cooling HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 23 of 1413

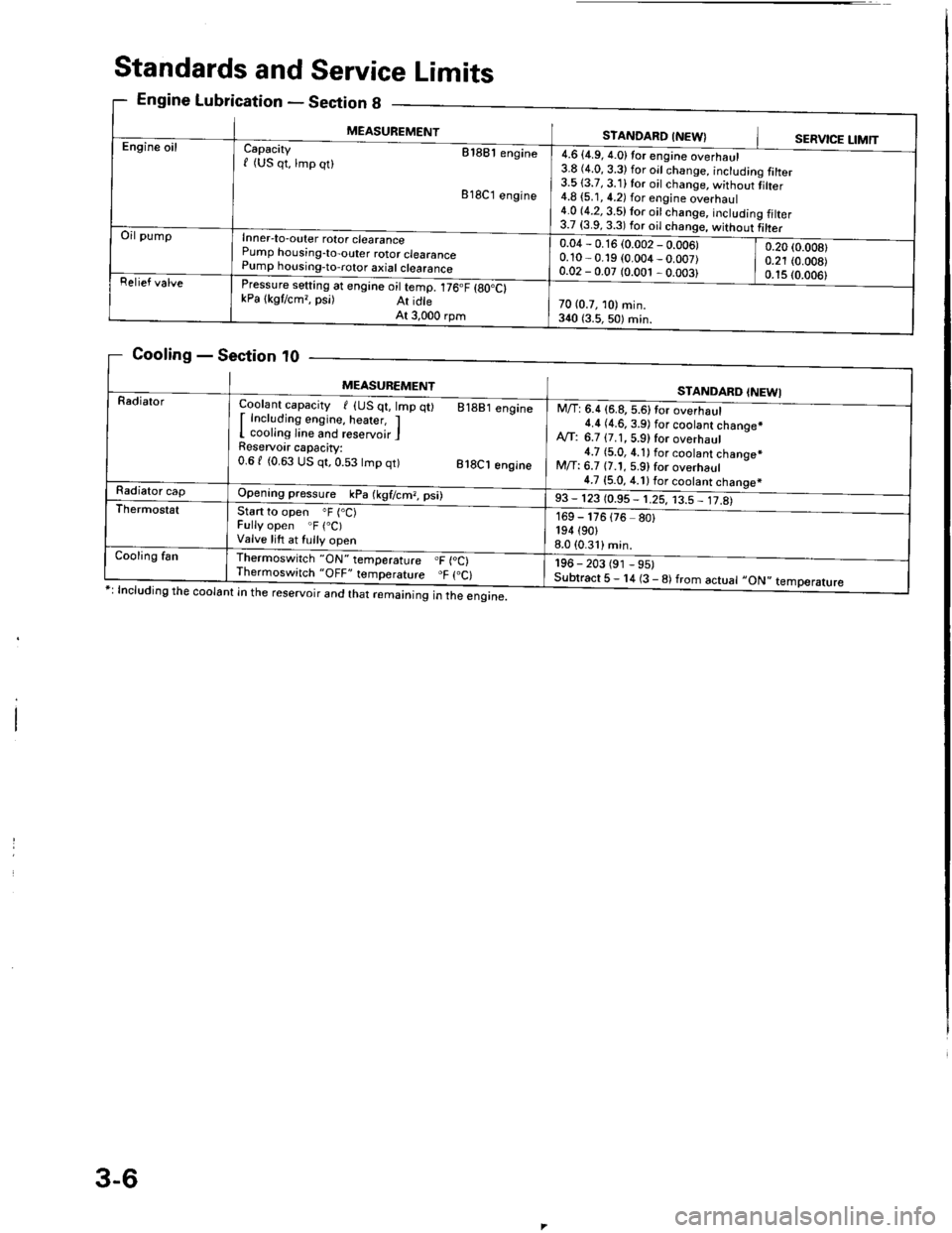

Standards and Service Limits

Engine Lubrication - Section g

Cooling - Section t0

ng the coolant in the reservoir and that remaining in the engine.

eclton u _

MEASUREMENTSTANDARD INEW}SERVICE LIMTT

g talter

tiher

g filter

Engine oilCapacity etaet engine

f (US qt, lmp qt)

818C1 engine

Inner-to-outer rotor clearance

Pump horising-to-outer rotor clearance

Pump housing-to,rotor axial clearance

rressure setting at engine oil temp. 176.F {gO.Ct

kPa lkgtcm,, psi) At idte

At 3,000 rpm

4.6 {4.9, 4.0}tor engine overhaul

3.8 (4.0, 3.3) for oil change, inctudin

3.513.7, 3.11 for oil change, without

4.8 {5.1, 4.2) for engine overhaul

4.0 (4.2, 3.5) lor oit change, includin

3.7 i3.9 3 3l fdr ^il .hi

Oil pump

0.04 - 0.16 (0.002 - 0.006)

0.10 - 0.19 (0.004 _ 0.007)

0.02 - 0.07 (0.001 , 0.003)

0.20 (0.008)

0.21 (0.008)

0.1s (0.006)

Relief valve

70 (0.7, 10) min.

3{0 {3.5,50) min.

MEASUBEMENTSTANDARD INEWI

RadialorCoolant capacity I {US qt, lmp

I Including engine, heater, I

I cooling line and reservoir I

Reservoir capacity:

0.61 (0.63 US qt,0.53 tmp qt)

q0 81881 engine

818C1 engine

Opening pressure kPa (kgf/cm?, psi)

start to open oF (.C)

Fully open .F (.C)

Valve lift at fully open

lhermoswitch "ON" temperature .F {oC)

Thermoswitch "OFF" temporature "F (.C)

M/T: 6.4 (6.8, 5.6)tor overhaul

4.4 (4.6.3.9) f6r s66lsn1gh66q.*

A,rf: 6.7 {7.1, 5.9) for overhaul

4.7 {5.0, 4.1) for coolant chanoe*

M/T: 6.7 {7.1, 5.9} for overhaul

4.7 {5.0, 4.1) for coolant chanoe*

,3 - 113 toss - trs, r3= Jt&

-

196 - 203 (91 - 95)

Subtract 5 - 14 (3 - 8) from actuat -ON',

169 - 176

194 (90,

8.0 (0.31)

{76 80}

temperature

Radiator cap

Thermostst

Cooling fan

3-6

Page 24 of 1413

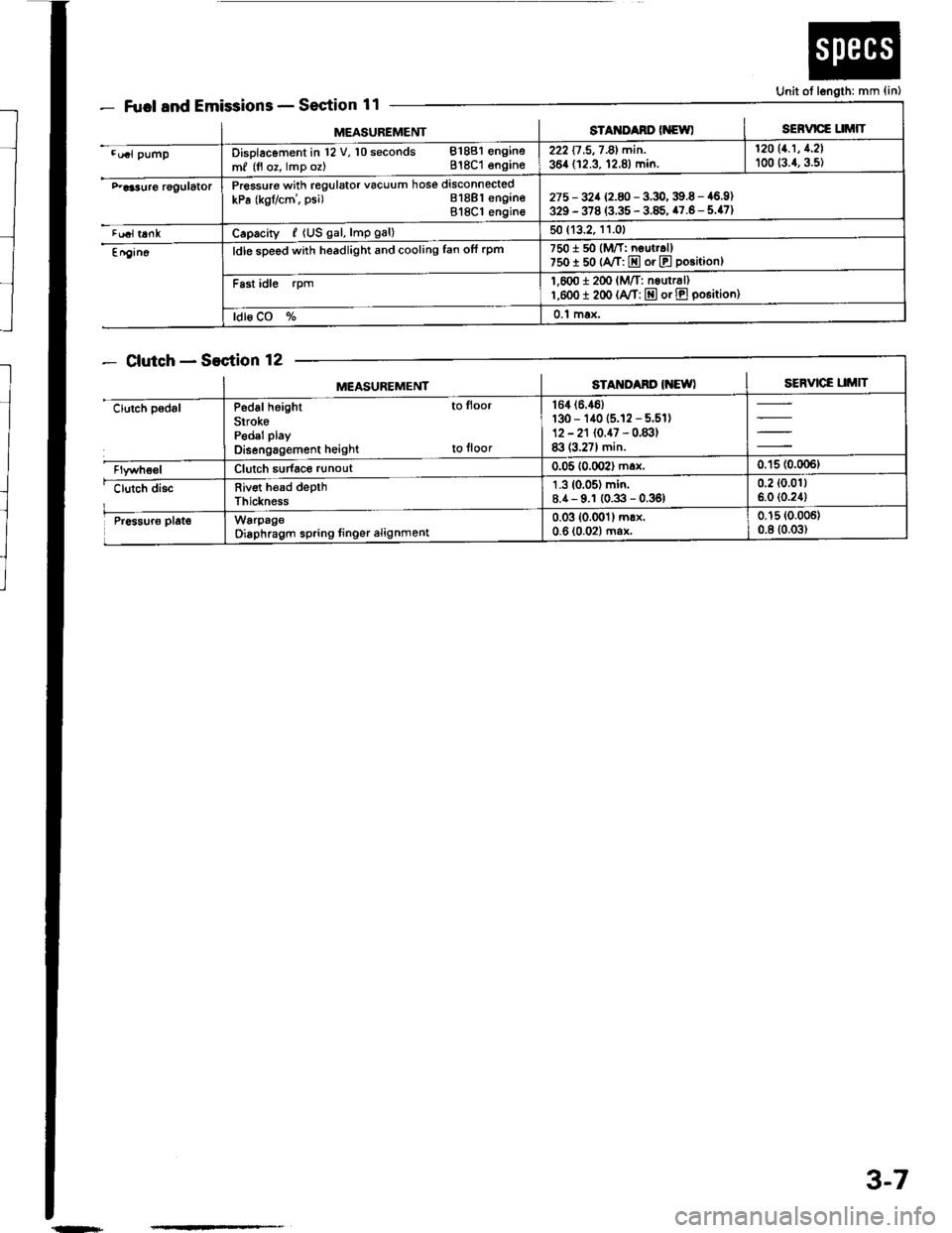

Fuel and EmissionsSection 11

ClutchSection 12

Unit ot length: mm {in)

MEASUREMENTsTAt{ItAno (NewlSERVICE UMIT

.u.l pumpDisolacoment in l2 V, 10 seconds 81881 engine

m, (fl oz, lmp oz) 818C1 engins222 17 .5,7 -81 min. | 12011.1' 1'21

364 (12.3, 12.8) min. I too (:.1, g.st

F aa3uro rggulatorPressure with regulator vacuum hose disconnected

kPa (kgflcm', psi) Bl8Bl engineBl8Cl engin€275 - 32a 12.8 -3.9,39.6 - 46.9)329 - 378 (3.35 - 3.85, 47.6- 5.47)

tualt6nkCaprcity, {US gal, lmp gal)50 (13.2, 11.01

En9in6ldle sDeed with headlight and cooling fan ofi rpm7501 50 (M/T: neut..ll750I 50 {A/T: E or E position}

Fast idle rpm1,600 i 2(x' lM/T: nsurr6l)l,eoo I 200 (A/T: E or E po6itioo)

ldl6 CO %0.1 max.

MEASUREMENTSTAM'Ad' IiEWISERVICE UMIT

clutch padslP6d6l height to lloor

SirokePedal play

Disengagement height to floor

164 (6.46)

130 - 140 (5.12 - 5.51)12 - 21 (0.47 - 0.83)83 (3.27) min.

Clutch sudace runout0.05 10.002) max,0.'15 (0.006t

clutch discRiv€t h€ad depthThickness

1.3 (0.05) min.8.4- 9.1 (0.3 - 0.36)0.2 (0.011

6.0 (0.24)

Pr6sur6 plat€WarpageOiaphragm spring linger alignment0.03 (0.001) mrx.0-6 (0.02) ma*0.15 (0.006)

0.8 (0.03)

{n+

3-7

Page 35 of 1413

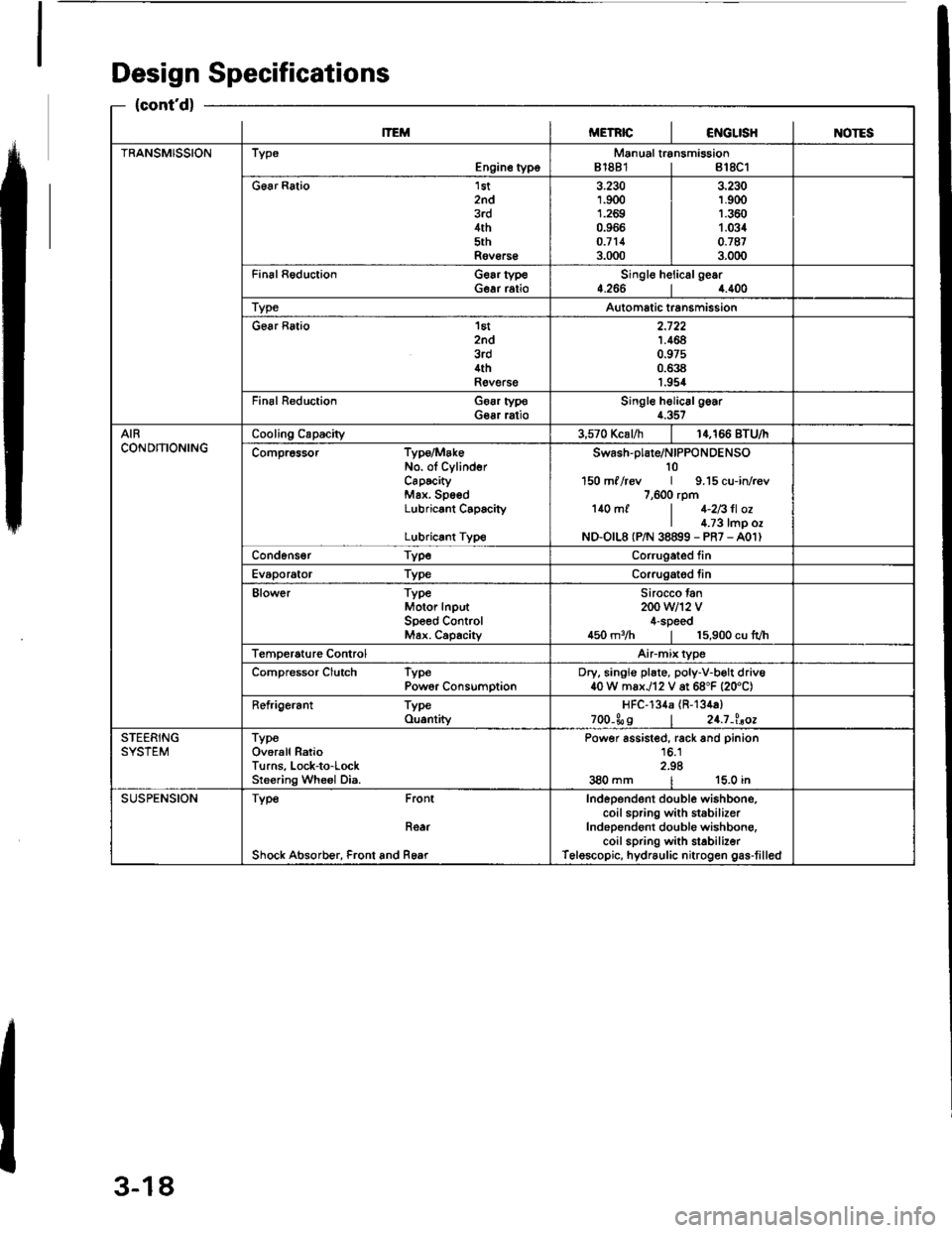

Design Specifications

{cont'd}

lTEMMETRICI€iIGLISHINOTES

TRANSMISSIONTypeEngine typoManual transmission81881 | 818C1

G6ar Ratio 1st2nd3rd4th5thRov€rs€

3.2301.9001.2690.966o.7113.000

3.230r.9(X)1.3601.0340.'t873.000

Fin6l Reduction Gear typeGear ratioSingle helicalge.r4.2664.400

TypeAutomatic transmission

Gear Ratio 'l6t

znd3rd4thRevelse

2.7221.4640.97s0.6381.954

Final R€duction Goar typoGear ratioSingle helic6lgoar4.357

AIRCONDITIONINGCooling Capacity3,570 Kcal/h14,166 BTU/I

Compr6ssor Type/MakeNo. ol CylinderCaPtcityMax. SpsedLubricant C6pacity

Lubricrnt Type

swash-plare/NIPPoNDENSO10150 ml /rcv | 9.15 cu-in/r€v7,600 rpm140 mf | 1-2Bll ozI l.;3 tmp ozND-O|L8 (P/N 38899 - PR7 - A01)

Cond6ns€r TypeCorrugated fin

Evaporator TypeCorrugatod tin

Blower TypeMotor InputSpeed ControMax. Capachy

Sirocco tan200 w12 v4-speed450 m3/h | 15,900 cu lvh

Temperature ControlAirmix type

Compressor Clutch TypePowor ConsumptionDry, singlo plate, poly-V-b€lt driv640 W max./12 V at 68"F {20'C)

Refrigerant TypeOu.ntityHFC-134a (R-134a)

zoo-Ss I 24.7-l.aoe

STEERINGSYSTEMTypeOverall RatioTurns, Lock-to-LockSreering Wheel Dia.

Power assisted, rack and pinion16.12.98380 mm | 15.0 in

SUSPENSIONType Front

Roar

Shock Absorb€r, Front and Rear

Independent double wishbono,coil spring with st6bilizerIndependont double wishbong.coil spring with stabilizerTelescopic, hydraulic nitrogen gas-tilled

3-18

Page 45 of 1413

Engine

Engine Removal/lnstallation ...''........ 5-1

Cylinder Head/Valve Train ..'............ 6-1

Engine Block ..........7-1

Engine Lubrication ......... 8-1

Intake Manifold/Exhaust System ...... 9-1

Cooling ....... 1O-1

Page 60 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual Insrall the left front mount, then tighten the bolts in

the numbered sequence as shown (O-@),

O 12 x 1.25 ]n]n83 N.m 18.5 kst.m,61 lbt.ftlReplace.

@ 12 r 1.25 mm59 N.m {6.0 kgl.n,43 tb{.ftlReplace.

@ HONDA INTEGRA 1994 4.G Workshop Manual Insrall the left front mount, then tighten the bolts in

the numbered sequence as shown (O-@),

O 12 x 1.25 ]n]n83 N.m 18.5 kst.m,61 lbt.ftlReplace.

@ 12 r 1.25 mm59 N.m {6.0 kgl.n,43 tb{.ftlReplace.

@](/img/13/6067/w960_6067-59.png)

Insrall the left front mount, then tighten the bolts in

the numbered sequence as shown (O-@),

O 12 x 1.25 ]n]n83 N.m 18.5 kst.m,61 lbt.ftlReplace.

@ 12 r 1.25 mm59 N.m {6.0 kgl.n,43 tb{.ftlReplace.

@ 10 r 1.25 mm44 N.m (4.5 kgf.m, 33 lbt.ftl

k-

5-15

a Check that the sp.ing clip on the end of each

driveshaft clicks into place.

GAUTION: Uso oow spring clips.

a Bleed air trom the cooling system at the bleed bolt

with the heater valve open (see page 10-5).

a Adjust the th.ottle cable (see section 1 1).

a Check the clutch pedal tree play lsee section 12).

a Check that the transmission shifts into gear

smoothlv,

a Adiust the tension of the following drive belts.

Alternator belt {s€e section 23).

P/S pump belt {see section 17).

A/C comoressor belt (see section 22).

a Inspect tor fuel leakage (see section 1 1).

. After assembling fuel line parts, turn on the ig-

nition switch (do not operate th€ starter) so

that the Juel pump operates for approximat€-

lV two seconds and the tuel line pressurizes.

Repeat this operation two or three times and

check for fuel leakage at any point in the fuel

line.

(cont'd)

Page 97 of 1413

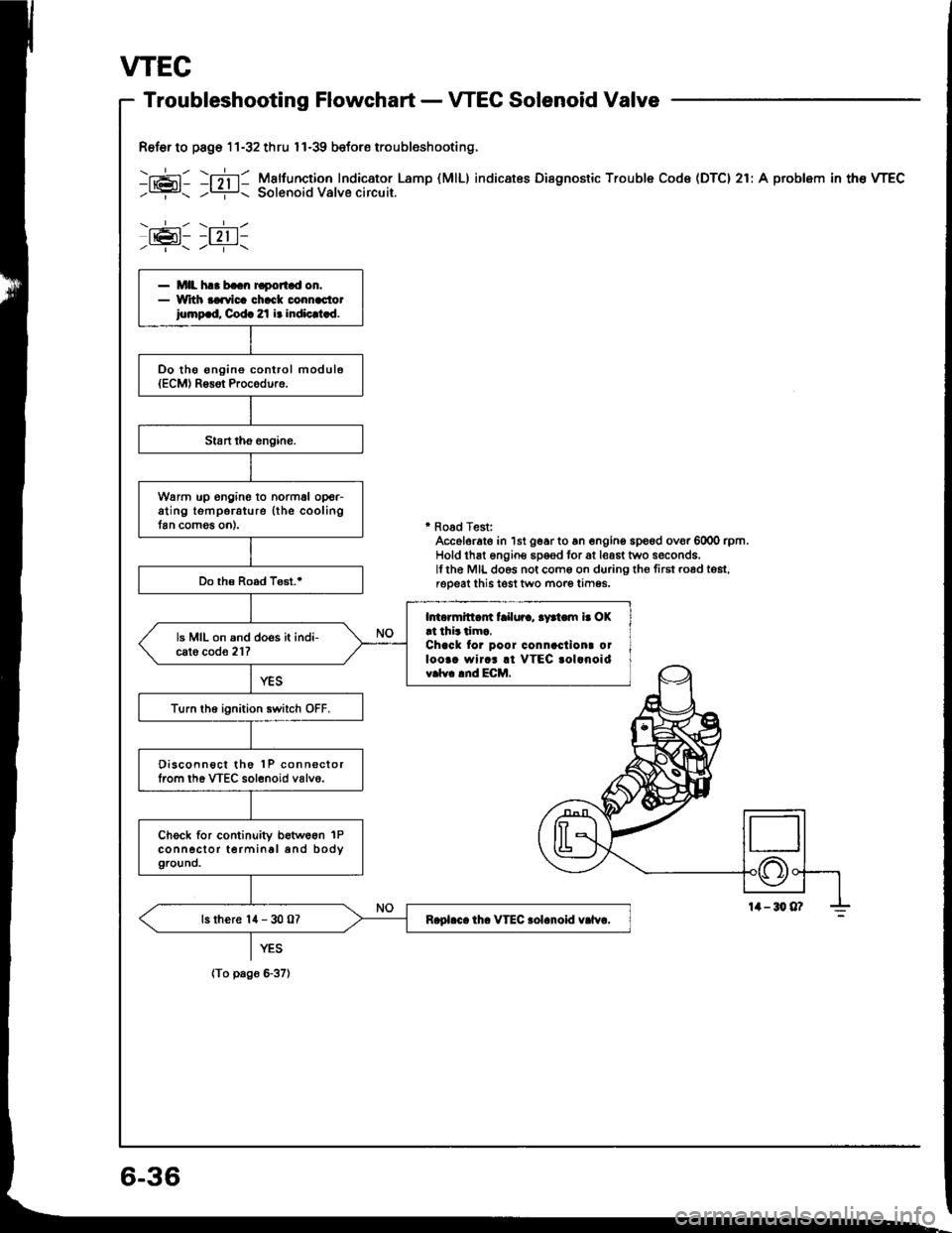

VTEC

Ref€r to page 11-32 thru I l-39 beforo troubleshooting.

-g: -mi !5*3ij'i:,*o:",,XTl.Lamp

(MlL) indicates Disenostic rrouble code (Drc) 2r:A problem in the wEc

\,__-:-/ \.---l-l

Iel- -l 2,1 l-

MIL h.. b..n Fport d on.Wrth aaavica chack connac,tot

iomp.d, Codc 2l i. indic.t.d.

Oo tho ongino control module(ECM) Rg3ot Procgduro.

w6rrn up engine to normal op€r-ating tsmporature (the coolingfan comog on).

Do th€ Road Test.'

lmormitt.m t ilur., .yrtom i. OK!t thi.tim..Chacl tor poor connactiont otloo.. wircr !l VTEC .ol.noidv.lv. lnd ECM.

ls MIL on and does it indi-cato cod€ 21?

Turn tho ignition switch OFF.

Oisconnect tho 1P connsctorlrom the VTEC solenoid valvo.

Chock for continuity betw66n 1Pconn6clor terminal and body

9rcUnO.

ls there '14 - 30 07R.pl.c. th. VTEC rolonoid v.lvr,

' Road Test:Accelerate in 1st gear to 6n engino spood ovor 6000 rpm.Hold thst engine sp€ed tor at least two seconds.lflhe MIL do6s not coms on during th€ first road tost,reoeat this test two more tim95.

YES

(To pago G37l

6-36

Page 99 of 1413

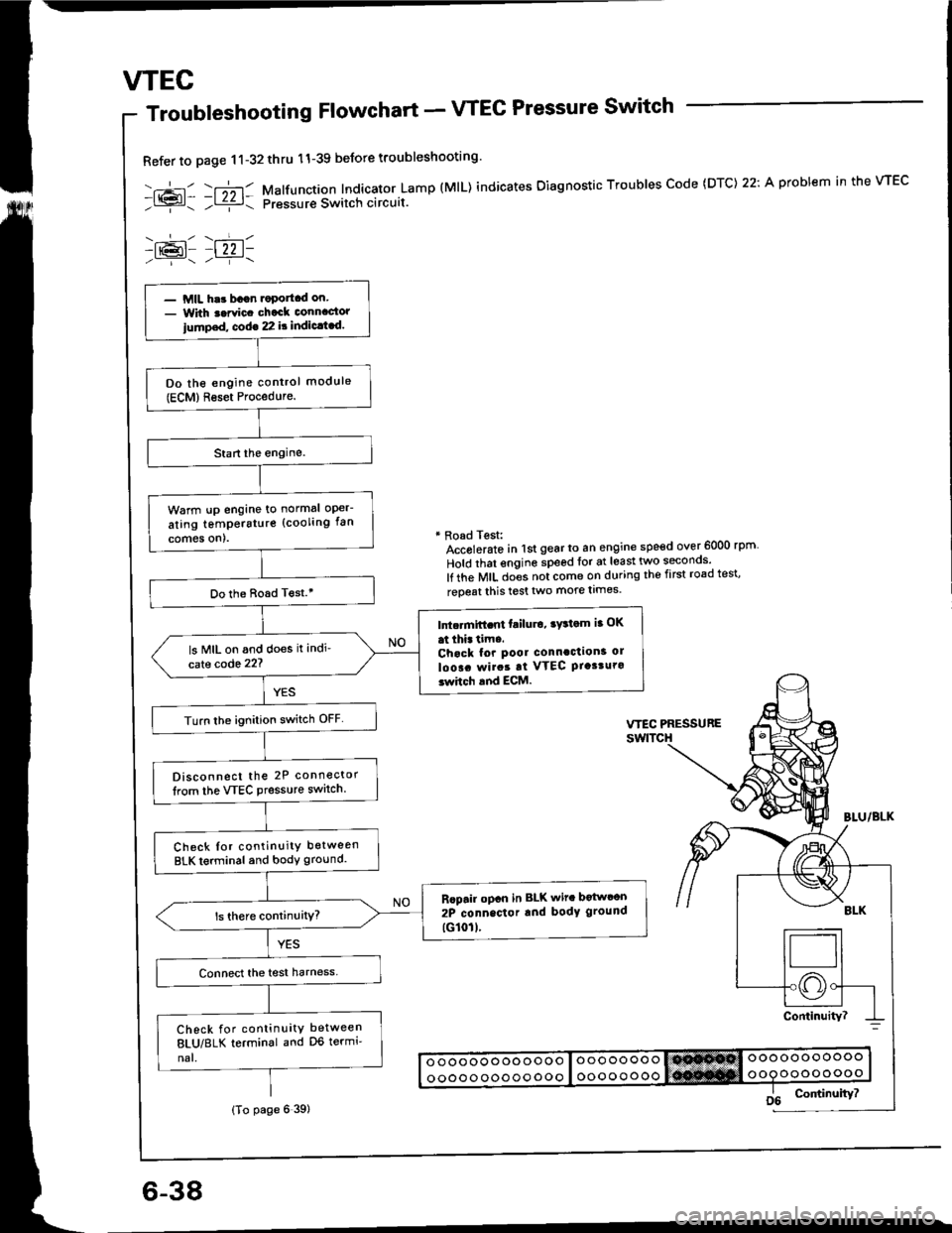

wEc

6-38

Troubleshooting Flowchart - VTEC Pressure Switch

Refer to page 11-32thru 11-39 beJore troubleshooting'

-.+- -r";-r- Malfunction Indicator Lamp (MlL) indicates Oiagnostic Troubles Code (DTC) 22: A problem in the VTEC- l{{?l- ;l ziz r: pressur€ Switch circuit.

-lr@l- |22 1-

* Road Test:Accolerato in lst gear to an engine speed over 6000 rpm

Hold that engine speed for at least two seconos'

lf the MIL does not come on during the first road test'

reoeat this test two more limes.

- MIL har bagn.oportcd on.- With t.rvic. chack connactor

iump.d, cod€ 22 it indic.t.d.

Do the engine control module(ECM)Reset Procedure.

Warm !p engine to normal oper-

ating temperstur€ (cooling fan

comes on).

Do the Boad T€st.'

Intc.mift.nt failu.o, ry3tom ia OK

at thi. tim..Chack for pool connaction3 ol

loo!. rvirat at VTEC Ptasturo3whch and ECM.

ls MIL on and does it indi'

cate code 22?

Turn lhe ignition switch OFF

Disconnect the 2P connector

lrom the VTEC Pressure switch.

Check Ior continuity between

BLK terminal and body ground.

Rcpair opcn in BLK wit. botwcon

2P connector rnd body ground

tG101l.

Check for continuity between

8LU/8LK terminal and D6 termi'

nal.

(To page 6 39)

Page 185 of 1413

Cooling

lllustrated Index

Radiator

Replacement ............................... 1 O-4

Engine Goolant Refilling and

Bleeding10-5

Cap Testing ............... 10-6

Pressure Testing ......... 10-6

Thermostat

Rep|acement ............................... 1 O-7

Testing .....1O'7

Water Pump

lllustrated Index ......... . 10-8

Inspection .10-9

Replacement ............................... 1 O-9

10-2

Page 186 of 1413

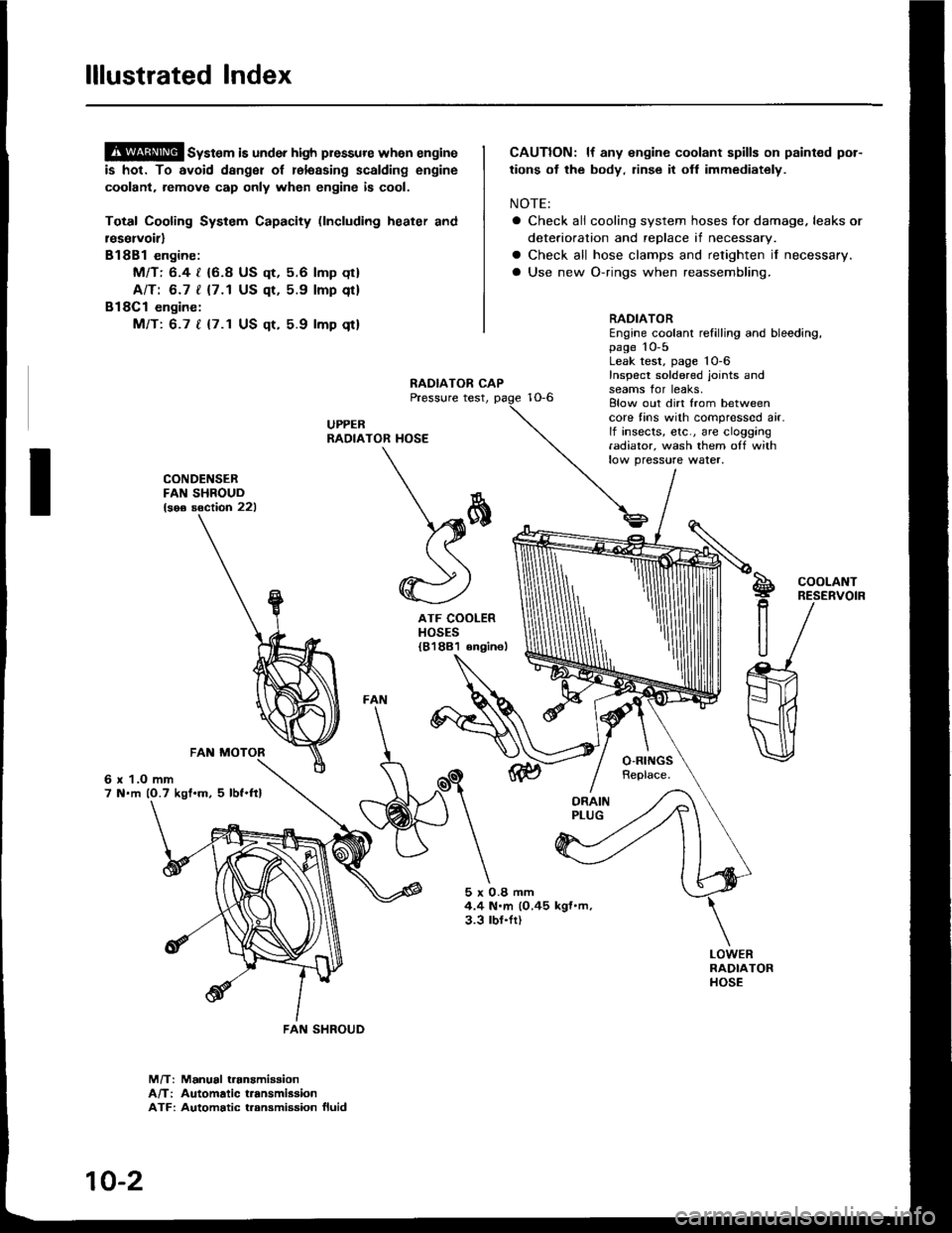

lllustrated Index

@ sy"t". is under high plessure when engine

is hot. To avoid dsnger of relsssing scalding engine

coolant. remove cap only when engine is cool.

Total Cooling System Capacity (lncluding heater and

r€servoirl

Bl8Bl engine:

Mfl: 6.4 | {6.8 US qt, 5.6 lmp qt}

AlTt 6.7 | {7.1 US qt, 5.9 lmp qt}

Bl8Cl engine:

Mfi: 6.7 t {7.1 US qt, 5.9 lmp qt}

CAUTION: lf any engine coolant spills on paint€d por-

tions ot the body, rinse it ofl immediately.

NOTE:

a Check all cooling system hoses for damage. leaks or

deterioration and replace if necessary.

a Check all hose clamps and retighten if necessary.

a Use new O-rings when reassembling.

CONDENSERFAN SHROUD{soe soction 221

6 x 1.O mm7 N.m (O.7 kgt.m. 5 lbf.ftl

ATF COOLERHOSES{81881 6ngine)

RADIATOREngine coolant refilling and bleeding,page 10-5Leak test, page 'l0-6

Inspect soldered joints andseams for leaks.Elow out dirt from betweencore fins with compressed air.lf insects, etc., are clogging.adiator, wash them off withlow pressure water,

S!

P

R

U

COOLANTRESERVOIR

5x0.8mm4.4 N.m (O.45 kgf.m,3.3 lbl.fr)

M/T: Manual t.anamiaaionA/T: Automatic t.ansmiasionATF: Automatic t.ansmission fluid

\*

*)

FAN SHROUD

10-2

Page 189 of 1413

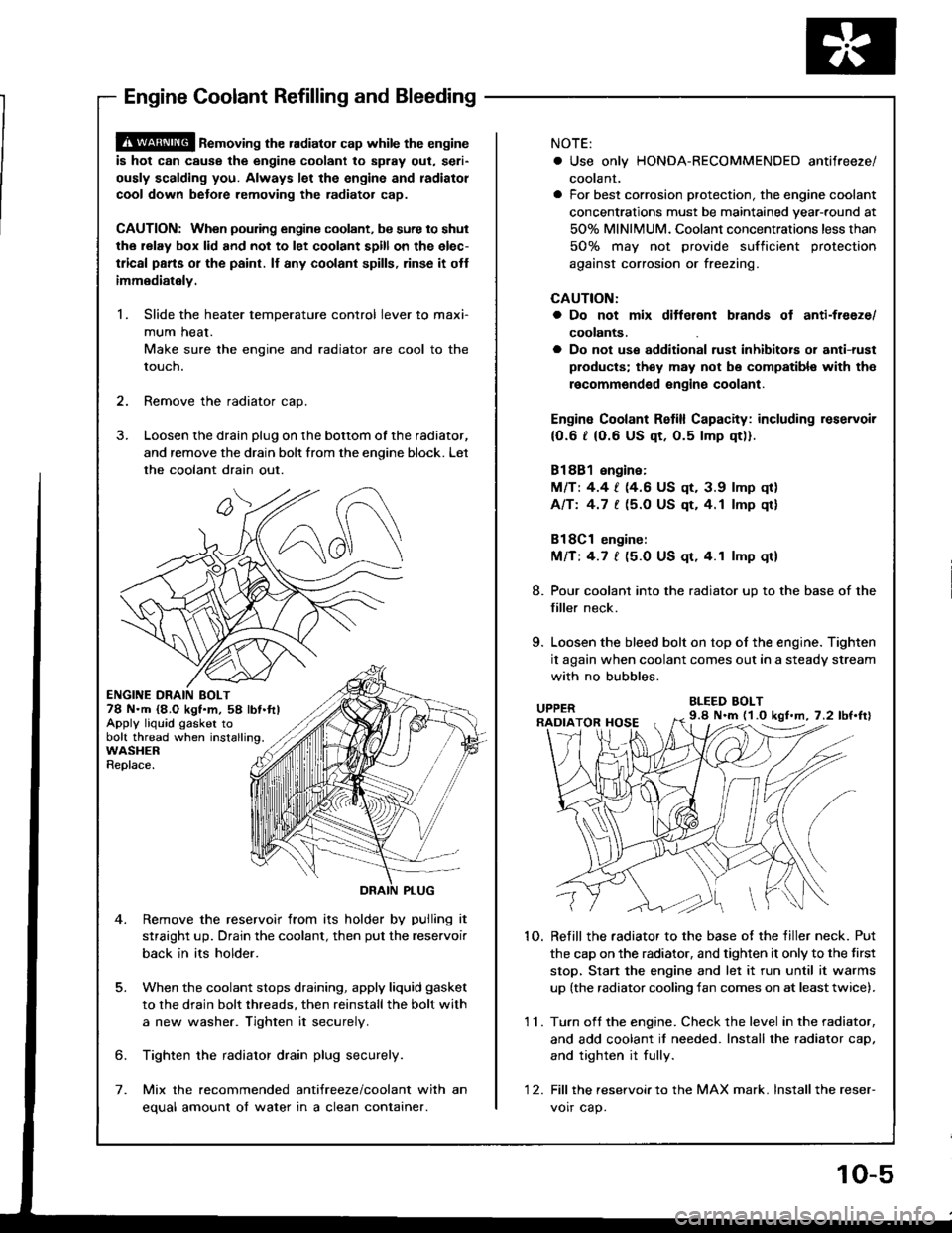

@ ne-oving the radiator cap while the engine

is hot can cause the engine coolant to splay out, seri-

ously scalding you. Always let the engine and radiatol

cool down betore removing the radiator cap.

CAUTION: When poudng engine coolant, be sure to shut

the relay box lid and not to let coolant spill on the elec-

tlical pans or the paint. ll any coolant spills, rinse it otf

immediately.

1. Slide the heater temperature control lever to maxi-

mum heat.

Make sure the engine and radiator are cool to the

touch.

2. Remove the radiator cao.

3. Loosen the drain plug on the bottom of the radiator,

and remove the drain bolt from the enoine block. Let

the coolant drain out.

ENGINE DRAIN BOLT78 N.m {8,O kgt.m, 58 lbt.ftlApply liquid gasker tobolt thread when installing.WASHERReplace.

5.

Remove the reservoir from its holder by pulling it

straight up. Drain the coolant, then put the reservoir

back in its holder.

When the coolant stops draining, apply liquid gasket

to the drain bolt threads, then reinstallthe bolt with

a new washer. Tighten it securely

6. Tighten the radiator drain plug securely.

7. Mix the recommended antifreeze/coolant with an

equal amount of water in a clean container.

NOTE:

. Use only HONDA-RECOMMENOED antifreeze/

coolant.

a For best corrosion protection, the engine coolant

concentrations must be maintained year-round at

50% MINIMUM. Coolant concentrations less than

50% may not provide sufficient protection

against corrosion or freezing.

CAUTION:

a Do not mix ditterent blands ot anti-freeze/

coolants.

a Do not use additional rust inhibitois or anti-rust

products; they may not bs compatibl€ with the

recommgndsd engins coolant.

Engin€ Coolant Retill Capacity: including reservoir

{0.6 t (0.6 US qt, 0.5 lmp qt)).

81881 engine:

MlTt 4.4 | (4.6 US qt, 3.9 lmp qr)

Afft 4.7 [ (5.O US qt,4.1 lmp qt]

Bl8Cl engine:

Mnt 4.7 | (5.0 US qt.4.1 lmp qt)

8. Pour coolant into the radiator up to the base of the

filler neck.

9. Loosen the bleed bolt on top of the engine. Tighten

it again when coolant comes out in a steady stream

with no bubbles.

BLEED BOLT

1O. Refill the radiator to the base of the tiller neck. Put

the cap on the radiator. and tighten it only to the tirst

stop, Stan the engine and let it run until it warms

up (the radiator cooling fan comes on at leasttwice).

11. Turn oft the engine. Check the level in the radiator,

and add coolant it needed. Install the radiator caD,

and tighten it fully.

'1 2. Fill thereservoirto the MAX mark. lnstallthe reser-

voir cap.

9.8 N.m (1.O kgl.m, 7.2 lbf.ftl

Engine Coolant Refilling and Bleeding

10-5