Radiator HONDA CR-V 2000 RD1-RD3 / 1.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 362 of 1395

![HONDA CR-V 2000 RD1-RD3 / 1.G Service Manual

ldle Gontrol System

Alternator (ALT) FR Signal (contdl

98 - 00 modols:

ALT CONNECTOR (C1I}5I

4P

rH] Arr FllltwHr/REo)l3laF1

I JUMPER WIRE JUMPER+ WIRE

ECM/PCM CONNECTORS

Wire side of female termi HONDA CR-V 2000 RD1-RD3 / 1.G Service Manual

ldle Gontrol System

Alternator (ALT) FR Signal (contdl

98 - 00 modols:

ALT CONNECTOR (C1I}5I

4P

rH] Arr FllltwHr/REo)l3laF1

I JUMPER WIRE JUMPER+ WIRE

ECM/PCM CONNECTORS

Wire side of female termi](/img/13/5778/w960_5778-361.png)

ldle Gontrol System

Alternator (ALT) FR Signal (cont'dl

'98 - 00 modols:

ALT CONNECTOR (C1I}5I

4P

rH] Arr Fl'l'ltwHr/REo)l3laF1

I JUMPER WIRE JUMPER+ WIRE

ECM/PCM CONNECTORS

Wire side of female terminals

ECM/PCM CONNECTOR C {31PI

Wire side of female terminals

Wire side of female terminals

ECM/PCM CONNECTOR C {31P}

": Canada

1 1-160

B (25P)

Insp€ction of ALT FR Signsl.

Check fo. a shon in th. wire {ALTF linel:1. Disconn6ct the 4P (3P)* con-nector from the ALT.2. Turn the ignition switch ON {ll).3. Measure voltage between ECM/PCM connector terminals C5and 820.Ch€ck for a sho.t in iho wirc lAlTF lino):1. Turn the ignition switch OFF.2. Disconnecl the negative bat,tery cable from the battery.3. Disconnect ECM,PCM connec-torC (31P).

4. Check for continuity betwoenbody ground and ECM/PCMconnector terminal c5.

ls there approx. 5 V7

Check the opcration of the ALT:1. Turn the ignitioo switch OFF.2. Reconnect rhe ALT 4P (3P)*connector to the ALT.3. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator lan comes on,then let it idle.4. Measure voltage between ECM/PCM connector terminals C5and 820.

Roprir lhort in tho wirc bstweentho ECM/PCM {Csl and the ALT.

Substitut. r known-good ECM/PCM and roch.ck. It Droscrib.dvoltage b now lvrilabls, .eplaccth. o.igin!l ECM/PCM.

Does the voltage decrease whenheadlights and rear defogger areturned on?ALT FR 3ignol is OK,

Chock lor an opon in tha wire (ALTF linel:1. Turn the ignition switch OFF.2. Disconnect the negative bat-tery cable from the battery.3. Disconnect ECM/PCM con-nector C (31P).4. Disconnect the 4P 13P)* con,nector from the ALT.5. Connect the ALT 4P {3P)* con-nector terminal No. 4 1No. 1)*to body ground with a jumper

6. Check for continuity betwe€nbody ground and ECM/PCMconnector terminal C5.

Rsprir opan wiro batw.en thoECM/PCM lcsl .nd th. ALT.ls there continuity?

AI.T F IWHT/REDI

ALT F {WHT/REDI

Wire side ot Iemale terminals

www.emanualpro.com

Page 370 of 1395

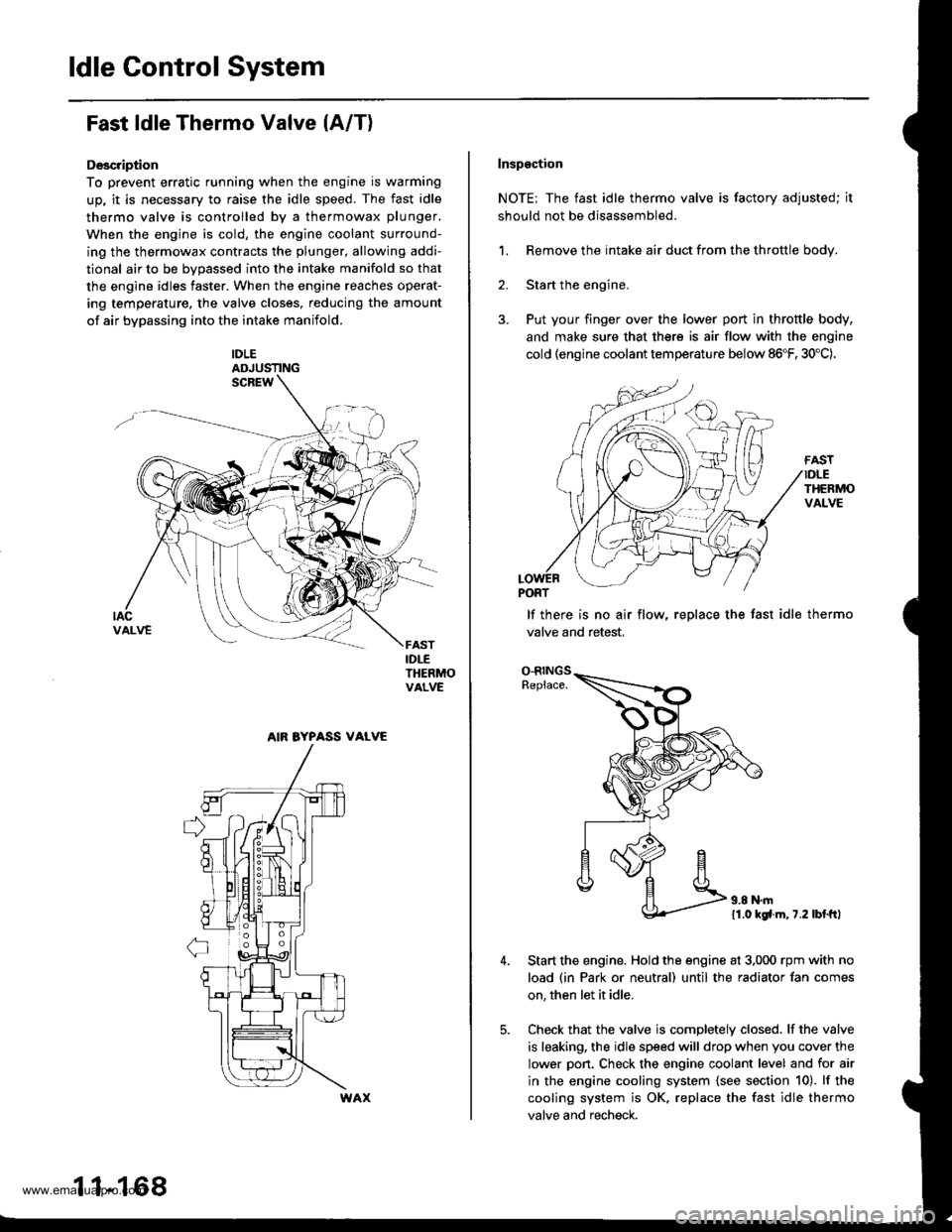

ldle Control System

Fast ldle Thermo Valve lA/T)

Description

To prevent erratic running when the engine is warming

up, it is necessary to raise the idle speed. The fast idle

thermo valve is controlled by a thermowax plunger.

When the engine is cold, the engine coolant surround-

ing the thermowax contracts the plunger, allowing addi-

tional air to be bvDassed into the intake manifold so that

the engine idles faster. When the engine reaches operat-

ing temperature. the valve closes, reducing the amount

of air bypassing into the intake manifold.

IDLEADJUSTING

IDLETHERMOVALVE

AIR BYPASS VALVE

11-168

Inspgction

NOTE: The fast idle thermo valve is factory adjusted; it

should not be disassembled.

1. Remove the intake air duct from the throttle body.

2. Start the engine,

3. Put your finger over the lower port in throttle body,

and make sure that there is air flow with the engine

cold (engine coolant temperature below 86"F, 30'C).

lf there is no air flow, replace the fast idle thermo

valve and retest,

O-RINGSReplace.

11.0 kgfl.m, 7.2 lbl.ftl

Start the engine. Hold the engine at 3,000 rpm with no

load (in Park or neutral) until the radiator fan comes

on, then let it idle.

Check that the valve is completely closed. lf the valve

is leaking, the idle speed will drop when you cover the

lower pon. Check the engine coolant level and for air

in the engine cooling system {see section 10). lf the

cooling system is OK, replace the fast idle thermo

valve and recheck.

www.emanualpro.com

Page 371 of 1395

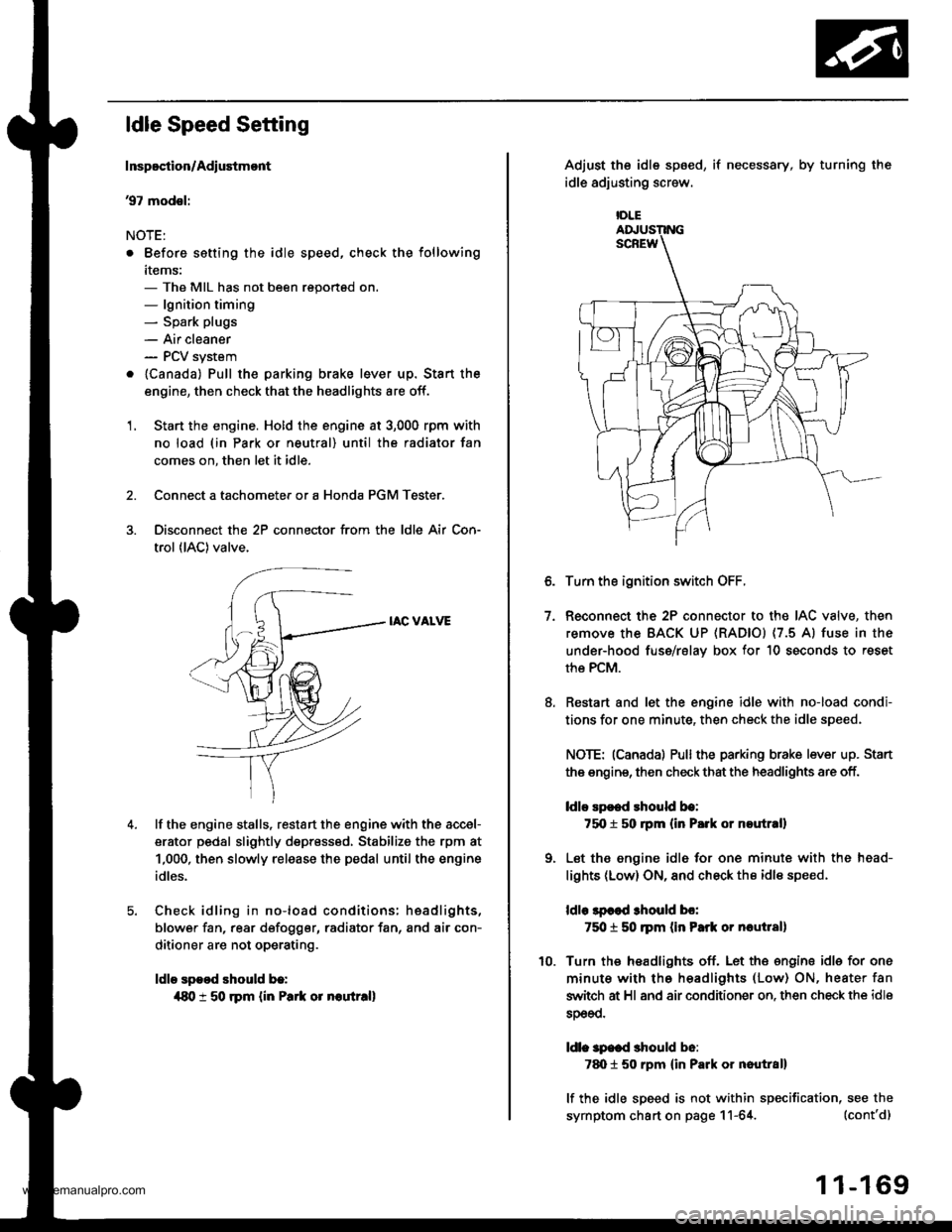

ldle Speed Setting

Inspoction/Adiustmont

37 modsl:

NOTE:

. Before setting the idle speed, check the following

items:- The MIL has not been reportsd on.- lgnition timing- Spark plugs

- Air cleaner- PCV system

. lcanada) Pull the parking brake lever up. Stan the

engine, then check that the headlights are off.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

Connect a tachometer or a Honda PGM Tester.

Disconnect the 2P connector from the ldle Air Con-

trol (lAC) valve.

IAC VALVE

lf the engine stalls, restart the engine with the accel-

erator pedal slightly depr6ss6d, Stabilize the rpm at

1,000, then slowly release the pedal until the engine

idles.

Check idling in no-load conditions: hsadlights,

blower fan, rear d€fogger, radiator fan, and air con-

ditioner are not operating.

ldle spood should b.:

{80 t 50 rpm {in Park or noutr.ll

IDLE

7.

Adjust the idle sp6ed,

idle adjusting screw.

if necessary, by turning the

Turn the ignition switch OFF.

Reconnect the 2P connector to the IAC valve, then

remove the BACK UP (RAD|Ol (7.5 Al fuse in the

under-hood fuse/rslav box for 10 seconds to reset

the PCM.

Restart and let the engine idle with no-load condi-

tions for one minute, then check the idle speed.

NOTE: (Canadal Pullthe parking brake lever up. Stan

the engine, then check that the headlights are off.

ldlo Ep€ed rhould be:

75O t 50 rpm (in P.rk or noutr.ll

Let the engine idl6 for one minute with the head-

lights (Low) ON, and check th€ idl€ speed.

ldle lpcod 3hould bo:

750 t 50 ]pm (in Park or nautlal)

Turn the headlights off. Let th€ engine idle for one

minute with the headlights (Low) ON, heater fan

switch at Hl and air conditioner on. then check the idle

sDeeo.

ldl. specd should b6:

7d) 1 50 rpm {in Park or nautral}

lf the idle speed is not within specification, see the

symptom chart on page 11-64. (cont'd)

1 1-169

www.emanualpro.com

Page 372 of 1395

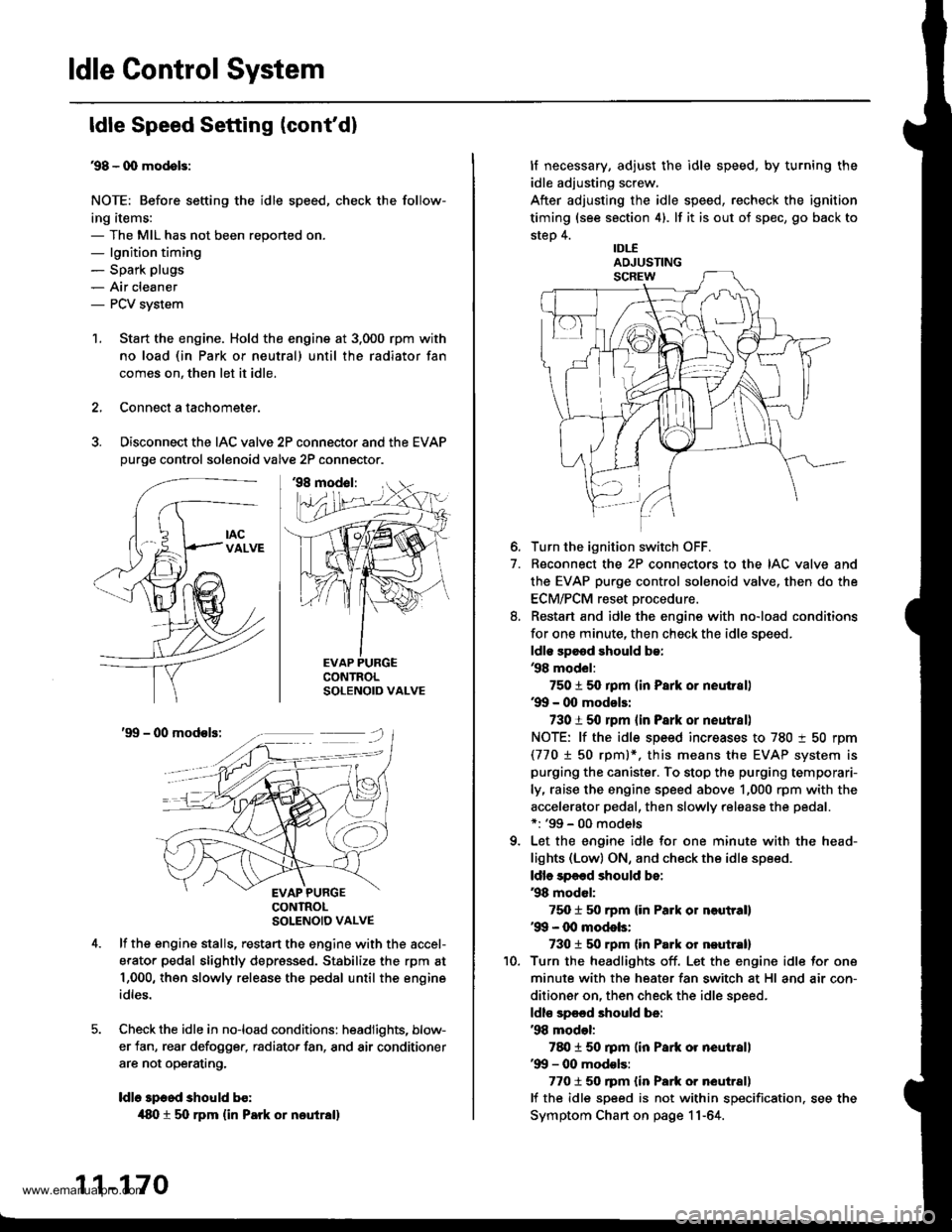

ldle Control System

ldle Speed Setting (cont'd)

38 - 0O mod6l3:

NOTE: Before setting the idle speed, check the follow-

ing items:- The MIL has not been reported on.- lgnition timing- Spark plugs

- Air cleaner- PCV system

1. Start the engine. Hold the engine at 3.000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

Connect a tachometer.

Disconnect the IAC valve 2P connector and the EVAP

purge control solenoid valve 2P connector.

CONTROLSOLENOID VALVE

SOLENOID VALVE

lf the engine stalls, restart the engine with the accel-

erato. pedal slightly depressed. Stabilize the rpm at

1,000, then slowly release the pedal until the engine

idles.

Che€k the idle in no-load conditions: headlights, blow-

er fan, rear defogger, radiator fan, and air conditioner

are not operating,

ldle speed should bo:

480 t 50 rpm {in PErk or noutrall

11-170

lf necessary, adjust the idle speed, by turning the

idle adjusting screw.

After adjusting the idle speed, recheck the ignition

timing (see section 4). lf it is out of spec, go back to

steo 4.tDt.E

6. Turn the ignition switch OFF.

7. Reconnect the 2P connectors to the IAC valve and

the EVAP purge control solenoid valve, then do the

ECM/PCM reset procedure.

8. Restart and idle the engine with no-load conditions

for one minute, then check the idle speed.

ldle speod should be:,98 model:

750 t 50 rpm tin Park or neutral)'9!l - 00 modsls:

730 i 50 lpm lin Psrk or neutral)

NOTE: lf the idle speed increases to 780 t 50 rpm(770 1 50 rpml*, this means the EVAP system is

purging the canister. To stop the purging temporari-

ly, raise the engine speed above 1,000 rpm with the

accelerator pedal, then slowly release the pedal.*: '99 - 00 models

9. Let the engine idle for one minute with the head-

lights (Low) ON, and check the idle speed.

ldle speed should be:

38 mod6l:

750 f 50 rpm (in Palk or neutrall'99 - 00 modols:

730 t 50 rpm (in Palk or neutral)

10. Turn the headlights off. Let the engine idle for one

minute with the heater fan switch at Hl and air con-

ditioner on, then check the idle speed.

ldls spqed should be:'98 model:

780 t 50 rpm (in Park or neutrall'99 - 00 mod€ls:

7701 50 rpm lin Park or neutral)

lf the idle speed is not within specification. see the

Symptom Chart on page 11-64.

ADJUSTING

www.emanualpro.com

Page 396 of 1395

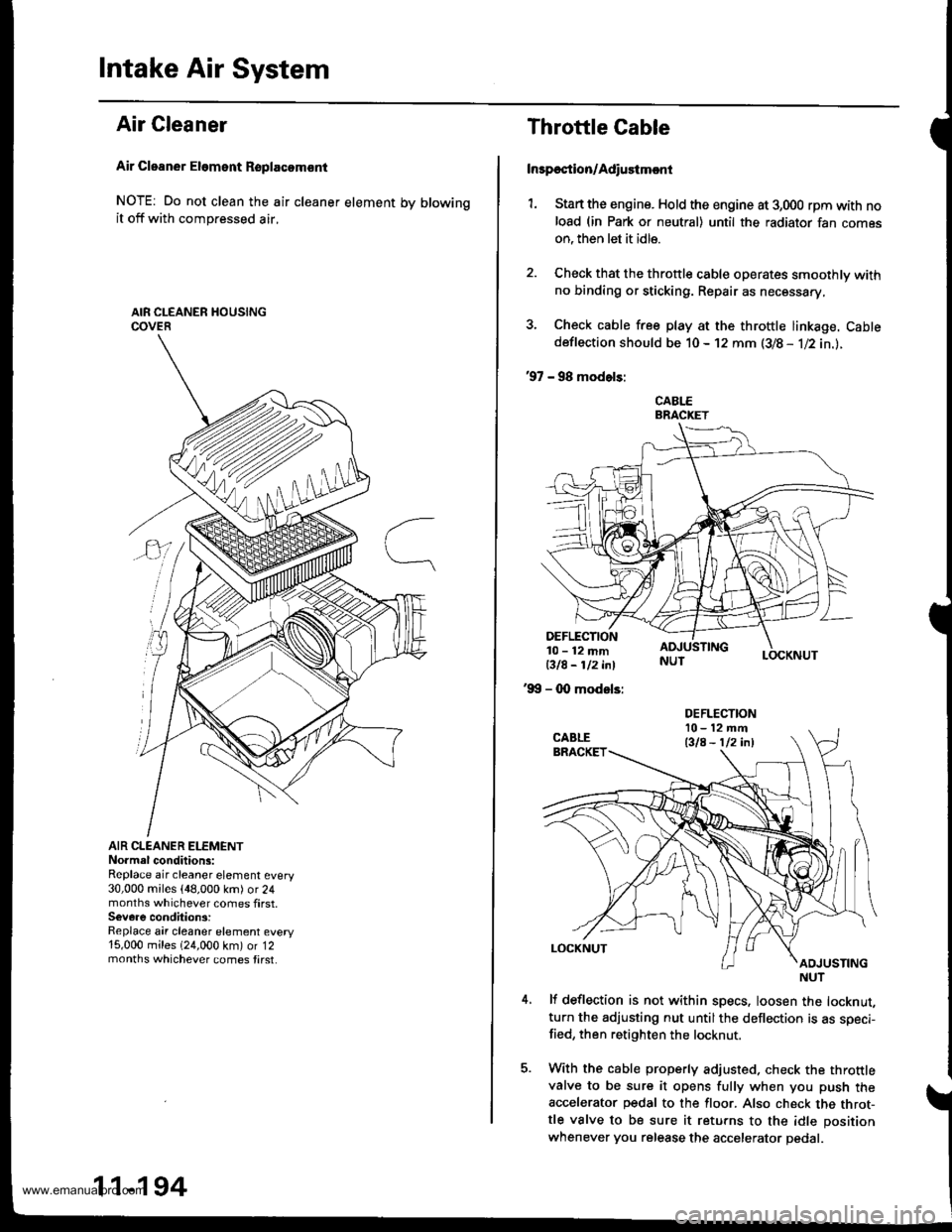

Intake Air System

Air Cleaner

Air Cleaner Eloment Rsplacomsnt

NOTE: Do not clean the air cleaner element by blowingit off with compressed air,

AIR CLEANER ELEMENTNo.mal conditions:Replace air cleaner element every30,000 miles {48,000 km) or 24months whichever comes first.Severe condition3:Replace air cleaner element every15,000 miles 124,000 km) or 12months whichever comes tirst.

m

11-194

Throttle Cable

Inrpection/Adiustmcnt

1. Stan the engine. Hold the engine at 3,000 rpm with noload (in Park or neutral) until the radiator fan comeson, then let it idle.

2. Check that the throttle cable operates smoothly withno binding or sticking. Repair as necessary,

3. Check cable free play at the throttle linkage. Cabtedeflection should be 10- 12 mm (3/8 - 1l2in.l.

'97 - 98 modols:

CABLEBRACKET

LOCKNUT

DEFLECTION10-12mmBIA- 112 i^l

'99 - 0O modsls:

lf deflection is not within specs, loosen the locknut,turn the adjusting nut untilthe deflection is as speci-fied, then retighten the locknut.

With the cable properly adjusted. check the throttlevalve to be sure it opens fully when you push theaccelerator pedal to the floor. Also check the throt-tle valve to be sure it returns to the idle position

whenever you release the accelerator pedal.

DEFLECTIONl0-12mft

Bla - 112 inl

NUT

www.emanualpro.com

Page 397 of 1395

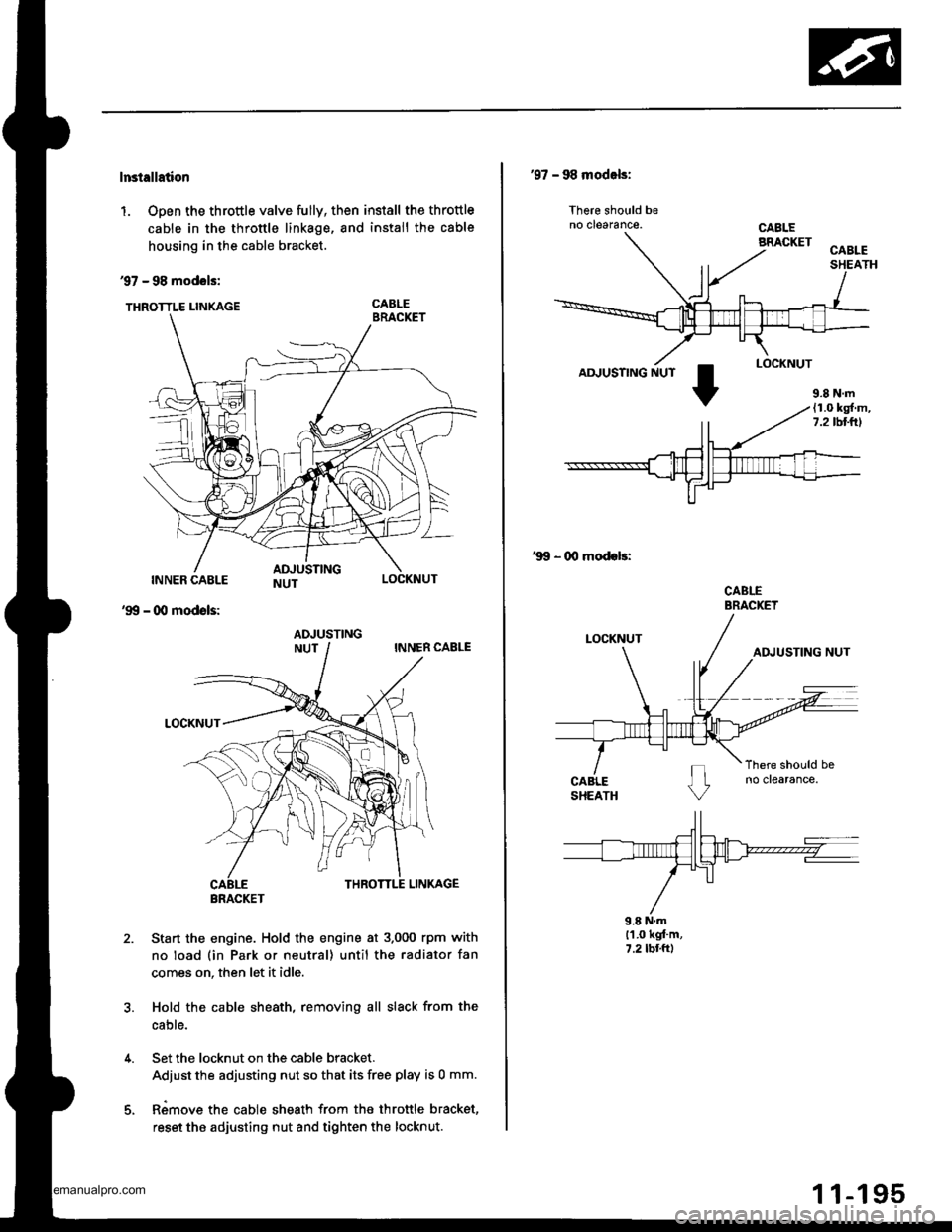

lnstellation

1. Open the throttle valve fully, then install the throttle

cable in the throttle linkage, and install the cable

housing in the cable bracket.

97 - 98 modols:

THRoTTLE LINKAGE CABLE

INNER CABLE

- (Xl modols:

LOCKNUT

'99

2.Sta.t the engine. Hold the engine at 3.000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

Hold the cable sheath, removing all slack from the

cable.

Set the locknut on the cable bracket.

Adiust the adjusting nut so that its free play is 0 mm.

Rimove the cable sheath from the throttle bracket,

reset the adjusting nut and tighten the locknut.

ADJUSTING

BRACKET

'97 - 98 modals:

lhere should beno clearance.

AD.'USTING NUT

'99 - 00 modeb:

CABLEBRACKET

9.8 N.ml'1.0 kgt'm,7.2 tbr.ft)

9.8 N.m(1.0 kg{.m,7.2lbllrl

www.emanualpro.com

Page 401 of 1395

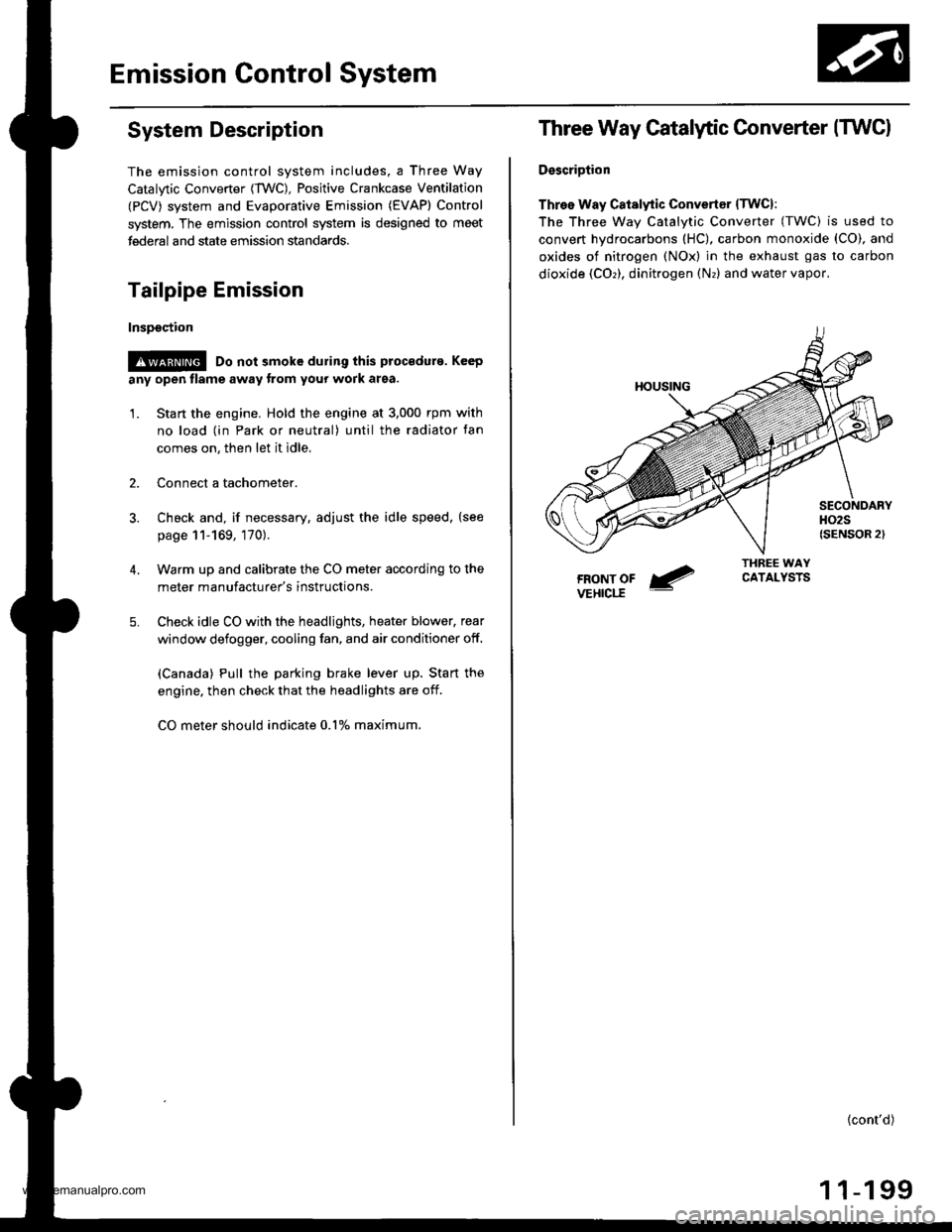

Emission Control System

System Description

The emission control system includes, a Three Way

Catalytic Converter {TWC), Positive Crankcase Ventilation

(PCV) svstem and Evaporative Emission (€VAP) Control

system. The emission control system is designed to meet

federal and state emission standards.

Tailpipe Emission

Inspsction

!@ Do not smoke during this procsdura. Keep

any open tlame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle,

Connect a tachometer.

Check and, if necessary, adjust the idle speed, (see

page 11-169, 170).

Warm up and calibrate the CO meter according to the

meter manufacturer's instructions.

Check idle CO with the headlights, heater blower, rear

window defogger, cooling fan, and air conditioner off.

(Canada) Pull the parking brake lever up. Start the

engine, then check that the headlights are off.

CO meter should indicate 0.1% maximum.

4.

Three Way Catalytic Converter (TWCI

DsscriDtion

Three Way Catalytic Convertsr lTwcl:

The Three wav Catalvtic Converter (TWC) is used to

convert hydrocarbons (HC), carbon monoxide (CO), and

oxides of nitrogen (NOx) in the exhaust gas to carbon

dioxide (COr), dinitrogen (Nr) and water vapor,

{cont'd)

1 1-199

www.emanualpro.com

Page 402 of 1395

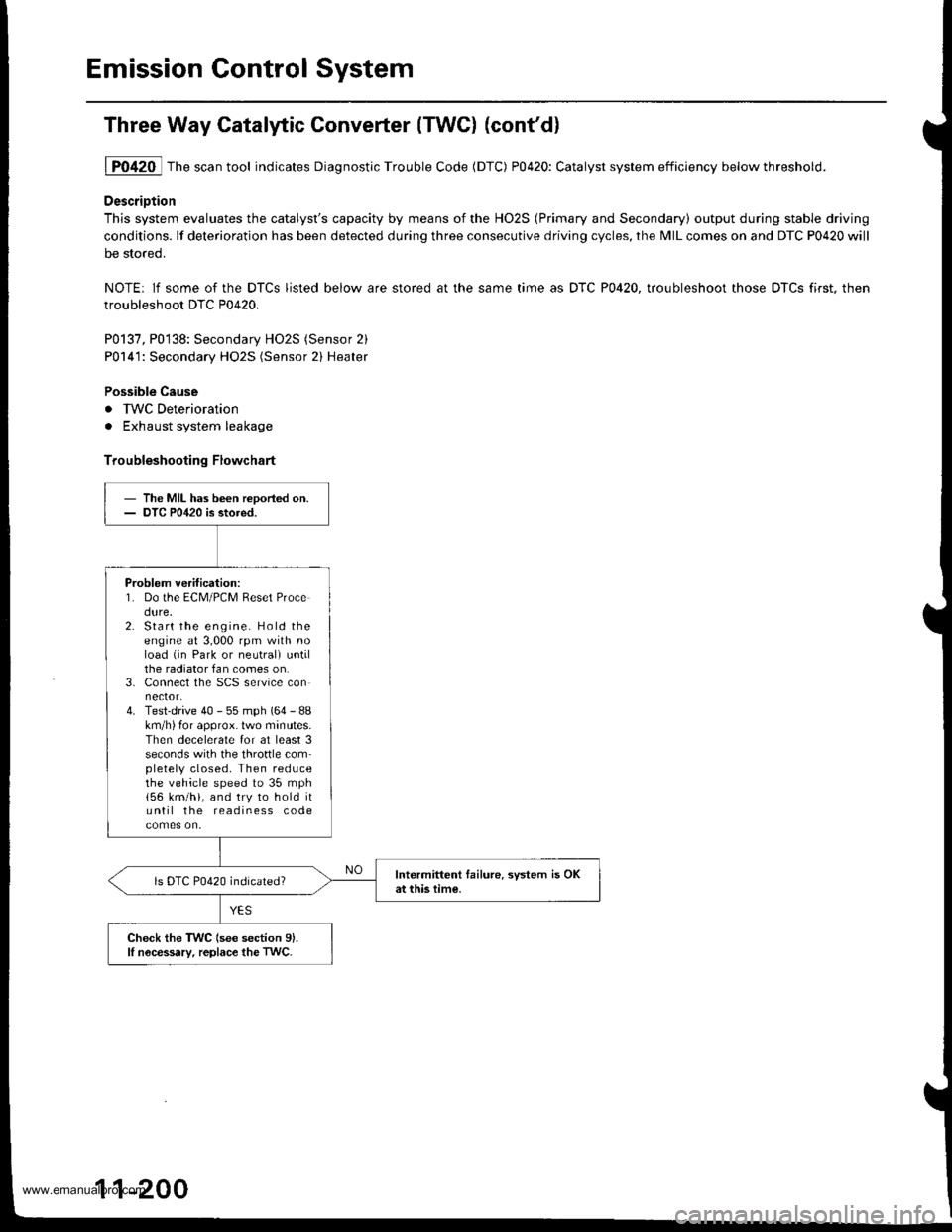

Emission Control System

Three Way Catalytic Converter {TWCI (cont'd}

1P0420 Thescantool indicates Diagnostic Trouble Code (DTC) P0420: Catalyst system efficiency belowthreshold.

DescriDtion

This system evaluates the catalyst's capacity by means of the HO2S (Primary and Secondary) output during stable driving

conditions. lf deterioration has been detected during three consecutive driving cycles, the MIL comes on and DTC P0420 will

be stored.

NOTE: lf some of the DTCS listed below are stored at the same time as DTC P0420, troubleshoot those DTCS first. then

troubleshoot DTC P0420.

P0137, P0138: Secondary HO2S (Sensor 2)

P0141: Secondary HO2S (Sensor 2) Heater

Possible Cause

. IWC Deterioration

. Exhaust system leakage

Troubleshooting Flowchart

- The MIL has been reDoried on.- DTC P0420 is stored.

Problem verification:1. Do the ECM/PCM Reset Procedure,2. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutrali untilthe radiator fan comes on.3. Connect the SCS service connector.4. Test-drive 40 - 55 mph (64 - 88km/h) for approx. lwo minutes.Then decelerate for at least 3seconds with the throftle completely closed. Then reducethe vehicle speed to 35 mph

156 km/h), and try to hold ituntil the readiness code

Intermittent tailure. system is OKat this time.ls DTC P0420 indicated?

Check the TWC (see section 9).lI nocessary, replace the TwC.

11-200

www.emanualpro.com

Page 407 of 1395

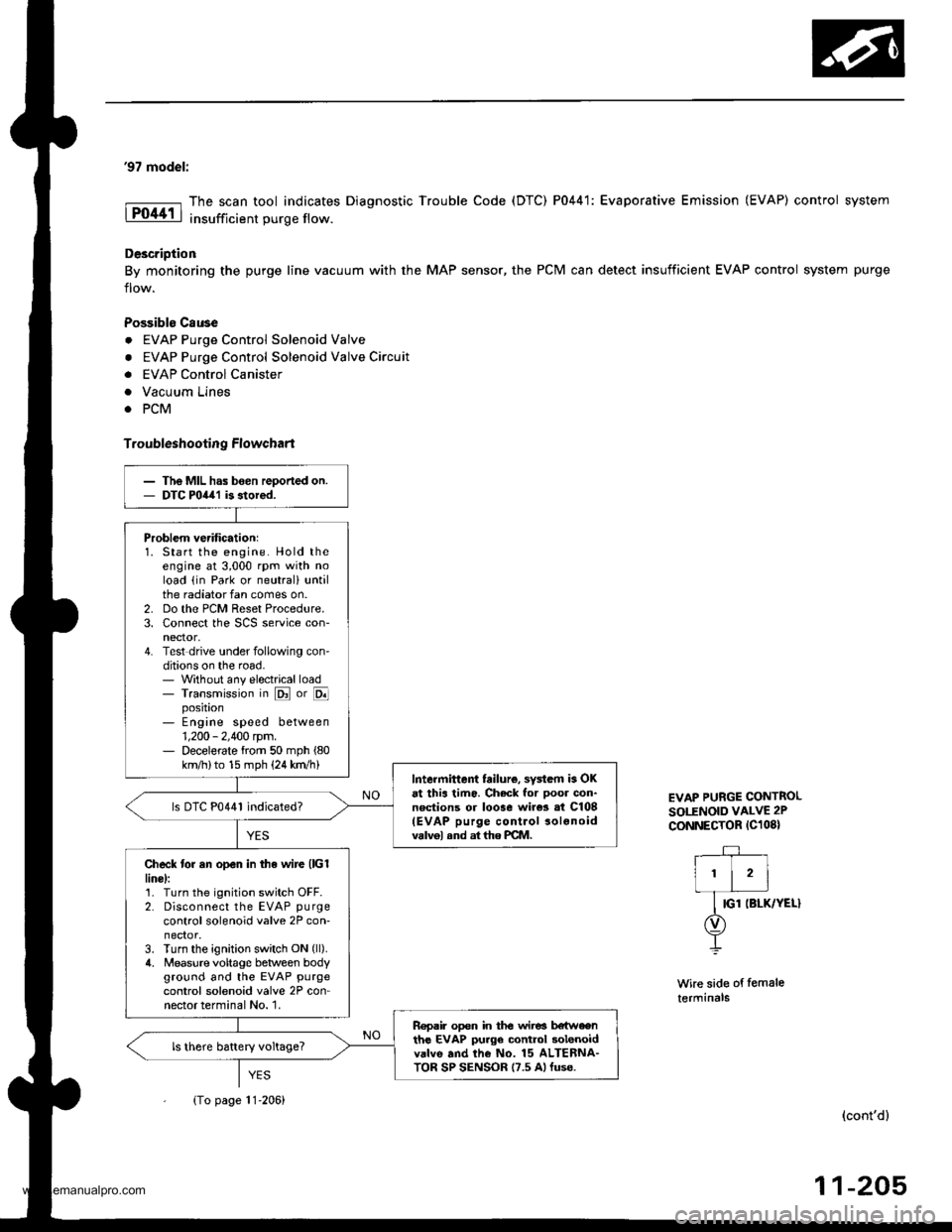

'97 model:

The scan tool indicates Diagnostic Trouble Code (DTC) P0441: Evaporative Emission (EVAP) control system

insufficient purge flow.

Description

By monitoring the purge line vacuum with the MAP sensor, the PCM can detect insufficient EVAP control system purge

flow.

Possiblo Cause

. EVAP Purge Control Solenoid Valve

. EVAP Purge Control Solenoid Valve Circuit

. EVAP Control Canister

. Vacuum Lines

. PCM

Troubleshooting Flowchart

EVAP PURGE CONTROL

SO1TNOID VALVE 2P

CoNNECTOR (C108)

(v)

YL

Wire side of female

termrnals

(cont'd)

11-205

Th€ MIL has b€en reooited on.DTC P0441 is .tored.

Problem verificationl1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neut.al) untilthe radiator fan comes on.2. Do the PCM Reset Procedure.3. Connect the SCS service con-nector,4. Test drive under following con'ditions on the road.- without any electrical load- Transmission in @ or @position- Engine speed between1 ,2OO - 2,4OO rpfi.- Decelerate from 50 mph (80

km/h)to 15 mph (24 km/h)Intermittent trilure, sydern is OKat this time. Check for Door con-nections or loose wir€3 at C108

IEVAP purge control solonoidvalvol .nd at the PCM.

ls DTC P0441 indicated?

Check tor an open in the wire (lcl

linel:1. Turn the ignition switch OFF.2. Disconnect the EVAP purge

control solenoid valve 2P con-nector.3. Turn the ignition switch ON (ll).

4. Measure voltage between bodyground and the EVAP purge

control solenoid valve 2P con-nector terminal No. '1,

R€pafu open in thc wir6 b€tw€enthG EVAP purge control solenoidvalve and the No. 15 ALTEBNA-TOR SP SENSOR (7.5 A)fuse.

ls there batlery voltage?

(To page 11'206)

www.emanualpro.com

Page 445 of 1395

Transfer Assembly

lnstallation

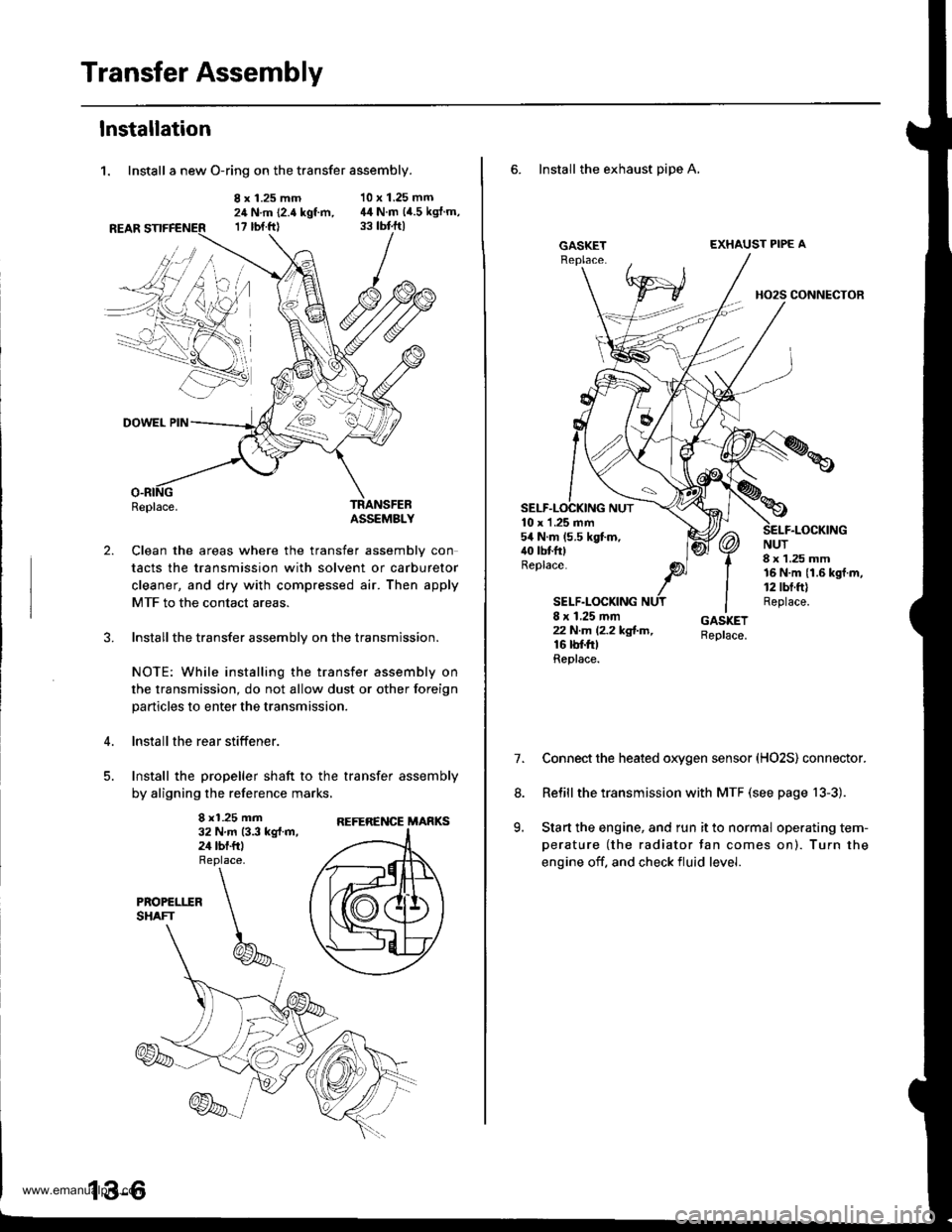

1. Install a new O-ring on the transfer assembly.

8 x 1.25 mm24 N.m (2.4 kgt m,17 rbt.ftl

10 x 1.25 mm44 N.m (4.5 kgJ.m,

2.

DOWEL PIN

Replace.TRANSFEBASSEMBLY

Clean the areas where the transfer assembly con

tacts the transmission with solvent or carburetor

cleaner, and dry with compressed air. Then apply

MTF to the contact areas.

Installthe transfer assembly on the transmission.

NOTE: While installing the transfer assembly on

the transmission, do not allow dust or other foreign

particles to enter the transmission.

lnstall the rear stiffener.

Install the propeller shaft to the transfer assembly

by aligning the reference marks,

8 x1.25 mm32 N.m 13.3 kg{.m,24 tbf.ftl

REFERENCE MARKS

6. Install the exhaust pipe A,

GASKETEXHAUST PIPE A

HO2S CONNECTOR

10 x 1 .25 mm54 N.m (5.5 kgt m,40 tbtfttReplace.

SELF.LOCKING

NUT8 x 1.25 mm16 N.m {1.6 kgf.m,12 tbt.ft)Replace.8 x 1.25 mmzzN.m l2.2kg!-m,16 rbf.trtReplace.

7.Connect the heated oxygen sensor (HO2S) connector.

Relill the transmission with MTF (see page 13-3).

Start the engine, and run it to normal operating tem-

perature (the radiator tan comes on). Turn the

engine off. and check fluid level.

8.

9.

www.emanualpro.com