lock HONDA ELEMENT 2007 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2007, Model line: ELEMENT, Model: HONDA ELEMENT 2007 1.GPages: 275, PDF Size: 4.16 MB

Page 163 of 275

Constant application of the brakes

when going down a long hill builds

up heat and reduces their ef f ective-

ness. Use the engine to assist the

brakes by taking your f oot of f the

accelerator and downshif ting to a

lower gear.The hydraulic system that operates

the brakes has two separate circuits.

Each circuit works diagonally across

the vehicle (the lef t-f ront brake is

connected with the right-rear brake,

etc.). If one circuit should develop a

problem, you will still have braking

at two wheels.

Resting your f oot on the pedal keeps

the brakes applied lightly, builds up

heat, and reduces their ef f ectiveness.

It also keeps your brake lights on all

the time, conf using drivers behind

you. Your vehicle is equipped with disc

brakes at all f our wheels. A power

assist helps reduce the ef f ort needed

on the brake pedal. The anti-lock

brake system (ABS) helps you retain

steering control when braking very

hard.

Check your brakes af ter driving

through deep water. Apply the

brakes moderately to see if they f eel

normal. If not, apply them gently and

f requently until they do. Be extra

cautious and alert in your driving.Braking System Design

Braking System

160

Page 164 of 275

If the brake pads need replacing, you

will hear a distinctive, metallic

screeching sound when you apply

the brake pedal. If you do not have

the brake pads replaced, they will

screech all the time. It is normal f or

the brakes to occasionally squeal or

squeak when you apply them.The anti-lock brake system (ABS)

helps prevent the brakes f rom

locking up, and helps you retain

steering control by pumping the

brakes rapidly, much f aster than a

person can do it.

The ABS also balances the f ront-to-

rear braking distribution according

to vehicle loading.

Let the ABS work f or you by always

keeping f irm, steady pressure on the

brake pedal. This is sometimes

ref erred to as ‘‘stomp and steer.’’You will f eel a pulsation in the brake

pedal when the ABS activates, and

you may hear some noise. This is

normal: it is the ABS rapidly

pumpingthebrakes.Ondry

pavement, you will need to press on

thebrakepedalveryhardbeforethe

ABS activates. However, you may

feel the ABS activate immediately if

you are trying to stop on snow or ice.

You should never pump the brake pedal.

Brake Wear Indicators

Anti-lock Brakes

Braking System, Anti-lock Brakes (ABS)

Driving

161

Page 165 of 275

If this indicator comes on, the anti-

lock function of the braking system

has shut down. The brakes still work

like a conven tional system, but

without anti-lock. You should have

your dealer inspect your vehic le as

soon as possible.

If the indicator comes on while

driving, test the brakes as instructed

on page .

If the ABS indicator and the brake

system indicator come on together

and the parking brake is fully

released, the front-to-rear braking

distribution system may also shut

down. Test

your brakes as instructed on

page . If the brakes f eel normal,

drive slowly and have your vehicle

repaired by your dealer as soon as

possible. Avoid sudden hard braking

which could cause the rear wheels to

lock up and possibly lead to a loss of

control.

The VSA indicator will come on

alongwiththeABSindicator.

It only helps with steering

control during braking. such as trying to take a

corner too f ast or making a sudden

lane change. Always drive at a safe

speed f or the road and weather

conditions.

Always steer moderately

when you are braking hard. Severe

or sharp steering wheel movement

can still cause your vehicle to veer

into oncoming traffic or off the road.

on loose or

uneven surf aces, such as gravel or

snow, than a vehicle without anti-

lock.

233

233

Anti-lock Brakes (ABS)

ABS Indicator

Important Saf ety Reminders

A BS does not reduce the time or

distance it takes to stop the

vehicle. A BS will not prevent a skid that

results f rom changing direction

abruptly,

A BS cannot prevent a loss of

stability.

A vehicle with A BS may require a

longer distance to stop

162

Page 177 of 275

Before you leave the pavement, be

sure to do all scheduled maintenance

and service, and inspect your vehicle

f or any problems. Pay special

attention to the condition of the tires,

and check the tire pressures.

After you return to the pavement,

caref ully inspect your vehicle to

make sure there is no damage that

could make driving it unsaf e.

Recheck the condition of the tires

and the tire pressures.

The route presents limits (too steep

or bumpy roads). You have limits

(driving skill and comfort). And your

vehicle has limits (traction, stability,

and power).

Driving of f -highway can be

hazardous if you f ail to recognize

limits and take the proper

precautions.Forbettertractiononallsurfaces,

accelerate slowly and gradually build

up speed. If you try to start too fast

on wet soil, mud, snow, or ice, you

might not have enough traction to

get underway, and you may dig

yourself a hole. Starting with the

shif t lever in second (2) gear will

help you have a smoother start on

snow or ice.

Keep in mind that you will usually

need more time and distance to

brake to a stop on unpaved surf aces.

Avoid hard braking. Do not ‘‘pump’’

the brakes; let the anti-lock braking

system pump them f or you.

Debris in the road can damage your

suspension or other components.

Because your vehicle has a high

center of gravity, driving over a large

obstacle, or allowing a wheel to drop

into a deep hole can cause your

vehicle to tip or roll over.

If you can’t clearly see all conditions

or obstacles on a slope, walk the

slope bef ore you drive on it. If you

have any doubt whether or not you

can saf ely drive on the slope, don’t

do it. Find another route.

If you are driving up a hill and f ind

that you cannot continue,

. Your vehicle could roll

over. Slowly back down the hill,

f ollowing the same route you took up

the hill.

do not try to

turn around

Of f -Highway Driving Guidelines

Check Out Your Vehicle

Remember A ccelerating and Braking A voiding Obstacles

Driving on Slopes

174

Page 194 of 275

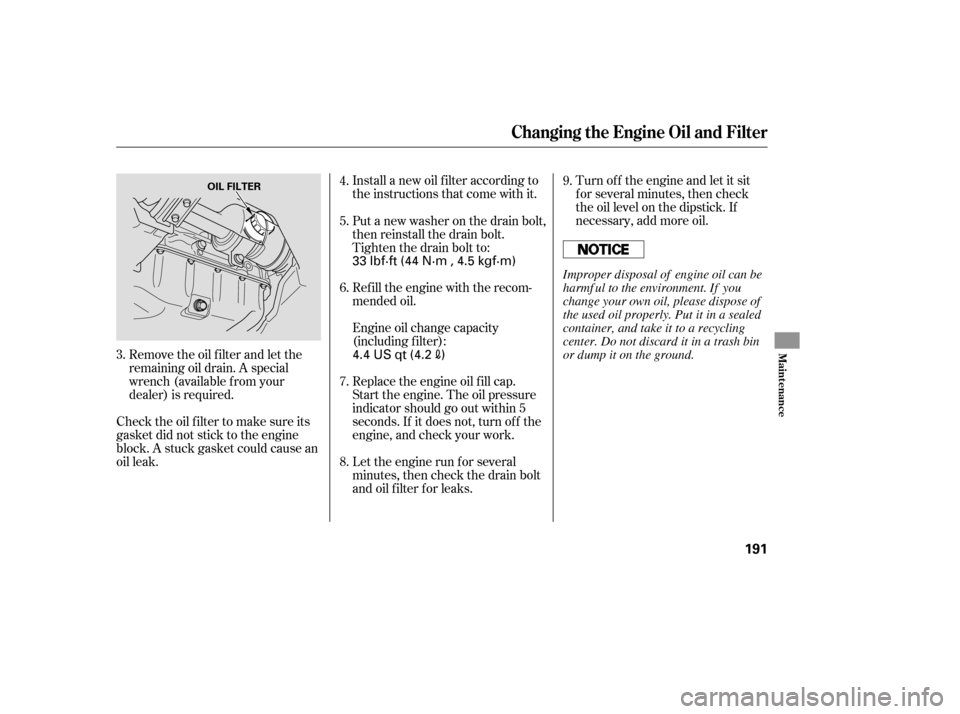

Remove the oil f ilter and let the

remaining oil drain. A special

wrench (available from your

dealer) is required.Install a new oil f ilter according to

the instructions that come with it.

Turn of f the engine and let it sit

f or several minutes, then check

the oil level on the dipstick. If

necessary, add more oil.

Let the engine run f or several

minutes, then check the drain bolt

and oil f ilter f or leaks. Replace the engine oil f ill cap.

Start the engine. The oil pressure

indicator should go out within 5

seconds. If it does not, turn of f the

engine, and check your work. Refill the engine with the recom-

mended oil.

Engine oil change capacity

(including f ilter): Put a new washer on the drain bolt,

then reinstall the drain bolt.

Tighten the drain bolt to:

Check the oil f ilter to make sure its

gasket did not stick to the engine

block. A stuck gasket could cause an

oil leak. 4.

3. 5.

6.

7.

8.9.

Changing the Engine Oil and Filter

Maint enance

191

OIL FILTER

4.4 US qt (4.2)

33 lbf·ft (44 N·m , 4.5 kgf·m)

Improper disposal of engine oil can be

harmf ul to the environment. If you

change your own oil, please dispose of

the used oil properly. Put it in a sealed

container, and take it to a recycling

center. Do not discard it in a trash bin

or dump it on the ground.

Page 196 of 275

The coolant level should be up to

the base of the filler neck. Add

coolant if it is low.

Pourthecoolantslowlyand

carefully so you do not spill any.

Clean up any spill imme diately; it

could damage componen ts in the

engine compartm ent.

Put the radiator cap back on and

tighten it.

Pour coolant into the reserve tank.

Fill it to halfway between the MAX

and MIN marks. Put the cap back

on the reserve tank.

Do not add any rust inhibitors or

other additives to your vehicle’s

cooling system. They may not be

compatible with the coolant or

engine components. Fill

the reservoir with a good-quality

windshield washer fluid. This

increases the cleaning capability and

prevents freezing in cold weather.

Check

the fluid level in the

windshield washer reservoir at least

monthly during normal use.

The low washer

level indicator comes on when the

level is low (see page ).

When you ref ill the reservoir, clean

the edges of the windshield wiper

blades with windshield washer f luid

on a clean cloth. This will help to

condition them.

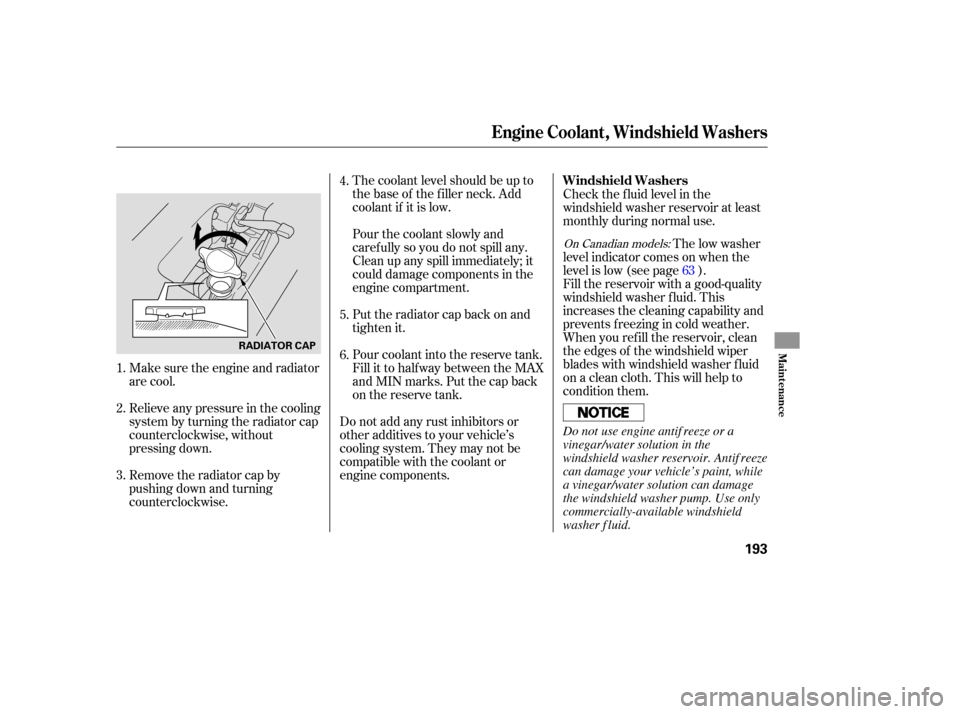

Remove the radiator cap by

pushing down and turning

counterclockwise. Make sure the engine and radiator

are cool.

Relieve any pressure in the cooling

system by turning the radiator cap

counterclockwise, without

pressing down. 4.

5.

2. 1.

3. 6.

63

On Canadian models:

Windshield Washers

Engine Coolant, Windshield Washers

Maint enance

193

RADIATOR CAP

Do not use engine antif reeze or a

vinegar/water solution in the

windshield washer reservoir. Antif reeze

can damage your vehicle’s paint, while

a vinegar/water solution can damage

the windshield washer pump. Use only

commercially-available windshield

washer f luid.

Page 200 of 275

A low power steering f luid level can

indicate a leak in the system. Check

the f luid level f requently, and have

the system inspected as soon as

possible.

To clean the gray composite body

panels, wash them with soap and

water only. Do not apply wax to the

panels; it will cause discoloration. Always use Honda Power Steering

Fluid. You may use another power

steering f luid as an emergency

replacement, but have the power

steering system f lushed and ref illed

with Honda PSF as soon as possible.

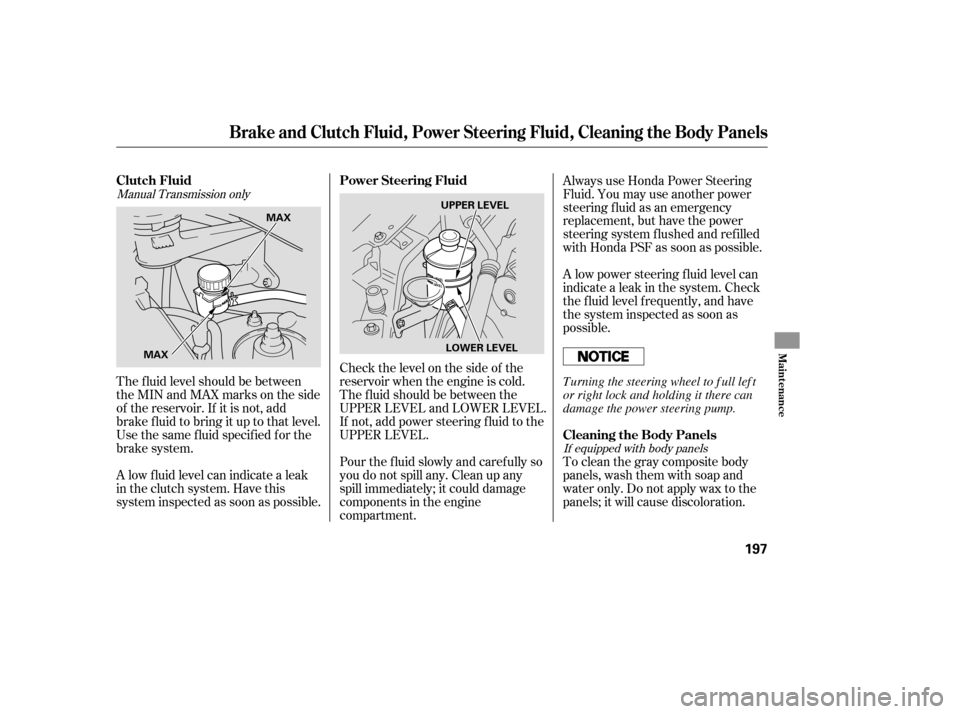

Check the level on the side of the

reservoir when the engine is cold.

The f luid should be between the

UPPER LEVEL and LOWER LEVEL.

If not, add power steering f luid to the

UPPER LEVEL.

Pour the f luid slowly and caref ully so

you do not spill any. Clean up any

spill immediately; it could damage

components in the engine

compartment.

The f luid level should be between

theMINandMAXmarksontheside

of the reservoir. If it is not, add

brake f luid to bring it up to that level.

Use the same fluid specified for the

brake system.

A low f luid level can indicate a leak

in the clutch system. Have this

system inspected as soon as possible.

If equipped with body panels

Manual Transmission only

Cleaning the Body Panels

Power Steering Fluid

Clutch Fluid

Brake and Clutch Fluid, Power Steering Fluid, Cleaning the Body Panels

Maint enance

197

UPPER LEVEL

LOWER LEVEL

MAX

MAX

Turning the steering wheel to f ull lef t

or right lock and holding it there can

damage the power steering pump.

Page 203 of 275

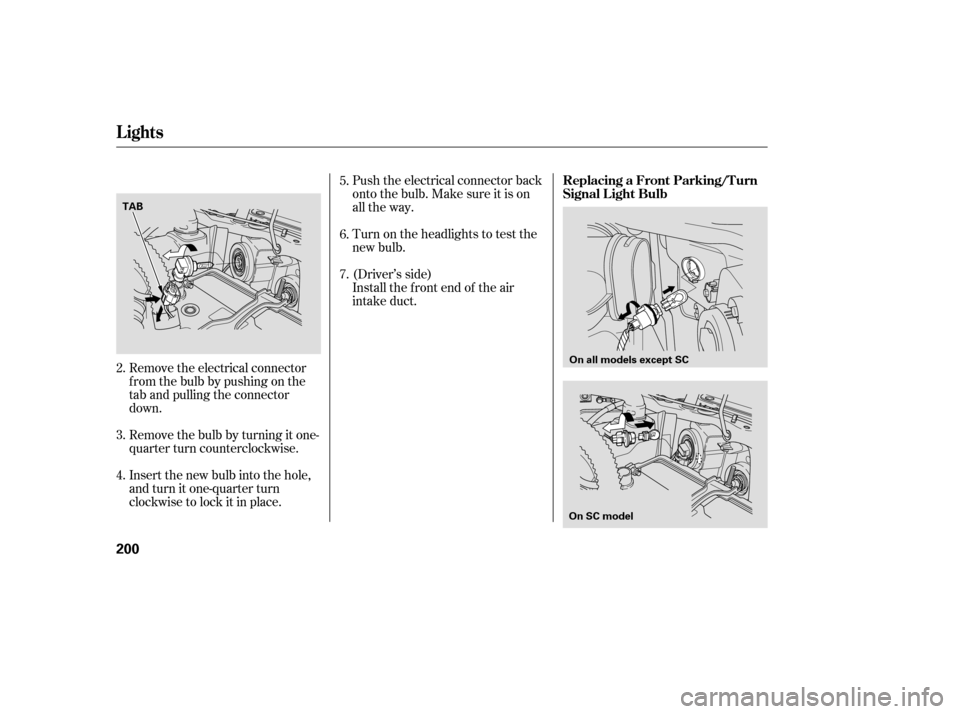

Push the electrical connector back

onto the bulb. Make sure it is on

all the way.

Turn on the headlights to test the

new bulb.

(Driver’s side)

Install the f ront end of the air

intake duct.

Insert the new bulb into the hole,

and turn it one-quarter turn

clockwise to lock it in place. Remove the bulb by turning it one-

quarter turn counterclockwise. Remove the electrical connector

f rom the bulb by pushing on the

tab and pulling the connector

down.

3.

4. 5.

6.

7.

2.

Lights

Replacing a Front Parking/Turn

Signal Light Bulb

200

On all models except SC

On SC model

TAB

Page 204 of 275

Remove the socket from the light

assembly by turning it one-quarter

turn counterclockwise.

Pull the bulb straight out of its

socket. Push the new bulb straight

into the socket until it bottoms.

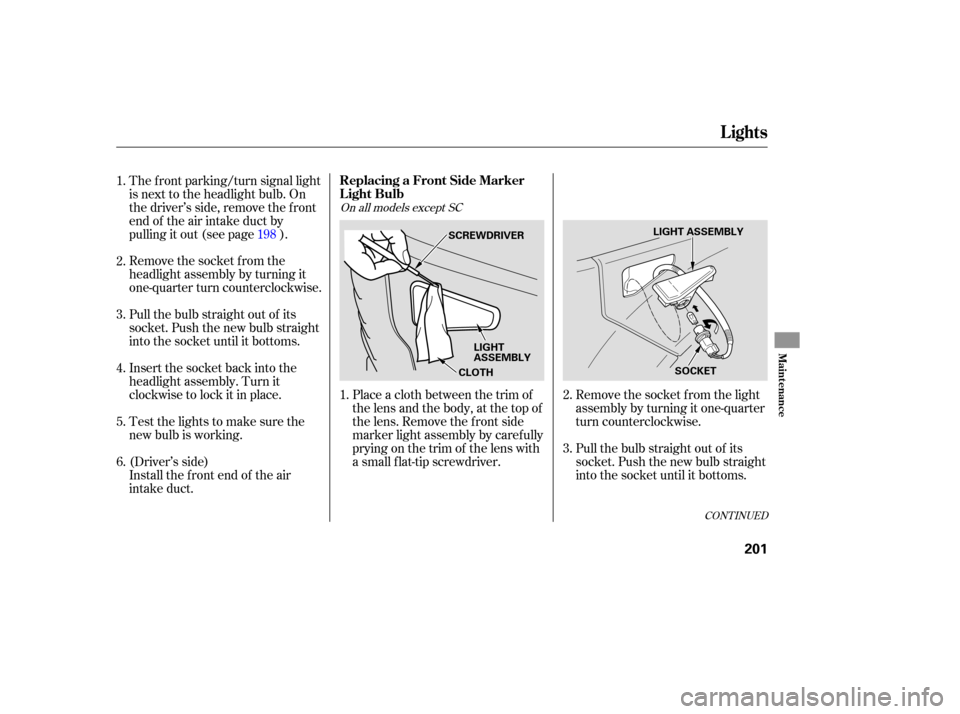

Place

a cloth between the trim of

the lens and the body, at the top of

the lens. Remove the front side

marker light assembly by carefully

prying on the trim of the lens with

a small flat-tip screwdriver.

The

front parking/turn signal light

is next to the headlight bulb. On

the driver’s side, remove the front

end of the air intake duct by

pulling it out (see page ).

Remove the socket from the

headlight assembly by turning it

one-quarter turn counterclockwise.

Pull the bulb straight out of its

socket. Push the new bulb straight

into the socket until it bottoms.

Insert the socket back into the

headlight assembly. Turn it

clockwise to lock it in place.

Testthelightstomakesurethe

new bulb is working.

Install the f ront end of the air

intake duct. 1.

2.

3.

1.

2.

3.

4.

5.

6.

198

(Driver’s side)

CONT INUED

On all models except SC

Lights

Replacing a Front Side Marker

Light Bulb

Maint enance

201

SCREWDRIVER CLOTH LIGHT

ASSEMBLY LIGHT ASSEMBLY

SOCKET

Page 205 of 275

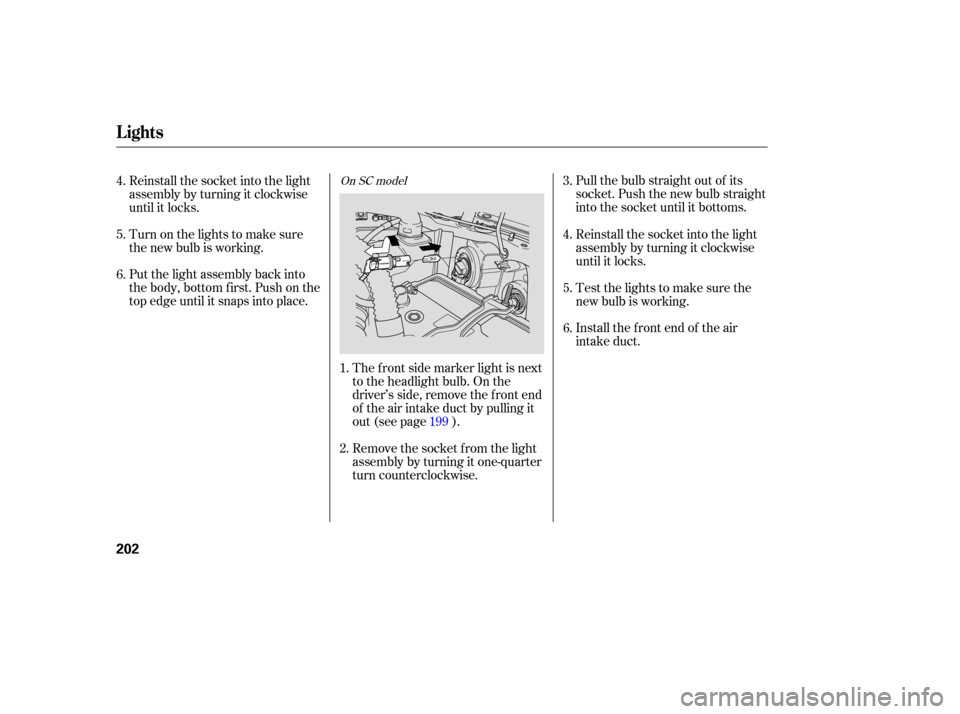

Pull the bulb straight out of its

socket. Push the new bulb straight

into the socket until it bottoms.

The front side marker light is next

to the headlight bulb. On the

driver’s side, remove the front end

of the air intake duct by pulling it

out (see page ).

Reinstall the socket into the light

assembly by turning it clockwise

until it locks.

Turn on the lights to make sure

the new bulb is working.

Put the light assembly back into

the body, bottom first. Push on the

top edge until it snaps into place.

Remove the socket f rom the light

assembly by turning it one-quarter

turn counterclockwise.Testthelightstomakesurethe

new bulb is working.

Install the f ront end of the air

intake duct. Reinstall the socket into the light

assembly by turning it clockwise

until it locks.

1. 3.

2. 4.

5.

6.

4.

5.

6.

199On SC model

Lights

202