Transfer HONDA CR-V 2000 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 704 of 1395

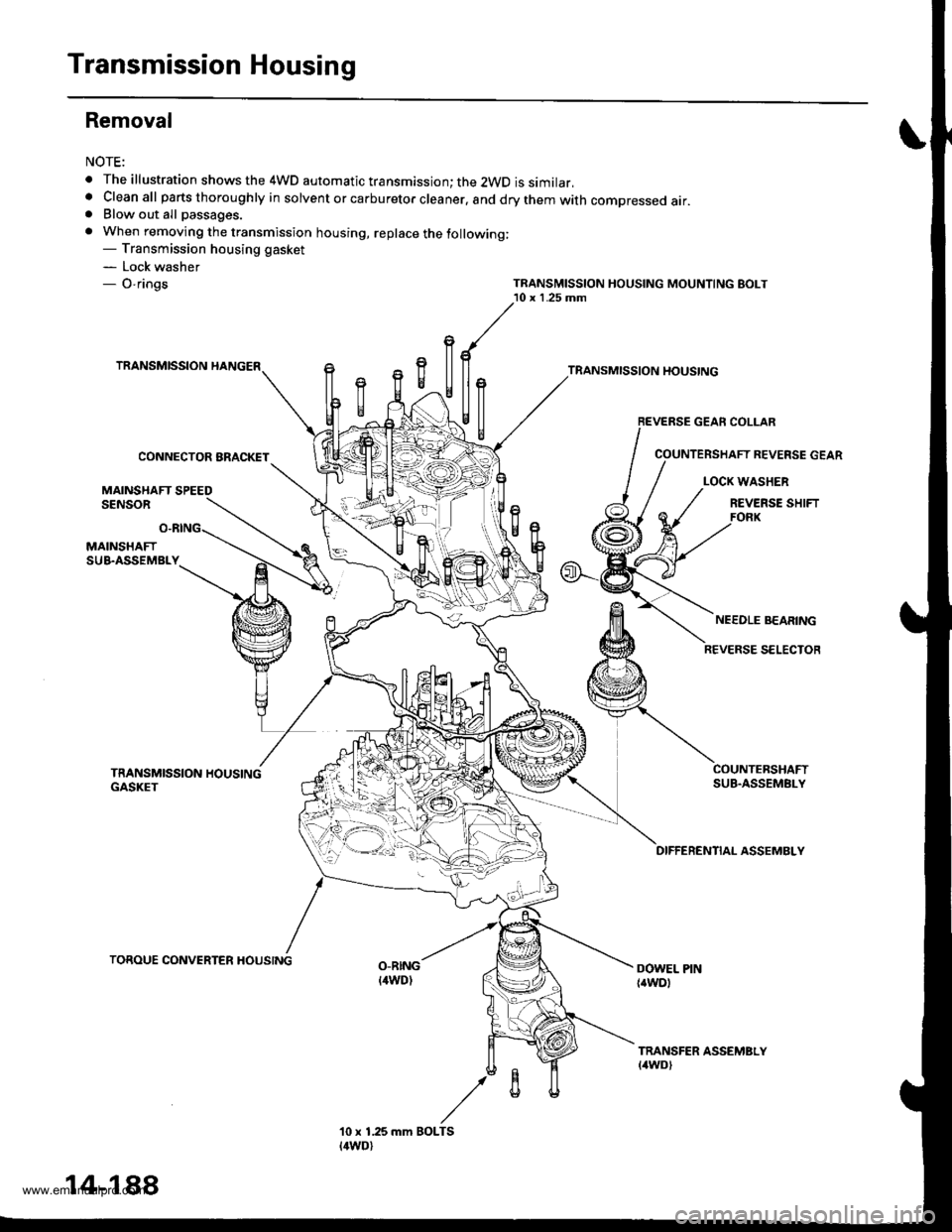

Transmission Housing

Removal

NOTE:

. The illustration shows the 4WD automatic transmission; the 2WD is similar,. Cleanall parts thoroughly in solvent or carburetor cleaner. and drythemwith compressed air.. Blow out all passages.

. When removing the transmission housing, replace the lollowing:- Transmission housing gasket- Lock washer- O-rings

TRANSMISSION HANGERTRANSMISSION HOUSING

REVERSE GEAN COLLAR

TRANSMISSION HOUSING MOUNTING EOLT

CONNECTOR BRACKET

MAINSHAFT SPEEDSENSOR

REVERSE GEAR

LOCK WASHER

REVERSE SHIFT

MAINSHAFTSUB.ASSEMBLY

TRANSMISSION HOUSINGGASKET

DIFFERENTIAL ASSEMBLY

TOROUE CONVERTER HOUSINGO-RINGt4wDl

TRANSFER ASSEMBLYt4wDt

10 x 1.25 mm

l4wo)

14-1 88

BOLTS

www.emanualpro.com

Page 705 of 1395

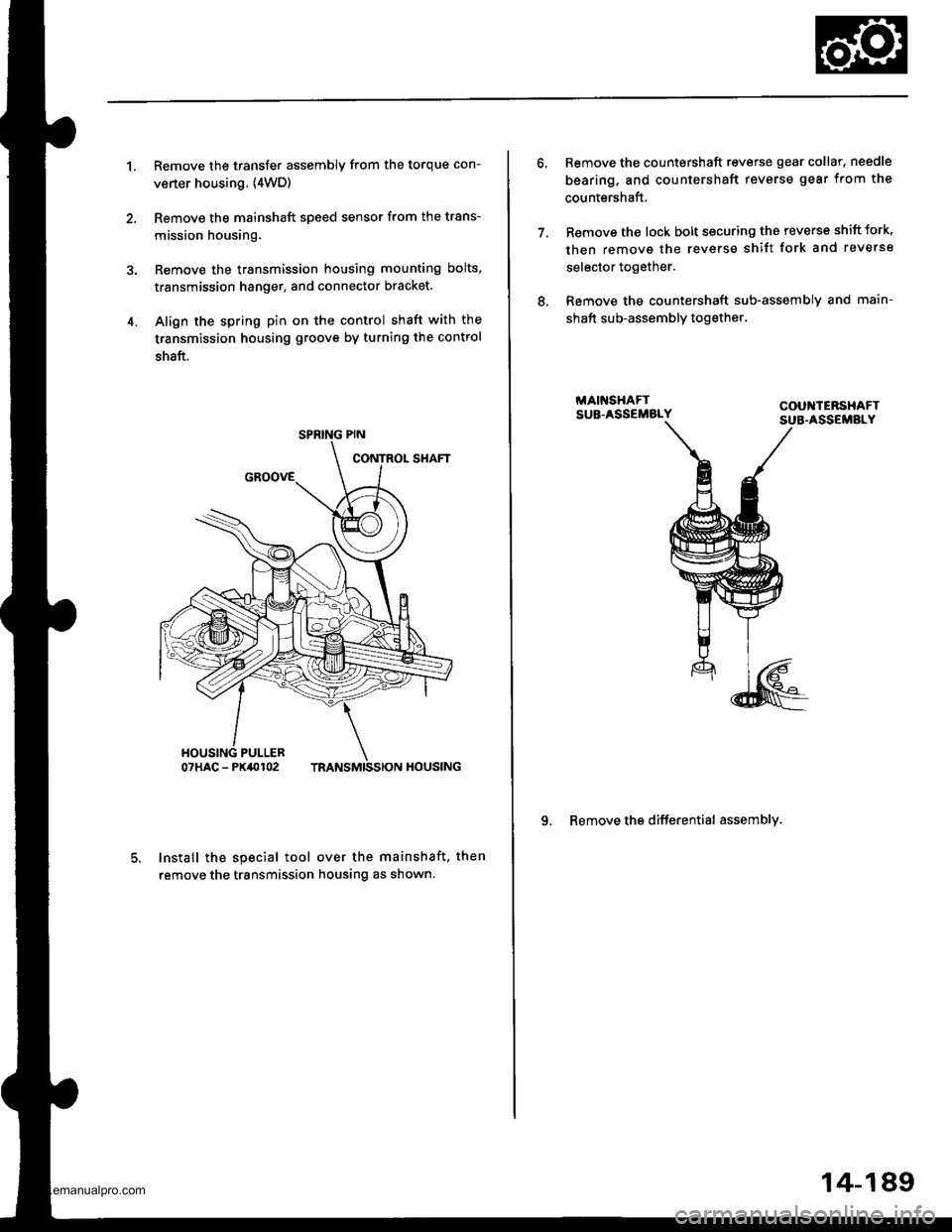

1.Remove the transfer assembly from the torque con-

verter housing. (4WD)

Remove the mainshaft speed sensor from the trans-

mission housing.

Remove the transmission housing mounting bolts,

transmission hanger, and connector bracket.

Align the spring pin on the control shaft with the

transmission housing groove by turning the control

shaft.

Install the special tool over the mainshaft. then

remove the transmission housing as shown.

4.

SPRING PIN

7.

Remove the countershaft reverse gear collar, needle

bearing, and countershaft revsrse gear from the

countershaft,

Remove the lock bolt securing tho reverse shift fork,

then remove the reverse shift fork and reverse

selector together.

Remove the countershaft sub-assemblv and main-

shaft sub-assembly together,

9. Remove the differential assembly.

8.

14-189

www.emanualpro.com

Page 738 of 1395

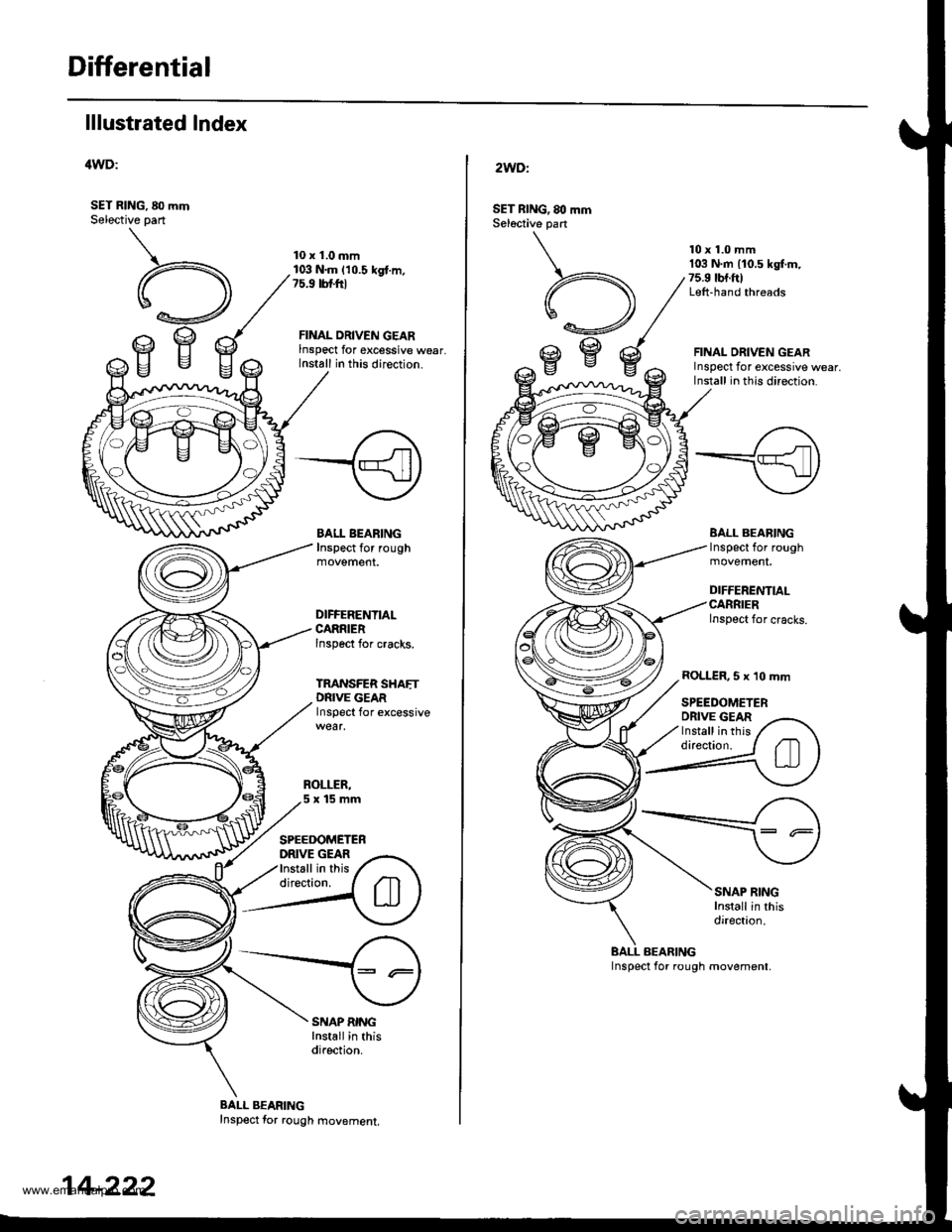

Differential

lllustrated Index

'lWD:

SET RING, 80 mmSelective part

10 x 1.0 mm103 N.m (10.5 kgt.m,?5.9 tbtftl

FINAL ORIVEN GEARlnspect for excessive wear,Install in this direction.

BALL BEARINGInspect for rough

DIFFERENTIAI.CARRIERlnspect for cracks.

TRANSFER SHAETDNlvE GEARInspect for excessive

SPEEDOMETERDRIVE GEARInstall in thisdirection.

SNAP RINGInstall in thisdirection.

BALL BEARINGInspect for rough movement,

14-222

2WDl

SET nlNG, 80 mmSel6ctive part

A,U

,gBc

10 x 1.0 mm103 N.m {10.5 kg[.m,75.9 tbt.ftlLeft-hand threads

FINAL ORIVEN GEARInspect for excessive wear,Install in thls direction.

BALL BEABINGInspect for rough

DIFFERENTIAI.CARRIERInspect for cracks.

ROLLER,5 x 10 mm

SPEEDOMETERDRIVE GEARInstall in thisdirection.

SNAP RINGInstall in thisdirection.

BALL BEARING

www.emanualpro.com

Page 740 of 1395

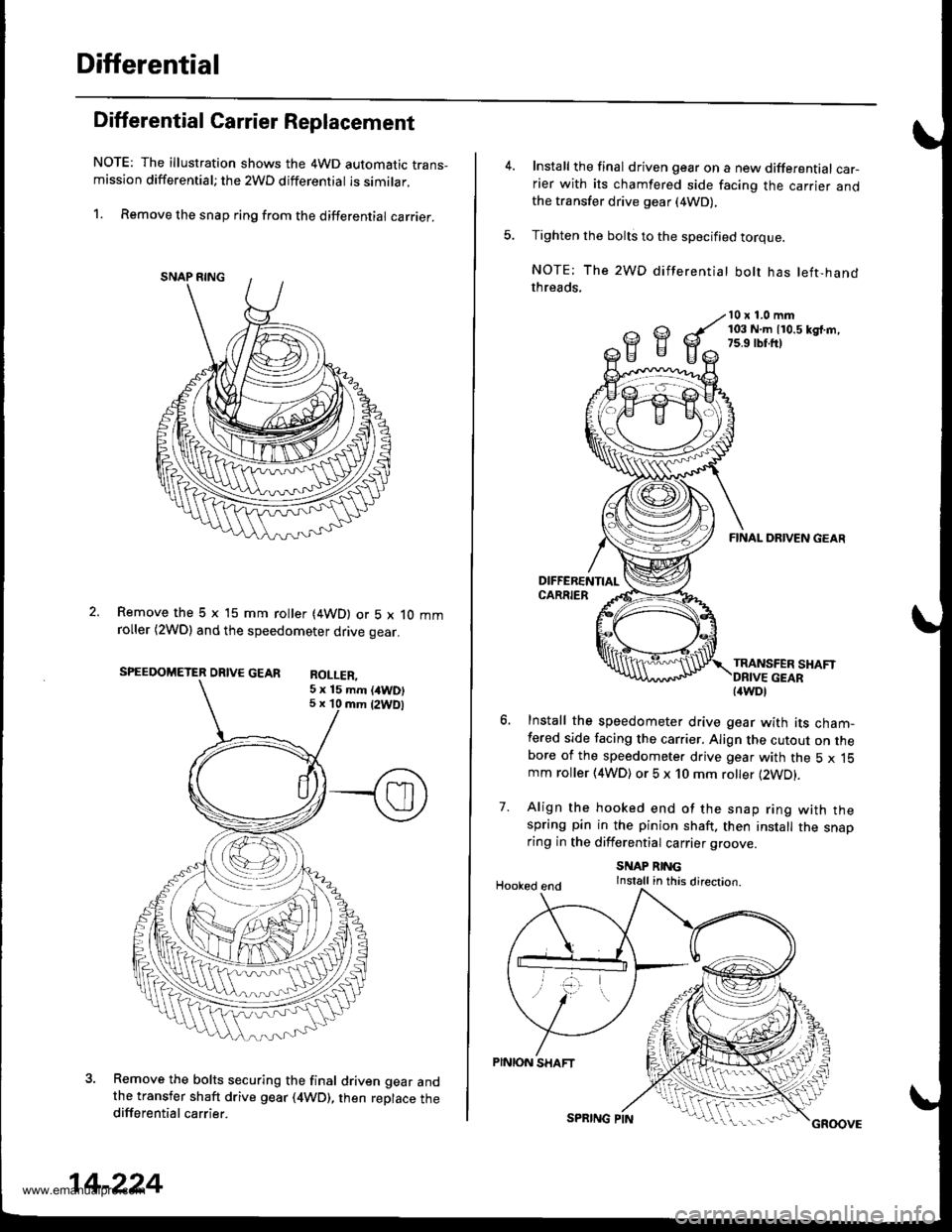

Differential

Differential Carrier Replacement

NOTE: The illustration shows the 4WD automatic trans-mission differential; the 2WD differential is similar.

1. Remove the snap ring from the differential carrier.

Remove the 5 x 15 mm roller (4WD) or 5 x 10 mmroller (2WDl and the speedometer drive gear.

SPEEDOMETER DRIVE GEAR RoI I FP

Remove the bolts securing the final driven gear andthe transfer shaft drive gear (4WD), then replace thedifferential carrier.

5 x 15 mm (/tWD)5 x 10 mm {2WDl

14-224

SPRING PINGROOVE

Install the final driven gear on a new differential car-rier with its chamfered side facing the carrier andthe transfer drive gear (4WD),

Tighten the bolts to the specified torque.

NOTE: The 2WD differentiat bolt has left-handthreads,

10 x 1.0 mm103 N.m 110.5 kd.m,7s.9 rbr.ft)

7.

FINAL DRIVEN GEAR

TRANSFER SHAFT

Install the speedometer drive gear with its cham-fered side facing the carrier. Align the cutout on thebore of the speedometer drive gear with the 5 x 15mm roller (4WD) or 5 x 10 mm roller (2WD).

Align the hooked end of the snap ring with thespring pin in the pinion shaft. then install the snaoring in the differential carrier groove

SNAP RINGInstall in this direction.Hooked end

PINION SHAFT

{4WDl

www.emanualpro.com

Page 748 of 1395

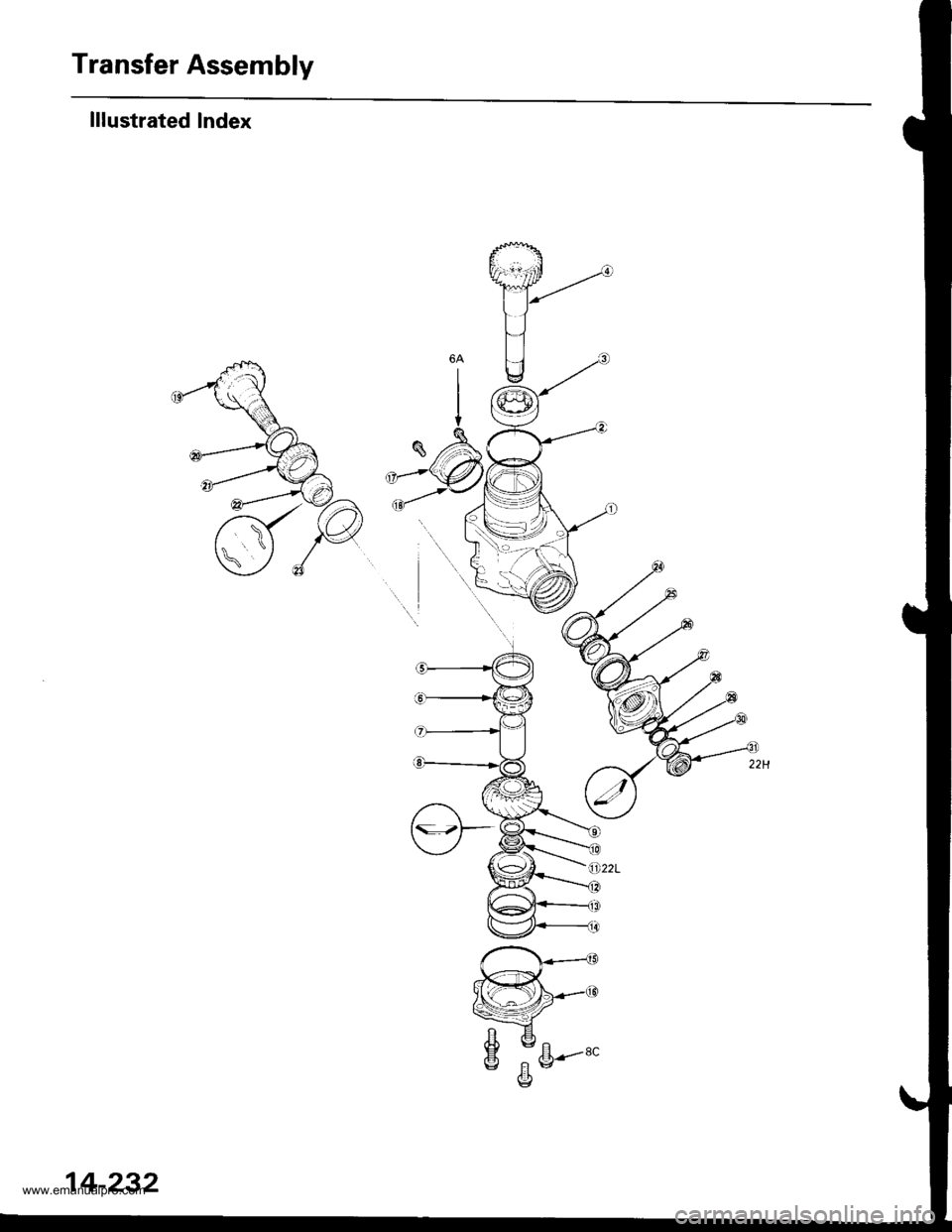

Transfer Assembly

lllustrated Index

www.emanualpro.com

Page 749 of 1395

O TRANSFER HOUSING

O o-RING Replace.

O TRANSFER HOUSING ROLLER BEARING

@ TRANSFER SHAFT

O TAPERED ROLLER BEARING OUTER RACE

@ TAPERED ROLLER BEARING

O TRANSFER SHAFT COLLAR

@ THRUST SHIM, 25 mm Selective part

€) TRANSFER DRtvE GEAR (HYPoID GEAR}

@ coNtcAL SPRtNG WASHER Reptace,

@ TRANSFER SHAFT LOCKNUT,22 x 1.25 mm Left-hand rhreads, replace.

(D TAPERED ROLLER EEARING

@ TAPERED ROLLER EEARING OUTER RACE(} THRUST SHIM, 68 mm Selective part

@ O-RING Replace.

@ TRANSFER coVER A

(} TRANSFER COVER B

@ o-RING Replace.

(9 TRANSFER DRIVEN GEAR SHAFT (HYPOID GEAR)

@ THRUST SHIM, 35 mm Selective part

@ TAPERED ROLLER BEARING

@ TRANSFER SPACER Reptace.

@ TAPERED RoLLER BEARTNG OUTER RACE

@ TAPERED ROLLER BEARING OUTER RACE

@ TAPERED BOLLER BEARTNG

@ olL SEAL Replace.

@ COMPANION FLANGE

@ o-RING Replace.

@ BACK-UP RING

@ coNtcAL SPRtNG WASHER Reptace.

@ TRANSFER DRIVEN GEAR SHAFT LOCKNUT,22 x 1.25 mm Replace.

TOROUE SPECIFICATIONS

Boh/Nut No.Torque ValueSizeRemarks

6A

8C

22L

22H

12 N'm (1.2 kgf.m,8.7 lbf.ft)

24 N.m (2.4 kgf.m, 17 lbnft)

118 N.m (12.0 kgim,87 Ibift)

132 216 N.m (13.5 22.0 kgf.m,

98 - 159 lbift)

6x1.0mm

8 x 1.25 mm

22 x 'l.25 mm

22 x 1.25 mm

Transfer shaft locknut:

Left hand threads

Transfer driven gear shaft locknut

Tightening torque: depending on

Total Starting Torque value

14-233

www.emanualpro.com

Page 750 of 1395

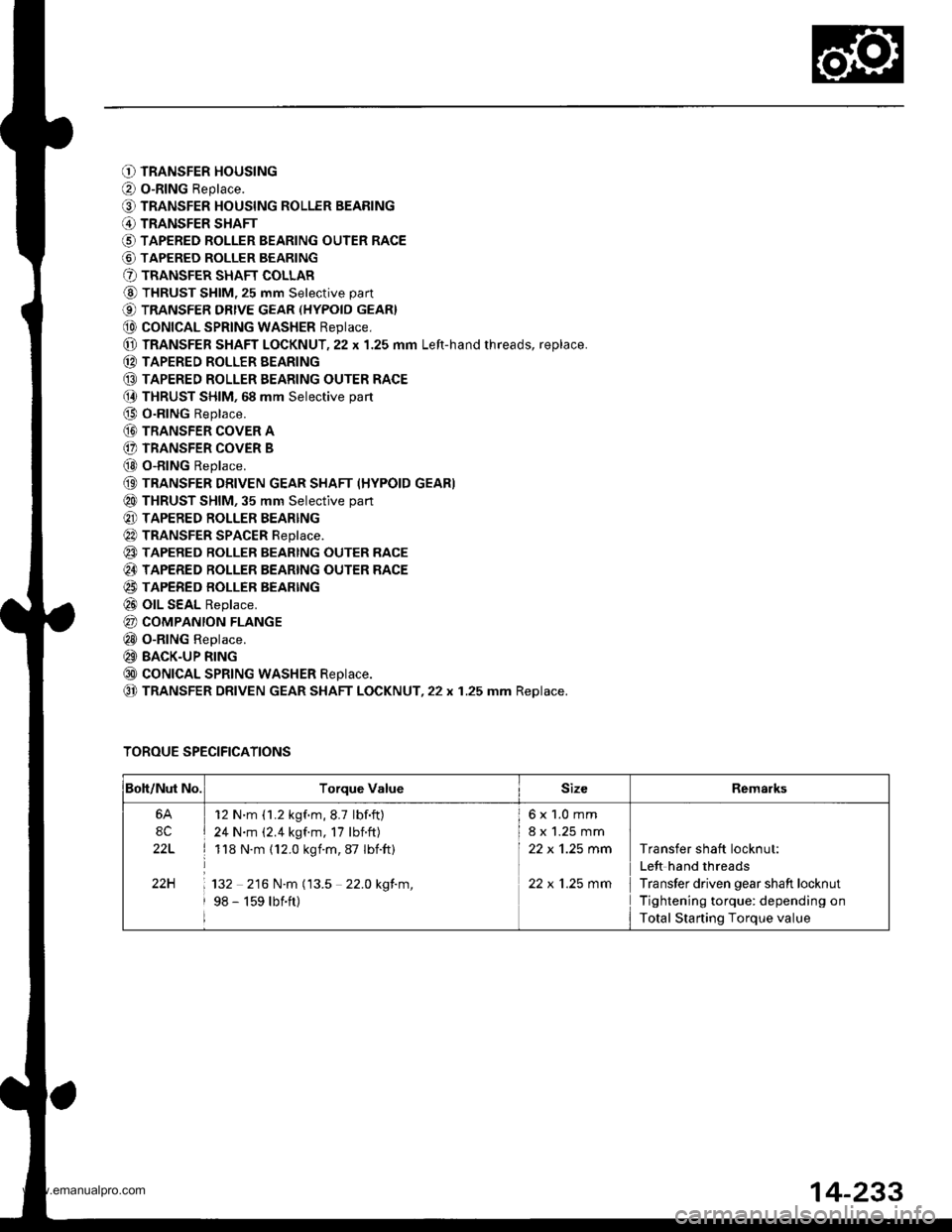

Transfer Assembly

Inspection

NOTE: To prevent damage to the transfer housing,

always use soft jaws or equivalent materials between

the transfer housing and the vise.

Trsnsfer Gear (Hypoid gear) Backl8sh M€asurem€nt

1. Set a dial indicator on the companion flange as

snown.

2. Measure the transfer gear backlash.

STANDARD: 0.06 - 0.16 mm {0.02 - 0.06 in)

Total Starting Torque Meagurgm€nt

3, Rotate the companion flange several times to seat

the tapered roller bearing.

4. Measure the starting torque (companion flange

side) using a torque wrench as shown,

STANDARD:

2.68 - 3.,17 N.m(27.3 - 35.,1 kgf.cm, 23.7 - 30.7 lbf.inl

TRANSFER SHAFT

DIAL INDICATOR

COMPANION FLANGE

14-234

Transfer Gear (Hypoid gear) Tooth Contact Inspection

5, Remove transfer cover B, then apply Prussian Blue

to both sides of the transfer gear teeth lightly and

Rotate the companion flange in both directions until

the transfer gear rotates one full turn in both direc-

tions.

Check the transfer gear tooth contact pattern. Thepattern should be centered on the gear tseth as

snown.

6.

7.

8.lf the statrting torque measurement or the tooth

contact pattern are not correct, disassemble the

transfer assembly, replace worn or damaged parts,

and reassemble it.

TRANSFER DRIVE G€AR

www.emanualpro.com

Page 751 of 1395

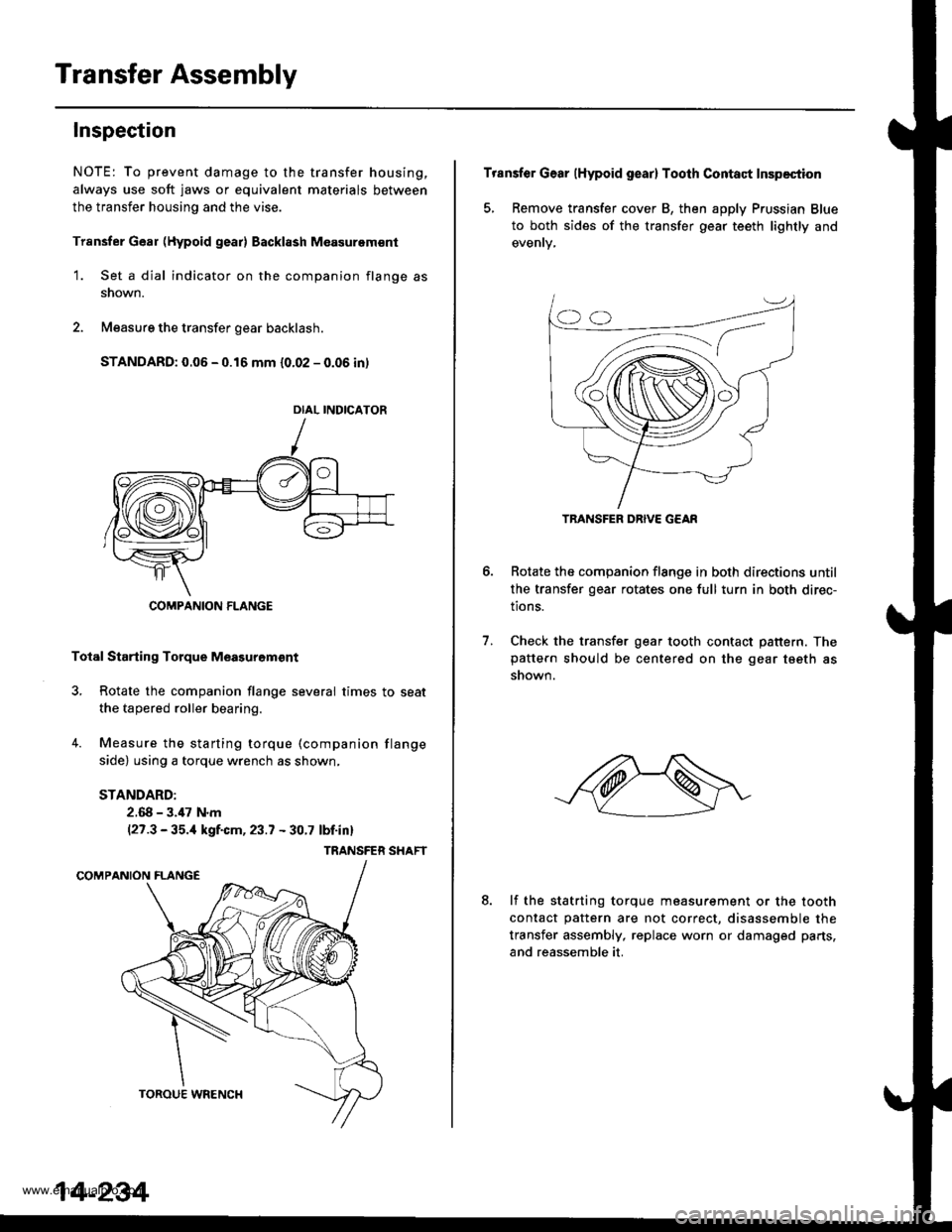

Disassembly

1. Remove the transfer covers A and B.

2. Cut the lock tabs of the locknut usino a chisel.

LOCK TAB

5.

Put a 14 mm Allen wrench in the gear side of the

transfer shaft, then secure the Allen wrench in a

bench vise.

Remove the transfer shaft locknut and the conical

spring washer. The transfer shaft locknut has left

hand threads.

Remove the transfer shaft, transfer drive gear, 25

mm thrust shim, transfer shaft collar, and tapered

roller bearing from the transfer housing.

TRANSFER SHAFT

THRUST SHIM,25 mrnSelective part

CONICAL SPRINGWASHERReplace.

(cont'd)

1a mm ALLEN WRENCH

14-235

www.emanualpro.com

Page 752 of 1395

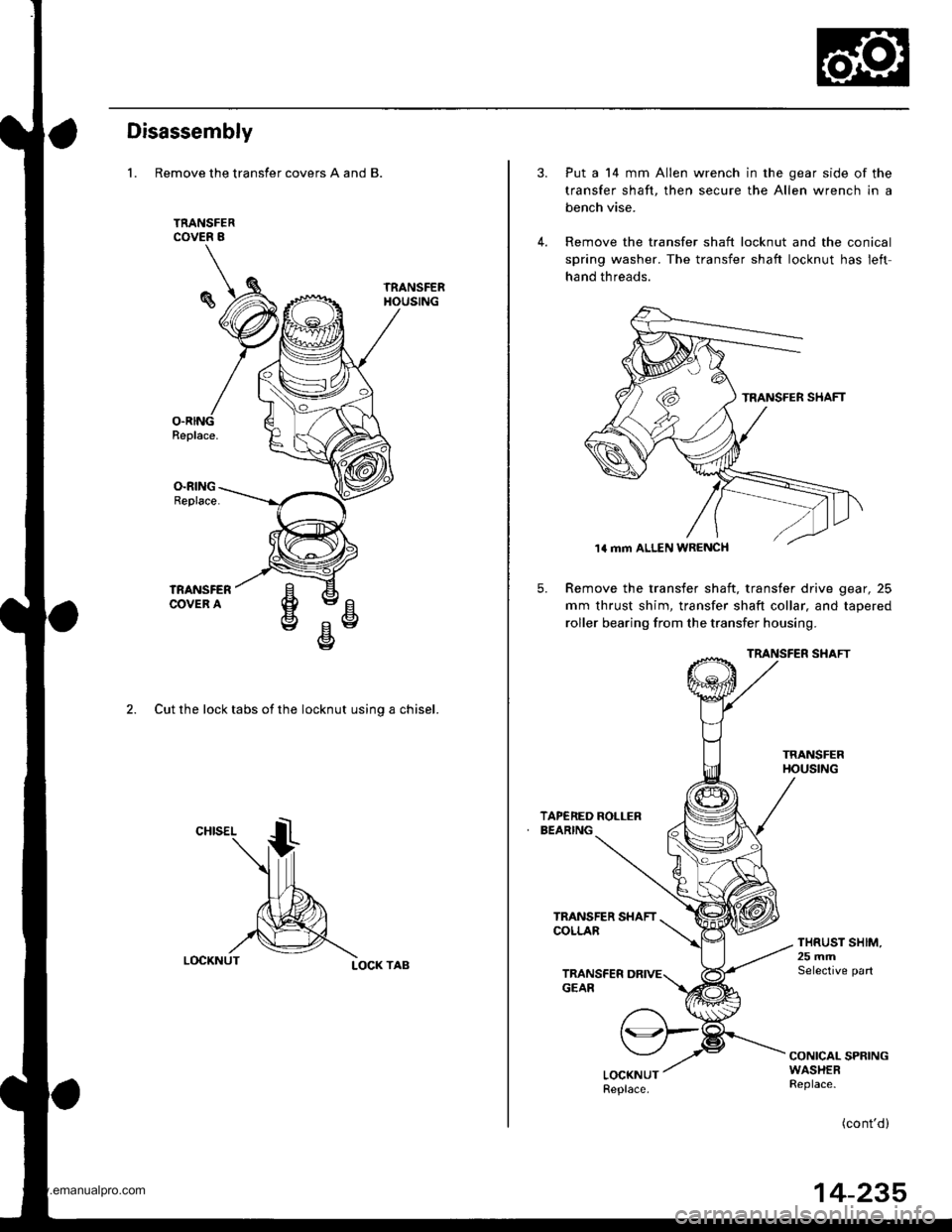

Transfer Assembly

Disassembly (cont'd)

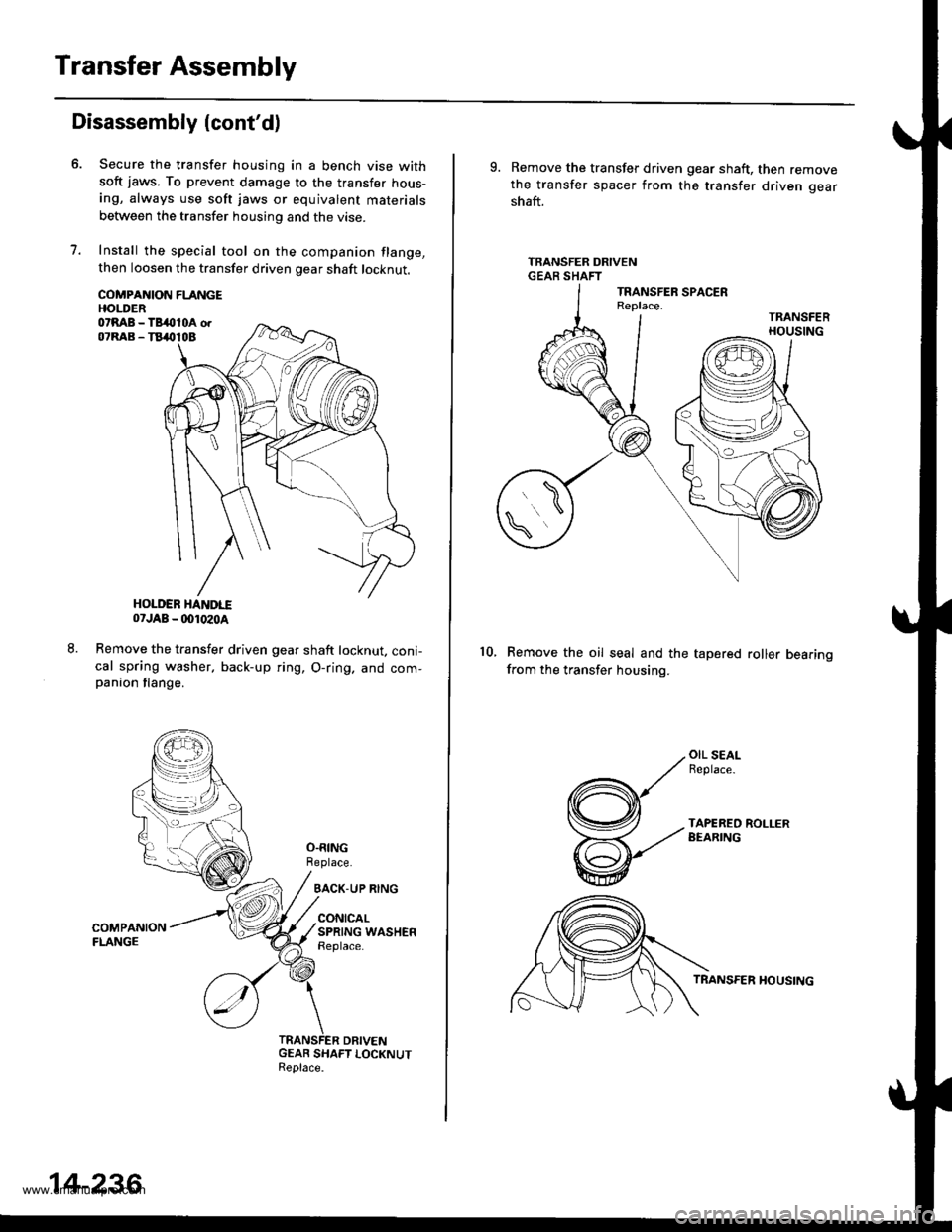

7.

Secure the transfer housing in a bench vise withsoft iaws. To prevent damage to the transfer hous-ing, always use soft jaws or equivalent materials

between the transfer housing and the vise.

Install the special tool on the companion flange,then loosen the transfer driven gear shaft locknut.

COMPANION FLANGEHOI.DER07RAB - TB4lll0A orOTRAB - TB&TOB

HOLDER HAITDI..E07JAB _ (x)1020a

Remove the transfer driven gear shaft locknut, coni-cal spring washer, back-up ring, O-ring. and com-panion flange.

O.RINGReplace.

BACK-UP RING

CONICALSPRING WASHENReplace.

GEAR SHAFT LOCKNUTReplace.

14-236

9. Remove the transfer driven gear shaft, then removethe transfer spacer from the transfer driven gear

shaft.

TRANSFER DRIVENGEAR SHAFT

Remove the oil seal and the tapered roller bearingfrom the transfer housing.

10.

OIL SEALFeplace-

TAPEREO ROLLERBEARING

TRANSFER HOUSING

www.emanualpro.com

Page 753 of 1395

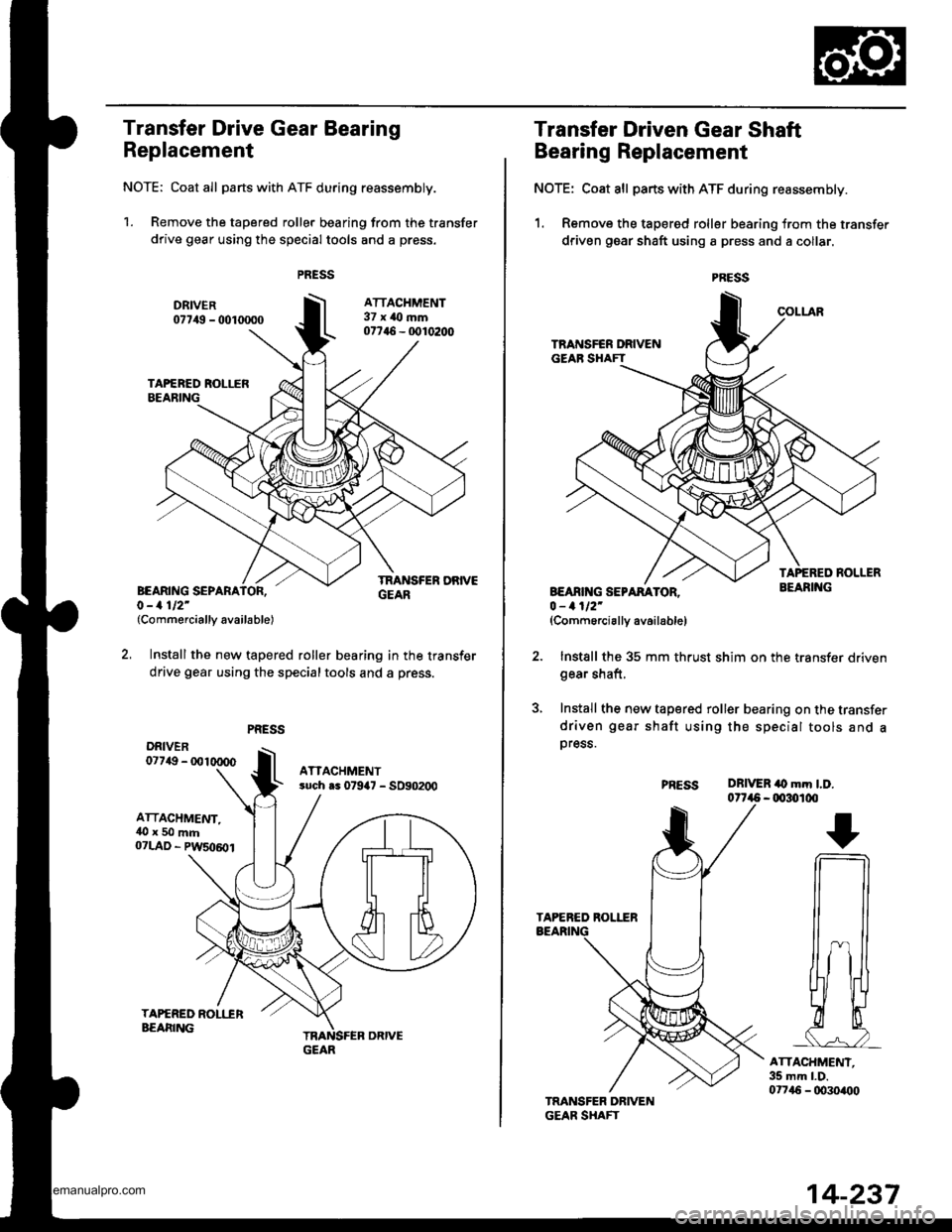

Transfer Drive Gear Bearing

Replacement

NOTE: Coat all parts with ATF during reassembly.

1. Remove the tapered roller bearing from the transfer

drive gear using the special tools and a press.

(Commercially available)

Install the new tapered roller bearing in the transfer

drive gear using the specialtools and a press.

ATTACHMENT,l()x50mm

07LAD - PWSo6o1

GEAR

14-237

Transfer Driven Gear Shaft

Bearing Replacement

NOTE: Coat all parts with ATF during reassembly.

1. Remove the tapered roller bearing from the transfer

driven gear shaft using a press and a collar.

B€ANf{G SEPARATO0 - 1112'(Comm6rcially availablel

2. Install the 35 mm thrust shim on the transfer drivengear shaft,

3, Install the new tapered roller bearing on the transfer

driven gear shaft using the special tools and apress.

PNESSDRIVER iO mm l.D.0t7a5 - 00:I)100

I

n

ru

ATTACHMENT.35 mm l.D.0t715 - 0030400

www.emanualpro.com