Rpm throttle HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 27 of 1395

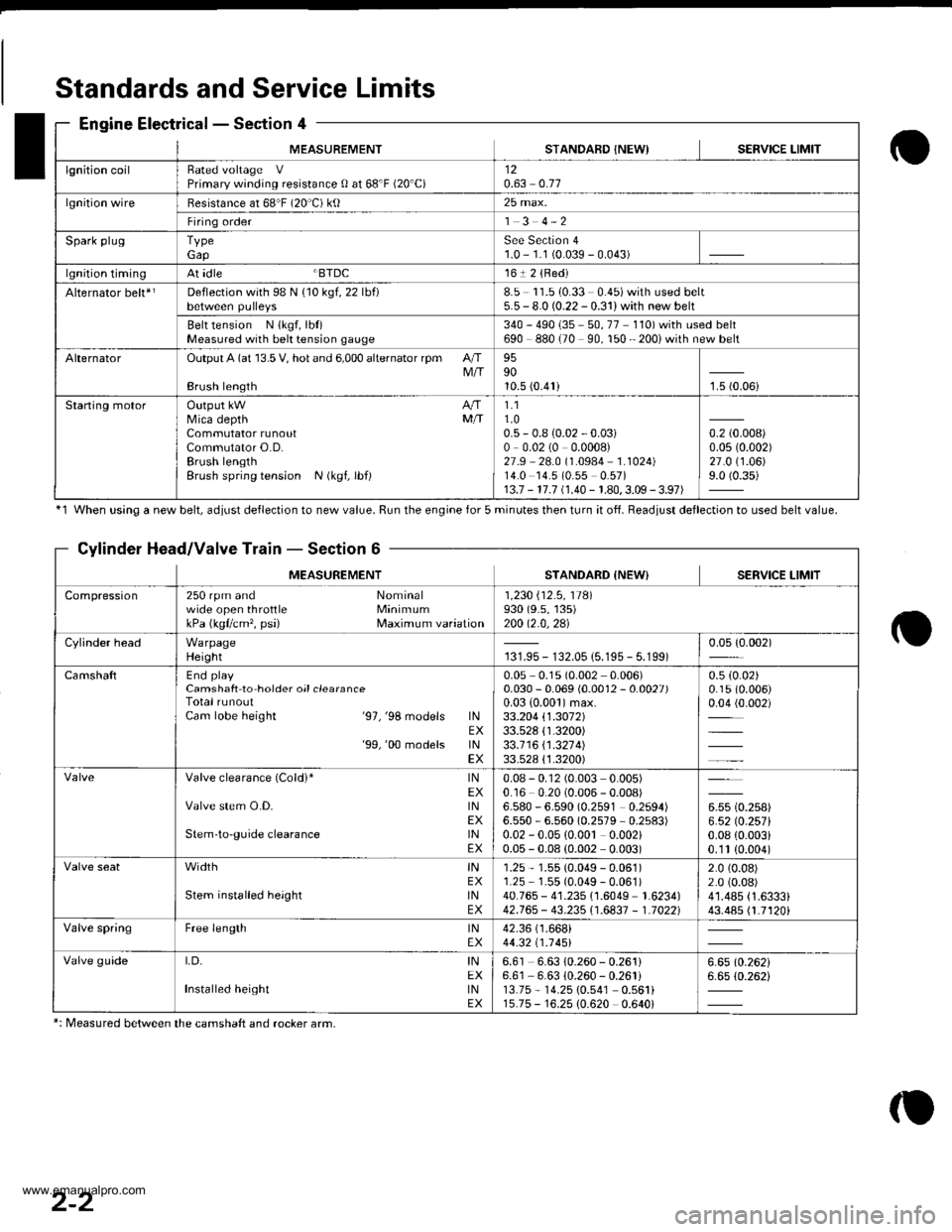

MEASUREMENTSTANDAFD INEWISERVICE LIMIT

lgnition coilRated voltage VPrimary winding resistance 0 at 68'F (20'C)120.63 0.77

lgnition wireBesistance at 68"F (20 C) ktl25 max.

Firing order1 3 4-2

Spark plugTypeGapSee Section 41.0 - 1.1 (0.039 - 0.043)

lgnition timingAt idle BTDC161 2 {Red)

Alternator belt*rDeflection with 98 N {10 kgf, 22 lbf)8.5 11.510.33 0.45)with used belt5.5 - 8.0 (0.22 - 0.31) with new belt

Belt tension N {kgf, lbt)Measured with bek tension gauge340 - 490 {35 - 50, 77 110) with used belt690 880 (70 90, 150 - 200i with new belt

AlternatorOutput A (at 13.5 V, hot and 6,000 alternator rpm AIIM/IBrush length

959010.5 (0.41)1.5 (0.06i

Staning motorOutput kW A/fMica depth MfiCommutator runoutCommutator O.D.Brush lengthBrush spring tension N (kgf, lbf)

1.11.00.5 - 0.8 {0.02 - 0.03)0,0.02 (0 0.0008)27.9 28.0 (1.0984 1.1024)14.0 14.5 (0.55 0.57)13.7 - 17.7 (1.40 - 1.80,3.09 - 3.97)

0.2 (0.008)

0.0s (0.002)

27.0 (1.06)

9.0 (0.35)

Standards and Service Limits

Engine Electrical - Section 4

'1 When using a new belt, ddiust deflection to new value. Run the engine for 5 minutes then turn it of{. Beadiust deflection to used belt value.

Cylinder Head/Valve Train - Section 6

MEASUREMENTSTANDARD {NEW} SERVICE LIMIT

Compression250 rpm and Nominalwide open throttle MinimumkPa (kgflcm'�, psi) Maximum variation

1 ,230 i'12 .5 , 11Al930 (9.s, 135)200 12.0,2al

Cylinder headWarpageHeight131.95 - 132.05 {5.195 - 5.199)0.05 {0.002)

CamshaftEnd playCamshaft to hoider oil clearanceTotal runoutCam lobe height '97,'98 models lNEX'99,'00 models lNEX

0.05 0.1s (0.002 0.006)0.030 - 0.069 (0.0012 - 0.0027)0.03 {0.001)max.33.204 \1.3072133.528 {1.3200)33.1 16 \1 .321 4)33.528 {'1.3200)

0.5 (0.02)

0.15 (0.006)

0.04 (0.002)

Valve clearance (Cold)* lNEXValve stem O.D. lNEXStem'to-guide clearance lNEX

0.08 - 0.12 (0.003 0.005)0.16 0.20 (0.006 - 0.008)6.580 - 6.590 (0.2591 0.2594)6.550 - 6.560 (0.2579 0.2s83)0.02 - 0.05 {0.00t 0.002)0.05 - 0.08 (0.002 0.003)

u* to.rutt6.52lO.257l0.08 {0.003i0.'1t (0.004)

width tNEXStem installed height lNEX

1.25 - 1.55 (0.049 - 0.061)1.25 1.55 (0.049 - 0.061)40.765 - 41.235 {1.6049 1.6234)42.765 - 43.235i'1.6837 - 1.70221

2.0 (0.08)

2.0 (0.08)

41.485 {1.6333}43.485 {1.7120i

Valve springFree length lNEX42.36 (1.668i

44.32 t1 .1 451

Valve guideI,D, INEXInstalled height tNEX

6.61 6.63 10.260 - 0.261)6.61 6.63 {0.260 - 0.261i13.75 - 14.25 10.541 0.561i15.75 - 16.25 {0.620 0.640i

6.6510.26216.65 (0.262i

*: Measured between the camshaft and rocker arm,

2-2

www.emanualpro.com

Page 268 of 1395

Troubleshooting

Troubleshooting Procedures (cont'd)

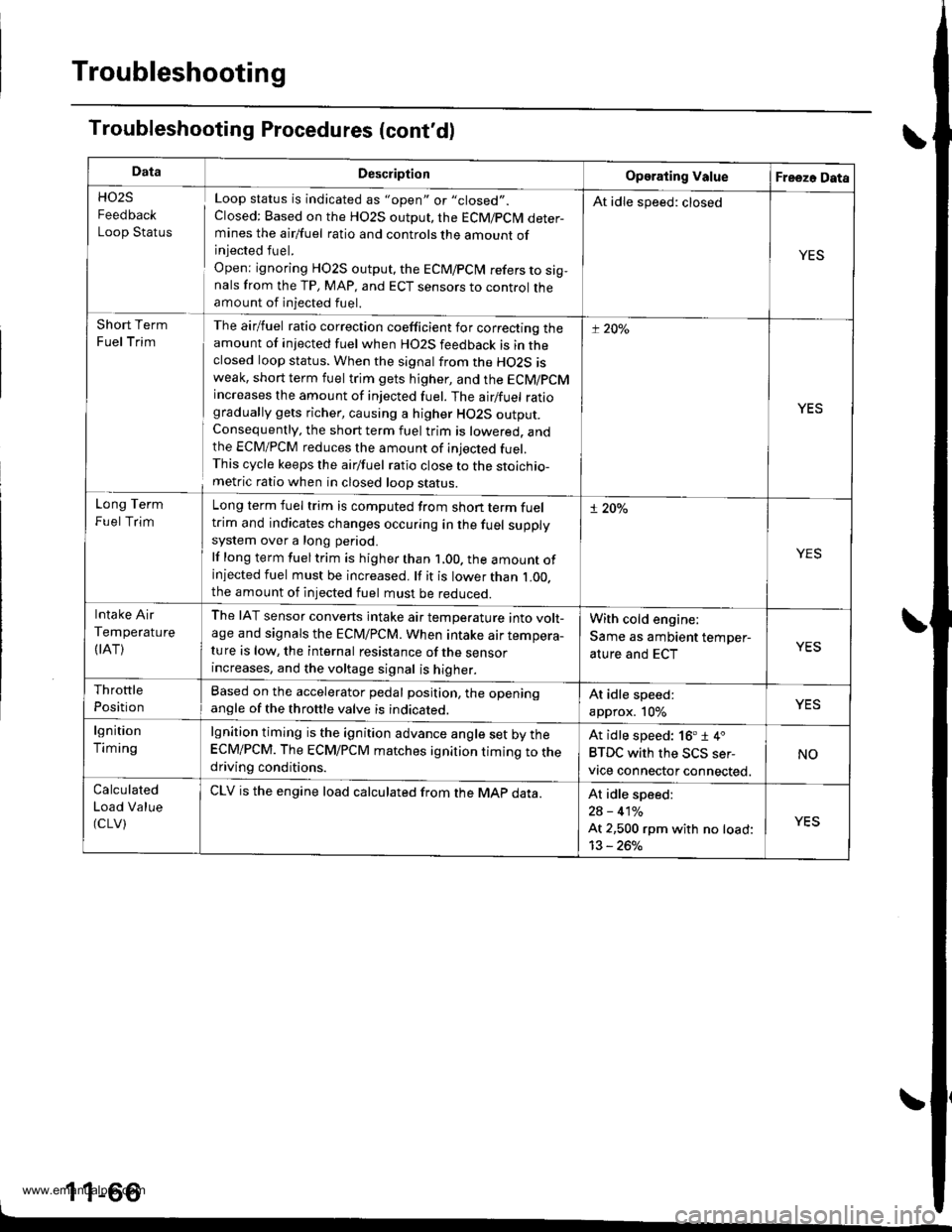

DataDescliptionOperating ValueFreezo Data

HO2S

Feedback

Loop Status

Loop status is indicated as "open" or "closed".

Closed: Based on the HO2S output, the ECM/pCM deter-mines the airlfuel ratio and controls the amount ofinjected fuel.

Open: ignoring HO2S output, the ECM/pCiM refers to sig,nals from the TP, MAP, and ECT sensors to control theamount of injected fuel.

At idle speed: closed

YES

Short Term

Fuel Trim

The airlfuel ratio correction coefficient for correcting theamount of injected fuel when HO2S feedback is in theclosed loop status. When the signal from the HO2S isweak, short term fuel trim gets higher, and the ECM/PCMincreases the amount of injected fuel. The airlfuel ratiogradually gets richer, causing a higher HO2S output.Consequently. the short term fuel trim is lowered. andthe ECM/PCM reduces the amount of injected fuel.This cycle keeps the airfuel ratio close to the stoichio-metric ratio when in closed looD status.

t:20y"

YES

Long Term

Fuel Trim

Long term fuel trim is computed from shon term fueltrim and indicates changes occuring in the fuel supplysystem over a long period.

lf long term fuel trim is higher than 1,00. the amount ofinjected fuel must be increased. lf it is lower than L00.the amount of injected fuel must be reduced.

! 20%

Intake Air

Temperature

(IAT)

The IAT sensor converts intake air temperature into volt-age and signals the ECrU/PCM. When intake air tempera-ture is low, the internal resistance of the sensorincreases, and the voltage signal is higher.

With cold engine:

Same as ambient temper-

ature and ECTYES

Throttle

Position

Based on the accelerator pedal position, the openingangle of the throttle valve is indicateo.At idle speed:

approx. 10%

lgnition

Timing

lgnition timing is the ignition advance angle set by theECM/PCM. The ECM/PCM matches ignition timing to thedriving conditions.

At idle speed: 16'1 4.

BTDC with the SCS ser-

vtce connector connected.

NO

Calculated

Load Value(cLV)

CLV is the engine load calculated from the MAp data.At idle speed:

2A - 410/o

At 2,500 rpm with no load:

13 - 260/o

YES

_

1 1_66

www.emanualpro.com

Page 283 of 1395

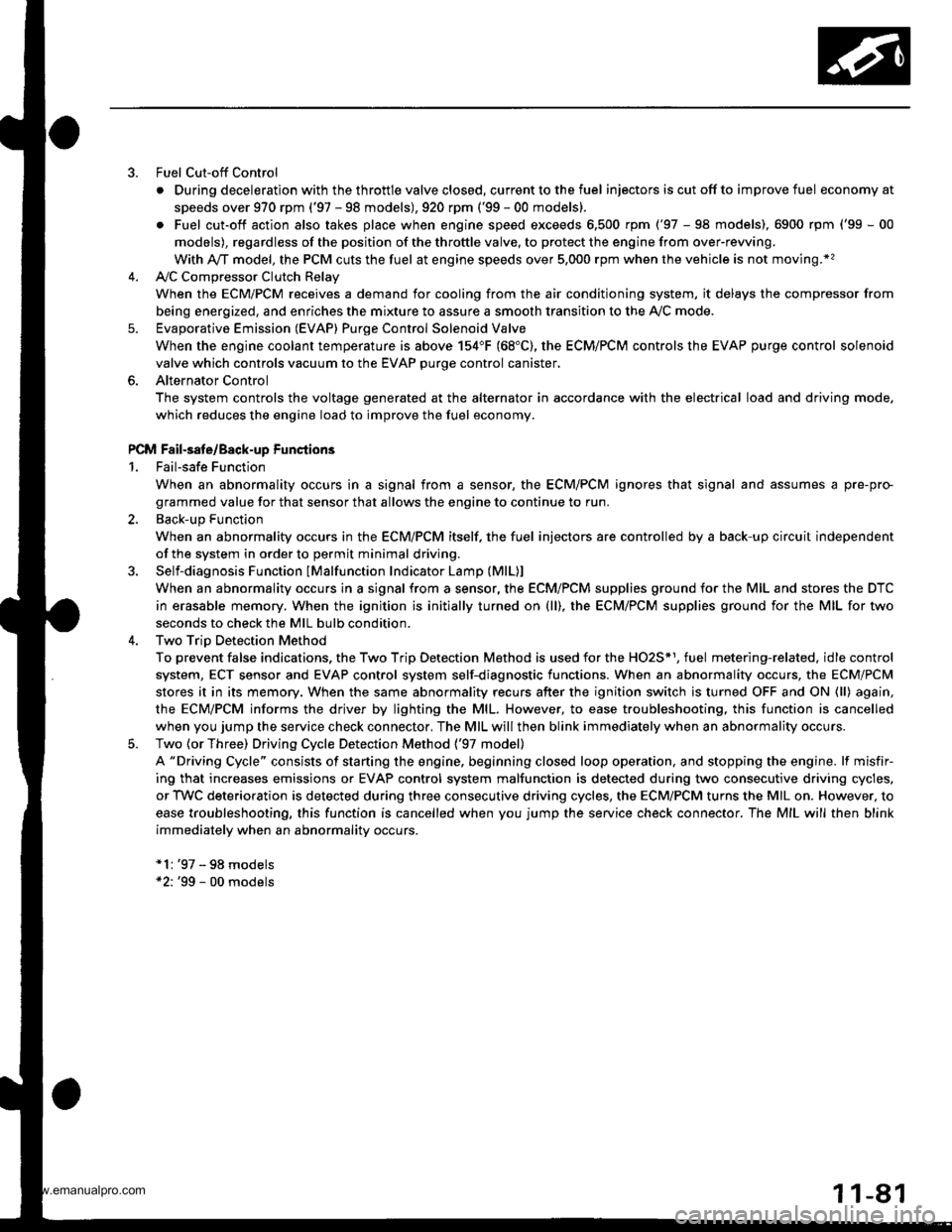

Fuel Cut-off Control

. During deceleration with the throttle valve closed, current to the fuel injectors iscutoffto improvefuel economyat

speeds over 970 rpm ('97 - 98 models), 920 rpm ('99 - 00 modelsl.

. Fuel cut-off action also takes place when engine speed exceeds 6,500 rpm ('97 - 98 models), 6900 rpm ('99 - 00

models), regardless of the position of the throttle valve, to protect the engine from over-rewing.

With Ay'T model. the PCM cuts the fuel at engine speeds over 5,000 rpm when the vehicle is not moving.*'�

4,./C Comoressor Clutch Relav

When the ECM/PCM receives a demand for cooling from the air conditioning system, it delays the compressor from

being energized, and enriches the mixture to assure a smooth transition to the Ay'C mode.

Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is above 154"F (68'C), the ECM/PCM controls the EVAP purge control solenoid

valve which controls vacuum to the EVAP purge control canister,

Alternator Control

The system controls the voltage generated at the alternator in accordance with the electrical load and driving mode.

which reduces the engine load to improve the fuel economy.

PCM Fail-saf e/Back-up Functions

1. Fail-safe Function

When an abnormality occurs in a signal from a sensor, the ECM/PCM ignores that signal and assumes a pre-pre

grammed value for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM/PCM itself, the fuel injectors are controlled by a back-up circuit independent

of the system in order to permit minimal driving.

3. Self-diagnosis Function IMalfunction Indicator Lamp (MlL)l

When an abnormality occurs in a signal from a sensor, the ECM/PCM supplies ground for the MIL and stores the DTC

in erasable memory. When the ignition is initially turned on {ll), the ECM/PCM supplies ground for the MIL for two

seconds to check the MIL bulb condition.

4. Two Trio Detection Method

To prevent false indications, the Two Trip Detection Method is used for the HO2S*1, fuel metering-related. idle control

system, ECT sensor and EVAP control system self-diagnostic functions. When an abnormality occurs, the ECM/PCM

stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (ll) again,

the ECM/PCM informs the driver by lighting the MlL. However, to ease troubleshooting, this function is cancelled

when you jump the service check connector, The MIL will then blink immediately when an abnormality occurs.

5. Two (or Three) Driving Cycle Detection Method {'97 model)

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. lf misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles.

or TWC deterioration is detected during three consecutive driving cycles, the ECM/PCM turns the MIL on. However, to

ease troubleshooting, this function is cancelled when you jump the service check connector. The MIL will then blink

immediately when an abnormality occurs.

*1: '97 - 98 models*2: '99 - 00 models

5.

www.emanualpro.com

Page 305 of 1395

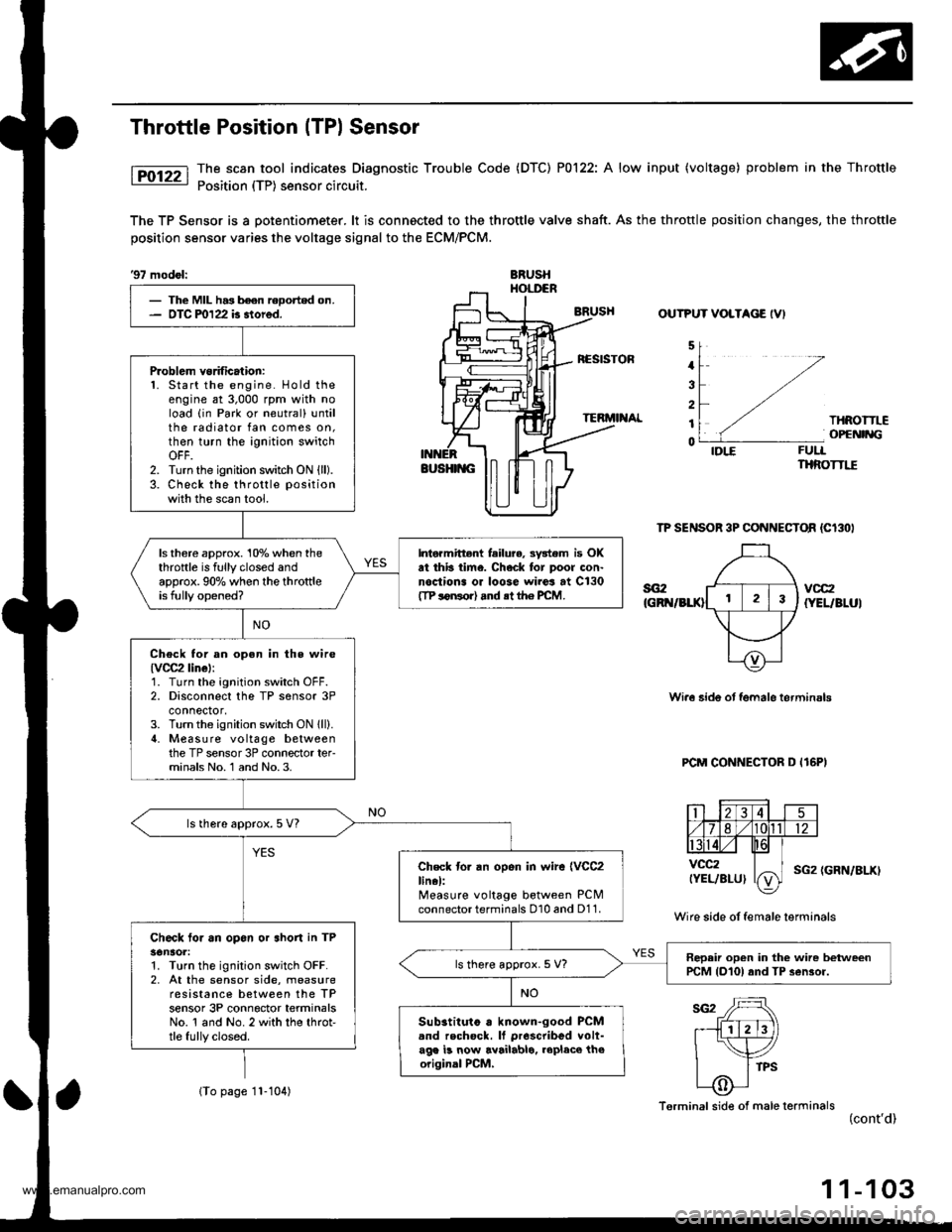

Throttle Position (TPl Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) P0122: A low input (voltage) problem in the Throttle

Position (TP) sensor circuit.

The TP Sensor is a potentiometer. lt is connocted to the throttle valve shaft. As the throttle position changes, the throftle

position sensor varies the voltage signal to the ECM/PCM.

'97 mod6l:BRUSHHOI,I'ER

OUTPUT VOLTAGE IVI

5

4

3

2

1

0

THROITLEOPCNIiIG

FUTIIHROTTI"E

TP SENSOR 3P CONNECTOR {Cl3OI

vcc2IYEL/BLUI

Wi.6 6ide ot fgmale terminsls

PCM CONNECTOR D I16PI

Wire side of female terminals

(GRN/BLX)

- The MIL h.3 been reoorted on.- OTC m122 b 3tored.

Problem vorificalion:1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutrall untilthe radiator fan comes on,then turn the ignition switchOFF.2. Turn the ignition switch ON (ll).

3. Check the throttle position

with the scan tool.

ls there approx. 10% when thethrottle is fully closed andapprox.90% when the throttleis fully opened?

Intormittent feilu?e, 3y3tem is OKat thb iime. Check tor poor con-nodiona or loose wiros at C130tTP loNorl .nd rt th€ PCM.

Check tor an open in the wire{vOC2linel:1. Turn the ignition switch OFF.2. Disconnect the TP sensor 3Pconnector,3. Turn the ignition switch ON lll).il. Measure voltage betweenthe TP sensor 3P connector ter-minals No. 1 and No. 3.

ls there approx.5 V?

Check to. an open in wir6 {VCC2linel:Measure voltage between PCMconnector terminals 010 and D11.

Ch6ck to. an opon or shon in TPsonaol:1. Turn the ignition switch OFF.2, At the sensor side, measureresistance between the TPsensor 3P connector terminalsNo. 1 and No. 2 with the throt-tle fully closed.

Repair open in the wirc betweenPCM {D10} and TP 3ensor.ls there approx. 5 V?

Sub3tituto . known-good PCMand rechock. It proscribed volt-ag. b now availablo. rcplaco th6originsl PCM,

Terminal side of male terminals(cont'd)

(To page 11-104)

1 1-103

www.emanualpro.com

Page 307 of 1395

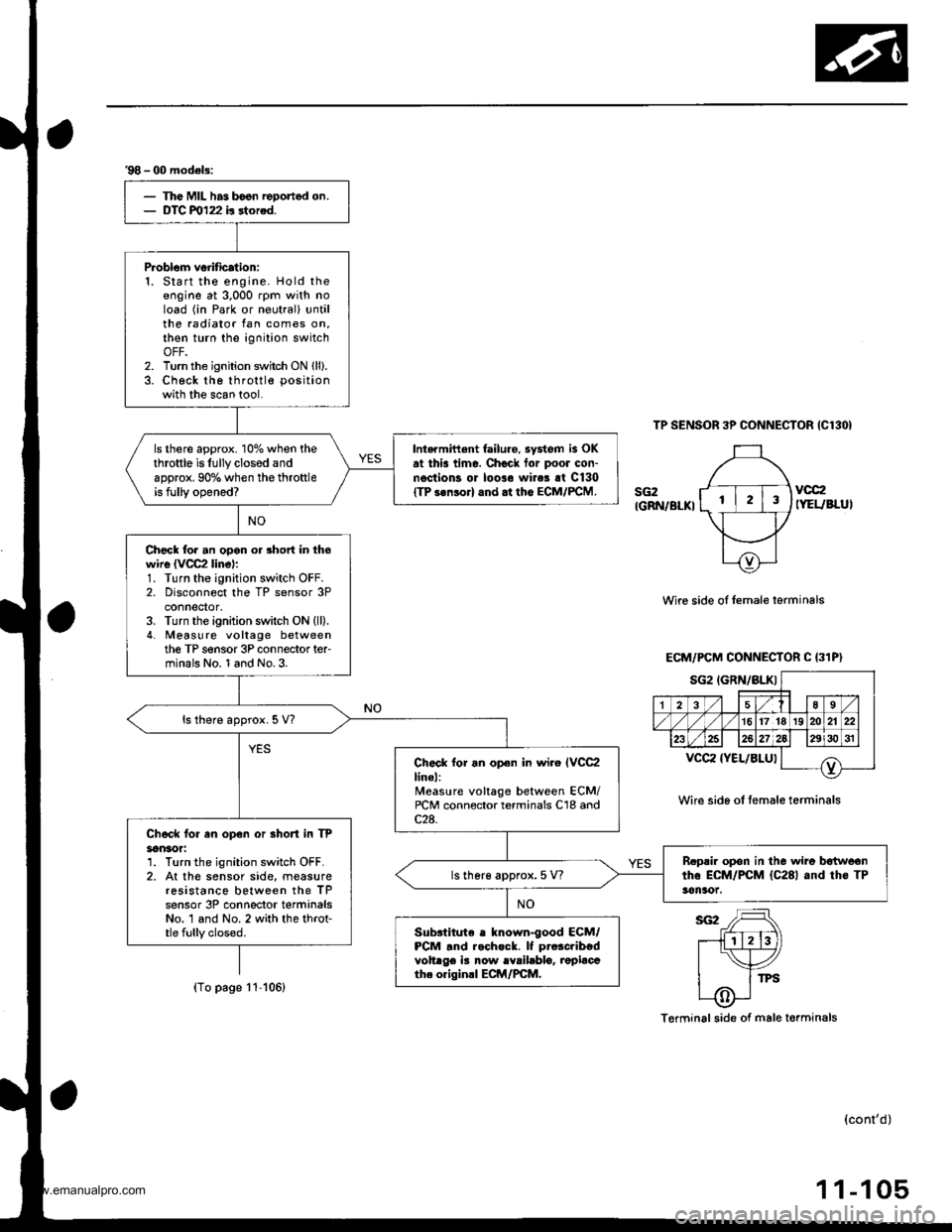

'98 - 00 model3:

The MIL has boon reDortod on.DTC m122 b rtorod.

P.oblom veiification:1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator tan comes on,then turn the ignition switchOFF.2. Turn the ignition switch ON lll).3. Check the throttle position

with the scan tool.

ls there approx. 10% when thethrottle is fully closed andapprox. 90% when the throttleis fully opened?

Intarmittent failure. system is OKat thia time. Check for poor con-n€ctions or loolo wires rt C130ITP s.nsorl and.t the ECM/FCM.

Check for an opon or short in thowire {VCC2 linel:1. Turn the ignition switch OFF.2. Disconnect the TP sensor 3Pconnedor,3. Turn the ignition switch ON (ll).

4. Meas! re voltage betweenthe TP s€nsor 3P connector ter-minals No. 1 and No.3.

ls there approx. 5 V?

Check lor an opon in wiro IVCC2linel:Measure voltage between ECM/rcM connector terminals C'18 andc2a.Chock for en op€n or Bhort in TP3an30r:1. Turn the ignition switch OFF.2. At the sensor side, measureresistance between the TPsensor 3P conneclor terminalsNo. 1 and No. 2 with the throt-tle fully closed.

B.psir opon in the wire b€{woontho ECM/PCM {C281 and th6 TP3en!xtt.ls lher€ approx. 5 V?

Subslitute e known-good ECM/PCM .nd r.chock. lf pro3cribedvoltrge iB now rYrilablo, replacath. originll ECM/PCM.

TP SENSOR 3P CONNECTOR {C130}

sG2IGRN/BLKI

vcc2IYEUBLUI

Wire side oI Iemale lerminals

Wire sid6 of temale terminals

Terminal side of male torminals

(cont'd)

1 1-105

ECM/PCM CONNECTOR C (31P}

sG2IGRN/BLKIa-,l 18 sl./|135

/1617lrs]zolzr zzl

232527)gJ lzgi3o sr I

T^vccz {YEL/8LUl

(To page 11-106)

www.emanualpro.com

Page 309 of 1395

![HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

The scan tool indicates Diagnostic Trouble Code (DTC) P0123: A high voltage problem in the Throttle Position

(TP) sensor circuit.

TP SENSOR 3P @]{NECTOR IC13O}

sG2(GnN/Br.XlvocrtYEt /8LU)

{GBIT/BLKI

HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

The scan tool indicates Diagnostic Trouble Code (DTC) P0123: A high voltage problem in the Throttle Position

(TP) sensor circuit.

TP SENSOR 3P @]{NECTOR IC13O}

sG2(GnN/Br.XlvocrtYEt /8LU)

{GBIT/BLKI](/img/13/5778/w960_5778-308.png)

The scan tool indicates Diagnostic Trouble Code (DTC) P0123: A high voltage problem in the Throttle Position

(TP) sensor circuit.

TP SENSOR 3P @]{NECTOR IC13O}

sG2(GnN/Br.XlvocrtYEt /8LU)

{GBIT/BLKI

(cont'd)

11-107

Wiro side of fom.le terminals

PCM CON'{ECTOF D I16PI

Wire side ot female terhinals

The MIL hlr br€n r.9ort.d on.DTC P0123 ir stored.

Pioblom vorificltion:1. Start the ongin6. Hold th€ongine at 3,000 rpm with noload {in Park or neutral) untilth6 radiator fan comes on.then turn the ignition switchOFF,2. Turn the ignition switch ON (ll).

3. Check the throttle position

with the scan tool.

Intarmittant tailuro, ryrtern b OKat this timo. Chock lor poor con-nections or loo3o wir€3 at C130

ITP 3orcorl .nd at tho ECM/FCM.

ls there spprox. 1oyo when thothrottle is Iully closed andapprox.90% when the throttleis tully open€d?

Choct toJ an opcn in th6 TP s6n-3t']:1. Turn the ignition switch OFF.2. Disconnect the TP sensor 3Pconnectol,3. Turn the ignition switch ON (ll).

4. At the wir6 harnoss side, mea-suro voltage betweon thg TPsensor 3P connector t€rminalsNo. 1 and No.3.

ls there approx.5 V?

Chack for an oDan in tha wira(SG2 linel:M6asu16 voltage b6tween PCMconn€ctor terminals Dl0 and D'! 1.

R.pai. opcn in tha wira botwcontho PcM {o111 rnd the TP 3en-3('t,

ls there approx. 5 V?

('97 model)

(To page 11-108)

www.emanualpro.com

Page 312 of 1395

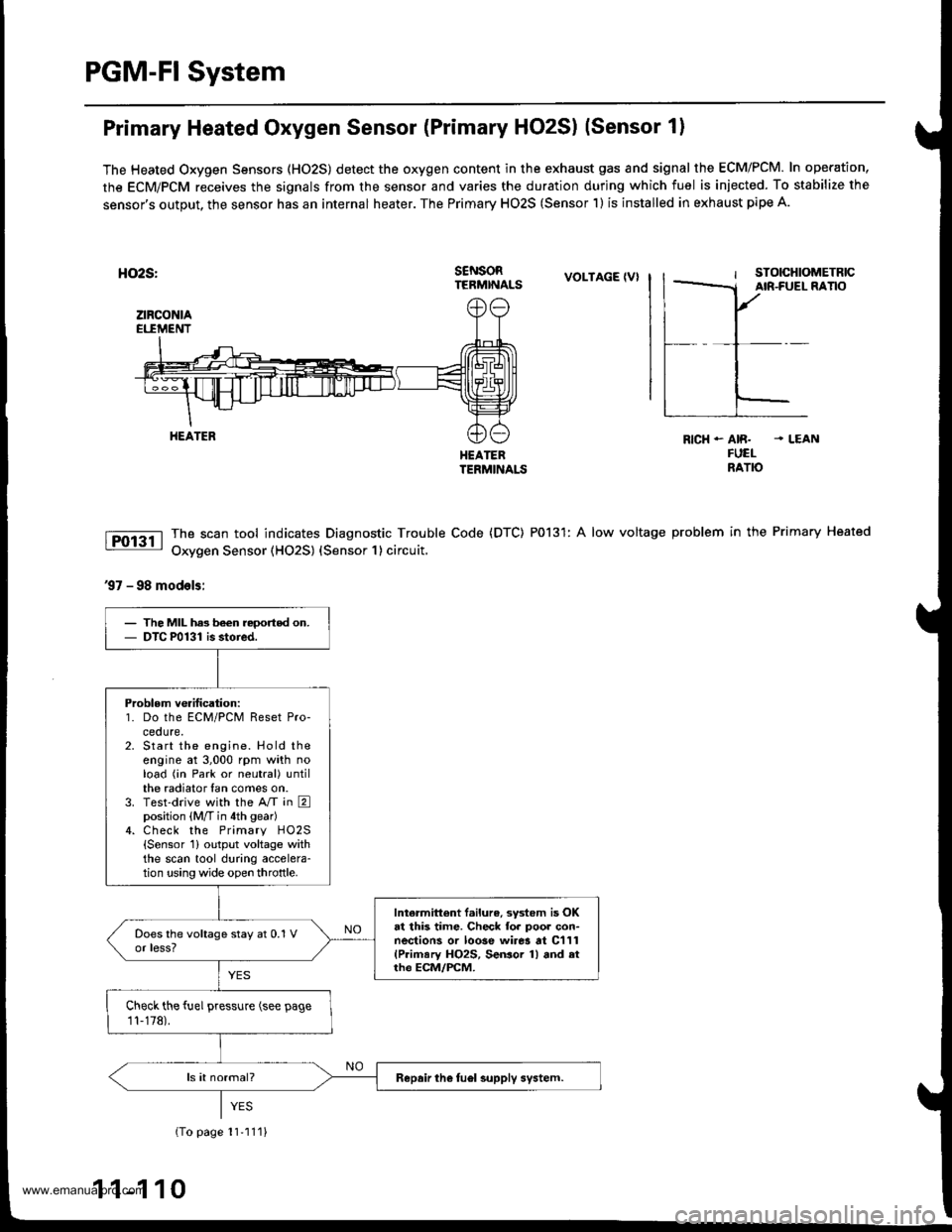

PGM-FI System

Primary Heated Oxygen Sensor (Primary HO2S) (Sensor 1)

The Heated Oxygen Sensors (HO2S) detect the oxygen content in the exhaust gas and signal the ECM/PCM. In operation,

the ECM/PCM receives the signals from the sensor and varies the duration during which fuel is iniected. To stabilize the

sensor's output, the sensor has an internal heater. The Primary HO2S (Sensor 1) is installed in exhaust pipe A.

HO2S:

ztRcoNtAEI.IMENT

s€NsoRTERMINALSVOLTAGE IVI

HEATEBTERMINALS

The scan tool indicates Diagnostic Trouble Code (DTC) P0131: A low voltage

Oxygen Sensor (HO2S) {Sensor 1} circuit,

RICH - AIR. . LEANFUELNATO

problem in the Primary Heated

37 - 98 models:

HEATER

The MIL has been reoorted on.DTC P0131 is stoied.

Problem verification:1. Do the ECM/PCM Reset Pro-ceoure.Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on.Test-drive with the A/T in Eposition (M/T in 4th gear)Check the Primary HO2S{Sensor 1} output voltage withthe scan tool during accelera-tion using wide open throttle.

Intermittent f.ilure, system is OKat this time. Check fo. poor con-nections or loose wirer at C111(Primary HO2S, SeGor 1) and atrh€ ECM/FCM.

Check the fuel pressure (see page

11-178).

Repair the fuel supply system.

{To page 11'111}

1 1-1 10

www.emanualpro.com

Page 314 of 1395

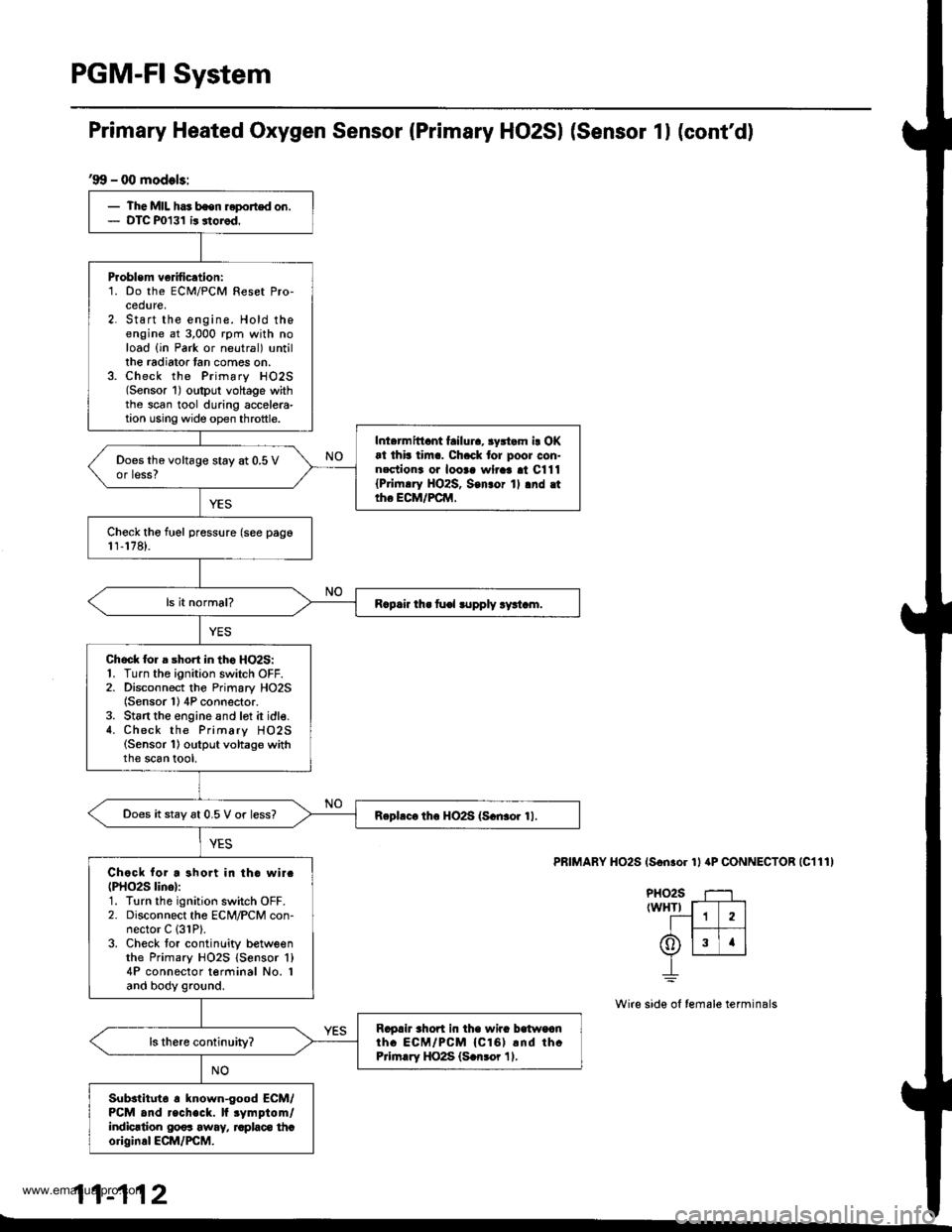

PGM-FI System

'99 - 00 models:

- The MIL has bsen reported on.- DTC P0131 ir storod.

Problem ve fication:1. Do the ECM/PCM Reset Pro-cedure,2. Start the engine. Hold theengine at 3,000 rpm with noload {in Park or neutral) untillhe radiator tan comes on.3. Check the Primary HO2S(Sensor 1) oltput voltage withthe scan tool during accelera-tion using wide op€n throttle.

Inl.rmittant failura, 3yrtam i! OKat thb tim.. Ch.ck tor poor con-nectiona oa looaa wlraa al C111{Pri|n.ry HO2S, Son3or 1l .nd .ttho ECM/FCM,

Does the voltage stay at 0.5 Vor less?

Check tho fuel pressure (see pago1r,178).

R.p.ir th. fu€l lupply ry!t.m.

Chock lor a short in tho HO2S:1. Turn the ignition switch OFF.2. Disconnect the Primary HO2S(Sensor 1) 4P connector.3. St6rt the engine and lot it idle.4. Check the Primary HO2S(Sensor 1) output voltage withthe scan tool,

Does it stay 6t 0.5 V or less?Rephc. th6 HO2S (S.n3or 11.

Chock for a short in tho wirc(PHO2S lino):1. Turn the ignition switch OFF.2. Disconnect the ECM/PCM con-nector C (31P).

3. Check tor continlity betweenthe Primary HO2S {Sensor 'l}

4P connector terminal No. Iand body ground.

Ragah rhort in tha wira balwoanth. ECM/PCM {Cl61 rnd thcPrirn.ry HO2S (S.n3or 11.

Substltut6 a known-good ECM/PCM and recheck. lf rymptom/indicrtion 00os away, raplaco thcoriginal ECM/PCM.

Primary Heated Oxygen Sensor (Primary HO2SI (Sensor 1l (cont'd)

PRIMARY HO2S (Son.or 1l aP CONNECTOR |C111)

PHO2S T--1rwHTr f-T---]

--1 1 2lI t--- 1t6)lslrlv L__r__J

_L

Wire side ol female terminals

11-112

www.emanualpro.com

Page 315 of 1395

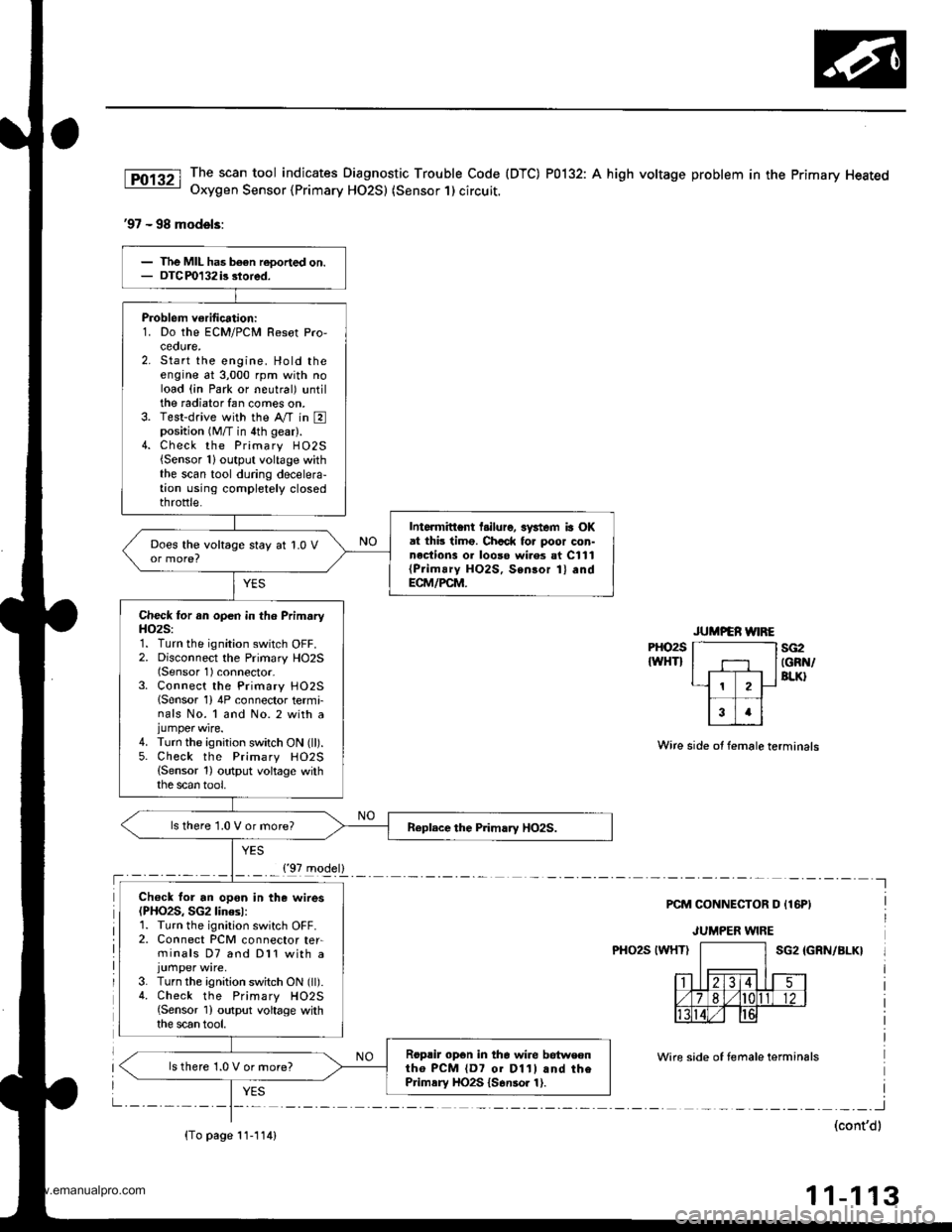

The scan tool indicates Diagnostic Trouble Code (DTC) P0132: A high voltage problem in the Primary HeatedOxygen Sensor {Primary HO2S) (Sensor 1) circuit.

'97 - 98 models:

PHO2S

IWHTIsG2IGRN/BLK}

Wire side ot female terminals

PCM CONNECTOR D {16PI

JUMPER WIRE

PHO2S IWHTISG2 IGRN/BLK}

Wire side of temale terminals

I

(cont'dl

11-113

Problem verification:1. Do the ECM/PCM Resot Pro,ceoute,2. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on.3. Test-drive with the Ay'T in Eposition (M/T in 4th gear).4. Check the Primary H02S{Sensor 1}output voltage withthe scan tool during decelera-tion using completely closedthrottle.

Intormittent l.ilure, 3ystem ia OKat thb timo. Chcck fo. poor con-nections 01 looso wi.es at C111{Prim!ry HO2S, Sensor 1} andECM/PCM.

Does the voltage stay at 1.0 V

Check for an open in th6 PrimaryH()2S:1. Turn the ignition switch OFF.2. Disconnect the Primary HO2S(Sensor 1) connector-3. Connect the Primary HO25lSensor 1) 4P connector termi-nals No. 1 and No. 2 with ajumper wire.4. Turn the ignition switch ON (ll).5. Check the Primary HO2S(Sensor 1) output voltage withthe scan tool,

ls there 1.0 V or more?

Ch€ck for an opon in the wires(PHO2S, SG2linesl:1. Turn the ignition switch OFF.2. Connect PCM connector ter-minals D7 and Dl1 with a

3. Turn the ignition switch ON (ll).4. Check the Primary HO2S{Sensor 1) output voltage withthe scan tool.

Roprir opon in the wire betweontho PCM {D7 01 D11l and thePrimsry HO2S {S6nsor 1).

ls there 1.0 V or more?

{'97 model}

{To page 11-114)

www.emanualpro.com

Page 339 of 1395

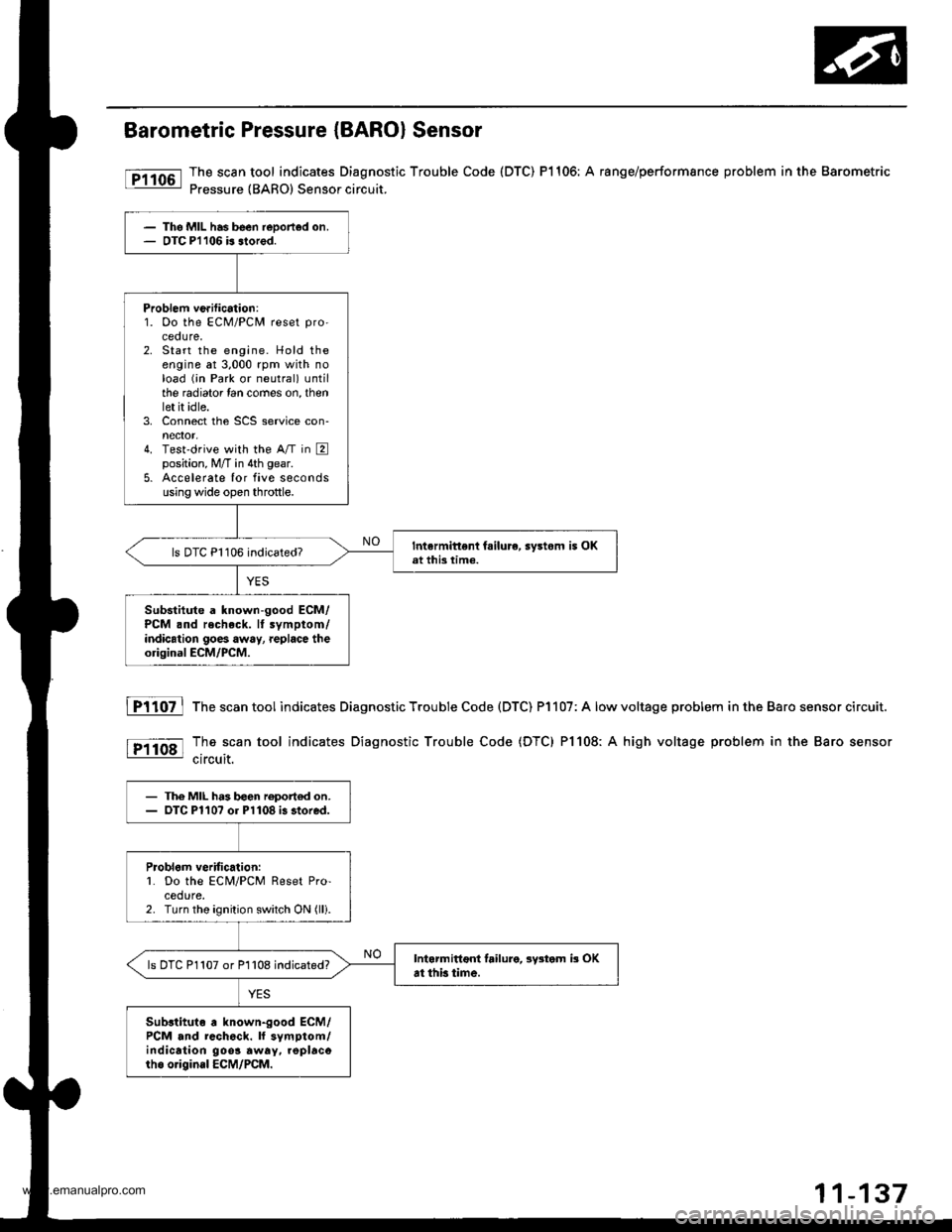

Barometric Pressure (BARO) Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) P1106: A range/performsnce problem in the Barometric

Pressure {BARO) Sensor circuit.

The MIL has been reDorted on.OTC Pl106 b slored.

Problem ve.ification:1. Oo the ECM/PCM reset pro'

ceoure.2. Start the engine. Hold theengine at 3,000 rpm with noload (;n Park or neutral) untilthe radiator lan comes on, thenlet it idle.3. Connect the SCS service con-nector,4. Test'drive with the A/T in Eposition, M/T in 4th gear.

5. Accelerate Ior five secondsusing wide open throttle.

Intermittent fsilure, sy3tom i5 OKat this time.ls DTC P1106 indicated?

Substitute a known-good ECM/PCM .nd recheck. It symptom/indication goes away, replace theorigioal ECM/PCM.

fTiloz l

tP11o8l

The scan tool indicates Diagnostic Trouble Code (DTC) P1107: A low

The scan tool indicates Diagnostic Trouble Code (DTC) Pl108: A

circuit.

voltage problem in the Baro sensor circuit.

high voltage problem in the Baro sensor

- The MIL h.3 b€en roport€d on.- OTC Pl10? or Pl108 i3 stored.

Problom veritic.lion:L Do the ECM/PCM Reset Pro-cedure.2. Turn the ignition switch ON (lli.

Intarmittoni failure, lystom b OKat thb time.ls DTC P1107 or P1108 indicated?

Sub3tituto a known-good ECM/PCM and rcch6ck. ll symptom/indication 9oo3 away. .oplacorho o.igin.l ECM/PCM.

www.emanualpro.com