Temperature HONDA CR-V 2000 RD1-RD3 / 1.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 302 of 1395

PGM-FI System

Engine Coolant Temperature (ECTI Sensor {cont'd)

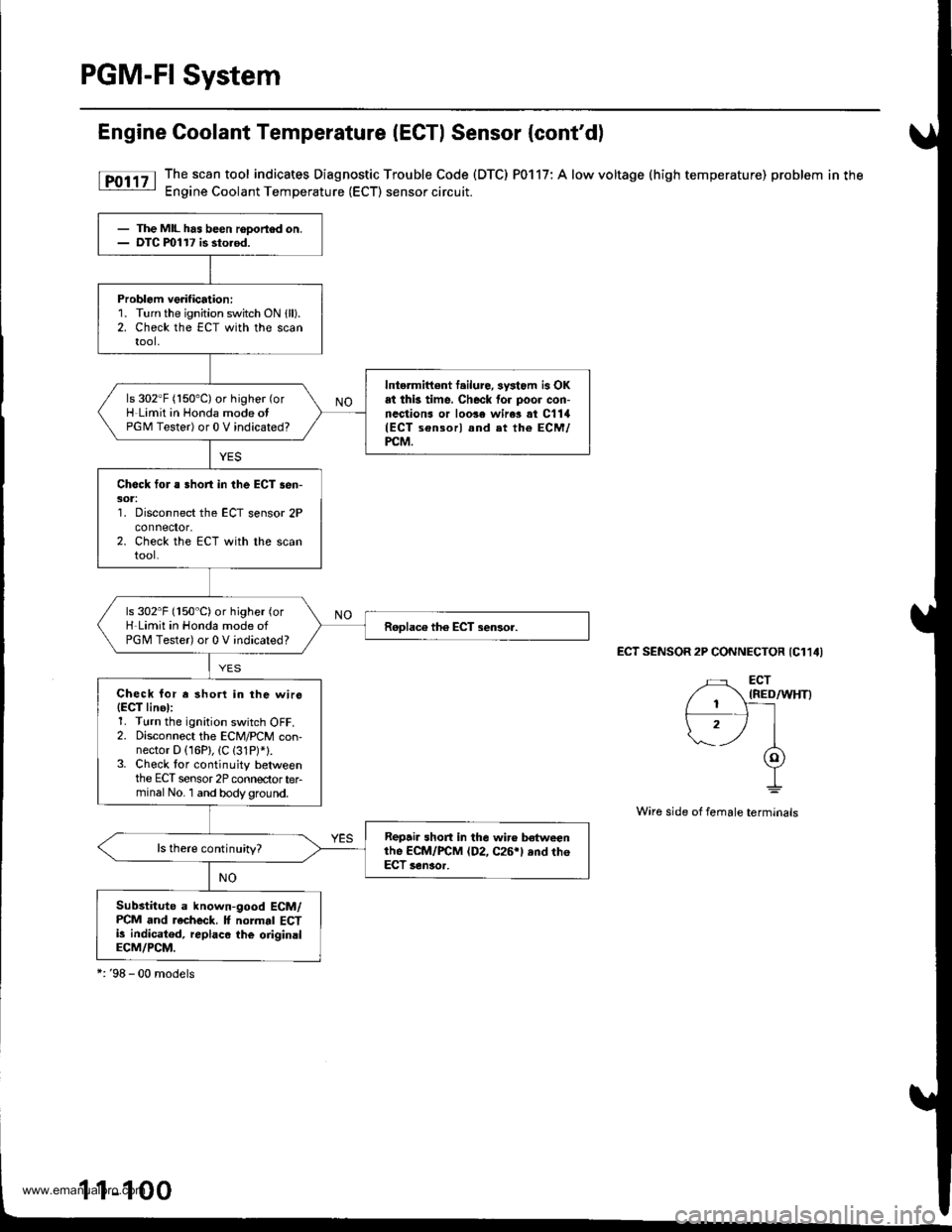

[F011' The.scan tool indicates Diagnostic Trouble Code (DTC) P0117: A low voltage (high temperature) problem in the: Engine Coolant Temperature (ECT) sensor circuit.

ECT SENSOR 2P CONNECTOR {C114I

Wire side of female terminals

- The MIL has been rooortod on.- DTC ml17 is sto.od.

Problem verification:1. Turn the ignition switch ON {ll).2. Check the ECT with the scantool,

Intermittont f.ilure, sysiom is OKat thk time. Check for poor con-nections or loo3e wire3 at C1lil(ECT sensorl and et the ECM/PCM.

ls 302"F (150'C) or higher (or

H Limit in Honda mode otPGM Tester) or 0 V indicated?

Check for a Bhort in the ECT sen-301:'1. Disconnect the ECT sensor 2Pconnefior,2. Check the ECT with the scantool.

ls 302"F (150"C)or higher (or

H-Limit in Honda mode ofPGM Tester) or 0 V indicated?

Check for r shorl in the wirs(EgT linel:1. Turn the ignition switch OFF.2. Disconnect the ECM/PCM con-nector D (16P), (C (31P)*1.3. Check tor continuity betweenthe ECT sensor 2P connectorterminal No. 1 and bodyground.

Repair short in the wir€ betweenthe ECM/FCM (D2, C26rl ,nd th6ECT senaor.

ls there continuity?

Substitute a known-good ECM/PCM and recheck. It normal ECTi! indicatod, replaco the oiiginalECM/PCM.

*:'98 - 00 models

1-1

www.emanualpro.com

Page 303 of 1395

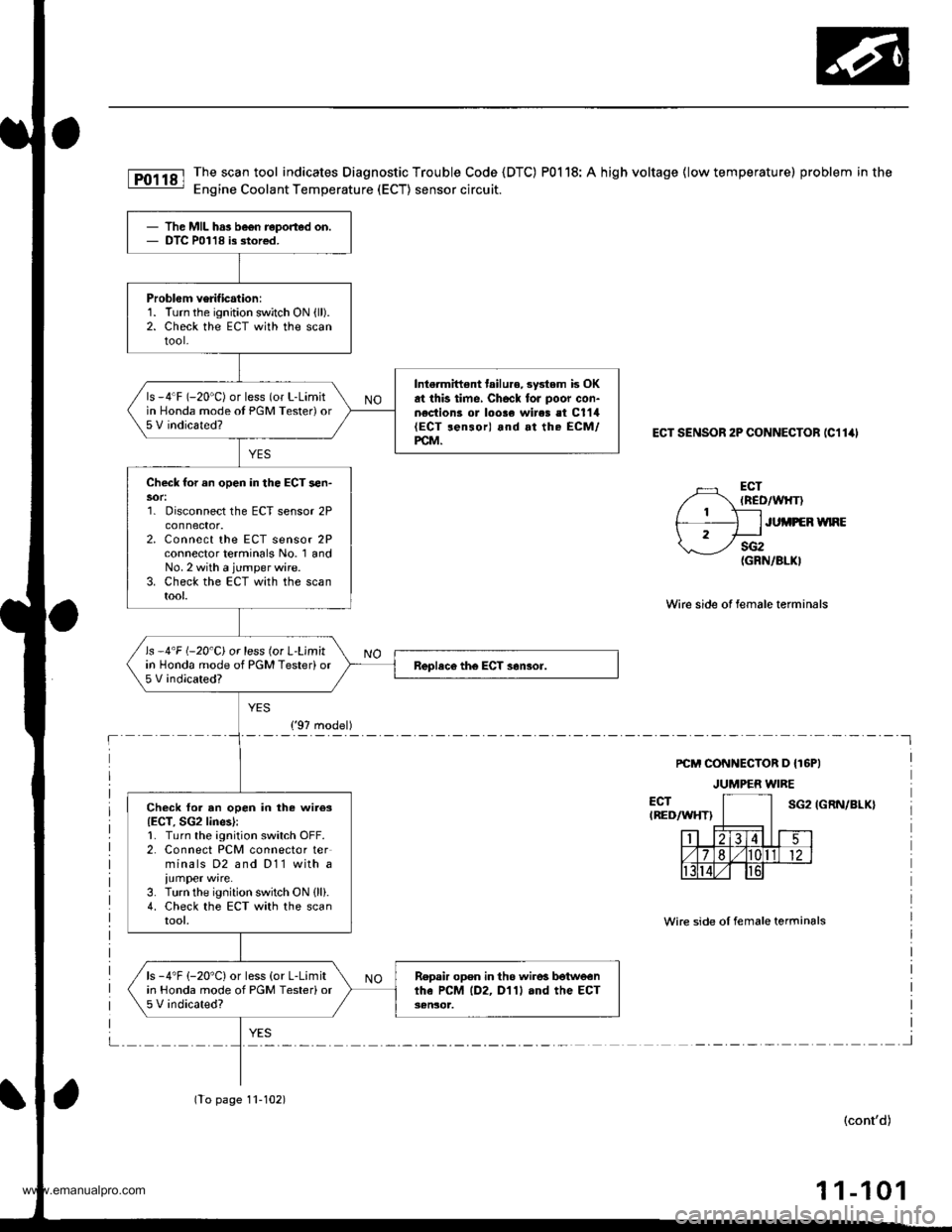

The scan tool indicates Diagnostic Trouble Code {DTC) P0118: A high voltage {low temperature) problem in the

Engine Coolant Temperature (ECT) sensor circuit.

ECT SENSOR 2P CONNECTOB (C11ill

ECT(ncD/wlrT)

ECTIREDAAIHT)

Wirc side of lemale terminals

sG2(GRN/8LKI

PCM CONNECTOR D {T6PI

JUMPER WIRE

JUi,IPEB WNE

IGRN/BLX}

Wire side oI female terminals

(cont'd)

1 1-101

The MIL has be€n reported on.DTC P01'18 is stor€d.

Problem verification:1. Turn the ignition switch ON {ll).2. Check the EcT with the scantool-

Intermiftent tailu.€,3ystem is OKat this time, Checl foJ poor con-n€ction3 or loose wires et C1'14(ECT ren3or) and at the ECM/PCM.

ls -4"F (-20'C) or less (or L-Limitin Honda mode ot PGM Tester) or5 V indicated?

Check for an open in the ECT sen-

1. Disconnect the ECT sensor 2Pconnector.2. Connect the ECT sensor 2Pconnector terminals No. 1 andNo. 2 with a jumper wire.3. Check the ECT with the scantool.

ls -4'F (-20'C) or less (or L'Limitin Honda mode of PGM Tester)or5 V indicated?

Check for an open in the wiies{ECT, SG2 lines):1. Turn the ignition switch OFF.2. Connect PCM connector terminals D2 and D11 with a

iumper wire.3. Turn the ignition switch ON {ll}.4. Check the ECT with the scantool,

ls -4"F (-20'C) or less (or L-Limitin Honda mode of PGM Testerior5 V indicated?

Repair open in th6 wire! botwe€nthe PCM lD2, D'l1l and the ECT3€n30t.

('97 model)

(To page 11-102)

www.emanualpro.com

Page 304 of 1395

PGM-FI System

Chack lor an open in the wires(ECT, SG2 lines):1. Turn the ignition switch OFF.2. Connect ECM/PCM connectorterminals C18 and C26 with a

3. Turn the ignition switch ON (ll).

4. Check the ECT with the scantool.

ls -4"F (-20"C) or less (or L-Limitin Honda mode of PGM Testerlor5 V indicated?

Ralpair open in tho wir6s b6twe€ntho ECM/PCM 1C18, c26l 6nd thoECT sensor.

Substitute a known-good ECM/PCM and rech.ck. lf normal ECTis indicrted, replace ths originslECM/PCM.

Engine Goolant Temperature (ECTI Sensor (cont'dl

(From page 11 101)

ECM/PCM OONNECTOR C 13lPI

(GRN/BLK)

JUMPER WIRE

Wire side of temale terminals

17I9

,/ 1617't8'1920n

ECT IRED/WHTIsG2

11-102

www.emanualpro.com

Page 351 of 1395

ldle Control System

System Description

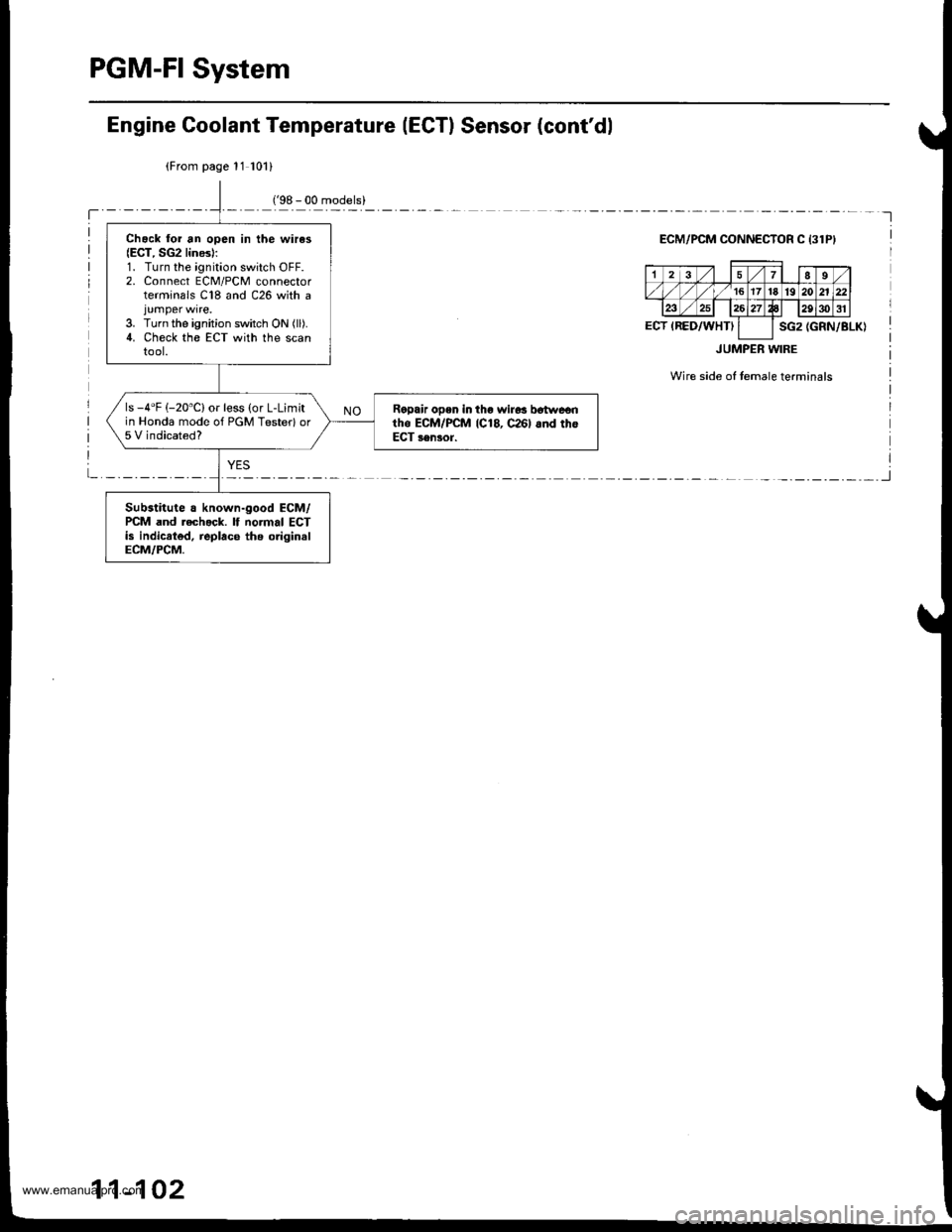

The idle speed of the engjne is controlled by the ldle Air Control (lAC) Valve'

The valve changes the amount of air bypassing into the intake manifold in response to electric current controlled by the

ECM/PCM. When the lAc valve is activated, the valve opens to maintain the proper idle speed.

YEL/ From PGM'FI

BLK TMAIN RELAY

VARIOUSSENSORS

4.

IAC VALVE

INTAKE MANIFOLD

After the engine starts, the IAC valve opens for a certain time. The amount of air is increased to raise the idle speed

about 150 - 300 rpm.

when the cootant temperature ts row, the lAc valve is opened to obtain the proper fast idle speed The amount o{

bvoassed air is thus controlled in relation to the engine coolant temperature

When the idle speed is out o{ specification and the scan tool does not indicate Diagnostic Trouble Code (DTC) P0505

or P1508, check the following items:

. Adjust the idle speed (see page 11-169, 170)

. Air conditioning signal (seepagell-1551

. ALT FR signal (see page 1l-159)

. Starter switch signal (see page 11-16'1)

. A,/T gear position signal (see section 14)

. PSP switch signal (seepagell-162)

. Brake switch signal (see page 11-165)

. Fast idlethermovalve (see page'11 168)

. Hoses and connecttons. IAC valve and its mounting O-rings

lf the above items are normat, suDslitute a known-good IAC valve and readjust the idle speed {see page 11-169, 170)

lf the idle speed still cannot be adjusted to specification (and the scan tool does not indicate DTC P0505 or Pl508)

after IAC valve reolacement, substitute a known-good ECM/PCM and recheck lf symptom goes away' replace the

original ECM/PCM.

11-149

www.emanualpro.com

Page 352 of 1395

ldle Control System

ldle Control System

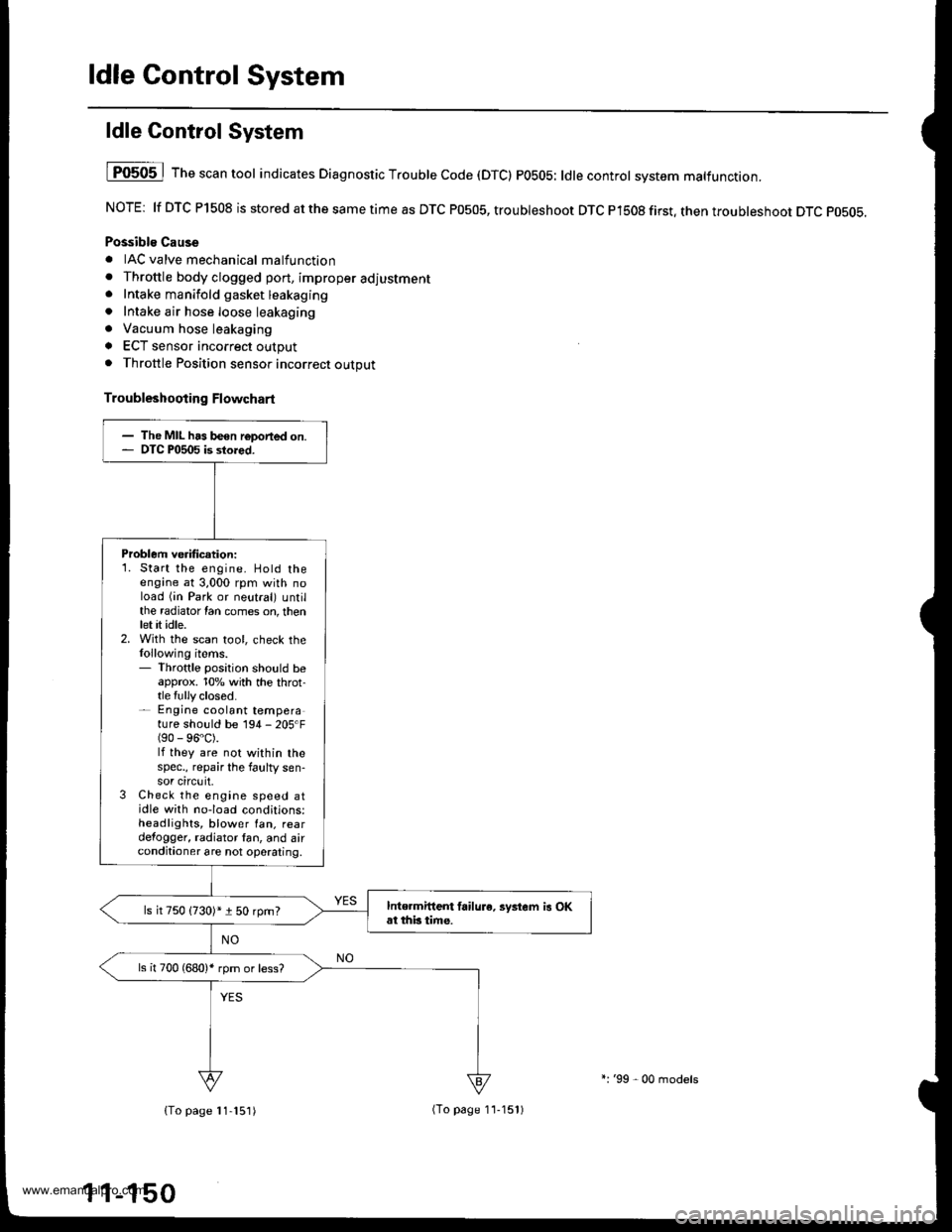

I P0505 | The scan tool indicates Diagnostic T.ouble Code (DTCI PO5O5: ldlecontrol svstem mattunction.

NOTE: lf DTC P1508 is stored at the same time as DTC P0505, troubleshoot DTC P1508 first. then troubleshoot DTC p0505.

Possibls Cause

. IAC valve mechanical malfunction. Throttle body clogged port, improper adlustment. Intake manifold gasket leakaging. Intake air hose loose leakaging. Vacuum hose leakaging

a ECT sensor incorrect output. Throttle Position sensor incorrect output

Troubleshooting Flowchart

The MIL has been reDorted on.DTC P0505 is sto.ed.

Problem verificationi1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator Ian comes on, thenlet it idle.2. With the scan tool, check thelollowing items.- Throttle position should beapprox. 10% with the throt-tle {ully closed.- Engine coolant temperature shorJld be 194 - 205'F(90 - 96"C).lf they are not within thespec., repair the faulty sen-sor circuit.3 Check the engine speed atidle with no-load conditions:headlights, blower fan. reardefogger, radiator lan, and airconditioner are not operaling,

Inte.mittent failure. syltem is OKat this time.ls it 750 {730)* i 50 rpm?

ls il 700 (680)' rpm or less?

{To page 11-151)(To page 1'l-151)

l:'99 - 00 models

www.emanualpro.com

Page 370 of 1395

ldle Control System

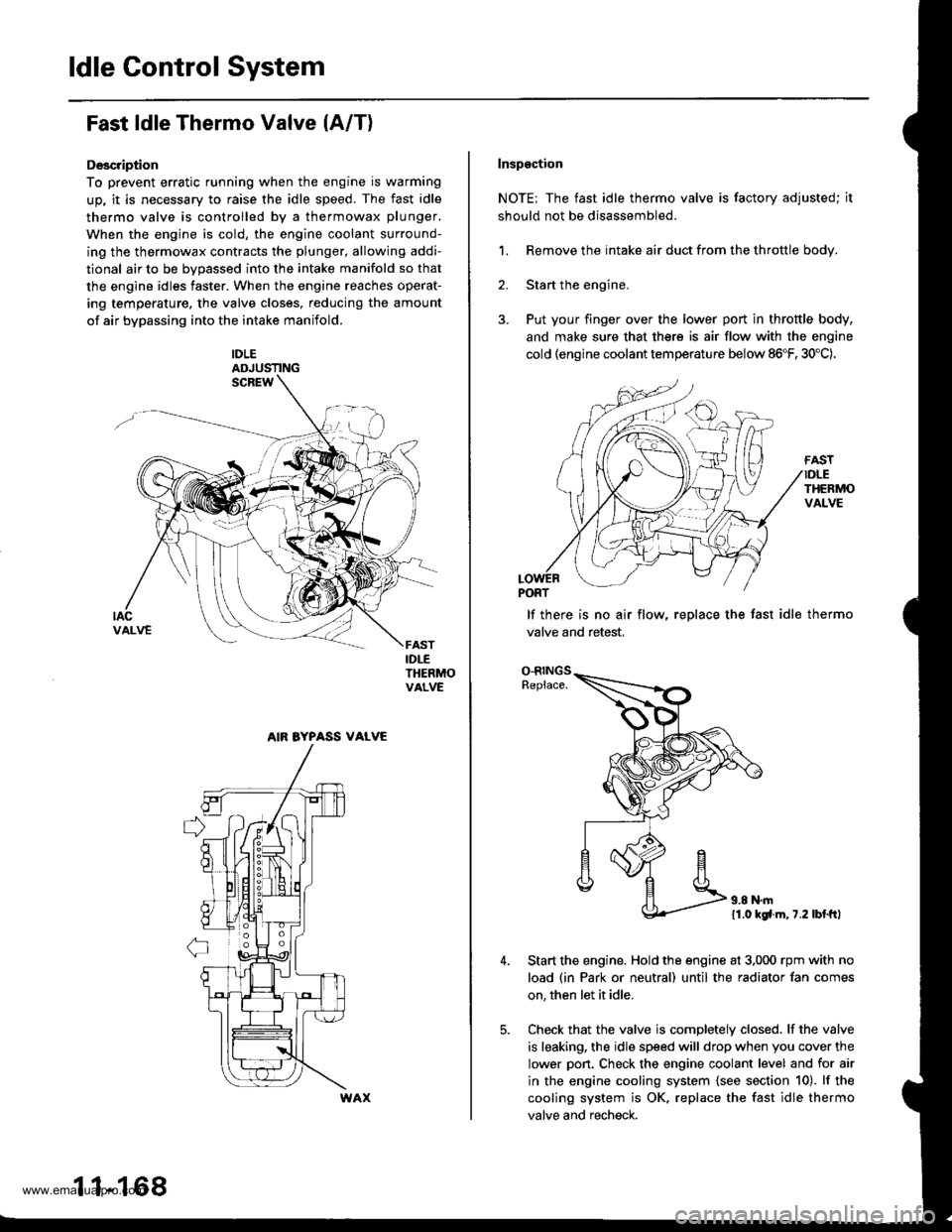

Fast ldle Thermo Valve lA/T)

Description

To prevent erratic running when the engine is warming

up, it is necessary to raise the idle speed. The fast idle

thermo valve is controlled by a thermowax plunger.

When the engine is cold, the engine coolant surround-

ing the thermowax contracts the plunger, allowing addi-

tional air to be bvDassed into the intake manifold so that

the engine idles faster. When the engine reaches operat-

ing temperature. the valve closes, reducing the amount

of air bypassing into the intake manifold.

IDLEADJUSTING

IDLETHERMOVALVE

AIR BYPASS VALVE

11-168

Inspgction

NOTE: The fast idle thermo valve is factory adjusted; it

should not be disassembled.

1. Remove the intake air duct from the throttle body.

2. Start the engine,

3. Put your finger over the lower port in throttle body,

and make sure that there is air flow with the engine

cold (engine coolant temperature below 86"F, 30'C).

lf there is no air flow, replace the fast idle thermo

valve and retest,

O-RINGSReplace.

11.0 kgfl.m, 7.2 lbl.ftl

Start the engine. Hold the engine at 3,000 rpm with no

load (in Park or neutral) until the radiator fan comes

on, then let it idle.

Check that the valve is completely closed. lf the valve

is leaking, the idle speed will drop when you cover the

lower pon. Check the engine coolant level and for air

in the engine cooling system {see section 10). lf the

cooling system is OK, replace the fast idle thermo

valve and recheck.

www.emanualpro.com

Page 405 of 1395

EVAP PURGE CONTROL SOLENOID VALVE DUTY CONTROLLED AFTER

STARTING ENGINE

ENGINE COOLANT TEMPERATURE ABOVE 154"F (68'C)

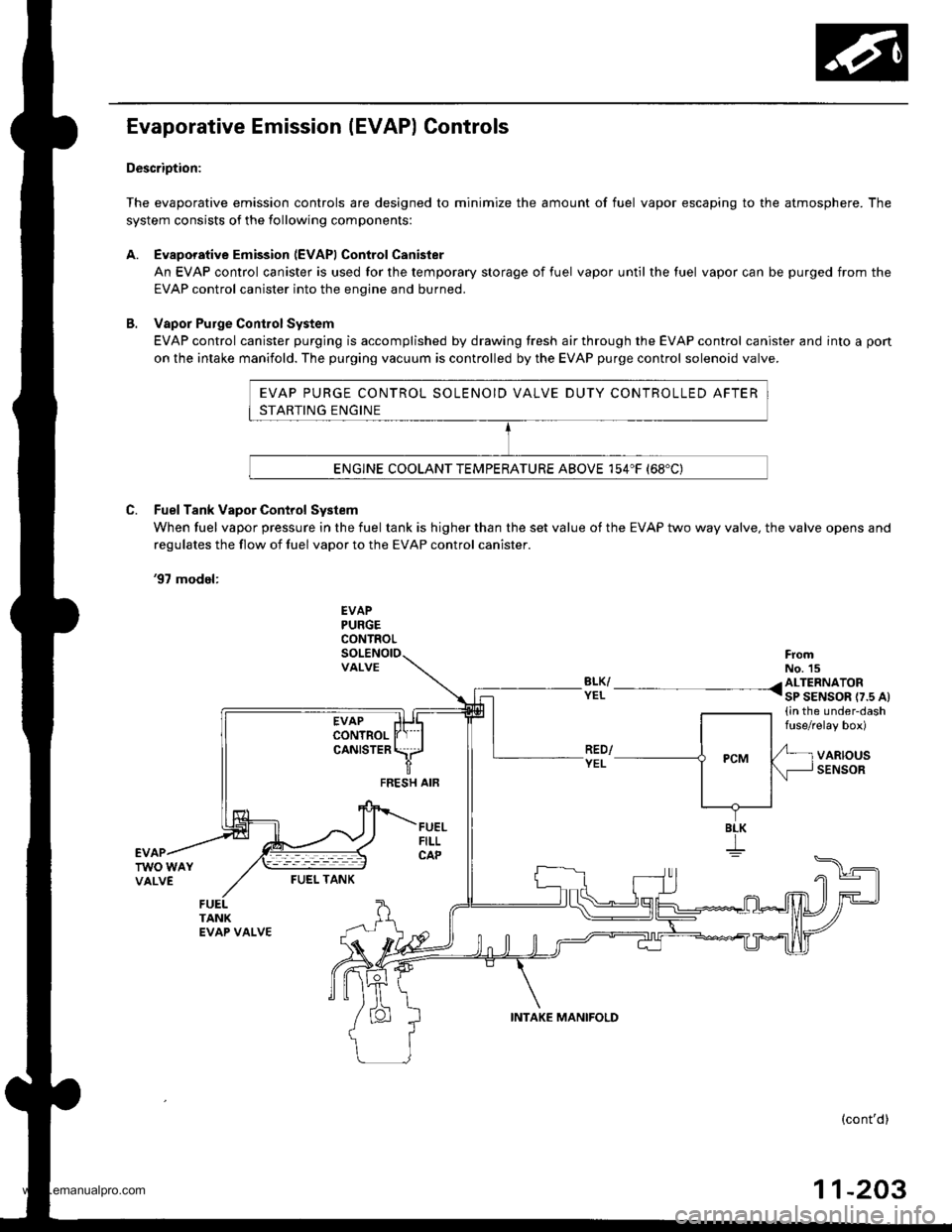

Evaporative Emission (EVAP) Controls

Description:

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the following components:

A. Evaporative Emission (EVAPI Control Canister

An EVAP control canister is used for the temporary storage of fuel vapor until the luel vapor can be purged from the

EVAP control canister into the enqine and burned.

B. Vapor Purge ConirolSystem

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a pon

on the intake manifold. The purging vacuum is controlled by the EVAP purge control solenoid valve.

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow ot fuel vapor to the EVAP control canister.

'97 model:

EVAPPURGECONTROL

VALVEFromNo. 15BLK/ /ALTERNATORYEL I sP SENSOR r7.s At(in the under-dashfuse/relay box)

VARIOUSSENSORFEESH AIF

BLK

I

FUEI- TANK

(cont'd)

11-203

INTAKE MANIFOLD

www.emanualpro.com

Page 425 of 1395

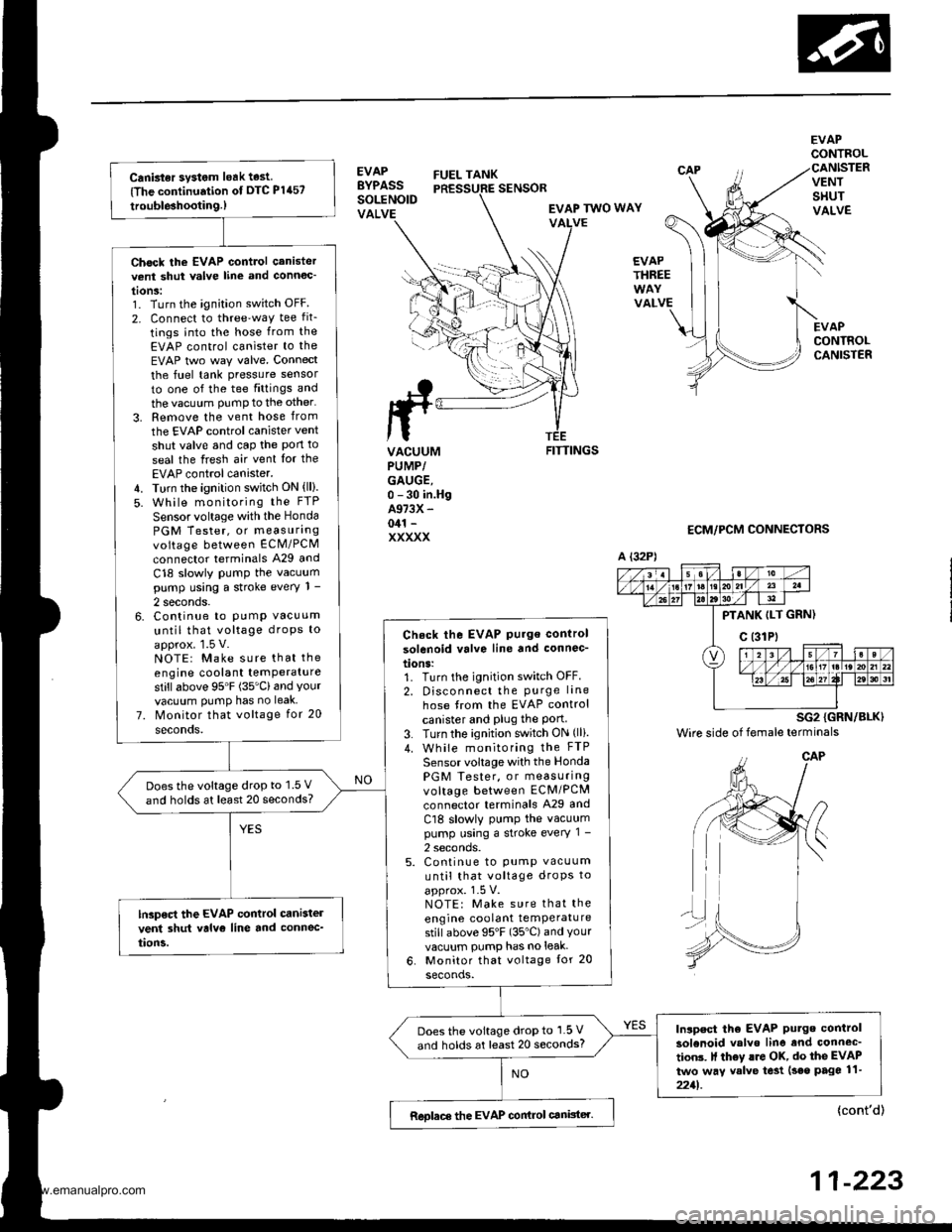

Canbter system leak test

{The continuation of DTC P1457

trouble3hootin9.)

Chock the EVAP control canistervent shut valve line and connoc'

tonS:1. Turn the ignition switch OFF

2. Connect to three'way tee fit_

tings into the hose from the

EVAP control canister to the

EVAP two way valve. Connect

the fuel tank pressure sensor

to one of the tee fittings and

the vacuum PumP to the other'

3. Remove the vent hose from

the EVAP control canister vent

shut valve and cap the Pon to

seal the fresh air vent Ior the

EVAP control canister.4. Turn the ignition switch ON (ll).

5. While monitoring the FTP

Sensor voltage with the Honda

PGM Tester, or measurangvoltage between ECM/PCM

connector terminals A29 and

C18 slowly PumP the vacuumpump using a stroke every 1 -

2 seconds.6. Continue to PumP vacuum

until that voltage droPs to

approx. 1.5 V.NOTE: Make sure that the

engine coolant temPeraturestillabove 95'F (35'Cland Yourvacuum PumP has no leak

7. Monitor that voltage for 20

seconds.

Check the EVAP Pu.ge control

solenoid valve line and connec-

tions:1. Turn the ignition switch OFF.

2. Disconnect the Purge lane

hose from the EVAP control

canister and Plug the Port3. Turn the ignition switch ON (lli.

4. While monitoring the FTP

Sensor voltage with the Honda

PGM Tester, or measuringvoltage between ECM/PCM

connector terminals A29 and

Cl8 slowly PumP the vacuumpump using a stroke every 1 -

2 seconds.5. Continue to pump vacuum

until that voltage droPs to

approx. 1-5 V.NOTE: Make sure that the

engine coolant temPeraturestill above 95'F (35"C) and Yourvacuum pump has no leak-

6. Monitor that voltage tor 20

seconds.

Doesthe voltage drop to 1.5 V

and holds at least 20 seconds?

lGp€ct the EVAP control cani3tel

vent 3hut valvo line and connec_

tion5.

Inlpect tho EVAP Putge control

solenoid valvo line and connec'

tion3. It th6y lro OK, do the EVAP

two way valve te3t (seo page 11-

2211.

Does the voltage drop to 1.5 V

and holds at least 20 seconds?

Reolace the EVAP conirol canister.

EVAPBYPASSSOLENOIDVALVE

FUEL TANK

EVAPCONTROL

VENTSHUTVALVE

EVAPCONTROLCANISTER

SENSOR

EVAP TWO WAYVALVE

EVAPTHREE

VALVE

ttrrL

ta

VACUUMPUMP/GAUGE,0 - 30 in.HgA973X -

041 -

XXXXX

FITTINGS

ECM/PCM CONNECTORS

A {32P)

PTANK ILT GRN)

c (31Pt

SG2 {GRN/BLK)

Wire side of female terminals

{cont'd)

11-223

www.emanualpro.com

Page 480 of 1395

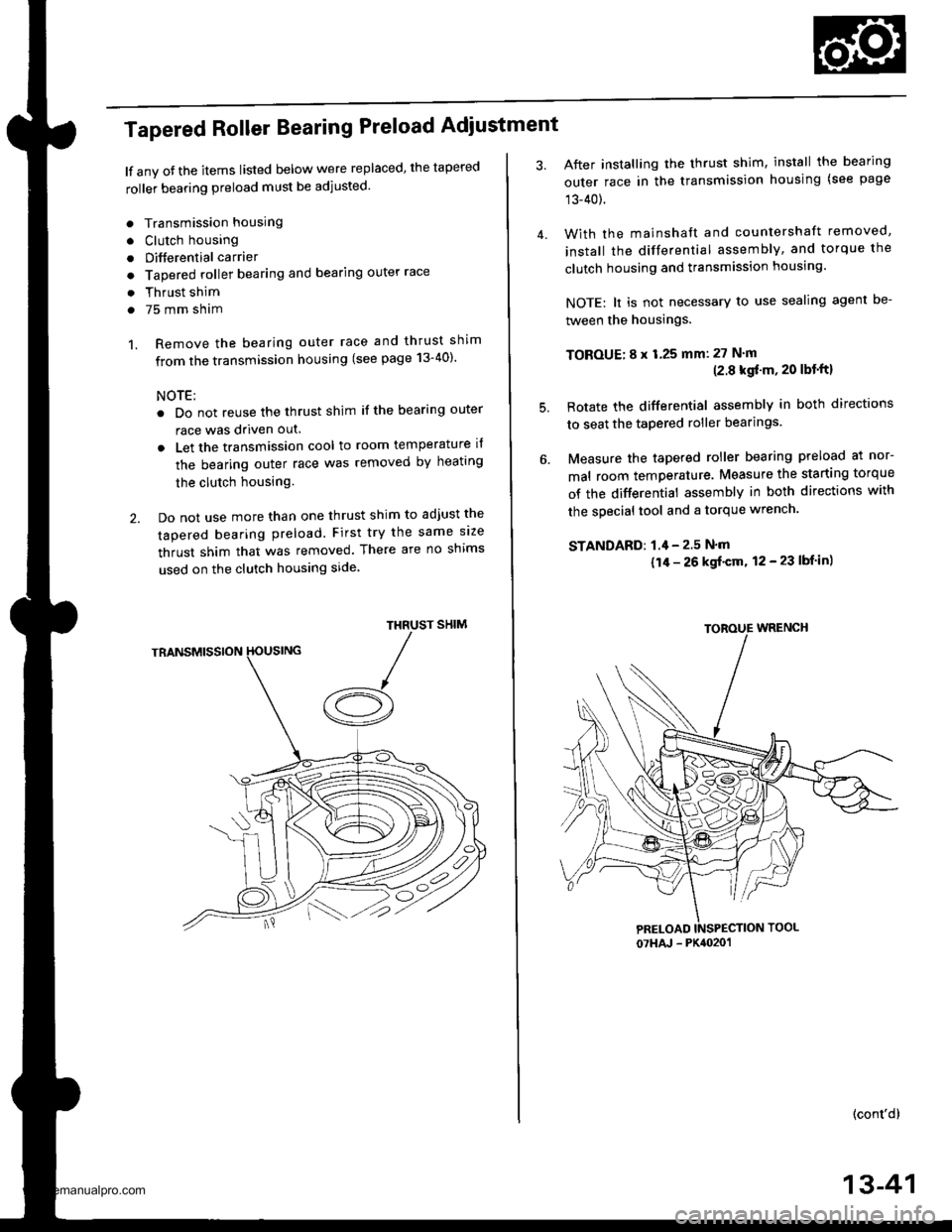

Tapered Roller Bearing Preload Adiustment

lf any oJ the items listed below were replaced, the tapered

roller bearing preload must be adjusted.

. Transmission housing

. Clutch housing

. Differential carrier

o Tapered roller bearing and bearing outer race

. Thrust shim

. 75 mm sham

1. Remove the bearing outer race and thrust shim

from the transmission housing (see page 13-40)'

NOTE:

. Do not reuse the thrust shim if the bearing outer

race was driven out.

. Let the transmission cool to room temperature il

the bearing outer race was removed by heating

the clutch housing.

2. Do not use more than one thrust shim to adjust the

tapered bearing preload. First try the same size

thrust shim that was removed. There are no shims

used on the clutch housing side

SHIMTHRUST

/A

After installing the thrust shim, install the bearing

outer race in the transmission housing (see page

13-40).

With the mainshaft and countershaft removed,

install the differential assembly, and torque the

clutch housing and transmission housing.

NOTE: lt is not necessary to use sealing agent be-

tween the housings.

TOBOUE; 8 x 1.25 mm: 27 N'm(2.8 kgf'm, 20 lbt'ftl

Rotate the differential assembly in both directions

to seat the tapered roller bearings.

Measure the tapered roller bearing preload at nor-

mal room temperature. Measure the starting torque

of the differential assembly in both directions with

the special tool and a torque wrench.

STANDAFD: 1.4 - 2.5 N'm

{1/r - 26 kgf'cm, 12 - 23 lbf in)

(cont'd)

4.

5.

07HAJ - PK4020'�1

13-41

www.emanualpro.com

Page 499 of 1395

Transfer Assembly

Reassembly (cont'd)

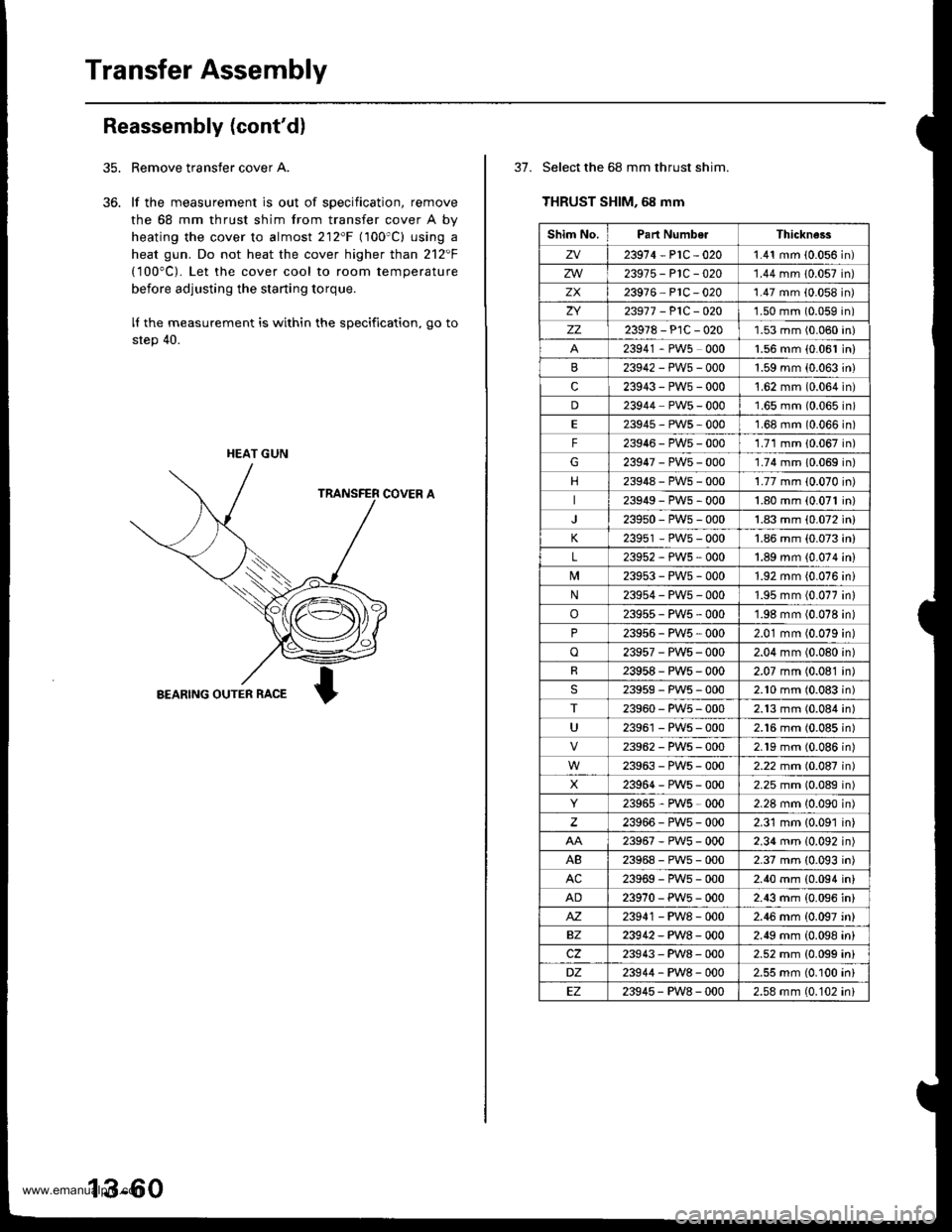

Remove transfer cover A.

lf the measurement is out of specification, remove

the 68 mm thrust shim from transfer cover A by

heating the cover to almost 212'F (100'C) using a

heat gun. Do not heat the cover higher than 212F

(100"C). Let the cover cool to room temperature

before adjusting the starting torque.

lI the measurement is within the specification, go to

step 40.

COVER A

BEARING OUTER RACE

35.

36.

HEAT GUN

13-60

37. Select the 68 mm thrust shim.

THRUST SHIM, 68 mm

Shim No.Part NumberThickne3s

zv23914-P1C-0201.41 mm (0.056 in)

zw23975-P1C-020'1.44 mm 10.057 in)

zx23916 PlC -020'1.47 mm (0.058 in)

ZI23917 -P1C-O201.50 mm (0.059 in)

zz23978-PlC-0201.53 mm (0.060 in)

23941 - PW5 0001.56 mm {0.061 in)

23942-PWs-0001.59 mm (0.063 in)

c23943-PW5-000't.62 mm (0.064 in)

D23944 PW5 - 0001.65 mm (0.065 in)

E23945-PWs-0001.68 mm (0.066 in)

F23946-PW5-0001.71 mm 10.067 in)

G23947-PW5-000'1.74 mm 10.069 in)

23948-PWs-0001.77 mm (0.070 in)

23949-PWs-0001.80 mm (0.071 in)

239s0-PW5-0001.83 mm (0.072 in)

K23951 - PW5 - 0001.86 mm (0.073 in)

L23952-PWs-0001.89 mm {0.074 in)

239s3-PWs-0001.92 mm {0.076 ini

N23954-PW5-0001.95 mm (0.077 in)

o23955-PW5-0001.98 mm (0.078 in)

P23956 - PW5 , 0002.01 mm (0.079 in)

o23957-PWs-0002.04 mm (0.080 in)

R23958-PWs-0002.07 mm (0.081 in)

23959-PW5-0002.10 mm (0.083 in)

T23960-PW5-0002.13 mm (0.084 in)

U23961 - PW5 - 0002.16 mm (0.085 in)

23962-PW5-0002.19 mm (0.086n)

23963-PWs-0002.22 mm (0.087n)

X23964-PWs-0002.25 mm (0.089n)

23965,PWs-0002.28 mm 10.090n)

23966-PW5-0002.31 mm {0.091 in)

23967-PWs-0002.34 mm (0.092 in)

AB23968-PWs-0002.37 mm (0.093 in)

AC23969-PWs-0002.40 mm {0.094 in}

AD23970-PW5-0002.43 mm (0.096 in)

M23941 - PW8 - 0002.46 mm {0.097 'n}

BZ23942-PW8-0002.49 mm (0.098 in)

cz23943-PW8-0002.52 mm {0.099 ini

DZ23944-PW8-0002.55 mm (0.100 in)

EZ23945-PW8-0002.58 mm (0.102 ini

www.emanualpro.com