lower control arm HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 267 of 1395

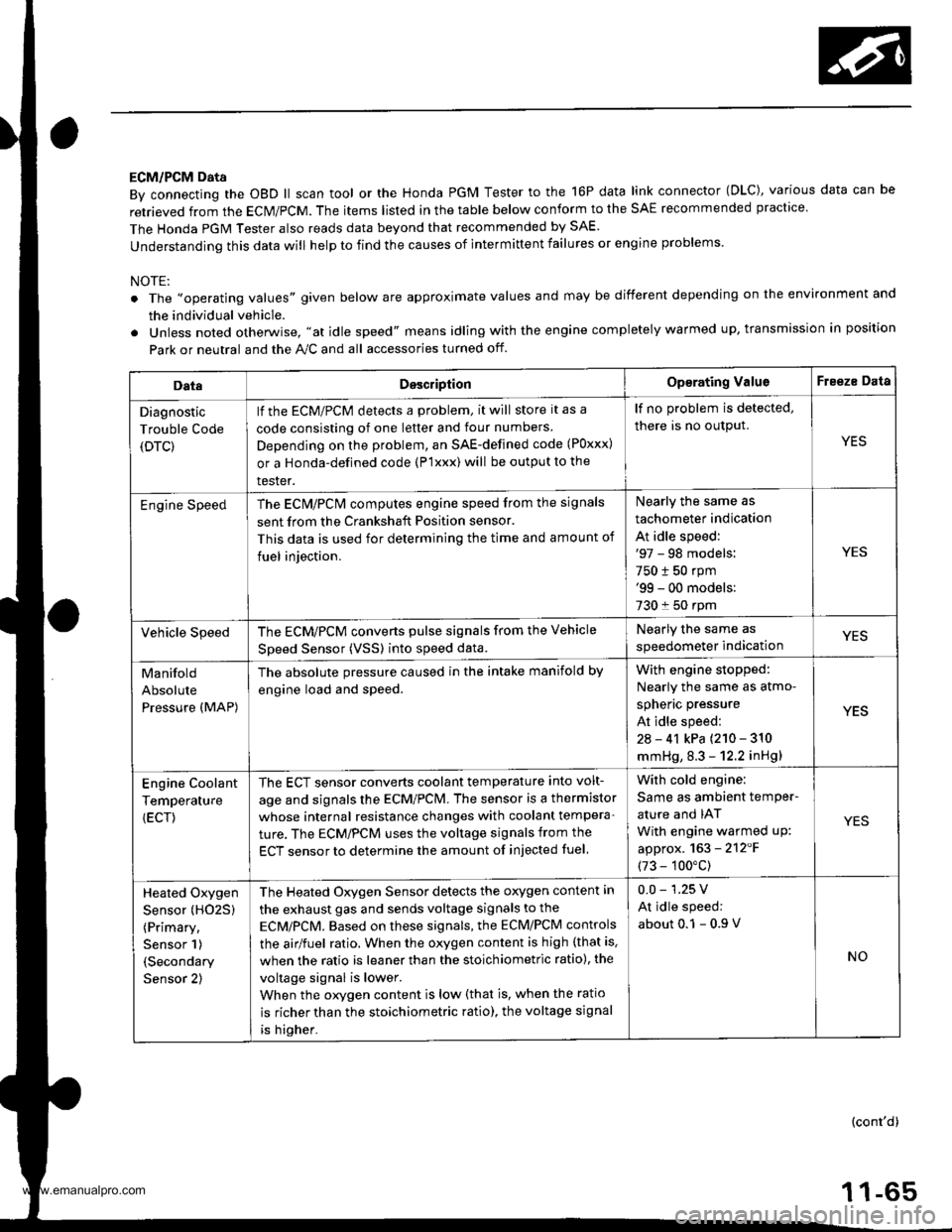

ECM/PCM Data

By connecting the OBD ll scan tool or the Honda PGM Tester to the 16P data link connector (OLC), various data can be

retrieved from the ECM/PCM. The items listed in the table below conform to the SAE recommended practice

The Honda PGM Tester also reads data beyond that recommended by SAE.

understanding this data will help to find the causes of intermittent failures or engine problems.

NOTE:

The ',operating values" given below are approximate values and may be different depending on the environment and

the individual vehicle.

Unless noted otherwise. "at idle speed" means idling with the engine completely warmed up, transmission in position

Park or neutral and the A,./C and all accessories turned otf.

DataDesc.iptionOp€rating ValuoFreeze Data

Diagnostic

Trouble Code

(DTC)

lf the ECM/PCM detects a problem, it will store it as a

code consisting of one letter and tour numbers

Depending on the problem, an SAE-defined code (Poxxx)

or a Honda-defined code (P'lxxx) will be output to the

tester.

lf no problem is detected,

there is no output.

YES

Engine SpeedThe ECN4/PCN4 computes engine speed from the signals

sent from the Crankshaft Position sensor.

This data is used for determining the time and amount of

fuel iniection.

Nearly the same as

tachometer indication

At idle speed:'97 - 98 models:

750 t 50 rpm'99 - 00 models:

730 f 50 rpm

YES

Vehicle SpeedThe ECM/PCM converts pulse signals from the Vehicle

Speed Sensor (VSSI into speed data.

Nearly the same as

speedometer indicationYES

Manifold

Absolute

Pressure (MAP)

The absolute pressure caused in the intake manifold by

engine load and speed.

With engin6 stopped:

Nearly the same as atmo-

spheric pressure

At idle speed:

2a - 41 kPa {210 - 310

mmHg, 8.3 - 12.2 inHg)

YES

Engine Coolant

Temperature

{ECT)

The ECT sensor converts coolant temperature into volt-

age and signals the ECM/PCM. The sensor is a thermistor

whose internal resistance changes with coolant tempera-

ture. The ECM/PCM uses the voltage signals from the

ECT sensor to determine the amount of injected fuel

With cold engine:

Same as ambient temPer-

ature and IAT

With engine warmed uP:

approx. 163 - 2'12'F

(73 - 100"c)

YES

Heated Oxygen

Sensor (HO25)

(Primary,

Sensor 1)

(Secondary

Sensor 2)

The Heated Oxygen Sensor detects the oxygen content in

the exhaust gas and sends voltage signals to the

ECMiPCM. Based on these signals, the ECM/PCM controls

the airlfuel ratio. When the oxygen content is high (that is.

when the ratio is leaner than the stoichiometric ratio), the

voltage signal is lower.

When the orygen content is low (that is, when the ratio

is richer than the stoichiometric ratio), the voltage signal

is higher.

0.0 - 1.25 V

At idle speed:

about 0.1 - 0.9

NO

(cont'd)

1 1-65

www.emanualpro.com

Page 370 of 1395

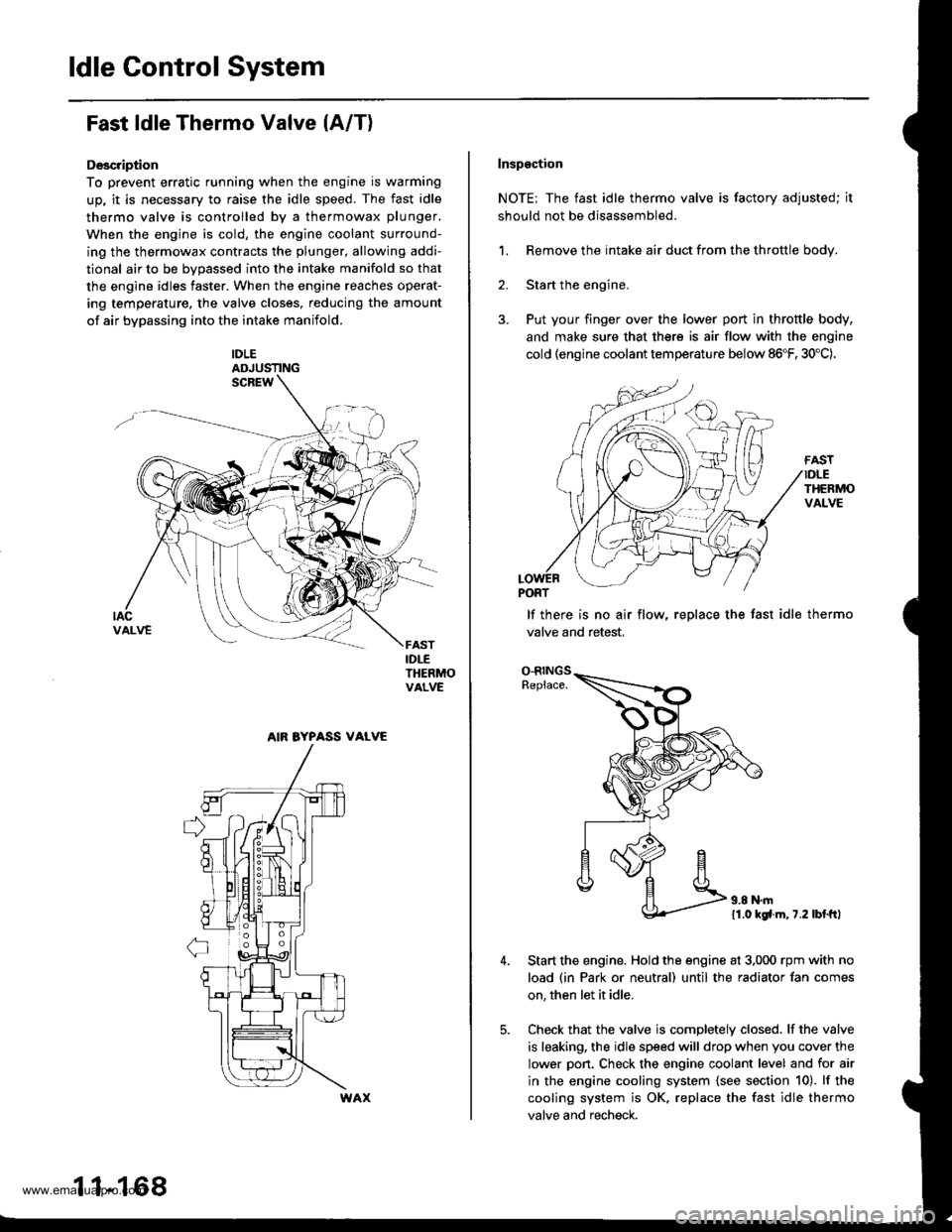

ldle Control System

Fast ldle Thermo Valve lA/T)

Description

To prevent erratic running when the engine is warming

up, it is necessary to raise the idle speed. The fast idle

thermo valve is controlled by a thermowax plunger.

When the engine is cold, the engine coolant surround-

ing the thermowax contracts the plunger, allowing addi-

tional air to be bvDassed into the intake manifold so that

the engine idles faster. When the engine reaches operat-

ing temperature. the valve closes, reducing the amount

of air bypassing into the intake manifold.

IDLEADJUSTING

IDLETHERMOVALVE

AIR BYPASS VALVE

11-168

Inspgction

NOTE: The fast idle thermo valve is factory adjusted; it

should not be disassembled.

1. Remove the intake air duct from the throttle body.

2. Start the engine,

3. Put your finger over the lower port in throttle body,

and make sure that there is air flow with the engine

cold (engine coolant temperature below 86"F, 30'C).

lf there is no air flow, replace the fast idle thermo

valve and retest,

O-RINGSReplace.

11.0 kgfl.m, 7.2 lbl.ftl

Start the engine. Hold the engine at 3,000 rpm with no

load (in Park or neutral) until the radiator fan comes

on, then let it idle.

Check that the valve is completely closed. lf the valve

is leaking, the idle speed will drop when you cover the

lower pon. Check the engine coolant level and for air

in the engine cooling system {see section 10). lf the

cooling system is OK, replace the fast idle thermo

valve and recheck.

www.emanualpro.com

Page 401 of 1395

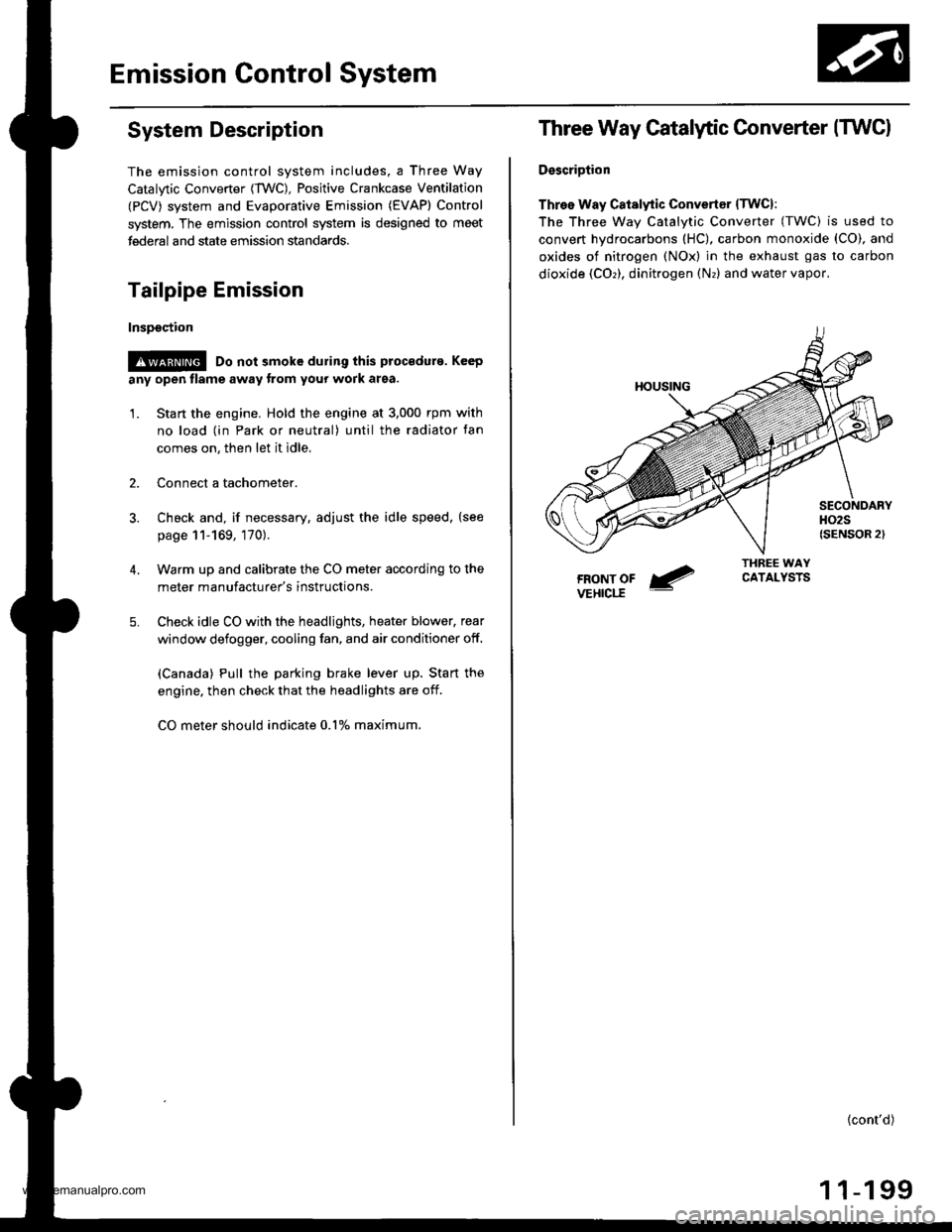

Emission Control System

System Description

The emission control system includes, a Three Way

Catalytic Converter {TWC), Positive Crankcase Ventilation

(PCV) svstem and Evaporative Emission (€VAP) Control

system. The emission control system is designed to meet

federal and state emission standards.

Tailpipe Emission

Inspsction

!@ Do not smoke during this procsdura. Keep

any open tlame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle,

Connect a tachometer.

Check and, if necessary, adjust the idle speed, (see

page 11-169, 170).

Warm up and calibrate the CO meter according to the

meter manufacturer's instructions.

Check idle CO with the headlights, heater blower, rear

window defogger, cooling fan, and air conditioner off.

(Canada) Pull the parking brake lever up. Start the

engine, then check that the headlights are off.

CO meter should indicate 0.1% maximum.

4.

Three Way Catalytic Converter (TWCI

DsscriDtion

Three Way Catalytic Convertsr lTwcl:

The Three wav Catalvtic Converter (TWC) is used to

convert hydrocarbons (HC), carbon monoxide (CO), and

oxides of nitrogen (NOx) in the exhaust gas to carbon

dioxide (COr), dinitrogen (Nr) and water vapor,

{cont'd)

1 1-199

www.emanualpro.com

Page 686 of 1395

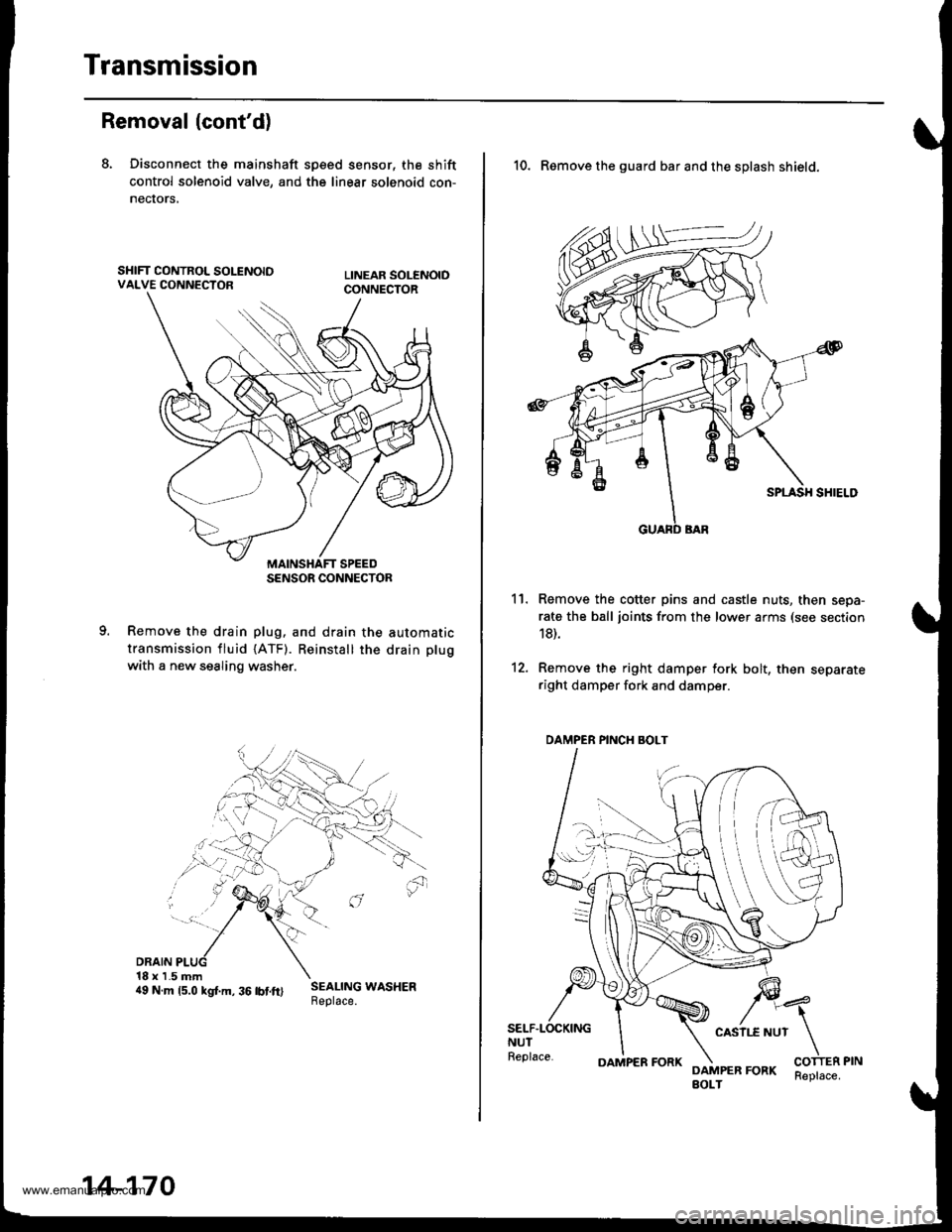

Transmission

Removal (cont'd)

8. Disconnect the mainshaft sp€ed sensor, the shift

control solenoid valve, and the linear solenoid con-

necrors,

Remove the drain plug. and drain the automatic

transmission fluid {ATF). Reinstall the drain plug

with a new sealing washer.

DRAIN18 x 1.5 mm4e N.m rs.o ksr.m. 36 rbrft) ;:i:$: *o"*."

SENSOR CONNECTOR

14-170

OAMPER FORKReplace.

10. Remove the guard bar and the splash shield.

Remove the cotter pins and castle nuts, then sepa-

rate the ball joints from the lower arms (see section

18).

Remove the right damper fork bolt, then separateright damper fork and damper.

11.

12.

SELF.LOCKINGNUTReplace.

CASII.E NUT

DAMPER FORKBOLT

DAMPER PINCH BOLT

www.emanualpro.com

Page 777 of 1395

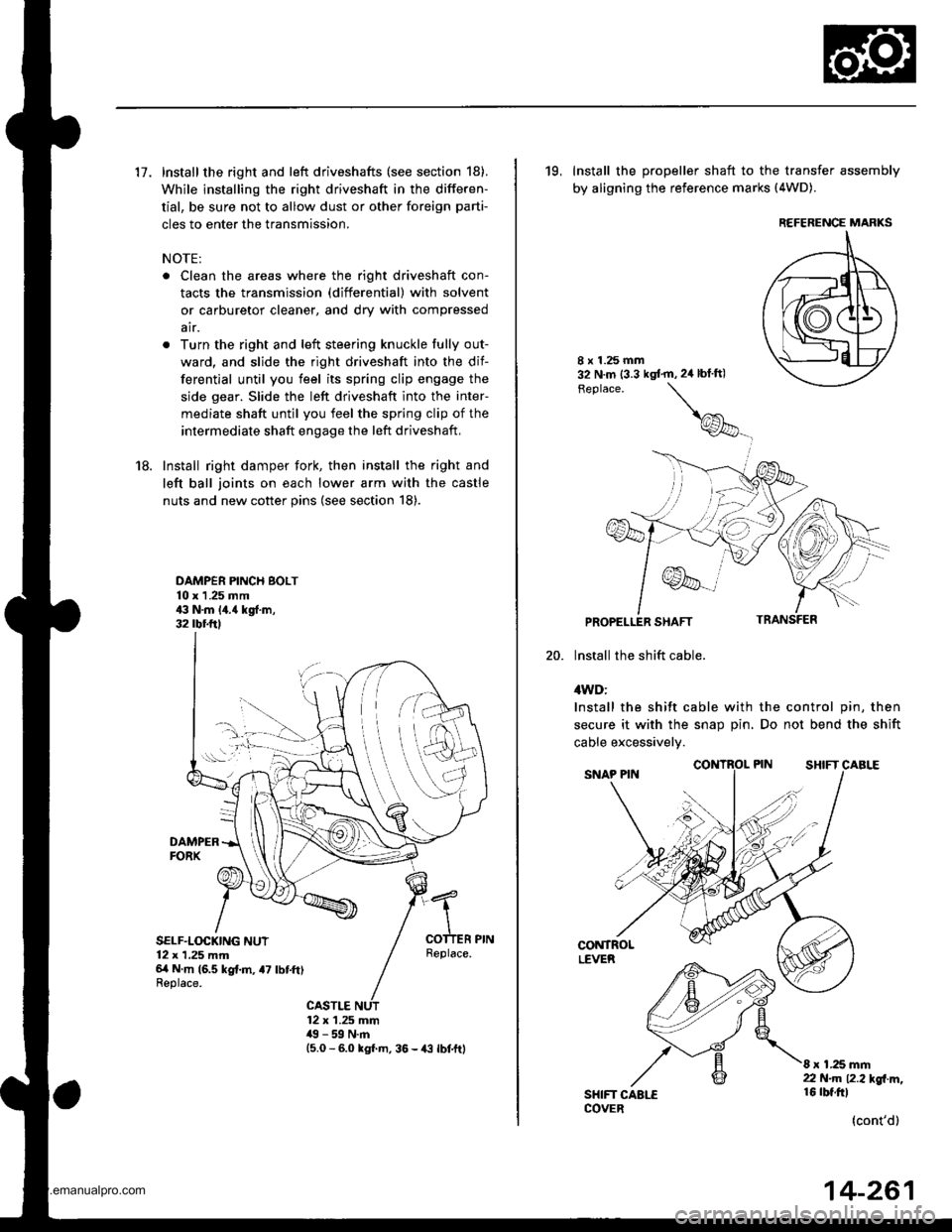

17. Install the right and left driveshafts (see section 18).

While installing the right driveshaft in the differen-

tial, be sure not to allow dust or other foreign parti-

cles to enter the transmission.

NOTE:

. Clean the areas where the right driveshaft con-

tacts the transmission (differential) with solvent

or carburetor cleaner, and dry with compressed

air.

. Turn the right and left steering knuckle fully out-

ward, and slide the right driveshaft into the dif-

ferential until you feel its spring clip engage the

side gear. Slide the left driveshaft into the inter-

mediate shaft until you feel the spring clip of the

intermediate shaft engage the left driveshaft,

18. Install right damper fork, then install the right and

left ball joints on each lower arm with the castle

nuts and new cotter pins (see section 18).

DAMPER PINCH BOLT10 x 1 .25 mm43 N.m 14.{ kgf.m,32 rbr.ftl

DAMPERFORX

SELF.LOCKING NUT12 x 1,25 mm6/t N m (6.5 kg{.m, a7 lbtft)Replace.

Replace.

CASTLE12 x 1.25 mm49 - 59 N.m15.0 - 6.0 kgl m, 36 - {3 lbtftl

19, Install the propeller shaft to the transfer assembly

by aligning the reference marks (4WD).

20.

8 x 1.25 mm32 N.m (3.3 kgt'm,2ir blft)

Feplace.

\

@_

PROPELLER SHAFT

lnstall the shift cable.

4WD:

Install the shift cable with the control pin, then

secure it with the snap Din. Do not bend the shift

cable excessivelv.

CONTROLLEVER

SHIFT CAALECOVER

8 x 1.25 mm22 N.m 12.2l'gl m,16 rbt.ftl

(cont'd)

REFERENCE MARKS

14-261

www.emanualpro.com