air box HONDA CR-V 2000 RD1-RD3 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 852 of 1395

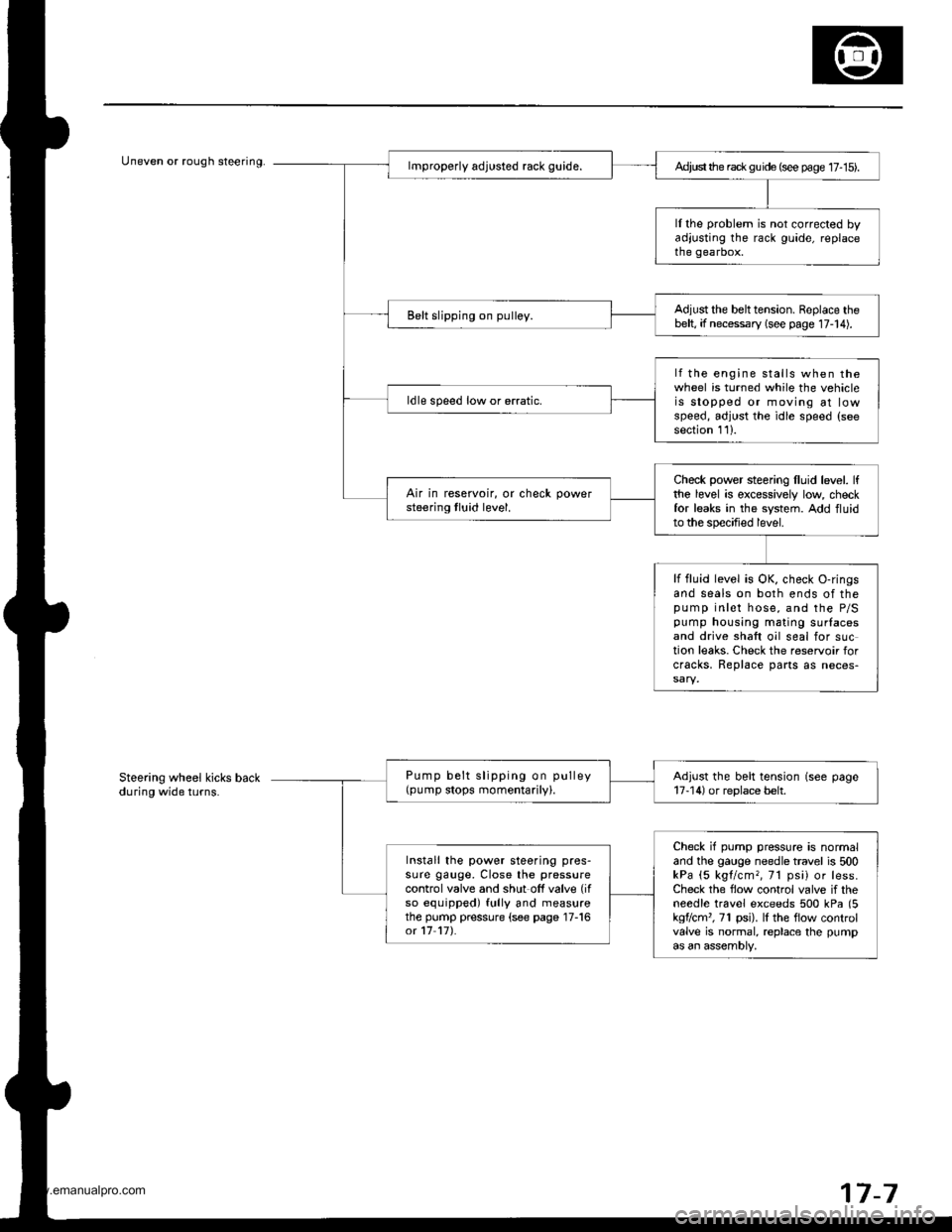

Uneven or rough steering.Ad,ust the rack gu ide (see page 17- 15).

ll the problem is not corrected byadjusting the rack guide, replacethe gearbox.

Adjust the belttension. Replace thebelt, if necessary (see page 17-14).Belt slipping on pulley.

lf the engine stalls when thewheel is turned while the vehicleis stopped or moving at lowspeed, adjust the idle speed (seesection 111.

ldle speed low or erratic.

Check power steering lluid level. lfthe level is excessively low checkfor leaks in the system. Add fluidto the specified level.

Air in reservoir, or check powersteering tluid level.

lf fluid level is OK, check O-ringsand seals on both ends of thepump inlet hose, and the P/Spump housing mating surlacesand drive shaft oil seal for suction leaks. Check the reservoir forcracks, Replace parts as neces-

Pump belt slipping on pulley(pump stops momentarily).Adjust the belt tension (see page17-14) or replace belt.

Check if pump pressure is normaland the gauge needle travel is 500kPa (5 kgl/cm,, 71 psi) or less.Check the flow control valve if theneedle travel exceeds 500 kPa (5kgflcm'�, 71 psi). lI the flow controlvalve is normal, replace the pumpas an assembly,

Install the power steering pres-sure gauge, Close the pressurecontrol valve and shut off valve (if

so equipped) fully and measurethe pump pressure (see page 17-16ot 17 17).

Steering wheel kicks backduring wide turns.

7-7

www.emanualpro.com

Page 860 of 1395

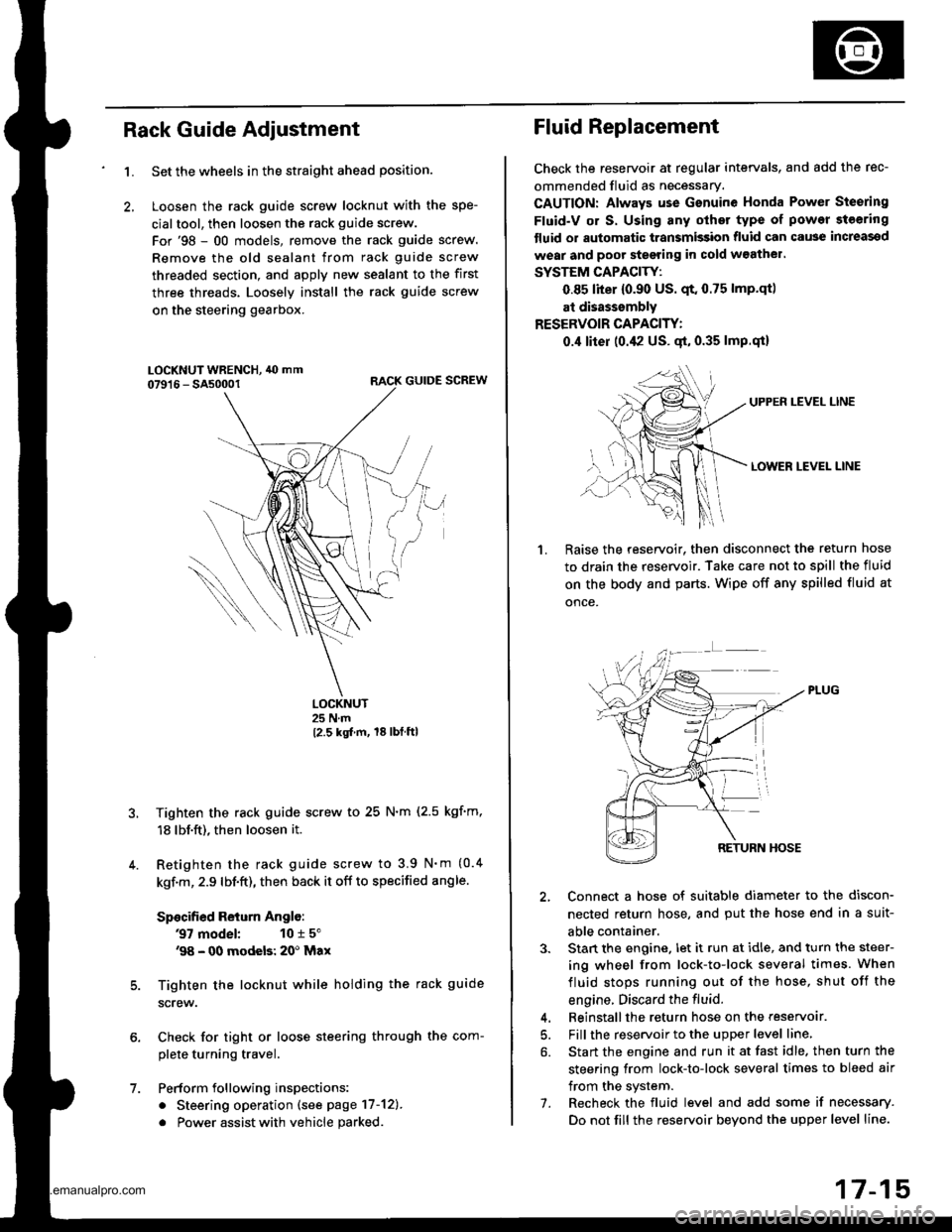

Rack Guide Adjustment

1.

6.

7.

5.

4.

Set the wheels in the straight ahead position.

Loosen the rack guide screw locknut with the spe-

cialtool, then loosen the rack guide screw.

For'98 - 00 models, remove the rack guide screw.

Remove the old sealant from rack guide screw

threaded section, and apply new sealant to the first

three threads. Loosely install the rack guide screw

on the steering gearbox.

RACK GUIDE SCREW

LOCKNUT25 N.m

12.5 kgt m, 18lbtftl

Tighten the rack guide screw to 25 N.m (2.5 kgf'm,

18 lbf.ft), then loosen it.

Retighten the rack guide screw to 3.9 N'm (0.4

kgf.m, 2.9 lbf.ft), then back it off to specified angle.

Specified Return Anglo:

37 model: 10 r 5"'98 - 00 modeb: 20' Max

Tighten the locknut while holding the rack guide

screw.

Check for tight or loose steering through the com-

plete turning travel.

Perform following inspections:

. Steering operation (see page 17-12).

. Power assist with vehicle parked

Fluid Replacement

Check the reseryoir at regular intervals, and add the rec-

ommended fluid as necessary.

CAUTION: Always use Gsnuine Honda Power Steering

Fluid-V or S. Using any other type of power steering

tluid or automatic transmission fluid can cause increassd

wear and poor steering in cold w3athel.

SYSTEM CAPACITY:

0.85 liter {0.90 US. qt. 0.75 lmp.qtl

at disasssmbly

RESERVOIR CAPACITY:

0.,1 liter (0.42 US. gt, 0.35 lmp.qi)

UPPEN LEVEL LINE

LOWER LEVEL LINE

1.Raise the reservoir. then disconnect the return hose

to drain the reservoir. Take care not to spill the fluid

on the body and parts. Wipe off any spilled fluid at

once.

2, Connect a hose of suitable diameter to the discon-

nected return hose, and put the hose end in a suit-

able container.

3. Stan the engine. let it run at idle, and turn the steer-

ing wheel from lock-to-lock several times. When

fluid stops running out of the hose, shut off the

engine. Discard the fluid.

4. Beinstallthe return hose on the reservoar.

5. Fill the reservoir to the upper level line,

6. Start the engine and run it at fast idle. then turn the

steering from lock-to-lock several times to bleed air

from the system.

7. Recheck the fluid level and add some if necessary.

Do not fill the reservoir beyond the upper level line.

www.emanualpro.com

Page 861 of 1395

lnspection and Adjustment

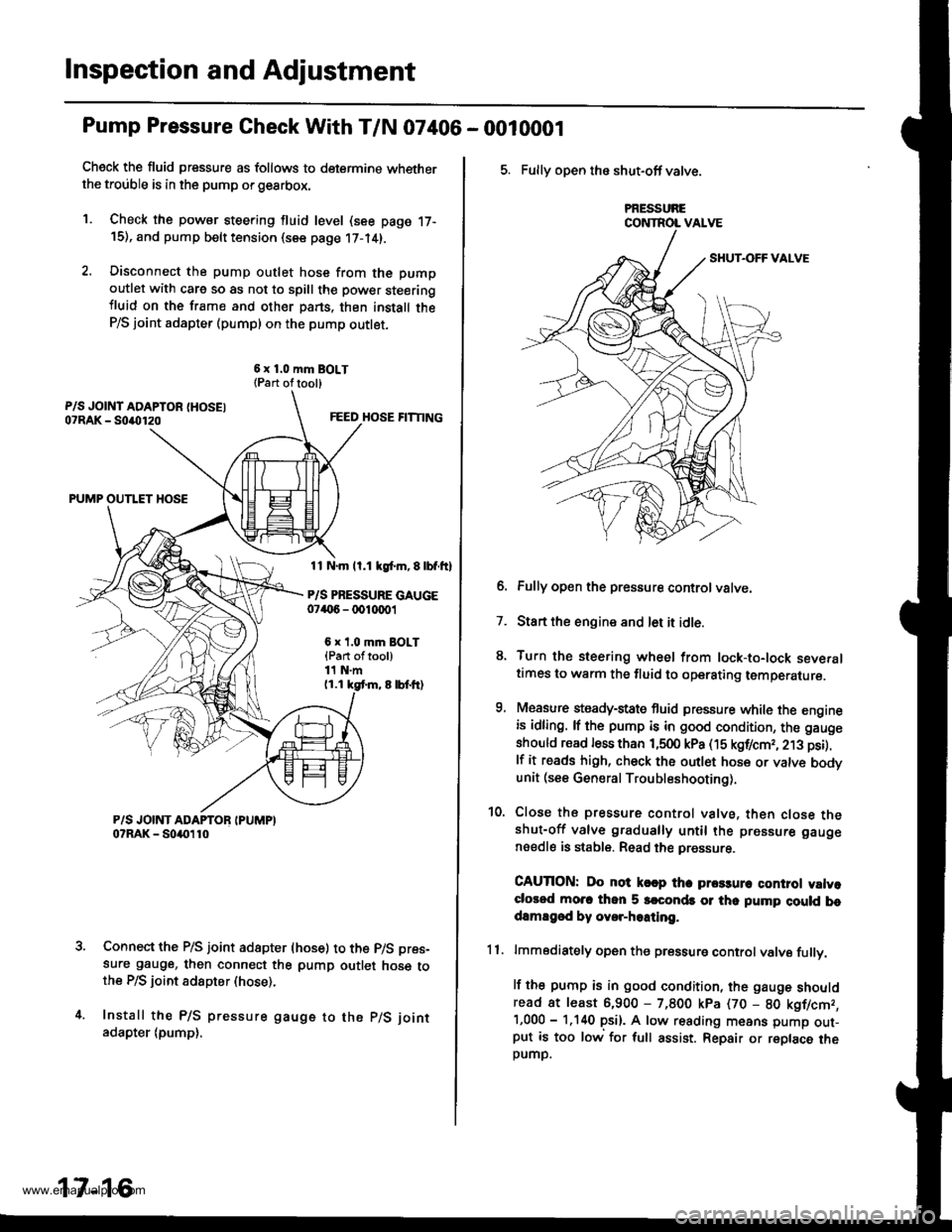

Pump Pressure Gheck With T/N 07406 - 0010001

Check the fluid pressure as follows to determine whetherthe trouble is in the pump orgearbox.

1. Check the powsr steering fluid level (see page 17-15), and pump belt tension (see page 17-14).

2. Disconnect the pump outlet hose from the pump

outlet with care so as not to spill the pow€r steeringiluid on the frame and other pans. thon install theP/S joint adapter (pumpl on the pump outlet.

6 x 1.0 mm BOLT{Part oftool)

FEED HOSE FITTING

PUMP OUTLET HOSE

11 N.m ll.1 kgl.m, E lbf.ftl

P/S PRESSURE GAUGE07('6 - 0010001

6 x t.0 mm BOLT{Part oftool)11 N.m(1.1 kgt m, 8 lbf.tr)

Connect the P/S joint adapter (hose) to the p/S pres-

sure gauge, then connect the pump outlet hose tothe P/S ioint adspter (hose).

Install the P/S pressure gauge to the p/S joint

adapter (pump),

17-16

5. Fully open the shut-off valve.

PRESSURECONTROL VALVE

6. Fully open the pressure controlvatve.

7. Start the engine and let it idle.

8. Turn the steering wheel from lock-to-lock severaltimes to warm the fluid to operating temperature.

9, Measure steady-state fluid pressure while the engineis idling. lf the pump is in good condition, the gauge

should read less than 1,500 kPa (15 kgf/cmr, 213 psi).

lf it reads high, check the outlet hose or valve bodvunit (see General Troubleshooting).

10. Close the pressure control valve, then close theshut-off valve gradually until the pressure gauge

nsedle is stable. Read the pressure.

CAUTION: Do not k€ap tha prca3un control valvoclorod mo.c thon 5 srconds or thc pump cluld bodamEgod by ovor-hoating.

11. lmmodiately open the pressure controlvalve fullv.

lf the pump is in good condition, the gauge shouldread at least 6,900 - 7,800 kpa (70 - 80 kgflcmr,'1,000 - 1.140 psi). A low reading means pump out-put is too low for full assist. Repair or replace theDUMD.

www.emanualpro.com

Page 862 of 1395

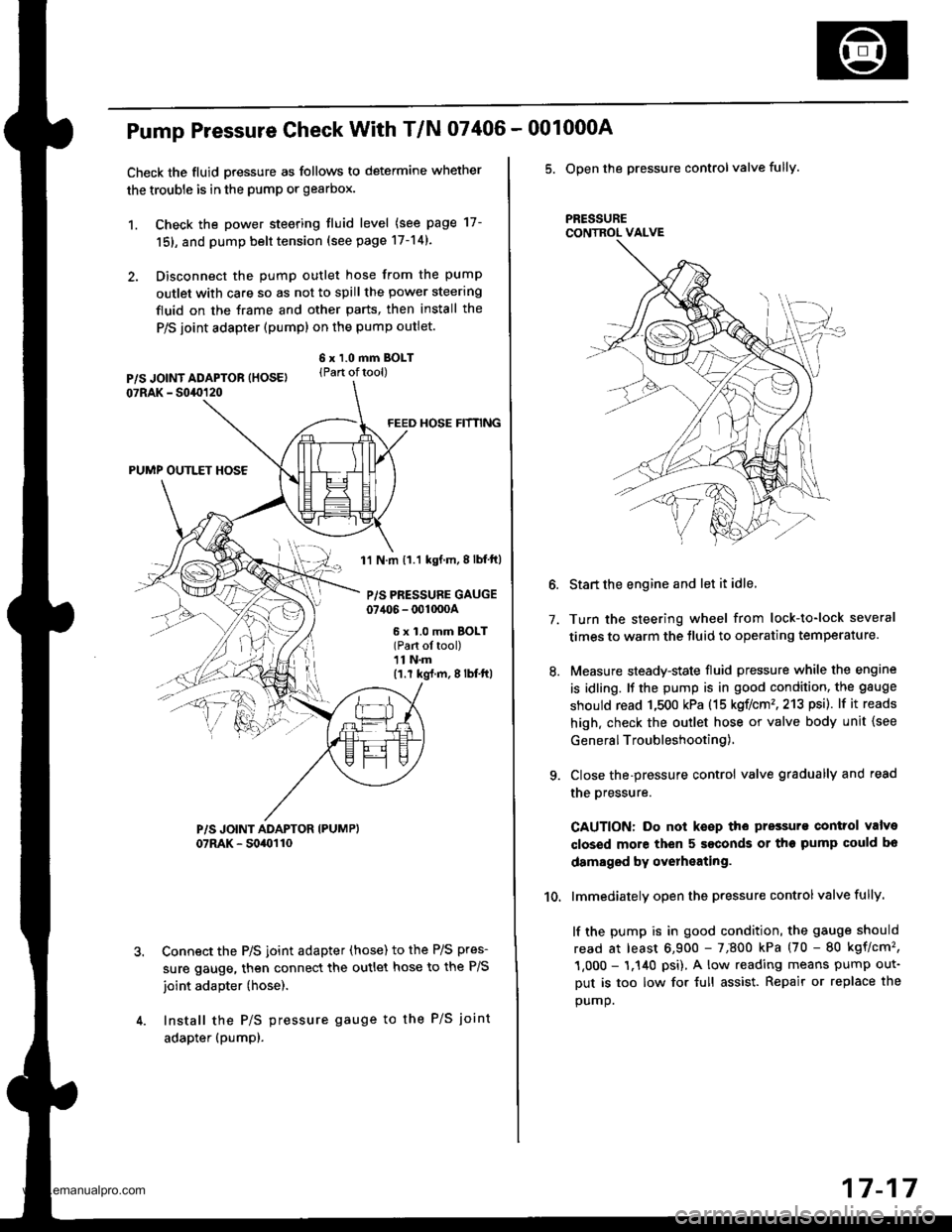

Pump Pressure Check With T/N 07406 -

Check the fluid pressure as follows to determine whether

the trouble is in the pump or gearbox.

1. Check the power steering tluid level (see page 17-

151, and pump belt tension (see page 17-14).

2. Disconnect the pump outlet hose from the pump

outlet with care so as not to spill the power steering

fluid on the frame and other parts, then install the

P/S joint adapter (pump) on the pump outlet.

6 x 1.0 mm BOLT(Part oftool)

FEED HOSE HfNNG

PUMP OUTLET HOSE

1'l N.m 11.1 kgf.m,8lbf ft)

P/S PRESSURE GAUGE07406 - 001000A

6 x 1.0 mm BOLT(Part ol tool)11 N.m(1.r kg{.m,8lbf'ft|

Connect the P/S joint adapter (hose) to the P/S pres-

sure gauge, then connect the outlet hose to the P/S

joint adapter (hose).

Install the P/S pressure gauge to the P/S joint

adapter (pumpl.

001000A

5. Open the pressure controlvalve fully.

PRESSURECONTROL VALVE

7.

10.

Start the engine and let it idle.

Turn the steering wheel from lock-to-lock several

times to warm the tluid to operating temperature.

Measure steady-state fluid pressure while the engine

is idling. It the pump is in good condition, the gauge

should read 1,500 kPa (15 koflcm'�,213 psi). lf it reads

high. check the outlet hose or valve body unit {see

General Troubleshooting),

Close the-pressure control valve gradually and read

the oressure.

CAUTION: Do not keep the pressurs control valve

closed more then 5 seconds or the pump could bo

damaged by overheating.

lmmediately open the pressure controlvalve fully.

lf the pump is in good condition, the gauge should

read at least 6,900 - 7;800 kPa (70 - 80 kgflcm'�,

1,000 - 1.140 psi), A low reading means pump out-

Dut is too low for {ull assist. Repair or replace the

oumo.

17-17

www.emanualpro.com

Page 876 of 1395

Power Steering Gearbox

Removal

Note these items during removal:

. Using solvent and a brush, wash any oil and dirt off

the valve body unit its lines, and the end if the gear-

box. Blow dry with compressed air.

. Be sure to remove the steering wheel before discon-

necting the steering joint. Damage to the cable reel

can occur.

. With 4WD. tilt the engine with a jack to expand the

clearance between the transfer assembly and rear

beam when removing the steering gearbox from the

rear oeam.

Do not remove the steering gearbox by removing the

transfer assembly from the transmission.

1. Drain the power steering fluid as described on page'17-15.

Raise the vehicle, and suppon it on safety stands in

the proper locations (see section 1).

Remove the front wheels,

Remove the drive/s airbag assembly {see section 24).

Remove the steering wheel {see page 17-18).

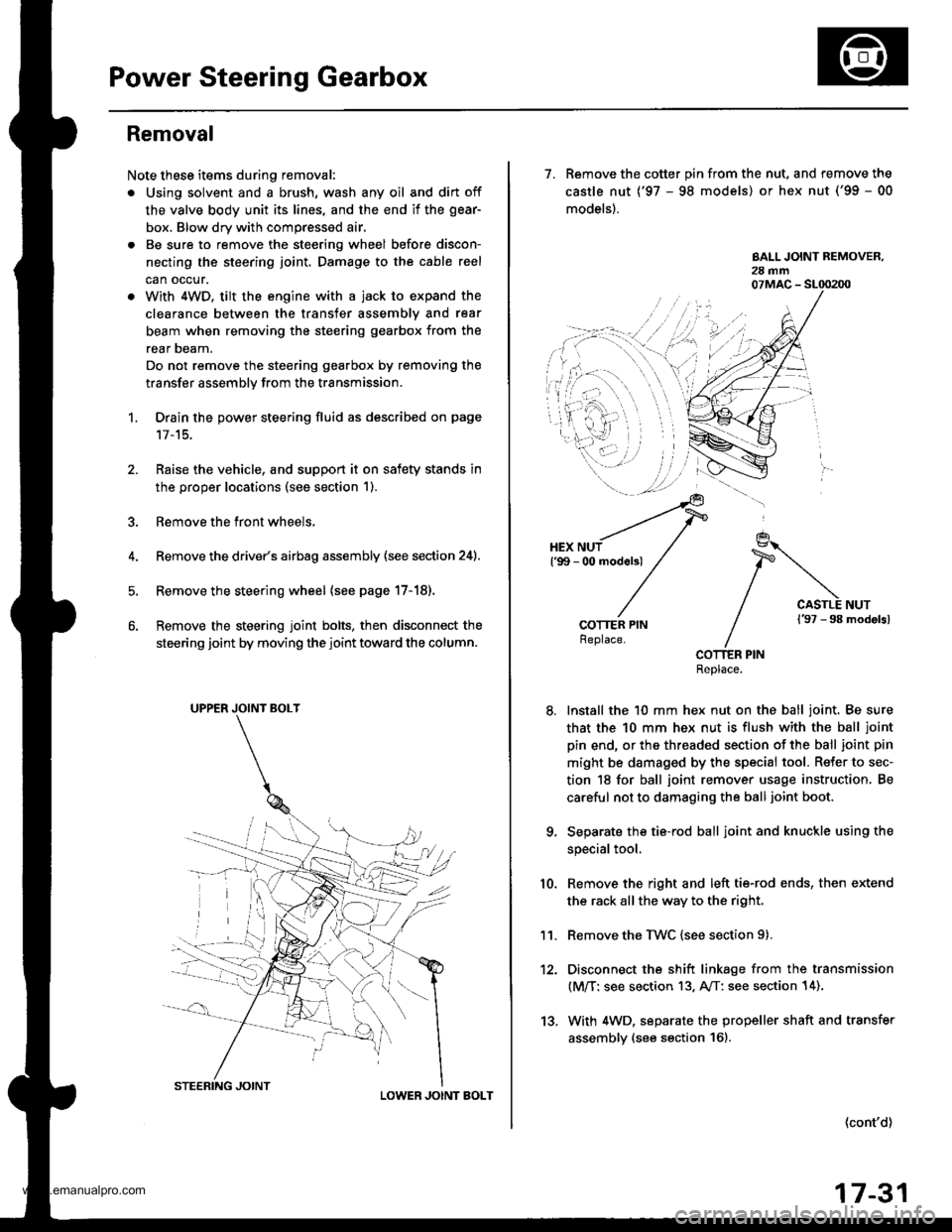

Remove the steering joint bolts, then disconnect the

steering joint by moving the joint toward the column.

UPPER JOINT BOLT

LOWER JOINT BOLT

13.

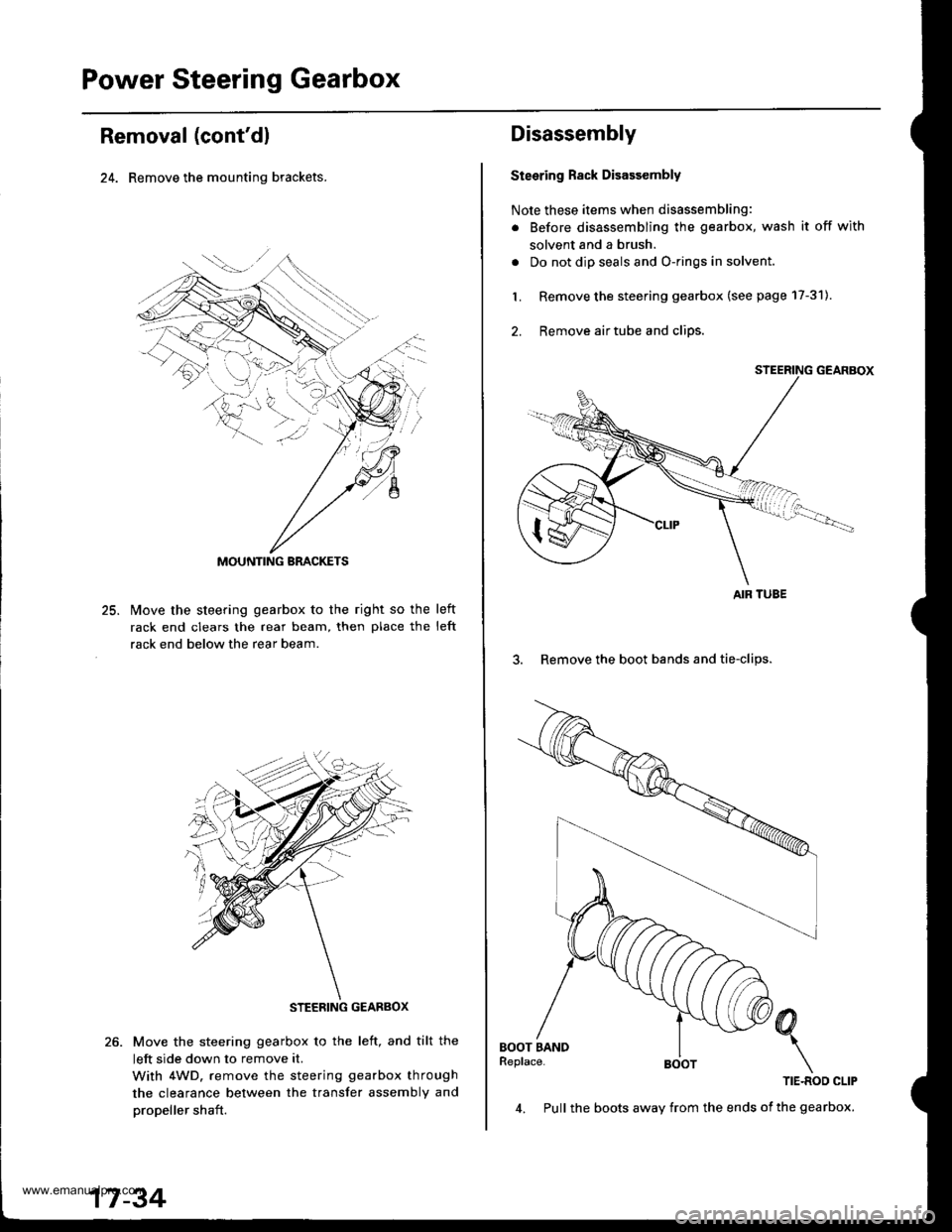

7. Remove the cotter pin from the nut, and remove the

castle nut {'97 - 98 models) or hex nut ('99 - 00

models).

COTTER PINReplace.

Install the 10 mm hex nut on the ball joint. Be sure

that the 10 mm hex nut is flush with the ball joint

pin end, or the threaded section of the ball joint pin

might be damaged by the special tool. Refer to sec-

tion 18 for ball joint remover usage instruction, Be

careful not to damaging the ball joint boot.

Separate the tie-rod ball joint and knuckle using the

special tool.

Remove the right and left tie-rod ends, then extend

the rack all the way to the right.

Remove the TWC (see section 9).

Disconnect the shift linkage from the transmission

(M/T: see section 13, A/T: see section 14).

With 4WD. separate the propeller shaft and transfer

assembly (see section 161.

10.

11.

(cont'd)

17-31

www.emanualpro.com

Page 879 of 1395

Power Steering Gearbox

Removal (cont'dl

24. Remove the mounting brackets.

25.lvlove the steering gearbox to the right so the

rack end clears the rear beam, then place the

rack end below the rear beam.

left

left

Move the steering gearbox to the left, and tilt the

left side down to remove it.

With 4WD. remove the steering gearbox through

the clearance between the transfer assembly and

propeller shaft.

MOUNTING BRACKETS

STEEBING GEARBOX

17 -34

4. Pull the boots away from the ends of the gearbox.

Disassembly

Steering Rack Disassembly

Note these items when disassembling:

. Before disassembling the gearbox, wash it off with

solvent and a brush.

. Do not dip seals and O-rings in solvent.

1. Remove the steering gearbox (see page 17-31).

2. Remove airtube and clips.

3. Remove the boot bands and tie-clips.

AIR TUBE

www.emanualpro.com

Page 885 of 1395

Power Steering Gearbox

Reassembly

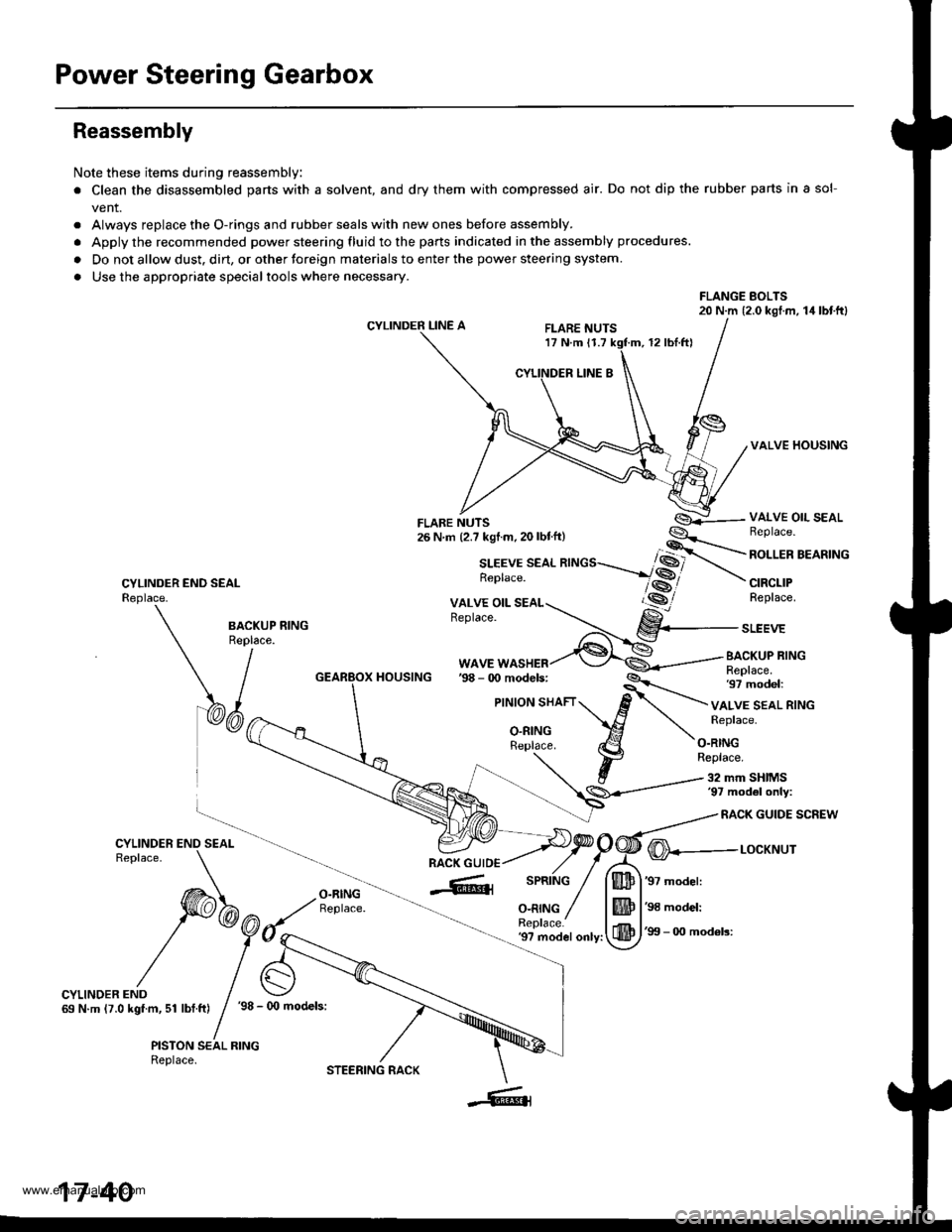

Note these items during reassembly

. Clean the disassembled parts with a solvent, and dry them with compressed air. Do not dip the rubber parts in a sol-

vent.

. Always replace the O-rings and rubber seals with new ones before assembly.

. Apply the recommended power steering fluid to the parts indicated in the assembly procedures.

. Do not allow dust. dirt, or other toreign materials to enter the power steering system.

. Use the appropriate specialtools where necessary.

FLANGE BOLTS20 N.m (2.0 kgl.m, 14lbtftl

CYLINDER LINE AFLARE NUTS17 N.m 11.712 rbl.ftl

VALVE HOUSING

CYLINDER END SEALReplace.

VALVE OIL SEALBeplace.

ROLLER BEARING

CIRCLIPReplace.

BA.KUP RING

\/^"

WAVE WASHERBACKUP RINGReplace.97 model:HOUSING

VALVE SEAL RINGReplace.

O.RINGReplace.

32 mm SHIMS'97 mod6l only:

RACK GUIDE SCREW

O-RINGReplace.

@---r-ocxr'rur

'97 model:

'98 model:

'99 - 0O mod6ls:'9? model only:

CYLINDER END69 N.m (7.0 kgf.m, 51 lbf.ft)'98 - (x) models:

PISTON SEAL RINGReplace.

17-40

STEERING RACK

www.emanualpro.com

Page 895 of 1395

Power Steering Gearbox

Reassembly (cont'd)

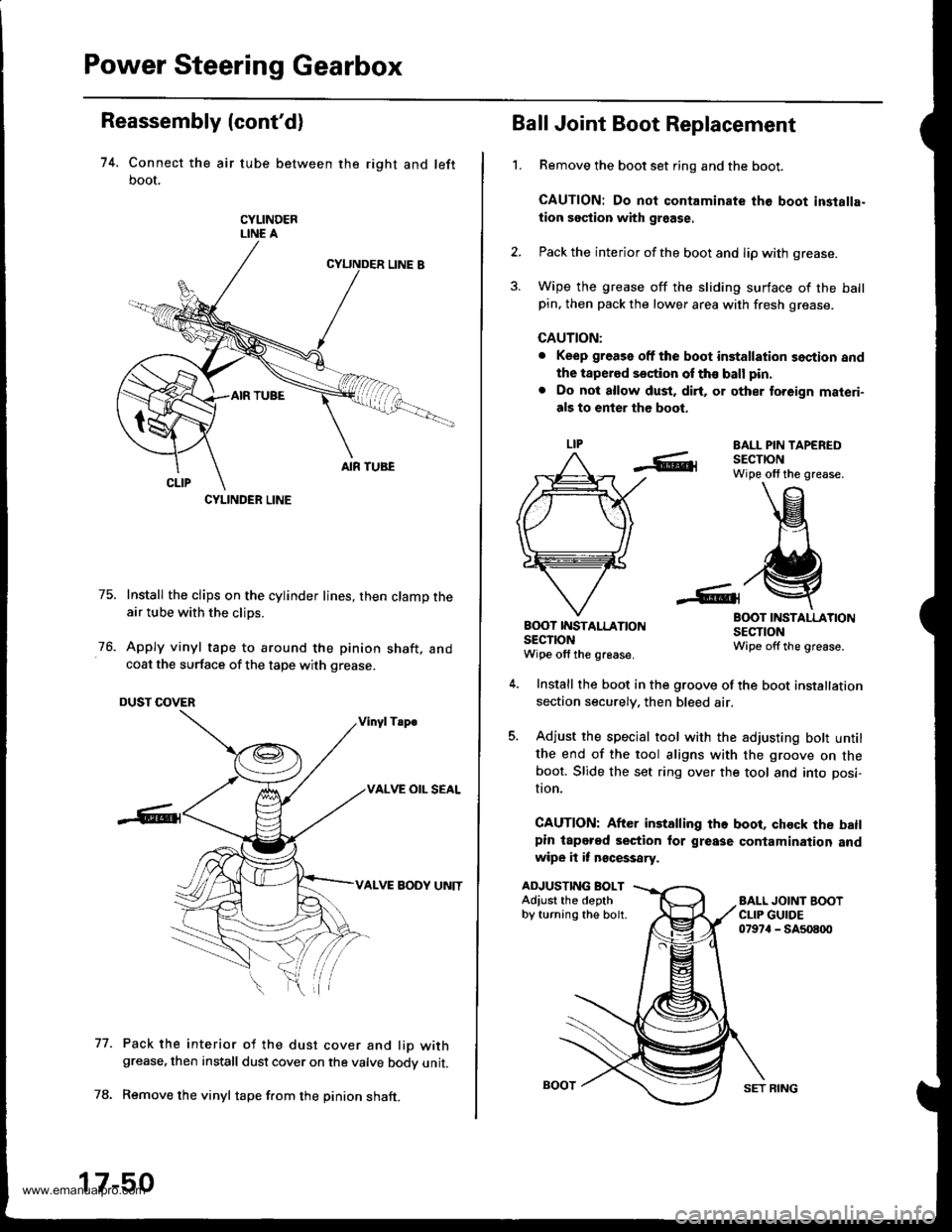

74. Connect the air tube between the right and left

boot,

CYLINDERLINE A

75. Install the clips on the cylinder lines, then clamp theair tube with the clips.

76. Apply vinyl tape to around the pinion shaft, andcoat the surface of the tape with grease.

DUST COVER

Vinyl Tsp€

VALVE OIL SEAL

VALVE BODY UNIT

Pack the interior of the dust cover and lio withgrease, then install dust cover on the valve bodv unit.

Remove the vinyl tape f.om the pinion shaft.

77.

CYLINDER LINE

17-50

SET RING

't.

Ball Joint Boot Replacement

Remove the boot set ring and the boot.

CAUTION: Do not contaminate the boot inslalla-

tion section with graase.

Pack the interior of the boot and lip with grease.

Wipe the grease off the sliding surface of the ballpin. then pack the lower area with fresh grease.

CAUTION:

. Keep grease off the boot installation section and

the tapered section of th€ ball pin.

. Do not allow dust, dirt, or other to.eign materi-

als to enter the boot.

EALL PIN TAPEREDSECTIONWipe olf the grease.

BOOT INSTALLATIONSECTIONWipe offthe grease.

B(X)T IT{STALLATIONsEclroNWipe off the grease.

ADJUSTING BOLTAdiust the depthby turning the bolt.

Install the boot in the groove of the boot installation

section securely. then bleed air.

Adjust the special tool with the adjusting bott untilthe end of the tool aligns with the groove on theboot. Slide the set ring over the tool and into posi-

I|on.

CAUTION: After installing the boot, chock the batlpin lapered section for grease contamination andwipe it it n€cessary.

www.emanualpro.com

Page 896 of 1395

lnstallation

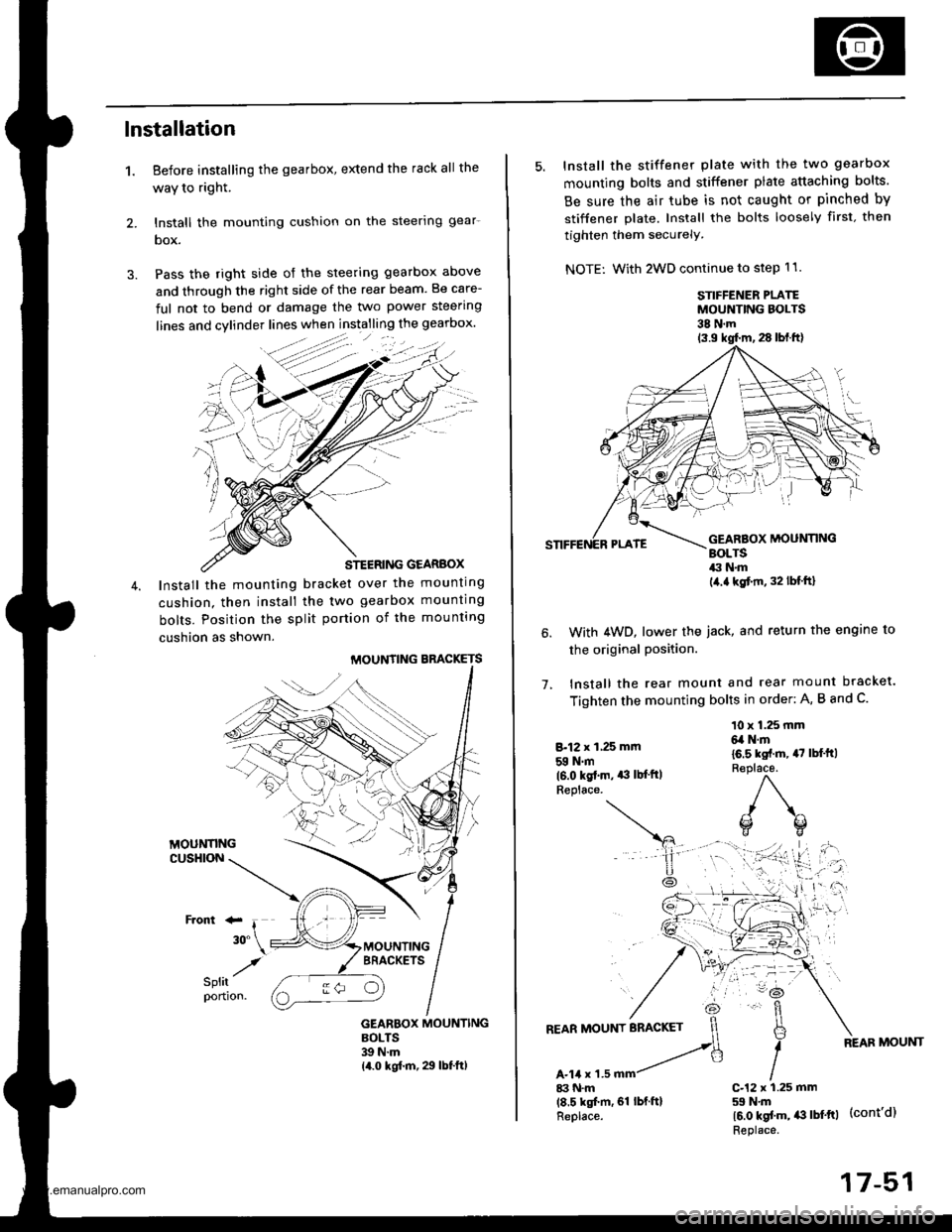

1. Before installing the gearbox, extend the rack all the

waY to right.

2. lnstall the mounting cushion on the steerlng gear-

box.

3. Pass the right side of the steering gearbox above

and through the right side of the rear beam. Be care-

ful not to bend or damage the two power steering

STEERING GEARBOX

Install the mounting bracket over the mounting

cushion. then install the two gearbox mounting

bolts. Position the split portion of the mounting

cushion as shown.

MOUNTING BBACKETS

GEARBOX MOUNTINGBOLTS39 N.m14.0 kgf.m, 29 lbf.ft)

:-

/

5. Install the stiffener plate with the two gearbox

mounting bolts and stiffener plate attaching bolts.

Be sure the air tube is not caught or pinched by

stiffener plate. Install the bolts loosely first. then

tighten them securely.

NOTE: With 2WD continue to step 11.

STIFFENER PLATEMOUNTING BOLTS38 N.m

1.

With 4WD, lower the iack, and return the engine to

the original Position.

lnstall the rear mount and rear mount bracket.

Tighten the mounting bolts in order: A, B and C.

8.12 x 1,25 mm

59 N.m(6.0 kgt.m. *l lb{'ftlReplace.

10 x 1.25 mm6,a N.m

16.5 kst.m, 47 lbl'ft)R€place.

)\^

o(]

17-51

www.emanualpro.com

Page 898 of 1395

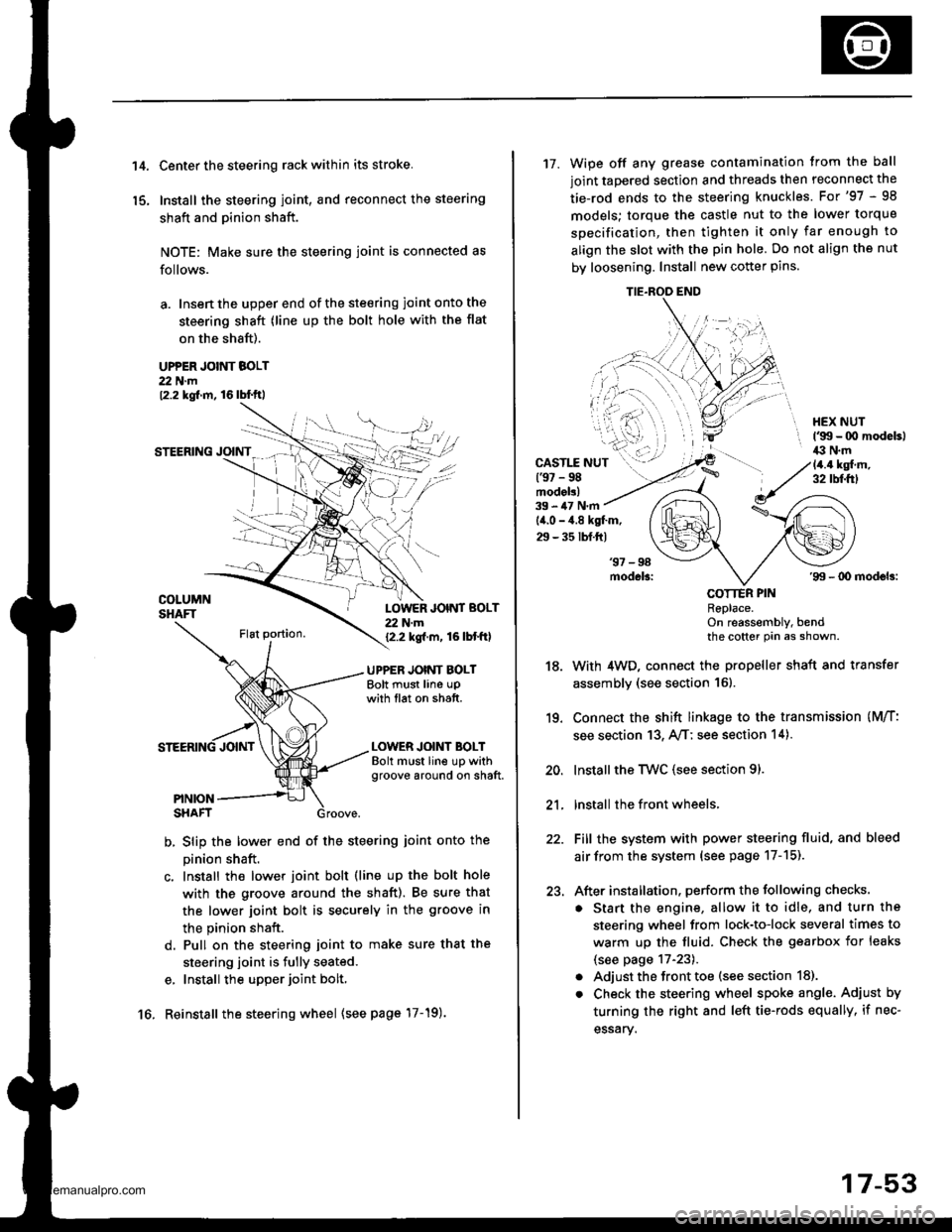

't 4.

15.

Center the steering rack within its stroke.

Install the steering joint, and reconnect the steering

shaft and pinion shaft.

NOTE: Make sure the steering joint is connected as

follows.

a. Insen the upper end of the steering joint onto the

steering shaft (line up the bolt hole with the flat

on the shaft).

UPPER JOINT BOLT22 N.m12.2 kgf.m, 16lbl.ft,

STEERING JOINT

COLUMNSHAFTLOWER JOINT BOLT22 N.m12.2 kgf.m, 16lbtftl

UPPER JOINT BOLTBolt must line upwith tlat on shatt.

LOWER JOINT BOLTBolt must line up withgroove around on shaft.

PINIONSHAFT

b, Slip the lower end of the steering ioint onto the

pinion shaft.

c. Install the lower joint bolt (line up the bolt hole

with ths groove around the shaft). Be sure that

the lower joint bolt is securely in the groove in

the pinion shaft.

d. Pull on the steering joint to make sure that the

steering joint is fully seated.

e, Install the upper joint bolt,

Reinstall the steering wheel {see page'17-19).16.

17-53

17. Wipe off any grease contamination trom the ball

joint tapered section and threads then reconnect the

tie-rod ends to the steering knuckles. For'97 - 98

models; torque the castle nut to the lower torque

specification, then tighten it only far enough to

align the slot with the pin hole. Do not align the nut

by loosening. Install new cotter pins.

CAST1T NUT(9t - 98modol!)

HEX NUTl'g!t - 00 modeb)il:l N.m14.4 ksl.m,32 tbf.f0

39 - iU N'm

lil.o - 4.8 kgl.m,

29 - 35 tbf.ftl

18.

19.

20.

21.

22.

23.

'99 - lD modeb:

COTTER PINRePlace.on reassembly, bendthe cotter Pin as shown.

With 4WD, connect the propeller shaft and transfer

assembly (see section 16).

Connect the shift linkage to the transmission (M/T:

see section 13, A,/T; see section 14).

Installthe Twc (see section 91.

lnstall the front wheels,

Fill the system with power steering fluid, and bleed

air from the system (see page 17-15).

After installation. perform the following checks.

. Start the engine, allow it to idle, and turn the

steering wheel from lock-to-lock several times to

warm up the fluid. Check the gearbox for leaks

(see page 17-23).

. Adjust the front toe (s€e section 18).

. Check the steering wheel spoke angl€. Adjust by

turning the right and left tie-rods equally, if nec-

essary.

TIE.ROO END

www.emanualpro.com