steering wheel adjustment HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 846 of 1395

Steering

Special Toofs ............. 17-2

Component Locations

Index ................ ....... 17-3

Troubleshooting

General Troubleshooting ................ 1 7-4

Noise and Vibration ......................... 17-8

Fluid Leaks ............. 17-10

Inspection and Adiustment

Steering Operation .......................... 17-12

Power Assist Check

With Vehicle Parked ....................

Steering Linkage and Gearbox .......

Pump Belt

Rack Guide Adjustment ...................

Fluid Rep|acement ...................,,.,....

Pump Pressure Check .................,,...

*Steering Wheel

Removal ................. 17-18

*Steering Column

Removal/lnstallation ................ ....... 17 -2O

lnspection .............. 17-21

Steering Lock Replacement ............ 17 -22

Power Steering Hoses, Lines

Ffuid Leakage Inspection ................. 17 -23

Repfacement .......... 17-23

Power Steering Pump

Repfacement .......... 17-24

Disassembly ...........17-25

fnspection .............. 17-26

Reassembly ............ 17-28

Power Steering Gearbox

Removal ................. 17-31

Disassembly ........... 17-34

Reassembly ............ 17-40

Ball Joint Boot Replacement .......... 17-50

Installation ............. 17-51

17-12

17-13

17-14

l7-15

17-15

17-16

Disassembly/Reassembly............... 17-18

4'%/b.......... -r'-7--a/

SUPPLEN\EN AL RES\RA(N SYSTES{ (SRS\

This model has an SRS which includes a driver's airbag in the steering wheel hub. a passenger's airbag in the dashboardabove the glove box ('97 - 00 models), and seat belt tensioners in the seat belt retractors ('98 - 00 models). Informationnecessary to safely service the SRS is included in this Service Manual. ltems marked with an asterisk (*) on the contentspage include, or are located near, SBS components. Servicing. disassembling or replacing these items will require specialprecautions and tools, and should only be done by an authorized Honda oearer.

To avoid rendering the SRS inoperative, which could lead to peFonal iniury or death in the event of a sevore trontalcollision. allSRS service work must be performod by an authorized Honda dealer.lmproper service procedurgs, including incorrect removal and installalion of the SRS, could lead to personal iniurycaused by unintontional deployment of th€ airbags {'97 - 00 models), and seat belt tensioners ('98 - 00 modelsl.Do not bump the SRS unit. Otherwise, the system may lail in case ot a collision, or the airbags may deploy when theignition switch is ON (lll.

SRS electrical wiring harnesses are identitied by yellow colof coding. Ralated components are located in the steeringcolumn, front console, dashboard, dashboard lower panel, and in the dashboard above the glove box. Do not use elec-trical test equipment on these cilcuits,

www.emanualpro.com

Page 848 of 1395

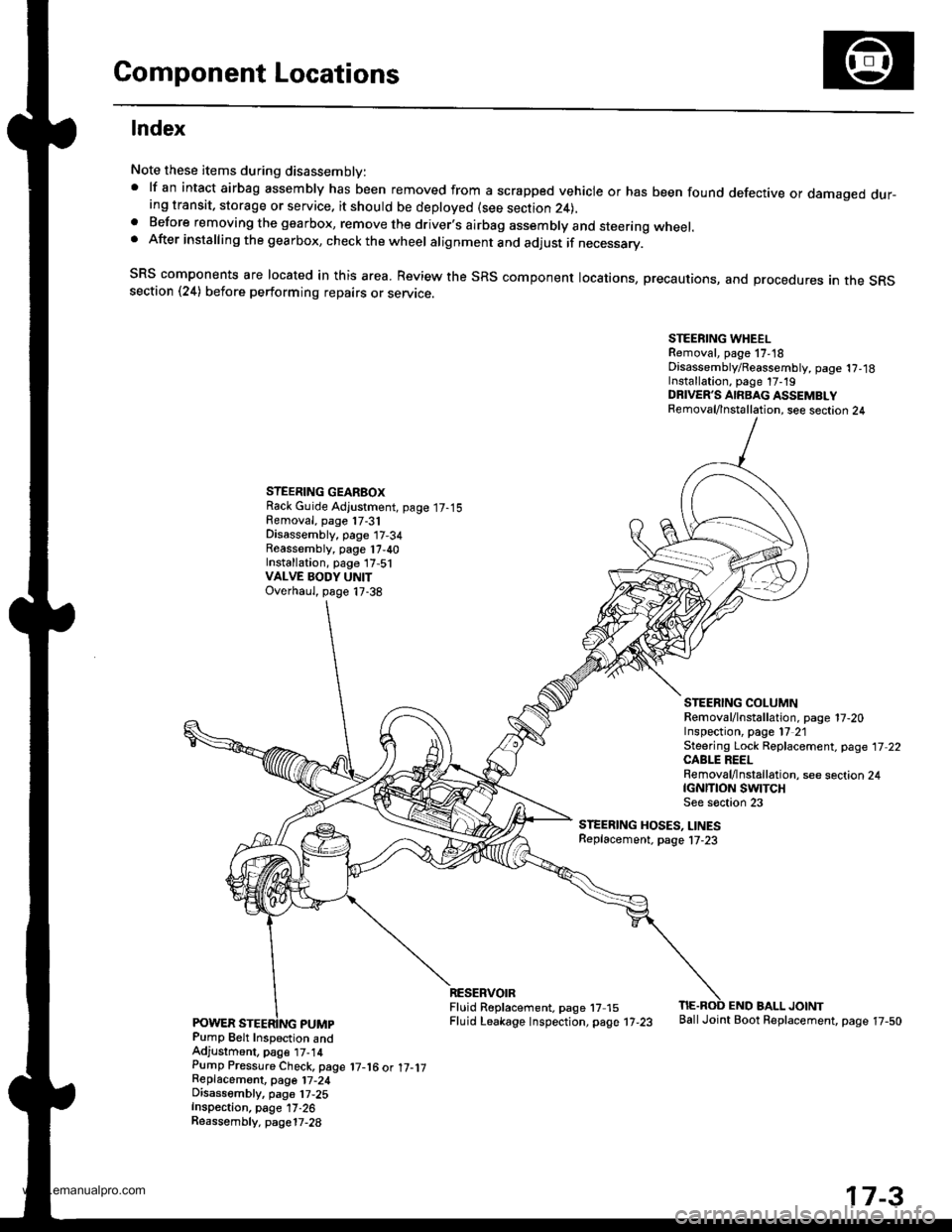

Component Locations

lndex

Note these items during disassembly:' lf an intact airbag assembly has been removed from a scrapped vehicle or has been found defective or damaged dur-ing transit, storage or service. it should be deployed (see section 24),a Before removing the gearbox, remove the driver.s airbag assembly and steering wheel.. After installing the gearbox, check the wheel alignment and adjust if necessary.

SRS components are located in this area. Review the SRS component locations, precautions, and procedures an the SRssection (24) before performing repairs or servrce.

STEERING WHEELRemoval, page 17,18Disassembly/Reassembly, page 1?,18Installation, page 17-19DRIVER'S AIRBAG ASSEMBLYRemoval/lnstallation, see section 24

STEERING GEARBOXRack Guide Adjustment, page 17-15Removal, page 17-31Disassembly, page 17-34Reassembly, page 17,40Installation, page 17,51VALVE BODY UNITOverhaul, page 17-38

STEERING COLUMNRemoval/lnstallation. page 17-20Inspection, page l7 21Steering Lock Replacement, page 17 22CABLE REELRemoval/lnstallation, see section 24tcNrnoN swtTcHSee s€ction 23

STEERING HOSES, LINESReplacement. page l7-23

Pump Belt Inspection andAdjustment, pag€ t7-14Pump Pressure Check, page 17-16 ot 17-1jReplacemont, page 17-24Disassembly, pa96 17,25Inspection, page 17-26Reassembly. page17-28

RESERVOIRFluid R6placement. page 17 15Fluid Leakage lnspection, page 17-23

END BALL JOINTBallJoint Boot Replacement, page 17-50

17-3

www.emanualpro.com

Page 850 of 1395

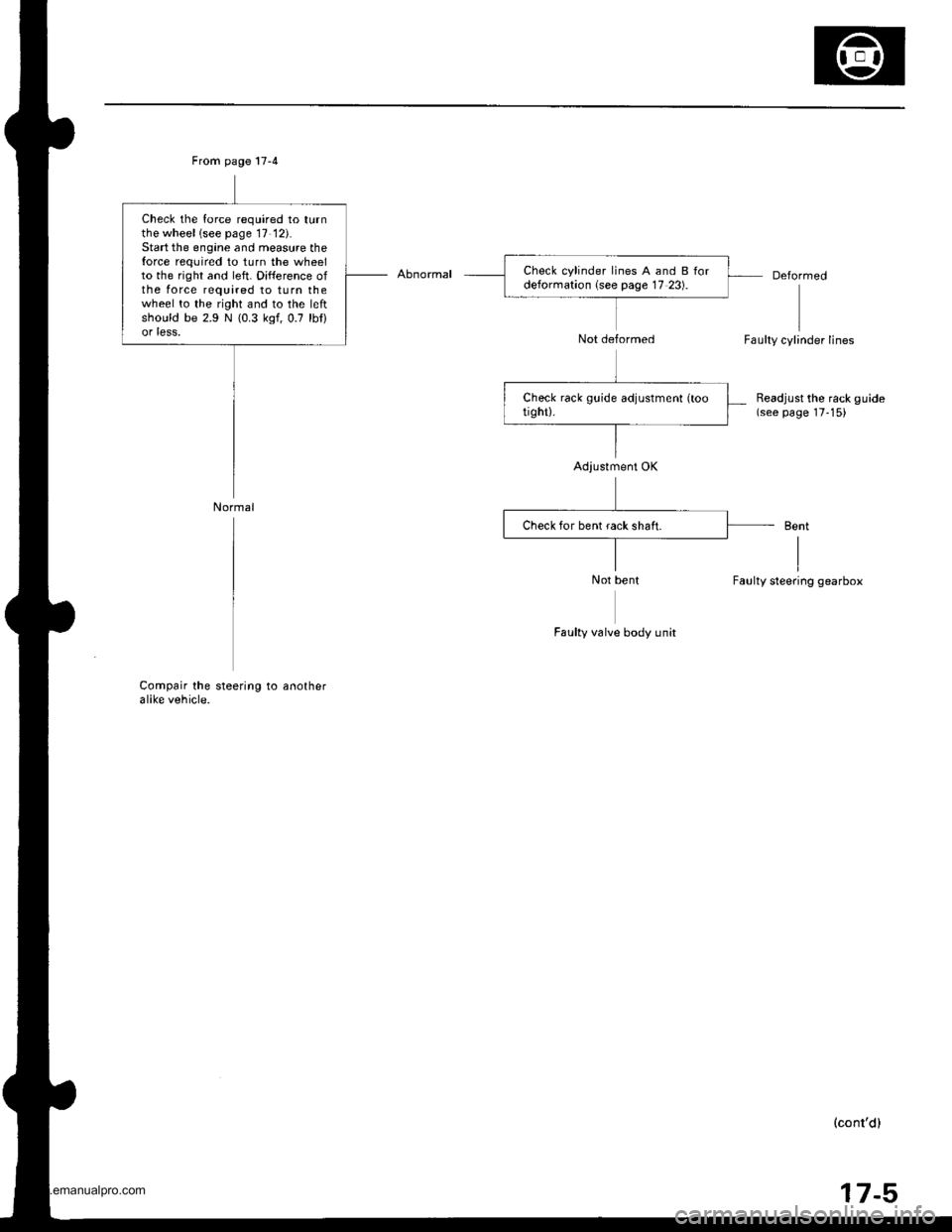

Abnormal

Not deformed

Deformed

Faulty cylinder lines

Readjust the rack guide(see page 17-15)

Bent

IFaulty steering gearbox

Compair the steering to anotheralike vehicle.

(cont'd)

17-5

Adjustment OK

Check the force required to turnthe wheel lsee page 17 12).Start the engine and measure theforce required to turn the wheelto the right and left. Difference ofthe force required to turn thewheel to the right and to the leftshould be 2.9 N (0.3 kgf,0.7 lbt)or less,

Normal

www.emanualpro.com

Page 851 of 1395

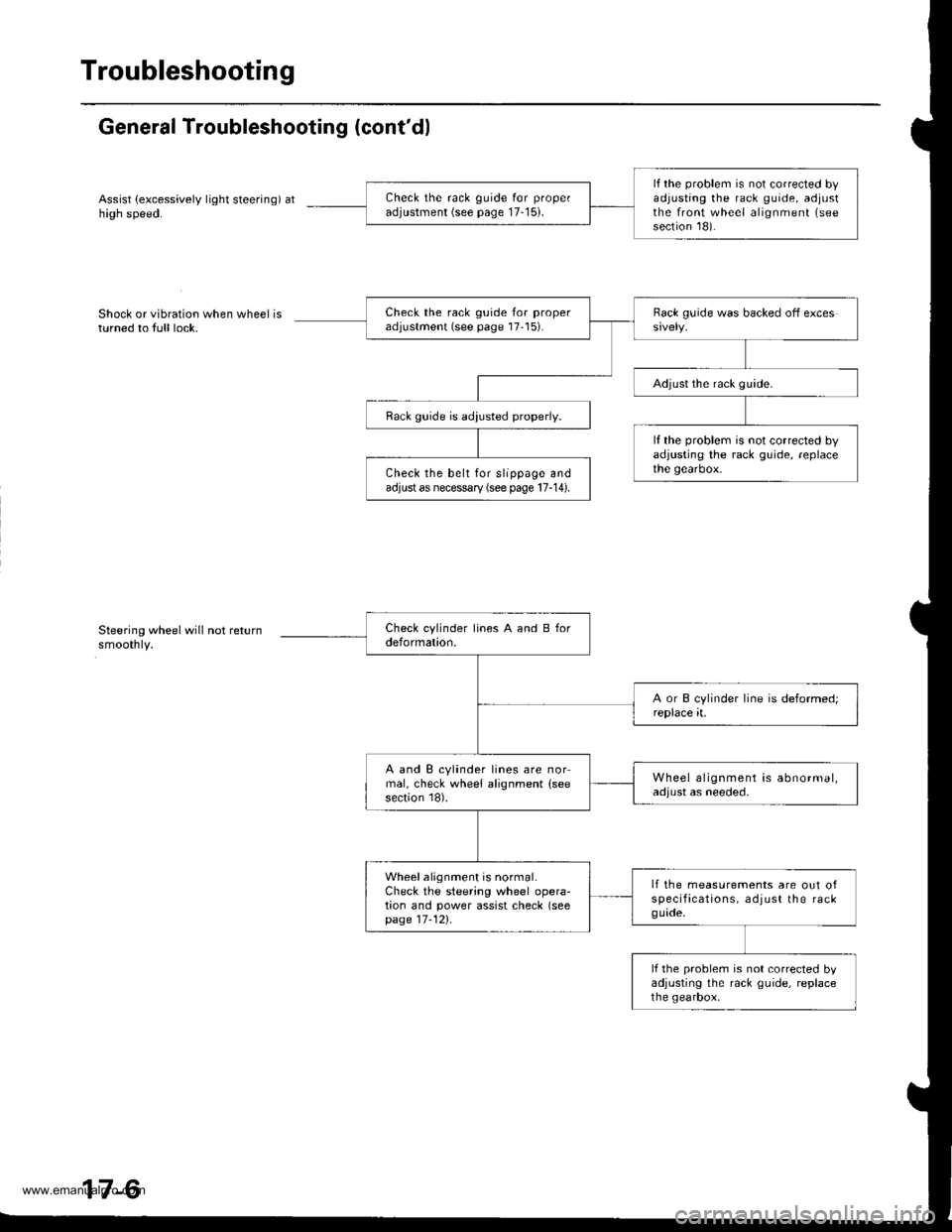

Troubleshooting

General Troubleshooting (cont'dl

Assist (excessively light steering) athigh speed.

Shock or vibration when wheel isturned to full lock.

Steering wheel will not returnsmoothly.

lf the problem is not corrected byadjusting the rack guide, adjustthe front wheel alignment (see

section 18).

Check the rack guide for proper

adjustment (see page 17-15).

Check the rack guide for properadjustment (see page 17'15).

Adjust the rack guide.

Rack guide is adiusted properly.

lf the problem is not corrected byadjusting the rack guide, replacethe gearbox.Check the belt for slippage andadjust as necessary (see page 17-14).

A and B cylinder lines are normal, check wheel alignment (see

section 18).

Wheel alignment is abnormal,adjust as needed.

Wheel alignment is normal.Check the steering wheel opera-tion and power assist check (seepage 17-121.

lf the measurements are out ofspecifacations, adjust the rackguade.

lf the problem is not corrected byadjusting the rack guide, replacethe gearbox,

www.emanualpro.com

Page 853 of 1395

Troubleshooting

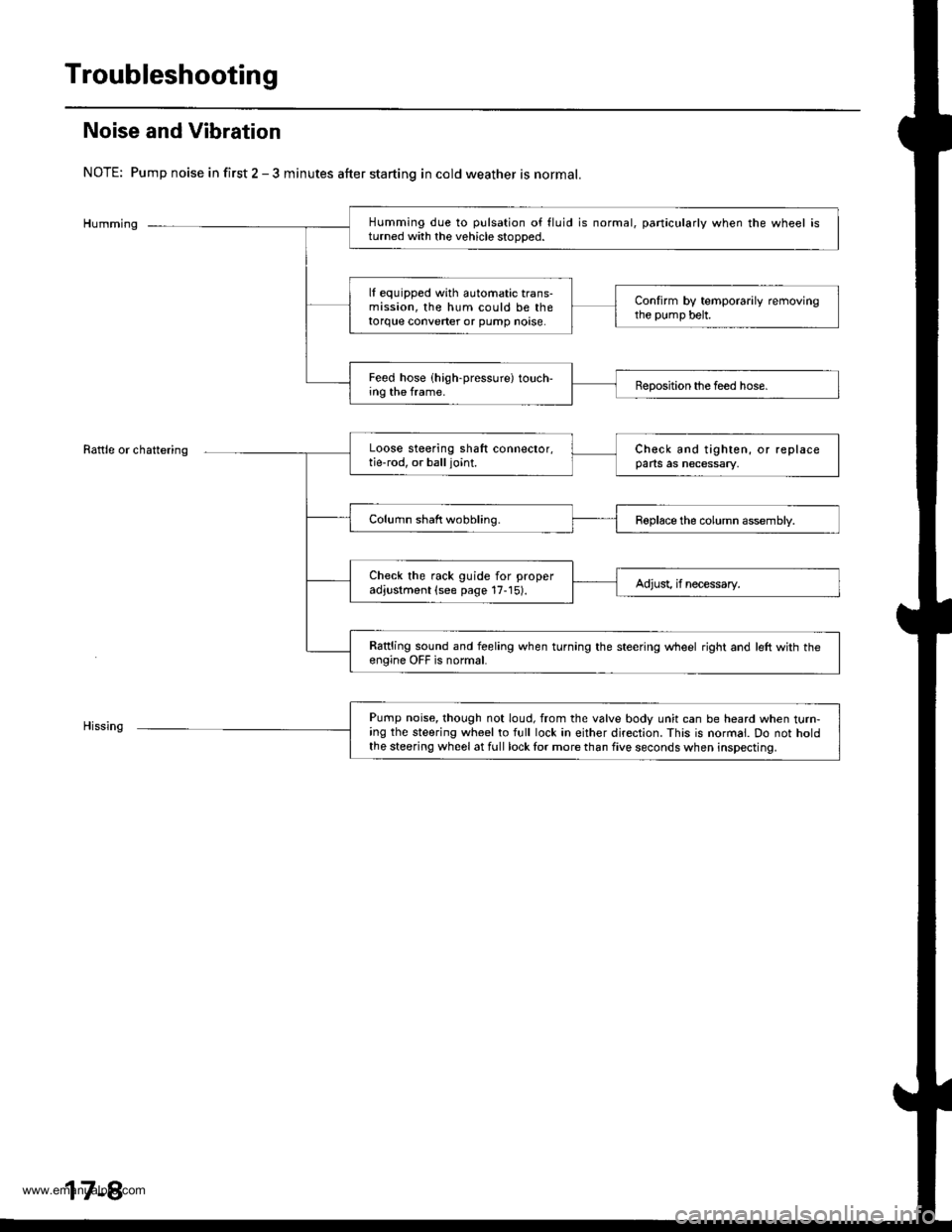

Noise and Vibration

NOTE: Pump noise in first 2 - 3 minutes after starting in cold weather is normal.

Humming

Rattle or chattering

Humming due to pulsation of fluid is normal, particularly when the wheel isturned with the vehicle stooDed.

lf equipped with automatic trans-mission, the hum could be thetorque converter or pump noase.

Confirm by temporarily removingthe pump belt.

Feed hose (high-pressure) touch-ing the frame.Beposition the feed hose.

Loose steering shaft connector,tie-rod, or balljoint.Check and tighten, or replaceparts as necessary,

Column shaft wobbling.Roplace the column assembly.

Check the rack guide for properadjustment (see page 17-15).Adjust, if necessary.

Rattling sound and feeling when turning the steering wheel right and left with th€engine OFF is normal.

Pump noise, though not loud, from the valve body unit can be heard when turn-ing the steering wheel to full lock in either direction. This is normal. Do not holdthe steering wheel at full lock lor more than five seconds when inspecting.

17-8

www.emanualpro.com

Page 857 of 1395

Inspection and Adjustment

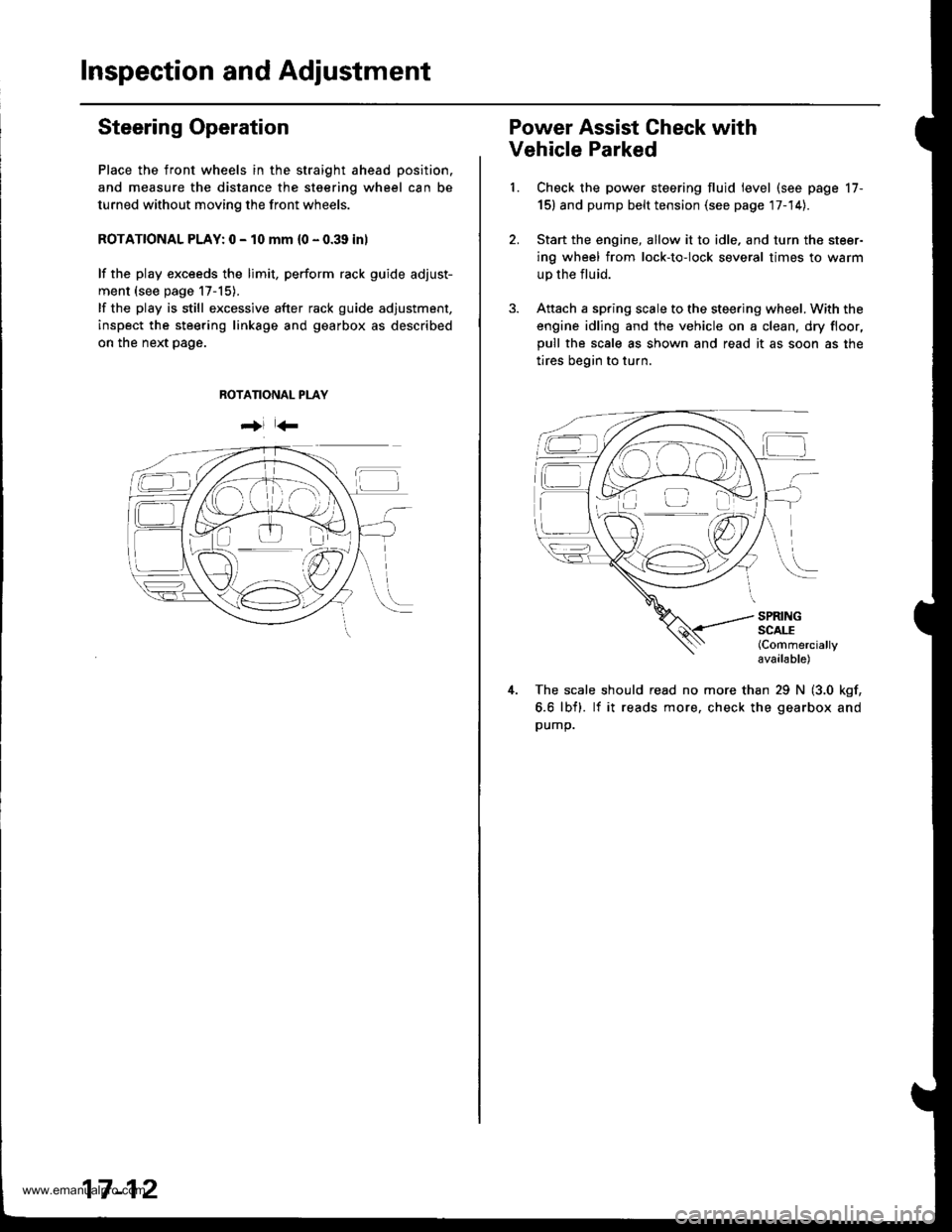

Steering Operation

Place the front wheels in the straight ahead position.

and measure the distance the steering wheel can be

turned without moving the front wheels.

ROTATIONAL PLAY: 0 - 10 mm (0 - 0.39 inl

lf the play exceeds the limit, perform rack guide adjust-

ment (see page 17-15).

lf the play is still excessive after rack guide adjustment,

inspect the steering linkage and gearbox as described

on the next page.

ROTANONAL PLAY

+i r

17-12

Power Assist Check with

Vehicle Parked

1. Check the power steering fluid level (see page 17-

15) and pump belt tension (see page 17-14).

2. Start the engine, allow it to idle, and turn the steer-

ing wheel from lock-toiock several times to warm

up the fluid.

3. Aftach a spring scale to the steering wheel, With the

engine idling and the vehicle on a clean. dry floor,

pull the scale as shown and read it as soon as the

tires begin to turn.

SPRINGSCALE(Commercially

available)

The scale should read no more than 29 N (3.0 kgf,

6.6 lbfl. lf it reads more, check the gearbox and

oumo.

f::1-tE

www.emanualpro.com

Page 859 of 1395

Inspection and Adjustment

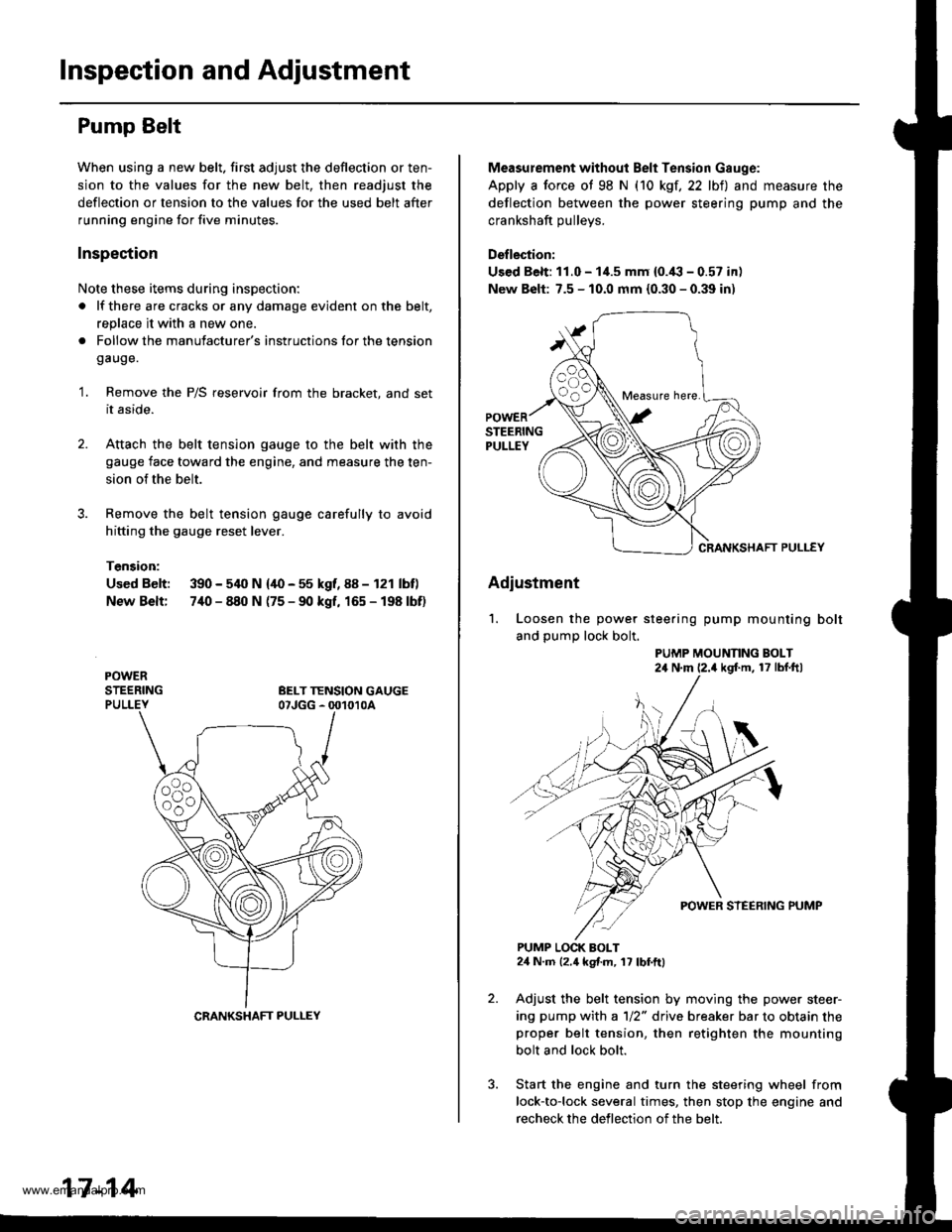

Pump Belt

When using a new belt. first adjust the deflection or ten-

sion to the values for the new belt, then readjust the

deflection or tension to the values for the used belt after

running engine for five minutes.

Inspection

Note these items during inspection:

a lf there are cracks or any damage evident on the belt,

replace it with a new one.

. Follow the manufacturer's instructions lor the tension

gauge.

'1. Remove the P/S reservoir from the bracket, and set

it aside.

2. Attach the belt tension gauge to the belt with the

gauge face toward the engine, and measure the ten-

sion of the belt.

Remove the belt tension gauge carefully to avoid

hitting the gauge reset lever.

Tension:

Used Belt: 390 - 540 N {40 - 55 kgf, 88 - 121 lbf)

New Belt: 7,[0 - 840 N (75 - 90 kgf, 165 - 198 lbf)

CRANKSHAFT PULLEY

17-14

Measurement without Belt Tension Gauge:

Apply a force ot 98 N (10 kgf,22 lbt) and measure the

deflection between the power steering pump and the

crankshaft oullevs.

Deflection:

Used Belt: 11.0 - 1i1.5 mm {0.'(l - 0.57 in)

New Belt: 7.5 - 10.0 mm {0.30 - 0.39 in)

CRANKSHAFT PULLEY

Adiustment

'1. Loosen the power steering pump mounting bolt

and pump lock bolt.

PUMP MOUNNNG BOLT24 N'm (2.4 kgf'm, 17 lbf ftl

PUMP LOCK BOLT24 N.m 12.4 kgf.m, 17 lbf.ftl

Adjust the belt tension by moving the power steer-

ing pump with a 1/2" drive breaker bar to obtain theproper belt tension, then retighten the mounting

bolt and lock bolt.

Start the engine and turn the steering wheel from

lock-to-lock several times, then stop the engine and

recheck the deflection of the belt.

Measure here.

www.emanualpro.com

Page 860 of 1395

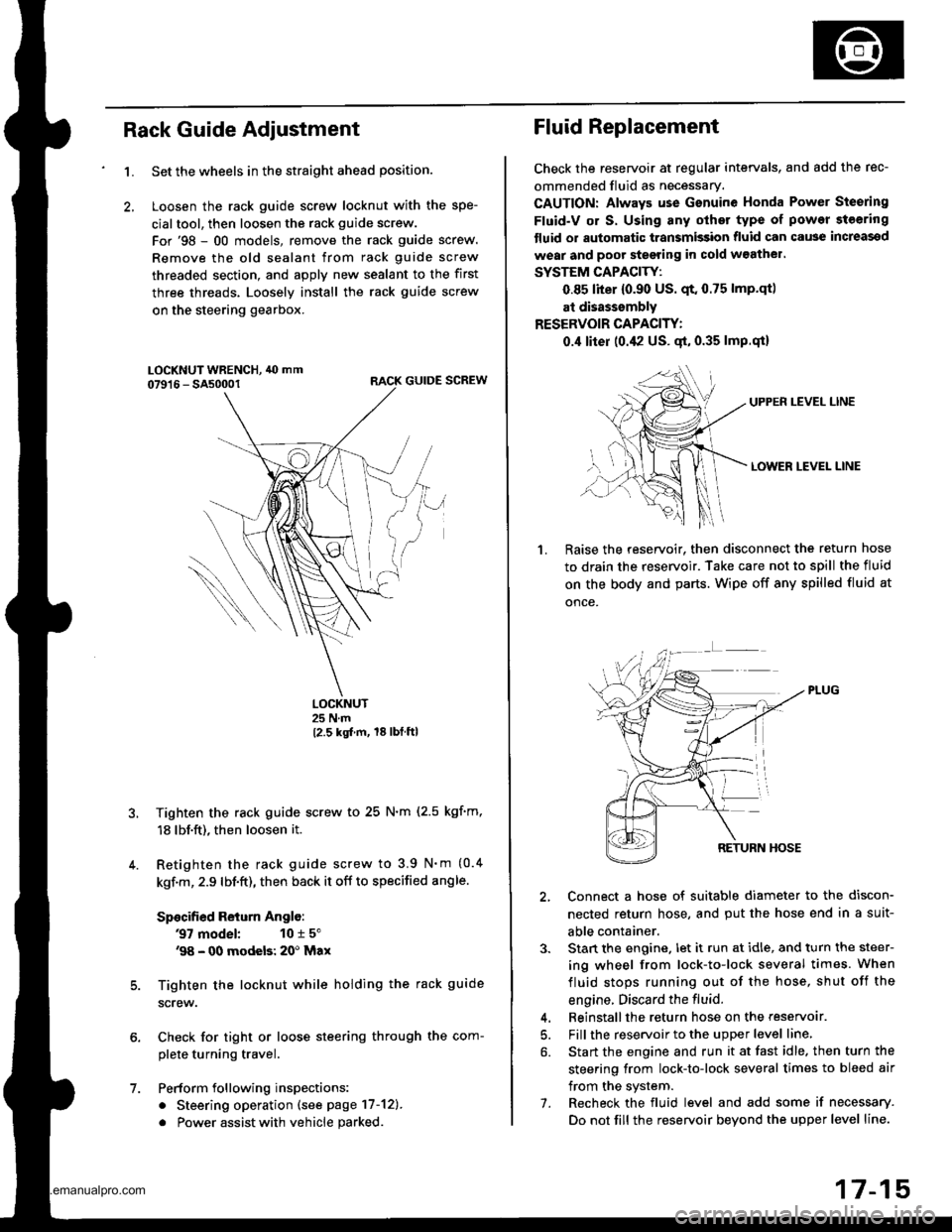

Rack Guide Adjustment

1.

6.

7.

5.

4.

Set the wheels in the straight ahead position.

Loosen the rack guide screw locknut with the spe-

cialtool, then loosen the rack guide screw.

For'98 - 00 models, remove the rack guide screw.

Remove the old sealant from rack guide screw

threaded section, and apply new sealant to the first

three threads. Loosely install the rack guide screw

on the steering gearbox.

RACK GUIDE SCREW

LOCKNUT25 N.m

12.5 kgt m, 18lbtftl

Tighten the rack guide screw to 25 N.m (2.5 kgf'm,

18 lbf.ft), then loosen it.

Retighten the rack guide screw to 3.9 N'm (0.4

kgf.m, 2.9 lbf.ft), then back it off to specified angle.

Specified Return Anglo:

37 model: 10 r 5"'98 - 00 modeb: 20' Max

Tighten the locknut while holding the rack guide

screw.

Check for tight or loose steering through the com-

plete turning travel.

Perform following inspections:

. Steering operation (see page 17-12).

. Power assist with vehicle parked

Fluid Replacement

Check the reseryoir at regular intervals, and add the rec-

ommended fluid as necessary.

CAUTION: Always use Gsnuine Honda Power Steering

Fluid-V or S. Using any other type of power steering

tluid or automatic transmission fluid can cause increassd

wear and poor steering in cold w3athel.

SYSTEM CAPACITY:

0.85 liter {0.90 US. qt. 0.75 lmp.qtl

at disasssmbly

RESERVOIR CAPACITY:

0.,1 liter (0.42 US. gt, 0.35 lmp.qi)

UPPEN LEVEL LINE

LOWER LEVEL LINE

1.Raise the reservoir. then disconnect the return hose

to drain the reservoir. Take care not to spill the fluid

on the body and parts. Wipe off any spilled fluid at

once.

2, Connect a hose of suitable diameter to the discon-

nected return hose, and put the hose end in a suit-

able container.

3. Stan the engine. let it run at idle, and turn the steer-

ing wheel from lock-to-lock several times. When

fluid stops running out of the hose, shut off the

engine. Discard the fluid.

4. Beinstallthe return hose on the reservoar.

5. Fill the reservoir to the upper level line,

6. Start the engine and run it at fast idle. then turn the

steering from lock-to-lock several times to bleed air

from the system.

7. Recheck the fluid level and add some if necessary.

Do not fill the reservoir beyond the upper level line.

www.emanualpro.com

Page 861 of 1395

lnspection and Adjustment

Pump Pressure Gheck With T/N 07406 - 0010001

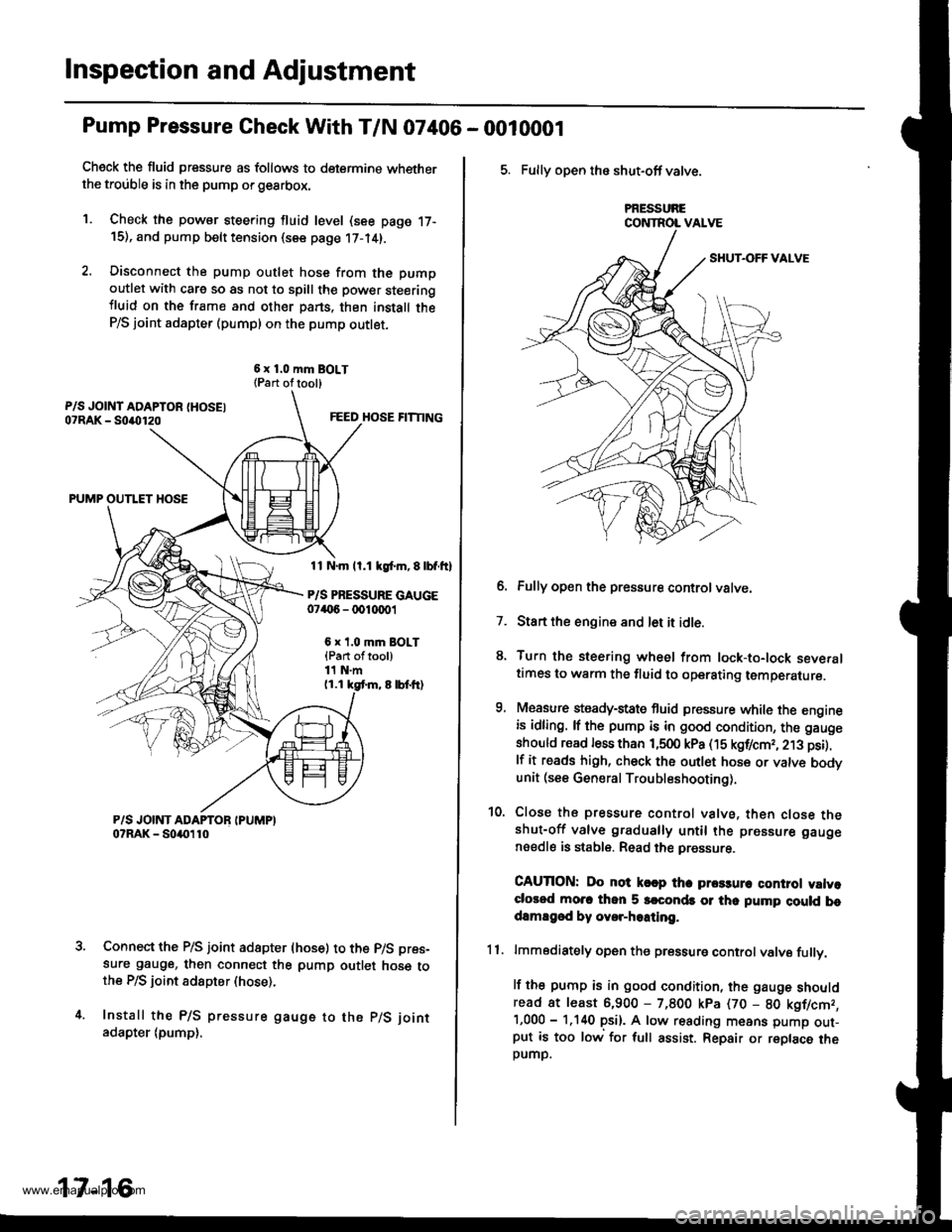

Check the fluid pressure as follows to determine whetherthe trouble is in the pump orgearbox.

1. Check the powsr steering fluid level (see page 17-15), and pump belt tension (see page 17-14).

2. Disconnect the pump outlet hose from the pump

outlet with care so as not to spill the pow€r steeringiluid on the frame and other pans. thon install theP/S joint adapter (pumpl on the pump outlet.

6 x 1.0 mm BOLT{Part oftool)

FEED HOSE FITTING

PUMP OUTLET HOSE

11 N.m ll.1 kgl.m, E lbf.ftl

P/S PRESSURE GAUGE07('6 - 0010001

6 x t.0 mm BOLT{Part oftool)11 N.m(1.1 kgt m, 8 lbf.tr)

Connect the P/S joint adapter (hose) to the p/S pres-

sure gauge, then connect the pump outlet hose tothe P/S ioint adspter (hose).

Install the P/S pressure gauge to the p/S joint

adapter (pump),

17-16

5. Fully open the shut-off valve.

PRESSURECONTROL VALVE

6. Fully open the pressure controlvatve.

7. Start the engine and let it idle.

8. Turn the steering wheel from lock-to-lock severaltimes to warm the fluid to operating temperature.

9, Measure steady-state fluid pressure while the engineis idling. lf the pump is in good condition, the gauge

should read less than 1,500 kPa (15 kgf/cmr, 213 psi).

lf it reads high, check the outlet hose or valve bodvunit (see General Troubleshooting).

10. Close the pressure control valve, then close theshut-off valve gradually until the pressure gauge

nsedle is stable. Read the pressure.

CAUTION: Do not k€ap tha prca3un control valvoclorod mo.c thon 5 srconds or thc pump cluld bodamEgod by ovor-hoating.

11. lmmodiately open the pressure controlvalve fullv.

lf the pump is in good condition, the gauge shouldread at least 6,900 - 7,800 kpa (70 - 80 kgflcmr,'1,000 - 1.140 psi). A low reading means pump out-put is too low for full assist. Repair or replace theDUMD.

www.emanualpro.com

Page 903 of 1395

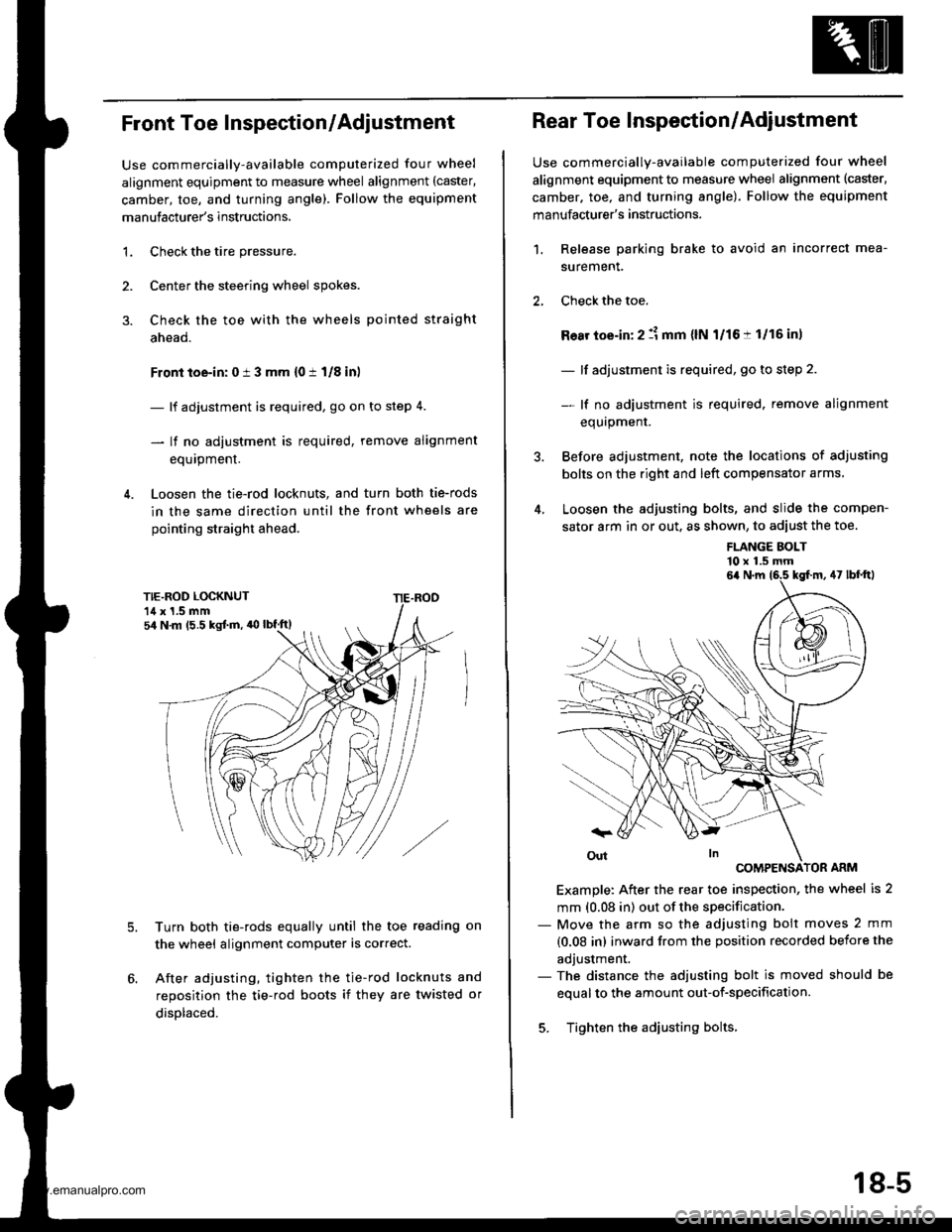

Front Toe Inspection/Adjustment

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment (caster,

camber, toe, and turning angle). Follow the equipment

manufacturer's instructions,

3.

1.Check the tire pressure.

Center the steering wheel spokes.

Check the toe with the wheels pointed straight

ahead.

Front toe-in: 0 i 3 mm {0 t 1/8 inl

- lf adjustment is required, go on to step 4.

- lf no adjustment is required, remove alignment

equipment.

Loosen the tie-rod locknuts, and turn both tie-rods

in the same direction until the front wheels are

pointing straight ahead.

5.Turn both tie-rods equally until the toe reading on

the wheel alignment computer is correct.

After adjusting, tighten the tie-rod locknuts and

reposition the tie-rod boots if they are twisted or

displaced.

sir N m (5.5 kgJ.m, 'O lbf.ft)

Rear Toe Inspection/Adjustment

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment (caster,

camber. toe, and turning angle). Follow the equipment

manufacturer's instructions.

Release parking brake to avoid an incorrect mea-

surement.

Check the toe.

Ro8r toe-in: 2 :1 mm {lN l/16:t 1/16 in,

- lf adjustment is required, go to step 2.

- lf no adiustment is required. remove alignment

equrpmenr.

Before adjustment, note the locations of adjusting

bolts on the right and left compensator arms.

Loosen the adjusting bolts, and slide the compen-

sator arm in or out. as shown, to adiust the toe.

1.

FLANGE BOLT'10 x 1.5 mm

COMPENSATOR ARM

Example: After the rear toe inspection, the wheel is 2

mm (0.08 in) out of the specification.- Move the arm so the adjusting bolt moves 2 mm

{0.08 in) inward from the position recorded before the

adjustment.- The distance the adjusting bolt is moved should be

equal to the amount out-of-specification.

5. Tighten the adjusting bolts.

6a N.m 16.5 kgf.m, 47 lbf'ftl

18-5

www.emanualpro.com