4-18 HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 51 of 1395

Engine Electrical

Speciaf Tools ............. 4-2

Starting System

Component Location Index ............ 4-3

Circuit Diagram ................................ 4-4

Starter Test ........... 4-5

Starter Solenoid Test ...................... 4'5

Starter Replacement ....................... 4-7

Field Winding Test ........................... 4-7

Starter Overhaul ............................,. 4-8

Brush Inspection ...........................,., 4-9

Overrunning Glutch Inspection ...... 4-9

Armature lnspection and Test ........4-10

Brush Holder Test ............................ 4-12

Starter Reassemb|y ......................... 4-1 2

Perf ormance Test ............................. 4- 1 3

lgnition System

Component Location Index ............ 4-14

Circuit Diagram ................................ 4-15

lgnition Timing Inspection and

Setting .......................................... 4-16

Distributor Replacement ........,........ 4-17

Distributor Overhaul .............,,......... 4-18

lgnition Control Module (lCM) Input

Test ..............................,................ 4-19

fgnition Coil Test .............................. 4-2O

lgnition Wire Inspection and

Test ............................................... 4-20

Spark Plug Inspection ..................... 4-21

-+

ENGINE

Charging System

Component Location Index ............ 4-22

Circuit Diagram ....................,........... 4-23

Troubleshooting .............................. 4-24

Alternator Replacement ..........,....... 4-30

Alternator Overhaul .......,,................ 4-31

Rectifier Test .........4-32

Alternator Brush Inspection ........... 4-32

Rotor Slip Ring Test ........................ 4-33

Stator Test ............. 4-33

Alternator Belt Inspection and

Adiustment ........4-34

Gruise Control

Component Location Index .,,,........ 4-36

Circuit Diagram ................................ 4-37

Control Unit Input Test ................... 4-38

Main Switch Test/Replacement ..... 4-40

Set/Resume Switch Test/

Replacement .......................,........ 4'40

Actuator Test ....,,., 4-41

Actuator Replacement ...............,.... 4-42

Actuator Cable Adiustment ............ 4-43

Clutch Switch Test .......................... 4-43

Brake Switch Test .................. .......... 4-44

Actuator Solenoid Test .............. ...,. 4-44

Actuator Disassembly ..................... 4-45

www.emanualpro.com

Page 64 of 1395

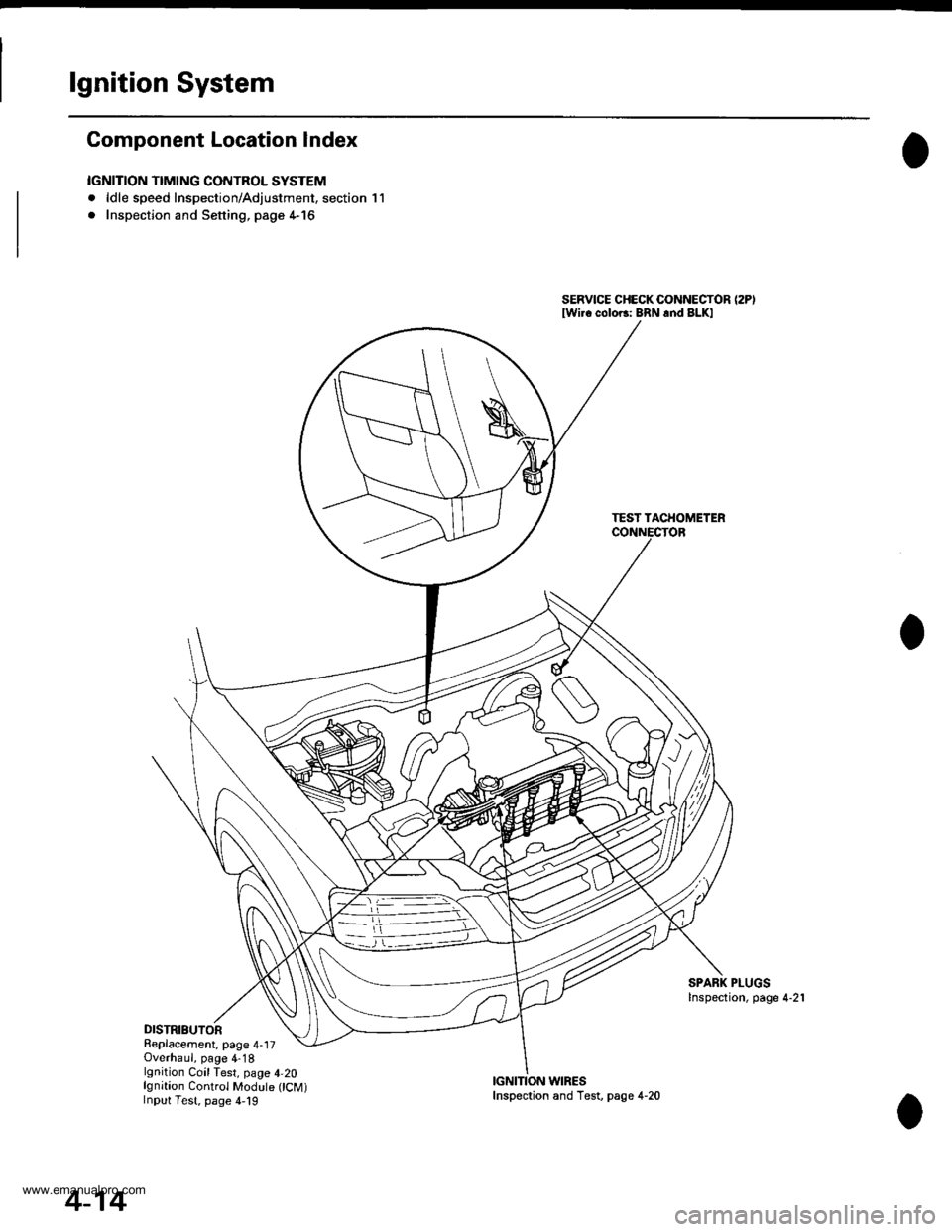

lgnition System

Component Location Index

IGNITION TIMING CONTROL SYSTEM

. ldle speed Inspection/Adjustment, section 11

. Inspection and Sening. page 4-16

DISTRIBUTORReplacement, page 4-17Overhaul, page 4-18lgnition CoilTest, page 4,20lgnition Control Module CM)Input Test, page 4,19

SERVICE CHECK CONNECTOR (2P)

lwi.c colo6: BRN rnd BLKI

TEST TACHOMETER

SPARK PLUGSInspection, page 4-21

WIRES

4-14

Inspection and Test, page 4-20

www.emanualpro.com

Page 68 of 1395

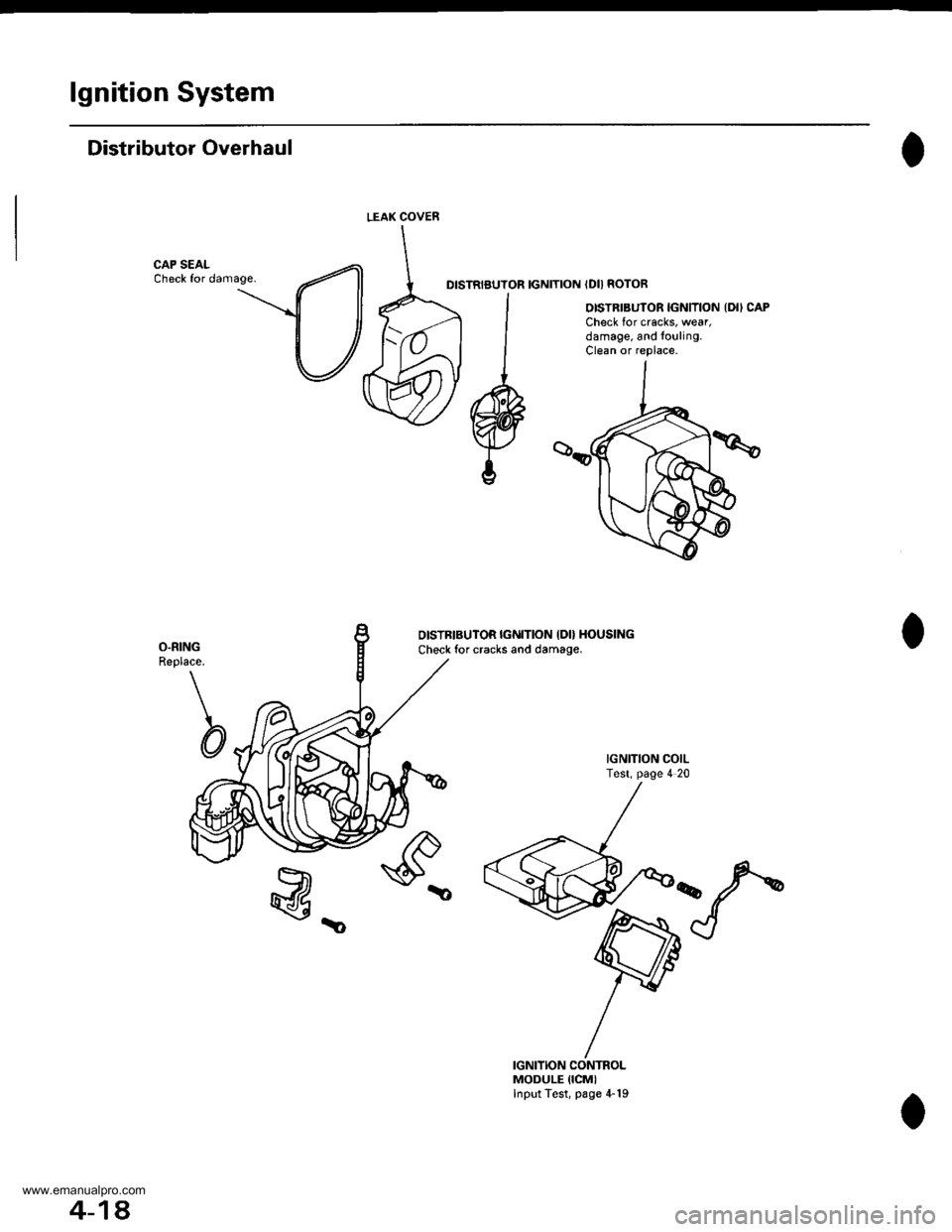

lgnition System

Distributor Overhaul

CAP SEALCheck for damage.DISTRIBUTOR IGNITION IDII ROTOR

OISTRIBUTOR IGNITION {DII CAPCheck for cracks, wear,damage, and to!ling.Clean or replace.

O.RINGReplace.

b

OISTBIBUTOR IGI{ITION IDO HOUSING

Check for cracks and damage.

IGNITION COILTest, page 4 20

@_

IGNITION CONTROLMODULE {ICMIInput Test, page 4-19

LEAK COVEN

4-18.

www.emanualpro.com

Page 517 of 1395

Automatic Transmission

Special Tools . 14'2OescriptionGeneral Operation . .... 14 3Power Flow . . .. '14_6

Electronic Control System .. .. . . .. .14_15Hydraulic Control .. 14 24Hydraulic Flow....-....... .. . .... .. .. . 14_29Lock'up Syslem .. .'t4'39Electrical SystemComponenl Locdlrons 14 45

PCM Circuil Dragram (A/T Control Svstem)'97 Model ....................... . . .. - . ... .14-46'98Model ................. . ... .. .. .1450'99 00Models.... . .... . . . 1452

PCM Terminal Voltage/Measuring ConditionsA"/T Control System-'97Model ...... ..14'48A,/T Control System -'98 00 Models . . .. . . 14 54

Troubleshooting Procedures .. ..... ... - 14_56Svmotom to comoonent CharlEiectr,cal Syslem -'97 Model . . 14 60Electrical System -'98 - OO Models . .. . . 14_62Electrical Troubleshooting ('97 Model)Troubleshooting Flowaharts .... ..... . .. . . 14_64

Electrical Troubleshooting ('98 - 00 Models)Troubleshootinq Flowclt"n" .... . ....- . .14-93ElectricalTroublesliooting('99 00Models)Troubleshootino FlowchartO/D OFF Indicator Light Does Not Come On 14 131

O/D OFF Indicator Liaht On ConstantlY . . . .1!-132O/D OFF Indicator Light Does Not Come OnEven Though O/D Switch ls Pressed . .... - 14_133

Lock up Control Solenoid Valve A,/B AssemblyTest....................-......... . .14-135Replacement . .ll_135Shifr ControlSolenoid Valve Ay'B Assembl,Test .............................. . .. 14-136

Replacement..............- . .14'136Linear Solenoid AssemblYTest.............................................. .. .... . 14_137Replacement .. . 14138Marnshaftlcountershafl Speed SensorsReplacement ...-... 14_138A/T Gear Position SwitchTest ..........................-... . .. 14-139ReplacementA/T Gear Positionlndicator.................. 14-140

Valve Eodynepair ............................... ..... . . .. - . .. ... 14 192

Assembly .................... .. 1{_193

Valve CapsDesciiption....-........................ .. ...... 14194

tnspeition ................... .. 14' 195

N4ain Valve BodyDisassembly/lnspection/Reassemblv - ...... .. 14_196

Secondarv Valve BodYDisassemblv4nspectron/ReassemblY .. . 14 198

Reoulator Valve Bodvbisassembtv,lnspiction/Reassemblv . 14199

Servo EodvDisassembly/lnspection/Reassembly ... ....14'200

Lock'uo Valve BodYDis;ssembly/lnspection/Reassembly .... . 14_201

MainshaftDisassembly/lnspection/Reassembly .. .. .. ..14'202

Inspection ....-.............. ..11_203

Sealing RingsReilaceient ...... ..... . 14'204

CountershaftDisassembly/lnspection/Reassembly .. . . . . . 11-205

Disassembly/Reassemb|y . . ........ ...... . .. 14_206Inspedron ................ . .... . 14 207

One wav ClutchDisassembly/lnspection/ReassemblY ... 11_209

Sub-shaftDisassembly/lnspection/Reassembly ... . .. . 14-210

oisassembly/Re6ssembly . . ... .-...... . . ..14-211

Sub-shaft BearingsReplacement .......14'212

Clutchllfustrated Index .......... . . .14-213

Disassembly .... .. .....14-216Reassembfy .... . .. .. . 14'218

Differentialllfustrated Index " 14-222Backlash Inspection . .... . .14'223

Bearing Repiacement .. 11-223

Differe-ntial Carrier Replacement .. .. . . . .. ..11-2?4

OifSeal Replacement. . .. 14'225

Side Clearance lnspection . . - .. ... . - ...... . .. 11'226

Transmission Housing BearingsMainshaJVCountershaft EearingsRepfacement .......14221Sub'siralt Eearing Replacement . . . . . . . . . ..11'224

Toroue Converter Housing BearingsMainshattEearing/OilSe6lReplacement . .. l4229

Countershaft Bea;ing Replacement.. .... .. ..14-230

Input Test - '97 - 98 ModelsInput Test '99 - 00 Models

Symptom to-Component ChartHydraulic System ...............

Checking

Removal ...,lllustrated Index (4WD)

Interlock SystemInterlock ControlUnit lnputTest. -..... -.. .... . - 14 144* Key Interlock Solenoid Test .- .. . . . - . . . ..... 14_146* Shift Lock Solenoid Test ..............-.-. . .. . ... .... 14 147*Shift LockSolenoidReplacement...... .. . .. .. 14 148* park pin Switch Test ......... 14 119' Park Pin Switch Replacement- '97 - 98 Models ....... 14-150* Park Pin Swirch/Over Drive (O/Di SwitchReplacemenl '99-00Models . .. 14_151over-Drive (O/D) Switch {'99 00 [4odels]Test........_..................... .......14-152Hydr.ulic System

..............._............... t4 142.................................. 14-143

Control Lever AssemblyR6placement ......,.,Reverse ldler Gear

lllustrated lndex

.......... 14-230

14 231

11-231

1nsta1|ation ..................Park StopInspeclion/AdjustmenlTransfer AssemblY.......14.232

RoadTest.............-.... ........ .StallSpeedTest ....._........................ ....... 14-159Fluid Level......_................... 14'160

Disessembly .................... 14-235Transfer Drive Gear BearingReplacementTrans{er Driven Gesf Shaft BearingReplacementTransfer Housing Roller BearingReplacementTransfer Cov€r A Bearing Outer RaceReplacementTransfer Housing Bearing Outer RaceReplacement ......-..,,,,,.....ReassemblvTransmassaonBeassembly ... -.. .... .14 250

Torque Converier/Drive Plate . .-. .... .. . ... .....14_258

Transmissionlnstatlation .................. ....... 14'259

Cooler Flushing . . ......11-261ATF Cooler HosesConnection.................. ....... 14-266I Shift LeverRemoval/lnstallation . .. 14'261

Disassemblv/Reassemblv - '97 - 98 Models . . 14_264

Disassembli/Reassemblv -'99 - 00 Models . 14-269

Over'Orive (O/D) Switch WireClearanceAdjustment. - ... . . . .. .. . 14'270

Detent Spring Replscement . . -.. ... .14'271*Shift CableAdiustment ....... 14'272

Repfacement.............. . 11'273

14 15711-237

11-237

14-238

$-234

11-23914-240

Transmigrion

Inspeclron ....., ...........Transfer AssemblyRemova1,.,,,..............,lnstallalion ........... .. ...Transmission

14 164

14-16514,167

14-169

End Cover/Transmissio . 14'174Transmission Housing .... ... .. . . .... .. 14-176Torque Converter Housingly'alve Body.. - ... -. 14 178

lllustrated lndex (2WD)End Cover/Transmissio ....... 14 180Transmission Housing . . ... . .. .... ... 14'182Torque Convener Housing/r'alve Body ......- 14-184

End CovefRemovat ...................... ....... 14'186Transmission HousingRemoval ...................... .. 14_188Torque Convener HousingA/alve BodYRemovat ................-..... .-..... 14-190

www.emanualpro.com

Page 518 of 1395

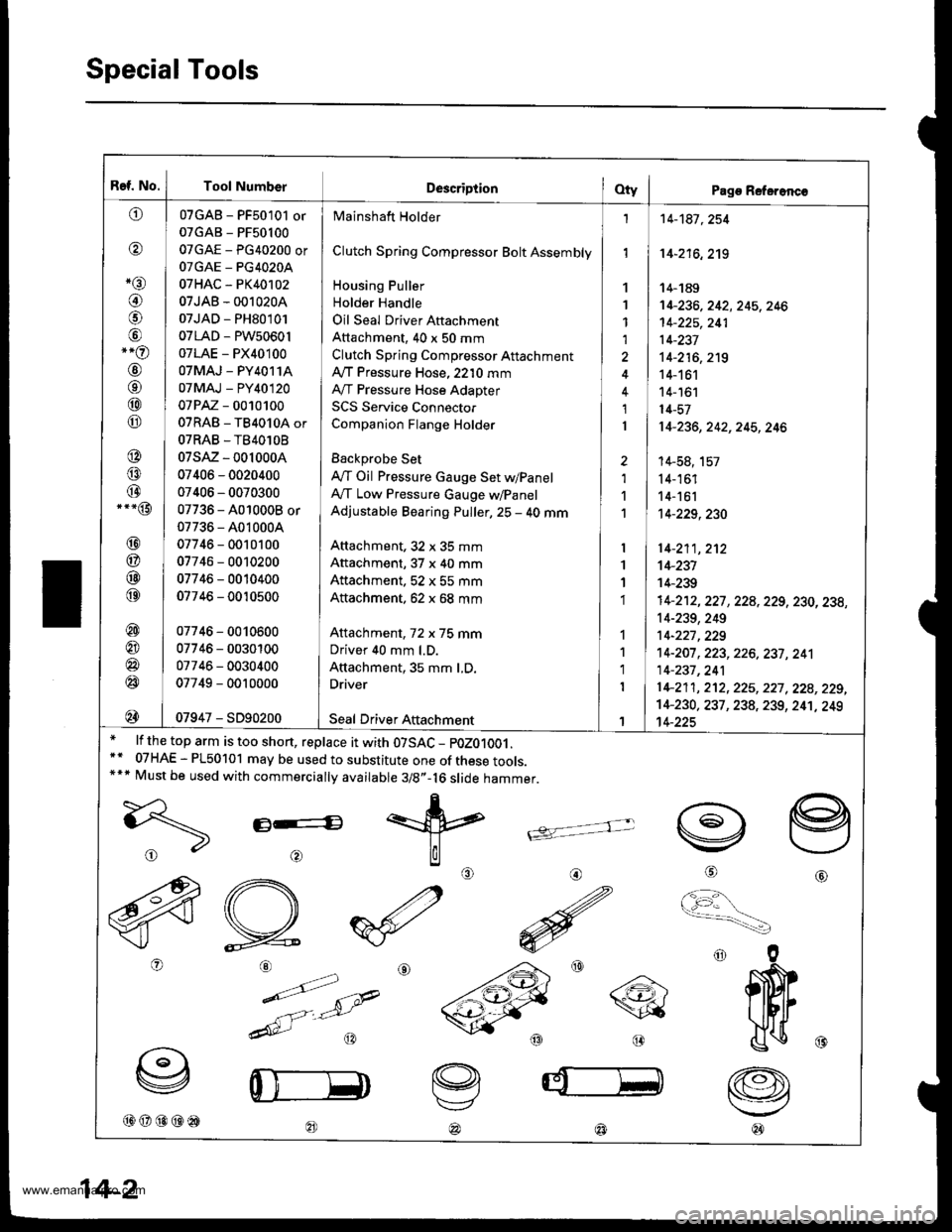

Ref. No.

^tl)

@

*rar

@

@

,-o

@

o

@

@

@

@

@.--@

@

@

@

@

@

@

@

@

@

Tool NumberDescriptionOty I Pago Referonc€

Mainshaft Holder

Clutch Spring Compressor Bolt Assembly

Housing Puller

Holder Handle

Oil Seal Driver Aftachment

Attachment, 40 x 50 mm

Clutch Spring Compressor Attachment

Ay'T Pressure Hose, 2210 mm

IVT Pressure Hose Adapter

SCS Service Connector

Companion Flange Holder

Backprobe Set

lVT Oil Pressure Gauge Set w/Panel

A,/T Low Pressure Gauge w/Panel

Adjustable Bearing Puller, 25 - 40 mm

Anachment, 32 x 35 mm

Attachment, 37 x 40 mm

Attachment. 52 x 55 mm

Attachment. 62 x 68 mm

Attachment, 72 x 75 mm

Driver 40 mm l.D.

Attachment, 35 mm LD.

Driver

07GAB - PF50101 or

07GAB - PF50100

07GAE - PG40200 or

OTGAE _ PG4O2OA

07HAC - PK40102

07JAB - 001020A

07JAD - PH80101

07LAD - PW50601

07LAE - PX40100

OTMAJ - PY4O114

07MAJ - PY40120

07 PAZ - 0010100

07RAB - TB4010A or

07RAB.TB40lOB

07sAz - 001000A

07406 - 0020400

07406 - 0070300

07736 - 4010008 or

07736 - A010004

07746 - 0010100

07746 - 0010200

07746 - 0010400

07746 - 0010500

07746 - 0010600

07746 - 0030100

07746 - 0030400

07749 - 0010000

07947 - SD90200Seal Driver Aftachment

1

1

1

1,l

1

I

2

1'l

1

I

1

1

1

1

1

1

I

1

14-181 , 254

14-216,219

14-189't4-236,242,245,246

't 4-225, 241

14-237

14-216,2't9

14-161

14- 161

14-57

14-236,242,245,246

14-58, 157

14-161

14-161'14-229,230

14-211, 2't2

14-231

14-239

14-212, 227 , 228,229, 230, 238,

14-239, 249

14-221 ,229't 4-207 , 223,226, 237 , 241

14-237,241

1 +21 1, 2't2, 225, 227, 228, 229,

14-230, 237 , 238, 239, 24't, 249't4-225

lf the top arm is too short, replace it with 07SAC - pOZ01OO1.

07HAE - PL50101 may be used to substitute one of these tools.Must be used with commercially available 3/8"-16 slide hammer.

E----G

@@@@@

@

tvj

'

@@@)

14-2

www.emanualpro.com

Page 697 of 1395

![HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

O END COVERiLl OIL SEAL Beplace.

O BALL BEARINGi.) A/T GEAR POSITION SWITCH COVER

i5] A/T GEAR POSITION SWITCH

aq) RoLLER

? COLLABi0 o-BtNG Replace.

€) FEED PIPE FLANGE

f,o) o-RING Replace.

1 SNAP HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

O END COVERiLl OIL SEAL Beplace.

O BALL BEARINGi.) A/T GEAR POSITION SWITCH COVER

i5] A/T GEAR POSITION SWITCH

aq) RoLLER

? COLLABi0 o-BtNG Replace.

€) FEED PIPE FLANGE

f,o) o-RING Replace.

1 SNAP](/img/13/5778/w960_5778-696.png)

O END COVERiLl OIL SEAL Beplace.

O BALL BEARINGi.) A/T GEAR POSITION SWITCH COVER

i5] A/T GEAR POSITION SWITCH

aq) RoLLER

? COLLABi0 o-BtNG Replace.

€) FEED PIPE FLANGE

f,o) o-RING Replace.

1' SNAP RING

1A 3RD CLUTCH FEED PIPE

O COUNTERSHAFT LOCKNUT 23 x 1.25 mm Replace.

[} coNtcal SPRING WASHER Replace.iO PARK GEAR(!I ONE.WAY CLUTCH

E COUNTERSHAFT lST GEAR

@ NEEDLE BEARING

@ COUNTERSHAFT 1ST GEAR COLLAR

Or o-RtNGS Reptace.

?] lST CLUTCH FEED PIPE

@ o-RING Replace.

e3 FEED PIPE FLANGE

4I SNAP RING

€i DOWEL PINi?0 END COVER GASKET Replace.

?7) PARK PAWL STOP

E9 PARK PAWL

C9 PARK PAWL SPRING

€D PARK PAWL SHAFT

OI A/T GEAR POSITION SWITCH HARNESS CIAMP

@ PARK LEVER

€3 LoCK WASHER Replace.

04 PARK sToP Selective part(!' PARK LEVER SPRING

@ DRAIN PLUG

Ot SEALING WASHER Replace.

60 MA|NSHAFT LocKNuT 21 x 1.25 mm Replace.(9 CONICAL SPRING WASHER Replace.

@ lST CLUTCH ASSEMBLY

TOROUE SPECIFICATIONS

,!4! O-RING Replace.

@I THRUST WASHER@ THRUST NEEDLE BEARINGi.!' NEEDLE BEARINGi MAINSHAFT lST GEAR

@i MAINSHAFT 1ST GEAR COLLAR!r, O-RING Replace.iO COUNTERSHAFT SPEED SENSOR

E ROLLER

@, coLLAR

Ct o-RING Replace.5.] FEED PIPE FLANGE

09 o-RING Replace.

6A SNAP RING

5' IST.HOLD CLUTCH FEED PIPE

@-] SUB-SHAFT LOCKNUT 19 x 1.25 mm Replace.

!t CONICAL SPRING WASHER Replace.

6i' SUB-SHAFT lST GEAR

G) LINEAR SOLENOID ASSEMBLY(6!) LINEAR SOLENOID ASSEMBLY GASKET Replace

G] HARNESS BRACKET

6a SEALING WASHERS Replace.

C' ATF COOLER LINE

@ L|NE BoLT

GI ATF DIPSTICK

GI ATF COOLER LINE

O LINE BOLT

@ SEALING wasHERs Replace.aoo VEHICI.E SPEED SENSOR IVSS)

f,E O-RING Replace.

Bolt/Nut No.Torque ValueSizeRemarks

6A

6B

8A

12J'18D

195

21M

12 N.m (1.2 kgf.m,8.7 lbf.ft)

14 N.m (1.4 kgf.m, 10lbf.ft)

22 N.m 12.2 kgim, 16lbf.ft)

28 N.m (2.9 kgim,21 lbf.ft)

49 N'm (5.0 kgim,36 lbf.ft)

93 N.m (9.5 kgf.m,69 lbf.ft)

78 N.m (8.0 kgf.m,58 lbf.ft)

103+ 0+ 103 N{n (10.5 + 0+ 10.5 kSfm,

75.9' 0 - 75.9 lbfft)

6x1.0mm

6x1.0mm

8 x 1.25 mm

12 x 1 .25 mm

18 x 1.5 mm

19 x 1.25 mm

21 x 1.25 mm

23 x 1.25 mm

Line bolt

Drain plug

Sub-shaft locknut

Mainshaft locknut: Left-hand threads

Countershaft locknut: Left-hand

threads

14-181

www.emanualpro.com

Page 701 of 1395

![HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

ai_la2,

(41/4.:4.

\7)

1.0)tl

(3]

t9.1q

oo,ID@,8!Itt\,29

€4

69

aa.21

600toa

04

6!)ent00t.@

ATF FEED PIPE, I x 145 mm

ATF STRAINERSERVO BODYSERVO SEPARATOB PLATESECONDABY VALVE BOOYDOWEL PINSECONDAR HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

ai_la2,

(41/4.:4.

\7)

1.0)tl

(3]

t9.1q

oo,ID@,8!Itt\,29

€4

69

aa.21

600toa

04

6!)ent00t.@

ATF FEED PIPE, I x 145 mm

ATF STRAINERSERVO BODYSERVO SEPARATOB PLATESECONDABY VALVE BOOYDOWEL PINSECONDAR](/img/13/5778/w960_5778-700.png)

ai_la2',

(41/4.:4.

\7)

1.0)tl

(3]

t9.1q

oo,ID@,8!Itt\,29

€4

69

aa.21

600toa

04

6!)ent00t.@

ATF FEED PIPE, I x 145 mm

ATF STRAINERSERVO BODYSERVO SEPARATOB PLATESECONDABY VALVE BOOYDOWEL PINSECONDARY SEPARATOR PLATE

SERVO DETENT BASE ('98 model onlvl

ATF FEED PIPE, 8 x 145 mmATF FEED PIPE.8 x 40 mmATF FEED PIPE,8 x 62 mmATF FEED PIPE, I x 112 mm

ATF FEED PIPE, 8 x 192.5 mm

ATF FEED PIPE, 8 x 105.8 mm

STOP SHAFT BRACKETATF LUERICATION PLATEATF FEED PIPEDOWEL PINLOCK-UP VALVE BODYLOCK-UP SEPARATOR PLATE

REGULATOR VALVE BOOYDOWEL PINCOOLER RELIEF VALVE SPRINGCOOLER BELIEF VALVETOROUE CONVERTER CHECK VALVE SPRING

TOROUE CONVERTER CHECK VALVECONTNOL SHAFTDETENT ARM SPRINGDETENT ARMDETENT ARM SHAFTFILTER Replace.CHECK BALLS1ST ACCUMULATOR CHOKEO-RING Replace.STATOR SHAFTSTOP SHAFTATF FEED PIPE. 8 x 112 mmMAIN VALVE BODYATF PUMP DRIVEN GEAR SHAFTATF PUMP DRIVEN GEAR

MAIN SEPARATOR PLATE

DOWEL PINATF PUMP DRIVE GEARSUCTION PIPE COLLARCOUNTEBSHAFT TOROUE CONVERTER HOUSING

BEARINGATF GUIDE PLATEATF MAGNETTOBOUE CONVERTER HOUSINGOIL SEAL Beplace.MAINSHAFT OIL SEAL Replace.MAINSHAFT TOROUE CONVERTER HOUSING

BEARINGLOCK.UP CONTROL SOLENOID VALVE A/B

FILTER/GASKET Replace.LOCK-UP CONTROL SOLENOID VALVE A/B

ASSEMELY

i4ll(4d

@@.!!l

art)@@@@li]t

TOROUE SPECIFICATIONS

Bolt/Nut No.Torque ValueSizeRemarks

12 N.m (1.2 kgim,8.7 lbf'tt)6x1.0mm

14-185

www.emanualpro.com

Page 702 of 1395

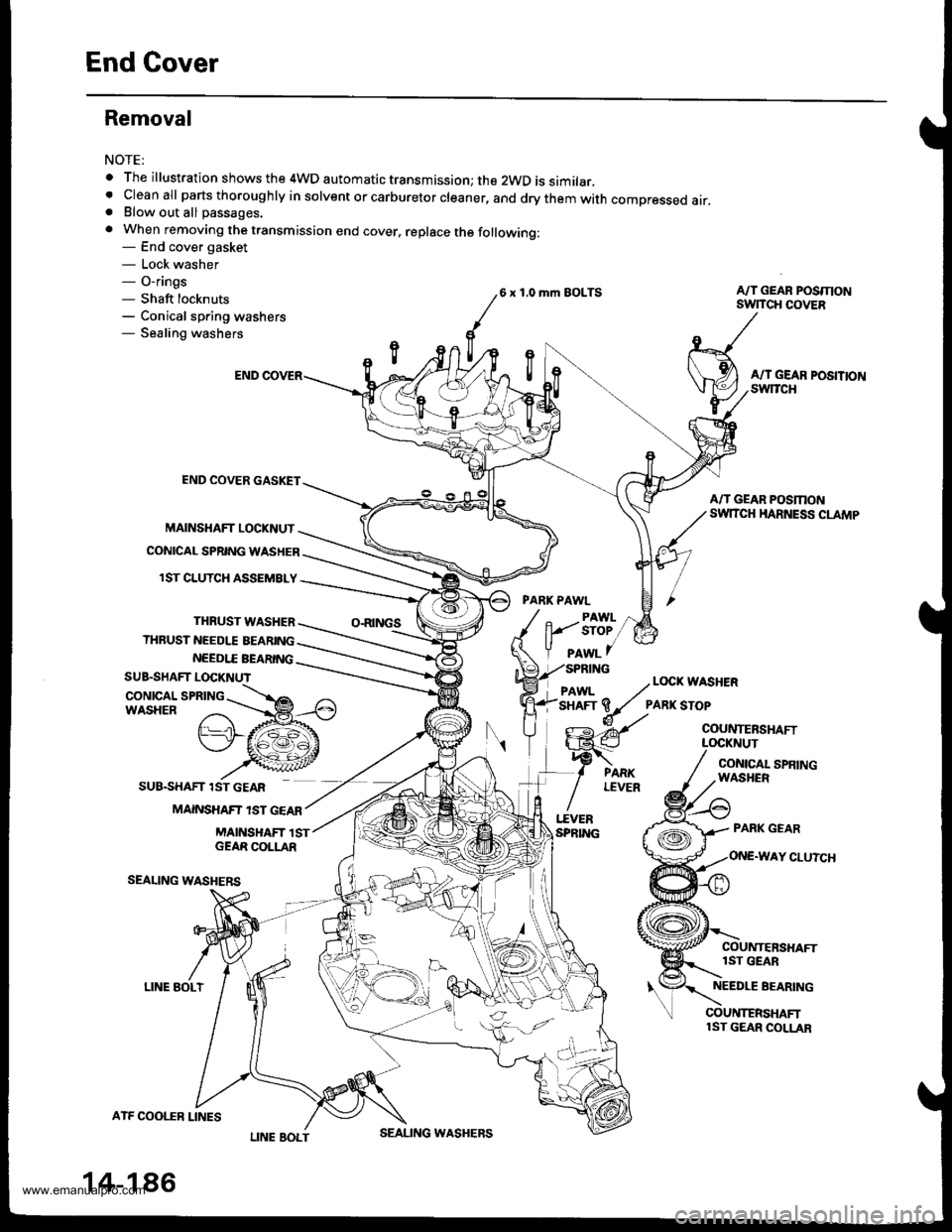

End Cover

Removal

NOTE:

o The illustration shows the 4WD automatic transmission; the 2WD is similar.. cleanall parts thoroughly in solvent or carburetor cleaner, and drythem with compressed air.. Blow out all passages.

. When removing the transmission end cover, replace the following:- End cover gasket- Lock washer- O-rings- Shaft locknuts- Conical spring washers- Sealing washers

END COVER GASKET

MAINSHAFT LOCKNUT

CONICAL SPRING WASHER

6 x 1 .0 rhm EOLTS

PARK PAWL

A/T GEAR POSMONSwlTCH COVER

NEEDI.T BEARING

SUB.SHAFT LOCKNUT

CONICAL SPRINGWASHER

LINE AOLT

ATF COOI.f B LINES

14-186

PAwL 7// Locx wASHER

'sHAFr 9/ ?ARK srop

o-- Ay' couNTERsHAFr

G-€ LocKNUr!€ / ..t,"o, "oo

A/T GEAR POSMONSW|TCH HARNESS CLAMP

CONICAL SPRINGWASHCR

A/T GEAR POSITION

PARK GEAR

Y CLUTCH

lST GEAR

NEEDLE BEARING

1ST CLUTCH ASSEMBLY

THRUST WASHER

THRUST NEEDLE AEARING

O.RINGS

\\

SUB.SHAFT 1ST GEAR

MAINSHAF? 'ST GEAR

MAINSHAFT 1STGEAR COLLAR

SEALING WASHERS

!€'-l

I"EVERSPRING

COUNTERSHAFTlST GEAR COLLAR

PAWL

lt1/ sroe

Y plwl f

L/'SPRING

LOCKNUT

LINE BOLTSEALING WASHERS

www.emanualpro.com

Page 703 of 1395

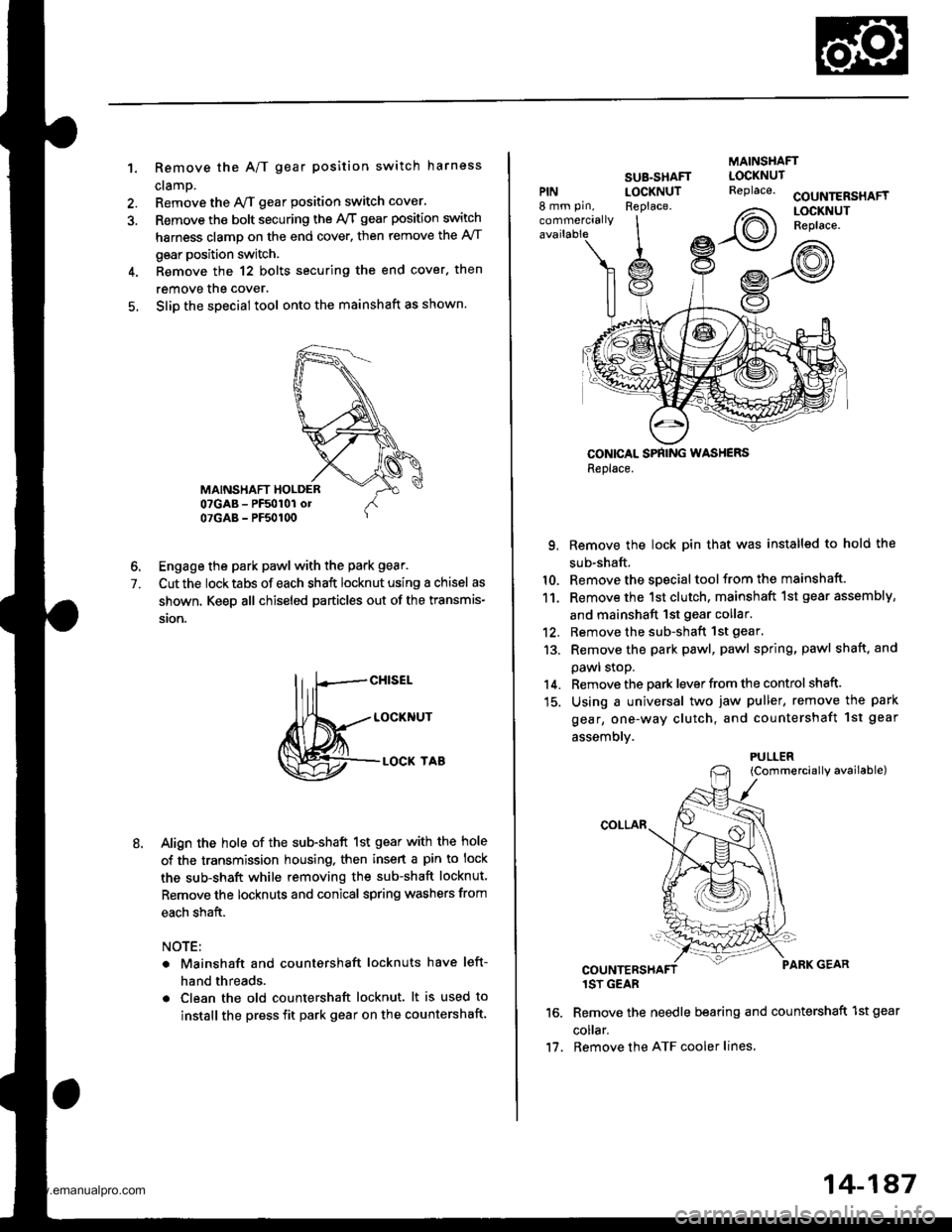

1. Remove the A/T gear position switch harness

cramp.

Remove the y'VT gear position switch cover.

Remove the bolt securing the ly'T gear position switch

harness clamp on the end cover, then remove the A/T

gear position switch.

Remove the 12 bolts securing the end cover. then

remove the cover.

Slip the special tool onto the mainshaft as shown.

6. Engage the park pawl with the park gear.

7. Cut the locktabs of each shaft locknut using a chisel as

shown. Keep all chiseled particles out of the transmis-

ston.

M=tt"

Align the hole of the sub-shaft 1st gear with the hole

of the transmission housing. then insert a pin to lock

the sub-shaft while removing the sub-shaft locknut.

Remove the locknuts and conical spring washers from

each shaft.

NOTE:

Mainshaft and countershaft locknuts have left-

hand threads.

Clean the old countershaft locknut. lt is used to

install the press fit park gear on the countershaft.

MAINSHAFT

PIN8 mm pin,

commercially

SUB-SHAFTLOCKNUTReplace.COUNTERSHAFTLOCKNUTReplace.

CONICAL SPNING WASHERSReplace.

9. Remove the lock pin that was installed to hold the

sub-shaft.

10. Remove the special tool from the mainshaft.

11. Remove the 1st clutch, mainshaft 1st gear assembly,

and mainshaft 1st gear collar.'12. Remove the sub-shaft 1st gear.

13. Remove the park pawl, pawl spring, pawl shaft. and

pawl stoP.

14. Remove the park lever from the control shaft.

15. Using a universal two jaw puller, remove the park

gear, one-way clutch, and countershaft 1st geal

assemblv.

{Commercially available)

1SY GEAR

Remove the needle bearing and countershaft 1st gear

co ar.

Remove the ATF cooler lines,

LOCKNUTReplace.

2\

Irot)

PULLER

11.

14-187

www.emanualpro.com

Page 705 of 1395

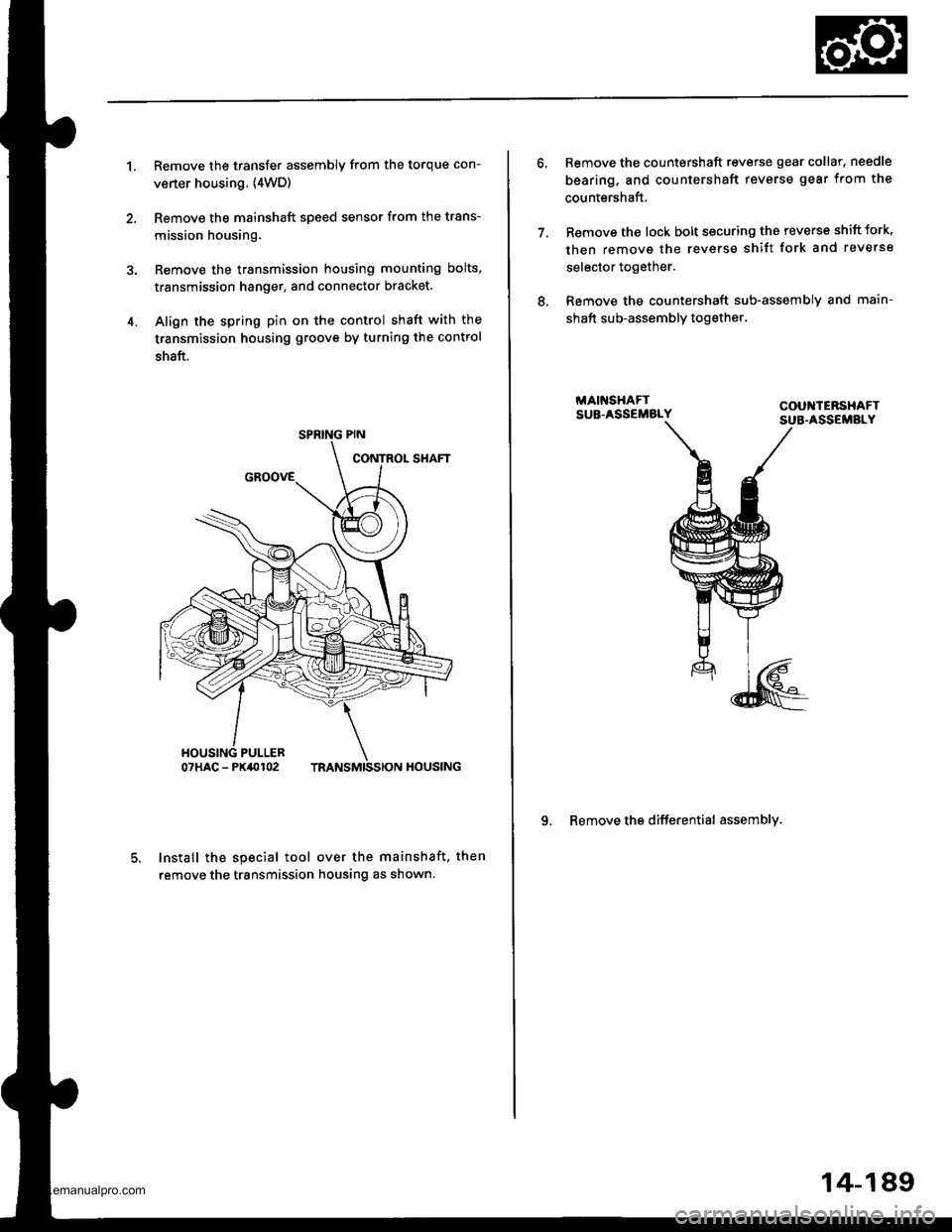

1.Remove the transfer assembly from the torque con-

verter housing. (4WD)

Remove the mainshaft speed sensor from the trans-

mission housing.

Remove the transmission housing mounting bolts,

transmission hanger, and connector bracket.

Align the spring pin on the control shaft with the

transmission housing groove by turning the control

shaft.

Install the special tool over the mainshaft. then

remove the transmission housing as shown.

4.

SPRING PIN

7.

Remove the countershaft reverse gear collar, needle

bearing, and countershaft revsrse gear from the

countershaft,

Remove the lock bolt securing tho reverse shift fork,

then remove the reverse shift fork and reverse

selector together.

Remove the countershaft sub-assemblv and main-

shaft sub-assembly together,

9. Remove the differential assembly.

8.

14-189

www.emanualpro.com