Gear box oil HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 35 of 1395

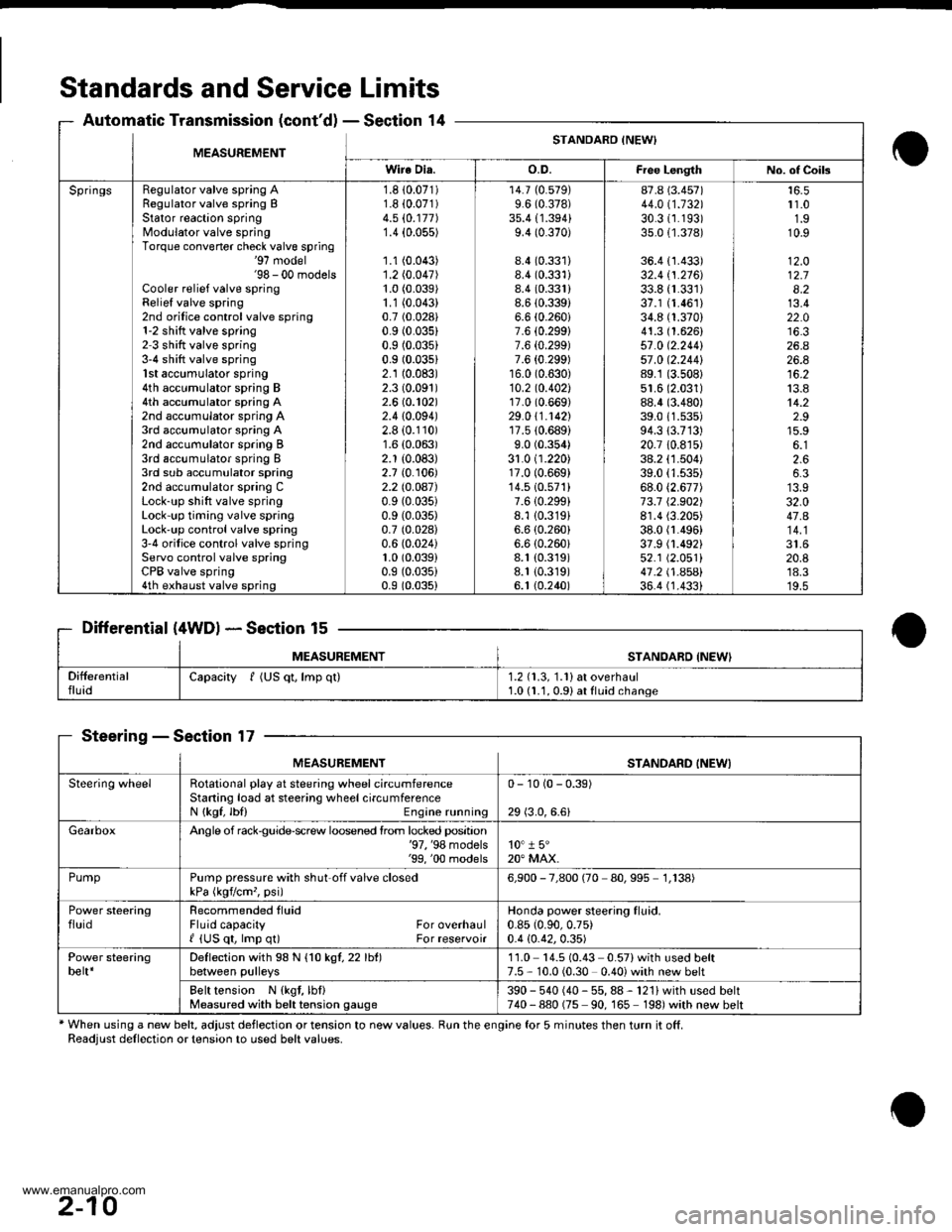

Standards and Service Limits

Automatic Transmission (cont'dl - Section 14

Differential (4WDl * Section 15

MEASUREMENTSTANOABD {NEW'

SteeringSection 17

* When using a new belt, adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off.Readjust dellection or tension to used belt values.

MEASUREMENTSTANDARO INEWI

Wire Dia.o.D.Fiee LengthNo. of Coils

SpringsRegulator valve spring ARegulator valve spring BStator reaction springModulator valve springTorque convener check valve spring'97 model'98 - 00 modelsCooler relief valve springRelief valve spring2nd orilice control valve spring1-2 shitt valve spring2 3 shift valve spring3-4 shift valve spring1st accumulator spring4th accumulator spring B4th accumulator spring A2nd accumulator spring A3rd accumulator spring A2nd accumulator spring B3rd accumulator spring I3rd sub accumulator spring2nd accumulator spring CLock-up shift valve springLock-up timing valve springLock'up control valve spring3'4 orifice control valve springServo control valve springCPB valve spring4th exhaust valve spring

1.8 10.071)1.8 i0.071)4.5 (0.177)

1.4 {0.055)

1.1 (0.043)

1.2 (0.047)

1.0 (0.039)

1.1 (0.043)

0.7 (0.028)

0.9 (0.035)

0.9 (0.035)

0.9 (0.03s1

2.1 (0.083)

2.3 (0.091)

2.6 (0.102)

2.410.094)2.8 (0.110)

1.6 (0.063)

2.1 (0.083)

2.7 {0. r06)2.2lO.OA7)0.9 (0.035)

0.9 (0.035)

0.7 (0.028)

0.6 (0.024)

1.0 (0.039)

0.9 (0.035)

0.9 (0.035)

14.7 (0.579)

9.6 (0.378)

35.4 {1.394}9.4 (0.370)

8.4 (0.331)

8.4 (0.331)

8.4 (0.331)

8.6 (0.3391

6.6 (0.260i

7.6 {0.299}7.6 {0.299)7.6 {0.299)16.0 (0.630)

10.2 to.402l17.0 (0.669)

29.0 \1.1421'r7.510.689)

9.0 (0.354)

31.0 (1.220)17.0 (0.669)

14.510.571)7.610.299i8.1 {0.319}6.6 (0.260)

6.6 (0.260i

8.1 (0.319)

8.1 {0.319)6. t (0.240)

87.8 (3.457)

44.011.132130.31r.193)35.0 {1.378)

36.4 {1.433)32.4 tl.216J33.8 {r.331)37.1 (1.461)

34.8 (1.370)

41.3 (1.626)

57 .0 (2.2441

57 .0 12.244189.1 (3.508)

51.6 (2.031)

88.4 (3.480)

39.011.s35)94.313.713)20.7 10.8r5)38.2 (1.504)

39.0 (1.535)

68.0 (2.677)

73.7 12.902)8r.4 (3.205)

38.0 fl.496)37.9 (1.492)

52.1 (2.051)

41 .2 t .A5Al36.4 (1.4331

r 1.01.910.9

12.O12.78.213.422.0

26.426.8

13.814.22.915.9

2.66.3

32.047.A

20.8'18.3'19.5

Capacity f (US qt, lmp ql)1.2 (1.3, 1.1) at overhaul1.0 (1.1, 0.91 at fluid change

MEASUREMENTSTANDARD INEWI

Steering wheelRotational play at steering wheel circumferenceStaning load at steering wheelcircumferenceN {kgf, lbl) Engine running

0- 10 (0 - 0.39)

29 (3.0,6.6)

GearboxAngle of rack$uide-screw loosened lrom locked position'97, '98 models'99, '00 models10" 1 5"20" MAX.

PumpPump pressure with shut off valve closedkPa (kgvcm,, psi)6,900 - 7,800 (70 80,995 1,138)

Power steeringfluidRecommended tluidFluid capacity For overhaulI {US qt, lmp q0 For reservoir

Honda power steering fluid.0.85 (0.90,0.75)

0.4 {0.42,0.35)

Power steeringbelt*Deflection with 98 N {1O kgl,22lht)between pulleys11.0 14.5 (0.43 0.57)with used belt7.5 - 10.0 (0.30 0.40) with new belt

Belt tension N {kgt, lbf}Measured with belt tension gauge390 - 540 (40 - 55, 88 - 121) with used belt740-880 (75 90, 165 198)with new belt

2-10

www.emanualpro.com

Page 41 of 1395

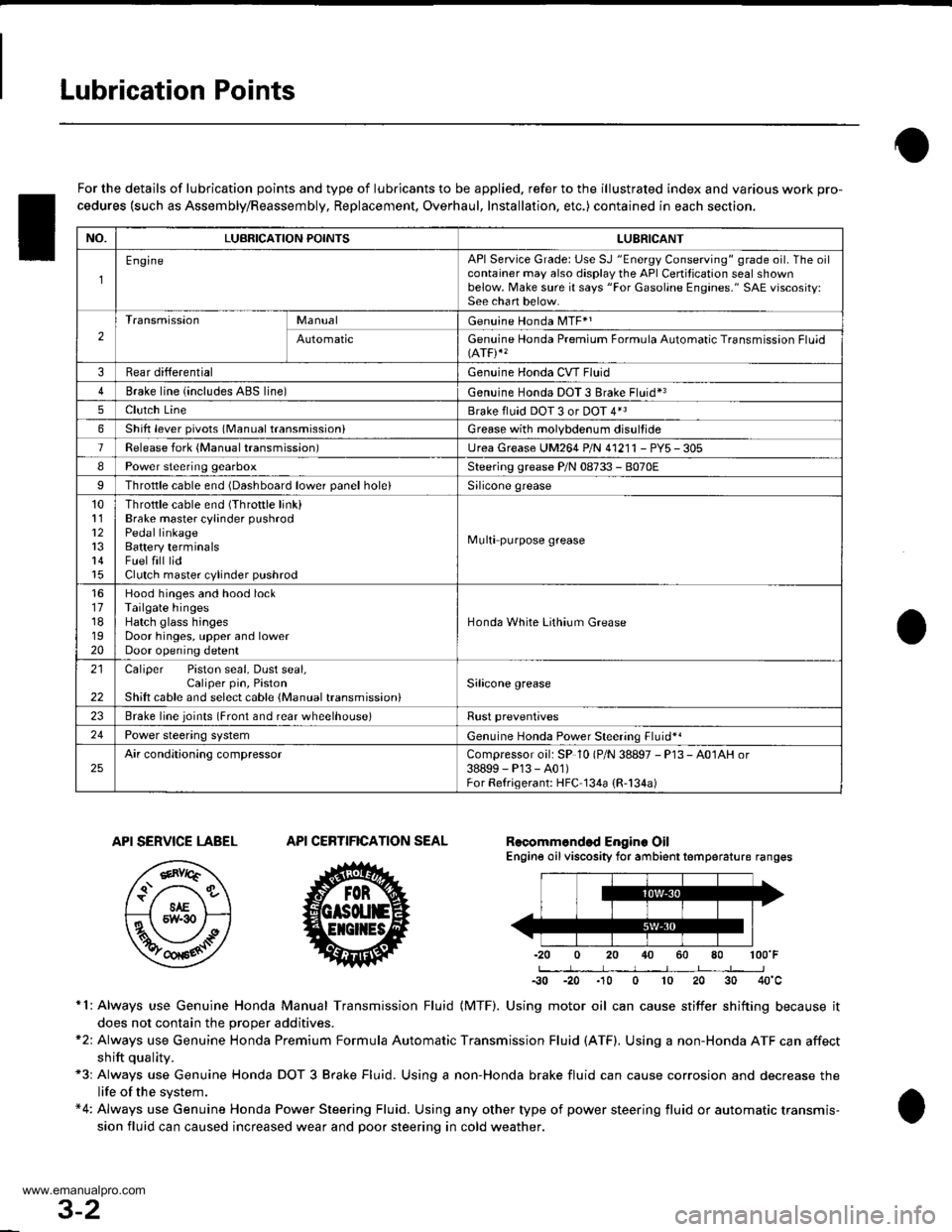

Lubrication Points

For the details of lubrication points and type of lubricants to be applied. refer to the illustrated index and various work pro-

cedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

Recomm6nded Engine OilEngine oil viscosity for ambient temperature ranges

100'F

-30 -20 .10 0 10 20 30 40'c

r1: Always use Genuine Honda Manual Transmission Fluid {MTF). Using motor oil can cause stiffer shifting because it

does not contain the orooer additives.*2: Always use Genuine Honda Premium Formula Automatic Transmission Fluid (ATF). Using a non-Honda ATF can affect

shift qualitv.+3r Always use Genuine Honda DOT 3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.*4: Always use Genuine Honda Power Steering Fluid. Using any other type of power steering fluid or automatic transmis-

sion fluid can caused increased wear and poor steering in cold weather.

API SERVICE LABEL

/,.*-G\

/.'z-\e\t/6AE\ll-;-1 5w-30 /---l

w

API CERTIFICATION SEAL

ffi-20 0 20

NO.LUBRICATION POINTSLUBRICANT

EngineAPI Service Grade: Use SJ "Energy Conserving" grade oil. The oilcontainer may also display the API Certitication seal shownbelow. Make sure it says "For Gasoline Engines." SAE vjscosity:See chart below.

2

TransmissionManualGenuine Honda MTF*1

AutomaticGenuine Honda Premium Formula Automatic Transmission Fluid(ATF)*'

3Rear differentialGenuine Honda CVT Fluid

4Brake line (includes ABS line)Genuine Honda DOT 3 Brake Fluid*3

5Clutch LineBrake fluid DOT 3 or DOT 4*3

6Shift lever pivots (Manual transmission)Grease with molybdenum disultide

1Release fork (Manual transmission)LJrea Grease UM264 P/N 4'1211 - PYs - 305

IPower steering gearboxSteering grease P/N 08733 - B070E

Throttle cable end {Dashboard lower panel holelSilicone grease

10l112

14

Throttle cable end (Throttle link)Brake master cylinder pushrodPedal linkageBattery terminalsFuelfill lidClutch master cylinder pushrod

Multi purpose grease

1617181920

Hood hinges and hood lockTailgate hingesHatch glass hingesDoor hinges, upper and lowerDoor opening detent

Honda White Lithium Grease

21

22

Caliper Piston seal, Dust seal,Caliper pin, PistonShilt cable and select cable {Manual transmission)Silicone grease

23Brake line ioints (Front and rear wheelhouse)Rust preventives

24Power steering systemGenuine Honda Power Steering Fluid-.

25Air conditioning compressorCompressor oil: SP 10 lP/N 38897 - P13 - A0lAH or38899-P13-A01)For Refrigerant: HFC 134a (R,134a)

3-2

www.emanualpro.com

Page 852 of 1395

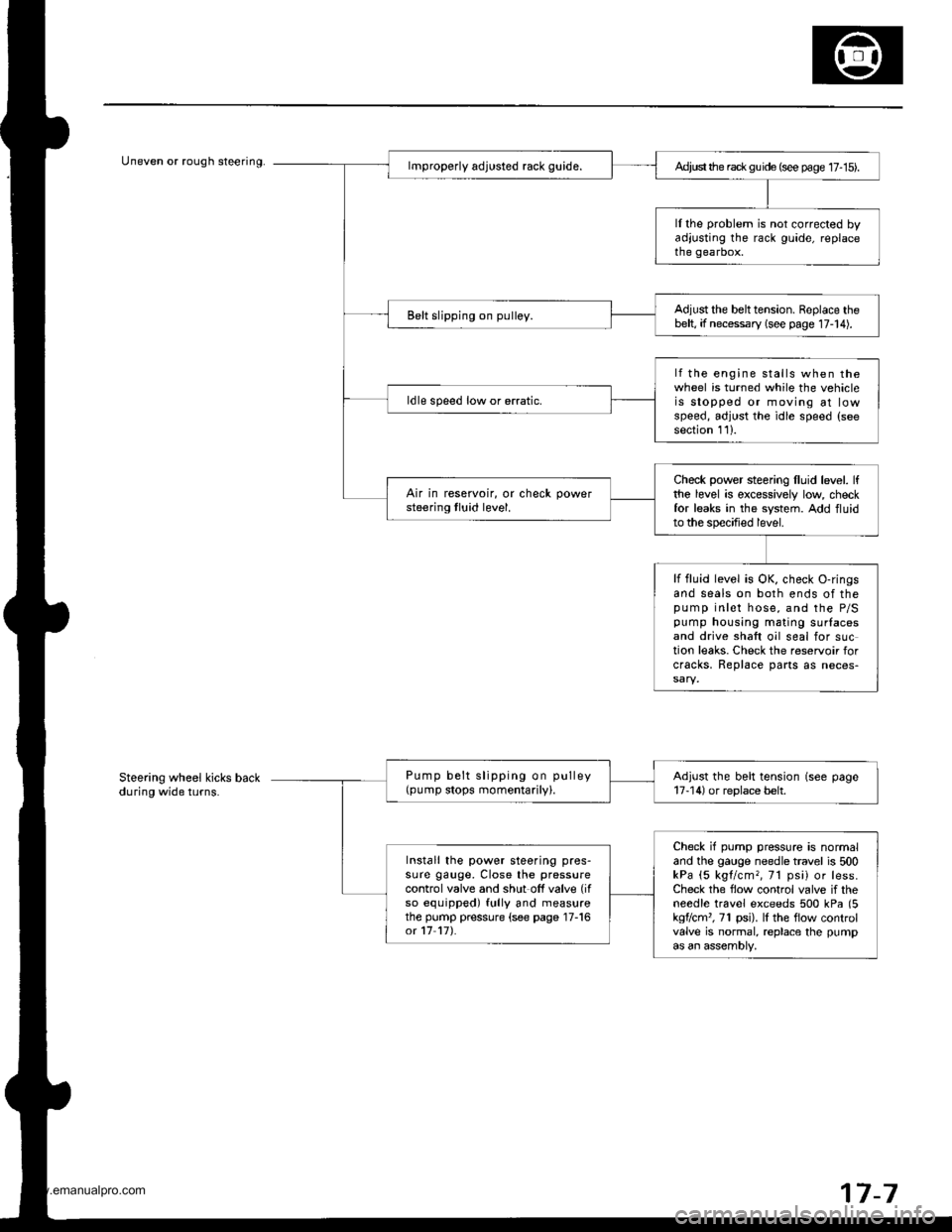

Uneven or rough steering.Ad,ust the rack gu ide (see page 17- 15).

ll the problem is not corrected byadjusting the rack guide, replacethe gearbox.

Adjust the belttension. Replace thebelt, if necessary (see page 17-14).Belt slipping on pulley.

lf the engine stalls when thewheel is turned while the vehicleis stopped or moving at lowspeed, adjust the idle speed (seesection 111.

ldle speed low or erratic.

Check power steering lluid level. lfthe level is excessively low checkfor leaks in the system. Add fluidto the specified level.

Air in reservoir, or check powersteering tluid level.

lf fluid level is OK, check O-ringsand seals on both ends of thepump inlet hose, and the P/Spump housing mating surlacesand drive shaft oil seal for suction leaks. Check the reservoir forcracks, Replace parts as neces-

Pump belt slipping on pulley(pump stops momentarily).Adjust the belt tension (see page17-14) or replace belt.

Check if pump pressure is normaland the gauge needle travel is 500kPa (5 kgl/cm,, 71 psi) or less.Check the flow control valve if theneedle travel exceeds 500 kPa (5kgflcm'�, 71 psi). lI the flow controlvalve is normal, replace the pumpas an assembly,

Install the power steering pres-sure gauge, Close the pressurecontrol valve and shut off valve (if

so equipped) fully and measurethe pump pressure (see page 17-16ot 17 17).

Steering wheel kicks backduring wide turns.

7-7

www.emanualpro.com

Page 855 of 1395

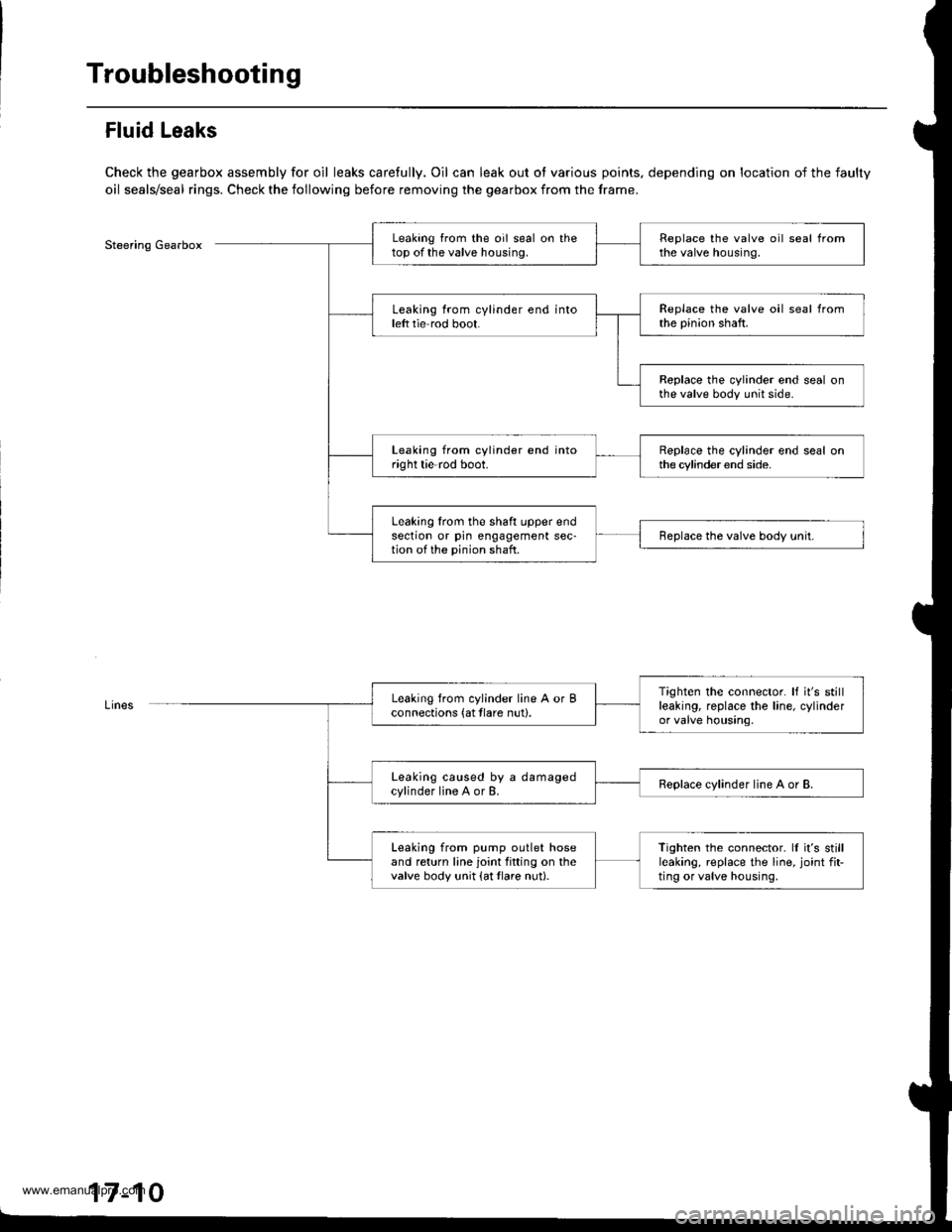

Troubleshooting

Fluid Leaks

Check the gearbox assembly for oil leaks carefully. Oil can leak out ot various points, depending on location of the faulty

oil seals/seal rings. Check the following before removing the gearbox from the frame.

Steering GearboxLeaking from the oil seal on thetop of the valve housing.Replace the valve oil seal fromthe valve housing.

Leaking from cylinder end intoleft tie rod boot.Replace the valve oil seal fromthe pinion shaft.

Replace the cylinder end seal onthe valve body unit side.

Leaking from cylinder end intoright tie-rod boot.Replace the cylinder end seal onthe cylinder end side.

Leaking lrom the shaft upper endsection or pin engagement sec-tion of the pinion shaft.Replace the valve body unit.

Tighten the connector. It it's stillleaking, replace the line, cylinderor valve housing.

Leaking from cylinder line A or Bconnections (at tlare nut).

Leaking caused by a damagedcylinder line A or B.Replace cylinder line A or B.

Leaking from pump outlet hoseand return line joint fitting on thevalve body unit {at tlare nut}.

Tighten the connector. ll it's stillleaking, replace the line, joint fit-ting or valve housing,

17-10

www.emanualpro.com

Page 876 of 1395

Power Steering Gearbox

Removal

Note these items during removal:

. Using solvent and a brush, wash any oil and dirt off

the valve body unit its lines, and the end if the gear-

box. Blow dry with compressed air.

. Be sure to remove the steering wheel before discon-

necting the steering joint. Damage to the cable reel

can occur.

. With 4WD. tilt the engine with a jack to expand the

clearance between the transfer assembly and rear

beam when removing the steering gearbox from the

rear oeam.

Do not remove the steering gearbox by removing the

transfer assembly from the transmission.

1. Drain the power steering fluid as described on page'17-15.

Raise the vehicle, and suppon it on safety stands in

the proper locations (see section 1).

Remove the front wheels,

Remove the drive/s airbag assembly {see section 24).

Remove the steering wheel {see page 17-18).

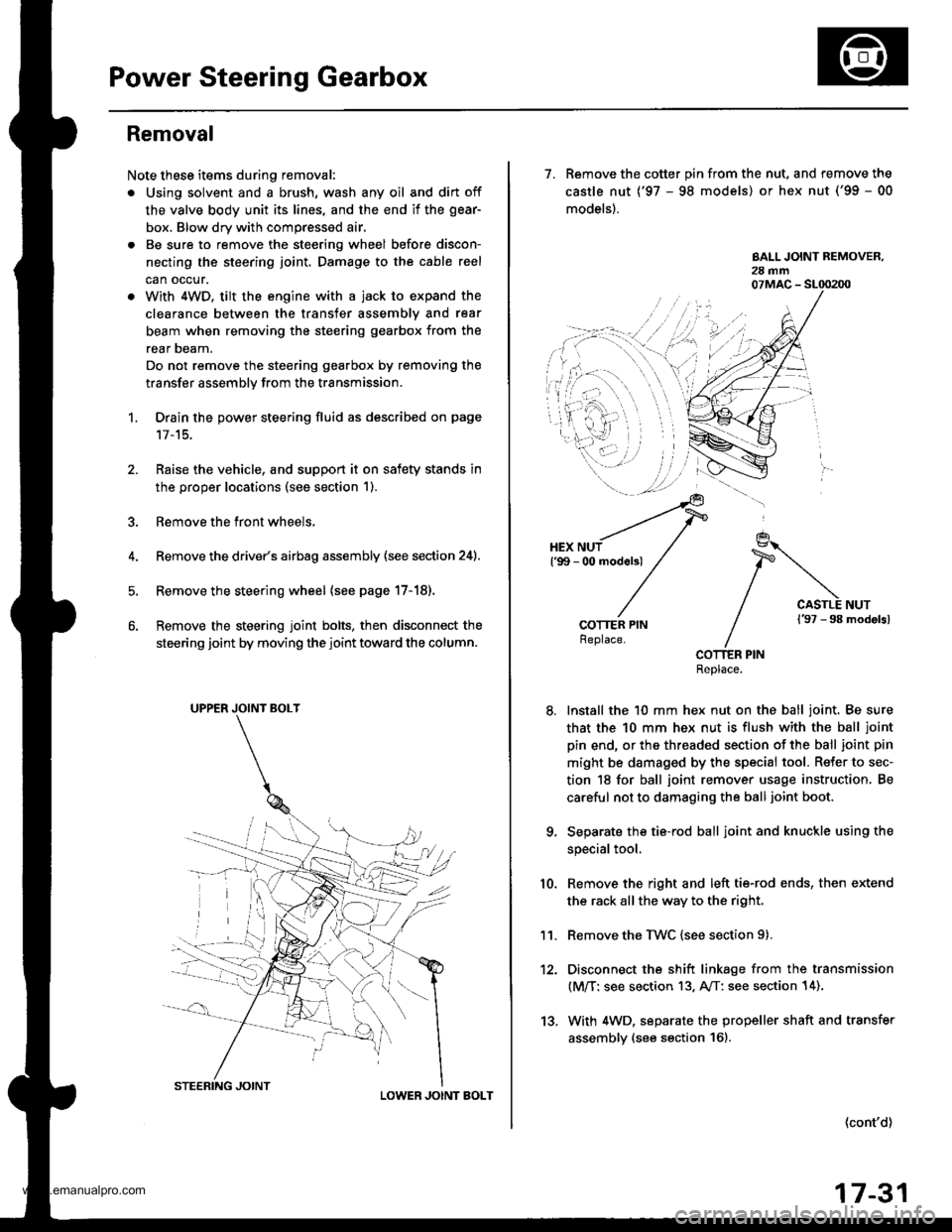

Remove the steering joint bolts, then disconnect the

steering joint by moving the joint toward the column.

UPPER JOINT BOLT

LOWER JOINT BOLT

13.

7. Remove the cotter pin from the nut, and remove the

castle nut {'97 - 98 models) or hex nut ('99 - 00

models).

COTTER PINReplace.

Install the 10 mm hex nut on the ball joint. Be sure

that the 10 mm hex nut is flush with the ball joint

pin end, or the threaded section of the ball joint pin

might be damaged by the special tool. Refer to sec-

tion 18 for ball joint remover usage instruction, Be

careful not to damaging the ball joint boot.

Separate the tie-rod ball joint and knuckle using the

special tool.

Remove the right and left tie-rod ends, then extend

the rack all the way to the right.

Remove the TWC (see section 9).

Disconnect the shift linkage from the transmission

(M/T: see section 13, A/T: see section 14).

With 4WD. separate the propeller shaft and transfer

assembly (see section 161.

10.

11.

(cont'd)

17-31

www.emanualpro.com

Page 885 of 1395

Power Steering Gearbox

Reassembly

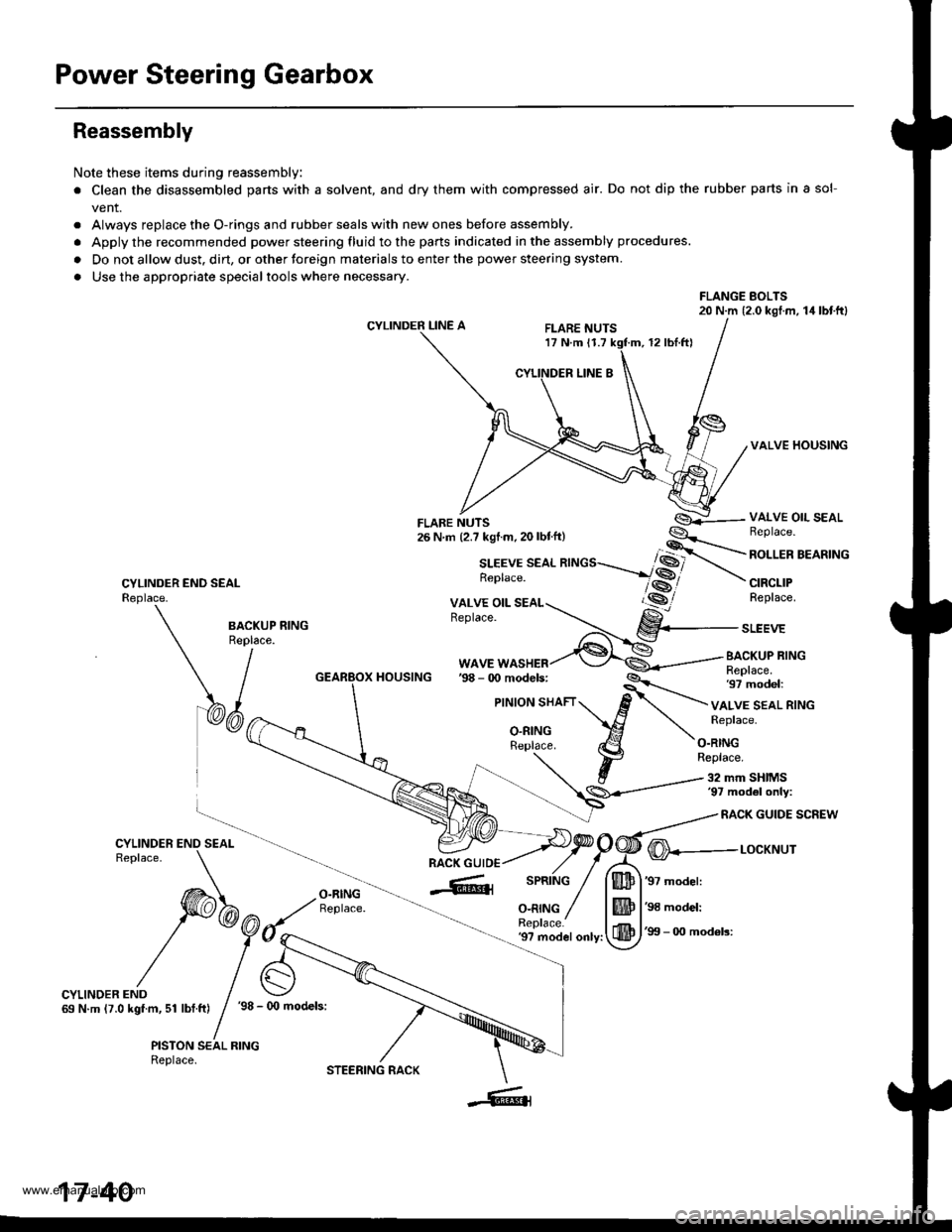

Note these items during reassembly

. Clean the disassembled parts with a solvent, and dry them with compressed air. Do not dip the rubber parts in a sol-

vent.

. Always replace the O-rings and rubber seals with new ones before assembly.

. Apply the recommended power steering fluid to the parts indicated in the assembly procedures.

. Do not allow dust. dirt, or other toreign materials to enter the power steering system.

. Use the appropriate specialtools where necessary.

FLANGE BOLTS20 N.m (2.0 kgl.m, 14lbtftl

CYLINDER LINE AFLARE NUTS17 N.m 11.712 rbl.ftl

VALVE HOUSING

CYLINDER END SEALReplace.

VALVE OIL SEALBeplace.

ROLLER BEARING

CIRCLIPReplace.

BA.KUP RING

\/^"

WAVE WASHERBACKUP RINGReplace.97 model:HOUSING

VALVE SEAL RINGReplace.

O.RINGReplace.

32 mm SHIMS'97 mod6l only:

RACK GUIDE SCREW

O-RINGReplace.

@---r-ocxr'rur

'97 model:

'98 model:

'99 - 0O mod6ls:'9? model only:

CYLINDER END69 N.m (7.0 kgf.m, 51 lbf.ft)'98 - (x) models:

PISTON SEAL RINGReplace.

17-40

STEERING RACK

www.emanualpro.com

Page 887 of 1395

Power Steering Gearbox

13.

Reassembly (cont'd)

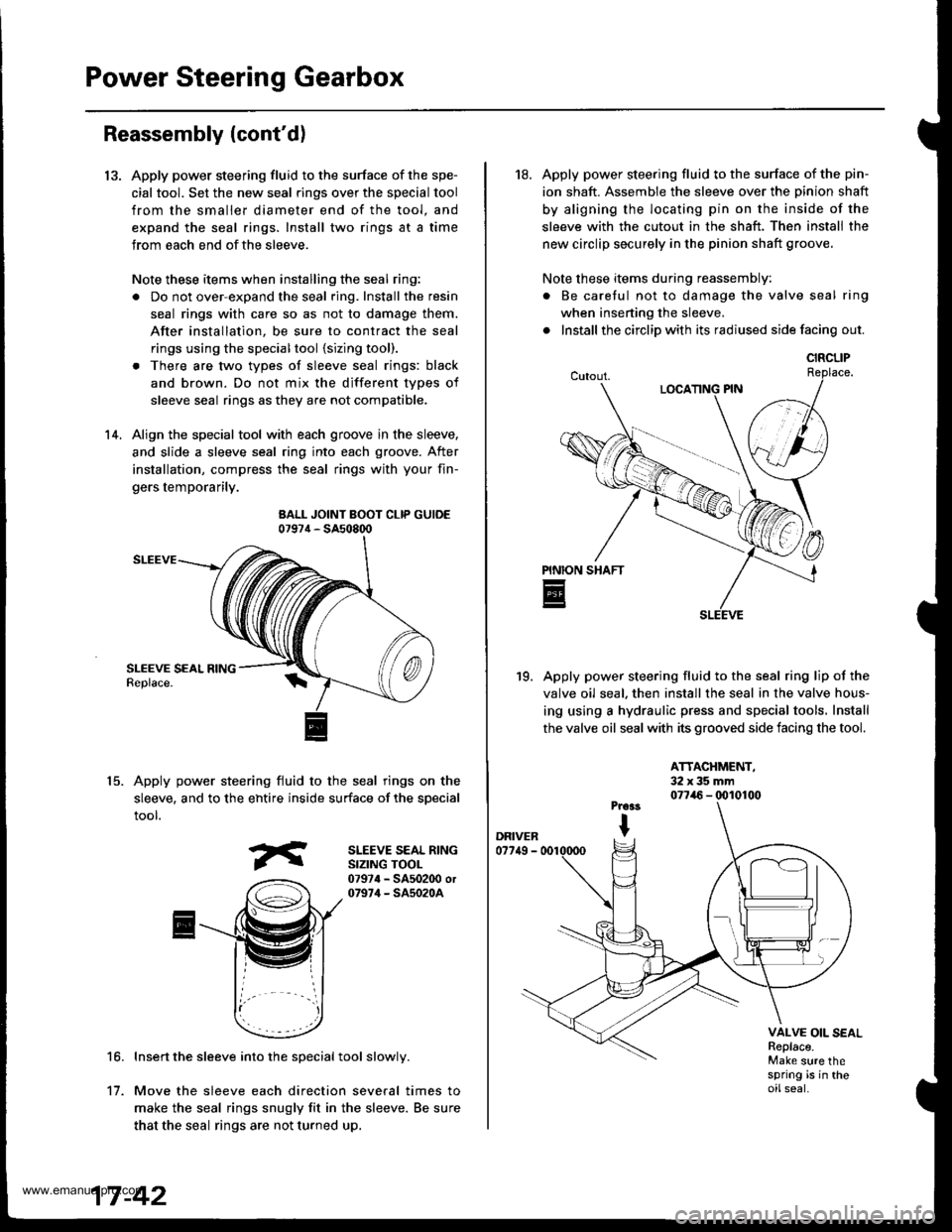

Apply power steering fluid to the surface of the spe-

cial tool. Set the new seal rings over the special tool

from the smaller diameter end of the tool. and

expand the seal rings. Install two rings at a time

Jrom each end ofthe sleeve.

Note these items when installing the seal ring:

. Do not over-expand the seal ring. Install the resin

seal rings with care so as not to damage them.

After installation, be sure to contract the seal

rings using the specialtool {sizing tool).

. There are two types of sleeve seal rings: black

and brown. Do not mix the different types of

sleeve seal rings as they are not compatible.

Align the special tool with each groove in the sleeve,

and slide a sleeve seal ring into each groove. After

installation, compress the seal rings with your fin-

gers temporarily.

BALL JOINT BOOT CLIP GUIDE07974 - SA508q)

SLEEVE

Apply power steering fluid to the seal rings on the

sleeve, and to the ehtire inside surface of the special

tool.

14.

15.

SLEEVE SEAL RINGSIZING TOOL07974 - SA502O0 or07974 - SA5020A

16.Insert the sleeve into the special tool slowly.

Move the sleeve each direction several times to

make the seal rings snugly fit in the sleeve. Be sure

that the seal rings are not turned up,

't1.

18. Apply power steering fluid to the surface of the pin-

ion shaft. Assemble the sleeve over the Dinion shaft

by aligning the locating pin on the inside of the

sleeve with the cutout in the shaft. Then install the

new circlip securely in the pinion shaft groove.

Note these items during reassembly:

. Be caretul not to damage the valve seal ring

when inserting the sleeve.

. Install the circlip with its radiused side facing out.

Apply power steering fluid to the seal ring lip of the

valve oil seal. then install the seal in the valve hous-

ing using a hydraulic press and special tools. Install

the valve oil seal with its grooved side facing the tool.

19.

ATTACHMENT,32x35mm077i16 - (x)10100

VALVE OIL SEALReplace.Make sure thespring is in theoilseal.

CIRCLIP

www.emanualpro.com

Page 895 of 1395

Power Steering Gearbox

Reassembly (cont'd)

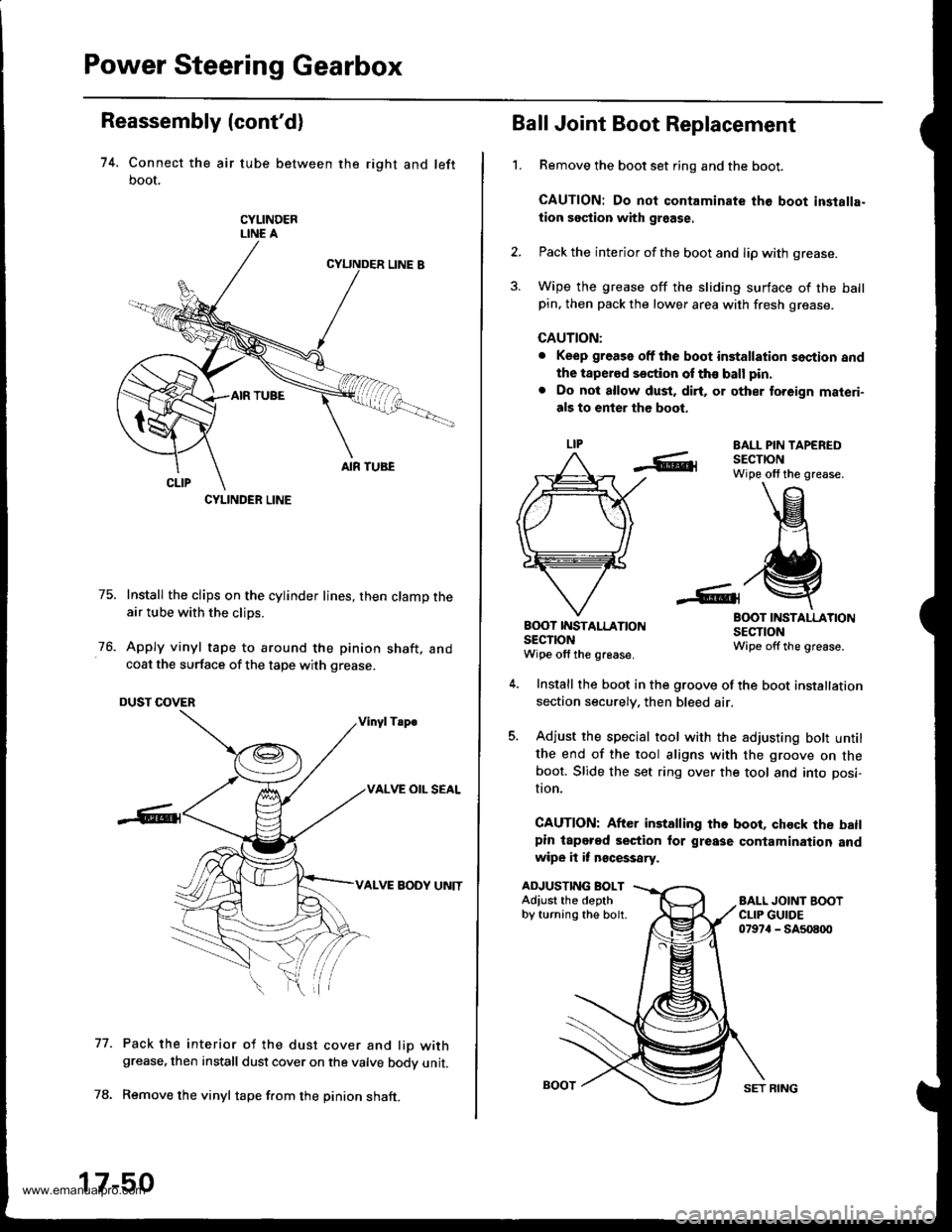

74. Connect the air tube between the right and left

boot,

CYLINDERLINE A

75. Install the clips on the cylinder lines, then clamp theair tube with the clips.

76. Apply vinyl tape to around the pinion shaft, andcoat the surface of the tape with grease.

DUST COVER

Vinyl Tsp€

VALVE OIL SEAL

VALVE BODY UNIT

Pack the interior of the dust cover and lio withgrease, then install dust cover on the valve bodv unit.

Remove the vinyl tape f.om the pinion shaft.

77.

CYLINDER LINE

17-50

SET RING

't.

Ball Joint Boot Replacement

Remove the boot set ring and the boot.

CAUTION: Do not contaminate the boot inslalla-

tion section with graase.

Pack the interior of the boot and lip with grease.

Wipe the grease off the sliding surface of the ballpin. then pack the lower area with fresh grease.

CAUTION:

. Keep grease off the boot installation section and

the tapered section of th€ ball pin.

. Do not allow dust, dirt, or other to.eign materi-

als to enter the boot.

EALL PIN TAPEREDSECTIONWipe olf the grease.

BOOT INSTALLATIONSECTIONWipe offthe grease.

B(X)T IT{STALLATIONsEclroNWipe off the grease.

ADJUSTING BOLTAdiust the depthby turning the bolt.

Install the boot in the groove of the boot installation

section securely. then bleed air.

Adjust the special tool with the adjusting bott untilthe end of the tool aligns with the groove on theboot. Slide the set ring over the tool and into posi-

I|on.

CAUTION: After installing the boot, chock the batlpin lapered section for grease contamination andwipe it it n€cessary.

www.emanualpro.com

Page 1174 of 1395

![HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1ll HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1ll](/img/13/5778/w960_5778-1173.png)

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1l'l

c112

c113

c't 14

cl16

cl16

c117

c118

c119

c120

c121

c't22

c't23

c't25

cl26

cl27

cr 28

cl29

c130

c131

c132

c 133

c134

c134

c135

c 136

10

6

1

2

1

2

1

10

20

31

16

22

l0

l0'14

14

1

Left side of engine compartment

Left side of engine compartment

Middle of engine

Middle of engine

Left side of engine compartment

Left side of engine compartment

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Right side of engine

Middle of engine

Behind right kick panel

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Right side of engine

Right side of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Left side of engine compartment

Middle of engine

Middle of engine

Main wire harness (C304)

Main wire harness (C305):'97 - 98 models

No. 1 fuel injector

Crankshaft speed fluctuation (CKF) sensor

Alternator

Alternator

Engine oil pressure switch

No.2 fuel injector

Evaporative emission (EVAP) purge

control solenoid valve

No. 3 fuel injector

No. 4 fuel injector

Primary heated oxygen sensor(Primary HO2S) (sensor 1)

Radiator fan switch

Coolant temperature sending unit

Engine coolant temperature (ECT) sensor

Mainshaft speed sensor

Lock-up control solenoid valve

Back-up light switch

Shift control solenoid valve

Linear solenoid valve

Countershaft speed sesnsor

Starter solenoid

Distributor

Junction connector

PCM

ECIWPCM

ECM/PCM

ECM/PCM

Main wire harness (C,|:}1)

IVT gear position switch

Vehicle speed sensor (VSS)

Throttle position (TP) sensor

MAP sensor

ldle air control (lAC)valve

lntake air temperature (lAT) sensor

Junction connector

Junction connector

Power steering pressure (PSP) switch

Junction connector

Knock sensor (KS)

A/r

USA

Canada

Alr

AlT

M/'r

Afi

'97mooel

'97 model'98 - 00

mooets

'99 - 00

models

T101

r102

Left side of en0ine companment

Right side of engine compartment

Alternator

Under-hood fuse/relay box

G101Middle of engineEngine ground, via engine wire harness

23-14

www.emanualpro.com