harness HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1176 of 1413

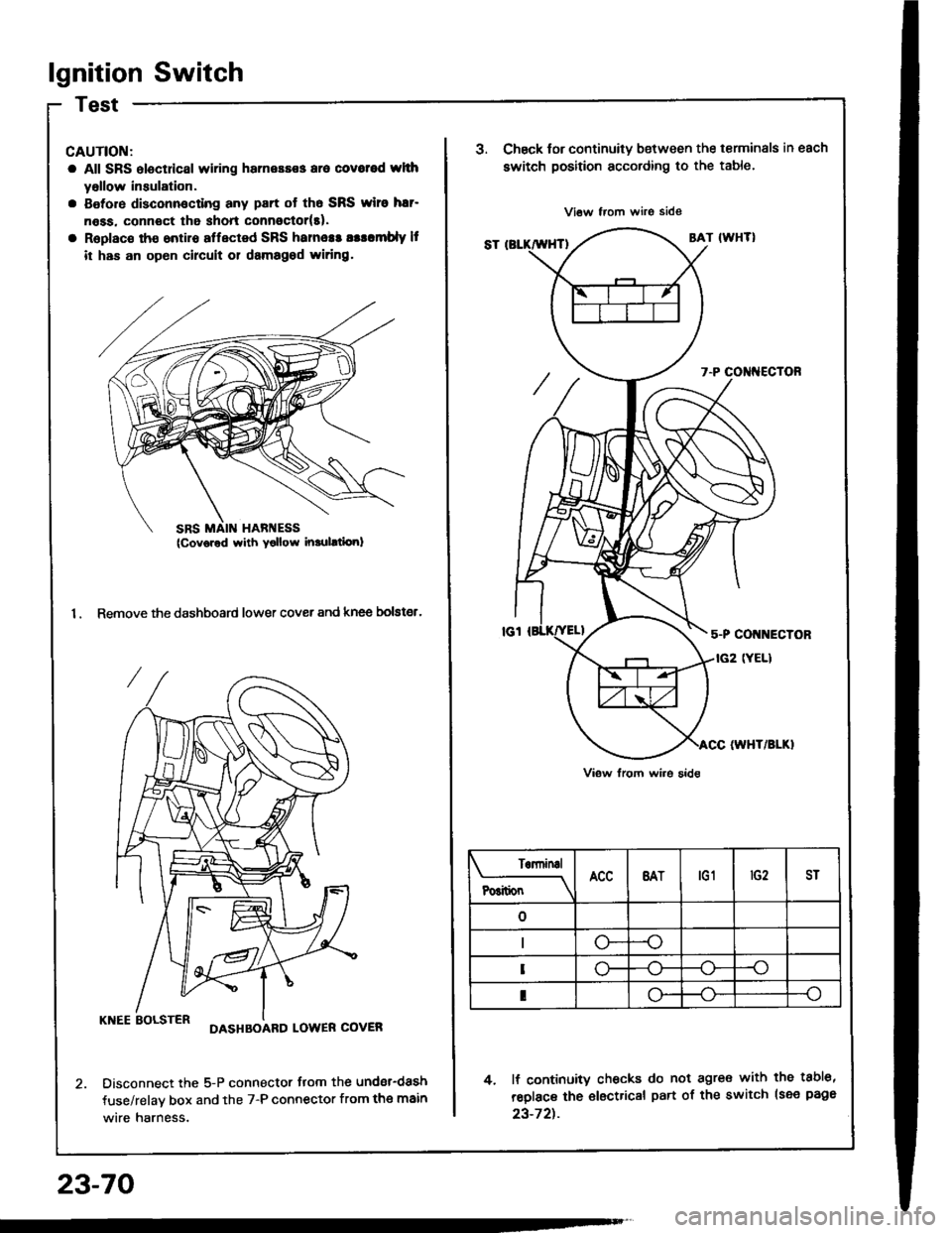

lgnition Switch

CAUTION:

a All SRS electdcal wiring harnessss aro covotod whh

yollow insulation.

a Botore disconnocting any part ot th6 SRS wiro har-

n6ss. connoct tha shon connoctor(t).

a Replac€ tho ontiro affected SRS hames! asllmbly It

it has an op6n circuit 01 damagod widng.

1. Remove the dashboard lower cover and knee bolster.

KNEE BOLSTERDASHBOARD LOWER COVER

Disconnect the 5-P connector flom the undsr-dash

fuse/relav box and the 7-P connector from the main

wire harness.

23-70

SRS MAIN HARI{ESS(Cov6red with Yollow inrulltiori)

J.Chsck tor continuity b€tween the terminals in each

switch position according to the table.

4. lf continuity checks do not agre€ with the tabl6,

reolace the €lectrical part of the switch lsee page

23-72t.

Terninal

P6itionBATtG1ST

--o

o-

I

Page 1177 of 1413

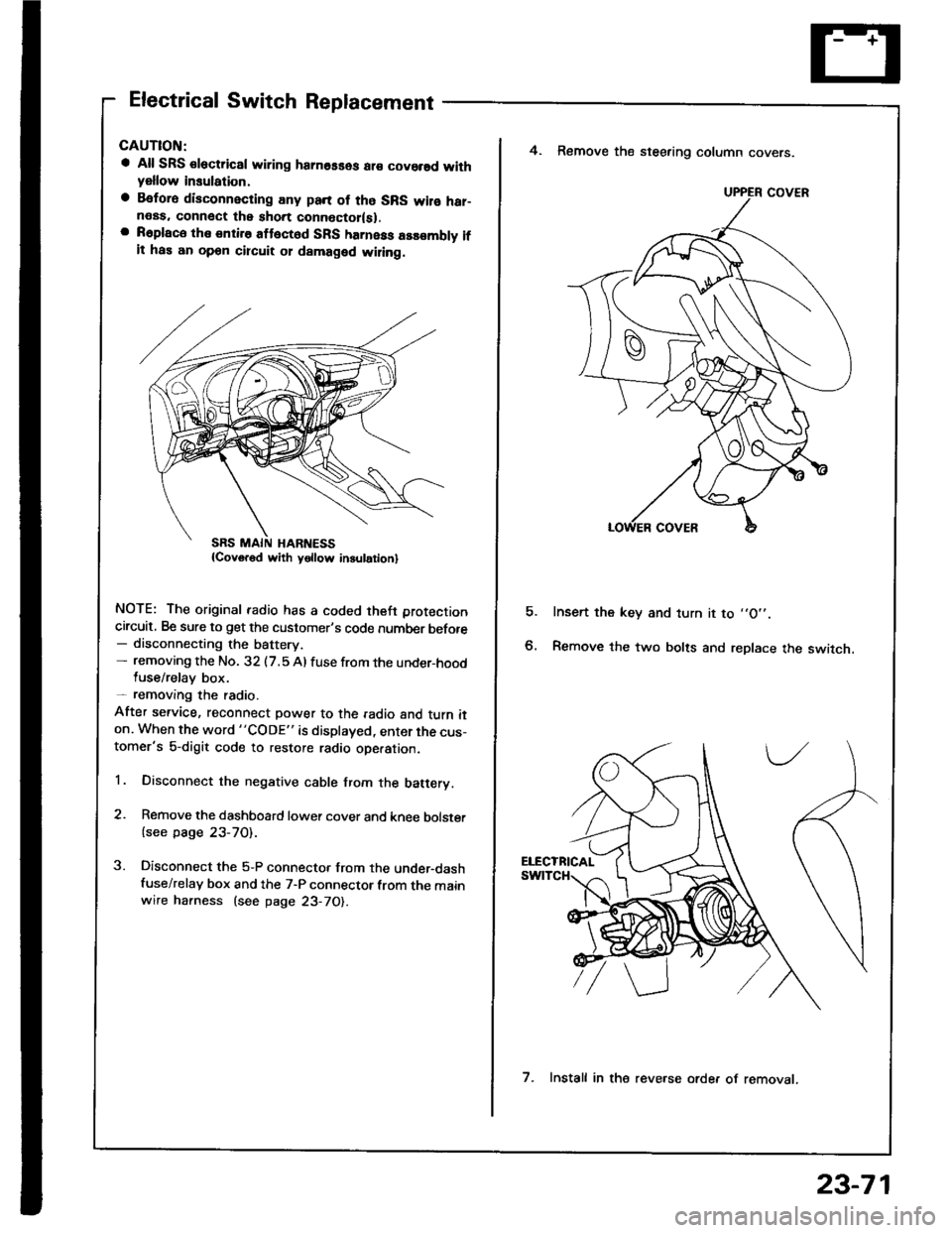

Electrical Switch Replacement

a All SRS €lectric8l wiring hamosses ar€ covorsd withyellow insulation,

a Befora disconnecting any pan of tho SRS wilo har-neas. connect the short connoctor(sl.a R6place the entire attect6d SFS harness assombly ifit has an opon circuit 01 damaged wiling.

NOTE: The original radio has a coded theft protection

circuit, Be sure to get the customer's code number before- disconnecting the battery.- removing the No. 32 (7.5 Al fuse from the under-hoodluse/relay box.- removang the radio.

After service, reconnect power to the radio and turn iton. When the word "CODE" is displayed, enter the cus-tomer's 5-digit code to restore radio ope.ation.

1. Disconnect the negative cable from the batery.

2. Remove the dashboard lower cover and knee bolster

{see page 23-70).

3. Disconnect the 5-P connector from the under-dashfuse/relay box and the 7-P connector from the mainwire harness (see page 23-70).

E

4. Remove the steering column covers.

Insert the key and turn it to ,,O',.

Remove the two bolts and replace the switch.

UPPER COVER

7. Install in the reve.se orde. of removat.

23-71

Page 1178 of 1413

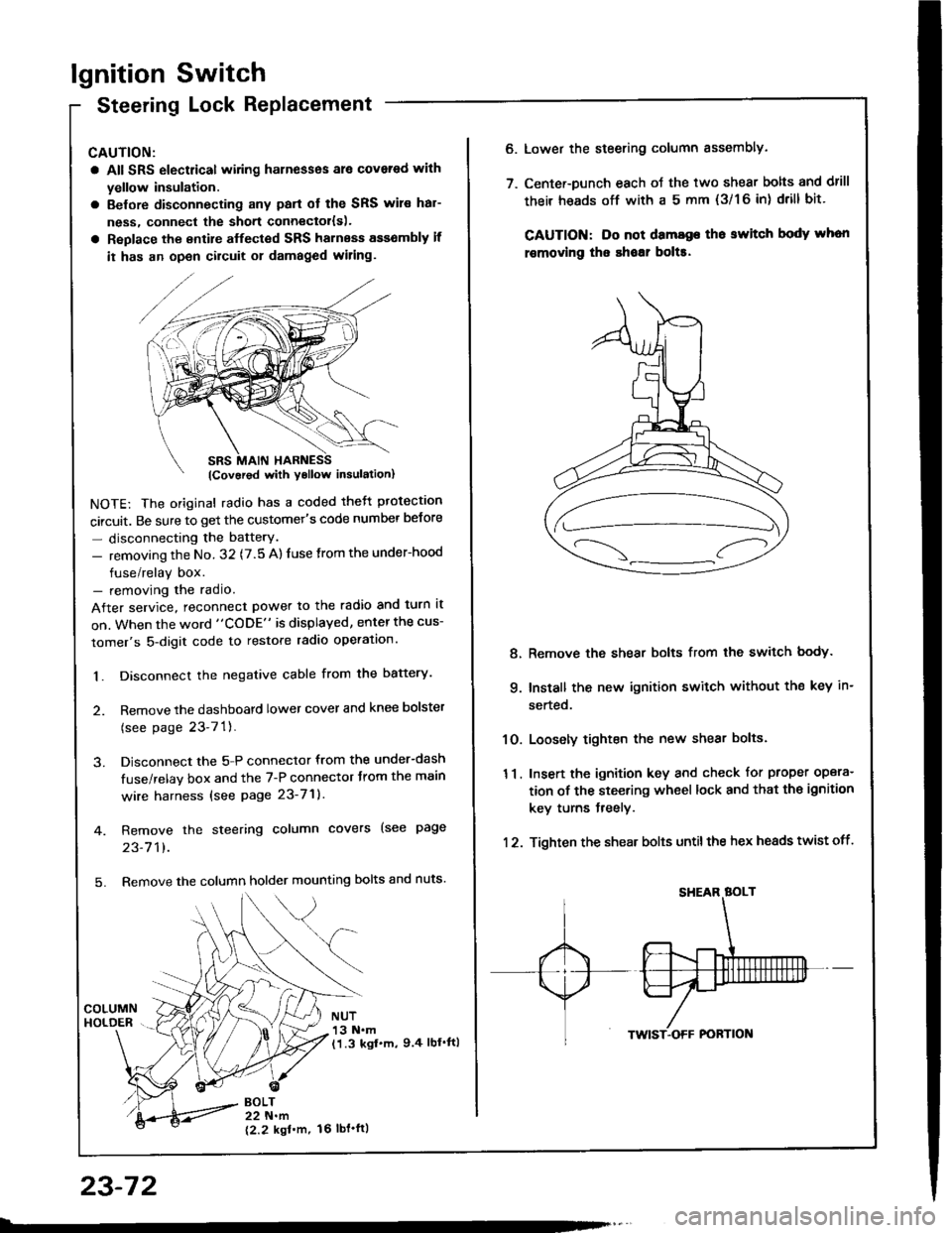

lgnition Switch

Steering Lock Replacement

CAUTION:

a All SRS electrical wiring harnesses ale covsred with

yellow insulation.

a Belore disconnecting any parl ot the SRS wir€ hal-

ness, connecl the short connector{s).

a Replace the entire alfected SRS harness a$6mbly il

it has an open circuit or damaged wiring.

NOTE: The original radio has a coded thett protection

circuit. Be sure to get the customer's code number betore

- disconnecting the batterY.

- removing the No. 32 (7.5 A) fuse from the under-hood

fuse/relay box.- removing the radio.

After service, reconnect power to the radio and turn it

on. When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

1. Disconnect the negative cable from the battery.

2. Remove the dashboald lower cover and knee bolster

(see page 23-7'l ).

3. Disconnect the 5-P connector from the under-dash

fuse/relay box and the 7-P connector trom the main

wire harness {see page 23-71).

4. Remove the steering column covers (see page

23-711.

5. Remove the column holder mounting bolts and nuts'

BOLT22 N.m

12.2 kgl'm.

NUT13 N.m(1.3 kgf.m, 9.4 lbl'ftl

23-72

16 tbt.ftl

6. Lower the steering column sssembly.

7. Center-Dunch each oJ the two shear bolts and drill

their heads off with a 5 mm {3/1 6 in) drill bit'

CAUTION: Do not dama96 tho switch body whon

r€movlng the shoar bol$.

Remove the shear bolts from the switch body.

Install the new ignition switch without the key in-

serted.

Loosely tighten the new shear bolts.

Insert the ignition key and check for proper opera-

tion of the steering wheel lock and that th€ ignition

key turns freely.

Tighten the shear bolts untilthe hex heads twist off.

8.

q

10.

11.

12.

Page 1185 of 1413

1.

2.

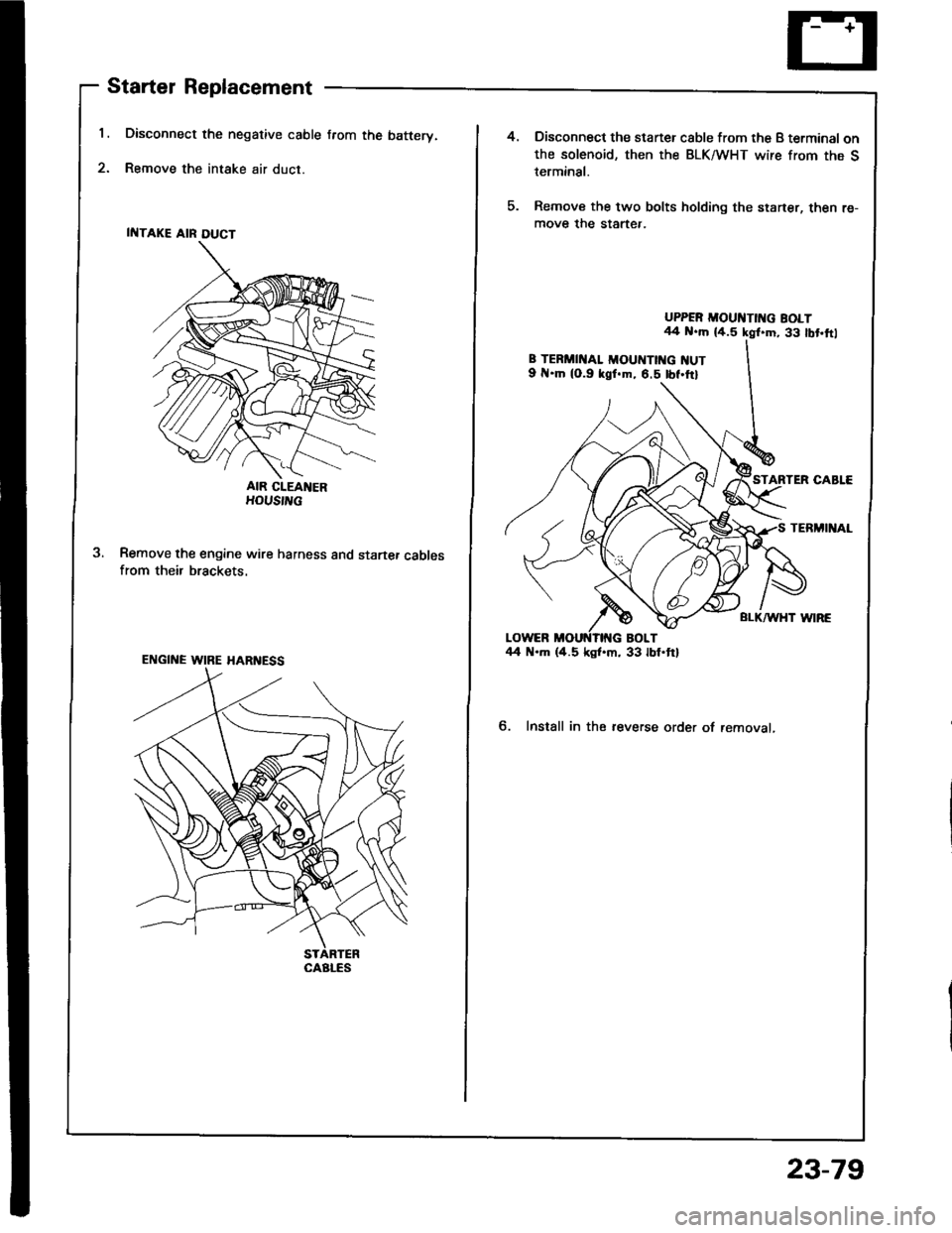

Starter Replacement

Disconnect the negative cable from the batterv.

Remove the intake air duct.

AIR CIEANERHOUS|L

Remove the engine wire harness and startef cablesfrom their brackets.

ENGINE WIRE HARI{ESS

CAALES

4.Disconnect the staner csble from the B terminal onthe solenoid, then the BLK/WHT wire from the Sterminal.

Remove the two bolts holding the staner, then re-move the startef.

UPPER MOUI{TII{G BOLT44 N..h (4.5 kgl.m, 33 lbt,ftl

8 TERMII{AL MOUIITTI{G NUT9 .ln (0.9 kgf.m, 6.5 tbf.ttl

TERMINAL

BLI(AA/HT WIRE

6. Install in the reverse order of removal,

23-79

Page 1186 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual Starting

Startel

System

Overhaul

from clutch side.

-s@]

MOLYBDENUMDISULFIDE

CAUTION: Disconnecl th€ battery n€gative cable befole

lomoving the startet.

NOTE: The original radio has a coded theft p HONDA INTEGRA 1994 4.G Workshop Manual Starting

Startel

System

Overhaul

from clutch side.

-s@]

MOLYBDENUMDISULFIDE

CAUTION: Disconnecl th€ battery n€gative cable befole

lomoving the startet.

NOTE: The original radio has a coded theft p](/img/13/6067/w960_6067-1185.png)

Starting

Startel

System

Overhaul

from clutch side.

-s@]

MOLYBDENUMDISULFIDE

CAUTION: Disconnecl th€ battery n€gative cable befole

lomoving the startet.

NOTE: The original radio has a coded theft protection

citcuit. Be sure to get the customer's code number before

- disconnecting the batterY.- removing the No.3 2 (7.5 A) fuse from the under-hood

fuse/relay box.- removing the tadio.

Atter service, reconnect power to the radio and turn at

on. When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

tr./.' BRUSH HOLDERTest, page 23-8'l

ERUSH

COVER

I

6

OVERRUNNING CLUTCH ASSEMBLYInspection, page 23_84

SOLENOIDPLUNGERInspection, page 23-85

BRUSH HOLOER

ARMATURE

STARTERSOLENOIDTest, page 23-78

PINION GEAR IDLER GEAR

Inspection, page 23-11

IDLER GEAR

I

@*

SOLENOID HOUSING

HARNESS BRACKET

STEEL BALL

install steel ball

lnspection and Test,page 23-82

ROLLER BEARINGSand CAGEPrevenl rollers trom being scattered and lost.

MOLYBDENUM DISULFIDE

_R1

MOLYADENUMDISULFIDE

23-80

ENO COVER

ARMATURE

GEAR HOUSING

Page 1219 of 1413

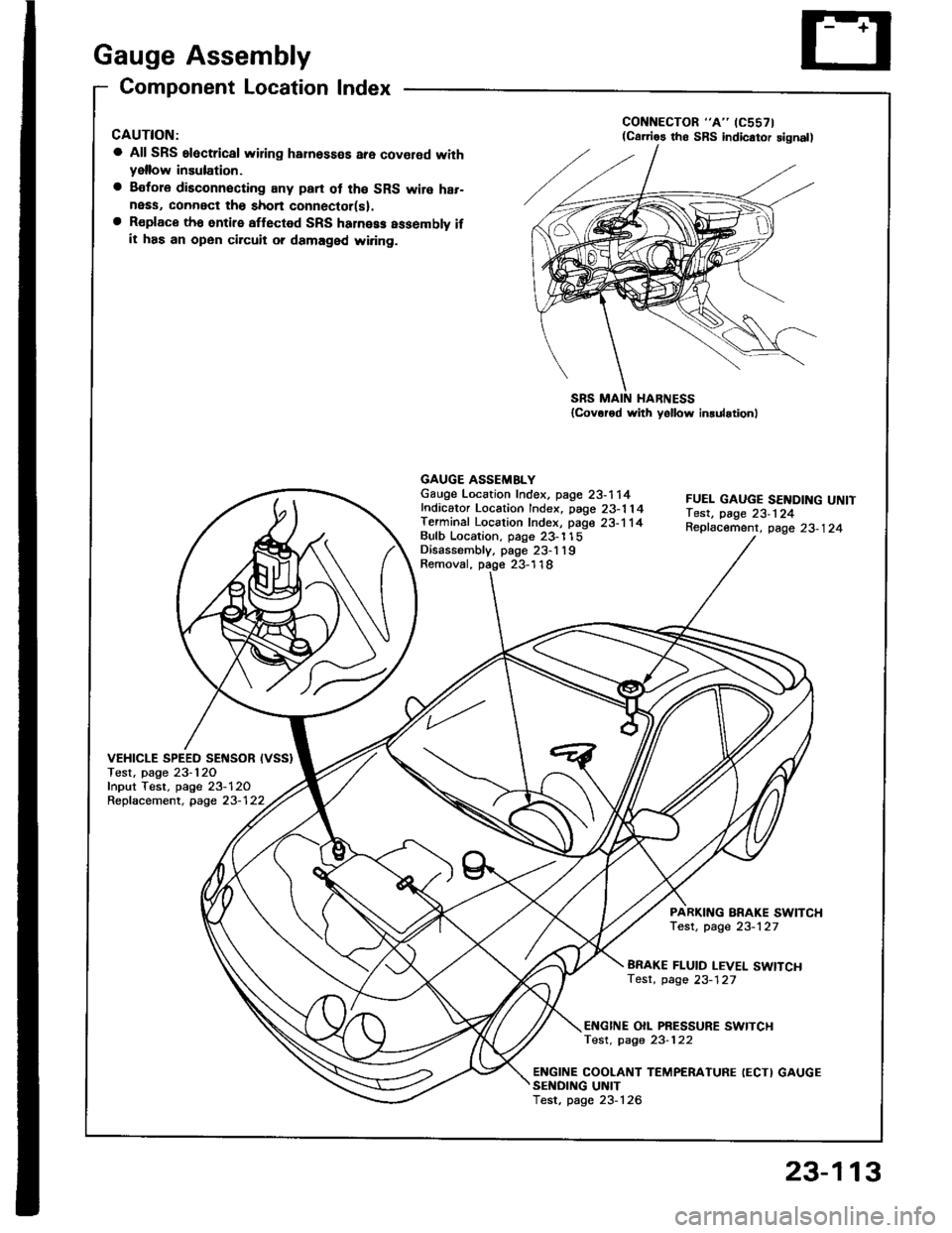

Gauge Assembly

Component Location Index

CAUTION:

a All SRS electrical wiring harnosses are cov€rod withyellow insulation.

a Bofore disconnecting any prn ot th€ SRS wire har-ness, connect tho short connector(sl.a R€place th6 entirs affGcted SRS halne$ assembly ifit has an open circuit o? damaged wiring.

SRS MAIN HARNESS{Cov.r6d with yollow inrularionl

GAUGE ASSEMBLYGauge Location Index, page 23-114Indicator Location Index, page 23-1 14Terminal Location Index, page 23-114Bulb Location. page 23-'l 15Disassembly. page 23-1 19Removal, page 23-118

FUEL GAUGE SENDING UNtTTest, page 23'124Repfacemenr, page 23-124

VEHICLE SPEEO SENSOB IVSS}Test, page 23-120fnput Test. page 23-120Repfacement, page 23-122

PARKITTG BRAKE SWITCHTest, page 23-127

BRAKE FLUID LEVEL SWITCHTesr, page 23-127

EI{GINE OIL PBESSURE SWITCHTest, page 23-122

ENGINE COOLANT TEMPERATURE IECTI GAUGESENOING UNITTest, page 23-126

(C61'ios tho SBS indicator signal)

23-113

Page 1220 of 1413

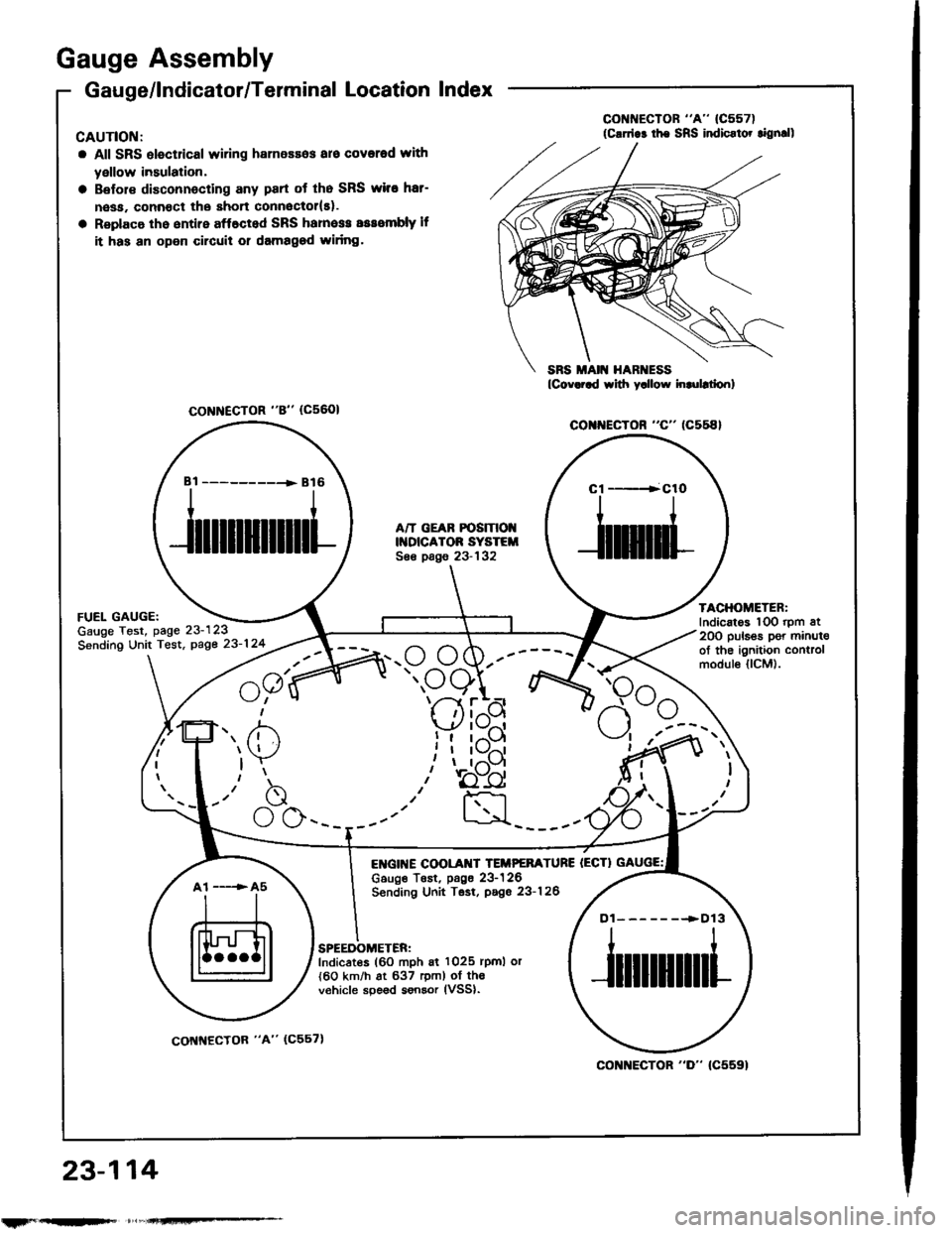

Gauge Assembly

Gauge/lndicator/Terminal Location Index

CAUTIOI{:

a All SRS olectrical wiring harnessos aro covorod with

yellow insulation,

Belol€ disconnecting any part ot tho SRS wiro hat-

nesa. connoct the short connoctol(El.

Replaco th6 entire aff6cted SRS hamess sssombly lf

it has an open circuil or damagod widng.

co r{EcroR "c" (c558}

FUEL GAUGE:Gauge Test, page 23-123

Sending Unit Tost, page 23-124

23,-114

A/T GEAR POSIT|OIIDICATOR SYSTEISee pags 23-132

E GI[{E COOLAI{T TEIIPEFATURE IECTIc6uge TEst, p6g6 23-126Sending Unit Tsst, pago 23-126

TACHOMETER:Indicatos lOO rpm at20O puls€s per minul€of the ignition controlmodul€ llCM).

SPEEDOMETER:Indicates (60 mph 6i 1025 rpml or{60 km/h at 637 rem) of th€v€hicle spe6d sonsor lVSSl.

CoNNECTOR "8" (c5601

Bi ----------+ B16Cl ----+ClO

f',. /i)

)Y

-"b

\_./ \J \-___--

a1 -----> A5

Dl-------.>D13

col{]{ECTOR "D" (C5591

rtrF --

coNNECfOR "A" (C557)

Page 1224 of 1413

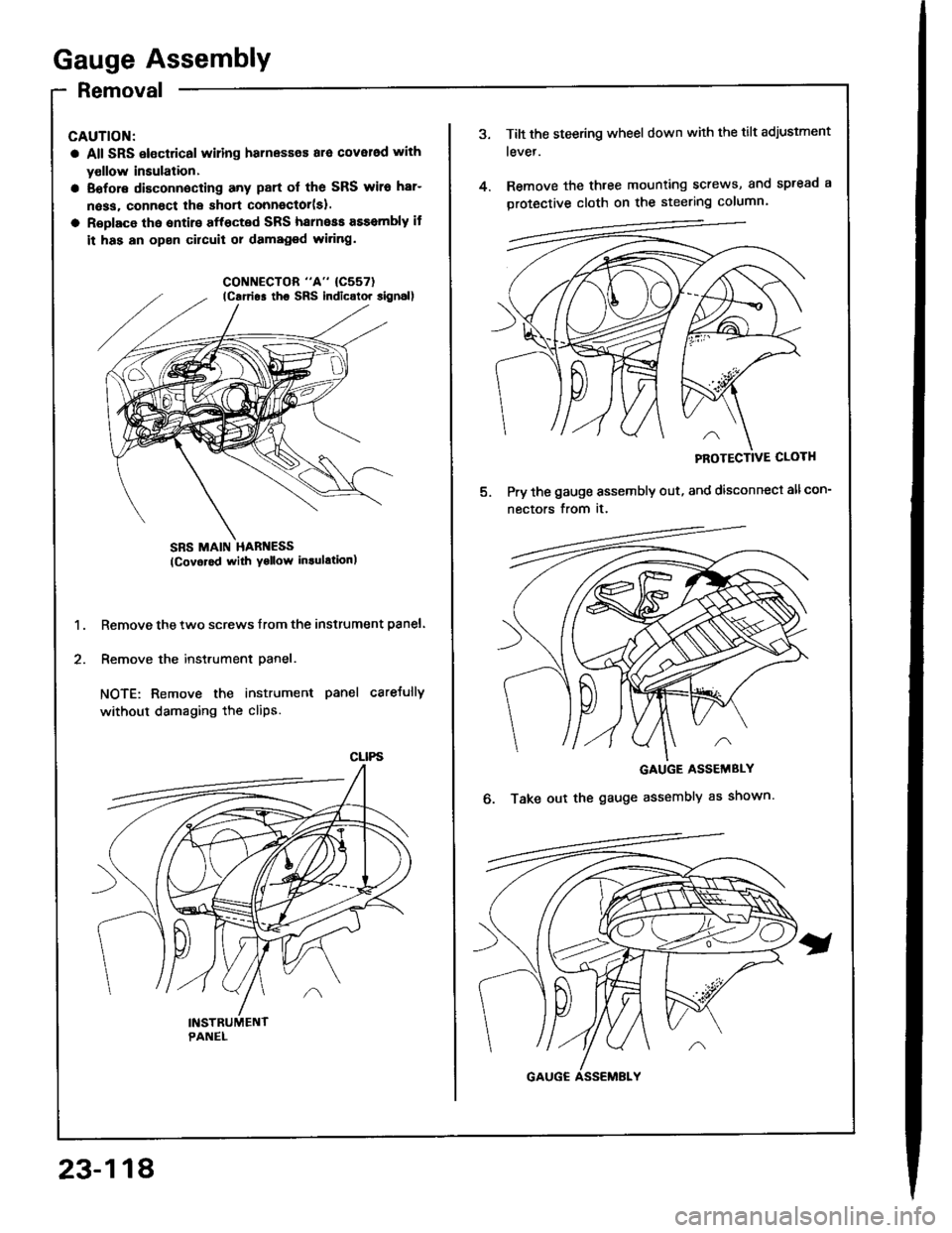

Gauge Assembly

Removal

CAUTION:

a All SRS electrical wiling harnesses ara cover6d with

yollow insulation.

a Eofore disconnecting any part ol the SRS wiro har-

n6ss, connoct lhe short connector(sl.

a Roplace tho entirs affocted SRS harneas assembly if

it has an open circuit 01 damaged wi.ing.

SBS MAIN HARI{ESS(Covor6d with Yollow in.ulationl

Remove the two screws lrom the instrument panel.

Remove the instrument panel.

NOTE: Remove the instrument panel careJully

without damaging the cliPs.

1.

2.

lcarrio. tho SRs indicolor 8ignal)

CLIPS

23-118

Tilt the steering wheel down with the tilt adjustment

tevet.

Remove the three mounting screws, and spread a

protective cloth on the steering column.

PROTECTIVE CLOTH

Pry the gauge assembly out, and disconnect allcon-

nectors from it.

GAUGE ASSEMBLY

Take out the gauge assembly as shown.o.

Page 1226 of 1413

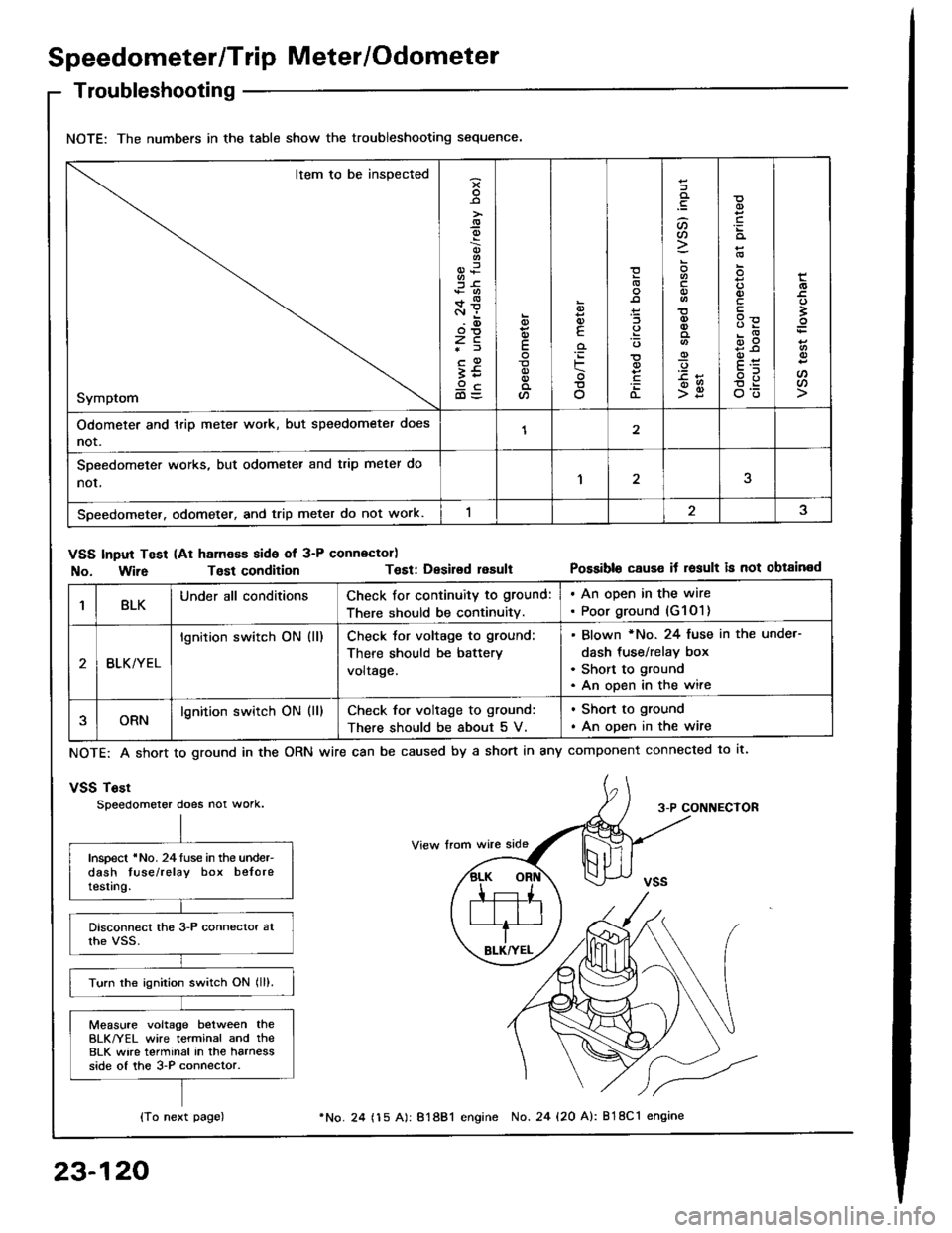

Speedometer/Trip Meter/Odometer

Troubleshooting

NOTE: The numbers in the table show the troubleshooting sequence.

Item to be inspected

Symptom

-9

;6+*c.r i.(D

zc*f

;59cd)=

E

a

6

E

'iF

o

(L

:lt)a

o

-9

>g

q)

qlv

E

'

E

oo

Odometer and trip meter wotk, but speedometer does

not.12

SDeedometer works, but odometer and trip meter do

nor,1

Speedometer. odometer, and trip meter do not work.

VSS Input Test (At ham€ss side of 3-P connector)

No. Wir6Tost conditionT€st: Desirsd resultPossible cause it result is not obtained

1BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. An open in the wire. Poor ground (G1O1)

BLK/YEL

lgnition switch ON (ll)Check tor voltage to ground:

There should be battery

voltage.

Blown *No. 24 fuse in the unde.-

dash tus€/relay box

Short to ground

An open in the wire

ORNlgnition switch ON (ll)Check for voltage to ground:

There should be about 5 V.

. Shon to ground

. An open in the wire

NOTE: A short to ground in the

vSS Tost

Speedometer does not work.

ORN wire can be caused by a short in any component connected to lt.

3-P CONNECTOR

Inspect 'No. 24luse in the under-dash tuse/relay box beloretesting.

Turn the ignition switch ON lll).

Measure voltage between theBLK/YEL wire terminal and the8LK wire terminal in the harnessside of the 3-P connector.

{To next page)

23-120

24 (15 A): 81881 engine No. 24 {20 A): 818C1 engine

Page 1243 of 1413

Replacement

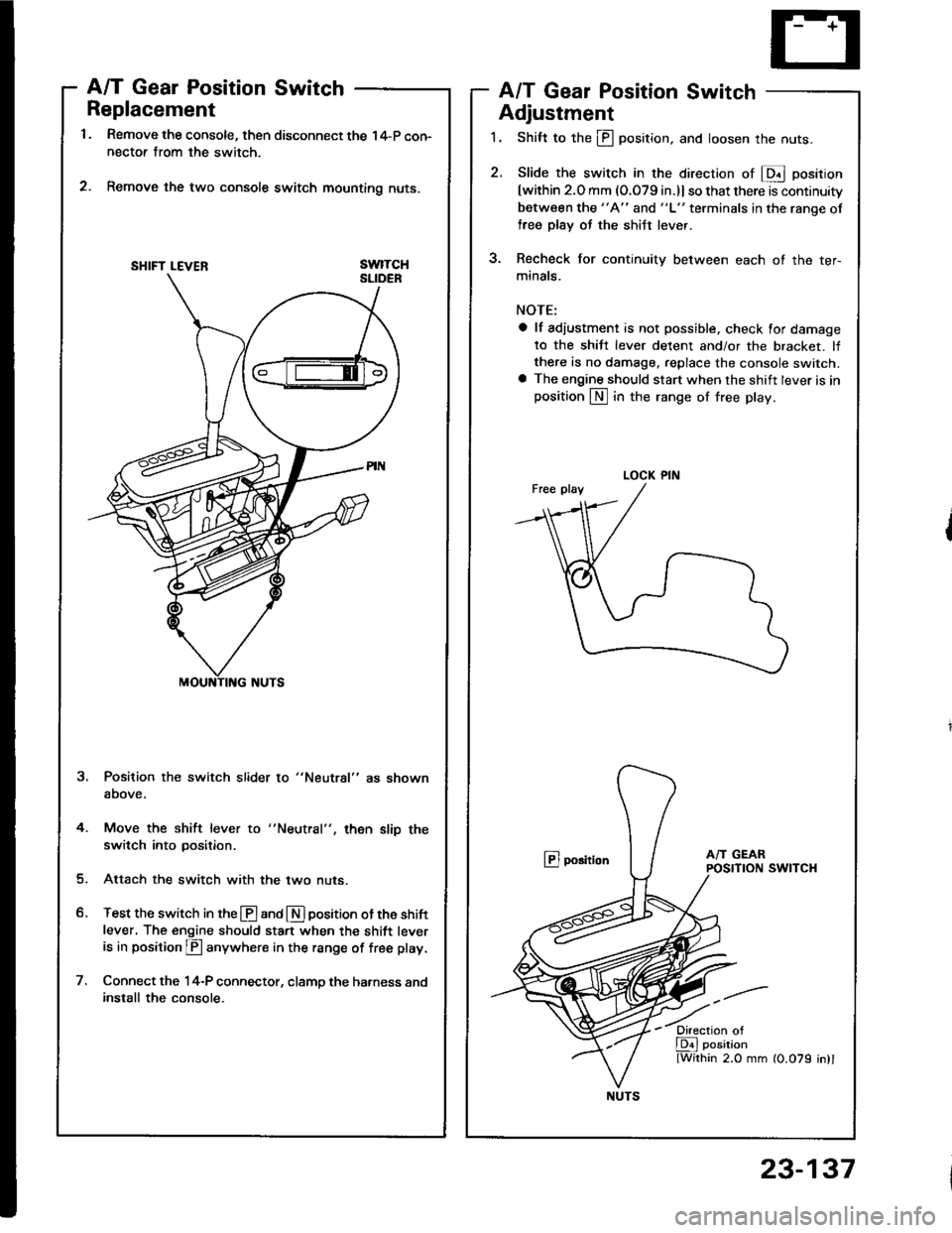

Remove the console, then disconnect the 14-P con-nectof from the switch.

Remove the two console switch mounting nuts.

swtTcH

A/T Gear Position SwitchA/T Gear Position Switch

Adjustment

1. Shift to the ill position, and loosen the nuts.

2. Slide the switch in the direcrion of E position

[within 2.O mm (O.079 in.)l so that there is continuity

between the "A" and "L" terminals in the ranqe of

free plsy oJ the shiJt lever.

3. Recheck for continuity between each ot the ter-

minals.

NOTE:

a lf adiustment is not possible. check for damage

to the shiJt lever detent and/or the bracket. lfthere is no damage, replace the console switch.a The engine should start when the shift lever is inposition LN] in the range of free play.

@ porition

Position the switch slider to "Neutral" as shown

above.

4. Move the shift lever to

switch into position.then slip the

Attach the switch with the two nuts.

Test the switch in the @ and E] position ot the shift

lever. The engine should sta.t when the shift leveris in position p anywhere in the range of free play.

Connect the 14-P connector, clamp the harness andinstall the console.

SHIFT LEVER

LOCK PIN

NUTS

23-137