air box HONDA CR-V 2000 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 627 of 1395

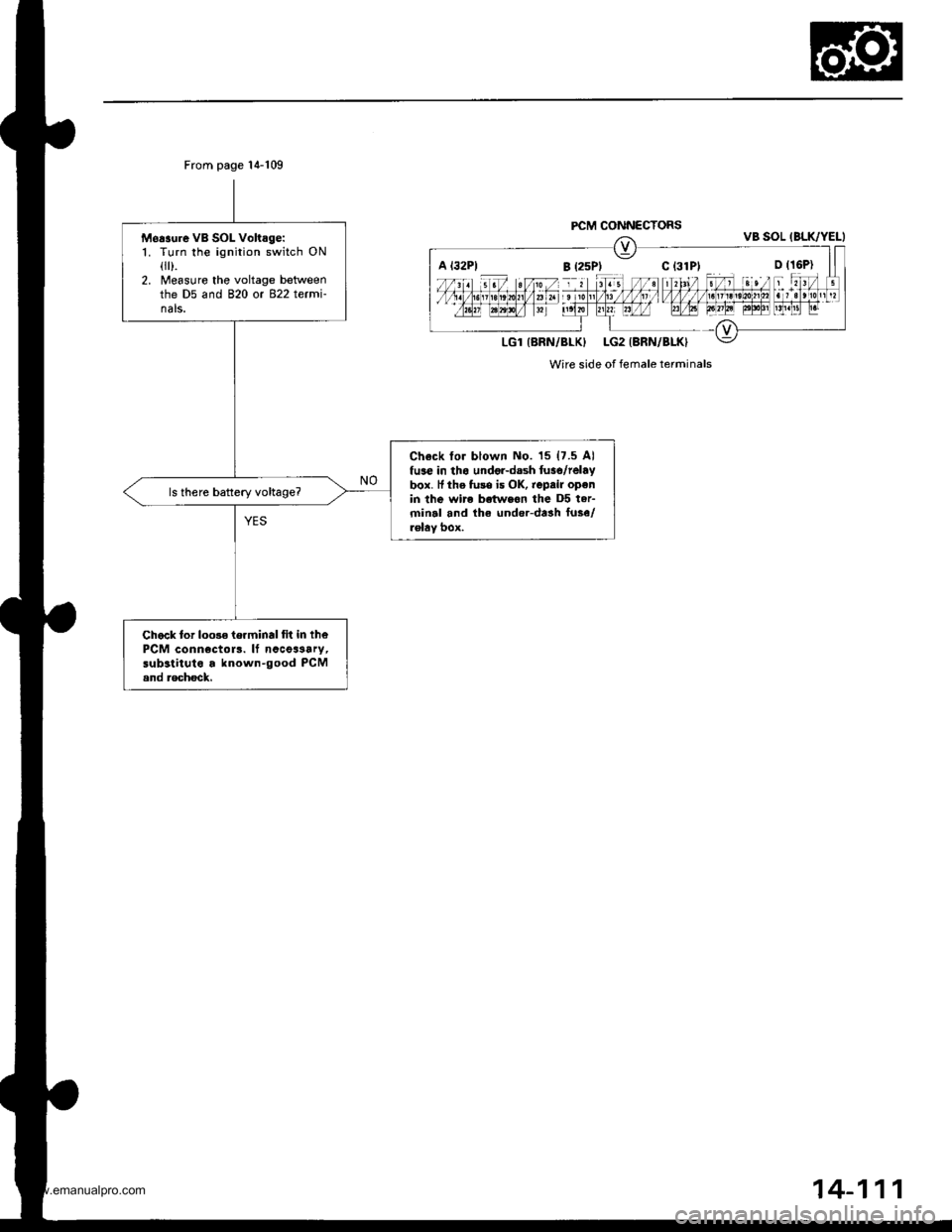

From page 14-109

M6r3ure vB SOL voltage:1. Turn ihe ignition switch ONflr).2. Measure the voltage betweenthe D5 and B20 or B22 termi-nals.

Ch6ck tor blown No. '15 {7.5 Alfuse in tho undo.-dash tuso/telaybox. It the fu3s is OK, tepair openin the wire bctweon the D5 ter-minal and the under-dash fose/rolaY box.

Chack to. loo3e te.minal fit in lhoPCM connectols. lf nccoa3ary,substituto a known-good PCMsnd rechock.

PCM CONNECTORS

A l32Pl B (25Pt C (31P1 o (16P)

Wire side of female terminals

14-111

www.emanualpro.com

Page 634 of 1395

ElectricalTroubleshooting ('98 - 00 Models)

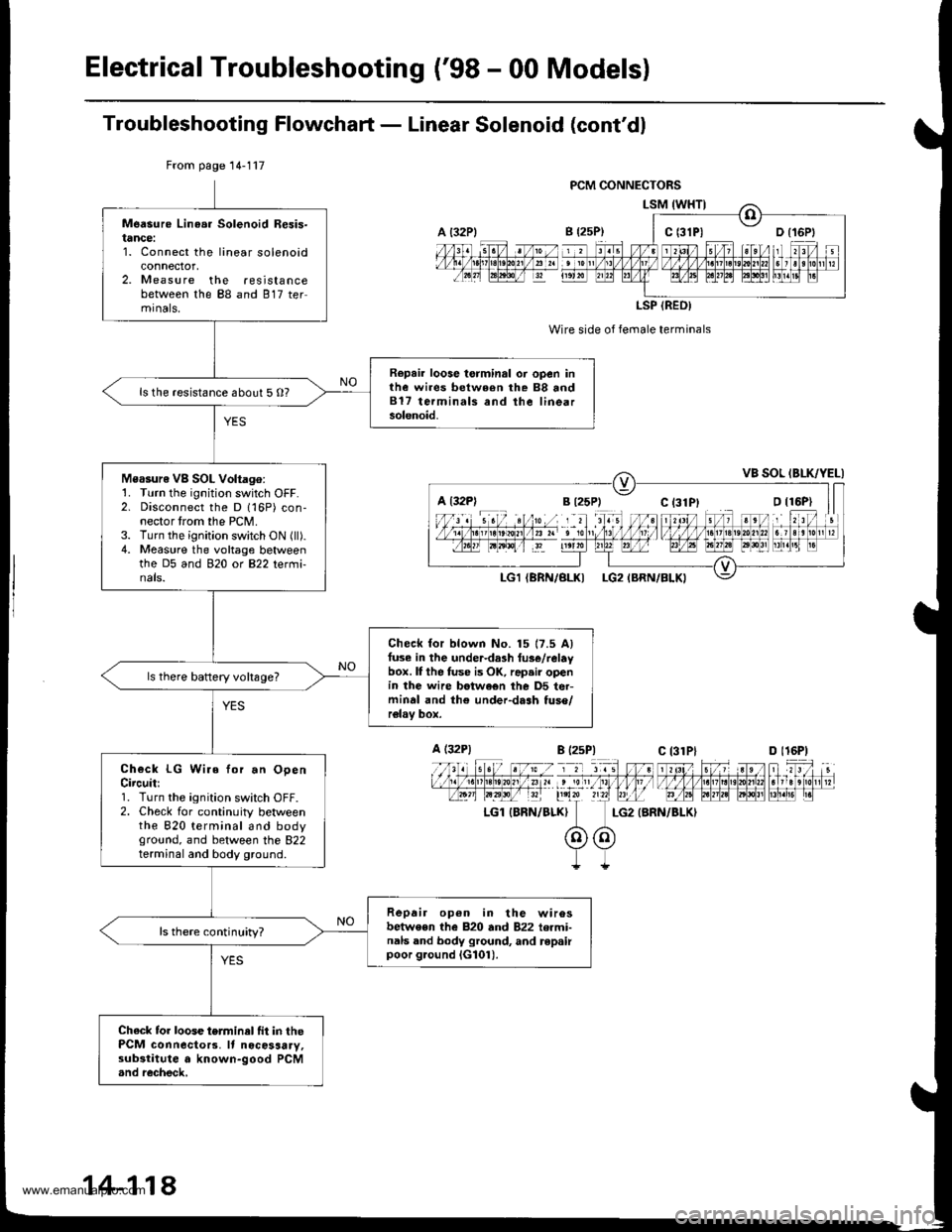

Troubleshooting Flowchaft - Linear Solenoid (cont'dl

Wire side of female terminals

LG2 {BRN/BLKI

From page 14-117

Measure Linea. Solenoid Resis-tance:1. Connect the linear solenoidconnector,2. Measure the resistancebetween the 88 and 817 termrnals,

Repair loose torminal oi open inthe wires between rhe 88 and817 terminals and the linearsolenoid.

ls the resistance about 5 O?

Measure VB SOL Voltago:1. Turn the ignition switch OFF.2. Disconnect the D 116P) con-nector trom the PCM.3. Turn the ignition switch ON (ll).4. Measure the voltage betweenthe D5 and 920 ot B22 tetmi-nals.

Check for blown No. 15 17.5 Alfuse in the under-da3h tus€/relaybox. lI the fuse is OK, rap.ir openin the wire betwe€n the D5 ter-minal and th€ under-dash tuso/relav box.

ls there baftery voltsge?

Check LG Wire for.n OpenCircuit:1. Turn the ignition switch OFF.2. Check for continuity betweenthe 820 terminal and bodyground, and between the 822terminal and body ground.

Repair op6n in the wirosbetwe€n the 820 and 822 termi-nals and body ground, and repairpoor g.ound iG101).

ls there continuity?

Chack tor loose terminel fit in thePCM connecto13. It nocosaary,substitute a known-good PCM.nd recheck,

a t32Plc t3lPl

LSP (REO)

a l32Pl

A (32P1

LGl IBRN/BLK}

B l2sP)c 13lPlD l16P)

14-118

www.emanualpro.com

Page 639 of 1395

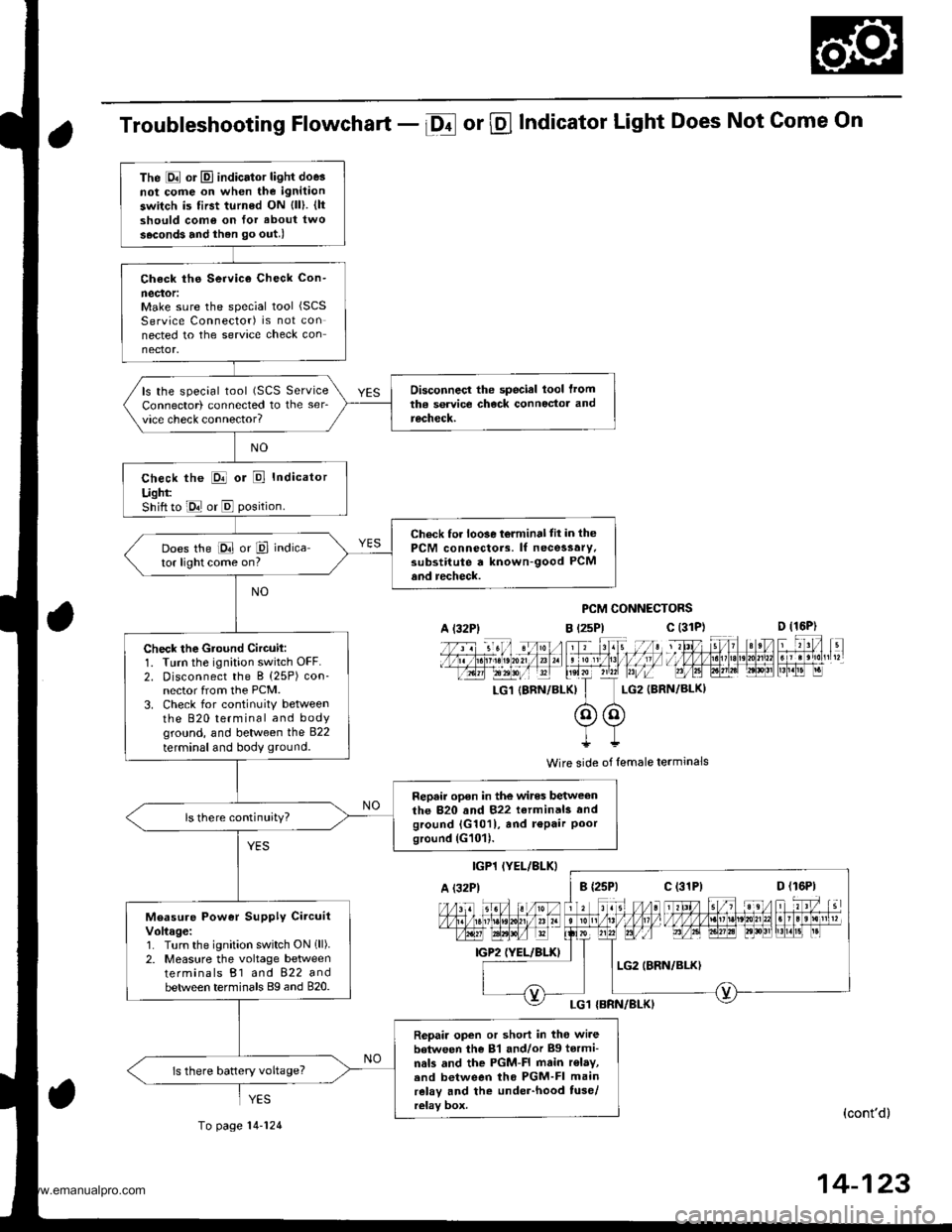

Troubleshooting Flowchart - Df or @ Indicator Light Does Not Come On

PCM CONNECTORS

B t2sPl c (31D (16P)

l*f4tr 8-

f - -- -6 3 rol ,: irr t lrpri$fe?0?r/a)1 e 'oI 13 11/ / l//|rrr I , ltelx ?r2? r,/i-T_LG1 {8RN/BI-KI I LG2 (BRN/BL()I

@@I++

Wire side of lemale terminals

(cont'd)

14-123

The E or El indicator light doe3not cofie on when the ignitaon

switch is first turned ON {ll). {ltshould como on for about two

s.cond3 and ihen go out.l

Check ths Service Check Con-

neclor:Make sure the special tool (SCS

Service Connector) is not connected to the service check connector.

Disconnecl the special lool lromtha service check connoctor andrecheck.

ls the special tool (SCS ServiceConnector) connected to the ser_vice check connector?

check the E or E Indicator

Ught:Shift to E or E position.

Check for loo3e t6lminal tit in thePCM connectors. lf necessary.substitute a known-good PCMand recheck.

Does the E or P indica-tor light come on?

Check the Gtound Circuil:1. Turn the ignition switch OFF.2. Disconnect the B (25P) con-nector from the PCM.3. Check for continuitY betweenthe 820 terminal and bodyground, and between the 822

terminal and body ground.

Repair open in the wires betweenthe 820 and 822 terminals andground {G1011, and r€Pair Poorground (G101).

ls there continuity?

Measure Power Supply CircuitVoltage:1. Turn the ignition switch ON 1ll).2. Measure the voltage betweenterminals B1 and 822 andbetween terminals Bg and 820.

Repair open or short in tho wi.ebetween the 81 and/or Bg tormi-nals and the PGM-FI main r€lay,.nd between tho PGM-FI mainrelay and the under-hood tuse/relay box.

ls there battery voltage?

A l32Plc (31P)

c (31P)

YES

To page 14-124

www.emanualpro.com

Page 644 of 1395

Electrical Troubleshooting ('98 - 00 Modelsl

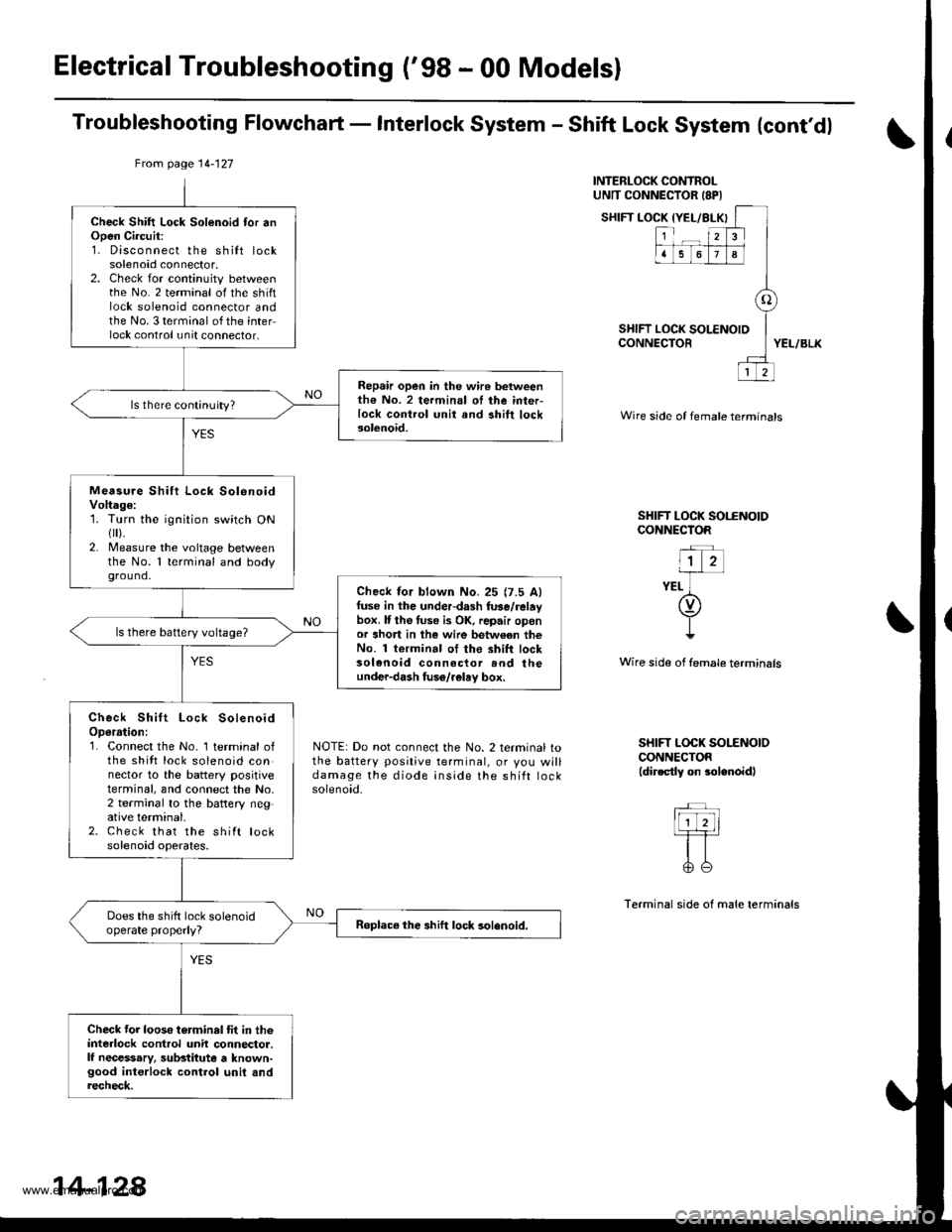

Troubleshooting Flowchaft - Interlock System - Shift Lock System {cont'dl

INTERLOCK CONTROLUNTT CONNECTOR ISPI

SHIFT LOCK IYEL/BLX

SHIFT LOCK tCONNECTOR

{YEL/BLKI

123

1678

o

LOCK SOLENOID

12

YEL/BLK

Wire side of female termtnals

SHIFT LOCK SOI.ENOIDCONNECTOR

"l z-irr-

YEL ](v)

I!

Wire side of female terminsls

NOTE: Do not connect the No. 2 terminal tothe battery positive terminal, or you willdamage the diode inside the shift rocKsolenoid.

SHIFT LOCK SOLENOIOCONNECTOR(dir.ctly on $lenoidl

Terminal side of male terminals

From page 14-127

Check Shift Lock Solenoid tor anOpen Ci.cuit:1. Disconnect the shilt locksolenoid connector,2. Check for continuity betweenthe No. 2 terminal of the shiftlock solenoid connector andthe No. 3 terminal of the interlock control unit connector,

Repair open in the wir6 betweenth€ No. 2 termin.l oI ihe inter-lock control unit and ahift locksolenoid.

ls there continuity?

Measu.e Shift Lock SolenoidVoltage:1. Turn the ignition switch ONflr).2. Measure the voltage betweenthe No. 1 terminal and bodyground.

Check lor blown No.25 {7.5 Alfuse in the underdash fuse/relaybox. It the tuse i3 OK, repair oponor short in lhe wire betw€en theNo. 1 terminal of tho shift locksolenoid connector rnd theunder-dash fuso/r€lay box,

ls there battery voltage?

Check Shift Lock SolenoidOperrtion:1. Connect the No. 1 terminal ofthe shitt lock solenoid connector to the battery positiveterminal, and connect the No,2 terminal to the battery neg,ative terminal.2. Check that the shift locksolenoid operates.

Does the shift lock solenoidoperate properly?Roplace the shift lock solenoid.

Check tor looso torminal tit in th6interlock control unit connector.lf necessary, substitute a known-good int€rlock control unil andrecheck.

14-128

www.emanualpro.com

Page 658 of 1395

A/T Gear Position Indicator

1.

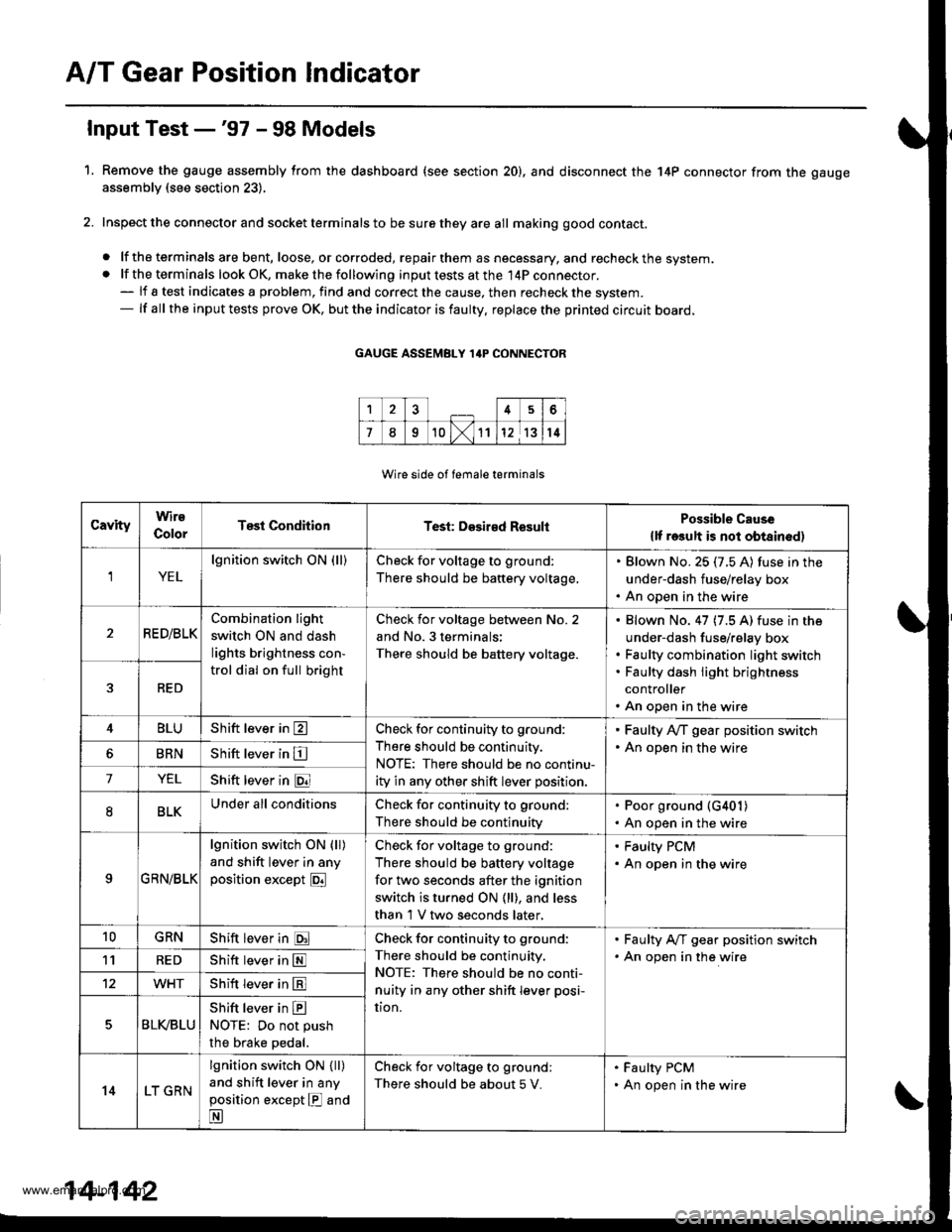

f nput Test -'97 - 98 Models

Remove the gauge assembly from the dashboard (see section 20). and disconnect the 14P connector from the gauge

assemblv (see section 23),

Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose, or corroded, repairthem as necessary, and recheck the system.. lf the terminals look OK, make the following input tests at the 14P connector.- lf I test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, but the indicator is faulty. replace the printed circuit board,

GAUGE ASSEMBLY 14P CONNECTOR

Wire side of female terminals

CavityWirs

ColorTest ConditionTest: Desir€d ResultPossible Cause

{lf rosult is not obtainod)

YEL

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage,

. Blown No. 25 (7.5 A) fuse in the

under-dash fuse/relay box. An open in the wire

RE D/BLKCombination light

switch ON and dash

lights brightness con-

trol dial on full bright

Check for voltage between No. 2

and No. 3 terminals;

There should be battery voltage.

Blown No. 47 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty combination Iight switch

Faulty dash iight brightness

controller

An open in the wire

RED

4BLUShift lever in ECheck for continuity to ground:

There should be continuity.

NOTE: There should be no continu-

ity in any other shift lever position.

' Faulty Ay'T gear position switch. An open in the wireBRNShift lever in E

7YELShift lever in @

8BLKUnder all conditionsCheck for continuity to ground:

There should be continuity

. Poor ground {G401). An open in the wire

9GRN/BLK

lgnition switch ON {ll)

and shift lever in any

position except E

Check for voltage to ground:

There should be battery voltage

for two seconds after the ignition

switch is turned ON {ll), and less

than 1 V two seconds later,

' Faulty PCM. An open in the wire

10GRNShift lever in ECheck for continuity to ground:

There should be continuity.

NOTE: There should be no conti-

nuity in any other shift lever posi-

UOn.

. Faulty A,ff gear position switch. An open in the wire1'lREDShift lever in @

12WHTShift lever in E

BLVBLU

Shift lever in ENOTE: Do not push

the brake pedal.

14LT GRN

lgnition switch ON { ll)

and shift lever in any

position except E and

E

Check for voltage to ground:

There should be about 5 V.

. Faulty PCM. An open in the wire

14-142

www.emanualpro.com

Page 659 of 1395

L

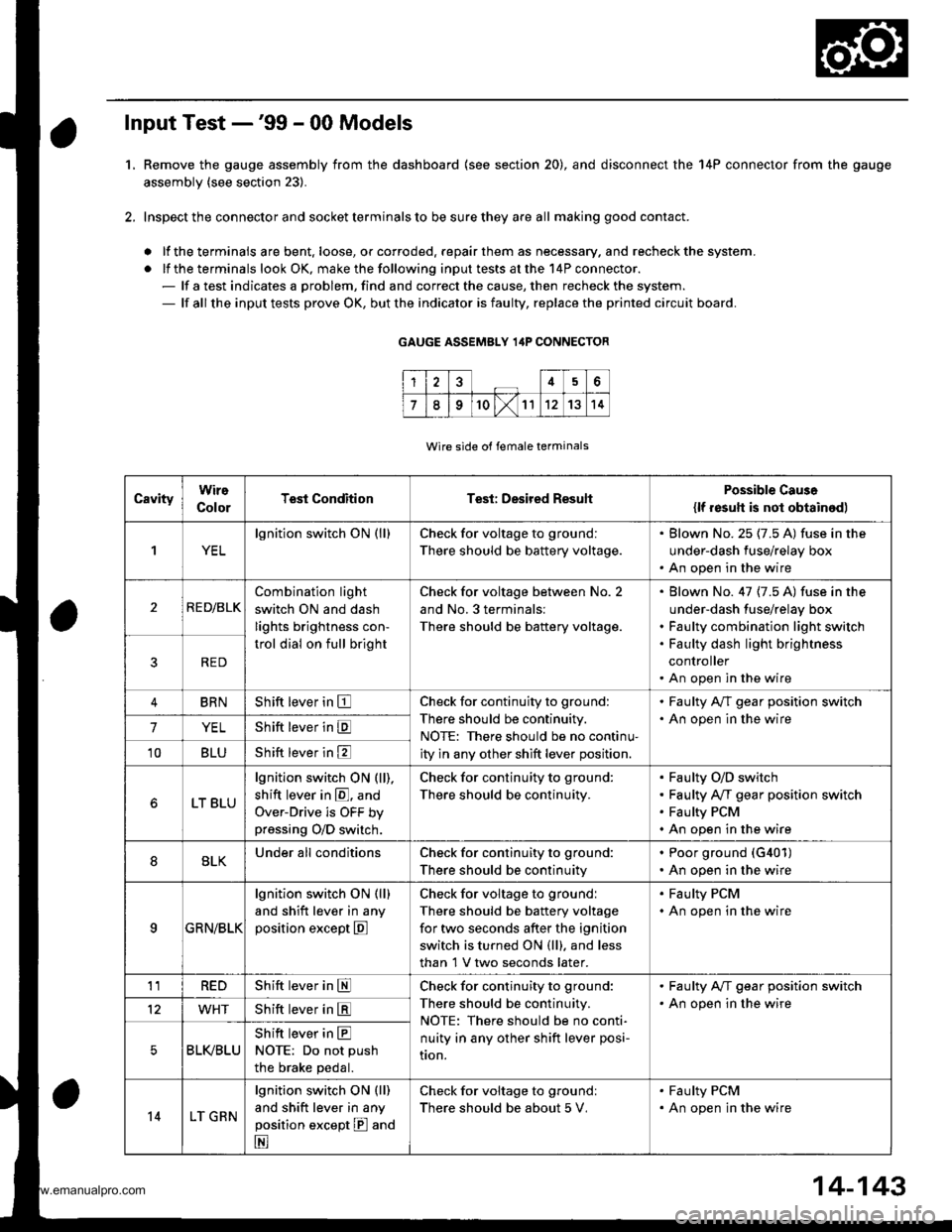

Input Test -'99 - 00 Models

Remove the gauge assembly from the dashboard {see section 20), and disconnect the 14P connector from the gauge

assembly (see section 23).

Inspect the connector and socket terminals to be sure they are all making good contact.

a lf the terminals are bent. loose, or corroded. repair them as necessary. and recheck the system.

. lf the terminals look OK, make the following input tests at the 14P connector.- lf a test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, but the indicator is faulty, replace the printed circuit board.

GAUGE ASSEMBLY 14P CONNECTOR

Wire side of female terminals

CavityWire

ColorTest ConditionTest: Desired ResuhPossible Caus6

{lf resutt is not obtainod)

1YEL

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage.

. Blown No.25 (7.5 A) fuse in the

under-dash fuse/relay box. An open in the wire

2RE D/BLK

Combination light

switch ON and dash

lights brightness con-

trol dial on full bright

Check for voltage between No. 2

and No.3 terminals:

There should be battery voltage.

Blown No. 47 {7.5 A) fuse in the

under-dash fuse/relay box

Faulty combination light switch

Faulty dash light brightness

controller

An open in the wire

5RED

BRNShift lever in ECheck for continuity to ground:

There should be continuity.

NOTE: There should be no continu-

ity in any other shift lever position.

. Faulty A/T gear position switch. An open in the wire7YELShift lever in E

'10BLUShift lever in E

LT BLU

lgnition switch ON (ll),

shift lever in E. and

Over-Drive is OFF bypressing O/D switch.

Check for continuity to ground:

There should be continuity.

Faulty O/D switch

Faulty A/T gear position switch

Faulty PCM

An open in the wire

8BLKUnder all conditionsCheck for continuity to ground:

There should be continuity

. Poor ground (G401)

. An open in the wire

9a:FI\|/Et| ta

lgnition switch ON (ll)

and shift lever in any

position except E

Check for voltage to groundl

There should be battery voltage

for two seconds after the ignition

switch is turned ON (ll). and less

than 1 V two seconds later.

. Faulty PCM. An open in the wire

11REDShift lever in SCheck for continuity to ground:

There should be continuity.

NOTE: There should be no conti-

nuity in any other shift lever posi-

Iton.

. Faulty A/T gear position switch. An open in the wire12WHTShift lever in E

BLI(BLU

Shift lever in ENOTE: Do not push

the brake pedal.

14LT GRN

lgnition switch ON (ll)

and shift lever in any

position except E and

E

Check for voltage to groundl

There should be about 5 V,

. Faulty PCM. An open in the wire

14-143

www.emanualpro.com

Page 846 of 1395

Steering

Special Toofs ............. 17-2

Component Locations

Index ................ ....... 17-3

Troubleshooting

General Troubleshooting ................ 1 7-4

Noise and Vibration ......................... 17-8

Fluid Leaks ............. 17-10

Inspection and Adiustment

Steering Operation .......................... 17-12

Power Assist Check

With Vehicle Parked ....................

Steering Linkage and Gearbox .......

Pump Belt

Rack Guide Adjustment ...................

Fluid Rep|acement ...................,,.,....

Pump Pressure Check .................,,...

*Steering Wheel

Removal ................. 17-18

*Steering Column

Removal/lnstallation ................ ....... 17 -2O

lnspection .............. 17-21

Steering Lock Replacement ............ 17 -22

Power Steering Hoses, Lines

Ffuid Leakage Inspection ................. 17 -23

Repfacement .......... 17-23

Power Steering Pump

Repfacement .......... 17-24

Disassembly ...........17-25

fnspection .............. 17-26

Reassembly ............ 17-28

Power Steering Gearbox

Removal ................. 17-31

Disassembly ........... 17-34

Reassembly ............ 17-40

Ball Joint Boot Replacement .......... 17-50

Installation ............. 17-51

17-12

17-13

17-14

l7-15

17-15

17-16

Disassembly/Reassembly............... 17-18

4'%/b.......... -r'-7--a/

SUPPLEN\EN AL RES\RA(N SYSTES{ (SRS\

This model has an SRS which includes a driver's airbag in the steering wheel hub. a passenger's airbag in the dashboardabove the glove box ('97 - 00 models), and seat belt tensioners in the seat belt retractors ('98 - 00 models). Informationnecessary to safely service the SRS is included in this Service Manual. ltems marked with an asterisk (*) on the contentspage include, or are located near, SBS components. Servicing. disassembling or replacing these items will require specialprecautions and tools, and should only be done by an authorized Honda oearer.

To avoid rendering the SRS inoperative, which could lead to peFonal iniury or death in the event of a sevore trontalcollision. allSRS service work must be performod by an authorized Honda dealer.lmproper service procedurgs, including incorrect removal and installalion of the SRS, could lead to personal iniurycaused by unintontional deployment of th€ airbags {'97 - 00 models), and seat belt tensioners ('98 - 00 modelsl.Do not bump the SRS unit. Otherwise, the system may lail in case ot a collision, or the airbags may deploy when theignition switch is ON (lll.

SRS electrical wiring harnesses are identitied by yellow colof coding. Ralated components are located in the steeringcolumn, front console, dashboard, dashboard lower panel, and in the dashboard above the glove box. Do not use elec-trical test equipment on these cilcuits,

www.emanualpro.com

Page 848 of 1395

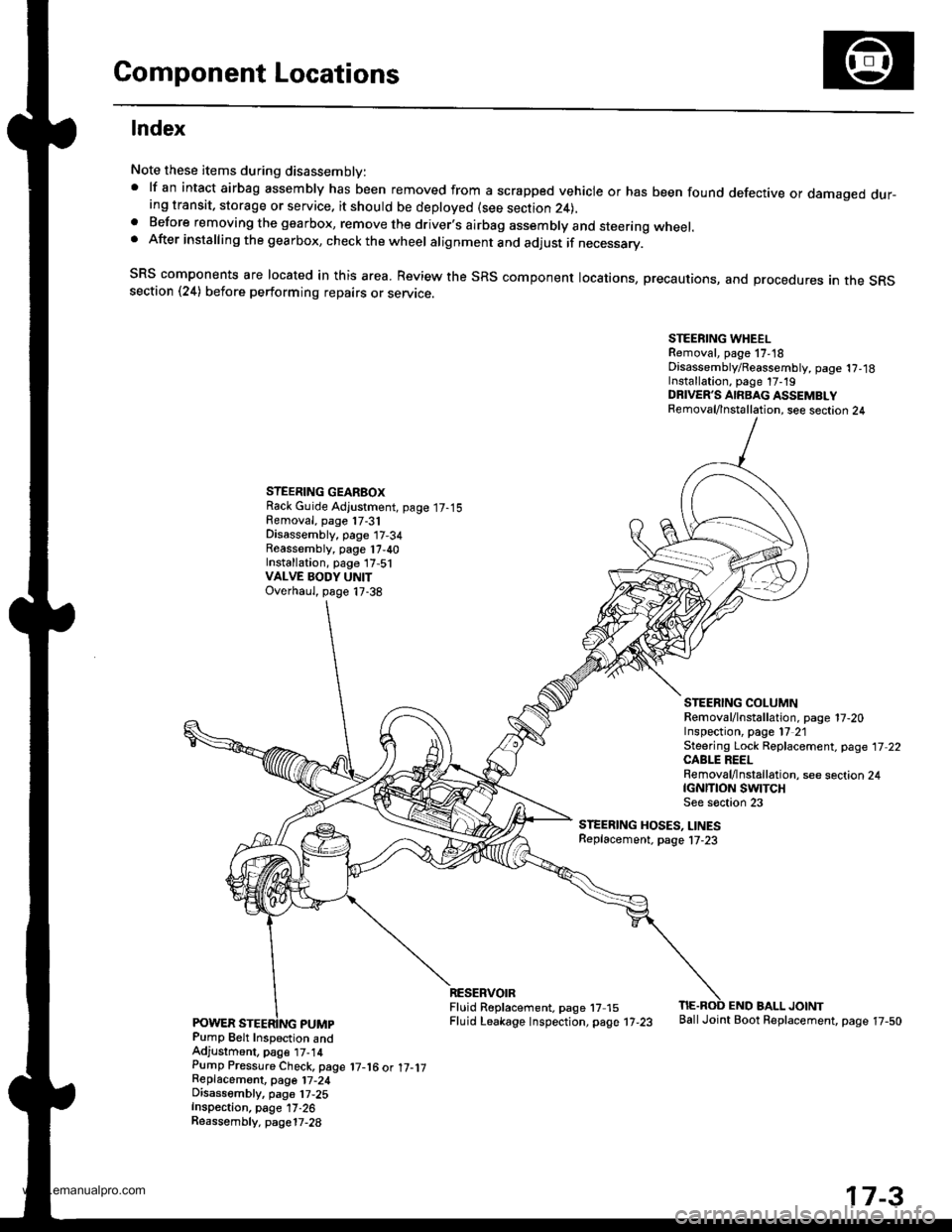

Component Locations

lndex

Note these items during disassembly:' lf an intact airbag assembly has been removed from a scrapped vehicle or has been found defective or damaged dur-ing transit, storage or service. it should be deployed (see section 24),a Before removing the gearbox, remove the driver.s airbag assembly and steering wheel.. After installing the gearbox, check the wheel alignment and adjust if necessary.

SRS components are located in this area. Review the SRS component locations, precautions, and procedures an the SRssection (24) before performing repairs or servrce.

STEERING WHEELRemoval, page 17,18Disassembly/Reassembly, page 1?,18Installation, page 17-19DRIVER'S AIRBAG ASSEMBLYRemoval/lnstallation, see section 24

STEERING GEARBOXRack Guide Adjustment, page 17-15Removal, page 17-31Disassembly, page 17-34Reassembly, page 17,40Installation, page 17,51VALVE BODY UNITOverhaul, page 17-38

STEERING COLUMNRemoval/lnstallation. page 17-20Inspection, page l7 21Steering Lock Replacement, page 17 22CABLE REELRemoval/lnstallation, see section 24tcNrnoN swtTcHSee s€ction 23

STEERING HOSES, LINESReplacement. page l7-23

Pump Belt Inspection andAdjustment, pag€ t7-14Pump Pressure Check, page 17-16 ot 17-1jReplacemont, page 17-24Disassembly, pa96 17,25Inspection, page 17-26Reassembly. page17-28

RESERVOIRFluid R6placement. page 17 15Fluid Leakage lnspection, page 17-23

END BALL JOINTBallJoint Boot Replacement, page 17-50

17-3

www.emanualpro.com

Page 849 of 1395

Troubleshooting

General Troubleshootin g

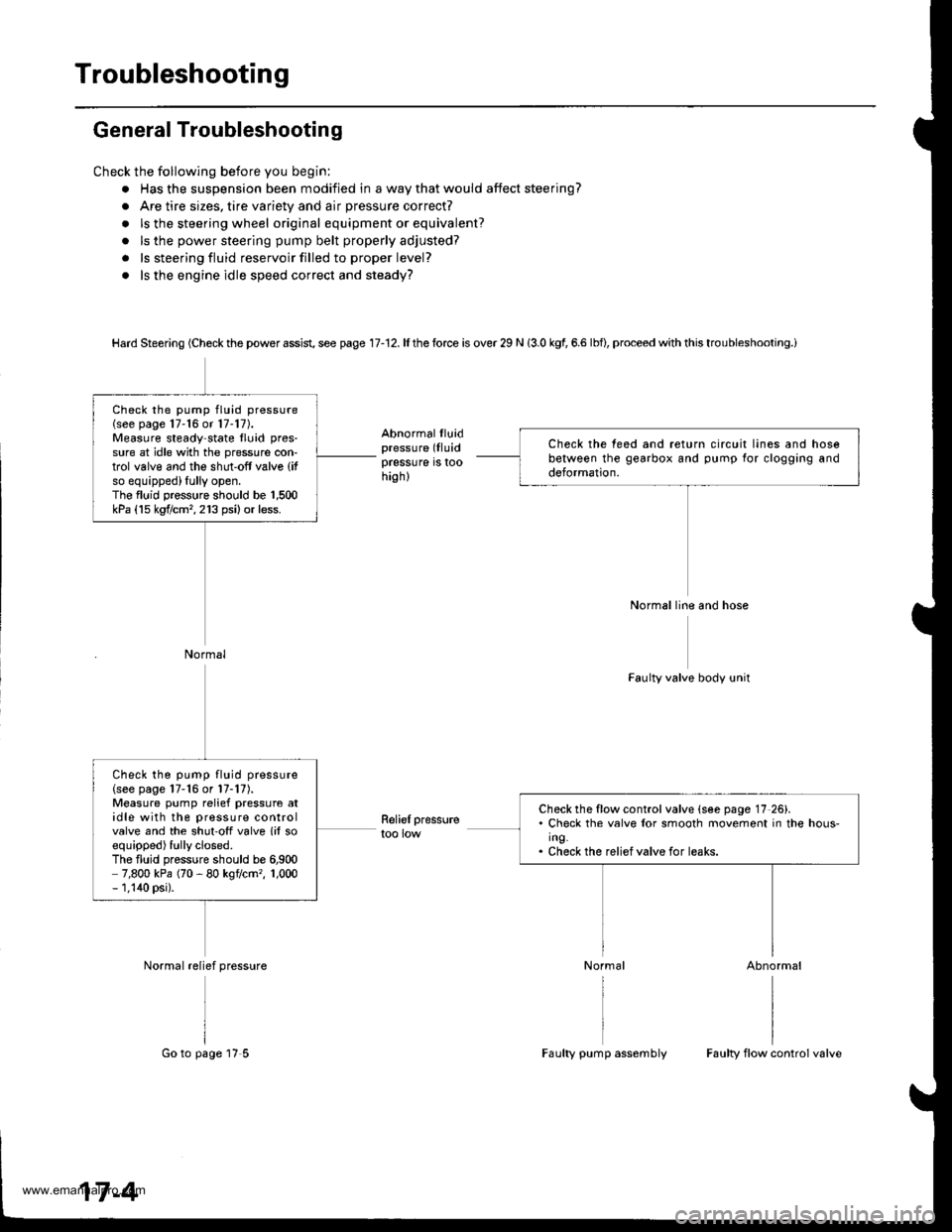

Check the following before you begin:

. Has the suspension been modified in a way that would affect steering?

. Are tire sizes, tire variety and air pressure correct?

. ls the steering wheel original equipment or equivalent?

. ls the power steering pump belt properly adjusted?

. ls steering fluid reservoir filled to proper level?

. ls the engine idle speed correct and steady?

Hard Steering (Check the power assist, see page 17-12. lf the force is over 29 N (3.0 kgl 6.6 lbfl, proceed with this troubleshooting.i

Abnormalthiidpressure (Iluidpressure is toohigh)

Relief pressuretoo low

Faulty valve body unit

Abnormal

Check the teed and return circuit lines and hosebetween the gearbox and pump for clogging anddeformation.

Normal line and hose

Check the pump fluid pressure(see page 17-16 or 17-17).Measure steady state lluid pres-

sure at idle with the pressure con-trol valve and the shut-off valve (it

so equipped) fully open.The fluid pressure should be 1,500kPa (15 kgf/cm,,213 psi)or less.

Normal

Check the flow control valve (see page 17 26).. Check the valv€ lor smooth movement in the hous-ing.. Check the relief valve for leaks.

Check the pump fluid pressure(see page 17-16 or l7-17).Measure pump relief pressure atidle with the pressure controlvalve and the shut'off valve lil soequipped) fully closed.The fluid pressure should be 6,9007,800 kPa (70 - 80 kgflcm,, 1,000- 1,140 psi).

Normal relief pressure

17-4

Go to page 17 5Faulty pump assemblyFaulty flow control valve

www.emanualpro.com

Page 850 of 1395

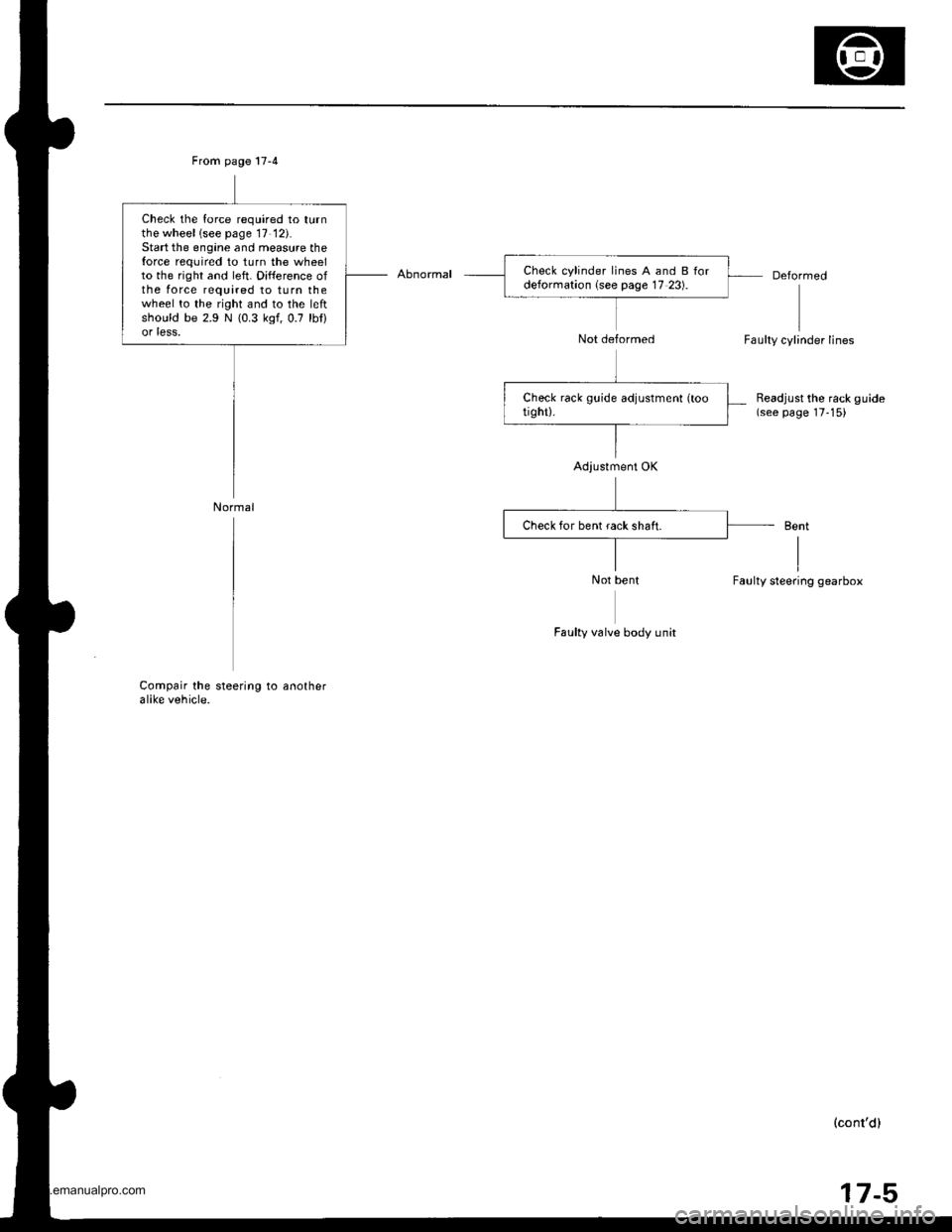

Abnormal

Not deformed

Deformed

Faulty cylinder lines

Readjust the rack guide(see page 17-15)

Bent

IFaulty steering gearbox

Compair the steering to anotheralike vehicle.

(cont'd)

17-5

Adjustment OK

Check the force required to turnthe wheel lsee page 17 12).Start the engine and measure theforce required to turn the wheelto the right and left. Difference ofthe force required to turn thewheel to the right and to the leftshould be 2.9 N (0.3 kgf,0.7 lbt)or less,

Normal

www.emanualpro.com