lock HONDA ELEMENT 2007 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2007, Model line: ELEMENT, Model: HONDA ELEMENT 2007 1.GPages: 275, PDF Size: 4.16 MB

Page 206 of 275

Reinstall the socket into the light

assembly by turning it clockwise

until it locks.

Testthelightstomakesurethe

new bulb is working.

When reinstalling the taillight

assembly, f irst place the two pins

in the holes in place. Tighten the

two mounting bolts.

Remove the socket by turning it

one-quarter turn counterclockwise.

Pull the bulb straight out of its

socket. Push the new bulb straight

into the socket until it bottoms.

Open the hatch and the tailgate.

Remove the two mounting screws

with a Phillips-head screwdriver,

and remove the taillight assembly

f rom the body by pulling it back.

Determine which of the three

bulbs is burned out: brake/

taillight, turn signal light or back-

up light. 6.

7. 5.

3.

4.

1.

2.

Lights

Replacing Rear Bulbs

Maint enance

203

SOCKET

SOCKET SOCKET

SCREW

SCREW

TAILLIGHT ASSEMBLY

Page 207 of 275

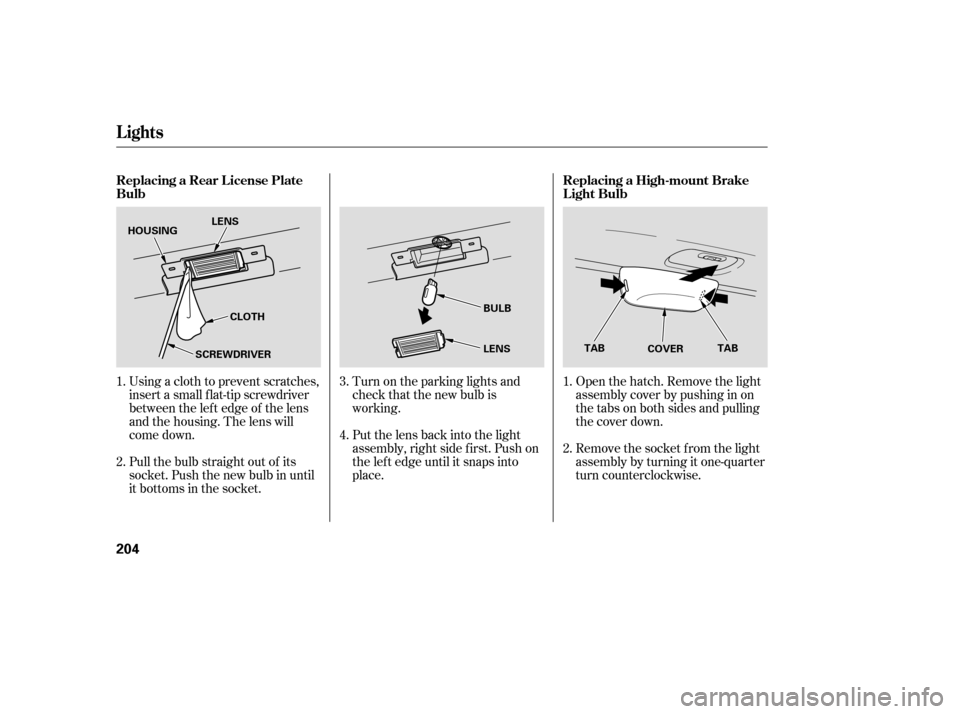

Open the hatch. Remove the light

assembly cover by pushing in on

the tabs on both sides and pulling

the cover down.

Remove the socket f rom the light

assembly by turning it one-quarter

turn counterclockwise.

Turn on the parking lights and

check that the new bulb is

working.

Put the lens back into the light

assembly, right side f irst. Push on

the lef t edge until it snaps into

place.

Using a cloth to prevent scratches,

insert a small f lat-tip screwdriver

between the lef t edge of the lens

and the housing. The lens will

come down.

Pull the bulb straight out of its

socket. Push the new bulb in until

it bottoms in the socket. 1.

2.

3.

4.

1.

2.

Lights

Replacing a High-mount Brake

Light Bulb

Replacing a Rear License Plate

Bulb

204

COVER

TAB TAB

BULB

LENS

SCREWDRIVER

HOUSING

LENS

CLOTH

Page 208 of 275

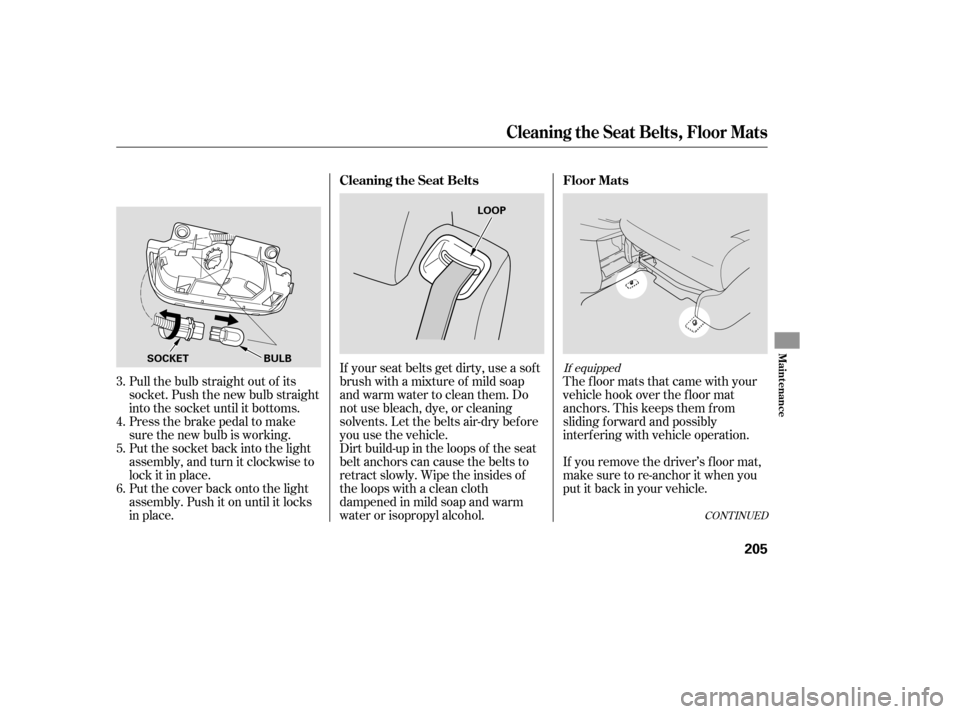

The floor mats that came with your

vehicle hook over the f loor mat

anchors. This keeps them f rom

sliding f orward and possibly

interf ering with vehicle operation.

If you remove the driver’s f loor mat,

make sure to re-anchor it when you

putitbackinyourvehicle.

If your seat belts get dirty, use a sof t

brush with a mixture of mild soap

and warm water to clean them. Do

not use bleach, dye, or cleaning

solvents. Let the belts air-dry bef ore

you use the vehicle.

Dirt build-up in the loops of the seat

belt anchors can cause the belts to

retract slowly. Wipe the insides of

the loops with a clean cloth

dampened in mild soap and warm

water or isopropyl alcohol.

Pull the bulb straight out of its

socket. Push the new bulb straight

into the socket until it bottoms.

Press the brake pedal to make

sure the new bulb is working.

Put the socket back into the light

assembly, and turn it clockwise to

lock it in place.

Put the cover back onto the light

assembly. Push it on until it locks

in place.

3.

4.

5.

6.

CONT INUED

If equipped

Cleaning the Seat Belts

Floor Mats

Cleaning the Seat Belts, Floor Mats

Maint enance

205

LOOP

BULB

SOCKET

Page 210 of 275

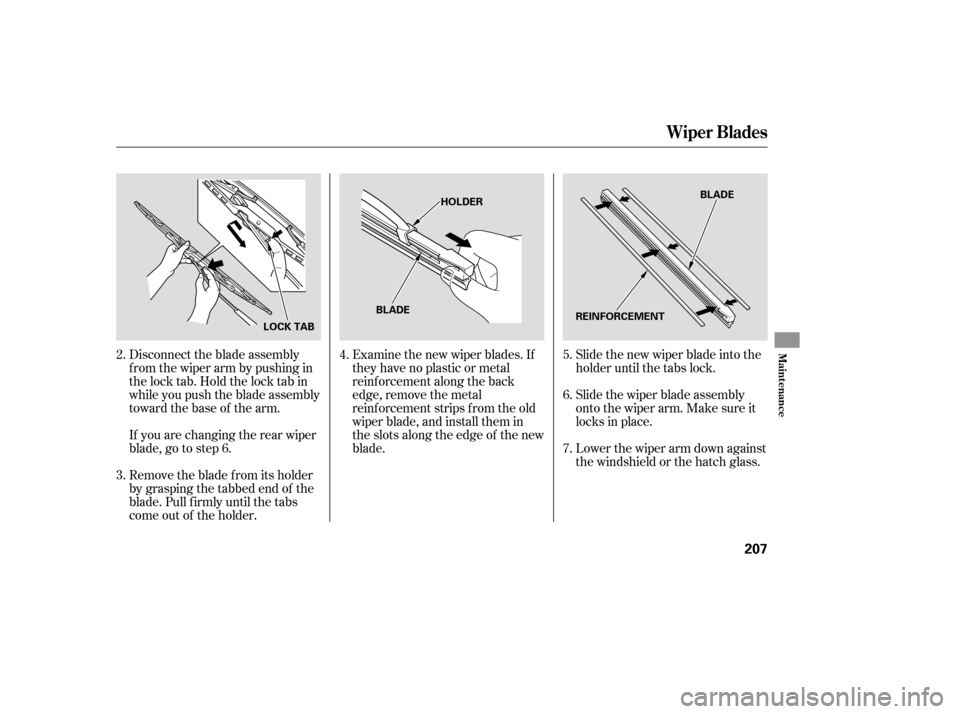

Slide the new wiper blade into the

holder until the tabs lock.

Slide the wiper blade assembly

onto the wiper arm. Make sure it

locks in place.

Lower the wiper arm down against

the windshield or the hatch glass.

Examine the new wiper blades. If

they have no plastic or metal

reinf orcement along the back

edge, remove the metal

reinf orcement strips f rom the old

wiper blade, and install them in

the slots along the edge of the new

blade.

Disconnect the blade assembly

fromthewiperarmbypushingin

the lock tab. Hold the lock tab in

while you push the blade assembly

toward the base of the arm.

If you are changing the rear wiper

blade, go to step 6.

Remove the blade f rom its holder

by grasping the tabbed end of the

blade. Pull f irmly until the tabs

come out of the holder. 5.

6.

7.

4.

2.

3.

Wiper Blades

Maint enance

207

REINFORCEMENT BLADE

HOLDER

BLADE

LOCK TAB

Page 218 of 275

Fill the f uel tank.

Change the engine oil and f ilter.

Wash and dry the exterior

completely.

Cleantheinterior.Makesurethe

carpeting, floor mats, etc., are

completely dry.Block the rear wheels.

If the vehicle is to be stored f or a

longer period, it should be

supported on jackstands so the

tires are of f the ground.

Cover the vehicle with a

‘‘breathable’’ cover, one made

f rom a porous material such as

cotton. Non-porous materials, such

as plastic sheeting, trap moisture,

which can damage the paint.

If you need to park your vehicle f or

an extended period (more than 1

month), there are several things you

should do to prepare it f or storage.

Proper preparation helps prevent

deterioration and makes it easier to

get your vehicle back on the road. If

possible, store your vehicle indoors. Leave one window open slightly (if

the vehicle is being stored

indoors).

Disconnect the battery.

Support the f ront and rear wiper

blade arms with a f olded towel or

ragsotheydonottouchthe

windshield.

To minimize sticking, apply a

silicone spray lubricant to all door

and tailgate seals. Also, apply a

vehiclebodywaxtothepainted

surfaces that mate with the door

and tailgate seals.

Leave the parking brake off. Put

the transmission in reverse

(manual) or Park (automatic). If possible, periodically run the

engine until it reaches f ull

operating temperature (the

cooling f ans cycle on and of f

twice). Pref erably, do this once a

month.

Vehicle Storage

Maint enance

215

Page 222 of 275

If you have a f lat tire while driving,

stop in a saf e place to change it.

Drive slowly along the shoulder until

you get to an exit or an area to stop

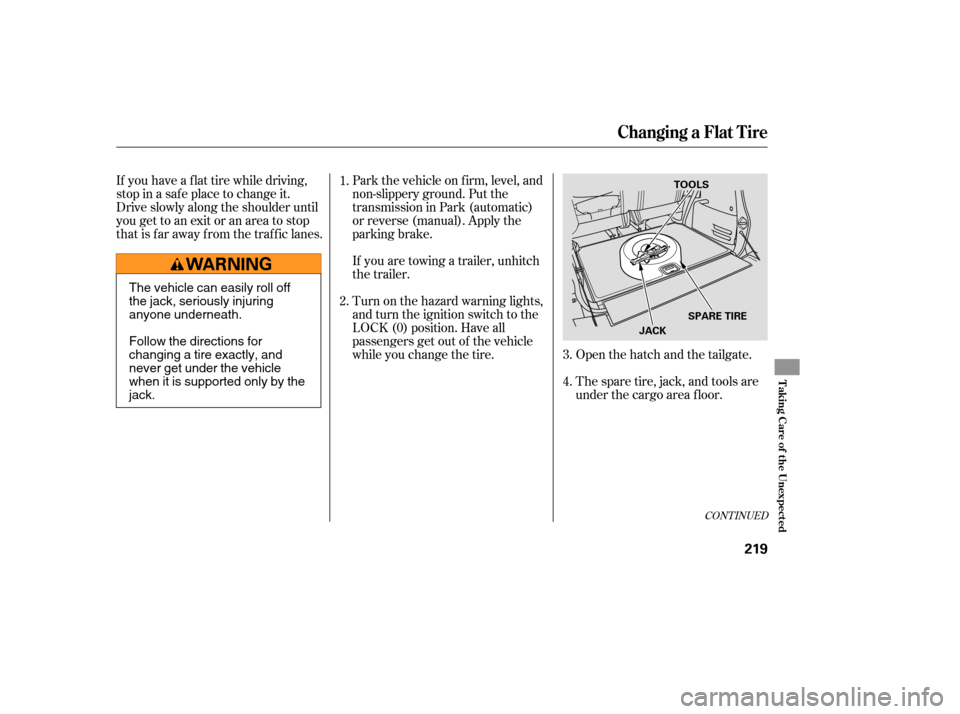

that is far away from the traffic lanes.Open the hatch and the tailgate.

The spare tire, jack, and tools are

under the cargo area f loor.

Park the vehicle on f irm, level, and

non-slippery ground. Put the

transmission in Park (automatic)

or reverse (manual). Apply the

parking brake.

If you are towing a trailer, unhitch

the trailer.

Turn on the hazard warning lights,

and turn the ignition switch to the

LOCK (0) position. Have all

passengers get out of the vehicle

while you change the tire.

1.

2.

3.

4.

CONT INUED

Changing a Flat Tire

T aking Care of t he Unexpect ed

219

TOOLS

SPARE TIRE

JACK

The vehicle can easily roll off

the jack, seriously injuring

anyone underneath.

Follow the directions for

changing a tire exactly, and

never get under the vehicle

when it is supported only by the

jack.

Page 223 of 275

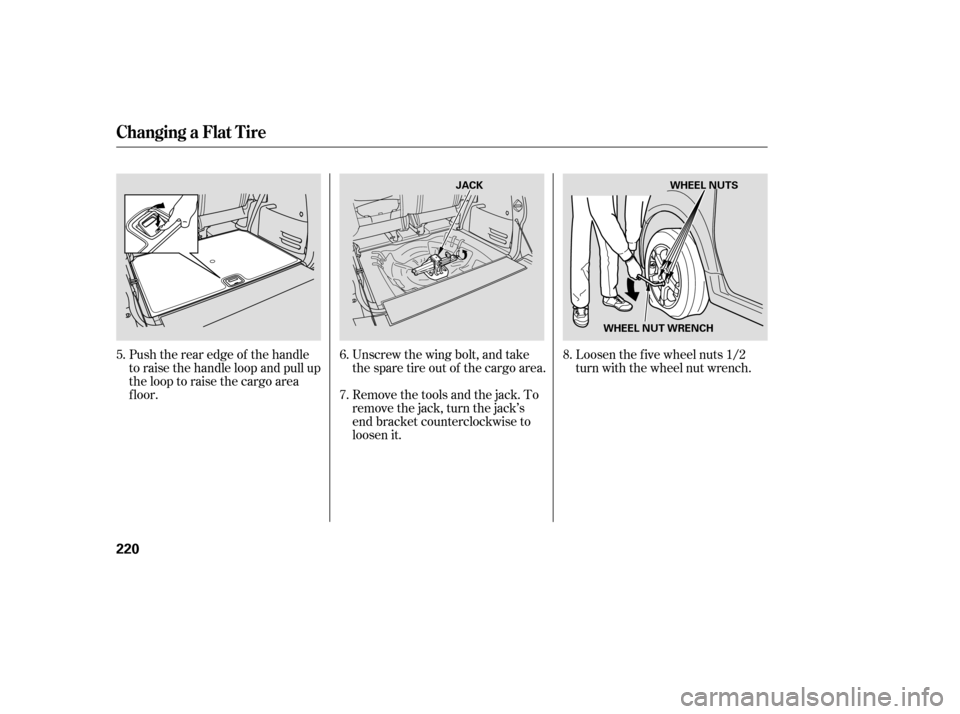

Push the rear edge of the handle

to raise the handle loop and pull up

the loop to raise the cargo area

f loor.Unscrew the wing bolt, and take

the spare tire out of the cargo area.

Remove the tools and the jack. To

remove the jack, turn the jack’s

end bracket counterclockwise to

loosen it.Loosen the f ive wheel nuts 1/2

turn with the wheel nut wrench.

8.

7. 6.

5.

Changing a Flat Tire

220

WHEEL NUTS

JACK

WHEEL NUT WRENCH

Page 224 of 275

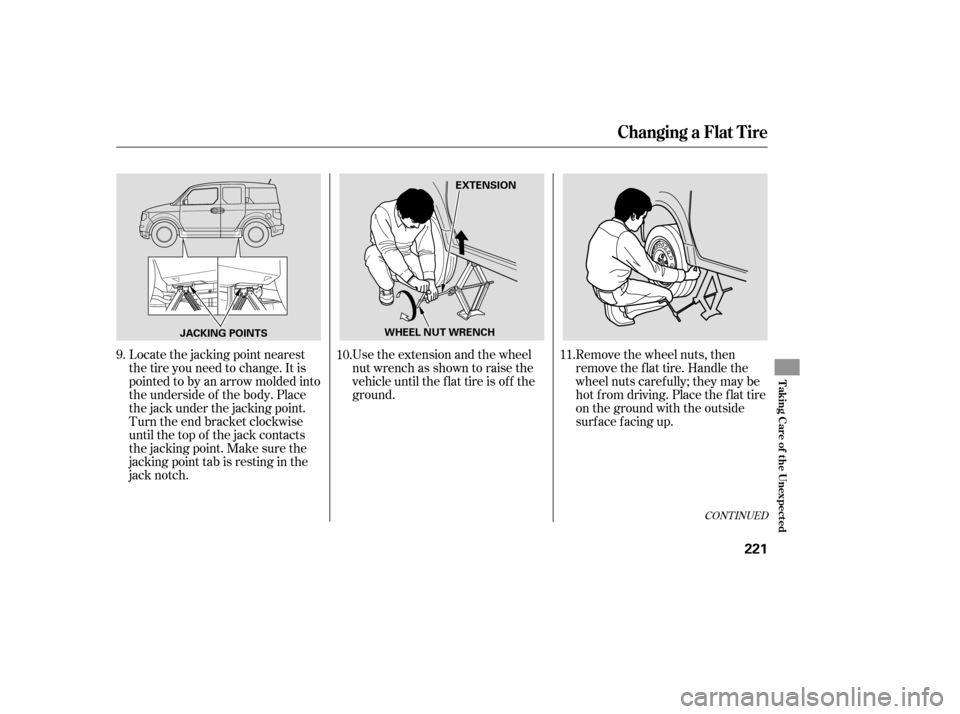

Locate the jacking point nearest

thetireyouneedtochange.Itis

pointed to by an arrow molded into

the underside of the body. Place

the jack under the jacking point.

Turn the end bracket clockwise

until the top of the jack contacts

the jacking point. Make sure the

jacking point tab is resting in the

jack notch.Use the extension and the wheel

nut wrench as shown to raise the

vehicle until the f lat tire is of f the

ground.

Remove the wheel nuts, then

remove the f lat tire. Handle the

wheel nuts caref ully; they may be

hot from driving. Place the flat tire

on the ground with the outside

surface facing up.

9.

10. 11.

CONT INUED

Changing a Flat Tire

T aking Care of t he Unexpect ed

221

EXTENSION

JACKING POINTS WHEEL NUT WRENCH

Page 226 of 275

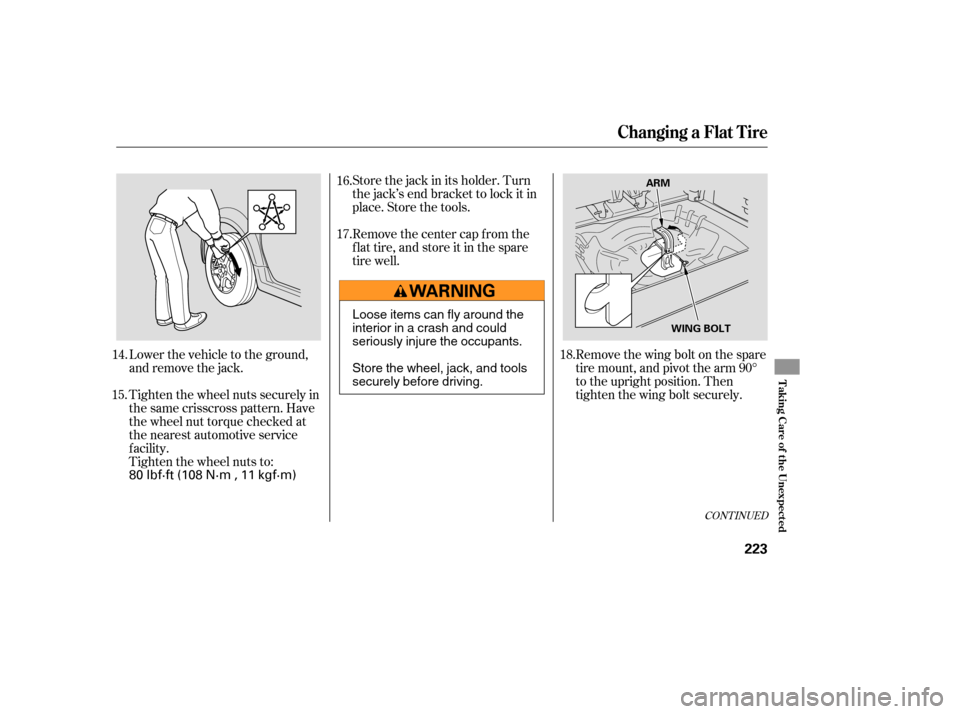

Store the jack in its holder. Turn

the jack’s end bracket to lock it in

place. Store the tools.

Remove the center cap from the

f lat tire, and store it in the spare

tire well.Removethewingboltonthespare

tire mount, and pivot the arm 90°

to the upright position. Then

tighten the wing bolt securely.

Tighten the wheel nuts securely in

the same crisscross pattern. Have

the wheel nut torque checked at

the nearest automotive service

f acility.

Tighten the wheel nuts to: Lower the vehicle to the ground,

and remove the jack. 18.

16.

17.

14.

15.

CONT INUED

Changing a Flat Tire

T aking Care of t he Unexpect ed

223

WING BOLT

ARM

80 lbf·ft (108 N·m , 11 kgf·m)

Loose items can fly around the

interiorinacrashandcould

seriously injure the occupants.

Store the wheel, jack, and tools

securely before driving.

Page 228 of 275

Diagnosing why the engine won’t

start falls into two areas, depending

on what you hear when you turn the

ignition switch to the START (III)

position: Wh

en you turn the ignition switch to

the START (III) position, you do not

hear the normal noise of the engine

trying to start. You may hear a

clicking sound, a series of clicks, or

nothing at all. Turn

the ignition switch to the

START (III) position. If the

headlights do not dim, check the

condition of the fuses. If the fuses

areOK,thereisprobably

something wrong with the

electrical circuit for the ignition

switch or starter motor. You will

need a qualified technician to

determine the problem. See

on page .

If the headlights dim noticeably or

go out when you try to start the

engine, either the battery is

discharged or the connections are

corroded. Check the condition of the

battery and terminal connections

(see page ). You can then try

jump starting the vehicle from a

booster battery (see page ).

You

hear nothing, or almost

nothing. The engine’s starter

motor does not operate at all, or

operates very slowly.

You can hear the starter motor

operating normally, or the starter

motor sounds like it is spinning

faster than normal, but the engine

does not start up and run.

Turn the ignition switch to the ON

(II) position. Turn on the

headlights, and check their

brightness. If the headlights are

very dim or do not come on at all,

the battery is discharged (see on page ).

Check the transmission interlock.

If you have a manual transmission,

the clutch pedal must be pushed

all the way to the f loor or the

starter will not operate. With an

automatic transmission, the shif t

lever must be in Park or neutral.

Check these things:

227 227

214 239

CONT INUED

Nothing Happens or the Starter

Motor Operates Very Slowly

Emergency T owing

Jump Starting

If theEngineWon’tStart

T aking Care of t he Unexpect ed

225