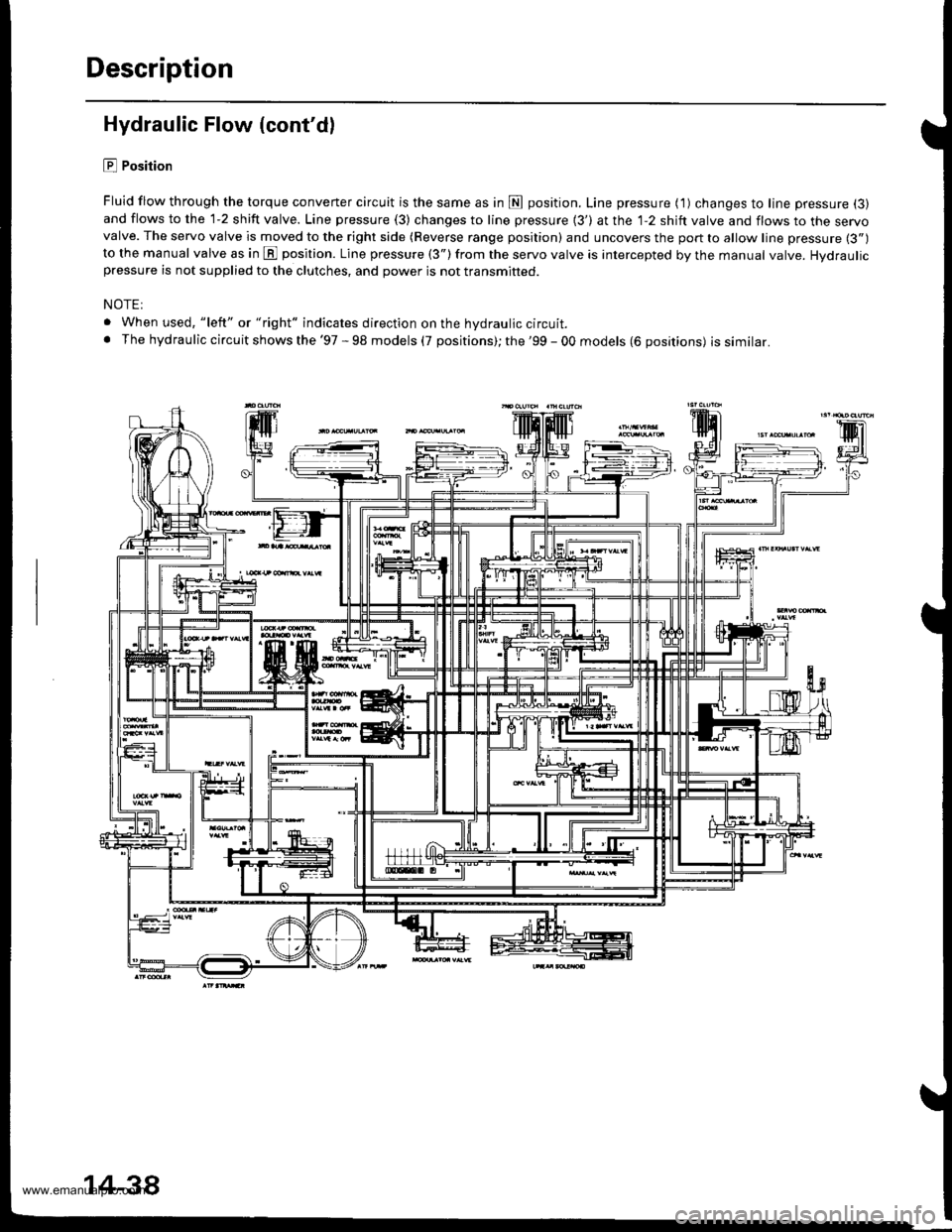

Description

Hydraulic Flow (cont'dl

E Position

Fluid flow through the torque converter circuit is the same as in fl position. Line pressure ( 1) changes to line pressure (3)

and flows to the 1-2 shift valve. Line pressure (3) changes to line pressure {3') at the 1-2 shift valve and flows to the servovalve. The servo valve is moved to the right side (Reverse range position) and uncovers the port to allow line pressure (3")

to the manual valve as in E position. Line pressure (3") from the servo valve is intercepted by the manual valve. Hydraulicpressure is not supplied to the clutches, and power is not transmitted.

NOTE:

. When used, "left" or "right" indicates direction on the hydraulic circuit.. The hydraulic circuit shows the '97 - 98 models (7 positions); the '99 - 00 models (6 positions) issimilar.

14-38

www.emanualpro.com

Page 555 of 1395

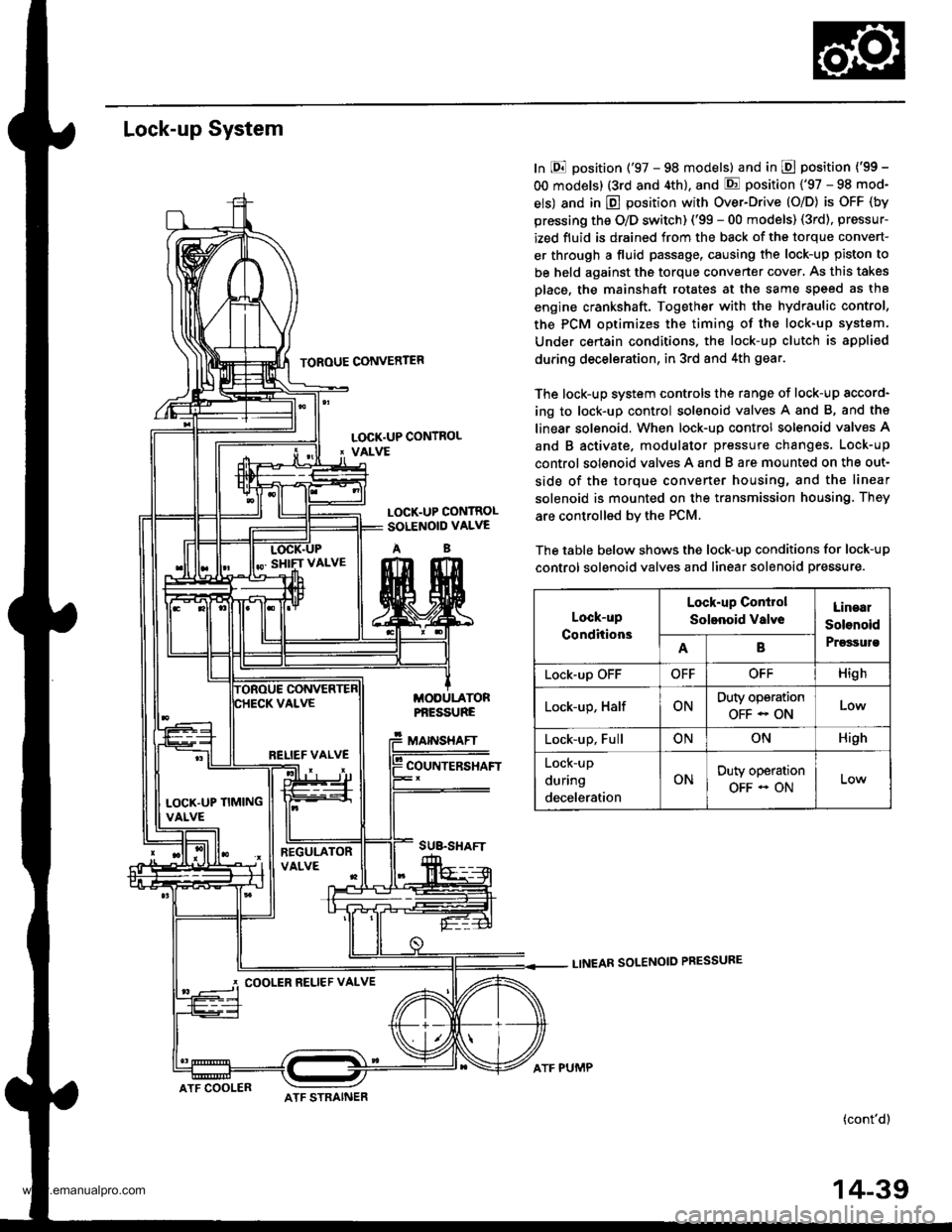

Lock-up System

TOROUE CONVERTER

In E position ('97 - 98 models) and in E position ('99 -

OO models) (3rd and 4th), and E position ('97 - 98 mod-

els) and in E position with Over-Drive (O/D) is OFF (by

pressing the O/D switch) ('99 - 00 models) (3rd), pressur-

ized fluid is drained from the back of the torque convert-

er through a fluid passage, causing the lock-up piston to

be held against the torque converter cover, As this takes

Dlace, the mainshaft rotates at the same speed as th8

engine crankshaft. Together with the hydraulic control,

the PCM optimizes the timing of the lock-up system.

Under certain condltions. the lock-up clutch is appli€d

during deceleration, in 3rd and 4th gear.

The lock-up system controls the range of lock-up sccord-

ing to lock-up control solenoid valves A and B, and ths

linear solenoid. When lock-up control solenoid valves A

and B activate. modulator pressure changes. Lock-up

control solenoid valves A and B are mounted on the out-

side of the torque converter housing, and the linear

solenoid is mounted on the transmission housing. They

are controlled bv the PCM.

The table below shows the lock-up conditions for lock-up

control solenoid valves and linear solenoid pressure.

LINEAR SOLENOID PRESSURE

(cont'd)

LOCK.UP CONTROL' VALVE

LOCK.UP CONTROLSOLENOID VALVE

AB

MODULATORPf,ESSURE

MAINSHAFT

COUNTERSHAFT

SUB.SHAFT

Lock-up

Conditions

Lock-up Conirol

Solenoid valveLinaal

Solenoid

PrgssulsAB

Lock-up OFFOFFOFFHigh

Lock-up, HalfONDuty operation

OFF - ONLow

Lock-up, FullONONHigh

Lock-up

during

deceleration

ONDuty operation

OFF - ON

RELIEF VALVE

LOCK'UP TIMINGVALVE

COOLER RELIEF VALVE

ATF COOLERATF STRAINER

ATF PUMP

14-39

www.emanualpro.com

Page 556 of 1395

Description

Lock-up System (cont'dl

Lock-up Clutch

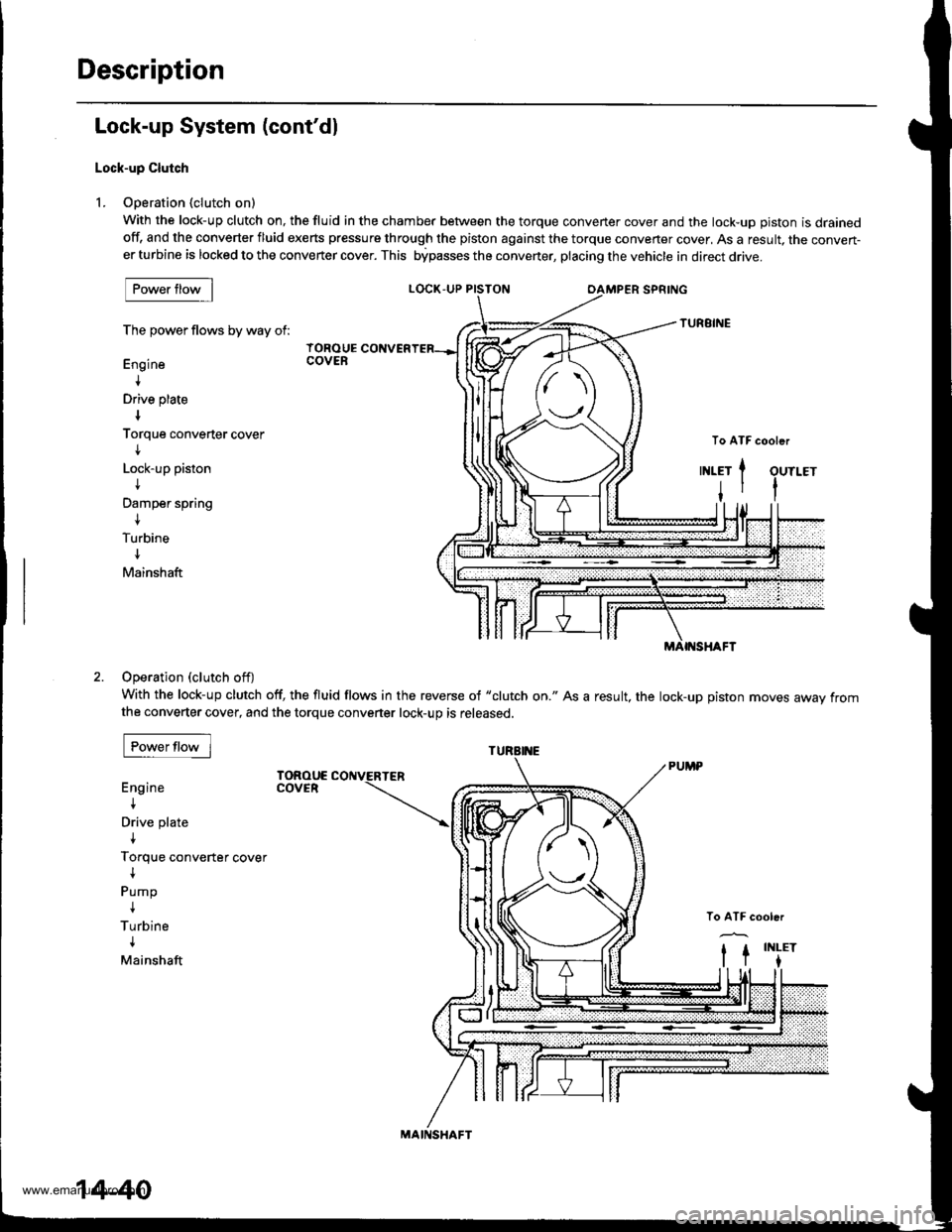

L Ooeration (clutch on)

With the lock-up clutch on, the fluid in the chamber between the torque convener cover and the lock-uD oiston is drainedoff, and the converter fluid exerts pressure through the piston against the torque converter cover, As a result, the conven-er turbine is locked to the converter cover. This bipasses the converter, placing the vehicle in direct drive.

LOCK,UP PISTON

The power flows by way of:

Engine

+

Drive plate

Torque converter cover

I

Lock-up piston

t

Damper spring

{

Turbine

Mainshaft

IOROUECOVER

Operation (clutch off)

With the lock-up clutch off, the fluid flows in the reverse of "clutch on." As a result, the lock-up piston moves away fromthe converter cover, and the torque converter lock-up is released.

Engine

I

Drive plate

{

Torque converter cover

{

Pump

I

Turbine

{

Mainshaft

TOROUECOVER

To ATF cooler{(1\\n1INLET

t

Jtl

ort

MAIf{SHAFT

MAII{SHAFT

14-40

www.emanualpro.com